Method for preparing sulfur-doped porous NiFe-LDH electrocatalyst at room temperature

An electrocatalyst and sulfur-doped technology, which is applied in the fields of electrolysis of water for oxygen production and material science, can solve problems such as poor activity, achieve the effects of improving oxygen evolution performance, simple and easy process, and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

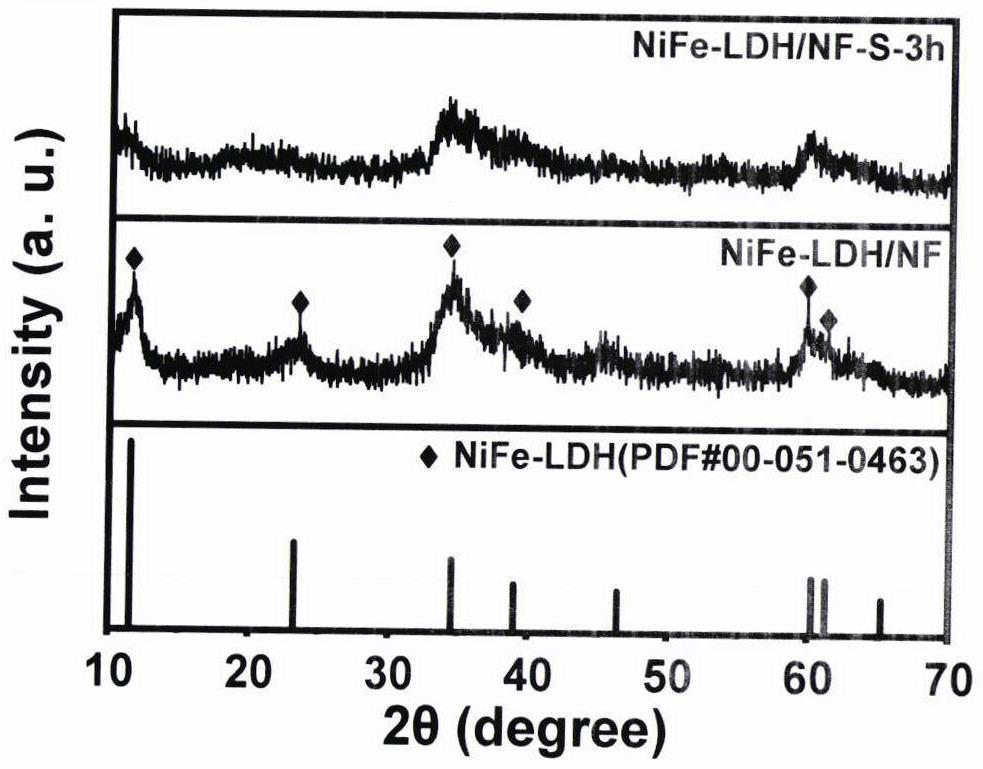

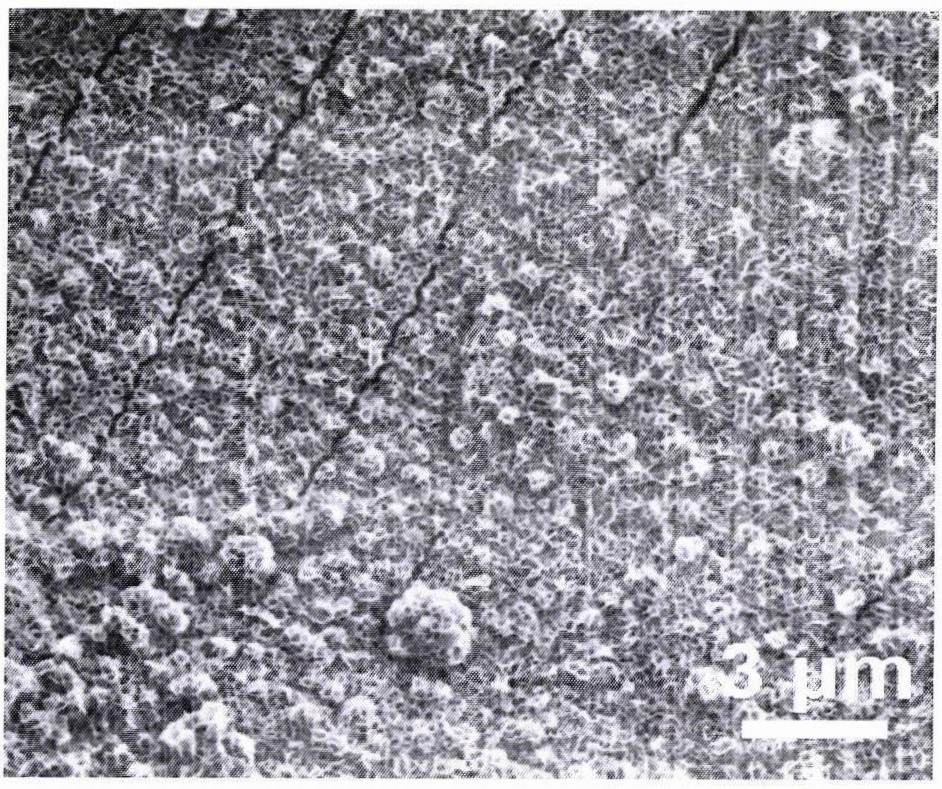

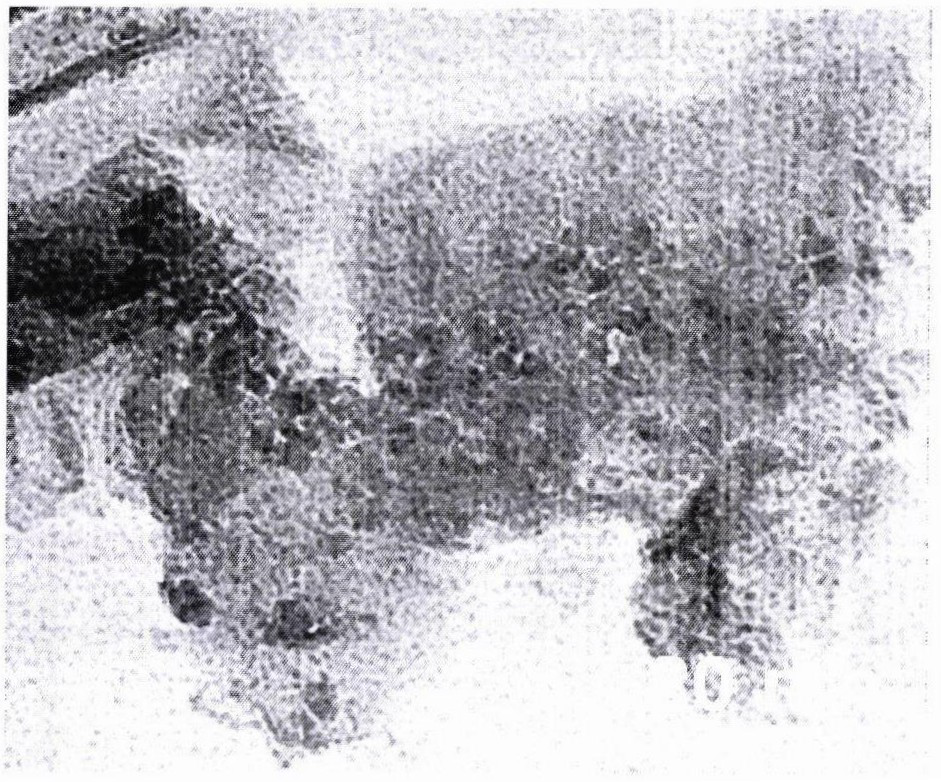

[0022] Specific embodiment 1: In this embodiment, the nickel foam is used as the substrate, and the three-dimensional NiFe-LDH nanosheets are grown on the nickel foam in situ by a hydrothermal method. NiFe-LDH was then infiltrated to a certain molar concentration of Na at room temperature 2 S 9H 2 Preparation of sulfur-doped porous NiFe-LDH nanosheet electrocatalysts in O solution.

[0023] The above method for preparing sulfur-doped porous NiFe-LDH nanosheet electrocatalyst at room temperature is carried out in the following steps:

[0024] (1) Cut the nickel foam into a rectangle of 2cm×4cm, ultrasonically treat it with 1M hydrochloric acid, acetone, alcohol and ultrapure water for 10 minutes to remove the oxide layer and dirt on the surface, and then vacuum dry at 60°C for 10 minutes;

[0025] (2) 35mL 0.5mM Fe(NO 3 ) 3 9H 2 O, 1.5mM Ni(NO 3 )·6H 2 O and 2.5mM CO(NH 2 ) 2 Stir the mixed solution of the mixed solution evenly, put it into a hydrothermal reaction kett...

specific Embodiment 2

[0030] Specific Example 2: In this embodiment, nickel foam is used as the substrate, and three-dimensional NiFe-LDH nanosheets are grown on the nickel foam in situ by a hydrothermal method. NiFe-LDH was then infiltrated to a certain molar concentration of Na at room temperature 2 S·9H 2 Preparation of sulfur-doped porous NiFe-LDH nanosheet electrocatalysts in O solution.

