Radiating water tank and plastic shield assembly

A technology of cooling water tank and shield, which is applied in the layout of power unit cooling combination, power unit, transportation and packaging, etc., can solve the problems of poor water circulation inside the water tank, inconsistency of installation lugs, and weak impact resistance. , to achieve the effect of more beautiful appearance, good water circulation, and improved impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

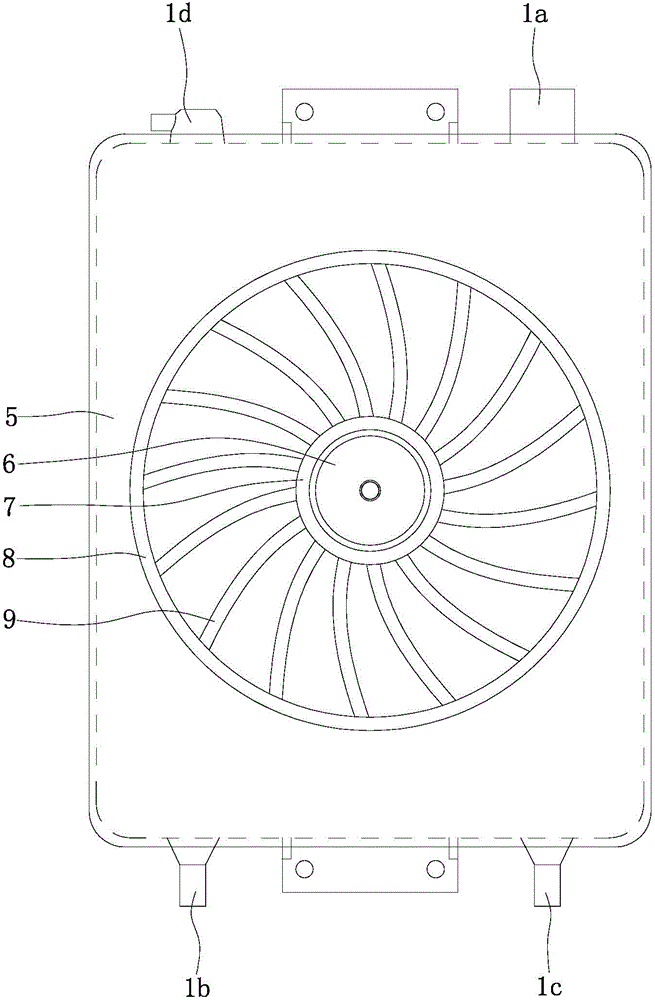

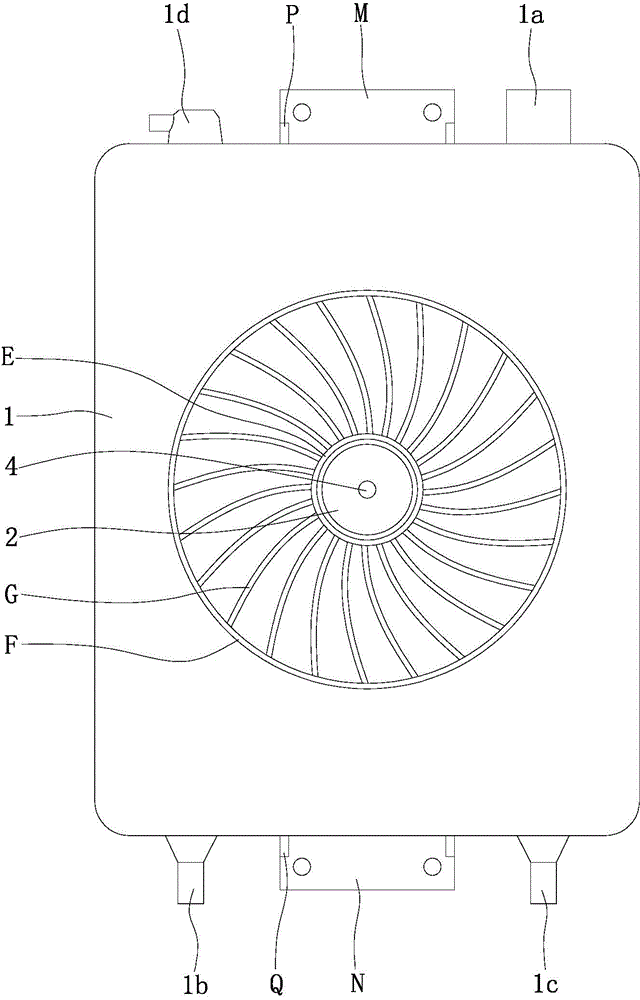

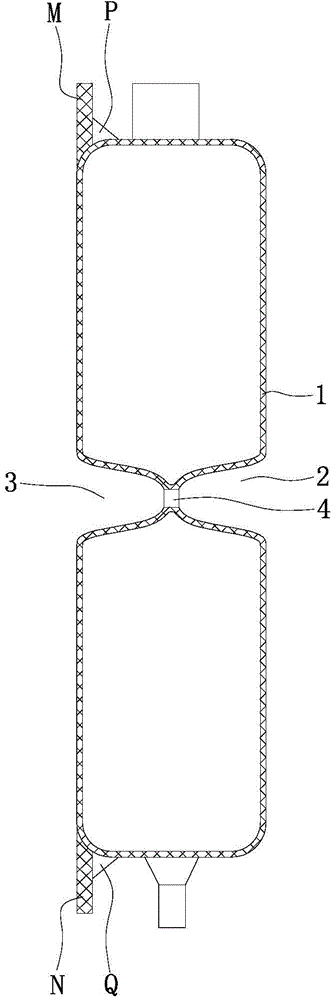

[0023] Such as figure 2 , image 3 As shown, the box body 1 is rectangular and molded by hollow blow molding. The pressure-reducing vent nozzle 1d is set on the left end of the top of the box body 1, and the water inlet 1a is set on the right end of the top of the box body 1; the water inlet 1b is set on the left end of the bottom of the box body 1, and the water outlet 1c is set on the right end of the bottom of the box body 1 . The pressure-reducing air nozzle 1d, the water inlet 1a, the water inlet 1b, the water outlet 1c and the box body 1 are integrated.

[0024] Such as figure 2 , image 3 As shown, the middle part of the front box wall of the box body 1 is recessed backwards to form a first sinker 2, the first sinker 2 is conical, and the first sinker 2 gradually becomes smaller from the notch to the bottom of the tank. The position of the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com