Space curved surface special-shaped steel box girder bridge section and precise welding processing forming method thereof

A technology of steel box girder and special-shaped steel, which is applied in the field of special-shaped steel box girder bridge section with curved space and its precision welding processing and forming. It can solve problems such as uneven space curved surface, bulging and deformation of beam bridge deck, and achieve scientific design. Reasonable, smooth appearance, linear structure, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and examples, and the modes of the present invention include but are not limited to the following examples.

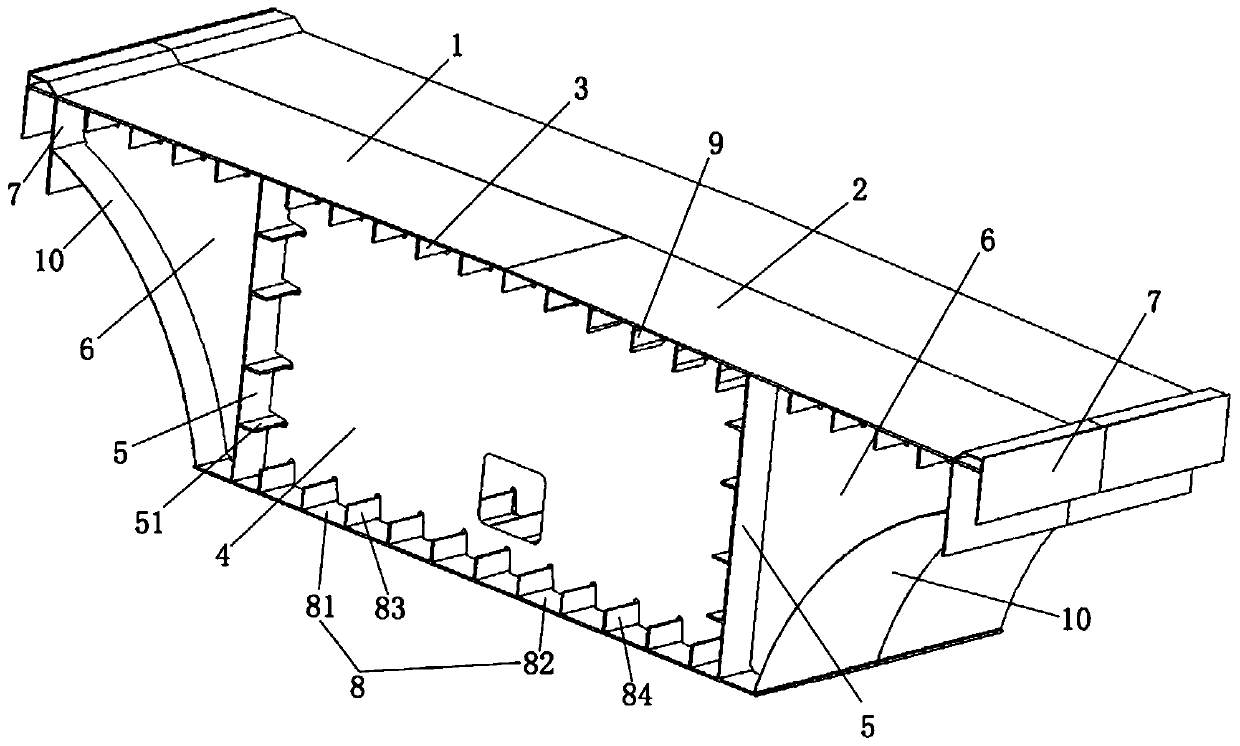

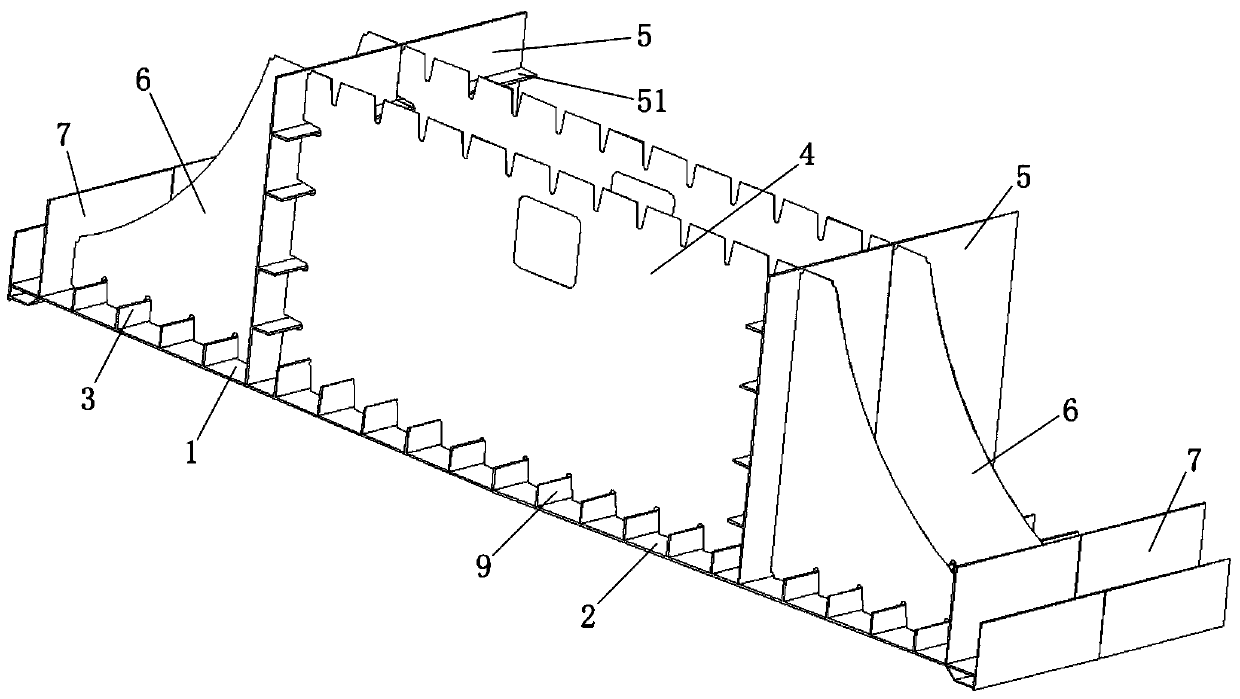

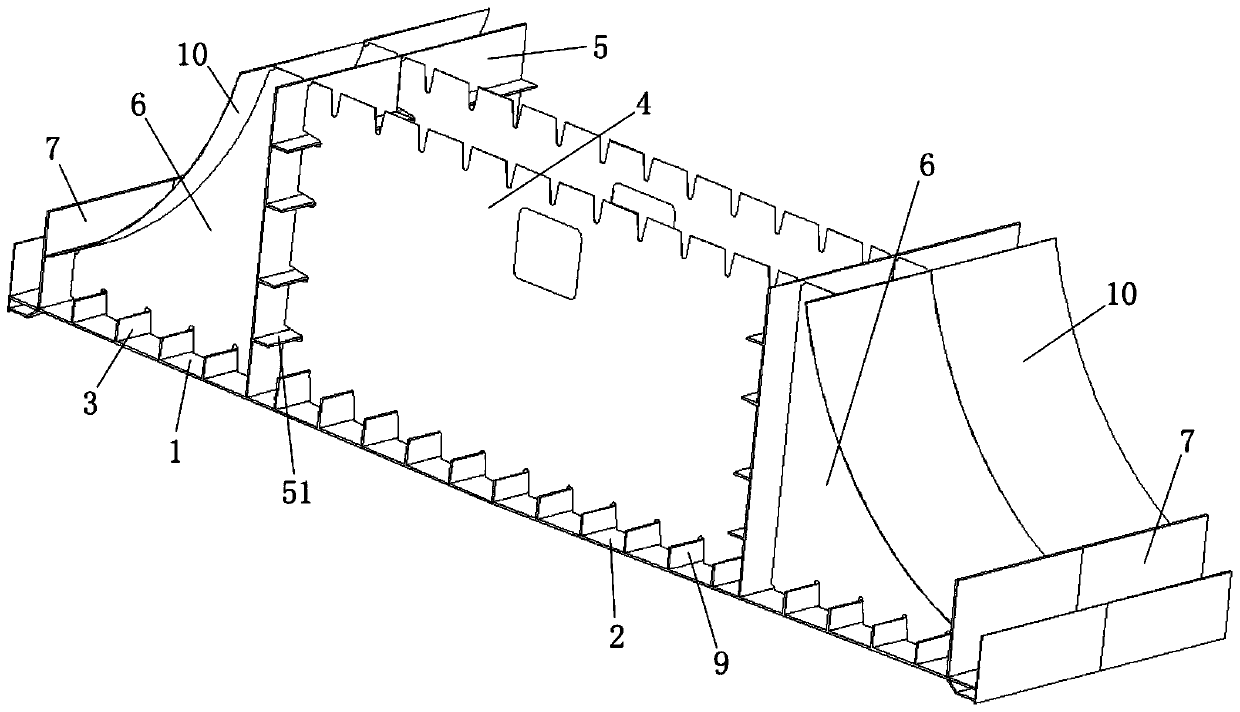

[0035] like figure 1 As shown in the figure, the present invention provides a special-shaped steel box girder bridge section with a space curved surface, which has a simple structure, a scientific and reasonable design, and is convenient to use. , which can effectively realize the dual functions of bridge load-bearing traffic and aesthetics. The present invention includes a horizontally distributed steel box girder bridge bottom plate 8, two steel box girder bridge webs 5 which are welded and fixed to the two ends of the top surface of the steel box girder bridge bottom plate 8 vertically relative to each other, and two steel box girder bridge web plates 5 are welded and fixed respectively on The arc-shaped lower sealing plates 10 on both sides of the steel box gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com