Method for knocking and inspecting molds of box-type module groups and applying z-shaped super-long profiles

A modular group and box-type technology, which is applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of delaying the delivery cycle of aircraft parts, large changes in part mechanism design, waste of mold manufacturing costs, etc., to reduce mold scrapping Risk, flexible and convenient partial adjustment, and the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

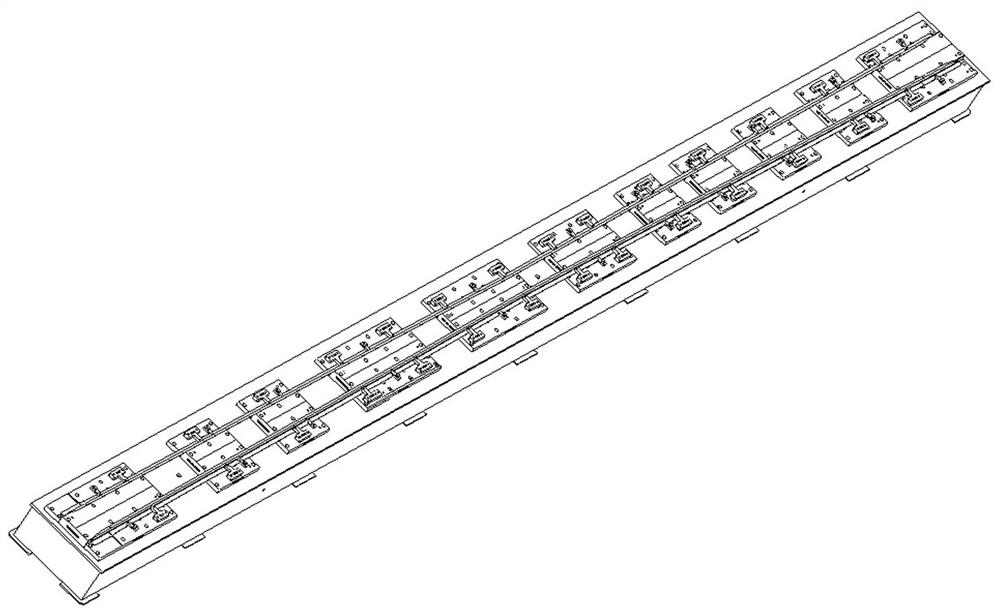

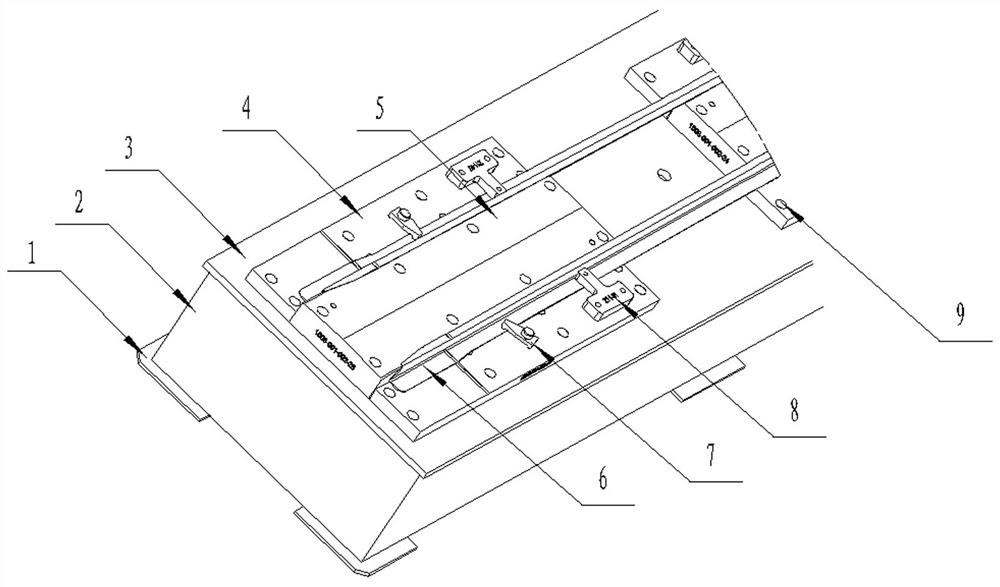

[0017] Such as figure 1 with figure 2 As shown, a box-type module group knocks and inspects the mould, the lower surface of the box-type frame 2 is connected to the base 1, the upper surface of the box-type frame 2 is connected to the platform 3, and several molded tire modules 5 are connected on the platform 3, and the molded tires The outer shape of the module 5 is consistent with the curvature of the Z-shaped super-long profile to be processed, and the molded tire module 5 is not provided at the corresponding position where the curvature of the Z-shaped super-long profile is close to 0; the outer side of the molded tire module 5 in the width direction is connected through a bolt hole 9 The supporting block 4 is provided with a top block 8 on the supporting block 4, and the top block 8 is tightly pressed against the side surface of the Z-shaped super long profile to be processed; The bottom of the profile is pressed against the upper surface.

[0018] In order to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com