Patents

Literature

86results about How to "Increase molding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

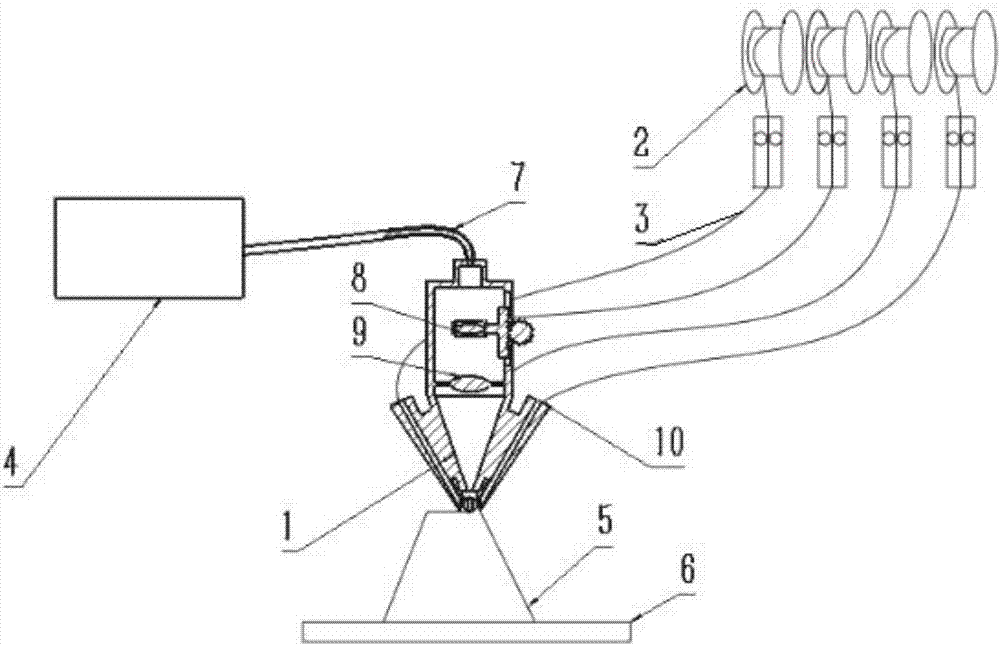

Multipath wire feed laser fused deposition modeling (LFDM) device and method

InactiveCN106926447AEfficient printingImprove molding efficiency3D object support structuresApplying layer meansEngineeringFused deposition modeling

