Carbon coated nickel nanoparticle and silicon resin composite microwave absorbing coating and preparation method thereof

A nano-particle and wave-absorbing coating technology, applied in the field of wave-absorbing materials, can solve the problem of inability to take into account strong electromagnetic wave absorption and broadband absorption, and achieve the effect of improving chemical stability, improving electromagnetic wave absorption capacity and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a carbon-coated nickel nanoparticle / silicone resin composite wave-absorbing coating, comprising the steps of:

[0038] (1) Preparation of carbon-coated nickel nanoparticles:

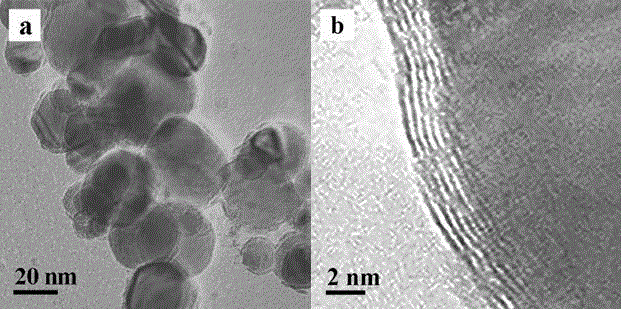

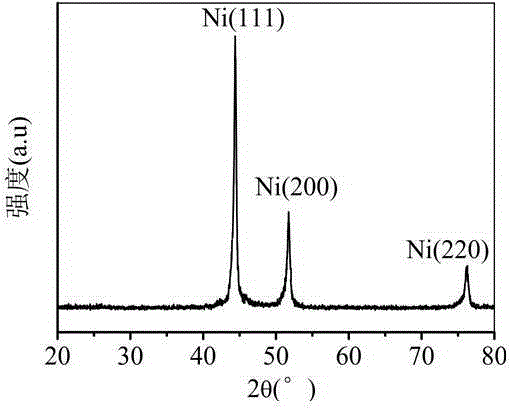

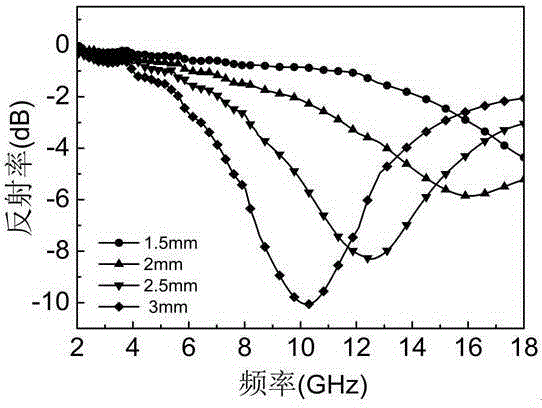

[0039] Use arc plasma to prepare nanomaterial system, use graphite rod as cathode, mix graphite powder (micron level) and reduced nickel powder (micron level) in a weight ratio of 4:1, and pass through the metallographic sample mounting machine Press into a cylindrical anode with a diameter of 25mm and a height of 30mm, and the distance between the two electrodes is 3-5mm; the reaction chamber is evacuated to 2-3Pa, and high-purity argon is introduced to make the pressure in the chamber reach 50kPa, and the direct current is controlled. The voltage is 22V and the DC current is 150A, so that a stable arc is generated between the two poles; the anode material is consumed during the arc radiation process and converted into soot and deposited on the inner surface of the reactio...

Embodiment 2

[0045] A preparation method of a carbon-coated nickel nanoparticle / silicone resin composite wave-absorbing coating, comprising the steps of:

[0046] (1) Preparation of carbon-coated nickel nanoparticles:

[0047] Use arc plasma to prepare nanomaterial system, use graphite rod as cathode, mix graphite powder (micron level) and reduced nickel powder (micron level) in a weight ratio of 2:3, and pass through the metallographic sample mounting machine Press into a cylindrical anode with a diameter of 25mm and a height of 30mm, and the distance between the two electrodes is 3-5mm; the reaction chamber is evacuated to 2-3Pa, and high-purity argon is introduced to make the pressure in the chamber reach 45kPa, and the direct current is controlled. The voltage is 30V and the DC current is 130A, so that a stable arc is generated between the two poles; the anode material is consumed during the arc radiation process and converted into soot and deposited on the inner surface of the reactio...

Embodiment 3

[0053] A preparation method of a carbon-coated nickel nanoparticle / silicone resin composite wave-absorbing coating, comprising the steps of:

[0054] (1) Preparation of carbon-coated nickel nanoparticles:

[0055] Use arc plasma to prepare nanomaterial system, use graphite rod as cathode, mix graphite powder (micron level) and reduced nickel powder (micron level) in a weight ratio of 3:2, and pass through the metallographic sample mounting machine Press into a cylindrical anode with a diameter of 25mm and a height of 30mm, and the distance between the two electrodes is 3-5mm; the reaction chamber is evacuated to 2-3Pa, and high-purity argon is introduced to make the pressure in the chamber reach 30kPa, and the direct current is controlled. The voltage is 20V and the DC current is 120A, so that a stable arc is generated between the two poles; the anode material is consumed during the arc radiation process and converted into soot and deposited on the inner surface of the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com