High-performance ferronickel-based oxygen evolution electrocatalytic nano composite material as well as preparation method and application thereof

A nano-composite material and composite material technology are applied in the field of nickel-iron-based oxygen evolution electrocatalytic materials and their synthesis, which can solve the problems of hindering the exposure of electron transport active sites, lack of oxygen evolution performance, uneven morphology, etc. Electron transfer, high electrochemical stability, effect of accelerating electron transport rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, nickel-based oxygen evolution electrocatalytic material (Ni 3 S 4 ) preparation

[0049] (1) Measure 30ml of deionized water in a clean beaker, add 0.2mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) Stir the mixture with magnetic force for 10 minutes, then add 1 mmol urea and stir evenly to form an alkaline environment until a transparent light green solution is obtained. Then, the solution was transferred into a 50 mL Teflon-lined autoclave and kept at 120 °C for 6 h. After naturally cooling to room temperature, the green powder was collected by centrifugation and vacuum-dried at 60°C to obtain the primary product.

[0050] (2) The initial product and 30mL containing 2mmol sodium sulfide (Na 2 S) The aqueous solutions are put together in an autoclave and kept at 90° C. for 9 hours. After the obtained black powder was cooled to room temperature, it was washed successively with deionized water and ethanol, and vacuum-dried at 60 °C for 12 h to ...

Embodiment 2

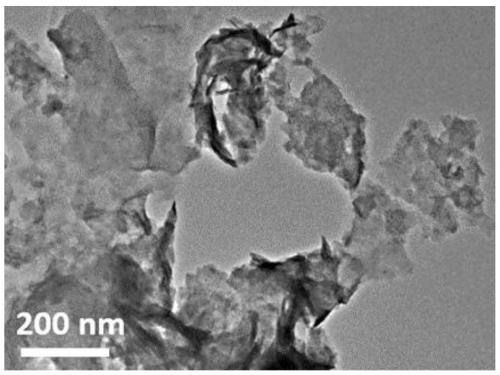

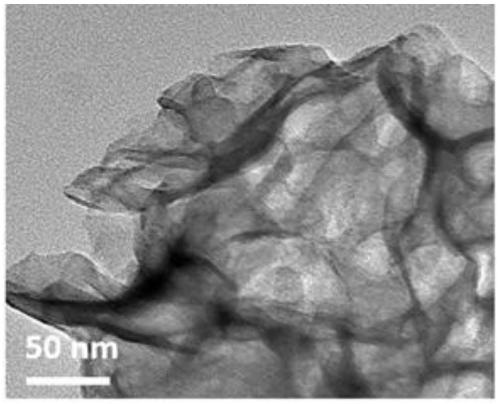

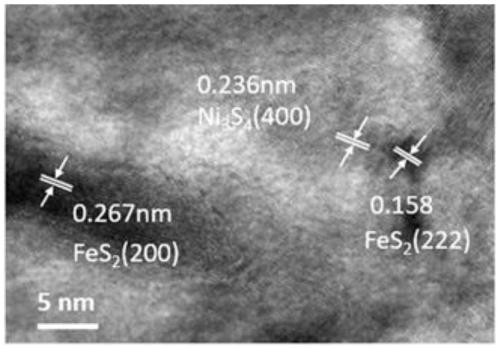

[0052] Embodiment 2, nickel-iron-based oxygen evolution electrocatalytic material (Ni 3 S 4 / FeS 2 ) preparation

[0053] (1) Measure 30ml of deionized water in a clean beaker, add 0.18mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 0.02mmol iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Stir the mixture with magnetic force for 10 minutes, then add 1 mmol urea and stir evenly to form an alkaline environment until a transparent light green solution is obtained. Then, the solution was transferred into a 50 mL Teflon-lined autoclave and kept at 120 °C for 6 h. After naturally cooling to room temperature, the green powder was collected by centrifugation and vacuum-dried at 60°C to obtain the primary product.

[0054] (2) The initial product and 30mL containing 2mmol sodium sulfur (Na 2 S) The aqueous solutions are put together in an autoclave and kept at 90° C. for 9 hours. After the obtained black powder was cooled to room temperature, it was washed successive...

Embodiment 3

[0055] Embodiment 3, nickel-iron-based oxygen evolution electrocatalytic material (Ni 3 S 4 / FeS 2 ) preparation

[0056] (1) Measure 30ml of deionized water in a clean beaker, add 0.167mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 0.033mmol iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Stir the mixture with magnetic force for 10 minutes, then add 0.8mmol urea and stir evenly to form an alkaline environment until a transparent light green solution is obtained. Then, the solution was transferred into a 50 mL Teflon-lined autoclave and kept at 120 °C for 6 h. After naturally cooling to room temperature, the green powder was collected by centrifugation and vacuum-dried at 60°C to obtain the primary product.

[0057] (2) The initial product and 30mL containing 1.6mmol sodium sulfur (Na 2 S) The aqueous solutions are put together in an autoclave and kept at 90° C. for 9 hours. After the obtained black powder was cooled to room temperature, it was washed succe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com