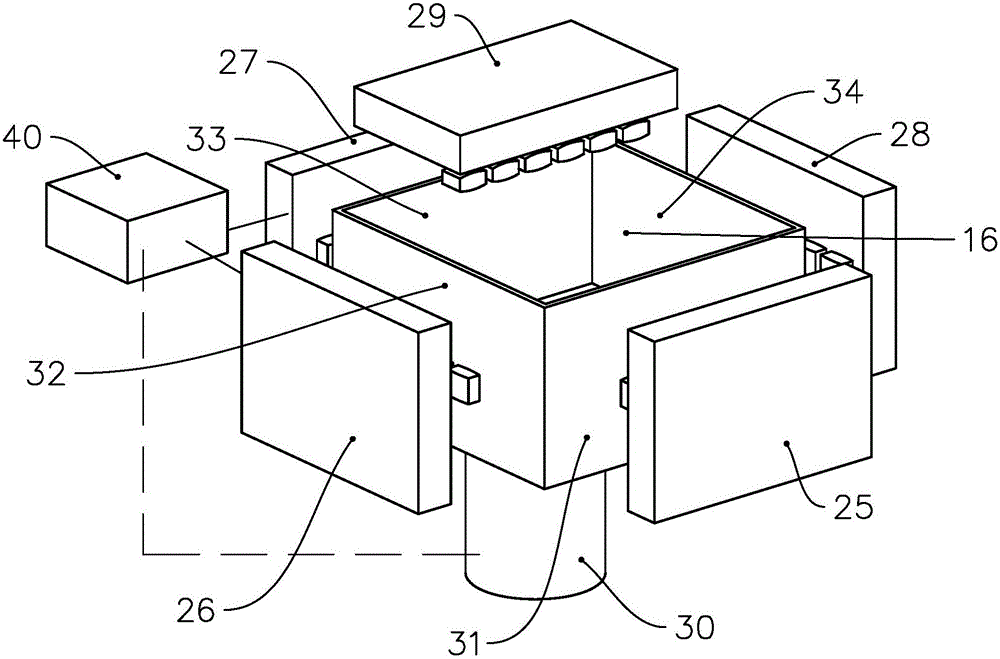

The invention discloses a multipath wire feed laser fused deposition modeling (LFDM) device and method. The device comprises a wire feed nozzle composed of multiple wire conveying pipelines, a laser head and a carbon dioxide laser. The wire feed nozzle and the laser head are fixedly connected together through a connecting part to form a composite printing head. A steering engine is mounted on the connecting part so as to increase the freedom degree of the composite printing head. The laser head can transmit a rectangular laser beam, and the rectangular laser beam ejects out from the lateral direction of the laser head and irradiates and covers the ends of corresponding wires stretching out of the outer portion of the wire feed nozzle to carry out fusing on the ends. According to the device, on the basis of a traditional fused deposition technology, a laser fused deposition technology is developed, some problems existing in traditional equipment are solved, meanwhile, more functions are given to the novel device, and more possibilities and methods and thoughts for solving the problems are provided for the fused deposition modeling technology. Meanwhile, by means of linear multipath wire feed, an effective multi-conveying-pipeline arrangement manner is provided.

