Patents

Literature

39results about How to "Prevent bulging deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

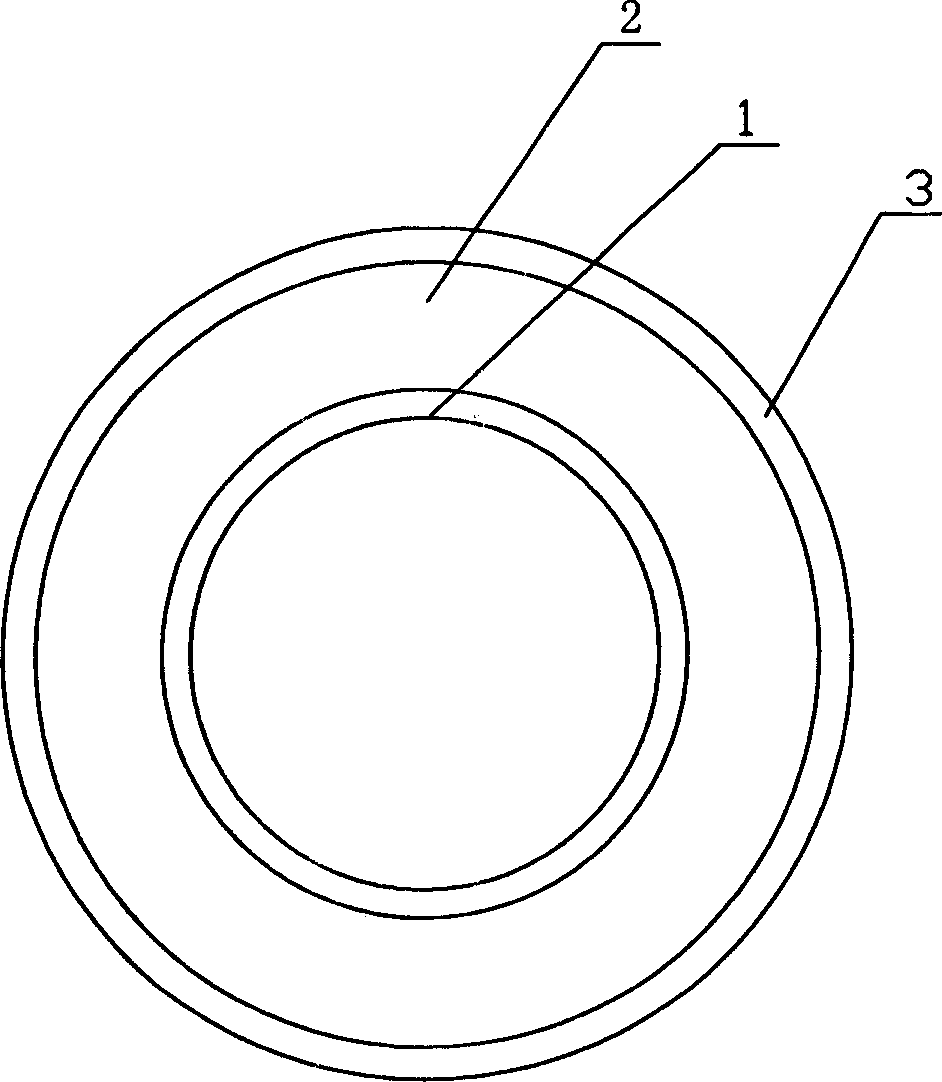

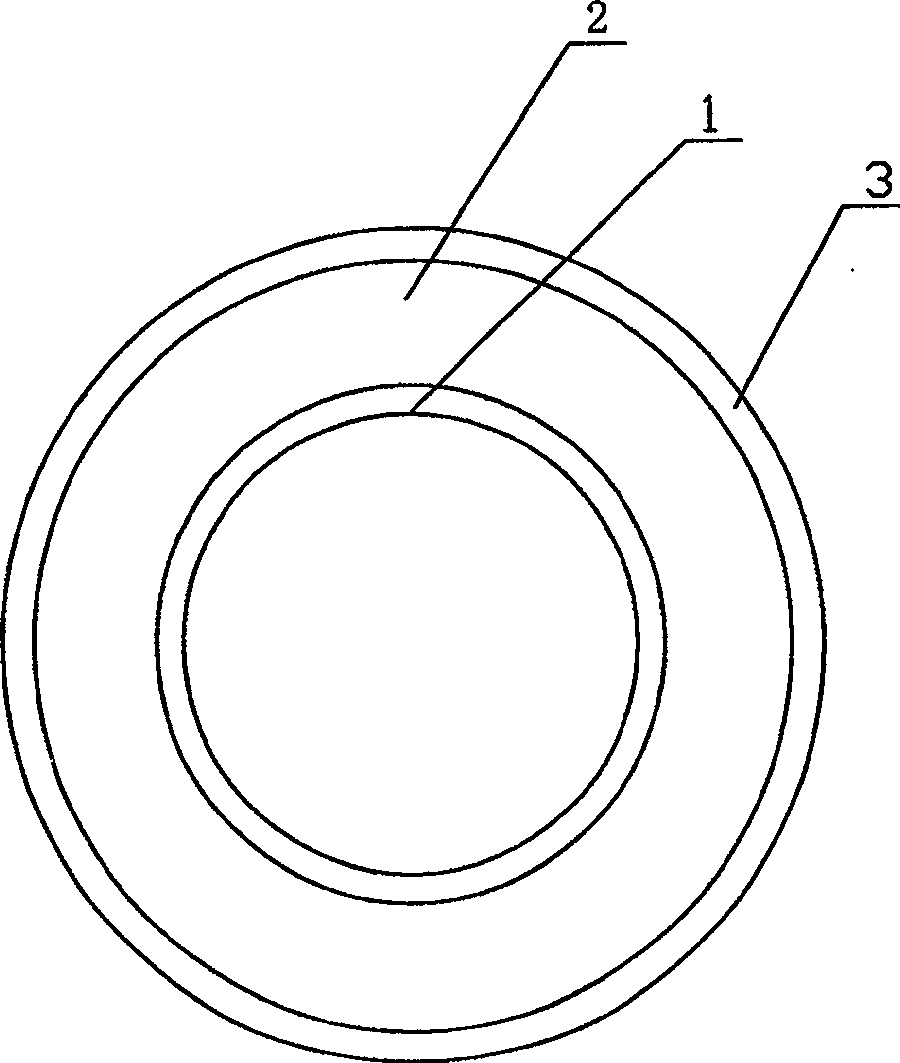

Sealing gasket and manufacturing method

The present invention relates to a method for preparing gasket seal. Said preparation method includes according to size requirement cutting metal ring; according to compression ratio of graphite plate and density of gasket cutting out width of graphite tape, according to the specification size required for gasket selecting proper mould; placing the graphite tape into the mould by turns and prepressing graphite ring; moulding the metal ring and graphite ring by means of mould and nesting metal ring with graphite ring together; demoulding; and edging and shaping so as to obtain the gasket seal.

Owner:NINGBO TIANSHENG SEALING PACKING

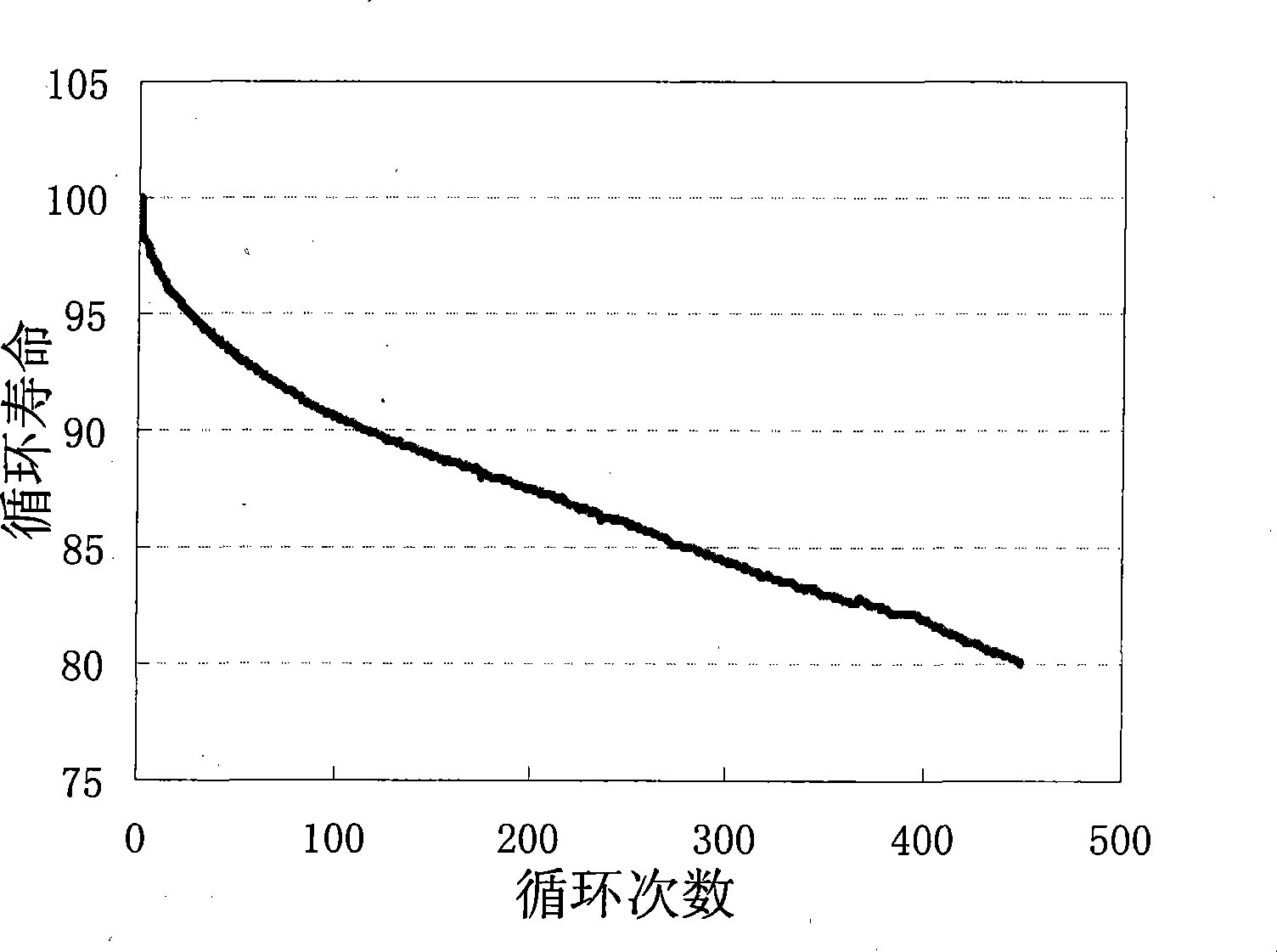

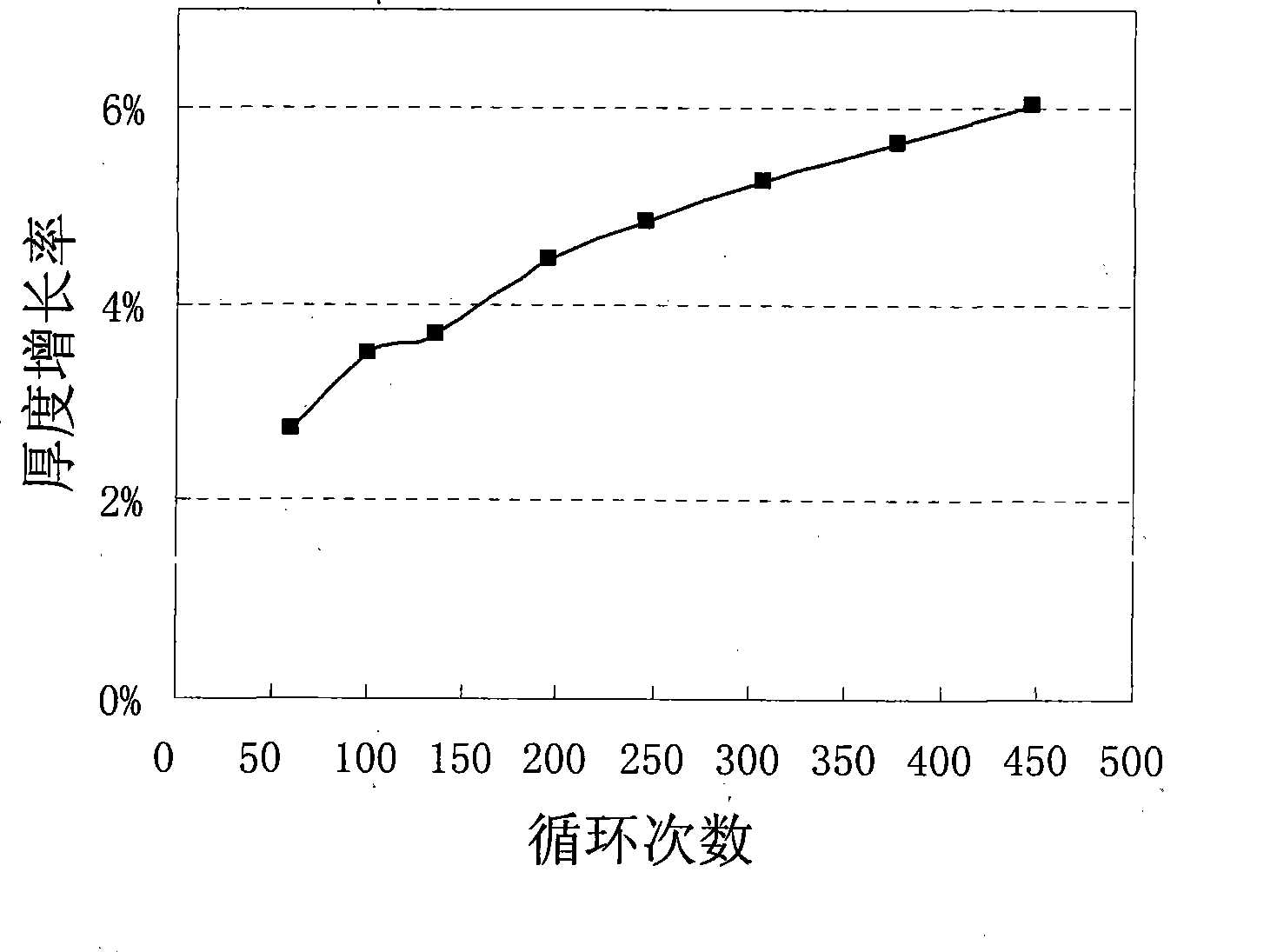

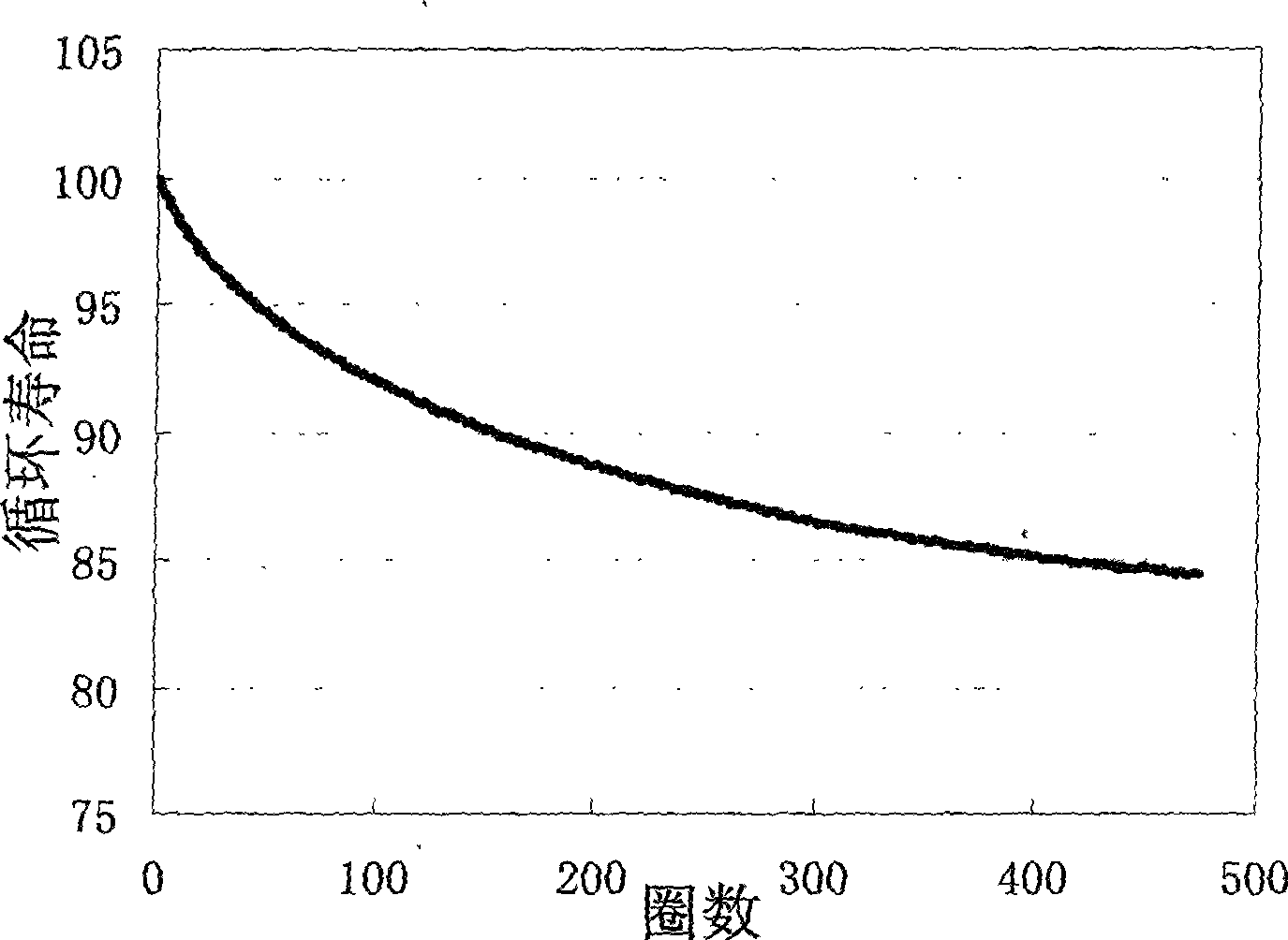

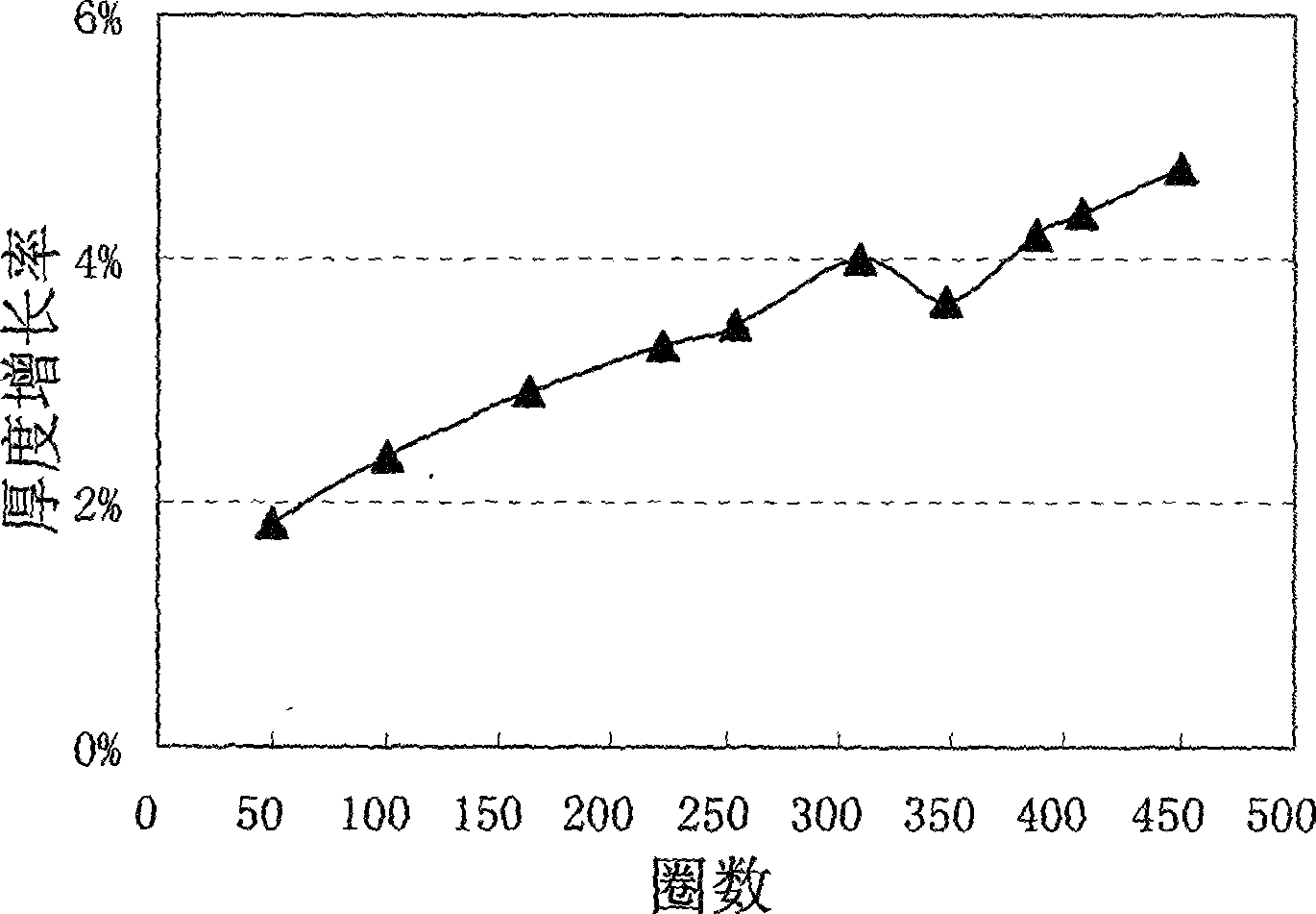

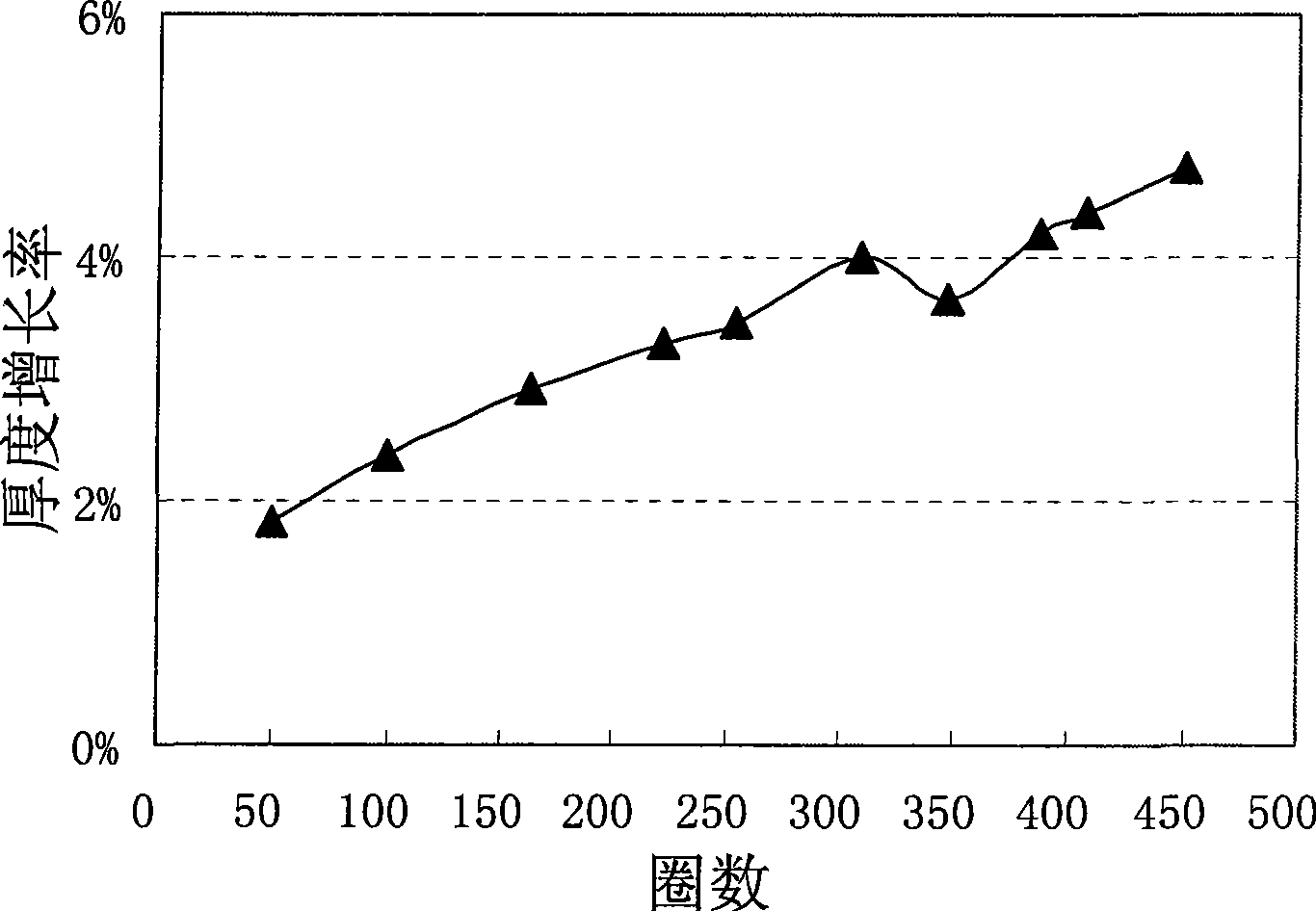

Method for inhibiting expansion of lithium ion polymer battery

InactiveCN102044704AImprove thermal stabilityPrevent bulging deformationCell electrodesFinal product manufacturePorosityPolyolefin

