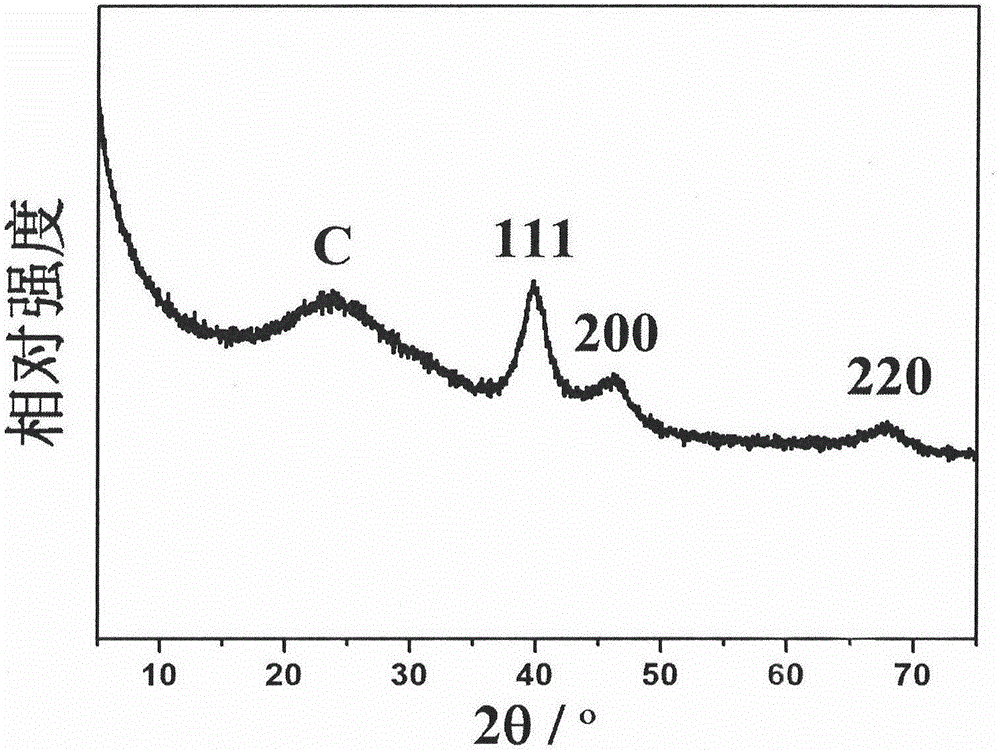

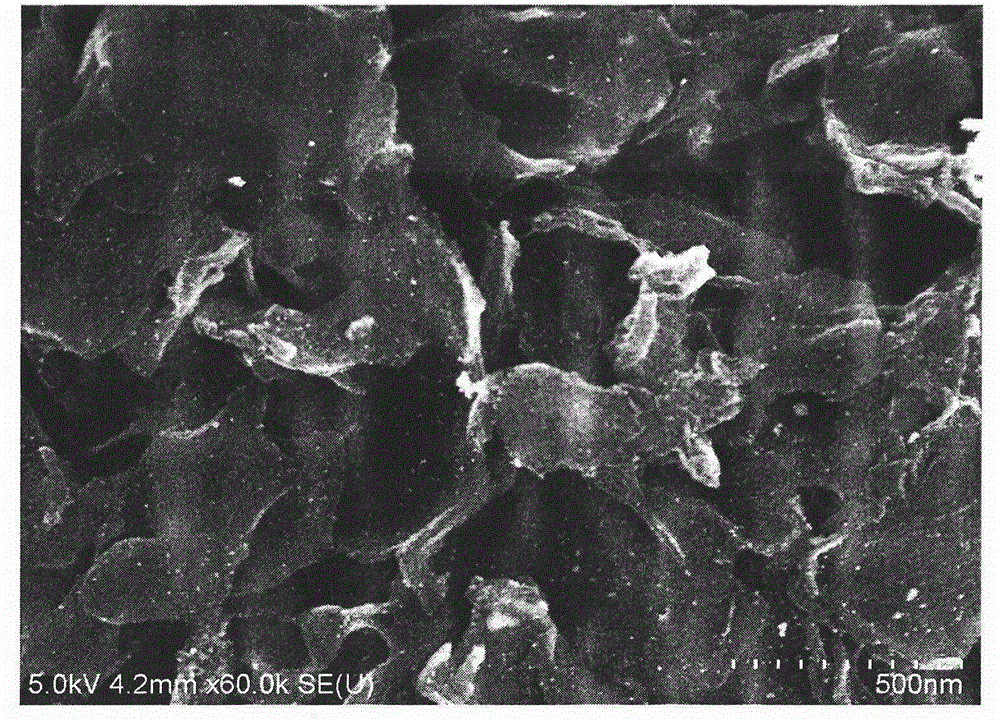

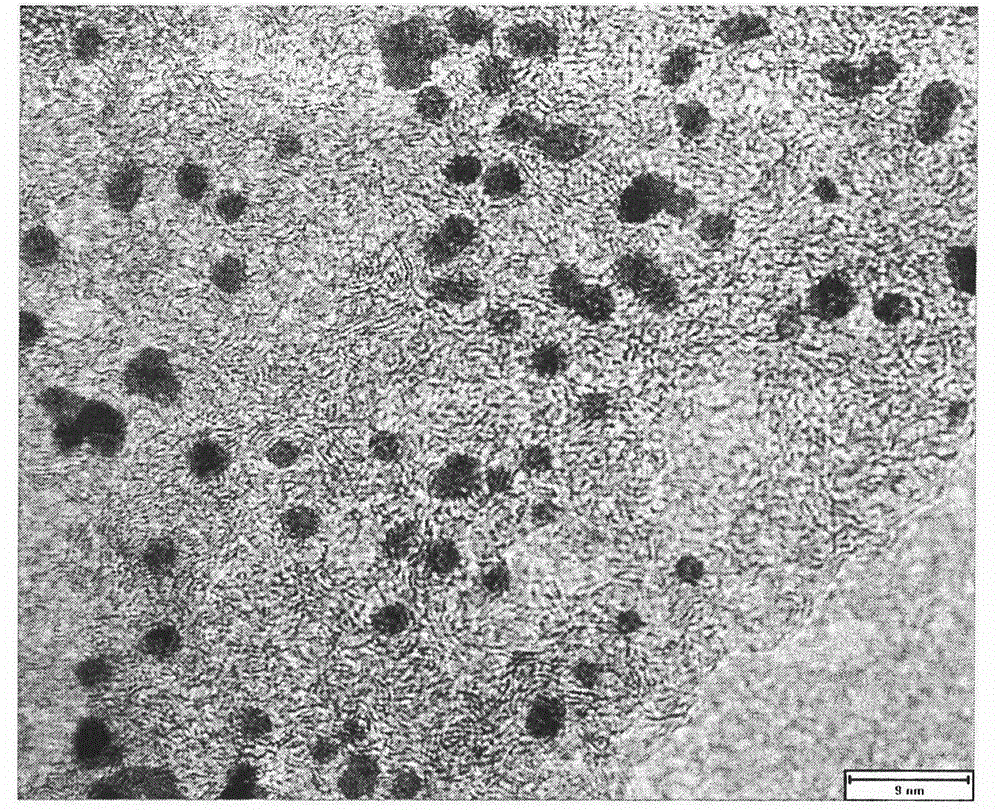

Preparation method and application of graphene based porous carbon supported metallic catalyst

A metal catalyst and metal-loaded technology, applied in electrochemical generators, nanotechnology for materials and surface science, fuel cells, etc., can solve the problems of low catalyst activity and poor catalyst stability, and achieve excellent electrocatalytic performance , high catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of graphene oxide

[0025] Adopt Hummers method to prepare graphene oxide, 230mL sulfuric acid (98%, H 2 SO 4 ) and 5g sodium nitrate (NaNO 3 ) after mixing, cool in an ice bath; when the temperature is 0°C, add 5g of graphite under stirring; after mixing for 4 to 5 hours, slowly add 30g of potassium permanganate (KMnO 4 ); react at 35°C for 2 hours, add 460mL deionized water to dilute, stir at 98°C for 15 minutes, add deionized water to dilute, and add 100mL hydrogen peroxide (30%, H 2 o 2 ); filter, wash with 2L of 5% dilute hydrochloric acid, and then wash with deionized water until neutral to obtain graphite oxide; ultrasonicate graphite oxide in water for 0.5-1 hour to obtain graphene oxide solution.