[0031] (1) the pretreatment of foam nickel substrate and the preparation mode of NiFe-LDH are identical with step (1), step (2) and step (3) of embodiment one;

[0032] (2) At room temperature of 25°C, infiltrate NiFe-LDH to 0.2M Na 2 S·9H 2 O solution to stand for 3h. Then the samples were taken out, rinsed with ethanol and deionized water three times respectively, and then dried under vacuum at 60°C for 6 hours;

[0033] (3) The electrochemical test of this embodiment is carried out in a three-electrode electrolytic cell under the condition of 25°C and normal pressure, the counter electrode is Pt (10×...

specific Embodiment 3

[0034] Specific Example 3: In this embodiment, the nickel foam is used as the substrate, and the three-dimensional NiFe-LDH nanosheets are grown on the nickel foam in situ by a hydrothermal method. NiFe-LDH was then infiltrated to a certain molar concentration of Na at room temperature 2 S·9H 2 Preparation of sulfur-doped porous NiFe-LDH nanosheet electrocatalysts in O solution.

[0035] (1) the pretreatment of foam nickel substrate and the preparation mode of NiFe-LDH are identical with step (1), step (2) and step (3) of embodiment one;

[0036] (2) At room temperature of 25°C, infiltrate NiFe-LDH into 1M Na 2 S·9H 2 O solution to stand for 3h. Then the samples were taken out, rinsed with ethanol and deionized water three times respectively, and then dried under vacuum at 60°C for 6 hours;

[0037] (3) The electrochemical test of this embodiment is carried out in a three-electrode electrolytic cell under the condition of 25°C and normal pressure, the counter electrode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com