Owner:SOUTH CHINA UNIV OF TECH

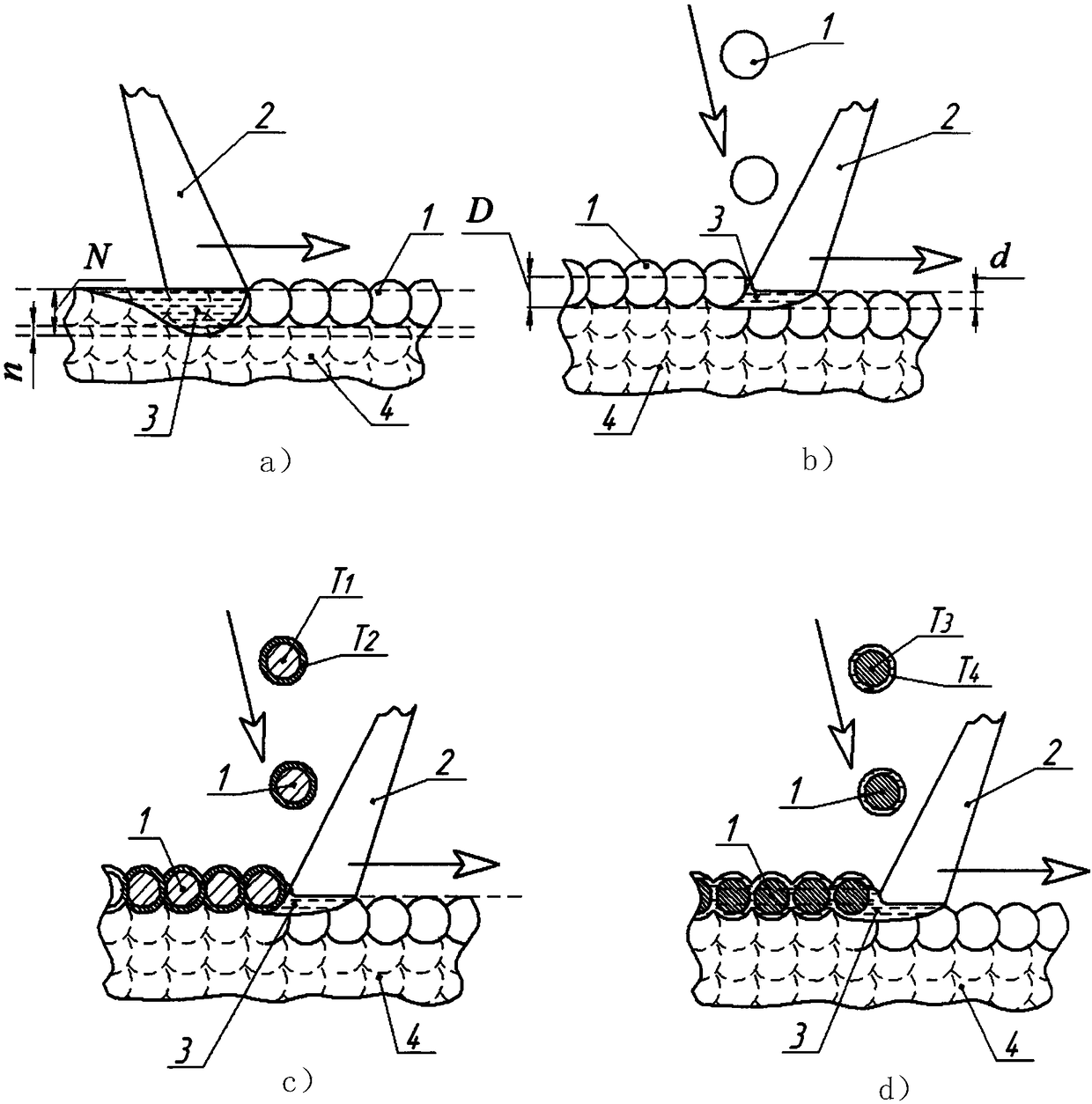

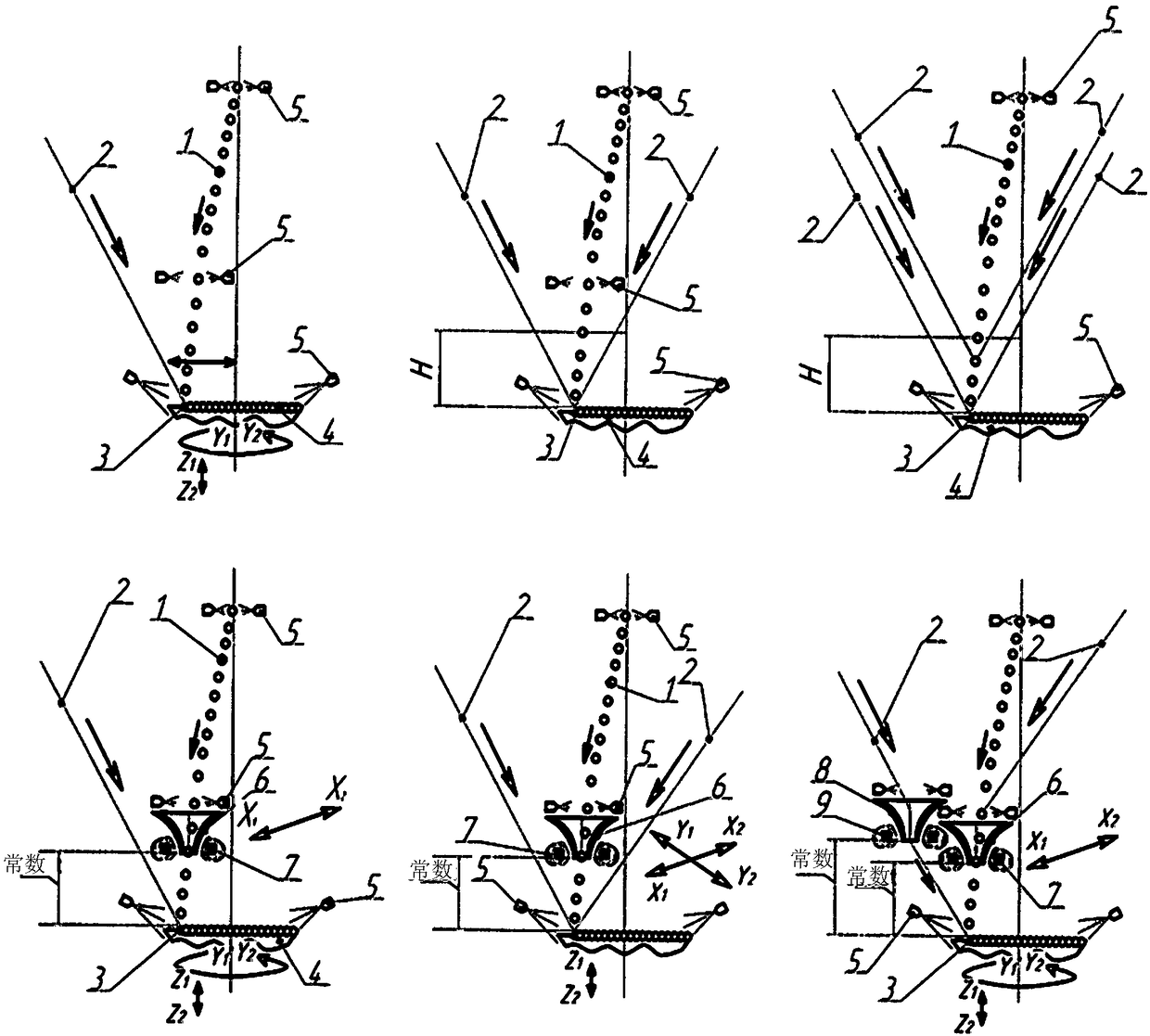

Method and device for the additive manufacturing of components

ActiveCN108136500AReduce consumptionImprove accuracyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLaser beams

The invention relates to the field of the additive manufacturing of components, which are formed by the direct deposition of a substance, in the form of granules of a metal or non-metal, which passesfrom a reservoir into a melt bath, produced by the thermal energy of a laser or electron beam, and subsequently crystallizes. The granules enter the melt bath without the intervention of a gas stream,the path and rate of travel of said granules changing while they are in flight under the effect of an electromagnetic field. The granules travel within a chamber, falling into the melt bath from above from a reservoir, from which they are fed at a set speed by the rotation of an adjustable screw feed, and passing through a system of electromagnetic devices, which control the path of the granulesby means of electromagnetic fields. The coordinates of this path are tracked by sensors, which transmit a signal to a computer, wherein the flight path of the granules is adjusted by control via the electronic devices and the delivery speed and volume of the substance is adjusted by adjusting the rotation of the screw feed. The invention increases the efficiency of the production cycle, reduces the dimensions of the equipment and increases the accuracy and speed with which material is delivered for the manufacture of a component, while enabling adjustment of the amount, temperature, path and fraction of said material and increasing the strength of the component.