[0026] (2) Preparation of graphene-based porous silica

[0027] Add 0.03g of graphene oxide into 100mL of water, and ultrasonically disperse to form a graphene oxide solution; add 0.04g of NaOH and 1g of CTAB into 100mL of water, and ultrasonical...

Embodiment 2

[0036] (1) Preparation of graphene oxide

[0037] Adopt improved Hummers method to prepare graphene oxide, 12mL sulfuric acid (98%, H 2 SO 4 ), 2.5g potassium persulfate (K 2 S 2 o 8 ) and 2.5g phosphorus pentoxide (P 2 o 5 ) and mix, add 3g of graphite at 80°C, stir for 4 to 5 hours; cool to room temperature, dilute with deionized water, and let stand overnight; slowly add pre-oxidized graphite to 120mL of concentrated sulfuric acid at 0°C, and then slowly add 15g Potassium permanganate (KMnO 4 ), stirred at 35°C for 2 to 4 hours; after diluting with 480ml of deionized water, add 20mL of hydrogen peroxide (30%, H 2 o 2 ); filtering, washing with dilute hydrochloric acid of 1:10 (volume ratio), and then washing with deionized water to neutrality to obtain graphite oxide; ultrasonicating graphite oxide in water for 0.5 to 1 hour to obtain a graphene oxide solution.

[0038] (2) Preparation of graphene-based porous silica

[0039] Add 0.02g of graphene oxide into 100mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com