Assembly type light lamp carrying and hanging type rear structure and mounting method

A prefabricated, light-weight technology, applied in lighting devices, lighting auxiliary devices, and components of lighting devices, etc., can solve problems such as changes in plate appearance, creep deformation, plate rupture, etc., to avoid apparent quality risks and Creep deformation risk, effect of increased strength, increased stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

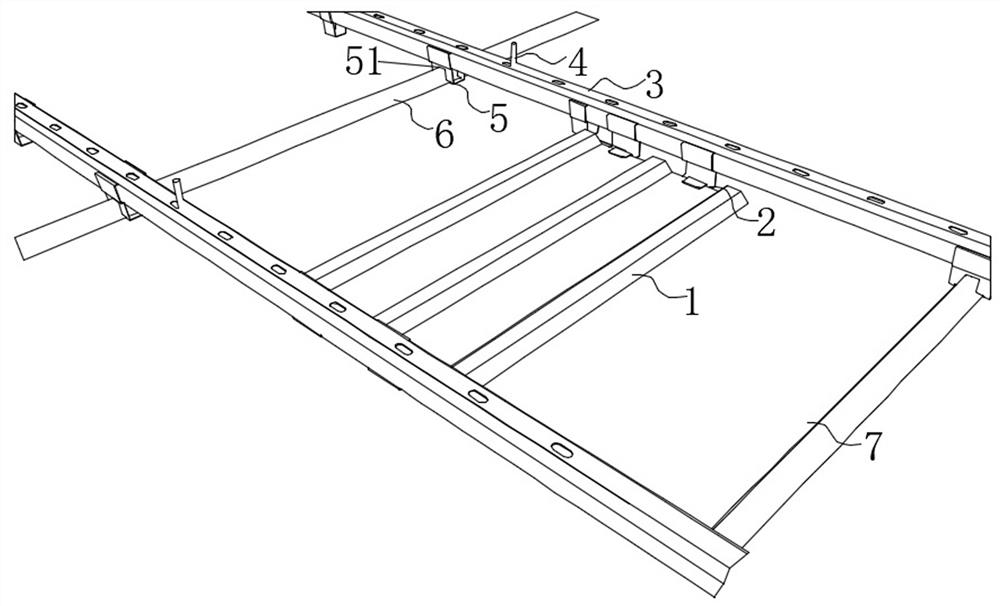

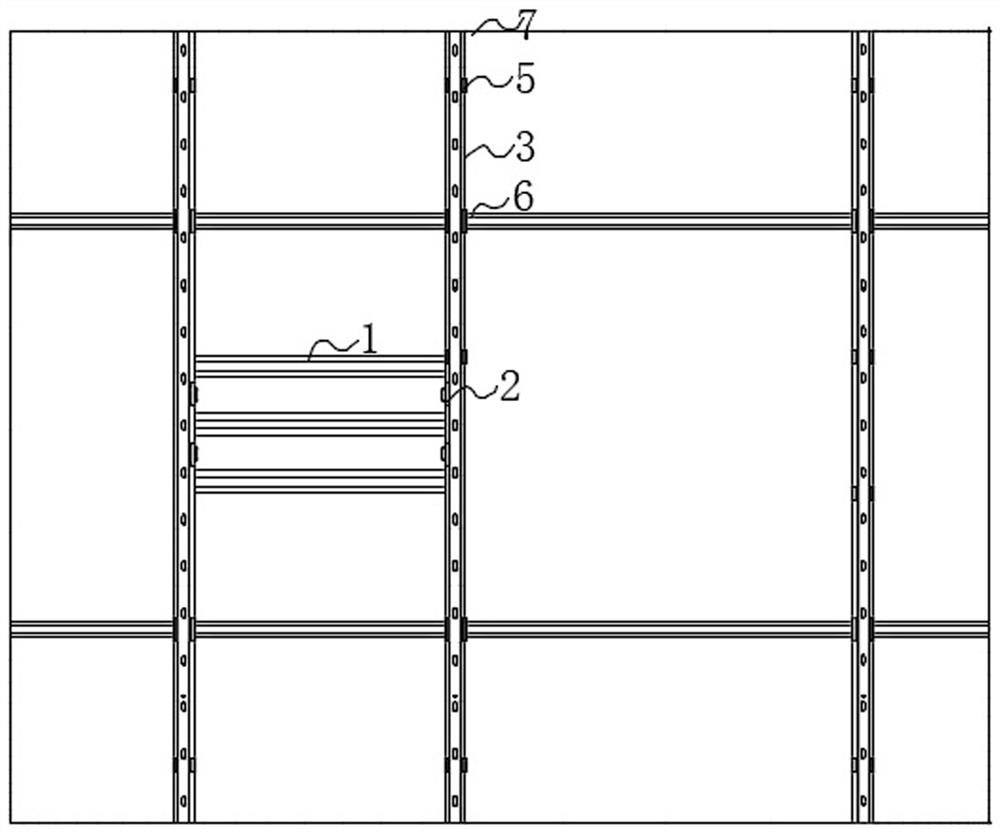

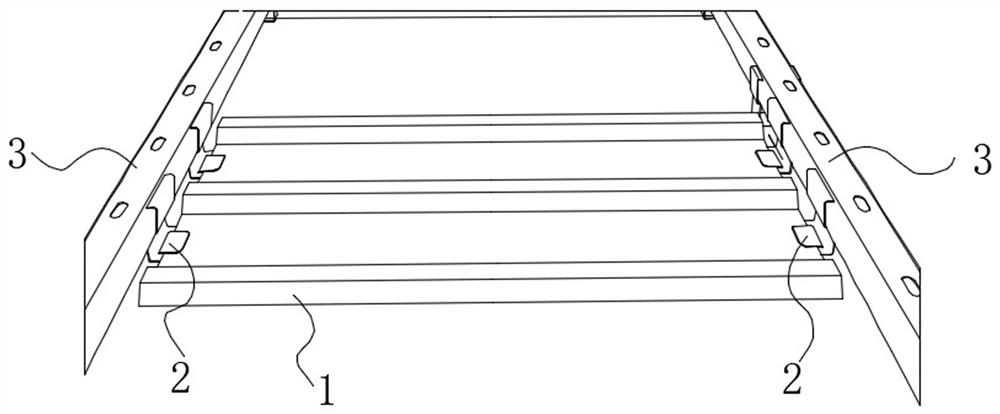

[0037] like Figure 1-3 As shown in the figure, an assembled light-duty lamp-mounted rear structure includes a corrugated lamp-carrying support plate 1, the concave surface 11 of the lamp-carrying support plate 1 and its convex surface 13 are connected by an inclined surface 12; including a lamp-carrying pendant 2, the The tongue 21 of the lamp-carrying pendant 2 is snapped into the concave surface 11 of the lamp-carrying bearing plate 1; it includes a main keel 3, the arc structures 23 of the lamp-carrying pendant 2 are hung on both sides of the main keel 3, and the top of the main keel 3 hangs It is installed on the building floor through the hanger 4; it includes an I-shaped piece 5, both ends of the I-shaped piece 5 are clipped into both sides of the main keel 3, and the middle of the I-shaped piece 5 forms an installation opening 51; including t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com