Preparation method of non-noble metal NiCoFe/NF electrocatalyst and application of electrocatalyst to oxygen evolution

An electrocatalyst and non-precious metal technology, applied in the field of electrocatalysis, can solve the problems of limiting large-scale commercial application, slow kinetics, and scarce reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

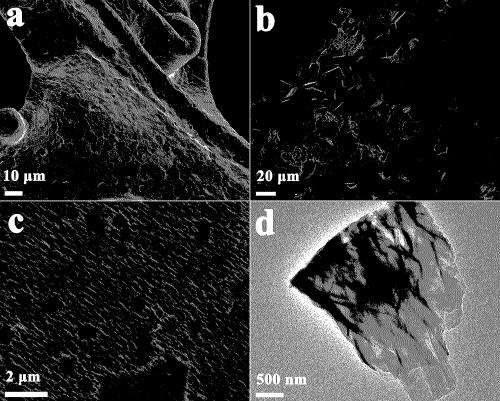

[0028] (1) Dissolve 0.60mmol of nickel acetate, 3.0mmol of cobalt acetate and 10.0mmol of 2-methylimidazole into 40.0ml of anhydrous methanol, sonicate for 20 minutes to fully dissolve, then transfer to a 100ml reaction kettle and put Add the pretreated nickel foam, set the temperature at 130°C, and the reaction time is 15 hours. After the reaction is completed, let it cool naturally and rinse the obtained sample (NiCo / NF) with methanol and secondary water, and dry it naturally for later use. .

[0029] (2) Dissolve 0.75mmol of ferrous sulfate in 10.0ml of secondary water, stir to dissolve it completely, then immerse the NiCo / NF sample obtained in the above steps for 0.5 hours, and take out the obtained sample after the end (NiCoFe / NF NF-0.5h) and rinsed with secondary water, dried for testing.

Embodiment 2

[0031] (1) Dissolve 0.60mmol of nickel acetate, 3.0mmol of cobalt acetate and 10.0mmol of 2-methylimidazole into 40.0ml of anhydrous methanol, sonicate for 20 minutes to fully dissolve, then transfer to a 100ml reaction kettle and put Add the pretreated nickel foam, set the temperature at 130°C, and the reaction time is 15 hours. After the reaction is completed, let it cool naturally and rinse the obtained sample (NiCo / NF) with methanol and secondary water, and dry it naturally for later use. .

[0032] (2) Dissolve 0.75mmol of ferrous sulfate in 10.0ml of secondary water, stir to dissolve it completely, then immerse the NiCo / NF sample obtained in the above steps for 1.0 hour, and take out the obtained sample after the end (NiCoFe / NF NF-1.0h) and rinsed with secondary water, dried for testing.

Embodiment 3

[0034] (1) Dissolve 0.60mmol of nickel acetate, 3.0mmol of cobalt acetate and 10.0mmol of 2-methylimidazole into 40.0ml of anhydrous methanol, sonicate for 20 minutes to fully dissolve, then transfer to a 100ml reaction kettle and put Add the pretreated nickel foam, set the temperature at 130°C, and the reaction time is 15 hours. After the reaction is completed, let it cool naturally and rinse the obtained sample (NiCo / NF) with methanol and secondary water, and dry it naturally for later use. .

[0035] (2) Dissolve 0.75mmol of ferrous sulfate in 10.0ml of secondary water, stir to dissolve it completely, then immerse the NiCo / NF sample obtained in the above steps for 2.0 hours, and take out the obtained sample after the end (NiCoFe / NF NF-2.0h) and rinsed with secondary water, dried for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com