Manufacturing method of sealing gasket

A manufacturing method and technology of sealing gaskets, which are applied in the directions of engine components, piston rings, mechanical equipment, etc., can solve the problems that metal sealing gaskets cannot form a complete seal and have poor sealing effect, and achieve good sealing performance, reduce requirements, and improve The effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

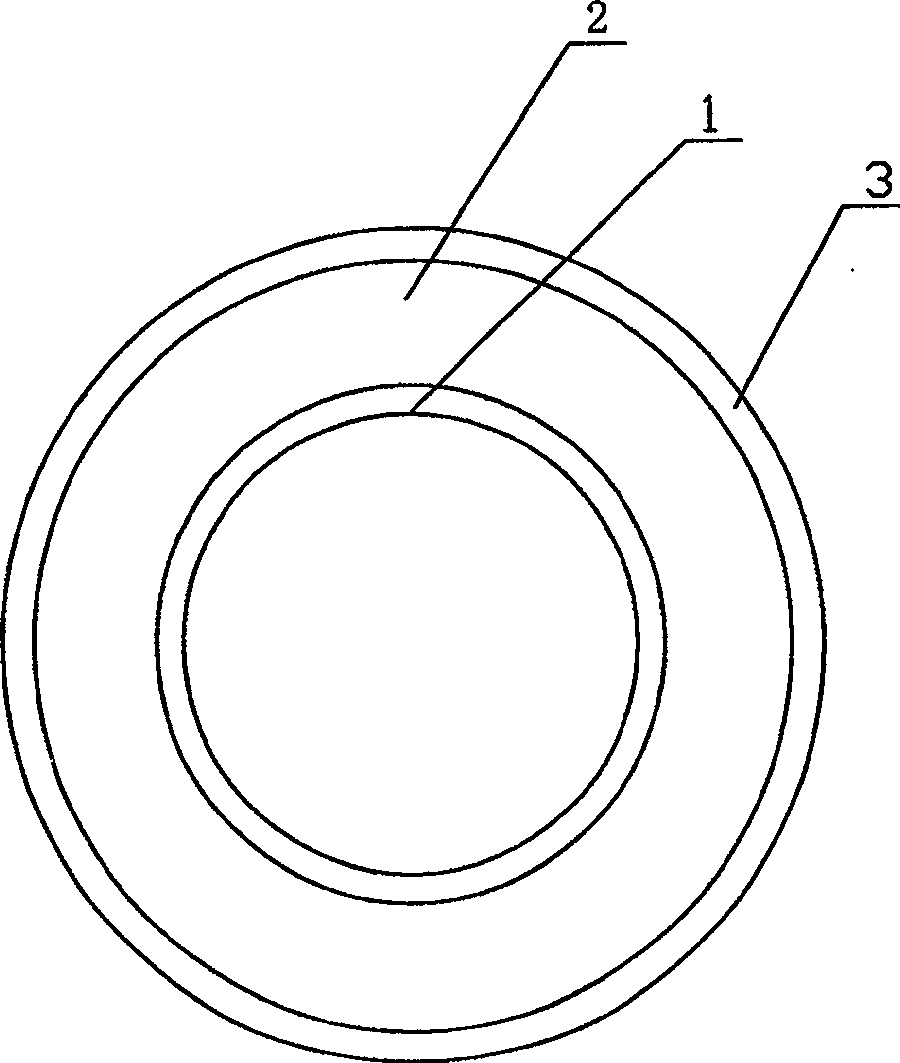

[0012] With reference to accompanying drawing, manufacturing method of the present invention comprises steps as follows: a, cut metal ring according to size requirement: inner ring 1, outer ring 3; b, according to the compression ratio of graphite plate and the density of spacer, cut out the width of graphite band : c. Select a suitable mold according to the required size of the gasket; d. Wrap the graphite tape round by round into the mould, and the corresponding joint parts of the graphite tape wound into the mould are misaligned with each other, and the graphite ring 2 is pre-pressed; e , The inner ring, the outer ring and the graphite ring are molded and nested with a mold; f, demoulding; g, trimming and shaping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com