The invention relates to a method for inhibiting expansion of a lithium ion polymer battery. The method comprises the following steps: (1) respectively rolling positive and negative plates in thermal state at the temperature of 50-150 DEG C, wherein a diaphragm is a polyolefin micropore one with thickness of 9-40mm and porosity of 25-50%; (2) winding the positive and negative plates and the diaphragm into a battery cell conventionally, and packaging the battery cell in an aluminium-plastic packaging film; (3) preparing non-water electrolyte containing lithium salt and a film-forming additive through uniform mixing, wherein the lithium salt contained in the non-water electrolyte is one of or a mixture of any two of LiPF6, LiBF4, LiBOB, LiN(CF3SO2)2 or LiN(C2F5SO2)2 and has concentration of 0.4-1.2mol / L; and the film-forming additive in the non-water electrolyte is vinylene carbonate (VC), propylene sulphite (PS) or any mixture of the VC and the PS and accounts for 0.5-4% by weight of the solvent; and (4) injecting the non-water electrolyte into the aluminium-plastic packaging film, and sealing the packaging film. The invention has the beneficial effect of effectively preventing the battery from bulging deformation under high temperature.

Owner:TIANJIN LISHEN BATTERY

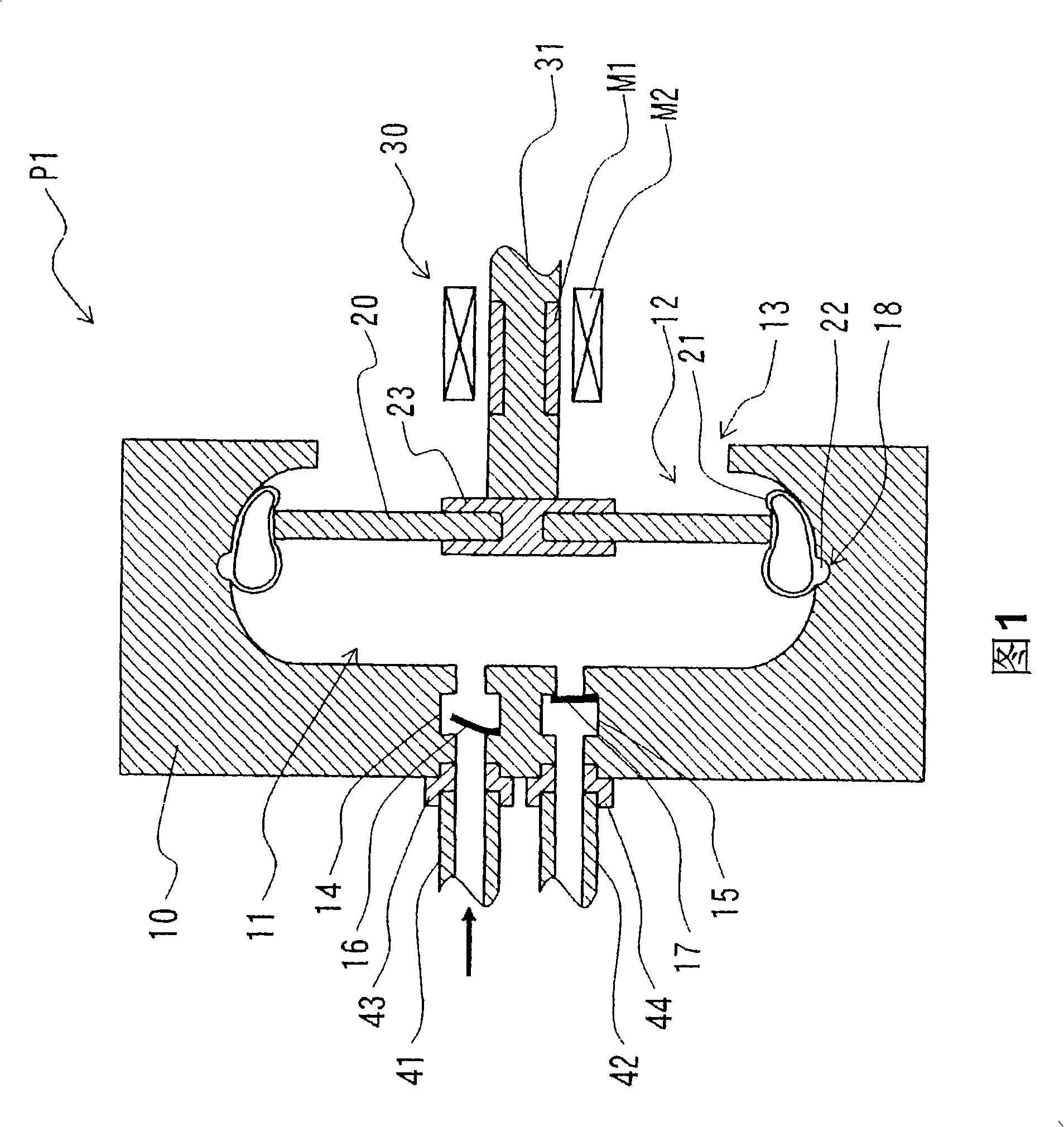

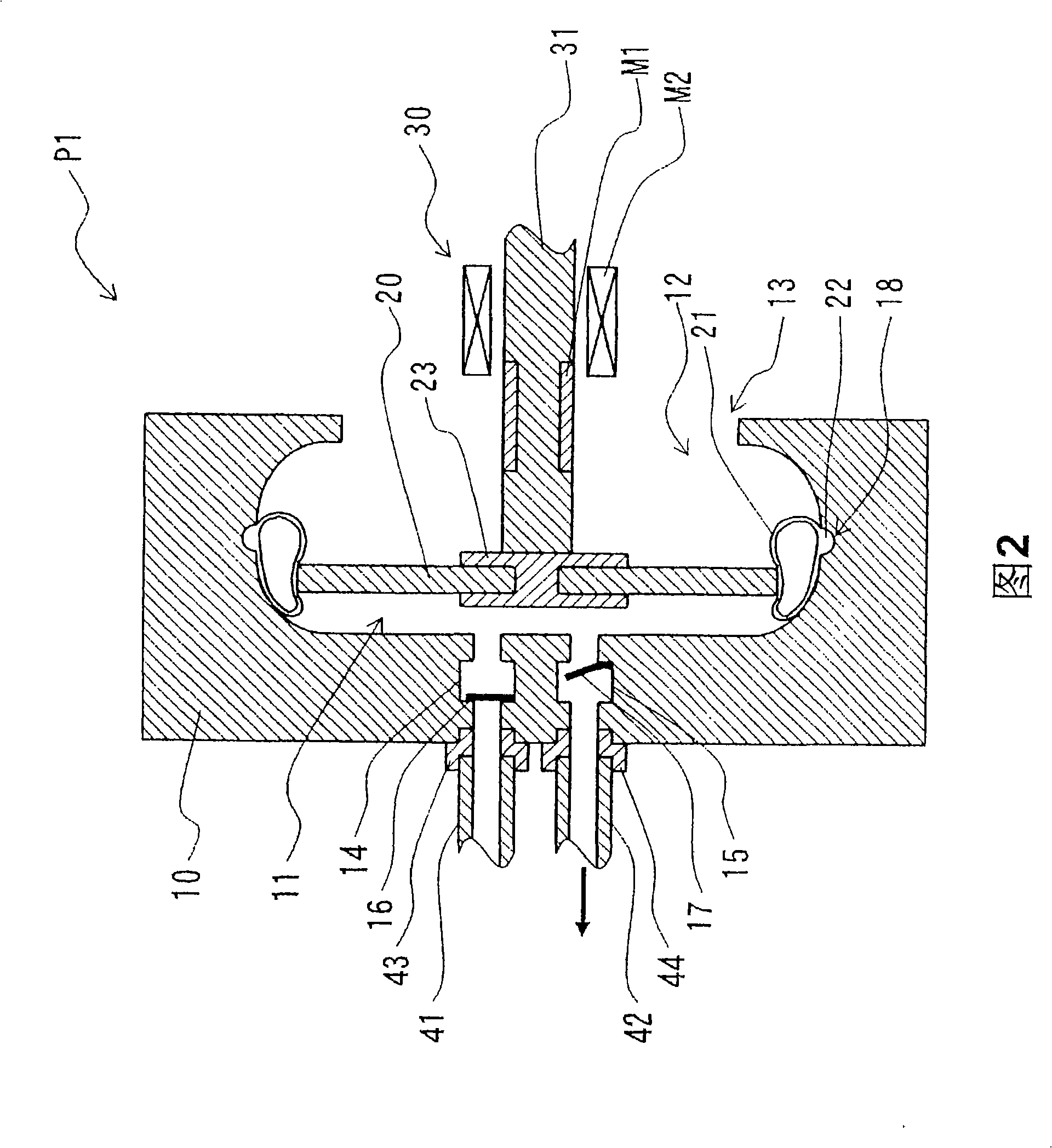

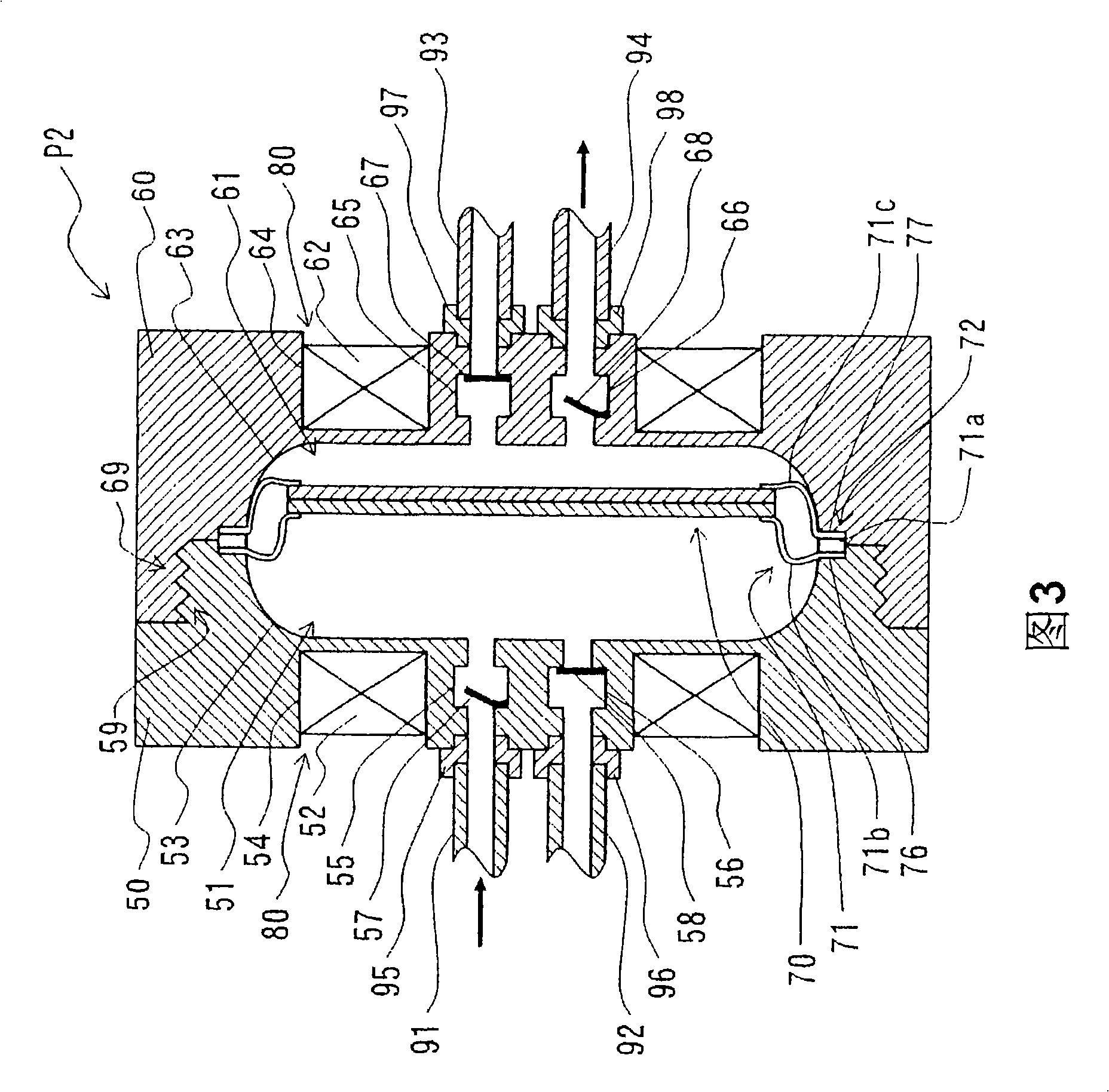

Pump

InactiveCN101273199APrevent bulging deformationEasy to moveFlexible member pumpsPiston pumpsEngineeringHigh pressure

A diaphragm type pump for feeding a low viscosity fluid such as air under high pressure while minimizing the size of a feeding means. The pump connected with a feeding pipe and a delivery pipe and delivering fluid fed from the feeding pipe from the delivery pipe, comprises a housing provided with a storage chamber communicating with the feeding pipe and the delivery pipe through a one-way valve, respectively, and storing the fluid temporarily, a diaphragm arranged oppositely to the storage chamber and driven to advance or retract thus sucking the fluid from the feeding pipe into the storage chamber and then pushing out the fluid to the delivery pipe, and a section for driving the diaphragm to advance or retract. The diaphragm is provided with a ring-like tube along the outer circumferential edge thereof, and the diaphragm is fixed to the housing through the tube thus advancing or retracting the diaphragm while deforming the tube elastically.

Owner:MINORU IND

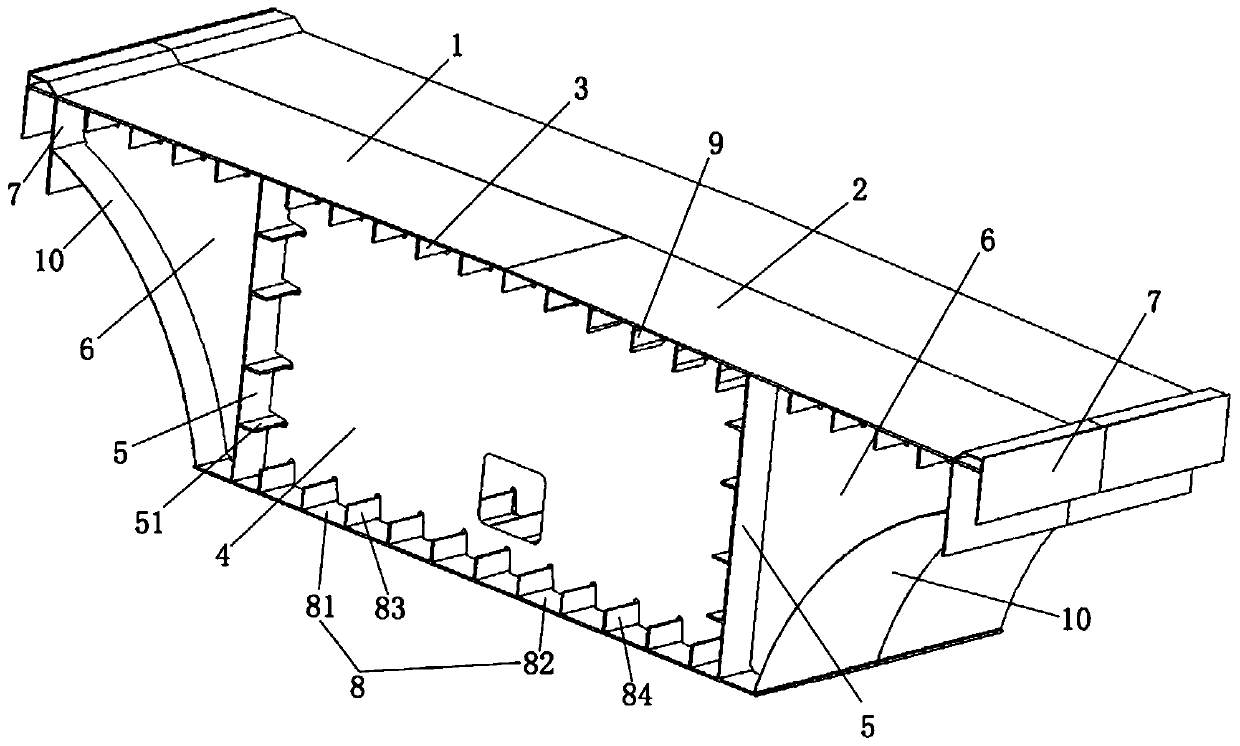

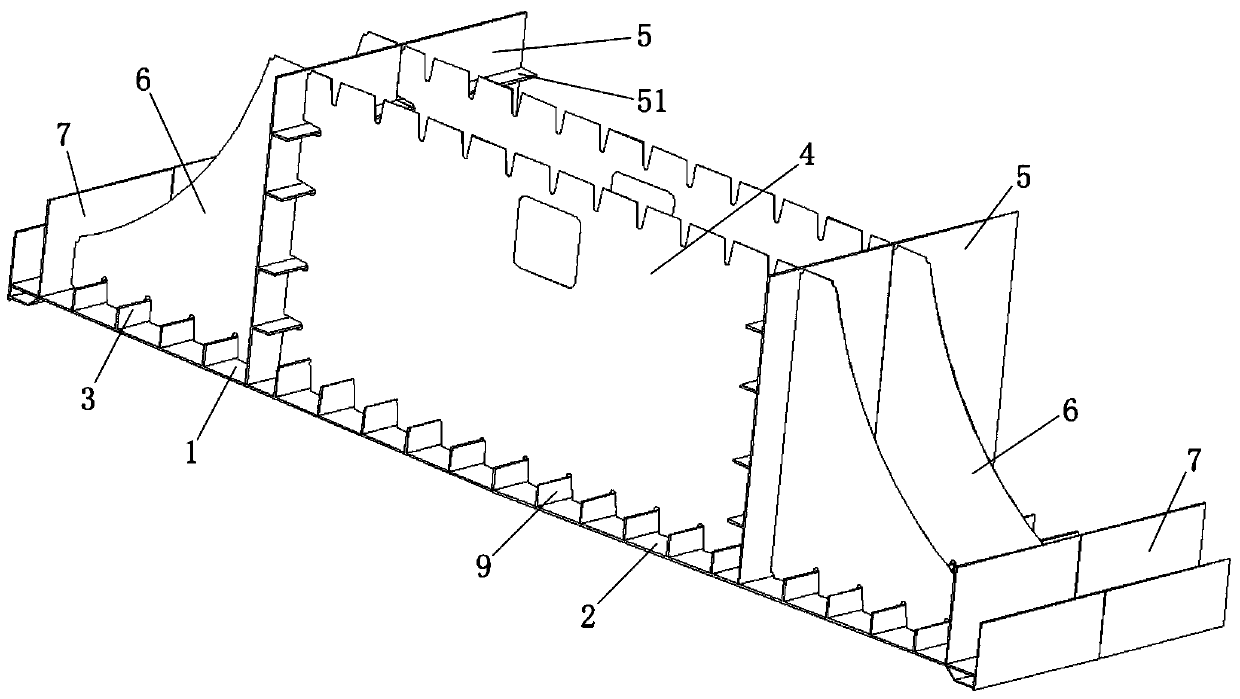

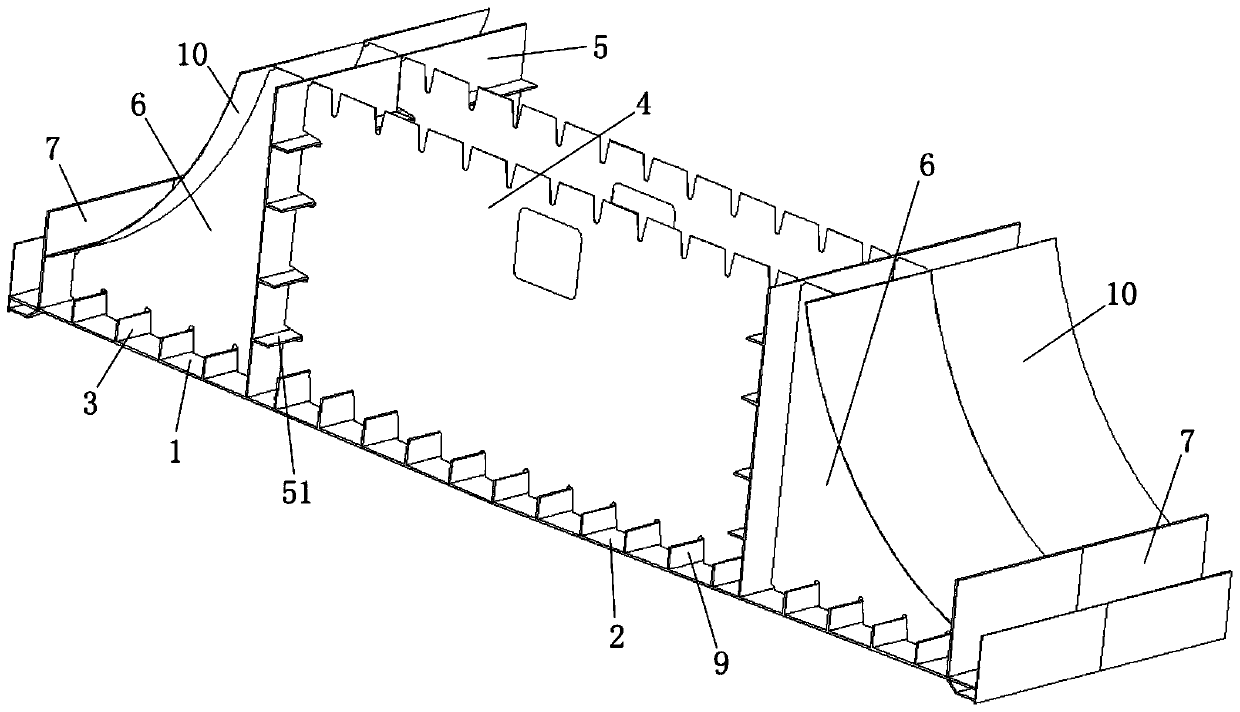

Space curved surface special-shaped steel box girder bridge section and precise welding processing forming method thereof

