Cobalt-doped tungsten sulfide nanosheets, preparation method thereof and application of electrochemical hydrogen evolution

A technology of tungsten sulfide and nanosheets, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve the problems of destroying active sites and reducing catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

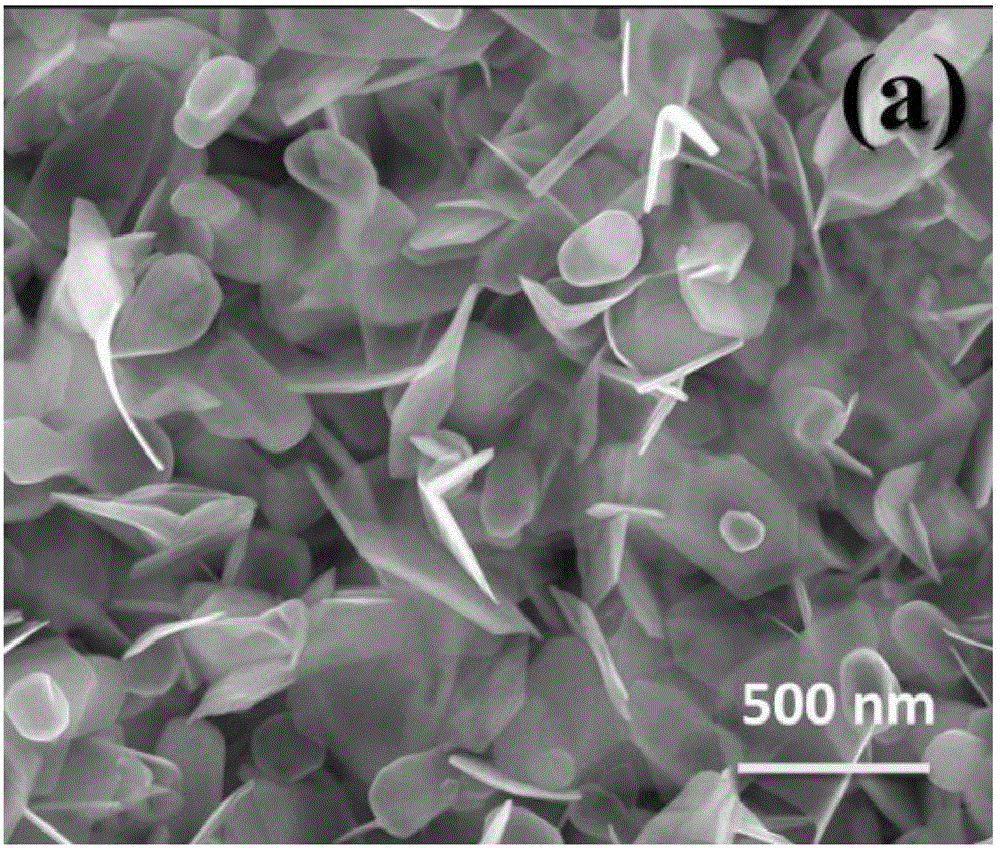

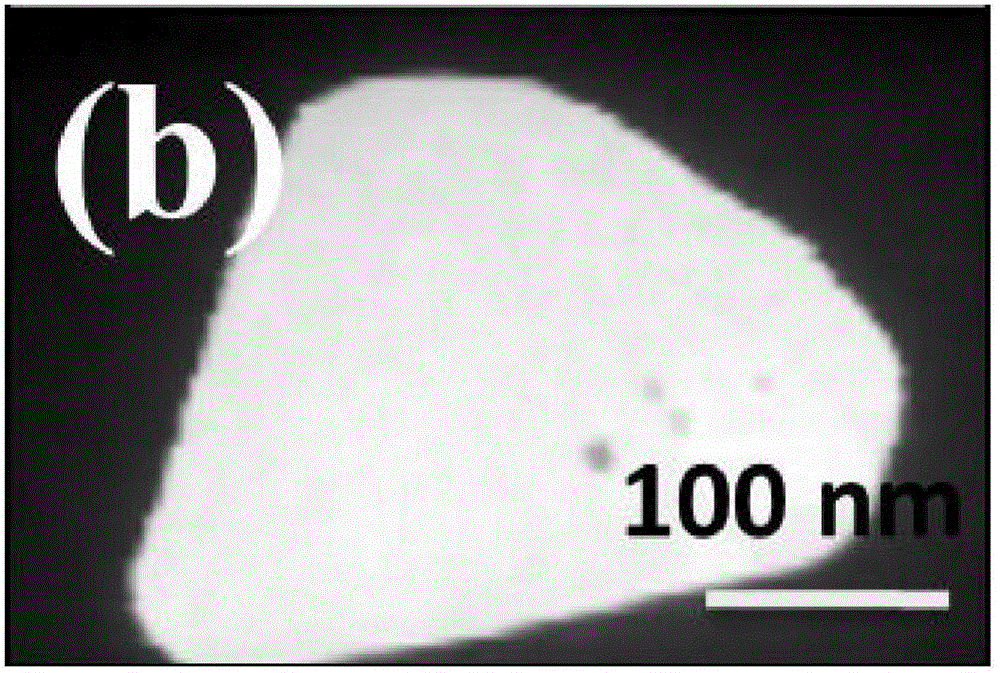

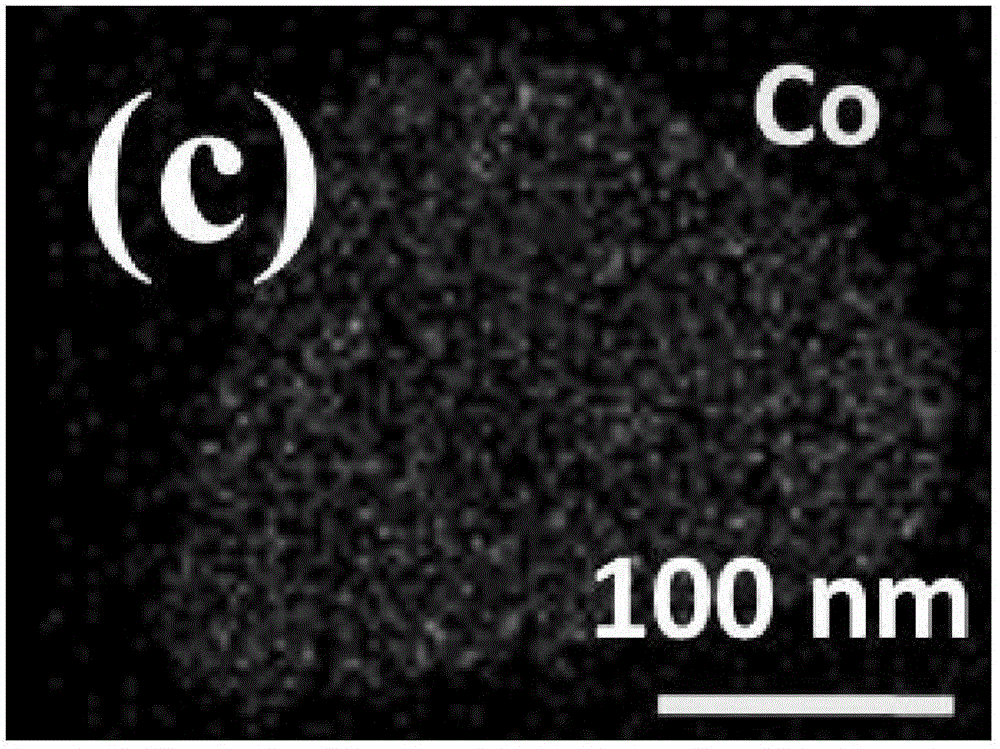

[0072] co x W (1-x) S 2 Preparation of nanosheets (see the schematic diagram of the preparation process Figure 3a ):

[0073] (1) Ultrasonic cleaning of the W foil with deionized water, ethanol, and acetone, followed by N 2 Blow dry, place in a furnace for annealing at 500°C for 30 minutes, and put 1.56g oxalic acid (H 2 C 2 o 4 2H 2 O), 0.2g rubidium sulfate (Rb 2 SO 4 ) and 313 μL nitric acid (HNO3 ) mixed solution in a reactor (50mL) heated to 150°C and kept for 72h. After the obtained sample was washed and dried, it was annealed in a furnace at 500°C for 30min to obtain WO grown on a W substrate. 3 nano tree;

[0074] (2) Sulfur powder (S) and WO obtained in step (1) 3 The nano-trees are respectively placed in the upstream and downstream central temperature zones of the dual-temperature zone tubular reaction furnace. After cleaning the quartz tube with argon (Ar), the furnace temperature in the upstream central temperature zone is raised to 150°C, and the furna...

Embodiment 2

[0085] co x W (1-x) S 2 Preparation of nanosheets (for the schematic diagram, see Figure 3a ):