Owner:阿迪鲁特有限责任公司

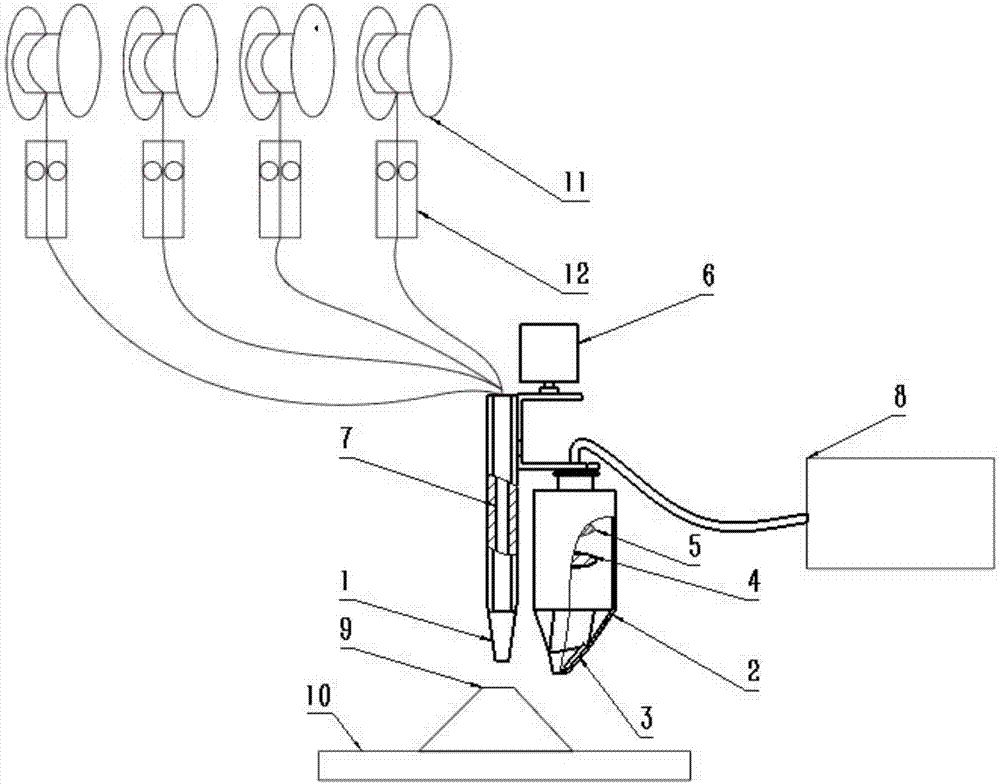

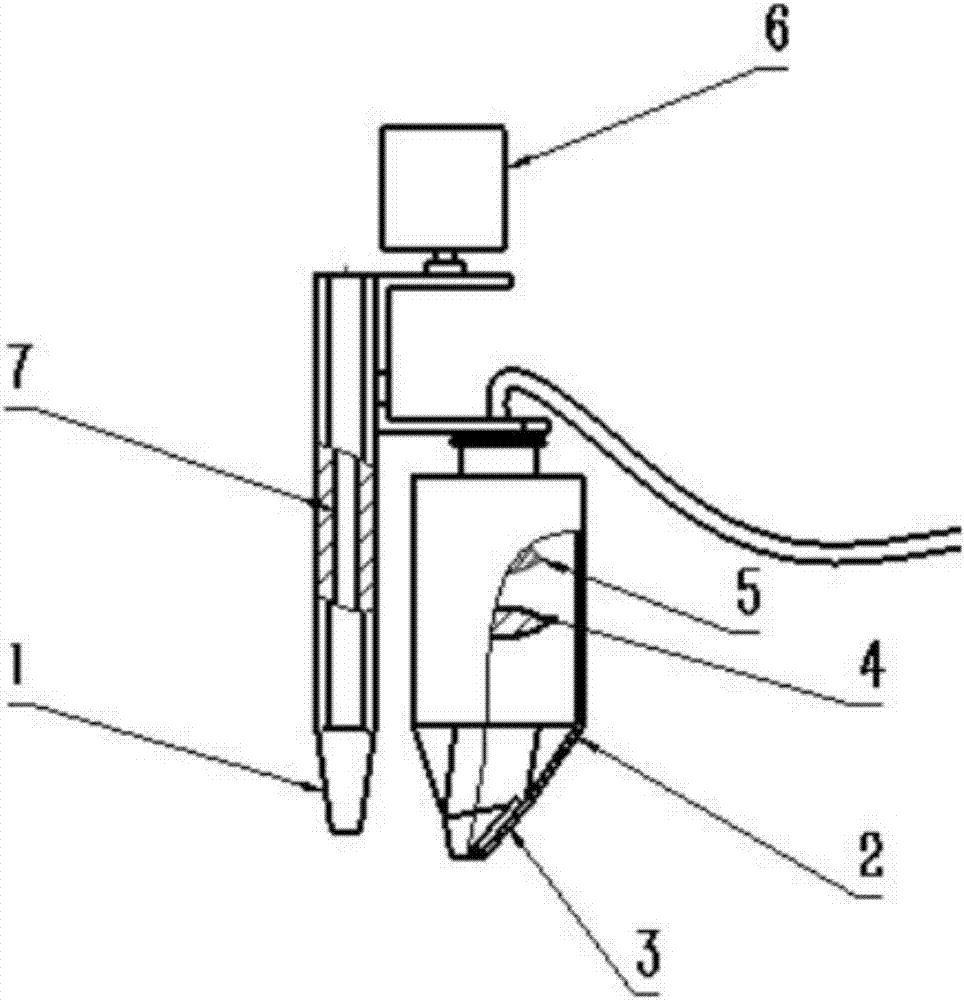