PendingCN110541349AAchieve load bearingRealize functionBridge structural detailsBridge erection/assemblyBridge deckStructural engineering

The invention discloses a space curved surface special-shaped steel box girder bridge section and a precise welding processing forming method thereof, and the section and the method solve the problemsthat a bridge deck surface is easy to bulge and deform and a space curved surface is not smooth in the prior art. The space curved surface special-shaped steel box girder bridge section comprises a steel box girder bridge bottom plate, a steel box girder bridge web plate, arc-shaped lower sealing plates on two sides of the steel box girder bridge, a steel box girder bridge top plate, a steel boxgirder bridge cantilever sealing plate, a first steel box girder bridge top plate and a second steel box girder bridge top plate. The space curved surface special-shaped steel box girder bridge section is firm, safe and durable, the appearance linear structure is smooth and attractive, and the dual functions of bridge bearing traffic and aesthetic appreciation can be effectively realized. The precise welding processing forming method comprises the steps of firstly blanking and processing and forming in a factory in units, then assembling from inside to outside and from bottom to top, completing welding of an internal vertical weld joint after assembling, then performing welding of a transverse weld joint, and controlling the position of an external part through accurate positioning of a web plate and a partition plate; and the precise welding processing forming method has smooth flow and can prevent the bridge section deck surface from bulging, deforming and being unsmooth.

Owner:CHINA MCC5 GROUP CORP

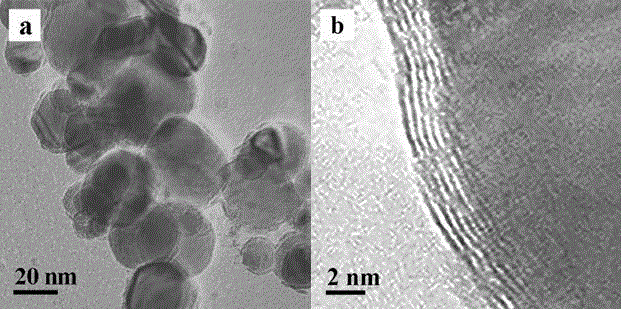

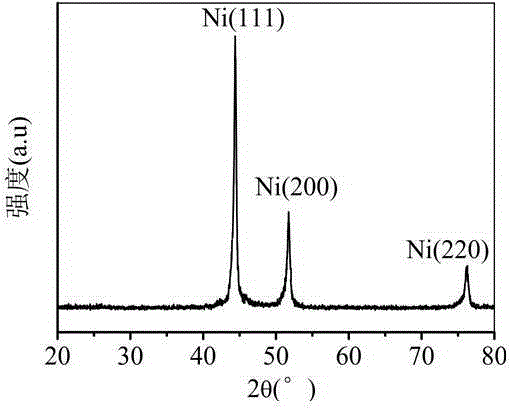

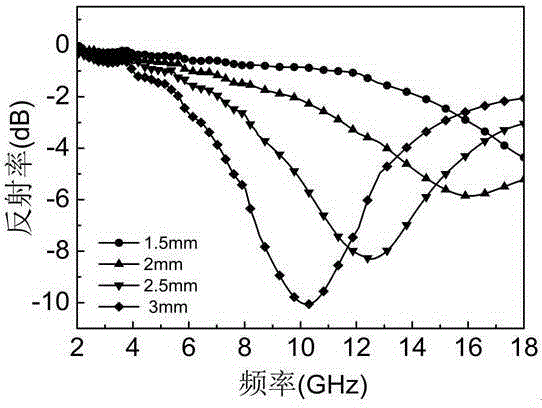

Carbon coated nickel nanoparticle and silicon resin composite microwave absorbing coating and preparation method thereof

InactiveCN105176384ANot easily oxidizedImprove absorbing performanceRadiation-absorbing paintsXylyleneMicrowave

The invention discloses a carbon coated nickel nanoparticle and silicon resin composite microwave absorbing coating and a preparation method thereof. The composite microwave absorbing coating is composed of 40%-60% by weight of carbon coated nickel nanoparticles and silicon resin. The preparation method comprises the steps that the carbon coated nickel nanoparticles are prepared through an arc discharge method; the carbon coated nickel nanoparticles are filled into the silicon resin to be evenly mixed, and coating slurry is obtained; an adequate amount of xylene is taken to serve as solvent to be added into the slurry, and the viscosity of the slurry is adjusted; a curing agent is added into the slurry, even stirring is conducted, and the coating with certain thickness is prepared. The composite microwave absorbing coating prepared through the method has the advantages of being wide in wave-absorbing band, good in wave-absorbing efficiency, low in reflectivity, high in stability, good in mechanical property and the like, the technology is simple, and the coating is easy to repair.

Owner:GUANGDONG UNIV OF TECH

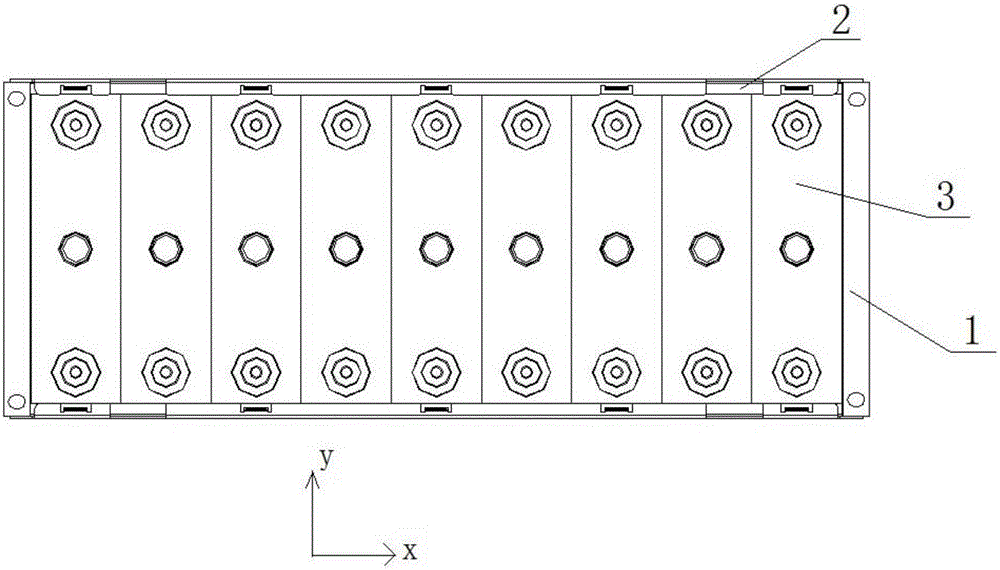

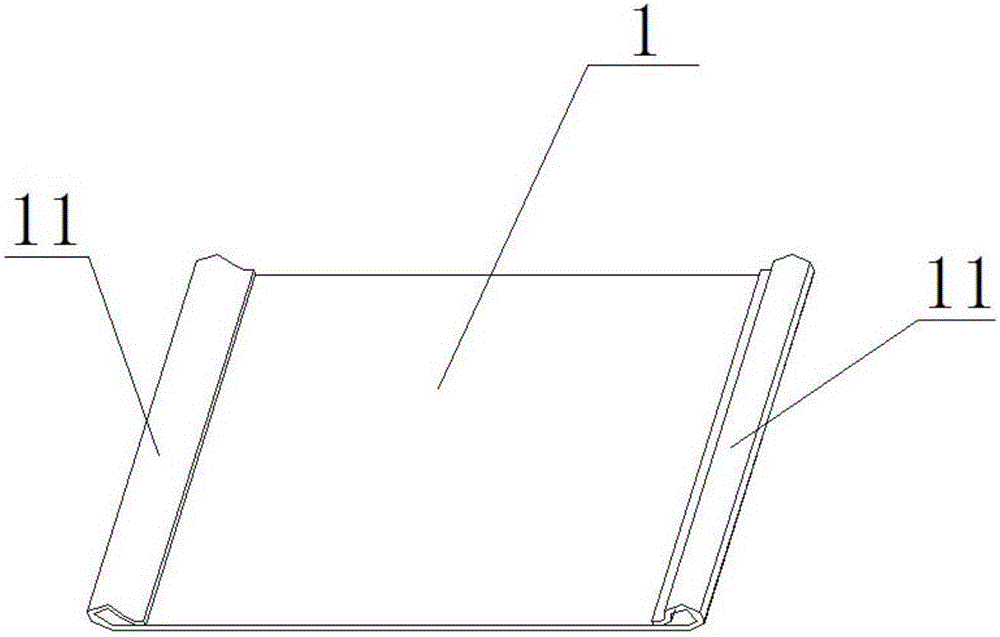

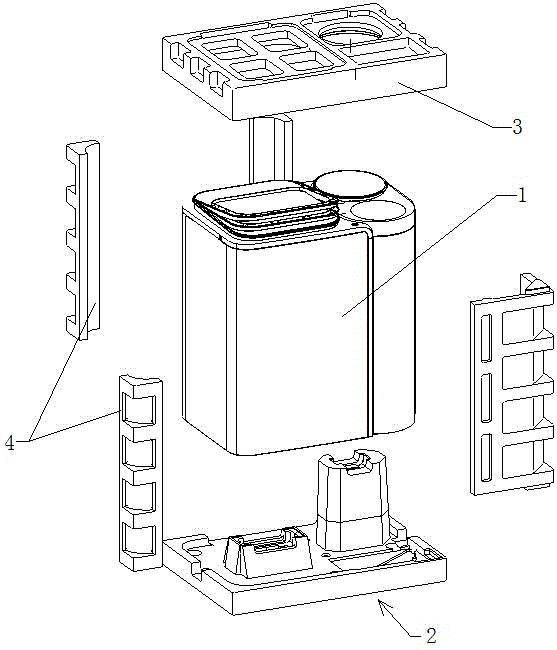

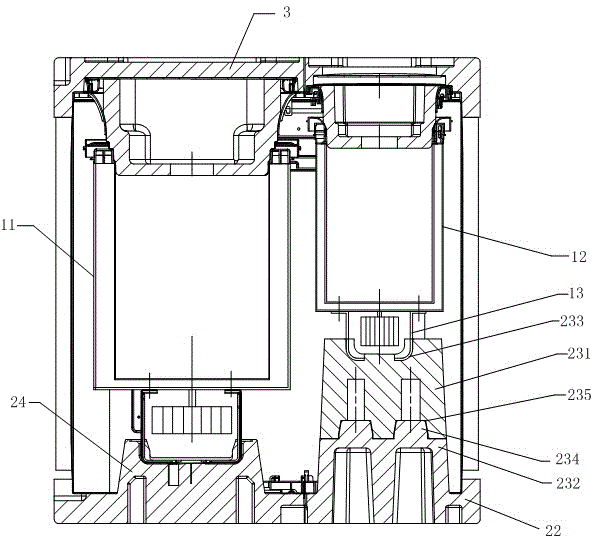

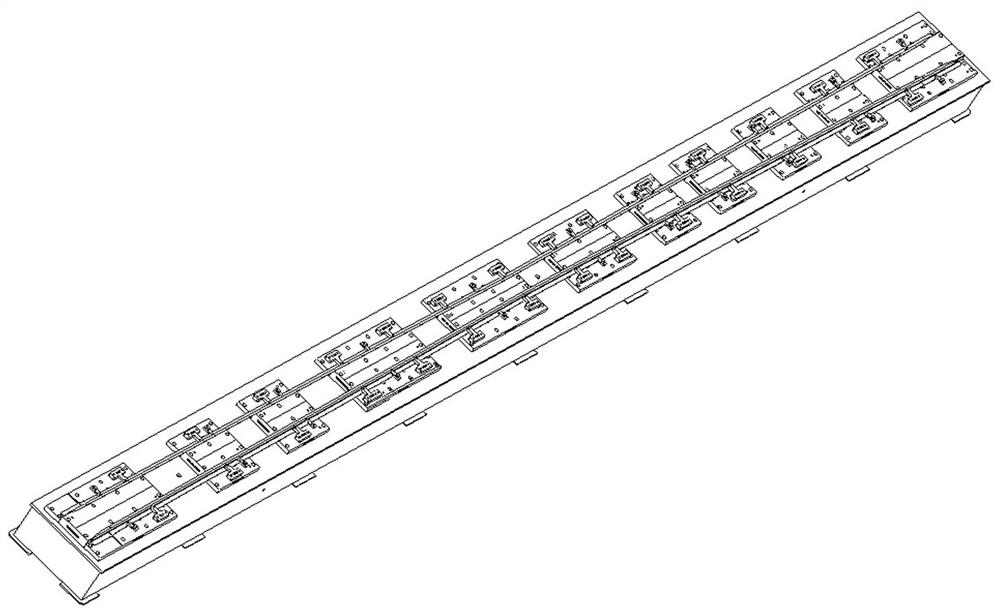

Battery core module

ActiveCN105742539AAvoid the problem of weak intermediate mechanical propertiesGood for distributing vertical pressureFinal product manufactureBattery isolationElectrical batteryEngineering

The application relates to the technical field of a battery pack, in particular to a battery core module. The battery core module comprises a substrate, a plurality of battery units, a pair of end plates, a pair of side plates and a plurality of fastening elements, wherein the pair of end plates are separately arranged on the two sides of a direction which the plurality of battery units are laminated, are close to the battery unit at the outermost part and extend along the length direction of the battery units, the end parts of the end plates in the length direction of the battery units are bent to form a pipe winding segment, the axial line direction of the pipe winding segment is the same as the height direction of the battery units, and the fastening elements are inserted into the pipe winding segment, extend towards a substrate direction in the pipe winding segment, protrude out of the pipe winding segment, and are fixed on the substrate. By arranging the pipe winding segment on the end plates, the fastening strength of the fastening elements is improved, and the battery can be reliably fixed on the substrate.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for manufacturing polymer lithium ion battery

InactiveCN101369675AImproved thermal stabilitySuppress gas productionFinal product manufactureSecondary cellsSolventDecomposition

The invention discloses a manufacturing method of polymer lithium ion battery to provide a manufacturing method of polymer lithium ion battery capable of preventing a cathode surface passivation film from decomposition and inhibiting secondary reaction between an electrolyte solvent and the anode and the cathode to reduce gas and control thickness of the battery effectively so as to prevent the battery from tympanites and deformation. The method comprises steps of: respectively coating the polymer substrate slurry on both surfaces of the dissepiment, and drying the same; roiling the anode, the cathode and the dissepiment coated with the polymer substrate to battery core and packaging the same in an aluminum plastic package film, drying the same to remove surplus water; infusing non water electrolyte to the aluminum plastic package film and sealing, the non water electrolyte composed of lithium salts, film forming additives, anti-tympanites additive triphenyl organic phosphate and the solvent; depositing the battery core sealed at 60 deg C to 120 deg C, enabling the non water electrolyte and the polymer substrate to form gel phase to obtain the polymer lithium ion battery of the invention.

Owner:TIANJIN LISHEN BATTERY

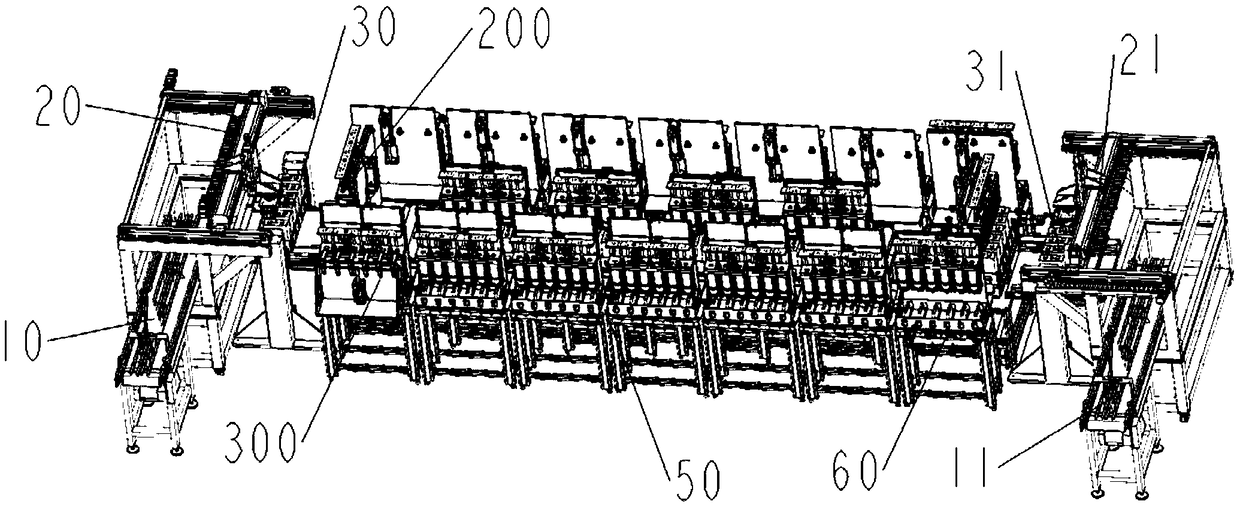

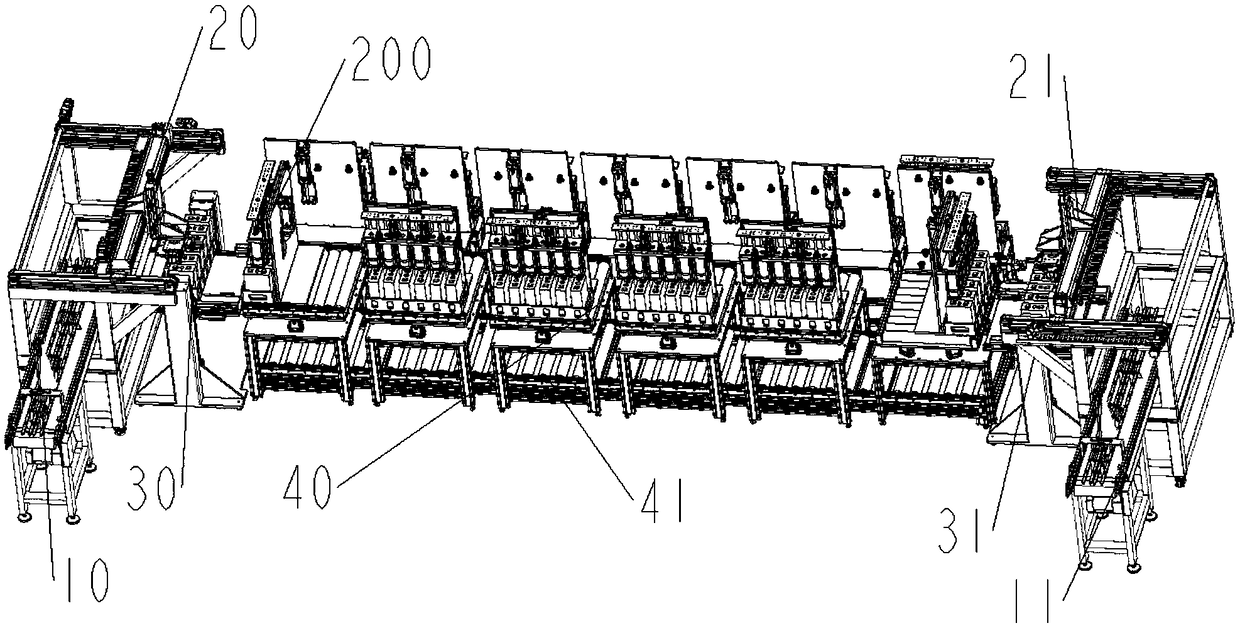

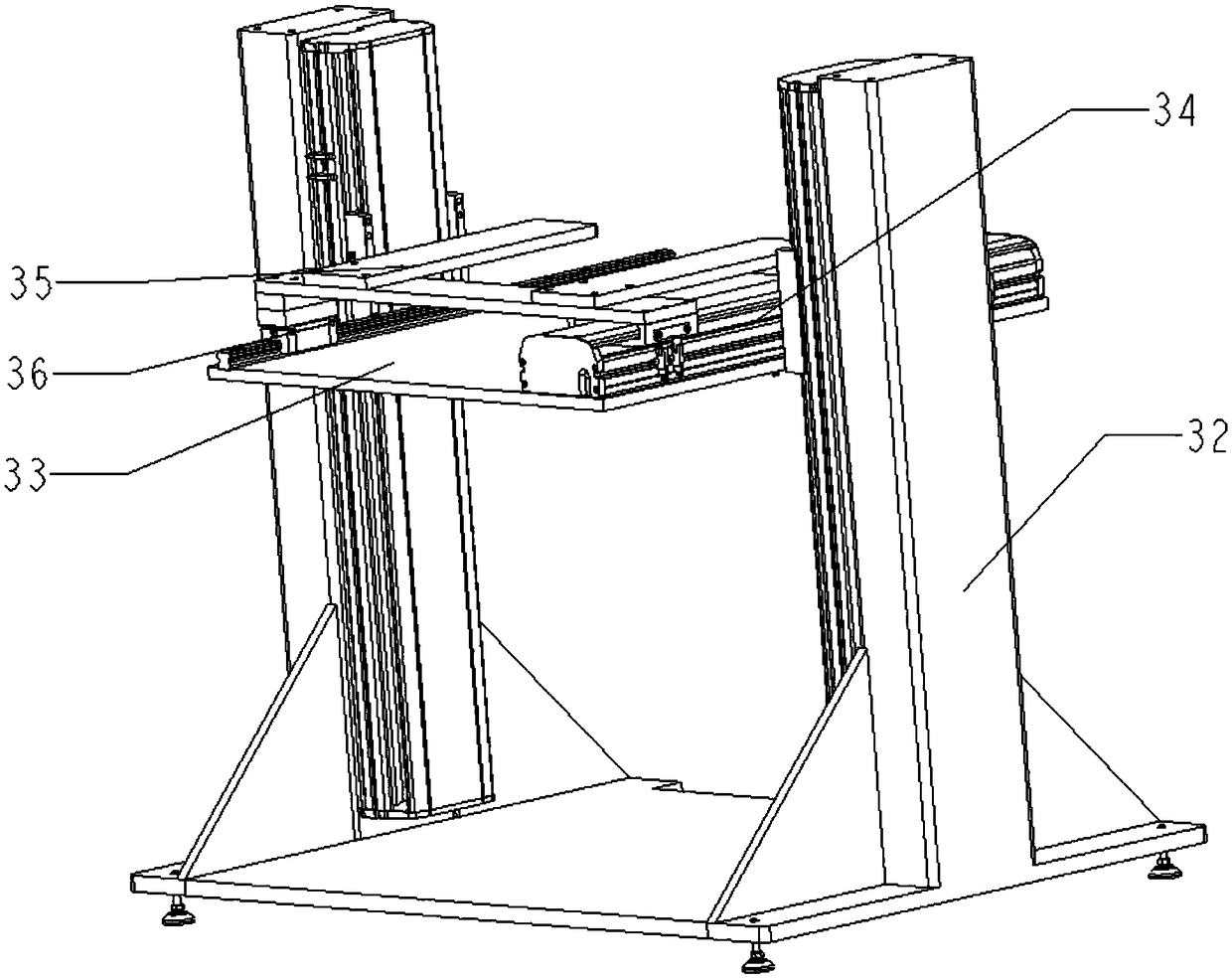

An automatic lithium battery liquid injection system

ActiveCN109216644AImprove scalabilityImprove maintainabilityFinal product manufactureNon-aqueous electrolyte cellsCore functionElectrical battery

