An automatic lithium battery liquid injection system

A lithium battery liquid injection and battery technology, which is applied to battery components, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc., can solve problems such as low efficiency and instability, and achieve improved utilization, improved reliability, The effect of improving scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

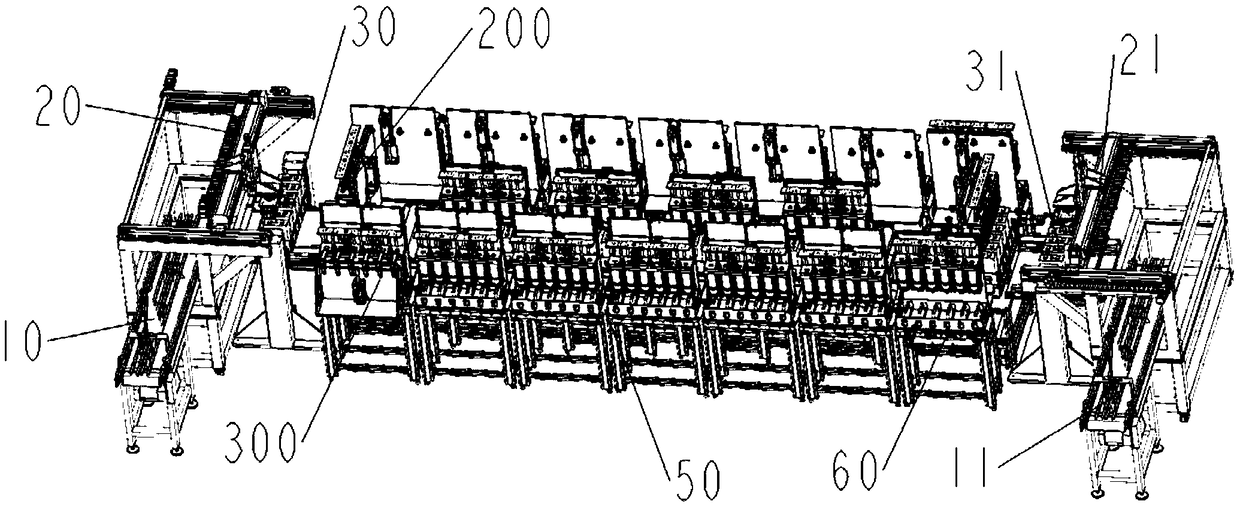

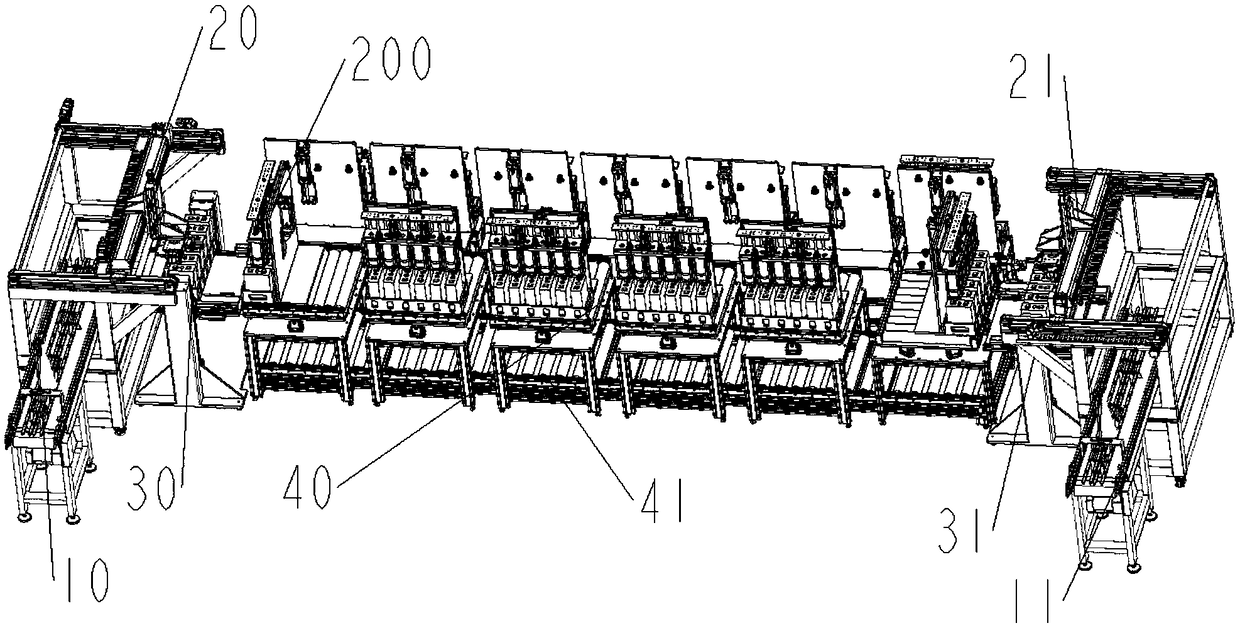

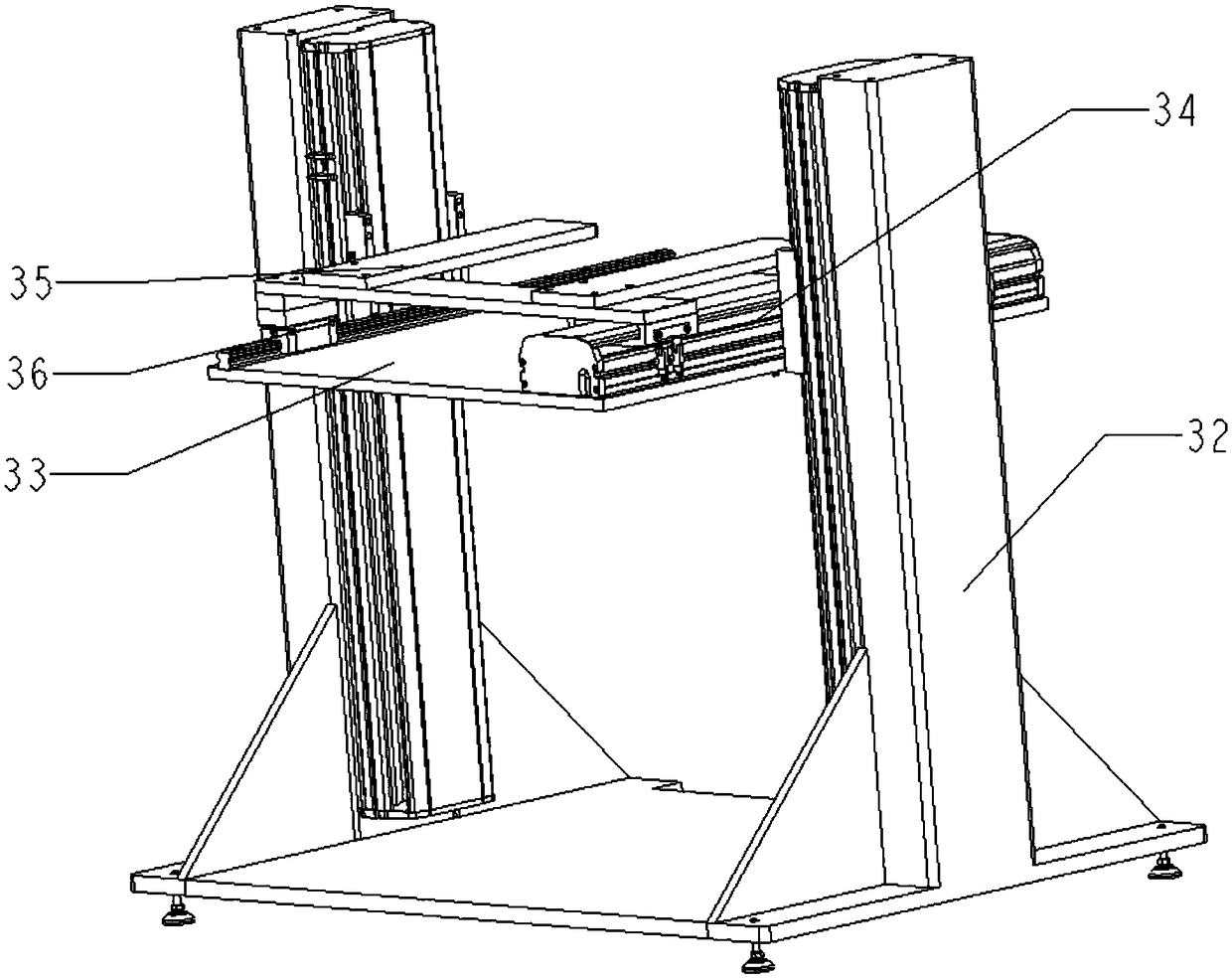

[0048] combine Figure 1-8 , the present application provides an automatic lithium battery liquid injection system, which includes more than two battery boxes 100 for placing batteries to be injected and more than two filling mechanisms 200 for battery injection, and also includes sequentially arranged The battery incoming line 10, the battery loading manipulator 20 for clamping the battery on the battery incoming line and putting it into the battery box, the first lifting and translation mechanism 30 for connecting the battery box, and the filling mechanism return roller Line 40, the empty battery box return drum line 41 located on the lower layer of the filling mechanism return drum line, the second lifting and translation mechanism 31 for connecting the battery box, the battery unloading manipulator 21, the battery output line 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com