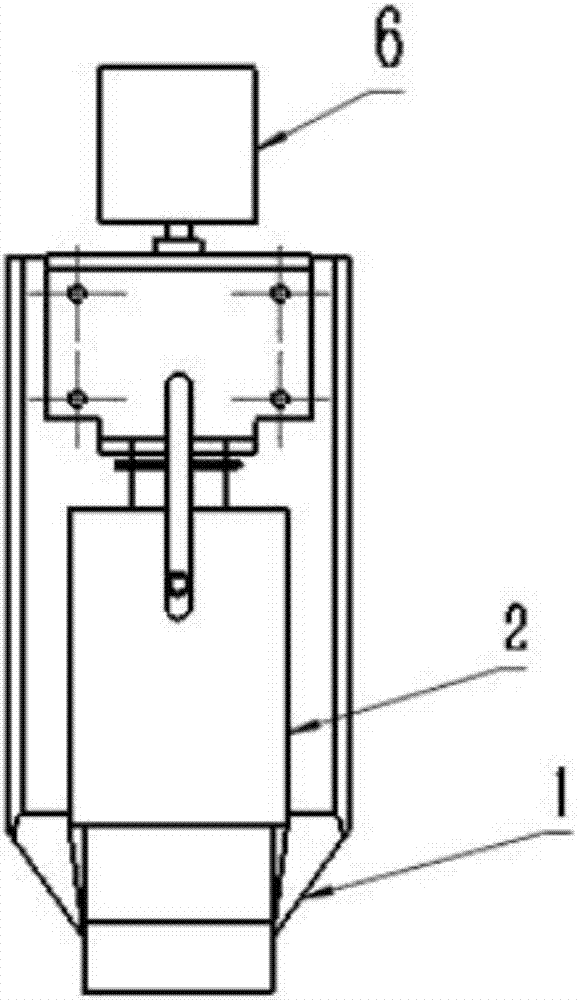

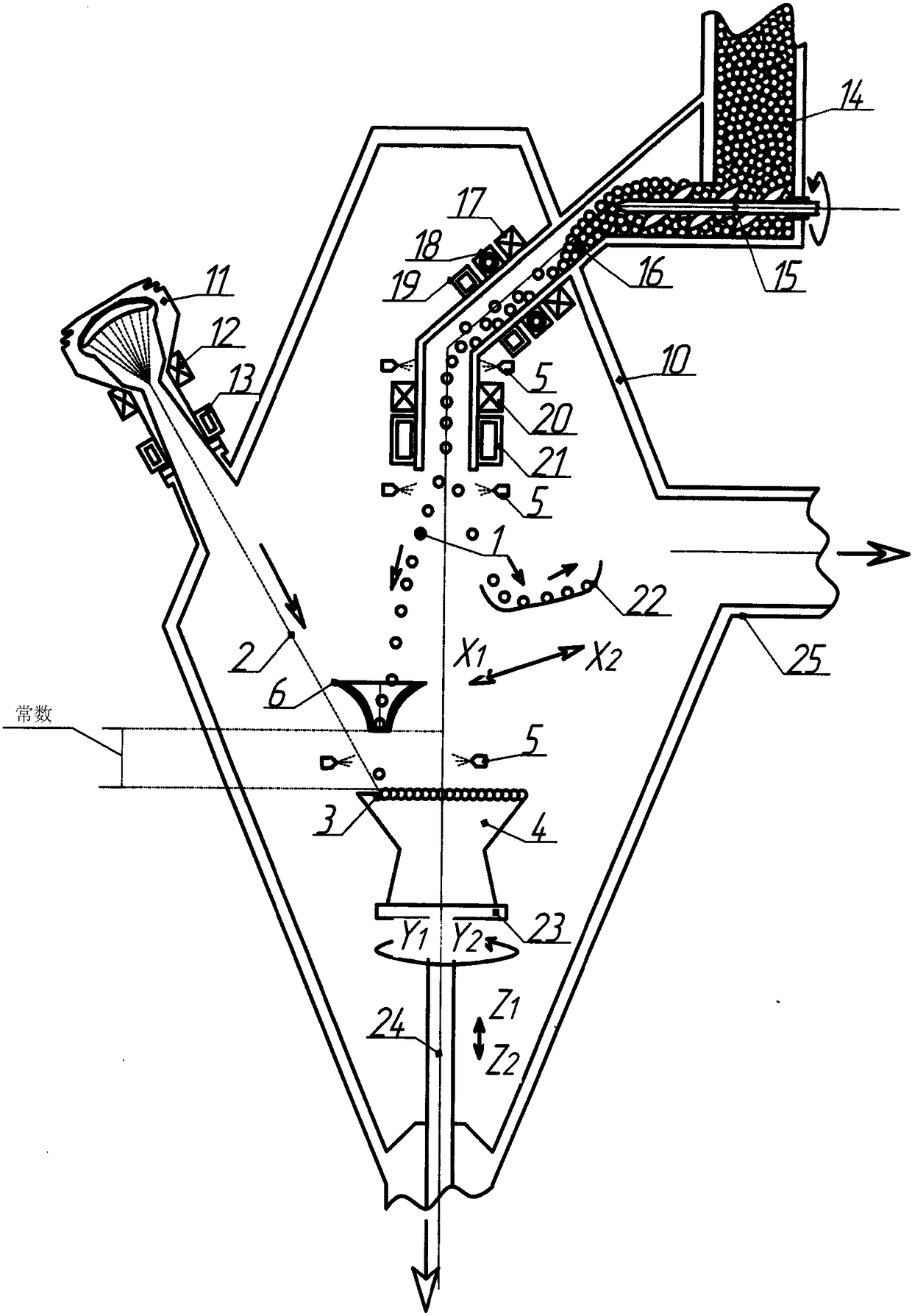