A liquid injection system for automate lithium battery comprises more than two battery boxes and a filling mechanism, the battery incoming lines arranged in turn are connected, Battery loading manipulator, a first lifting and translating mechanism for engaging the battery case, Filling mechanism return drum line, An unload battery case return drum line located below that return drum line of the fil mechanism, a second lifting and translating mechanism for engaging the battery case, Battery blanking manipulator, a battery output line and a static drum line arranged side by side with the backflow drum line of the filling mechanism, wherein the first lifting and translating mechanism is provided with a battery loading level, the battery loading level is located in the working range of the battery loading manipulator, the second lifting and translating mechanism is provided with a battery blanking level, and the battery blanking level is located in the working range of the battery blankingmanipulator; The invention adopts a more concise and efficient structural mode around the core function of the liquid injection package, remarkably reduces the structural cost of the system, and improves the reliability, stability and economy of the whole system.

Owner:郑州鼎能实业有限公司

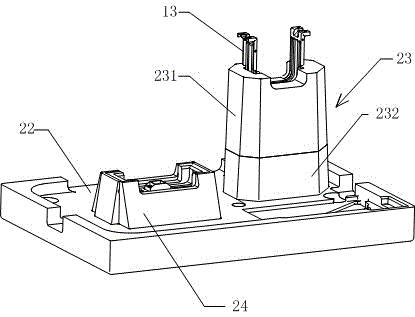

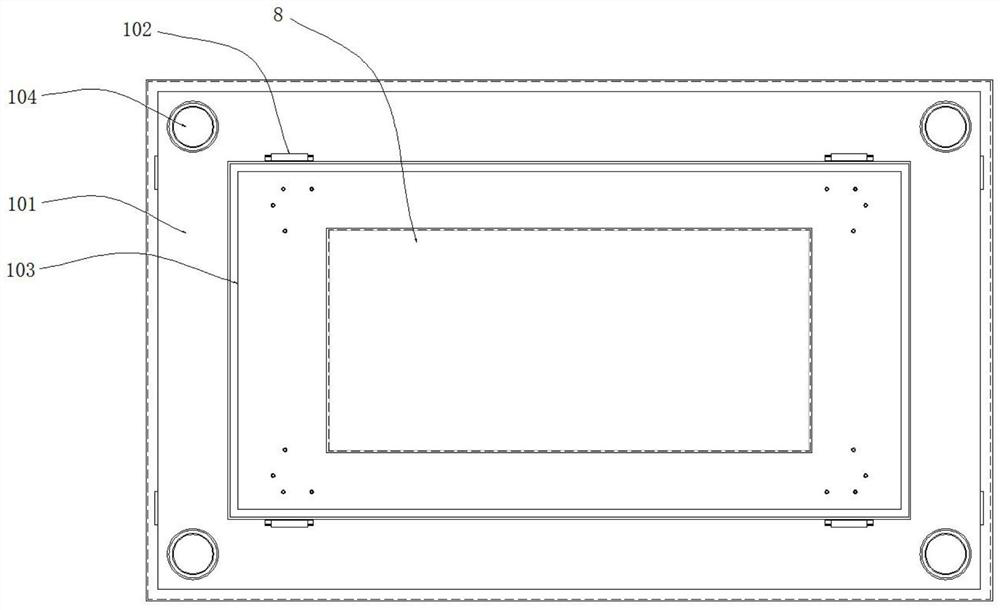

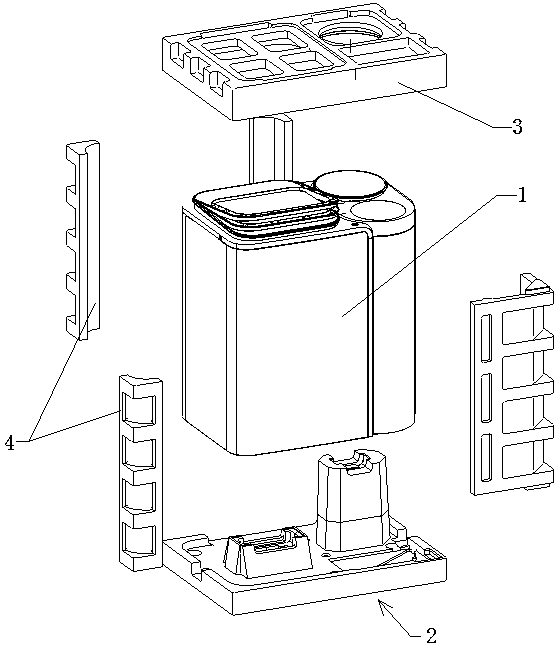

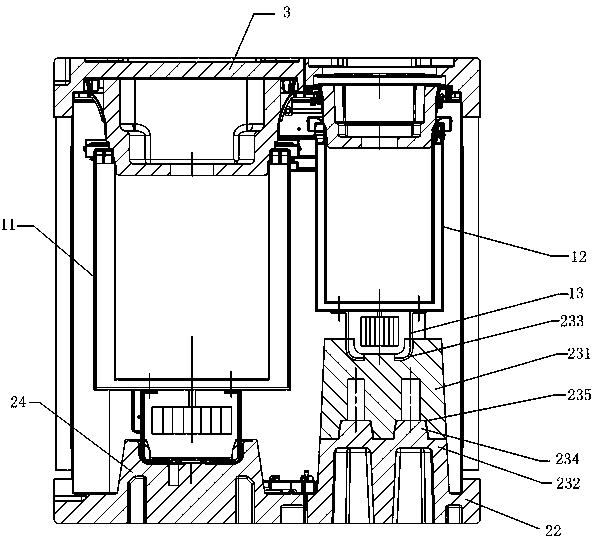

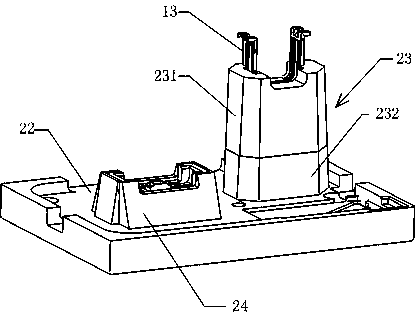

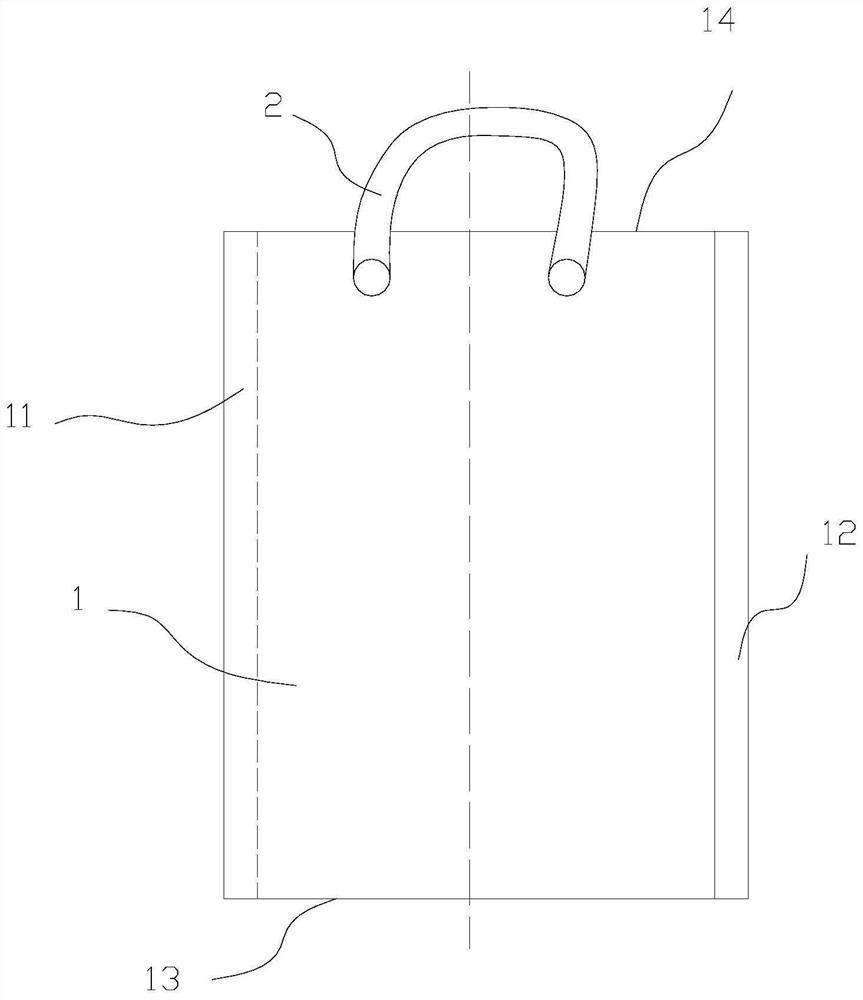

Package bottom lining assembly, washer and washer packaging and dismounting method

ActiveCN106516429AAchieve fixationPrevent bulging deformationContainers to prevent mechanical damageInterference fitEngineering

The invention provides a package bottom lining assembly which comprises a box-shaped bottom support with an upper opening and a bottom lining. The bottom lining is wrapped with the bottom support; two supporting tables with different heights are arranged on the bottom lining; the height of at least one supporting table can be movably adjusted; and the two supporting tables are supported at the bottoms of different barrel bodies correspondingly. The invention further provides a washer packaging and dismounting method and a washer. The package bottom lining assembly can be applied to logistics impacting monitoring schemes of household electrical appliances which include but not limited to washers, refrigerators, freezers, air-conditioners and the like. Washer outer barrels with different heights can be fixed through a bottom lining plugging structure, and the problem that bumping and deforming of box bodies occur due to displacement of the outer barrels in the conveying process is solved. The upper supporting table and a U-shaped protective cover are in interference fit and can move along with a whole machine, pre-installing can be conducted in advance, the upper supporting table and the lower supporting table are fixed through plugging connection, and the assembly can be installed and operated conveniently on the production site.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Polyether ether ketone pipe joint and welding method thereof

ActiveCN111550633AEasy to weldGuaranteed interference fitPipe connection arrangementsRubber materialPolymer science

The invention discloses a polyether ether ketone pipe joint, and relates to the technical field of pipe joints. The polyether ether ketone pipe joint comprises a joint body, two ends of the joint bodyare provided with openings, an annular groove and a limiting piece are arranged in the inner wall of the joint body, and the annular groove is positioned between the limiting piece and the end part of the joint body. The invention also provides a welding method of the polyether ether ketone pipe joint. The pipe joint and the welding method have the beneficial effects that the polyether ether ketone pipe joint can be matched with a polyether ether ketone pipe,the subsequent welding is conveniently, and the polyether ether ketone pipe joint is large in welding area, high in welding seam connection strength, good in sealing property, attractive in appearance, free of accumulation of overflow rubber materials, and capable of controlling the feeding depth of a straight polyether ether ketonepipe through the limiting piece in the welding process.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

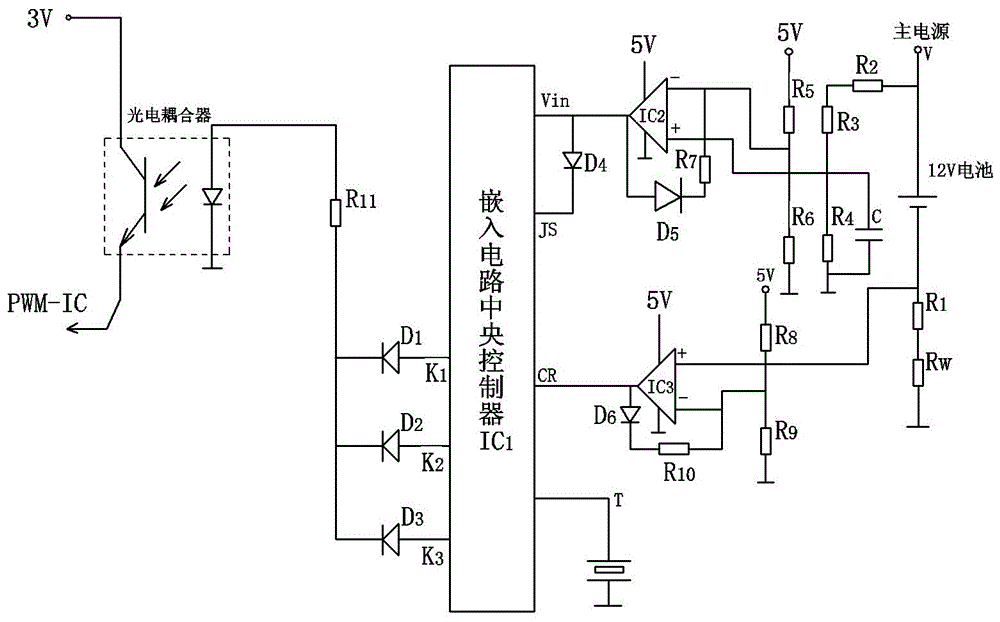

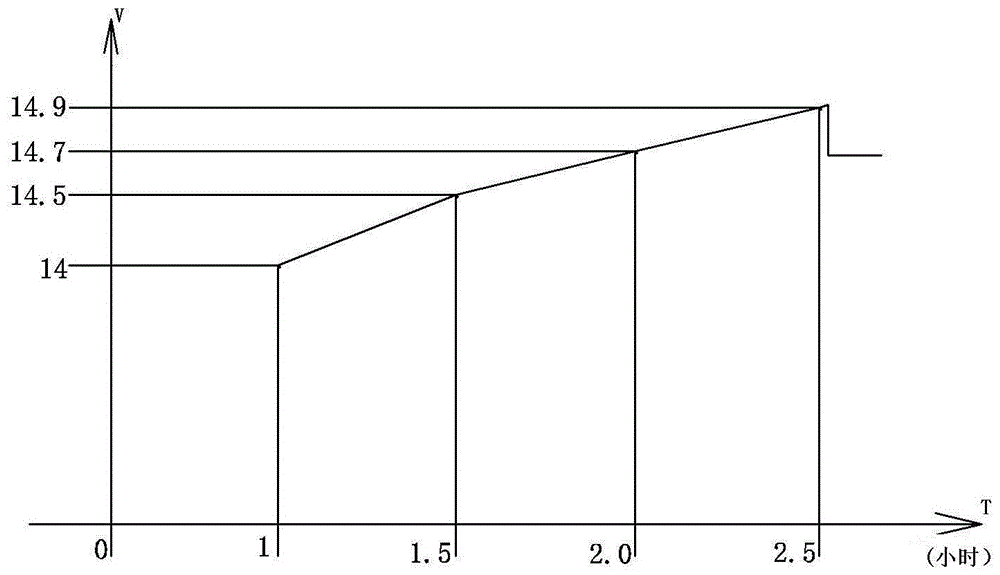

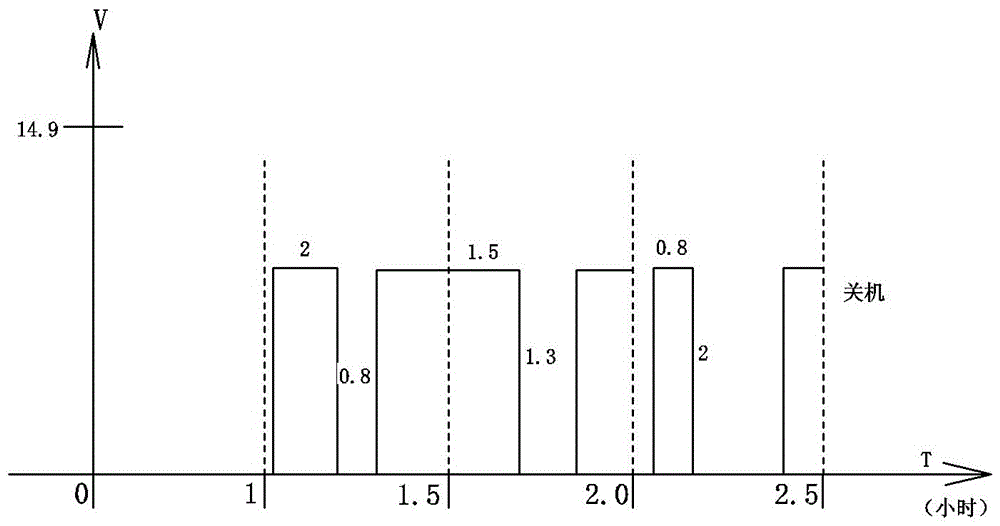

Charging method and control apparatus for lead storage battery suitable for electric vehicle

ActiveCN106374570AAvoid thermal runawayPrevent bulging deformationCharging stationsSecondary cells charging/dischargingTime rangeInternal resistance

The invention discloses a charging method and a control apparatus for a lead storage battery suitable for an electric vehicle, and belongs to the field of the electric vehicle. The control apparatus comprises a central control unit, a photoelectric coupler, a voltage detection unit and a battery internal resistance detection unit, wherein the central control unit is provided with pins of Vin end, JS end, CR end, T end and K1 end, K2 end and K3 end; the Vin end is used for receiving a voltage signal corresponding to a battery end voltage from the output end of the voltage detection unit; the K1 end, the K2 end and the K3 end are output ends of the central control unit; the primary PWM-IC working state of a charger is controlled through the photoelectric coupler; the JS end is a timing triggering end of the central control unit for timing charging periods; and the CR end is used for receiving a battery internal resistance state signal from the battery internal resistance detection unit. According to the charging method and the control apparatus, a low-frequency pulse charging mode limited by a time range is adopted, so that a common industrial phenomenon of early degradation of the capacity service life caused by a single backward failure in cyclic use of a 36-72v battery pack can be effectively solved; and instead, one-time balance charging saturation for the battery pack can be realized, and the charger can be turned off.

Owner:任红雷

Round pin-point gate pouring molding structure

The invention discloses a round pin-point gate pouring molding structure. The structure comprises a supporting mechanism, a mold closing mechanism is arranged at the top of the upper end of the supporting mechanism, a base plate is arranged at the bottom of the lower end of the supporting mechanism, screws are arranged on the periphery of the outer side of the supporting mechanism, and a lower mold cavity is formed in the top of the upper end of the supporting mechanism. A molding mechanism is arranged on the inner side of the upper end of the mold closing mechanism. Auxiliary feeding mechanisms are arranged on the two sides of the interior of the molding mechanism. According to the structure, a heating wire layer is used for heating the upper mold cavity, so that the situation that the temperature in the mold cavity is too low, water vapor is generated due to direct contact with melt, even the water vapor is accumulated in the mold cavity, flowing and molding pressure of the melt are affected, and bubbles are generated in a product is avoided. Through the heating of the heating wire layer, preheating operation can be carried out before molding, so that the situation that melt flows discontinuously in the mold cavity due to too large mold temperature difference is avoided.

Owner:深圳市华中思明通科技有限公司

Liquid packing structure

The invention discloses a liquid packing structure. The liquid packing structure comprises a transfer box and a liquid packing bag put in the transfer box; the liquid packing bag includes a bag cover, a bag body, a bag bottom and a valve port; the bag cover is thermally sealed on the bag body; the valve port is formed in the bag cover; the bag cover consists of inner and outer two layers of films; the edge of the outer layer of film extends to the outer side so as to form a flange on the outer side of the bag body; and the flange is fixed with a lining plate positioned in the transfer box. The liquid packing structure is used for replacing a traditional filling iron barrel; and the liquid packing bag is easy to be recovered and free of being cleaned, so that the cost can be largely reduced.

