Light environment-protecting calcium silicate board

A calcium silicate board, an environmentally friendly technology, applied in building components, building elements, covering/lining, etc., can solve the problems of calcium silicate boards without connecting devices, inconvenient transportation and installation, and affecting surface smoothness, etc., to achieve Simple installation, convenient packaging and transportation, simple adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

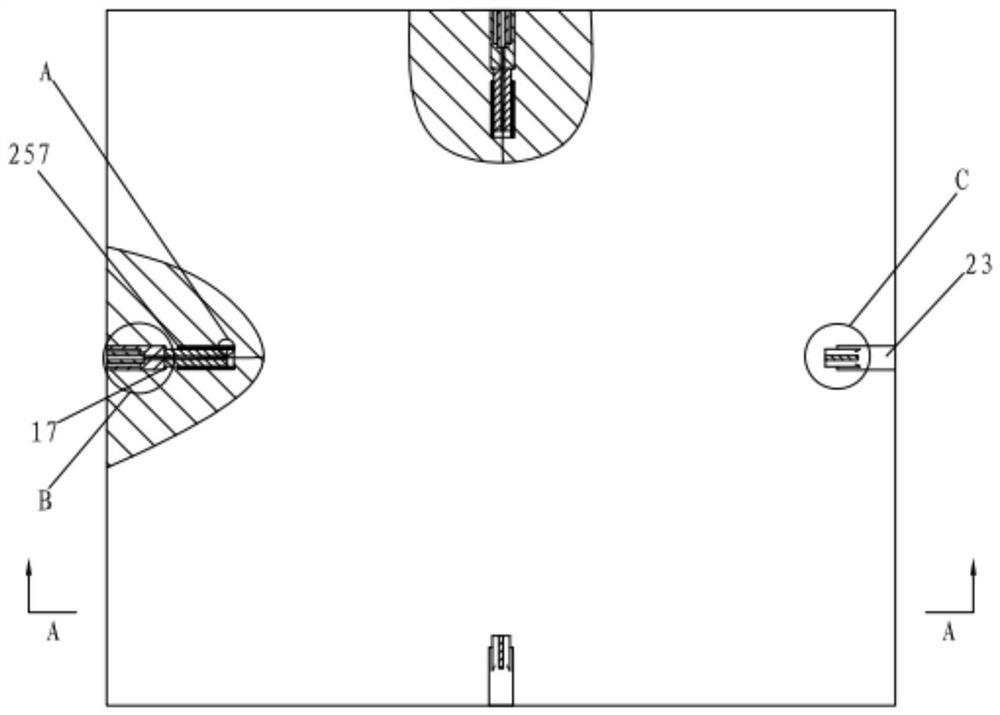

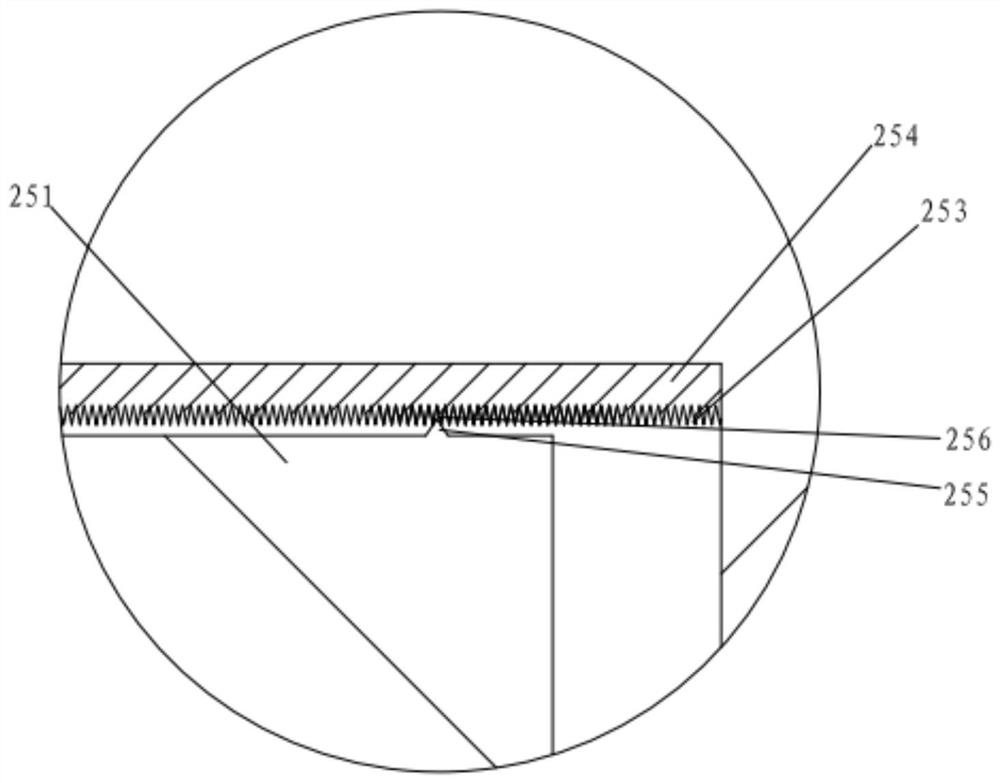

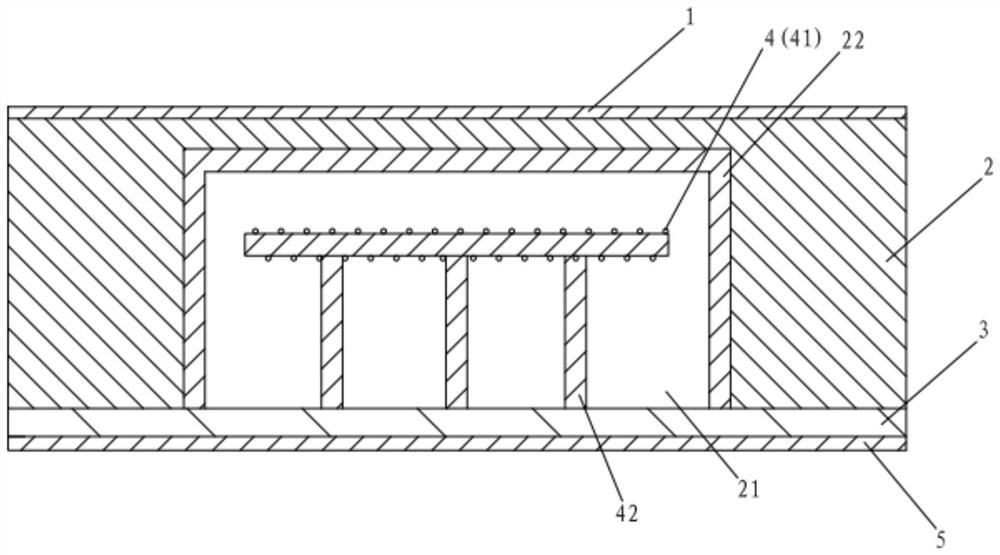

[0027] refer to Figure 1 to Figure 5 , this embodiment relates to a lightweight environmentally friendly calcium silicate board, including an upper connection layer 1, an intermediate layer 2, a heat conduction layer 3, a heater 4 and a lower connection layer 5 that are stacked and bonded together from top to bottom; The intermediate layer 2 is U-shaped, and the heater 4 is fixedly installed in the U-shaped groove 21 of the intermediate layer 2. The inner wall of the U-shaped groove 21 of the intermediate layer 2 is provided with a heat insulating layer 22, and the heat-conducting layer 3 covers the opening of the U-shaped groove 21 of the middle layer 2 to seal the opening; two adjacent sides of the middle layer 2 are provided with card holes 23, and the other two sides of the middle layer 2 are provided with card holes 23. The card post 24 that the hole 23 matches, the female plug 231 that is connected with the power input end of the heater 4 is provided in the described ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com