Hydrophobic and ultraviolet radiation aging-resistant wood-based composite material and preparation method thereof

A composite material, anti-ultraviolet technology, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of reducing the degree of material photodegradation and moisture absorption, water absorption, etc., to achieve high promotion and application value, mild reaction conditions, and weather resistance outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the hydrophobic and anti-ultraviolet aging wood-based composite material of the present invention includes preparation of precursor solution, multi-stage impregnation and drying process, specifically including:

[0023] The preparation of the precursor solution refers to dispersing the water-soluble titanium source in a 5-7mol / L sodium chloride aqueous solution, stirring evenly to obtain solution a, so that the concentration of the water-soluble titanium source in the solution is 0.001-0.500 mol / L; add the alkaline substance into the solution a and stir evenly to obtain solution b, namely the precursor solution, so that the concentration of the alkaline substance in the solution is 0.001-0.500mol / L.

[0024] The first-level impregnation and drying refers to immersing the wood substrate to be treated in the precursor solution, reacting at room temperature for 1-10 days, taking out the treated wood substrate, washing with water, and drying at room...

Embodiment 1

[0041] (1) Preparation of the hydrophobic and anti-ultraviolet aging wood-based composite material of the present invention

[0042] Disperse titanium trichloride in 6 mol / L sodium chloride aqueous solution, and stir evenly with magnetic force to obtain solution a, so that the concentration of titanium trichloride in the solution is 0.500 mol / L. Add sodium hydroxide to solution a, and stir evenly with magnetic force to obtain solution b, namely the precursor solution, so that the concentration of sodium hydroxide in the solution is 0.500 mol / L.

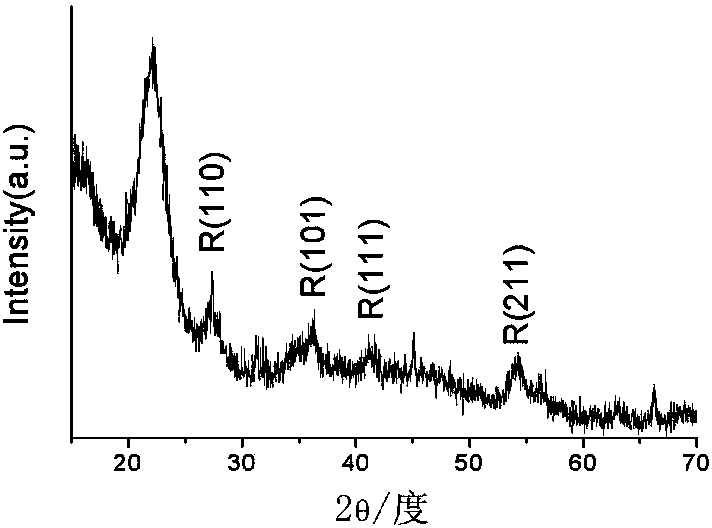

[0043] Cut Yunnan pine wood with a moisture content of 10% into pieces of 0.1 cm x 1.58 cm x 5.13 cm, immerse in the precursor solution, and react at room temperature for 5 days, take out the treated wood chips, and rinse with deionized water Wash and dry at room temperature for 2 days to obtain a wood-based composite material whose surface layer is a titanium dioxide layer with a rutile micro-nano secondary structure.

[0044] I...

Embodiment 2

[0049] (1) Preparation of the hydrophobic and anti-ultraviolet aging wood-based composite material of the present invention

[0050] Disperse titanium tetrachloride in a 5 mol / L sodium chloride aqueous solution, and stir evenly with a magnetic force to obtain solution a, so that the concentration of titanium tetrachloride in the solution is 0.010 mol / L. Add ethylenediamine into solution a, and stir evenly with magnetic force to obtain solution b, that is, the precursor solution, so that the concentration of ethylenediamine in the solution is 0.010 mol / L.

[0051] Cut Yunnan pine wood with a moisture content of 15% into slices of 0.1 cm x 1.58 cm x 5.13 cm, immerse in the precursor solution, and react at room temperature for 1 day, take out the treated wood slices, and rinse with deionized water Wash and dry at room temperature for 1 day to obtain a wood-based composite material whose surface layer is a titanium dioxide layer with a rutile micro-nano secondary structure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com