Owner:NANJING HUJIANG COMPOSITE MATERIALS

Super capacitor casing

InactiveCN106128798AFlexible designImprove efficiencyHybrid cases/housings/encapsulationsSurvivabilitySupercapacitor

The invention discloses a super capacitor casing. The super capacitor casing comprises a casing formed by walls, wherein the casing is provided with an accommodation space used for accommodating electrolyte and solid liquid phase substances including other structures and further comprises reinforcement ribs, the reinforcement ribs are formed on the walls and project towards an internal space, connection portions of the walls and the reinforcement ribs and / or the reinforcement ribs and / or the walls are provided with diversion structures at one side of the accommodation space, and the diversion structures are used for facilitating electrolyte flowing. The super capacitor casing has advantages of simple structure, high electrolyte conveying efficiency, high casing strength, good environment survivability and long service life.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

High temperature hot delivery steel billet transportation special vehicle chassis

PendingCN107187454AImprove structural rigidityImprove structural strengthUnderframesAxle-box lubricationThermal insulationEngineering

The invention discloses a high temperature hot delivery steel billet transportation special vehicle chassis. The high temperature hot delivery steel billet transportation special vehicle chassis comprises a chassis component and a low-layer floor, a heat preservation thermal insulation layer assembly is arranged above the low-layer floor, and comprises a thermal insulation layer cross beam, a thermal insulation layer side beam, a thermal insulation layer support cross beam, a thermal insulation layer longitudinal beam and an upper-layer floor, the thermal insulation layer longitudinal beam is placed in the middle of the chassis and is welded to the thermal insulation layer cross beam, the thermal insulation layer cross beam and the thermal insulation layer support cross beam are assembled and welded into a simply supported beam structure, then the simply supported beam structure and the thermal insulation layer side beam are assembled and welded to form a frame-shaped grid beam structure, the frame-shaped grid beam structure is paved with the upper-layer floor, and a cavity formed by the whole frame-shaped grid beam structure is filled with a heat preservation material. The high temperature hot delivery steel billet transportation special vehicle chassis has a good heat preservation function, and the chassis is applicable to safe loading and transportation of a steel billet not higher than 700 DEG C in a steel enterprise; moreover, the thickness of the heat preservation material can be adjusted according to the temperature of the loaded and transported steel billet, therefore achieving safe loading and transportation of steel billets with different temperatures in all steel enterprises.

Owner:CRRC MEISHAN

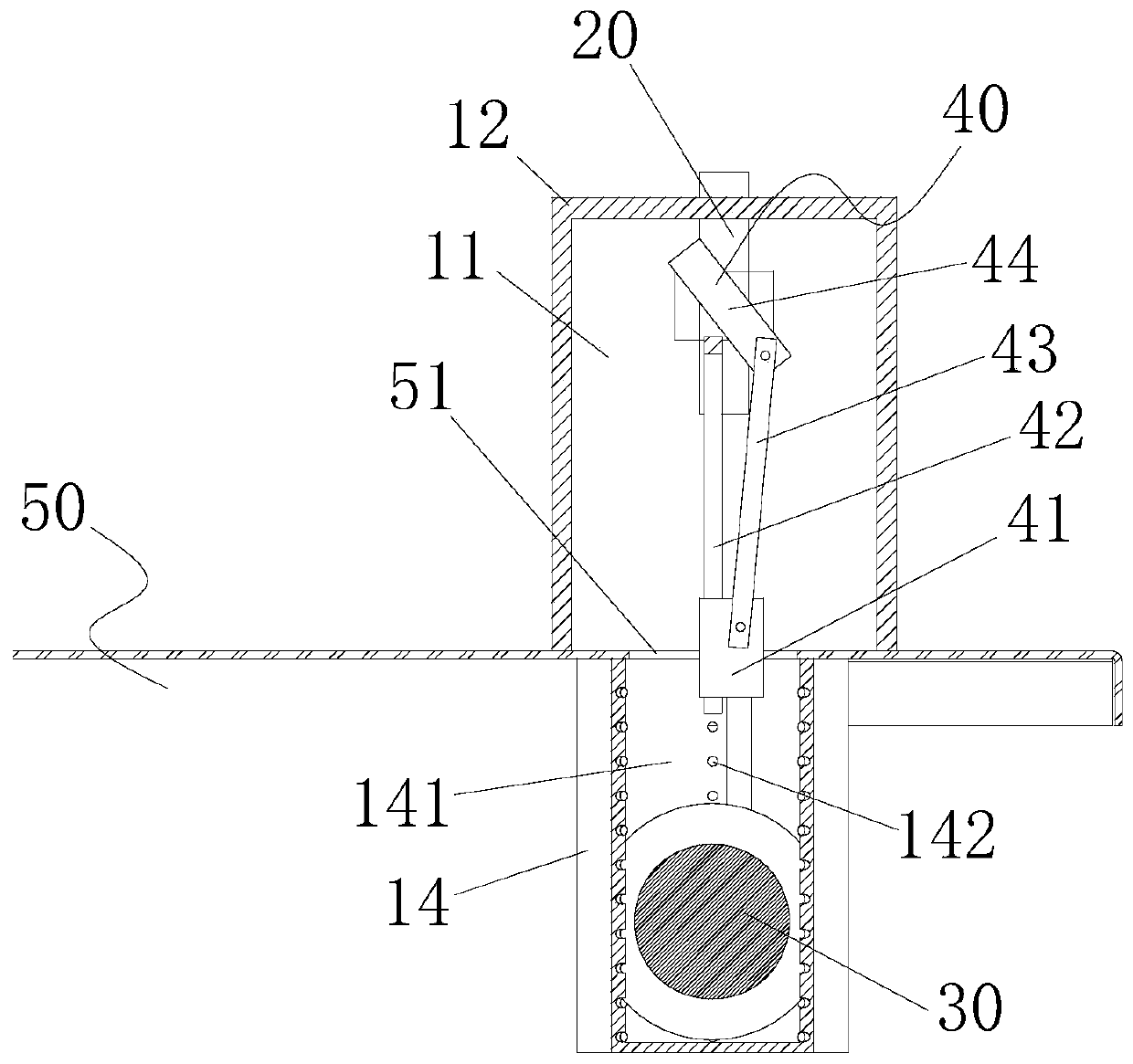

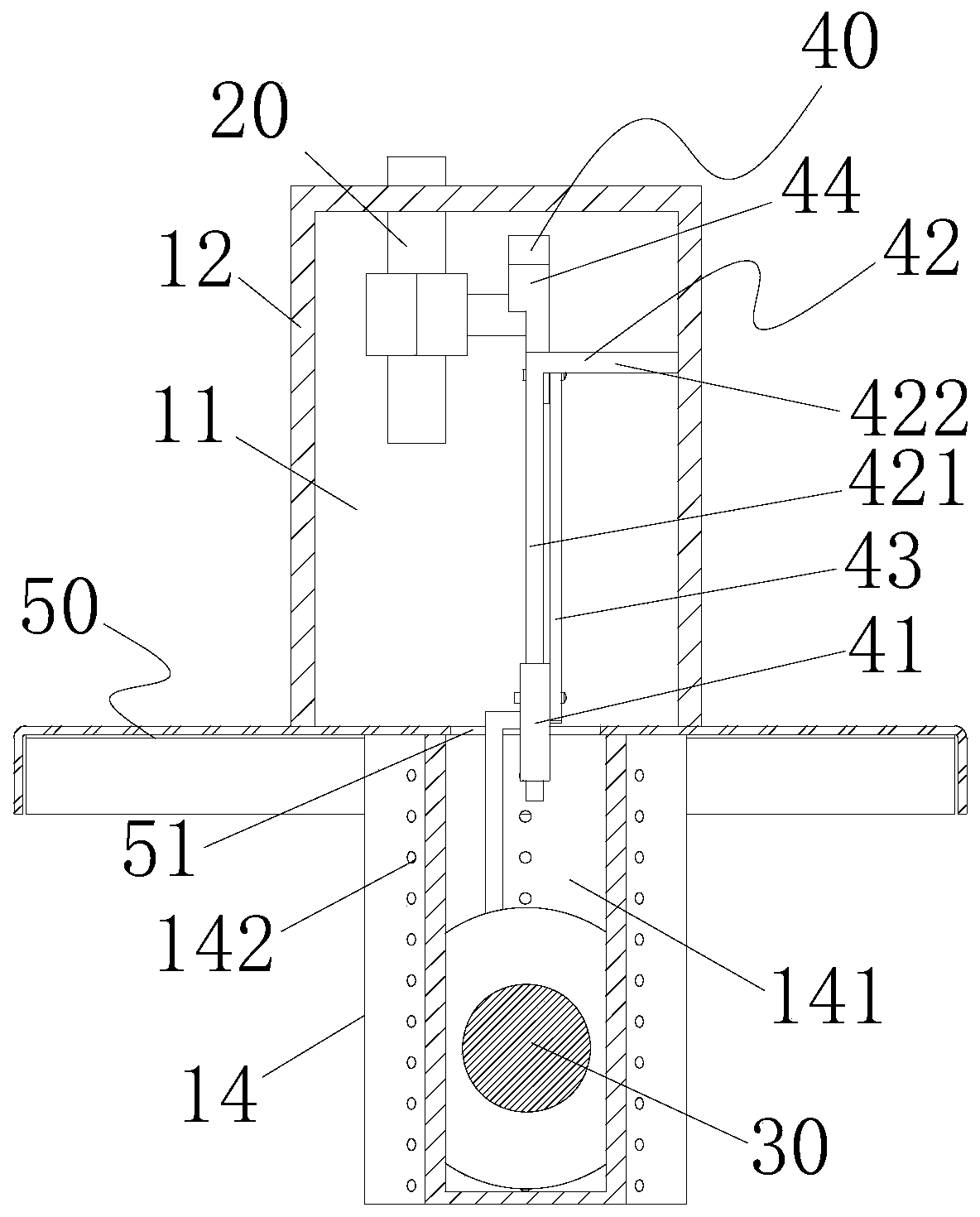

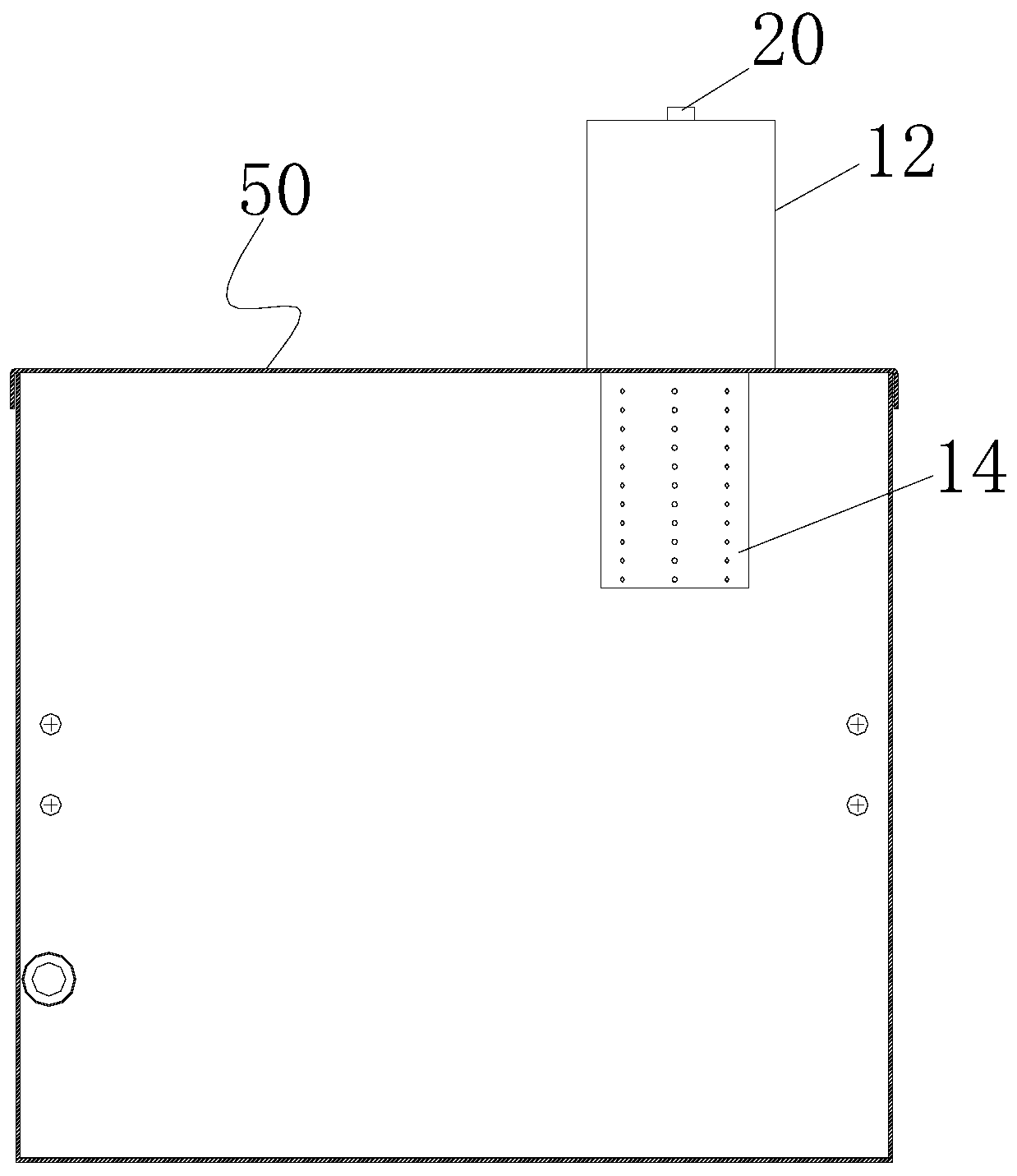

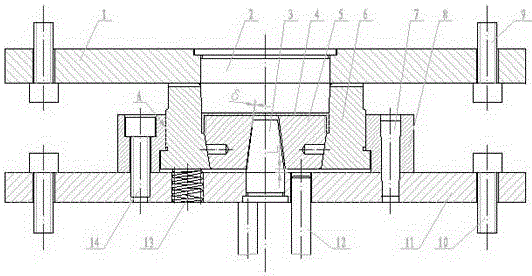

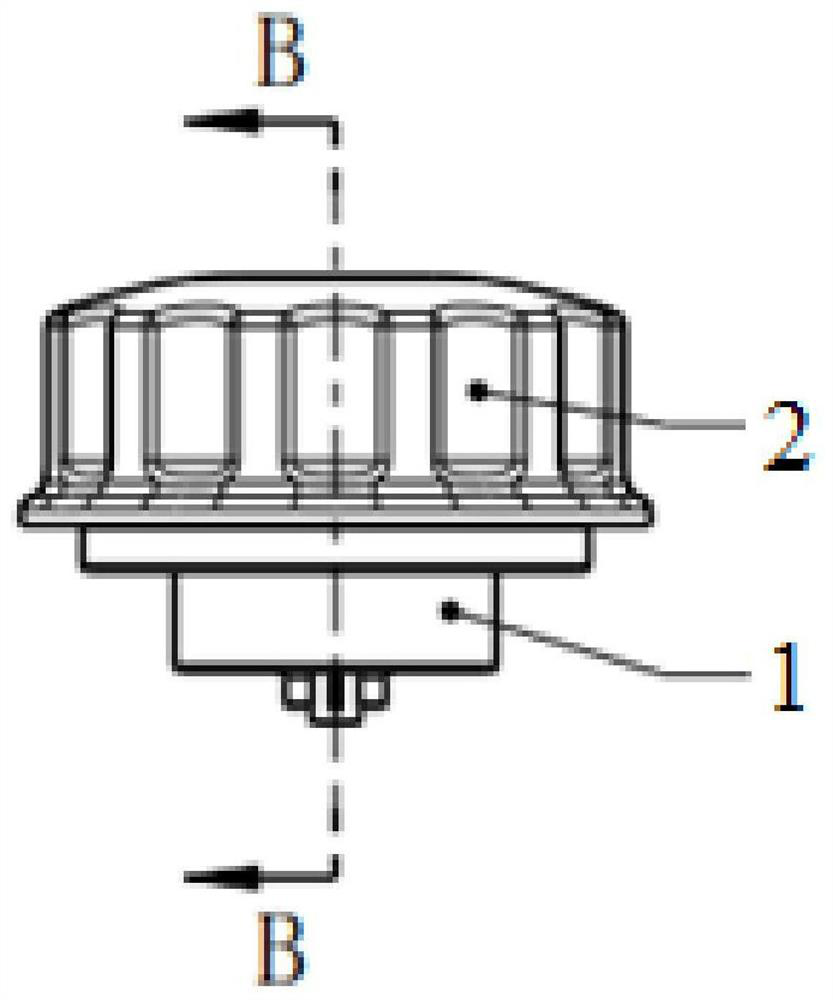

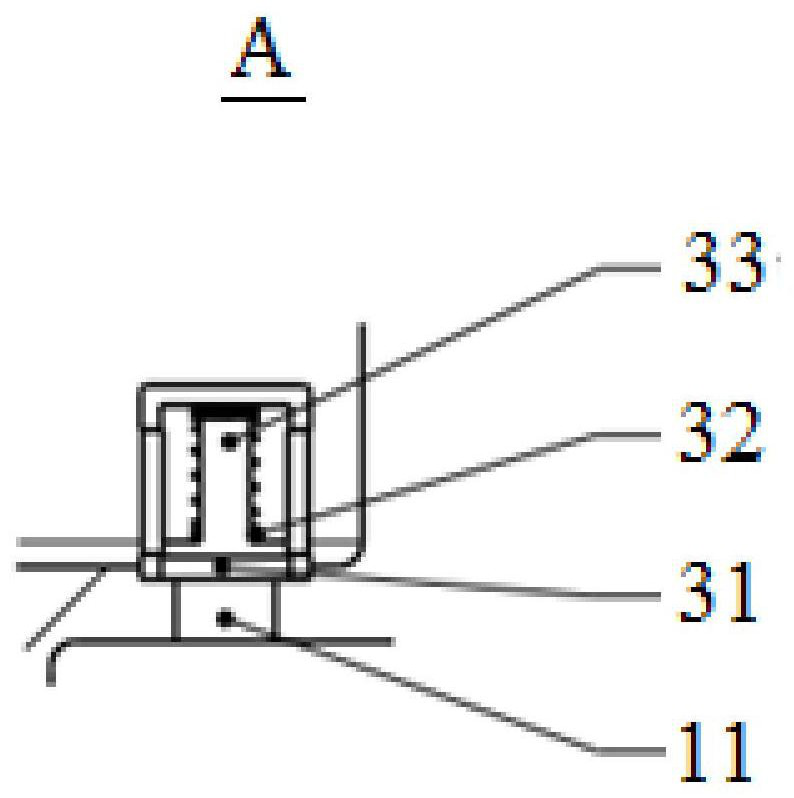

Pressure balance device capable of preventing ballooning of liquid storage tank, liquid storage tank and machine tool cooling machine

ActiveCN110405530ADischarge in timePrevent bulging deformationMaintainance and safety accessoriesInternal pressureLiquid storage tank

The invention discloses a pressure balance device capable of preventing ballooning of a liquid storage tank, the liquid storage tank and a machine tool cooling machine. The pressure balance module isused for the liquid storage tank of the machine tool cooling machine, and comprises an air valve and a floater, wherein a first end of the air valve communicates with the internal of the liquid storage tank, and a second end of the air valve communicates with external air; the air valve is provided with an opening state and a closing state; the floater is arranged in the liquid storage tank, and moves along with the liquid level change in the liquid storage tank; the floater is connected with the air valve through a transmission structure; and the floater is used for controlling opening or closing of the air valve according to the liquid level height in the liquid storage tank. The pressure balance module is provided with the air valve and the floater, and the floater controls opening andclosing of the air valve through the transmission structure, so that air in the liquid storage tank can be timely exhausted to prevent the ballooning deformation of the water tank caused by higher internal pressure of the liquid storage tank during water feeding.