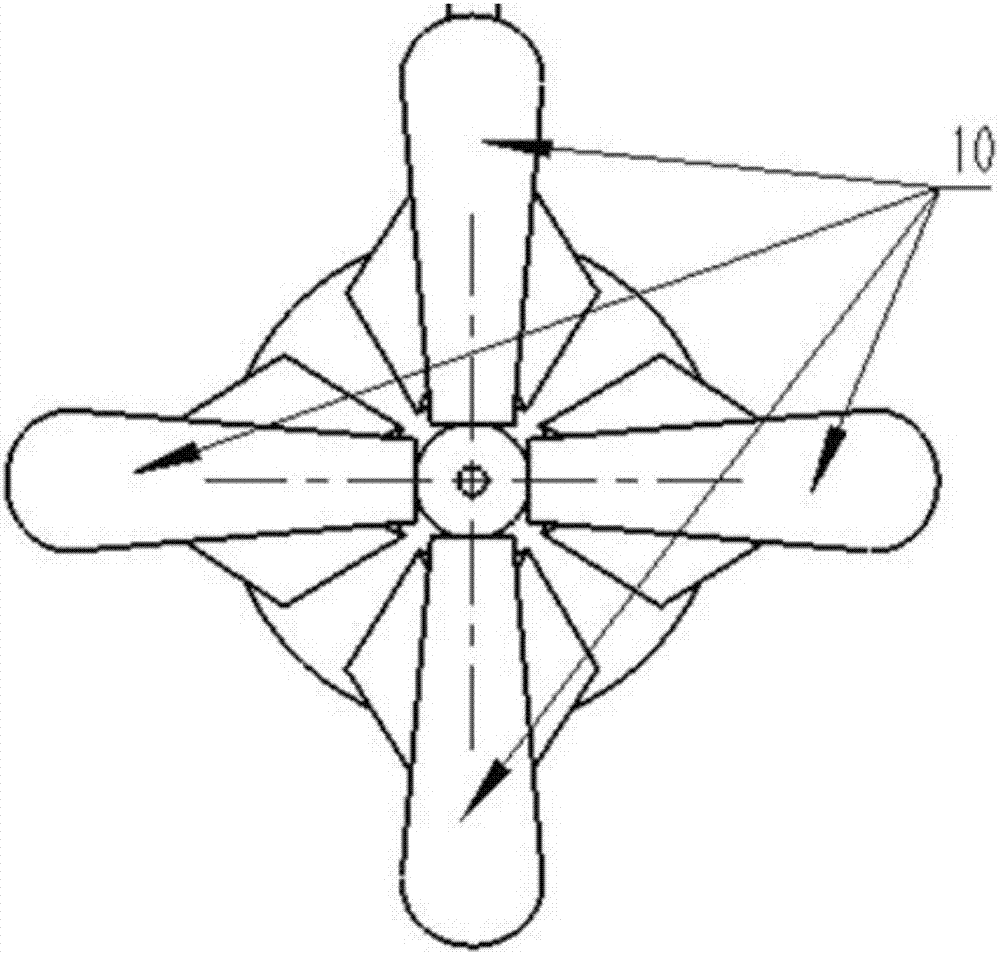

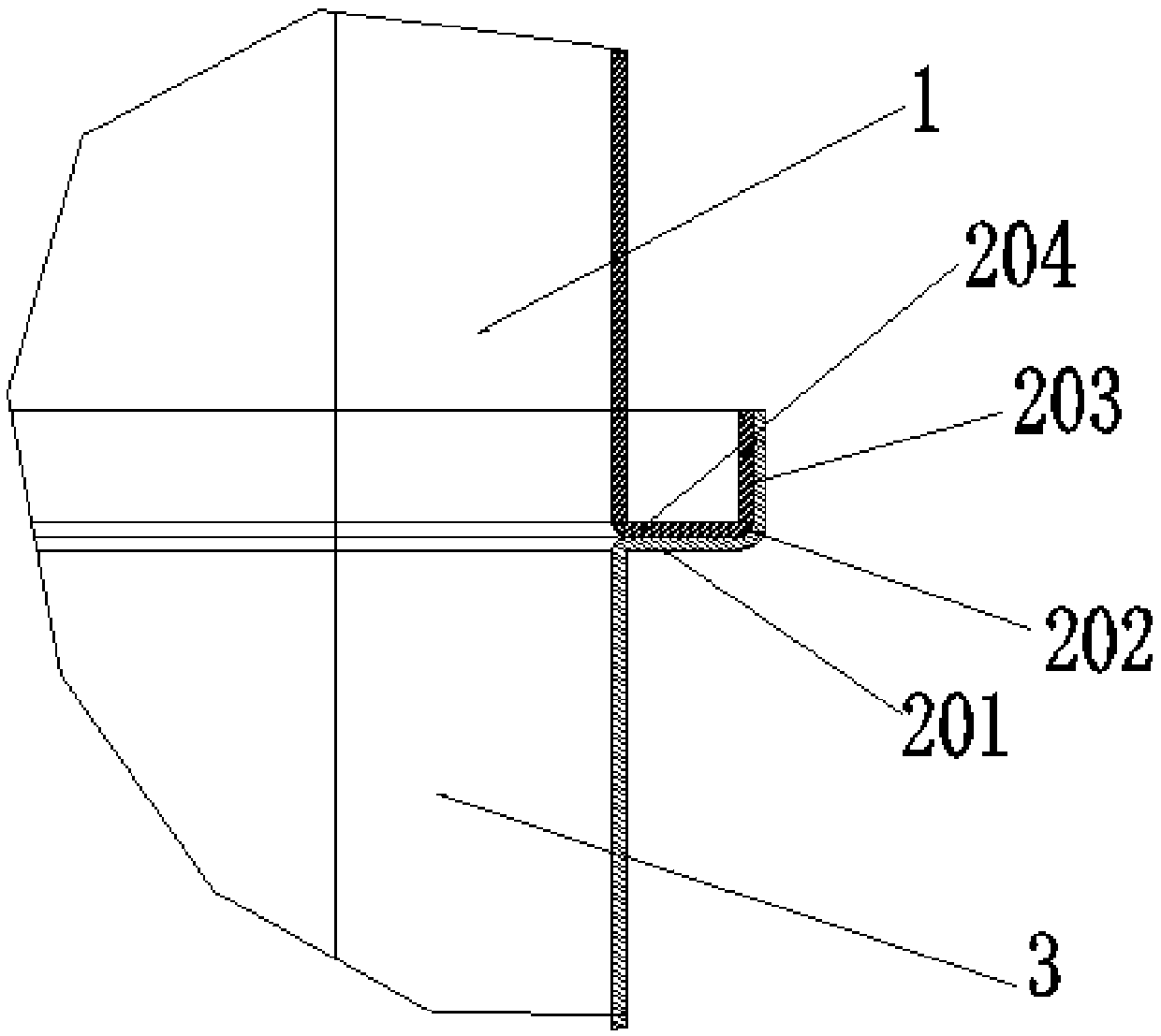

