Coated type nanoscale zero-valent iron as well as preparation method and application thereof

A nano-zero-valent iron, coated technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. Mobility and other issues, to achieve the effect of reducing mobility and bioavailability, good mobility and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

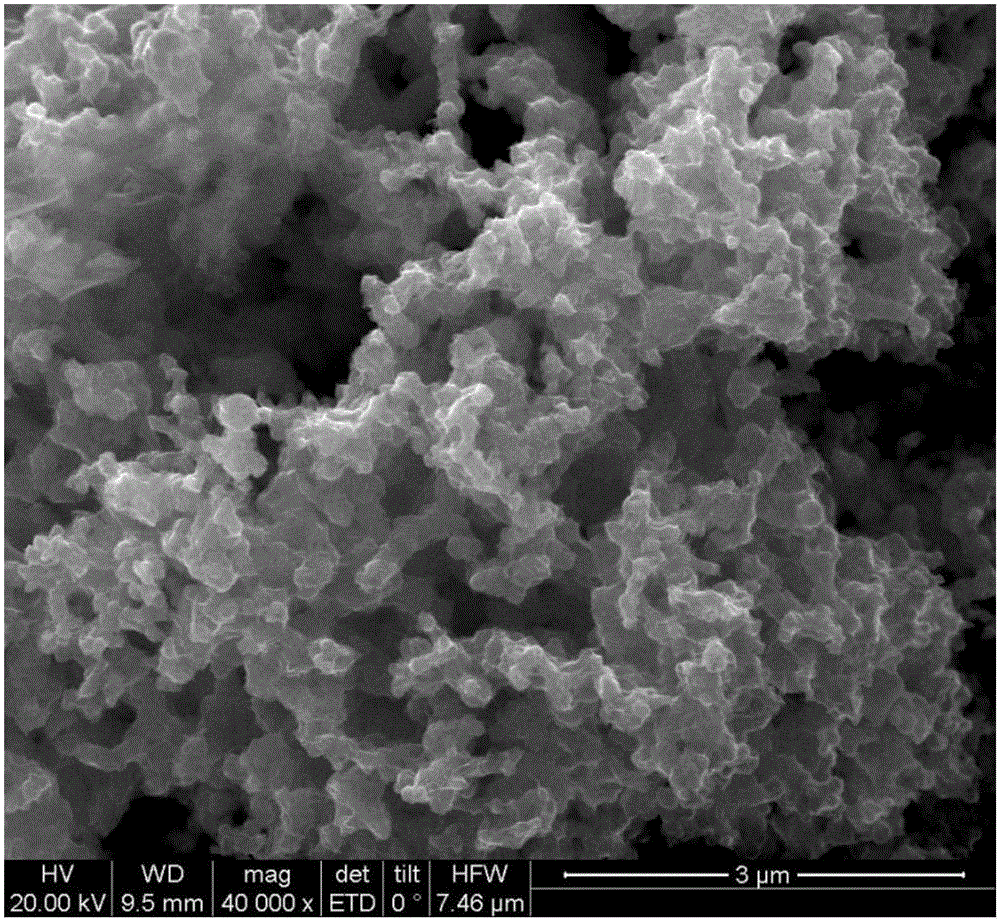

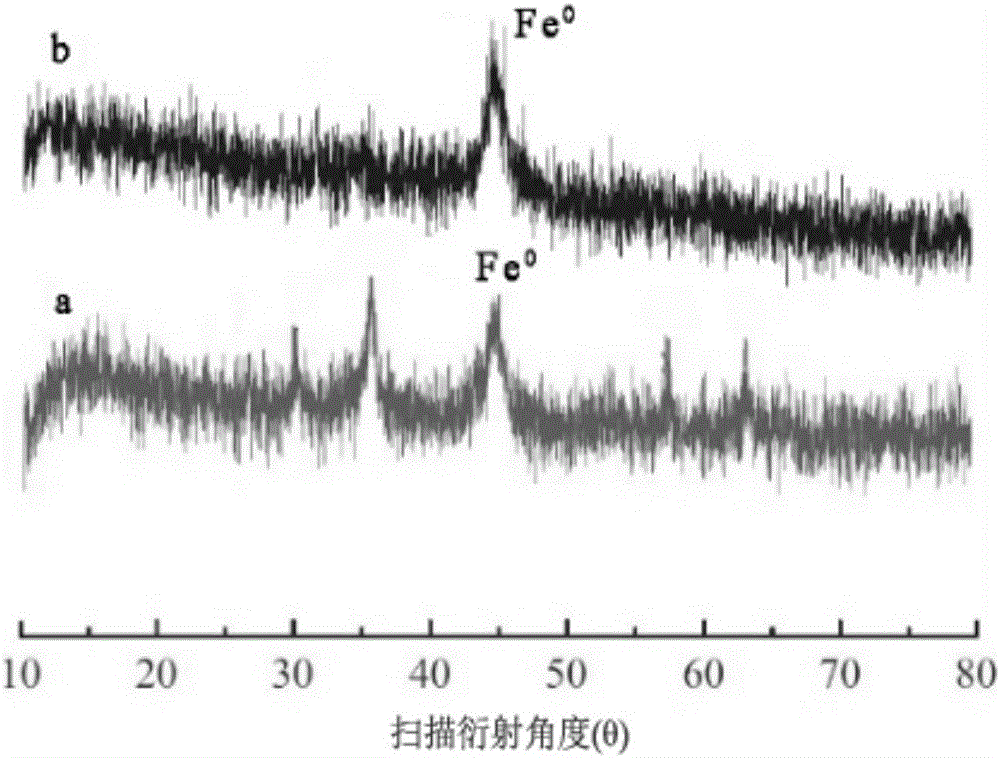

[0034] A coated nano-zero-valent iron of the present invention, the coated nano-zero-valent iron includes nano-zero-valent iron and sodium alginate, and the sodium alginate is coated on the surface of the nano-zero-valent iron, wherein the sodium alginate and nano-zero The mass ratio of valence iron is 0.1:1.