Owner:GREE ELECTRIC APPLIANCES INC

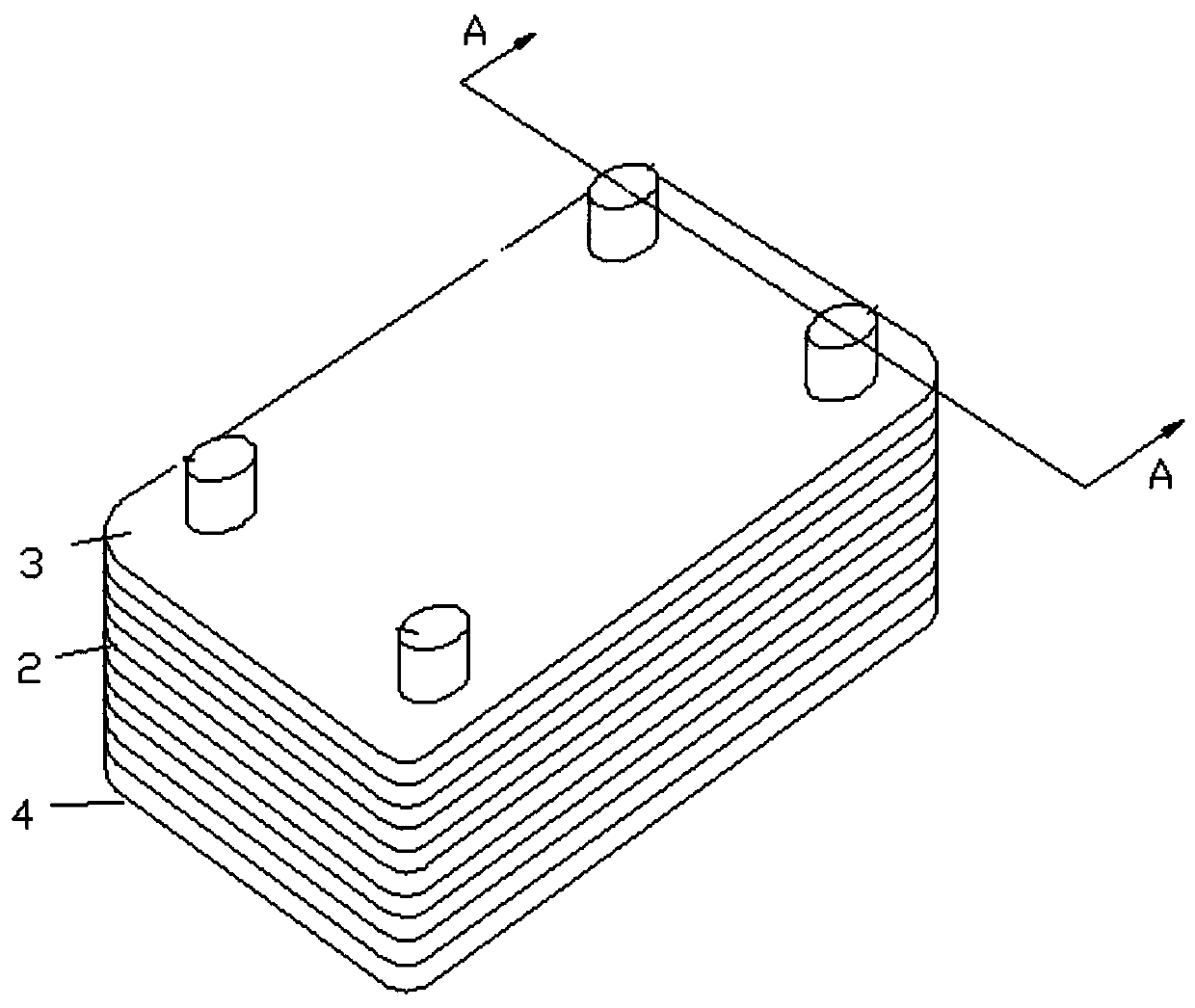

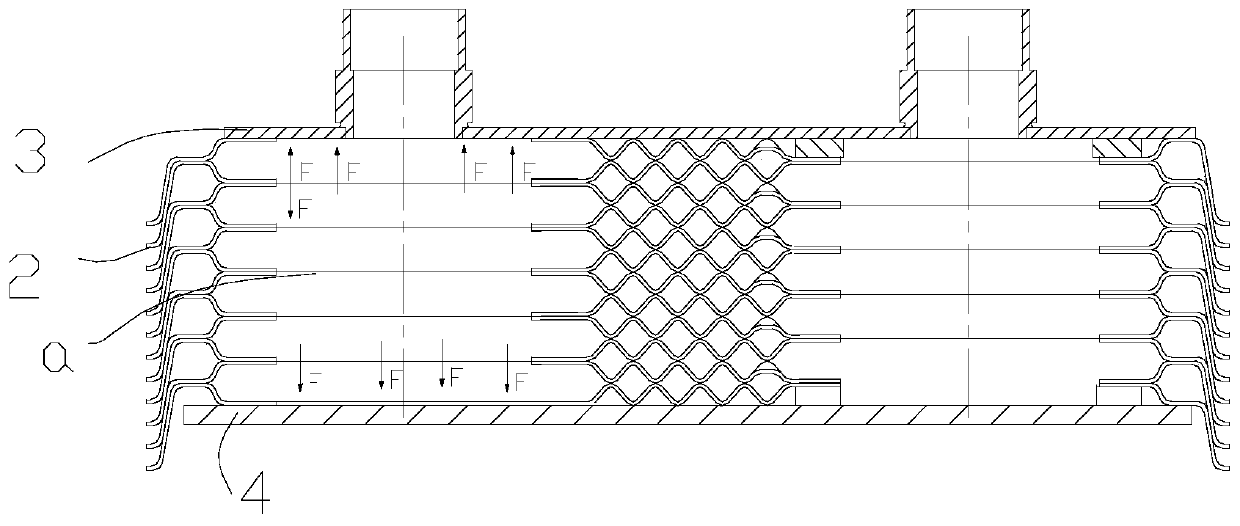

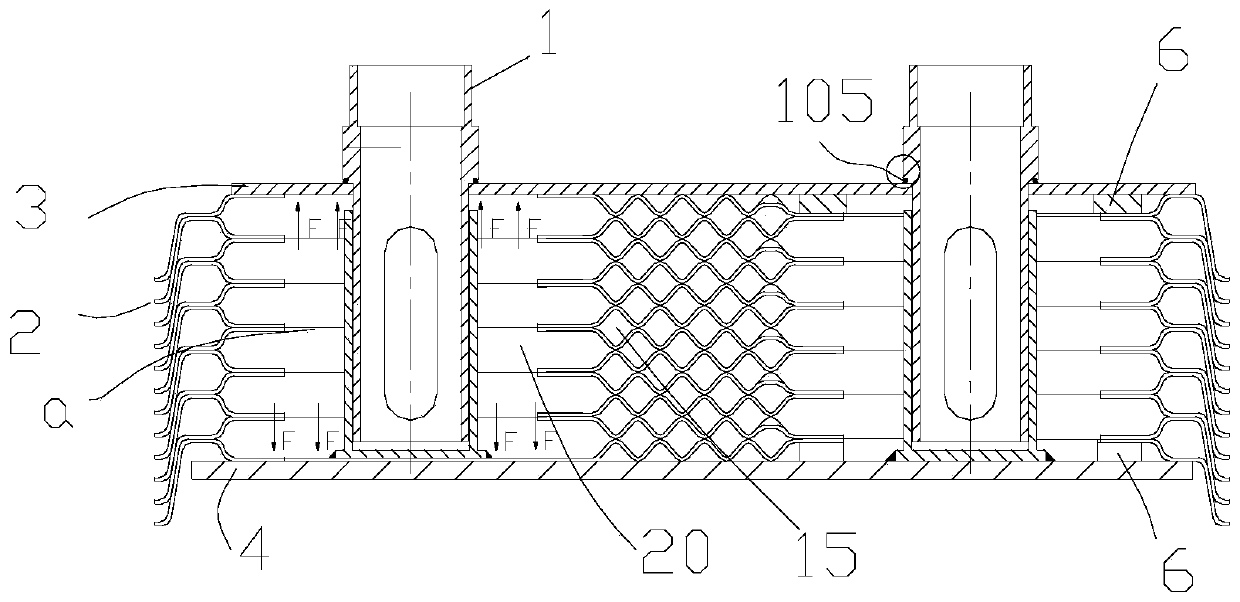

Pressure bearing type plate heat exchanger

PendingCN109827451AReduced risk of deformationPrevent bulging deformationHeat exchanger casingsWelding apparatusEngineeringPlate fin heat exchanger

The invention relates to a pressure bearing type plate heat exchanger. The pressure bearing type plate heat exchanger comprises an upper end plate, a lower end plate and a series of heat exchange plates laminated between the upper end plate and the lower end plate in order. Heat exchange runners allowing a cold / heat medium to alternately flow through are formed between the adjacent heat exchange plates, corner holes are formed in each heat exchange plate, the same corner holes a are through to form fluid runners, and the fluid runners correspondingly communicate with the heat exchange runners.The upper end plate is provided with openings communicating with the fluid runners, connecting pipe devices are fixedly mounted at the positions of the openings, the upper ends of the connecting pipedevices are exposed out of the upper end plate, the lower ends of the connecting pipe devices penetrate through the whole fluid runners downwards and are fixedly connected to the lower end plate, andthe connecting pipe devices are provided with runner holes to enable the fluid runners to communicate with the heat exchange runners. The connecting pipe devices share expansive force borne by the main heat exchange plates and the end plates, expansion deformation of the heat exchange plates and the end plates is effectively avoided, and the pressure bearing capacity of the plate heat exchanger is improved overall.

Owner:江苏远卓设备制造有限公司

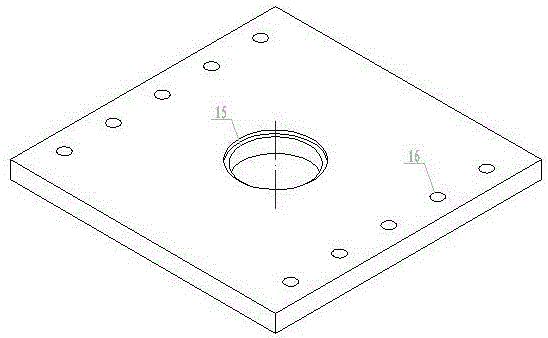

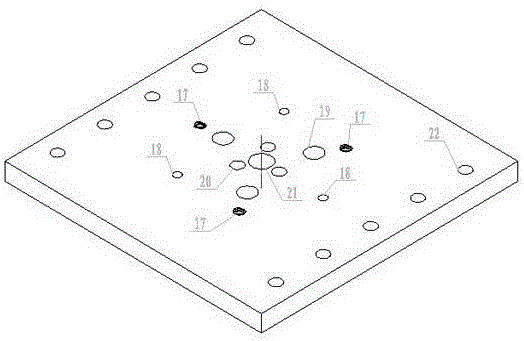

Glass fiber reinforced molded plastic internal thread end cover compression mold

A glass fiber reinforced molded plastic internal thread end cover compression mold comprises an upper mold plate, a male mold, a thread mold core, a female mold, a mold sleeve and a lower mold plate. The upper mold plate is fixed on an upper mold frame through upper mold plate fixing screws, the lower mold plate is fixed on a lower mold frame through lower mold plate fixing screws, an inverted-cone-shaped hole is formed in the center of the thread mold core and connected with a center rod through a center rod cone-shaped face, the center rod is fixed on the lower mold plate which is provided with an ejector rod and a cylindrical helix compression spring, the ejector rod is arranged at the bottom of the thread mold core, the cylindrical helix compression spring is arranged at the bottom of the female mold, and a closed cavity of an end cover product is defined by the male mold, the female mold, the thread mold core and the center rod. It is guaranteed that mold opening and exhausting are synchronously conducted in the end cover compression molding process, the problem that exhausting between the bottom face of an end cover inner cavity and the end face of the thread mold is difficult is solved, therefore, compression molding of the molded plastic internal thread end cover product can be achieved rapidly and efficiently, and the advantages of reducing the working intensity of operators and increasing the product yield are achieved.

Owner:江西长江化工有限责任公司

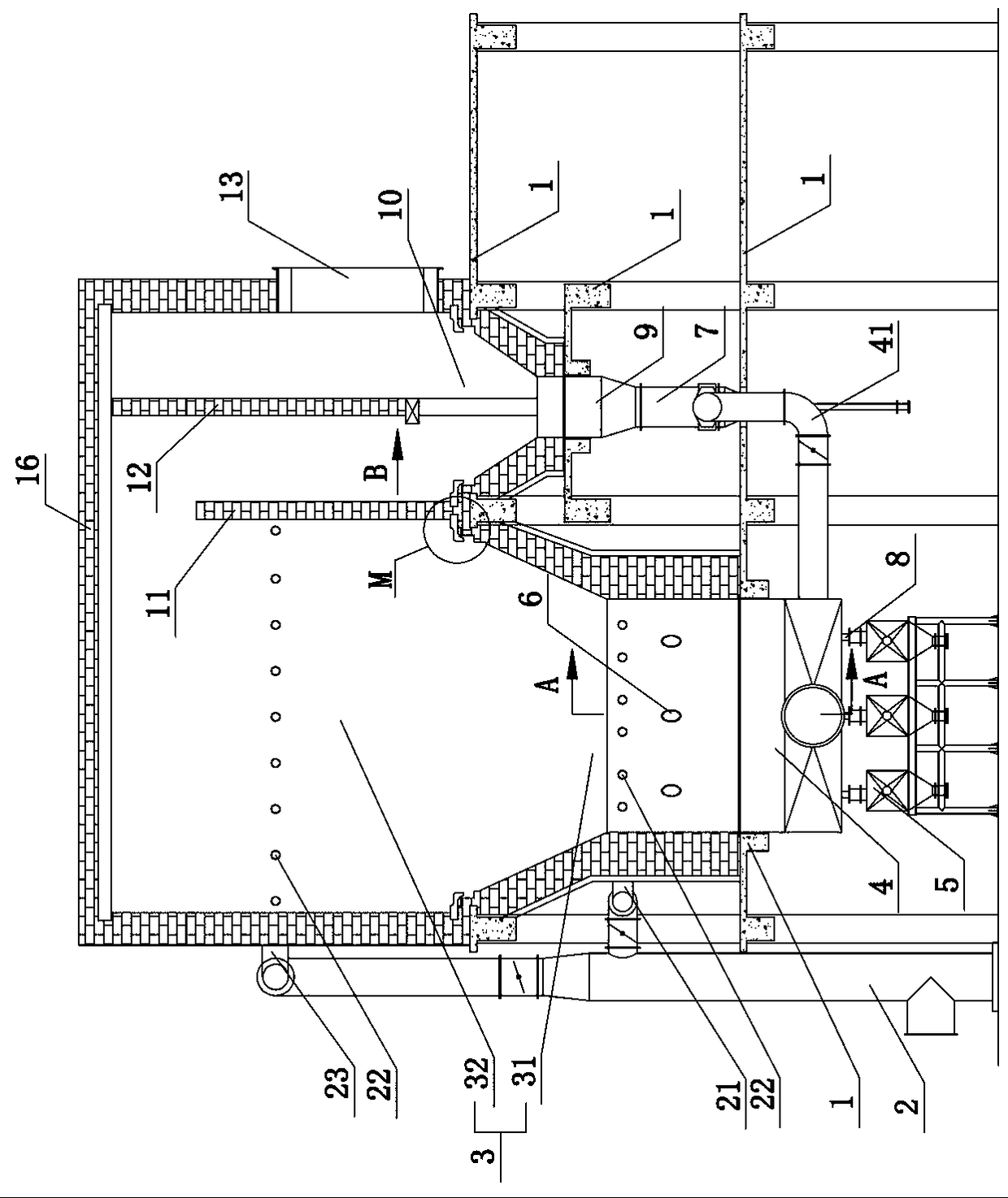

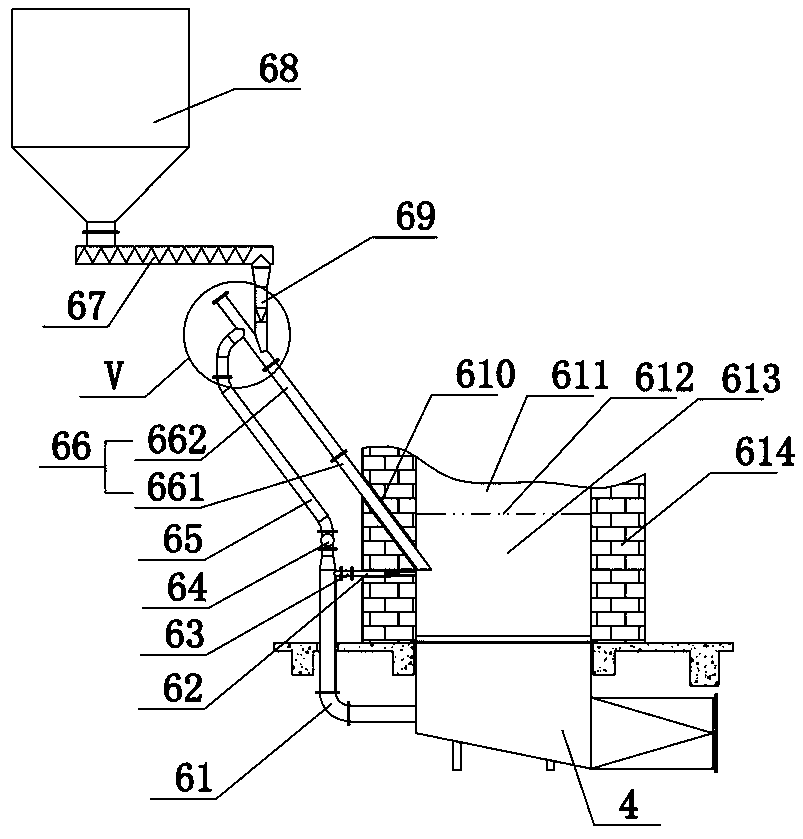

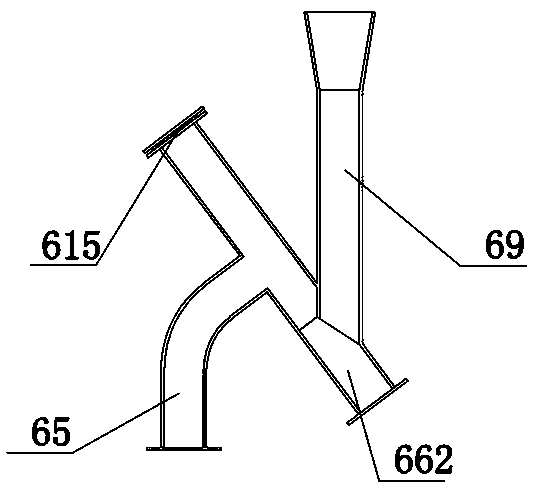

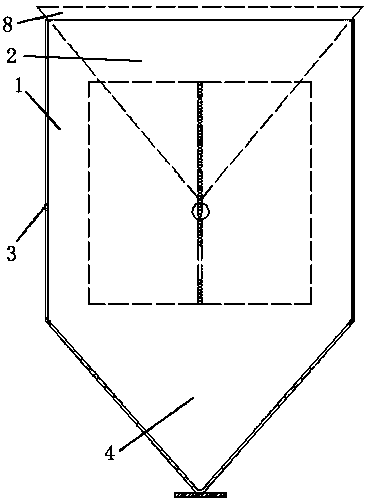

Novel fluidized bed smoke furnace

PendingCN109340742ALower the altitudeImprove adaptabilityFluidized bed combustionApparatus for fluidised bed combustionCombustionPositive pressure

The invention discloses a novel fluidized bed smoke furnace. The novel fluidized bed smoke furnace comprises a supporting platform. The supporting platform is provided with a furnace body. The furnacebody is internally provided with a main hearth and an auxiliary hearth. A fire barrier is arranged between the main hearth and the auxiliary hearth. The auxiliary hearth is internally provided with adust collection wall, and the auxiliary hearth is provided with a smoke outlet. An air bellow for supplying air to the main hearth is arranged below the main hearth, and the air bellow is provided with an auxiliary combustion air pipe for supplying air to the auxiliary hearth. The supporting platform is divided into two parts, one part is used for supporting lean-phase zones of the main hearth and the auxiliary hearth, and the other part is used for supporting dense-phase zones of the main hearth and the auxiliary hearth. A furnace wall of the main hearth is provided with a plurality of setsof gravity type positive pressure high-temperature feeders. Each gravity type positive pressure high-temperature feeder comprises a feeding pipe extending into the hearths, wherein the inner end of the feeding pipe extends into positive pressure zones in the hearths. One end of the air bellow is provided with a main air pipe, the main air pipe is provided with a nozzle extending into the hearths and an air guiding pipe connected with the outer ends of the feeding pipes. By means of the novel fluidized bed smoke furnace, the fuel adaptation and the combustion intensity are improved, and meanwhile the service life of a furnace body is not affected.

Owner:HUBEI JINLU ENERGY SAVING LTD CO

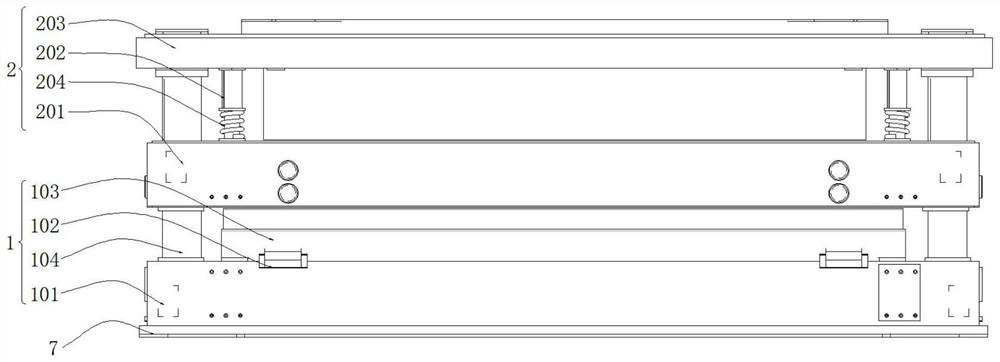

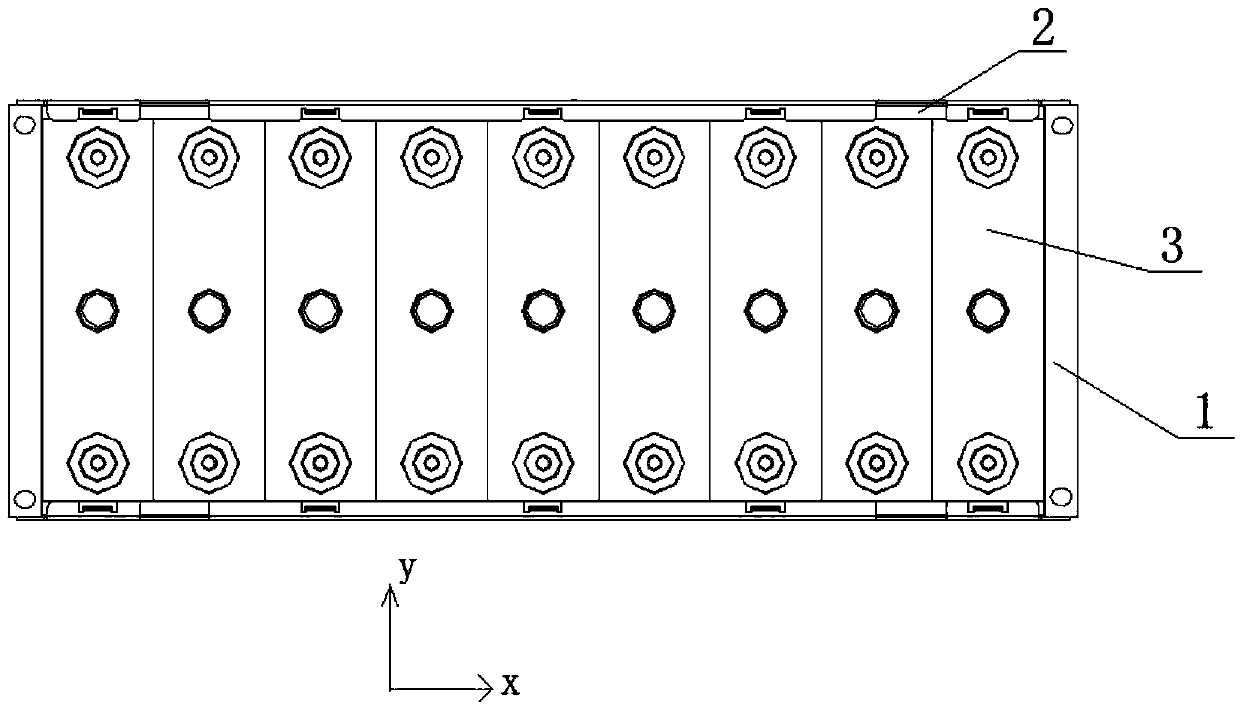

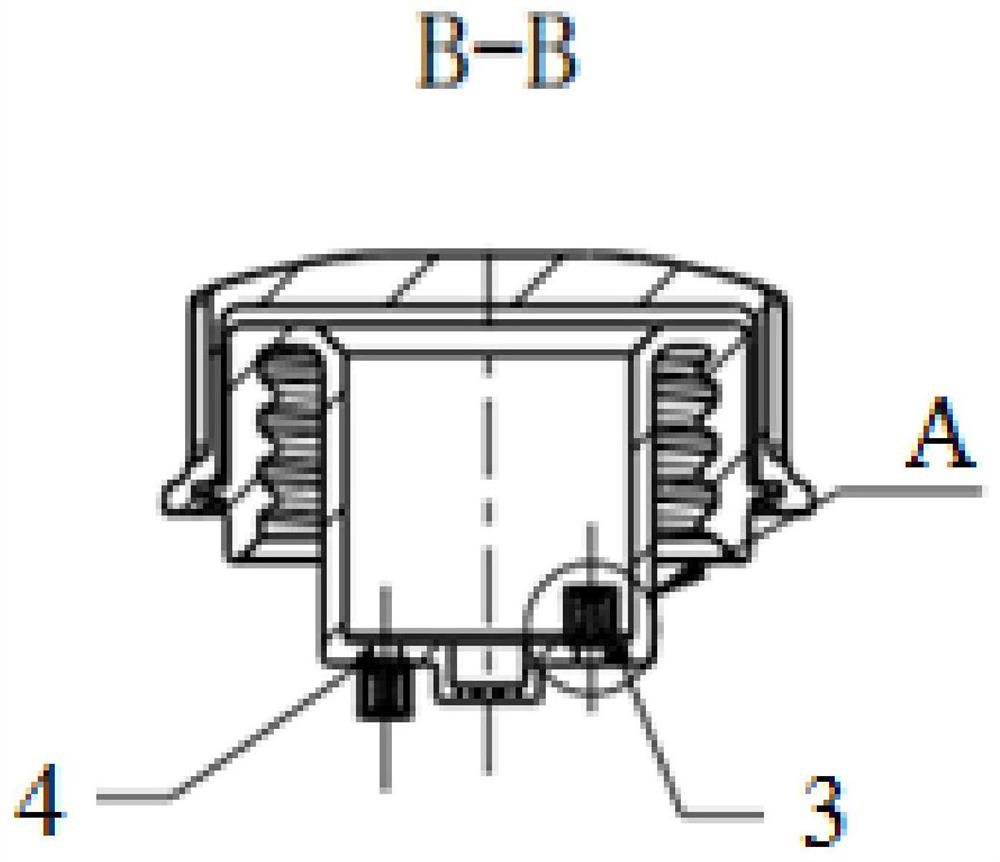

A battery module

ActiveCN105742539BAvoid the problem of weak intermediate mechanical propertiesGood for distributing vertical pressureFinal product manufactureBattery isolationBattery cellElectrical and Electronics engineering

The present application relates to the technical field of battery packs, in particular, to a cell module, including a substrate, a plurality of battery cells, a pair of end plates, a pair of side plates and a plurality of fasteners; a pair of end plates are respectively Located on both sides of a plurality of battery cells in the stacking direction, adjacent to the outermost battery cell, and extending along the length direction of the battery cells; and the ends of the end plates in the length direction of the battery cells Bend into a tube to form a rolled tube section, the axial direction of the rolled tube section is in the same direction as the height direction of the battery unit; the fastener is inserted into the rolled tube section, and in the rolled tube section, faces the The direction extends and protrudes out of the coiled tube section and is fixed on the base plate; by arranging the coiled tube segment on the end plate, the fastening strength of the fastener is improved, and the reliable fixing of the battery pack on the substrate can be realized.

