High-efficiency bifunctional water decomposition electrocatalyst and preparation method thereof

A dual-function, catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of difficult to improve the electrocatalytic activity of cobalt selenide electrode materials, poor active surface area, and electron transport. Influence and other issues, to achieve good hydrogen evolution and oxygen evolution activity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a high-efficiency dual-function hydroelectric catalyst for splitting water, including the following steps:

[0030] (1) Mix cobalt acetate, ammonium fluoride, urea and a solvent to obtain a mixed solution;

[0031] (2) Immerse the carbon cloth in the mixed solution for hydrothermal reaction to obtain the carbon cloth on which the cobalt nanorod precursor is grown on the surface;

[0032] (3) Electrochemically transforming the carbon cloth on which the cobalt nanorod precursors are grown on the surface, to obtain the high-efficiency dual-function water splitting electrocatalyst;

[0033] The electrochemical conversion adopts a three-electrode system, a carbon cloth with a cobalt nanorod precursor grown on the surface as a working electrode, a saturated calomel electrode as a reference electrode, and a mixed solution of selenium dioxide, potassium chloride and water as the working electrode. Electrolyte.

[0034] In the present inventi...

Embodiment 1

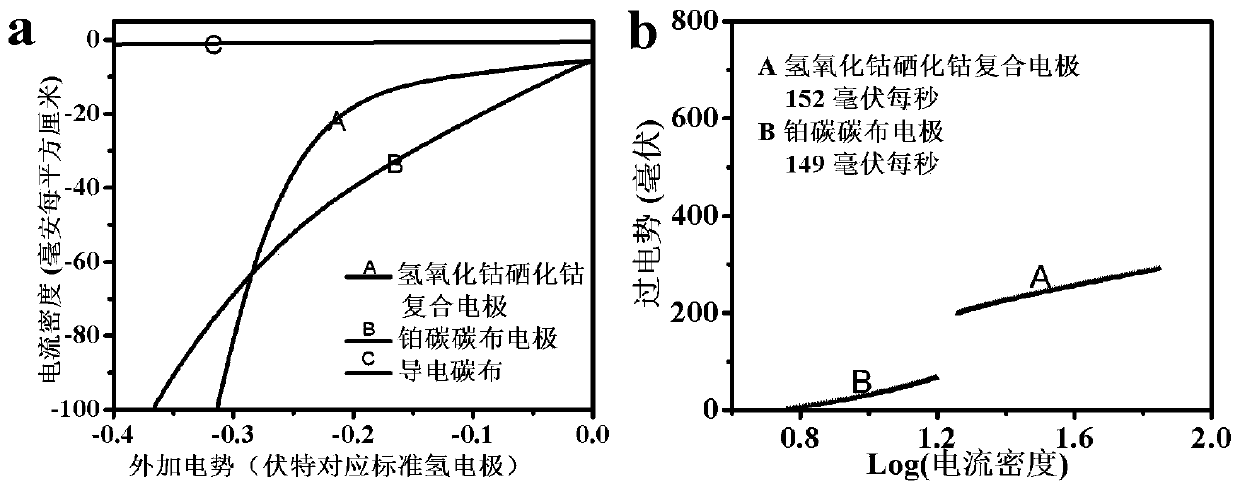

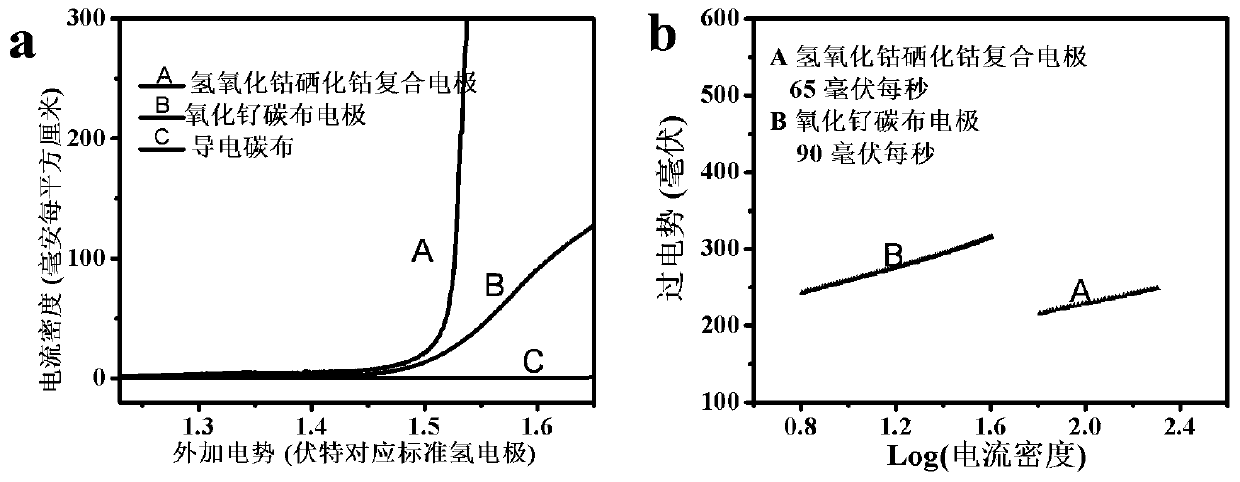

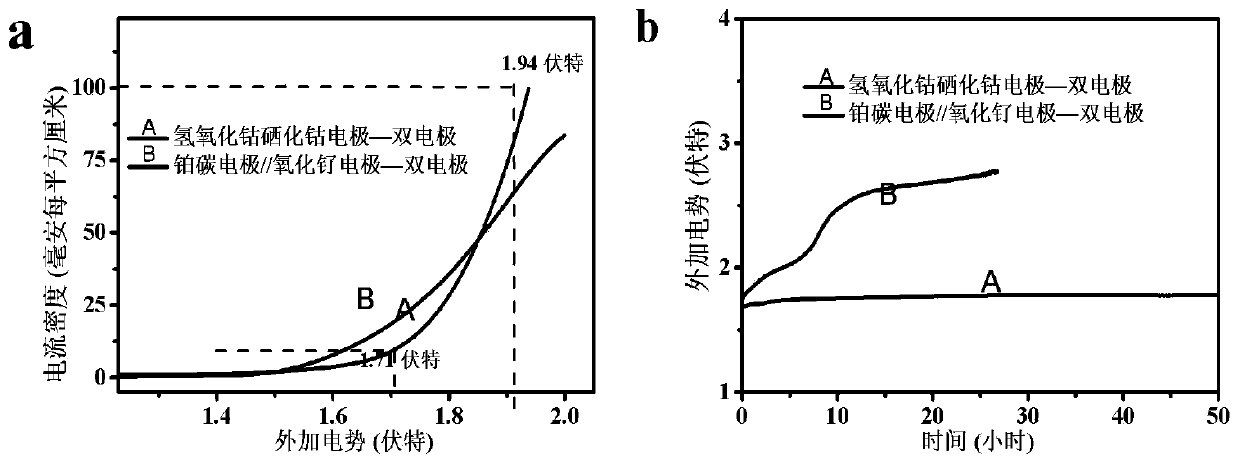

[0043] Preparation of high-efficiency dual-function hydrolysis electrocatalyst (cobalt hydroxide-cobalt selenide composite electrode):

[0044] (1) Growing cobalt nanorod precursor on the surface of carbon cloth: Dissolve 4mmol cobalt acetate, 8mmol ammonium fluoride and 20mmol urea in 105mL mixed solvent (water:ethanol volume ratio 2:1), and magnetically stir for 30 minutes. Uniform pink solution. The solution was added to a 50 mL tetrafluoroethylene lined stainless steel hydrothermal reactor with a filling volume of 70%. Then a piece of carbon cloth was added to the solution, and the reaction kettle was placed in a high-temperature oven and heated at 100°C for 10 hours. Naturally cool to room temperature, take out the carbon cloth, ultrasonically wash with deionized water and ethanol for 5 minutes, and place it in a 60°C vacuum drying oven for 2 hours.

[0045] (2) Preparation of cobalt hydroxide-cobalt selenide composite electrode by electrochemical conversion: using a three-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com