A kind of urea tank and its cover for scr post-processing system

A technology of urea tank and tank cover, which is applied in the direction of exhaust gas treatment, arrangement combined with internal combustion engine fuel supply, separation method, etc., which can solve the problem of limited ventilation capacity of waterproof and breathable membrane, easy blowout of waterproof and breathable membrane, failure of ventilation function, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] For ease of understanding, the present invention will be further described below with reference to the accompanying drawings.

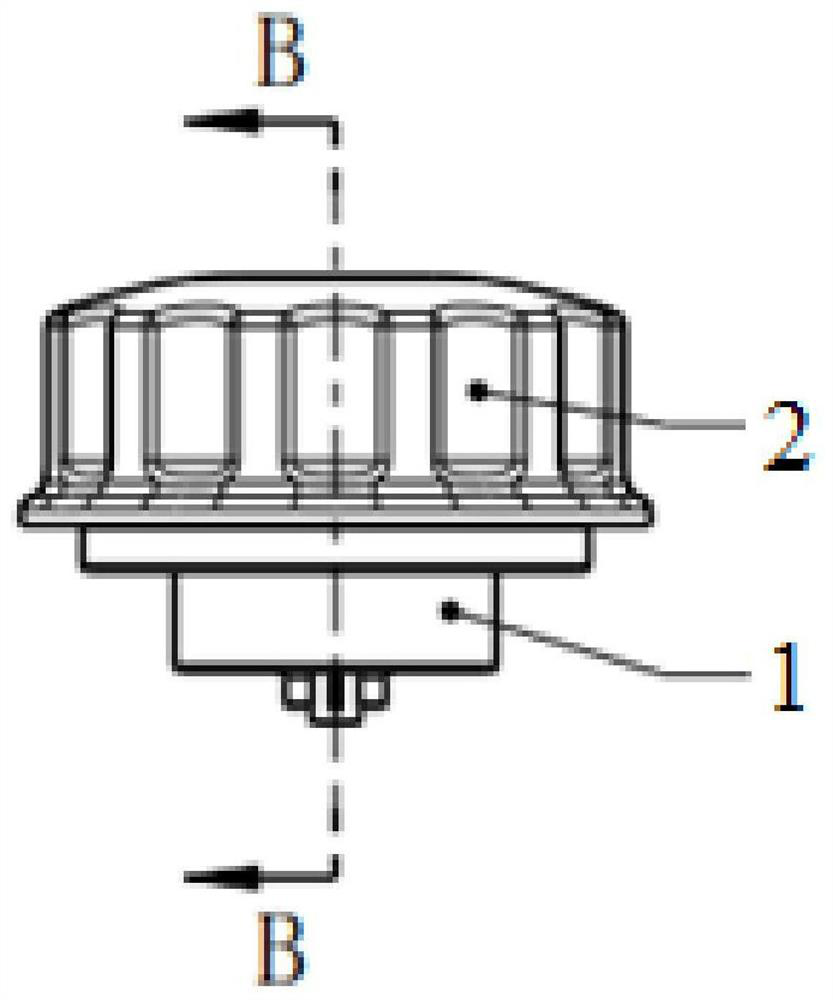

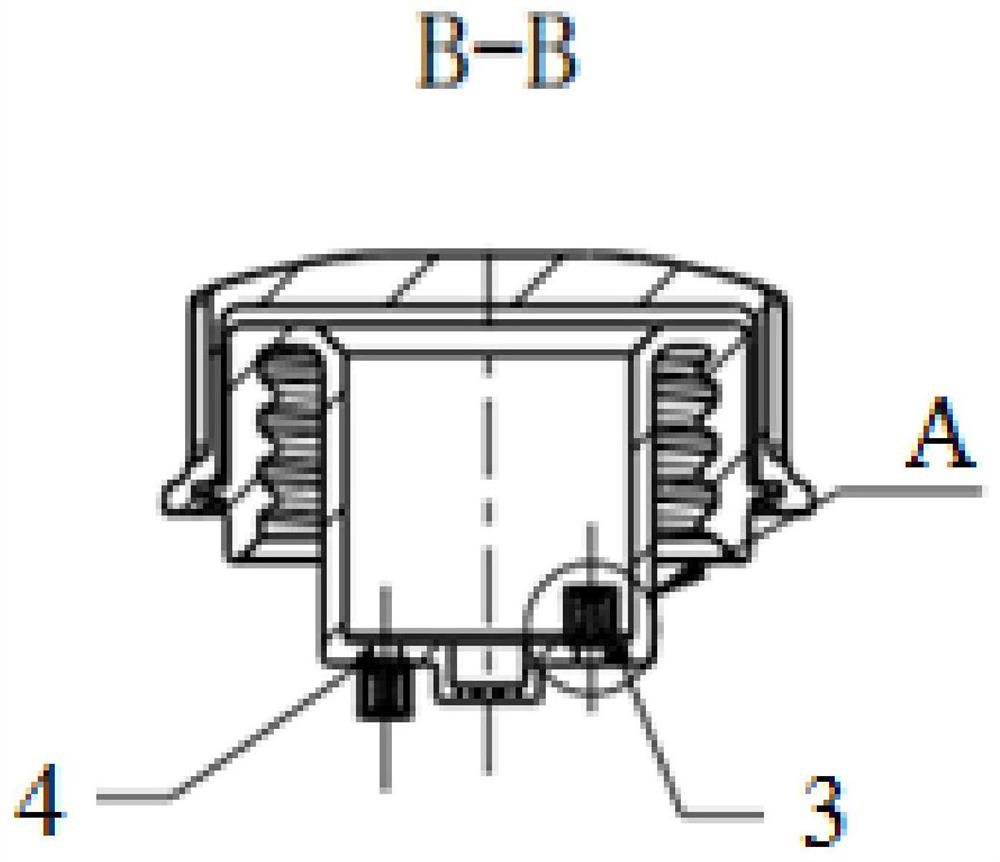

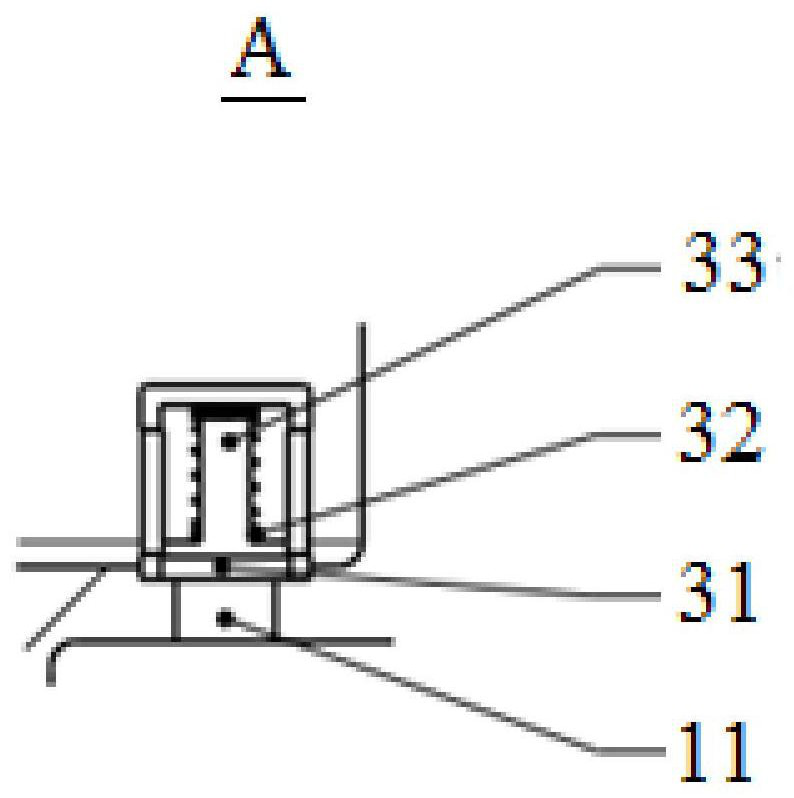

[0032] see Figure 1 to Figure 4 , figure 1 is a schematic diagram of a tank cover of a urea tank used in an SCR post-treatment system provided by an embodiment of the present invention, figure 2 Yes figure 1 B-B sectional view in, image 3 Yes figure 2 The enlarged view at A, Figure 4 Yes figure 1 bottom view.

[0033] The tank cover provided in the embodiment of the present invention is installed at the liquid injection port of the tank body of the urea tank, and the part of the tank cover corresponding to the liquid injection port is provided with ventilation holes, and the ventilation holes are covered by a waterproof and breathable film 5, such as Figure 4 shown. At the same time, the part of the tank cover corresponding to the liquid injection port is also provided with an air intake hole (not marked in the figure) and an exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com