Owner:CONTEMPORARY AMPEREX TECH CO LTD

A packaging base assembly, washing machine and washing machine packaging and disassembly method

ActiveCN106516429BPrevent bulging deformationEasy to install and operate on the production siteContainers to prevent mechanical damageInterference fitEngineering

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Manufacturing method of sealing gasket

The present invention relates to a method for preparing gasket seal. Said preparation method includes according to size requirement cutting metal ring; according to compression ratio of graphite plate and density of gasket cutting out width of graphite tape, according to the specification size required for gasket selecting proper mould; placing the graphite tape into the mould by turns and prepressing graphite ring; moulding the metal ring and graphite ring by means of mould and nesting metal ring with graphite ring together; demoulding; and edging and shaping so as to obtain the gasket seal.

Owner:NINGBO TIANSHENG SEALING PACKING

A liquid packaging structure

Owner:NANJING HUJIANG COMPOSITE MATERIALS

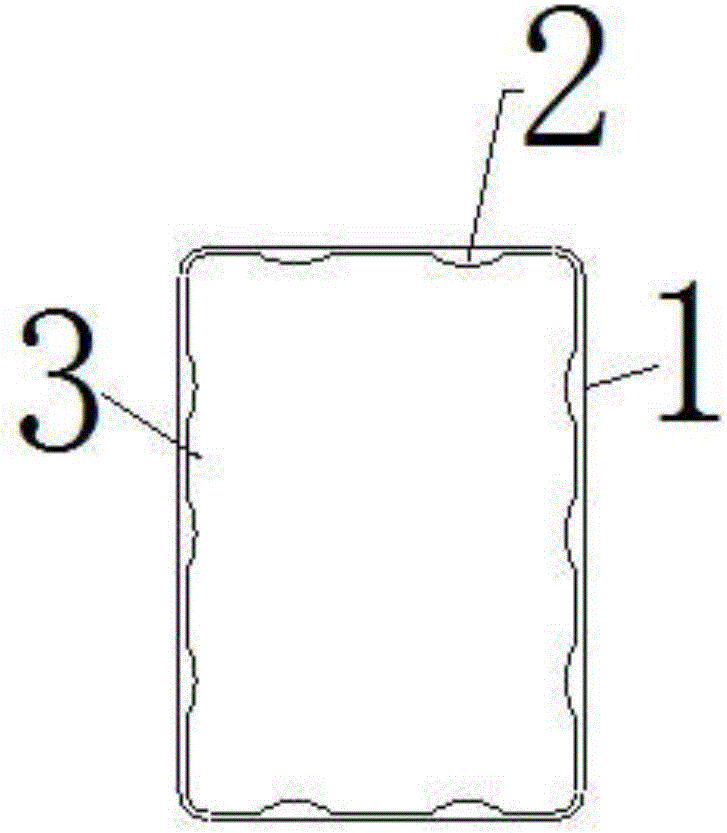

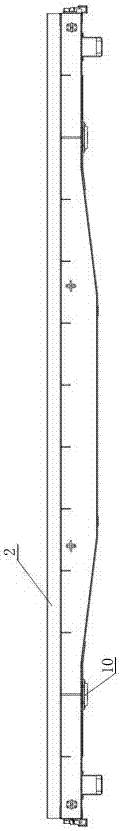

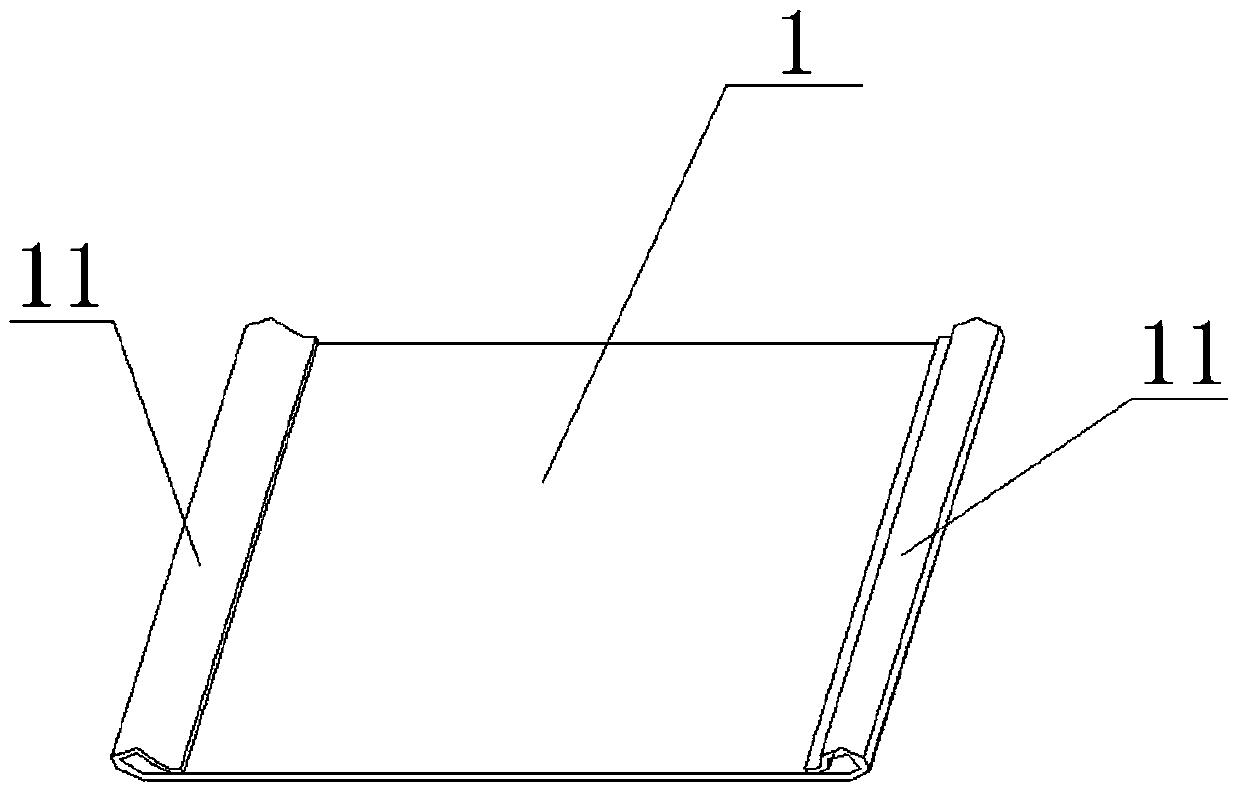

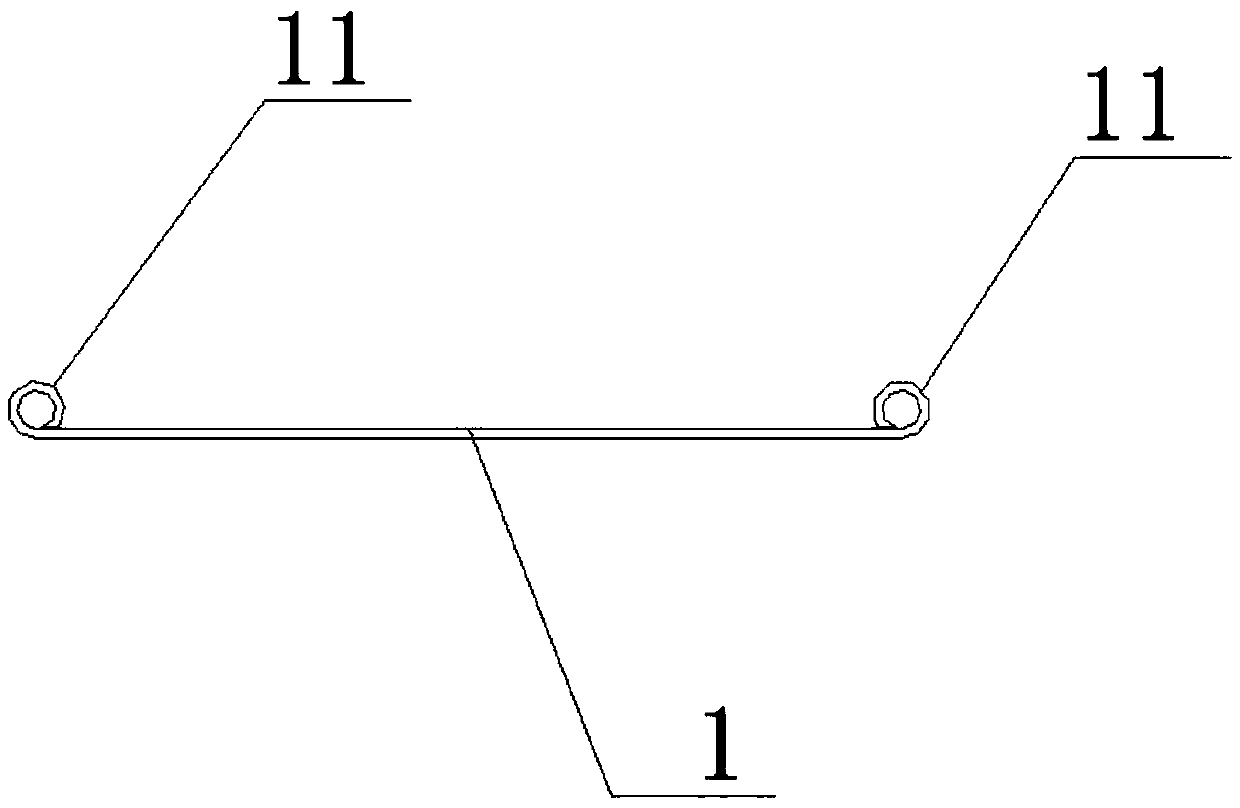

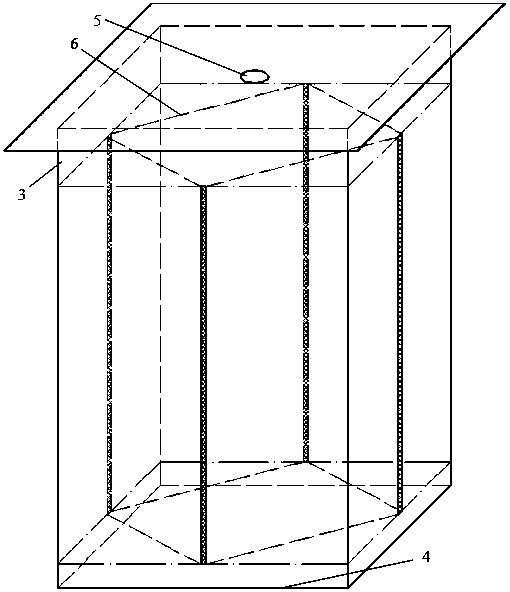

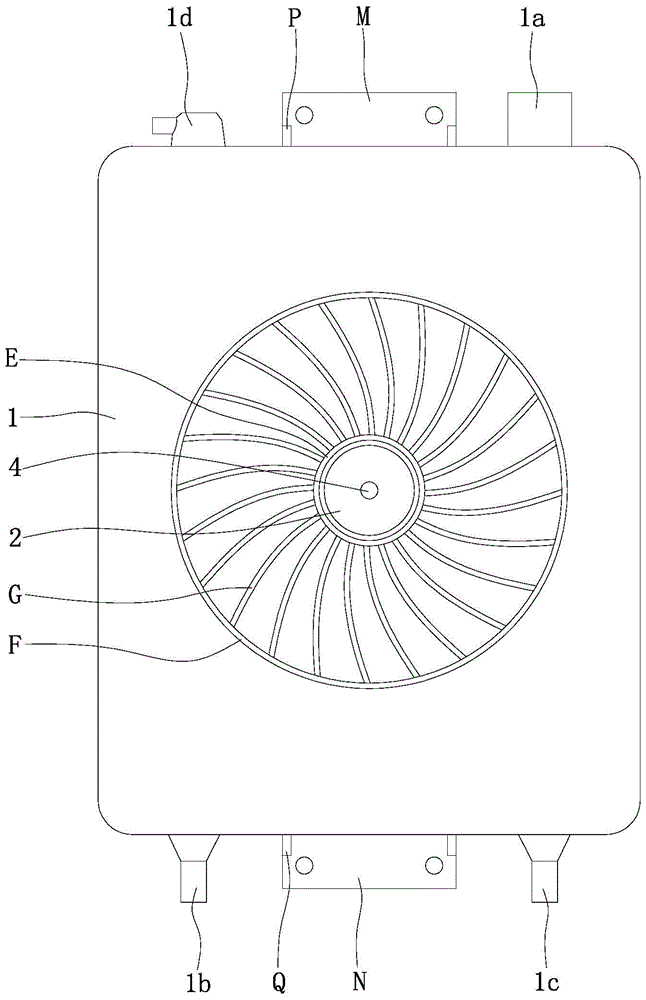

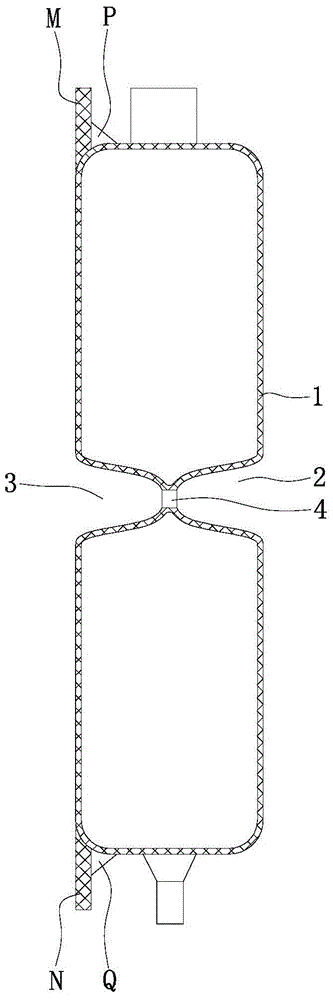

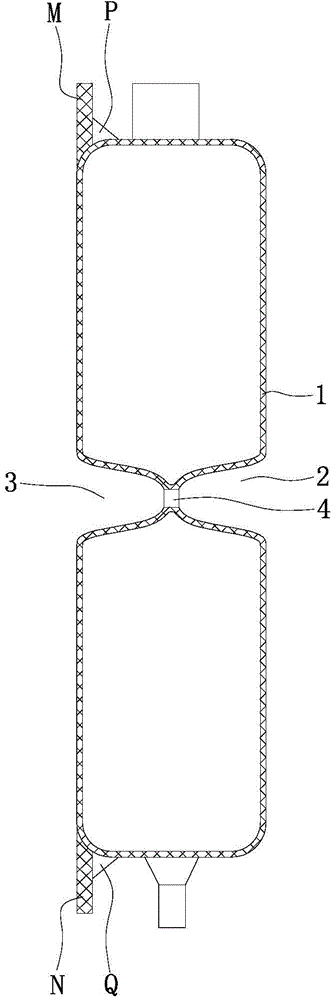

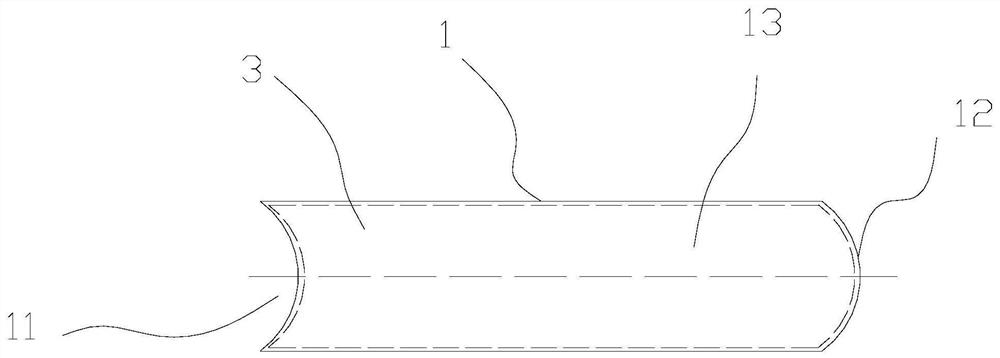

A Three-wheeled Motorcycle Circulating Cooling Water Tank Structure

ActiveCN104405495BImprove structural strengthPrevent bulging deformationMachines/enginesEngine cooling apparatusEngineeringImpact resistance

The invention discloses a circulating radiating type water tank structure of a motor tricycle. The circulating radiating type water tank structure is characterized in that a medium part of the front wall of a tank body (1) is backwards sunken to form a first sunken groove (2); the rear wall of the tank body (1) is forwards sunken corresponding to the first sunken groove (2) to form a second sunken groove (3); a first convex rib (E) and a second convex rib (F) are integrally formed on the front surface of the tank body (1); the middle part of the top end of the rear wall of the tank body (1) upwards integrally extends to form an upper positioning plate (M), and while the lower middle part of the bottom end of the rear wall of the tank body (1) downwards integrally extends to form a lower positioning plate (N). The circulating radiating type water tank structure is high in structural intensity, high in impact resistance, free of expansion-caused deformation, high in internal water circulating performance, simple and compact in structure, easy to be processed and manufactured, and small in production cost; the structural intensity can be further improved through a fan-shaped bulge on the front surface of the tank body, and the appearance can be beautified; a mounting point on the water tank is of a plate structure, so that the firmness is high, and the breaking can be avoided.