[0035] A method for preparing the coated nanometer zero-valent iron of the above-mentioned present embodiment, comprising the following steps:

[0036] (1) FeSO 4 Solution preparation: weigh 2.8000g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer it to a 100mL volumetric flask, use ultrapure water to make up the volume to the mark, and shake well to obtain FeSO with a concentration of 0.1M. 4 solution.

[0037] (2)NaBH 4 Solution preparation: weigh 0.7566g NaBH 4 Put it in a beaker, add an appropriate amount of ultrapure water to dissolve it and transfer it to a 100mL volumetric flask, use ultrapure water to ma...

Embodiment 2

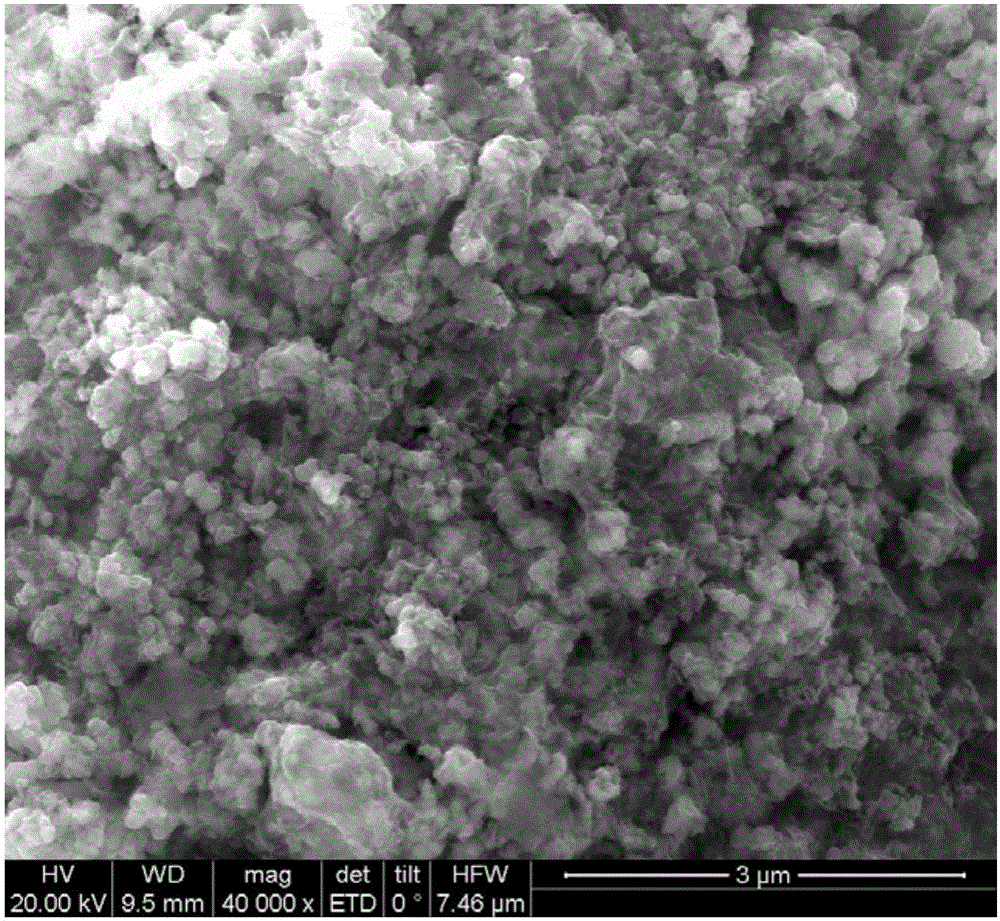

[0043] A coated nano-zero-valent iron of the present invention, the coated nano-zero-valent iron includes nano-zero-valent iron and sodium alginate, and the sodium alginate is coated on the surface of the nano-zero-valent iron, wherein the sodium alginate and nano-zero The mass ratio of valence iron is 0.2:1.

[0044] A method for preparing the coated nanometer zero-valent iron of the above-mentioned present embodiment, comprising the following steps:

[0045] (1) FeSO 4 Solution preparation: weigh 3.3600g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve it and transfer it to a 100mL volumetric flask, use ultrapure water to make the volume up to the mark, shake well, and obtain FeSO with a concentration of 0.12M 4 solution.

[0046] (2)NaBH 4 Solution preparation: weigh 0.9079g NaBH 4 Put it in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer it to a 100mL volumetric flask, use ultrapure water to make...

Embodiment 3

[0053] A coated nano-zero-valent iron of the present invention, the coated nano-zero-valent iron includes nano-zero-valent iron and sodium alginate, and the sodium alginate is coated on the surface of the nano-zero-valent iron, wherein the sodium alginate and nano-zero The mass ratio of valence iron is 0.3:1.

[0054] A method for preparing the coated nanometer zero-valent iron of the above-mentioned present embodiment, comprising the following steps:

[0055] (1) FeSO 4 Solution preparation: weigh 5.3200g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve it and transfer it to a 100mL volumetric flask, use ultrapure water to set the volume to the mark, shake well, and obtain FeSO with a concentration of 0.19M 4 solution.

[0056] (2)NaBH 4 Solution preparation: weigh 1.4375g NaBH 4 Put it in a beaker, add an appropriate amount of ultrapure water to dissolve and transfer it to a 100mL volumetric flask, use ultrapure water to make up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com