[0086] (1) Ultrasonic cleaning of the W foil with deionized water, ethanol, and acetone, followed by N 2 Blow dry, place in a furnace for annealing at 450°C for 45 minutes, and put 1.17g oxalic acid (H 2 C 2 o 4 2H 2 O), 0.08g rubidium sulfate (Rb 2 SO 4 ) and 209 μL nitric acid (HNO 3 ) mixed solution in a reactor (50mL) heated to 145°C and kept for 72h. After the obtained sample was washed and dried, it was annealed in a furnace at 465°C for 40min to obtain WO grown on a W substrate. 3 nano tree;

[0087] (2) Sulfur powder (S) and WO obtained in step (1) 3 The nano-trees are respectively placed in the upstream and downstream central temperature zones of the dual-temperature zone tubular reaction furnace. After cleaning the quartz tube with argon (Ar), the furnace temperature in the upstream central temperature zone is raised to 100°C, and the furnace temperature in t...

Embodiment 3

[0093] co x W (1-x) S 2 Preparation of nanosheets (for the schematic diagram, see Figure 3a ):

[0094] (1) Ultrasonic cleaning of the W foil with deionized water, ethanol, and acetone, followed by N 2 Blow dry, place in a furnace for annealing at 520°C for 30 minutes, and put 1.95g oxalic acid (H 2 C 2 o 4 2H 2 O), 0.32g rubidium sulfate (Rb 2 SO 4 ) and 626 μL nitric acid (HNO 3 ) mixed solution in a reactor (50mL) was heated to 165°C and kept for 60h. After the obtained sample was washed and dried, it was annealed in a furnace at 520°C for 30min to obtain WO grown on a W substrate. 3 nano tree;

[0095] (2) Sulfur powder (S) and WO obtained in step (1) 3 The nano-trees are respectively placed in the upstream and downstream central temperature zones of the dual-temperature zone tubular reaction furnace. After cleaning the quartz tube with argon (Ar), the furnace temperature in the upstream central temperature zone is raised to 180°C, and the furnace temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com