Owner:重庆和金汽车配件有限公司

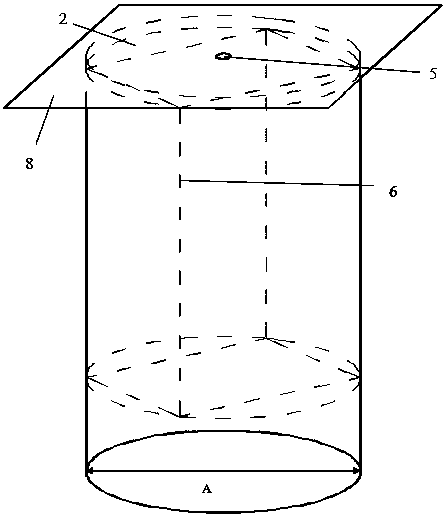

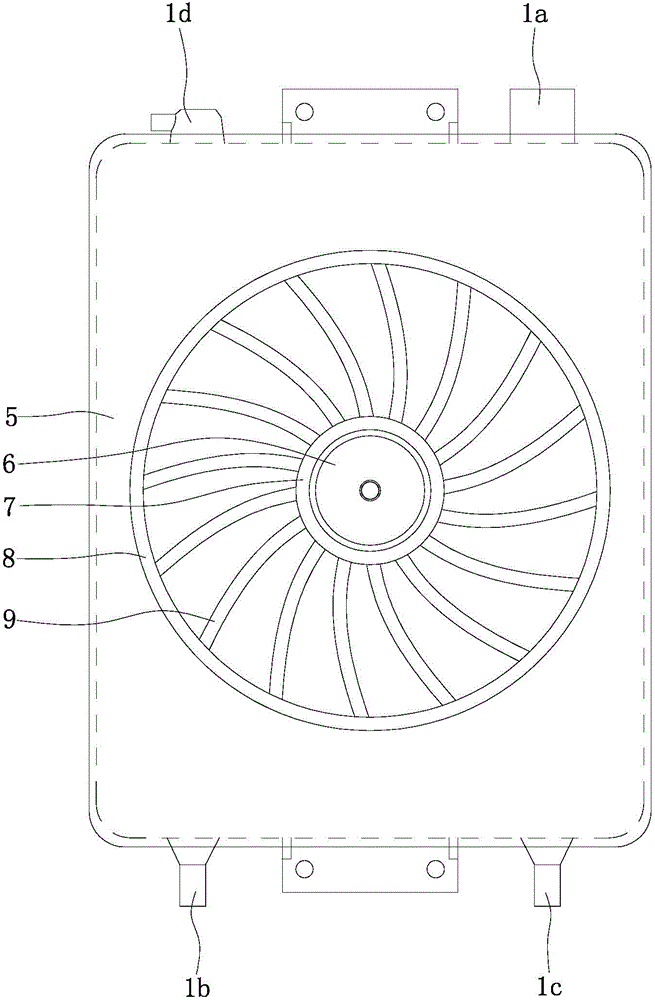

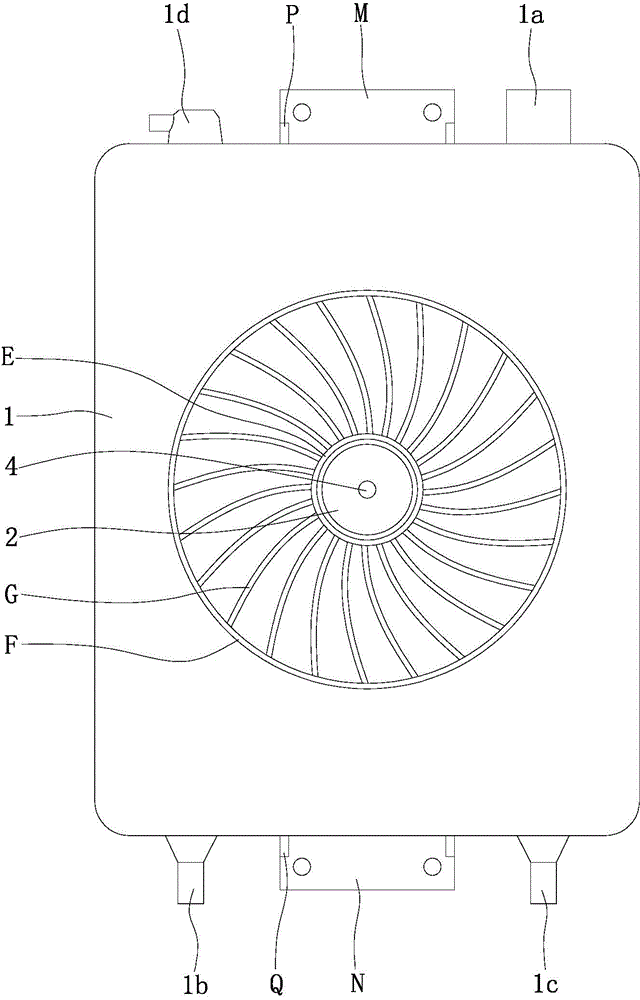

Radiating water tank and plastic shield assembly

ActiveCN104385902AEasy to shapeImprove structural strengthPropulsion coolingBiochemical engineeringConical tube

The invention discloses a radiating water tank and plastic shield assembly. An upper positioning plate (M) extending up is integrated to the middle of the top end of the rear wall of a tank body (1); a lower positioning plate (N) extending down is integrated to the bottom end of the rear wall of the tank body (1); the front of the tank body (1) is covered by a shield (5); the middle of the shield (5) is provided with a conical tube (6); an inner protrusion (7) which is circular is provided around an opening of the conical tube (6); an outer protrusion (8) concentric with the inner protrusion (7) is provided outside the inner protrusion (7). The radiating water tank and plastic shield assembly has the advantages that the tank body is high in structural strength, high in impact resistance and free of bulging; mounting points of the tank body are in plate structures, firmness is good, and breakage never occurs; the shield is provided outside the tank body, attractiveness is achieved, protection is also achieved, and the shield is convenient to demount and mount and firm and reliable to connect; the shield is provided with a vent structure, and good radiating performance of the tank body is ensured.

Owner:重庆和金汽车配件有限公司

Method for manufacturing polymer lithium ion battery cathode and polymer lithium ion battery

InactiveCN101369652BImprove thermal stabilityPrevent bulging deformationElectrode manufacturing processesFinal product manufactureDecompositionSlurry

The invention discloses a manufacture method of polymer lithium iron battery cathode and polymer lithium iron battery, which aims to provide a manufacture method of cathode and battery preventing decomposition of passive film at the cathode surface and inhibiting secondary reaction between electrolyte solvent as well as anode and cathode, reducing the generation of gases and preventing battery deformation at high temperature. The cathode manufacture method includes the following steps: mixing the cathode active material and a conductive agent evenly; adding deionized water to prepare cathode slurry material; dissolving Li2CO3 additive in the deionized water to prepare a solution with a percentage concentration by weight of 0.3-1.5%; adding the solution containing Li2CO3 in the cathode slurry material to prepare a mixed slurry material; wholly dissolving a caking agent in a solvent, adding in the mixed slurry material for even stirring, coating on the surface of copper-collected fluid,and then drying, pressing and cutting to prepare the cathode for polymer lithium iron battery.

Owner:TIANJIN LISHEN BATTERY

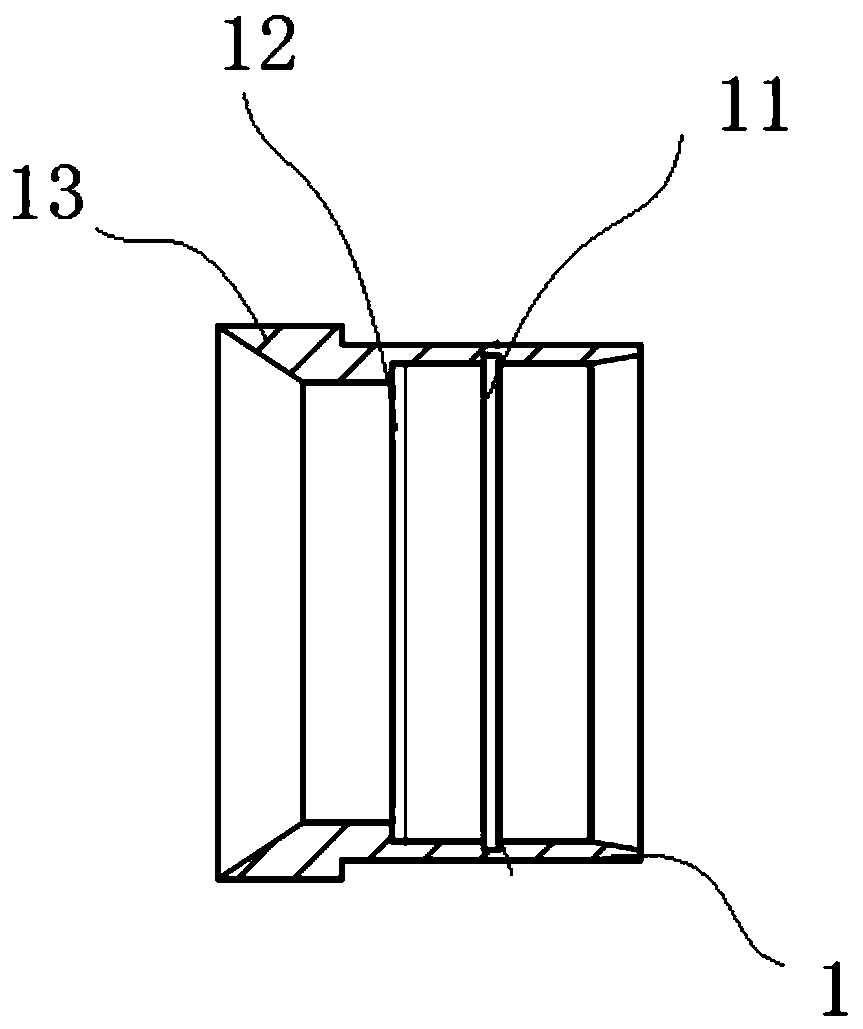

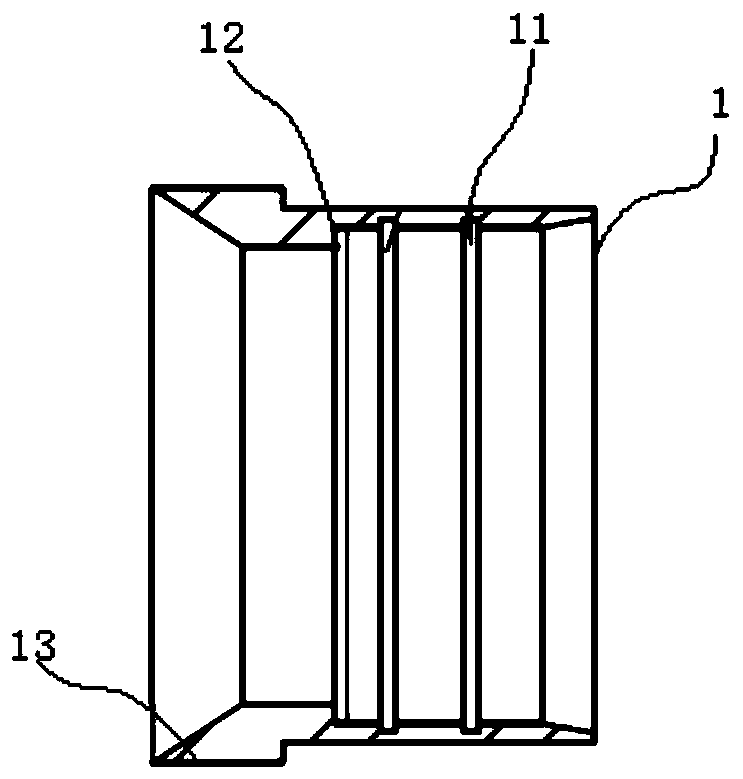

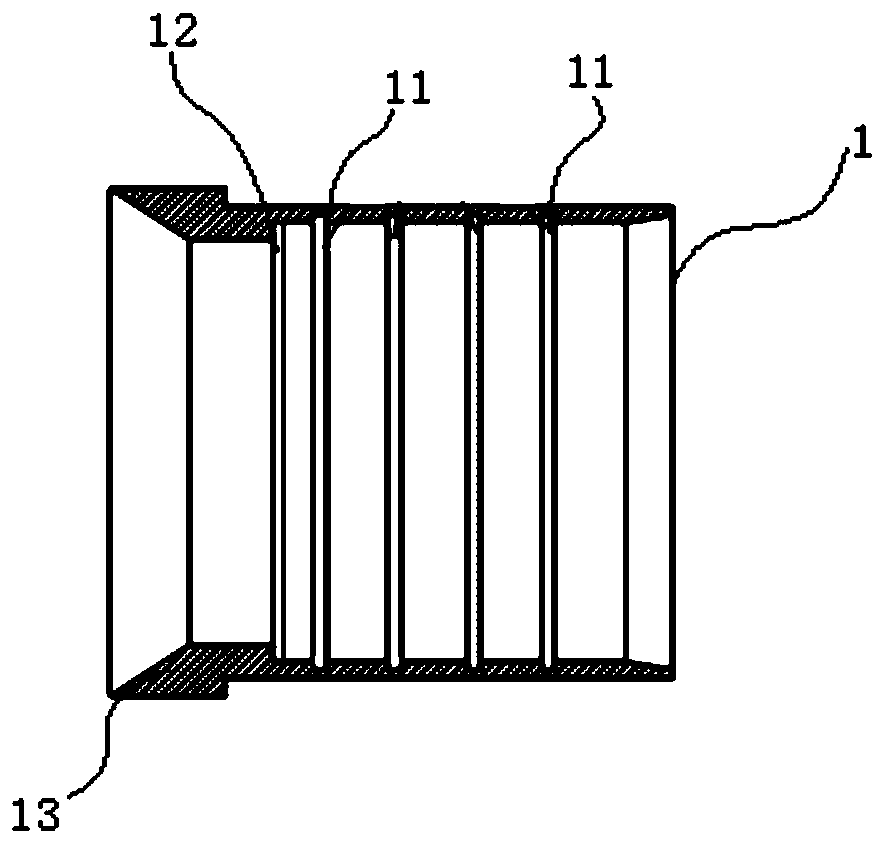

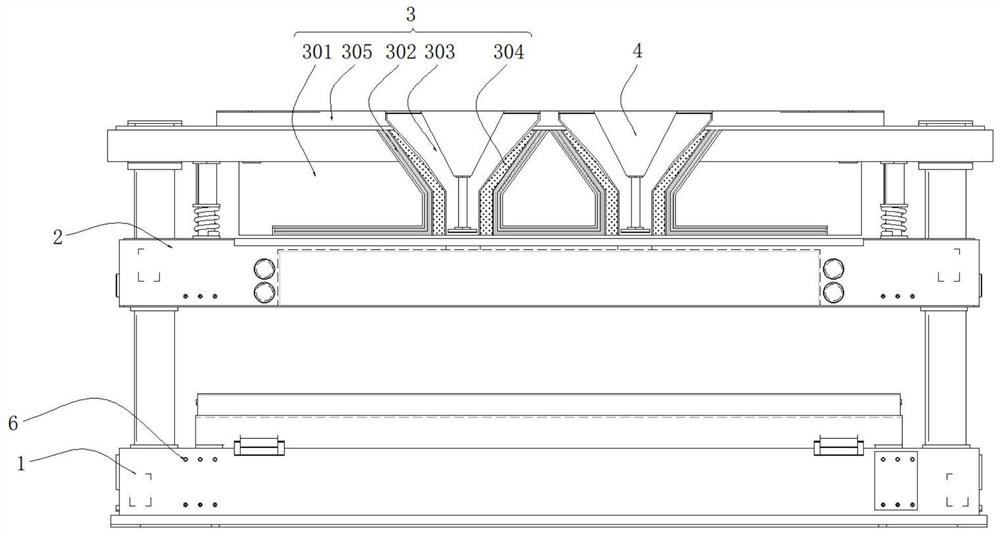

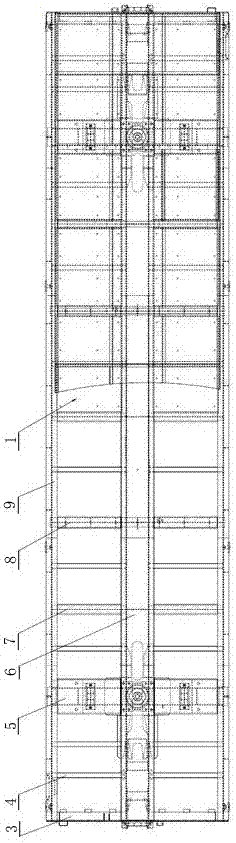

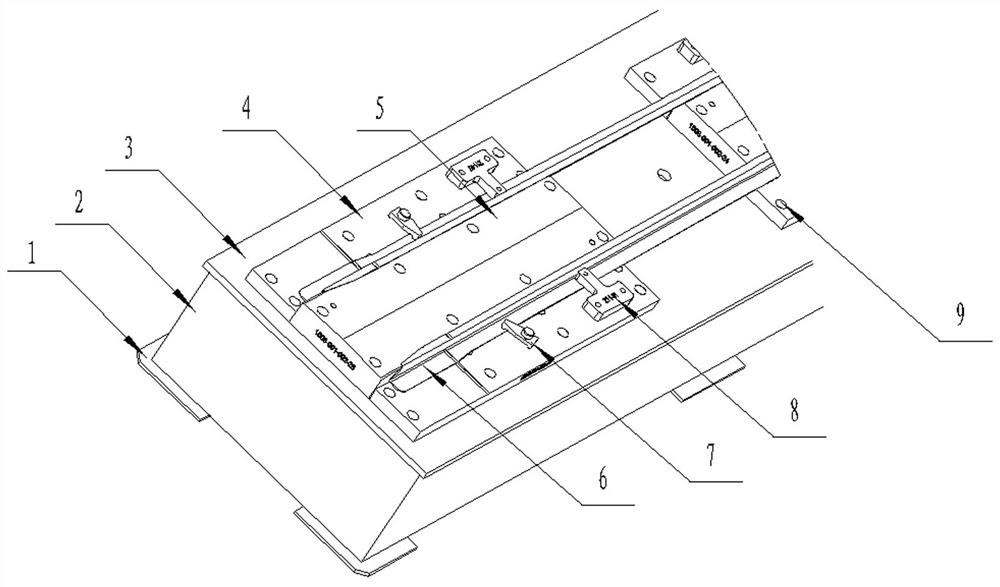

Method for knocking and inspecting molds of box-type module groups and applying z-shaped super-long profiles

ActiveCN110947800BIncrease flexibilityIncrease variabilityMetal working apparatusIndustrial engineeringForming processes

The invention relates to a box-type module group knocking inspection mold, in which a base is connected to the lower surface of the box-type frame, a platform is connected to the upper surface of the box-type frame, and a plurality of tire modules are connected on the platform, the shape of the outer side of the tire module is the same as that to be The curvature of the Z-shaped super-long profile is consistent; there is a supporting block on the outside of the width direction of the tire module, and a top block is provided on the supporting block, and the top block is pressed against the side surface of the Z-shaped super-long profile to be processed; on the supporting block A pressing plate is provided, and the pressing plate is pressed against the upper surface of the bottom edge of the Z-shaped super long profile to be processed. Through the replacement capability of the detachable mold group, the mold eliminates the problem of tooling scrapping and tooling remanufacturing cycle delay caused by the change of the mold, and improves the flexible automation ability of clamping, so that the ultra-long profile forming process develops in the direction of flexible manufacturing. Lay the foundation for flexible and intelligent manufacturing in the future.

Owner:AVIC SAC COMML AIRCRAFT

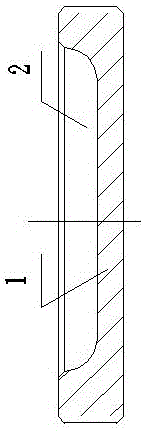

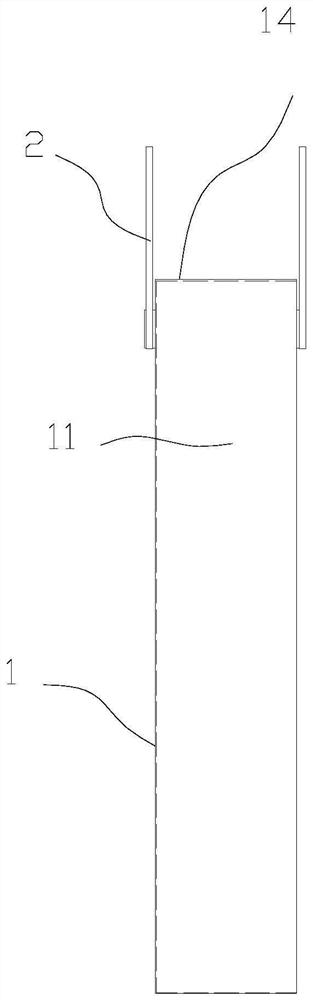

Large-diameter thin plate sealing diaphragm and method for preventing deformation by turning

ActiveCN102581303BGuarantee processing qualityPrevent bulging deformationHeat exhanger sealing arrangementPositioning apparatusThin slabNichrome

A large-diameter thin plate sealing diaphragm and a method for preventing deformation by turning. Used in high temperature and high pressure heat exchanger products, there is a kind of nickel - chromium - ferroalloy SB-168NO6600 The sealing diaphragm of the material is expensive, and the manufacturing precision is very high. Because it is used for sealing, the surface roughness and unevenness of the parts are very strict. A large-diameter thin plate sealing diaphragm and a method for anti-deformation through turning, the composition of which includes: processing a disc-shaped steel plate into a dish shape, ( 1 ), making a concentric blind hole on the wafer with a diameter smaller than the diameter of the wafer and a thickness smaller than the thickness of the wafer ( 2 ) , Install an auxiliary backing plate of sufficient thickness under the part to be processed. There is a hole on the backing plate, and the spot welding with the part is firm at the opening, and the assembly is fixed in a bowl-shaped piece filled with water, and the water The vertical lathe processing is adopted below, and the cutting heat generated during the turning process is dissipated in time during the processing. The invention is used for sealing large-diameter thin-plate sealing diaphragms in high-temperature and high-pressure heat exchangers.

Owner:HARBIN BOILER CO LTD

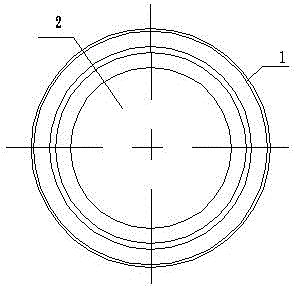

Flood-control moisture-absorbing and water-absorbing bag

InactiveCN112900358APrevent bulging deformationStrong cohesionDamsDykesStructural engineeringMechanical engineering

The invention discloses a flood-control moisture-absorbing and water-absorbing bag. According to the flood-preventing moisture-absorbing and water-absorbing bag, a bag body and a water-absorbing core body are packaged in a separated mode, the water-absorbing core body can be repeatedly used, and in the using process, the water blocking effect is good after building is conducted. The flood-preventing moisture-absorbing and water-absorbing bag comprises the bag body made of a flexible permeable material, the bag body is in a three-dimensional shape, the bag body is provided with a bag opening, the bag opening is provided with an opening and closing accessory, the water-absorption bag is characterized in that the water absorption core body is placed in the bag body, the bag body is stretched to be in a three-dimensional shape after the water absorption core body absorbs water, a bag opening liner is further arranged in the opening and closing accessory of the bag opening, a connecting piece is arranged on the butt joint face of the bag body, and an ultraviolet-proof covering layer is arranged on the top surface of the bag body. The water-absorbing bag is high in coagulation force, stable and firm, water in the single water-absorbing bag can be dried in the sun, and the water-absorbing core body in the bag can be repeatedly used.

Owner:JIANGSU ELECTRIC POWER CO +2

A kind of urea tank and its cover for scr post-processing system

ActiveCN111971460BAvoid crackingPrevent suction deformationInternal combustion piston enginesExhaust apparatusEngineeringCheck valve

The invention provides a urea tank and its cover for an SCR post-treatment system. The cover is installed at the liquid injection port of the tank body of the urea tank, and the part of the tank cover corresponding to the liquid injection port is provided with ventilation holes. , the ventilation hole is covered by a waterproof and breathable membrane (5), the part of the box cover corresponding to the liquid injection port is also provided with an air intake hole and an exhaust hole (11), and a first constant pressure check valve (3) is installed on the box cover. ) and the second constant pressure check valve (4), the inlet of the first constant pressure check valve (3) is connected to the exhaust hole (11), and the outlet of the first constant pressure check valve (3) is connected to the outlet of the box. The outside is communicated, the inlet of the second constant pressure check valve (4) is butted with the air inlet hole, and the outlet of the second constant pressure check valve (4) is communicated with the inside of the box. After the box cover provided by the invention is adopted, the inner pressure and the outer pressure of the box body will not be seriously unbalanced due to the insufficient air permeability of the waterproof breathable membrane, so the occurrence of deflated deformation or bulging deformation can be effectively avoided, and the urea tank is safer ,reliable.

Owner:WEICHAI POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com