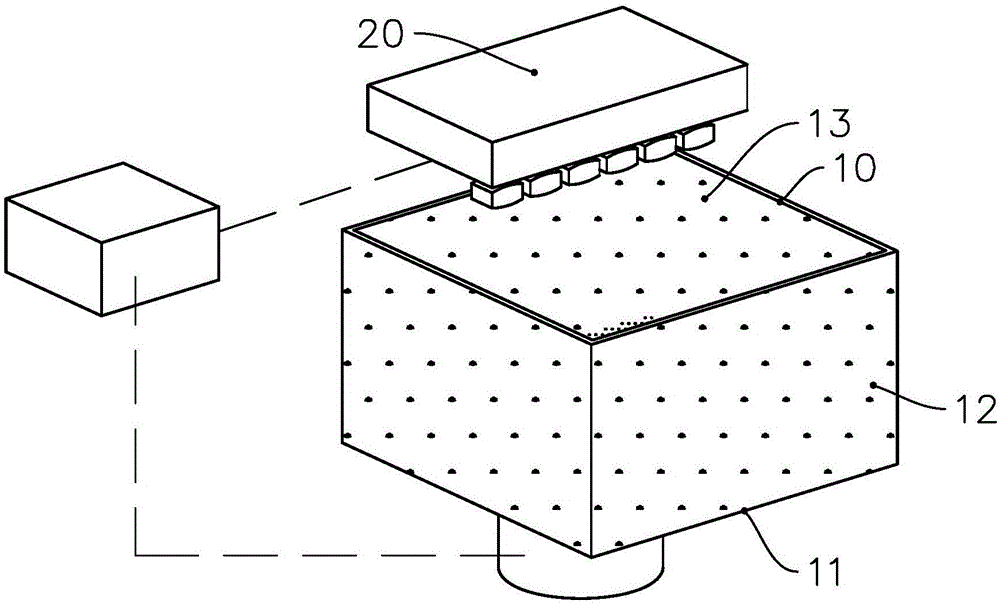

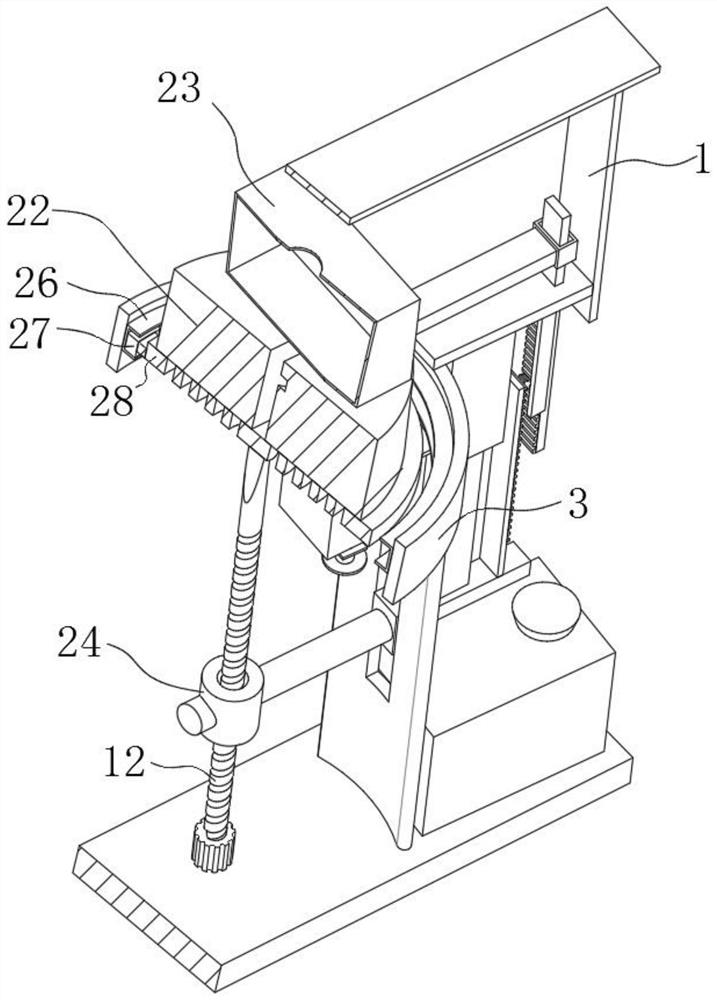

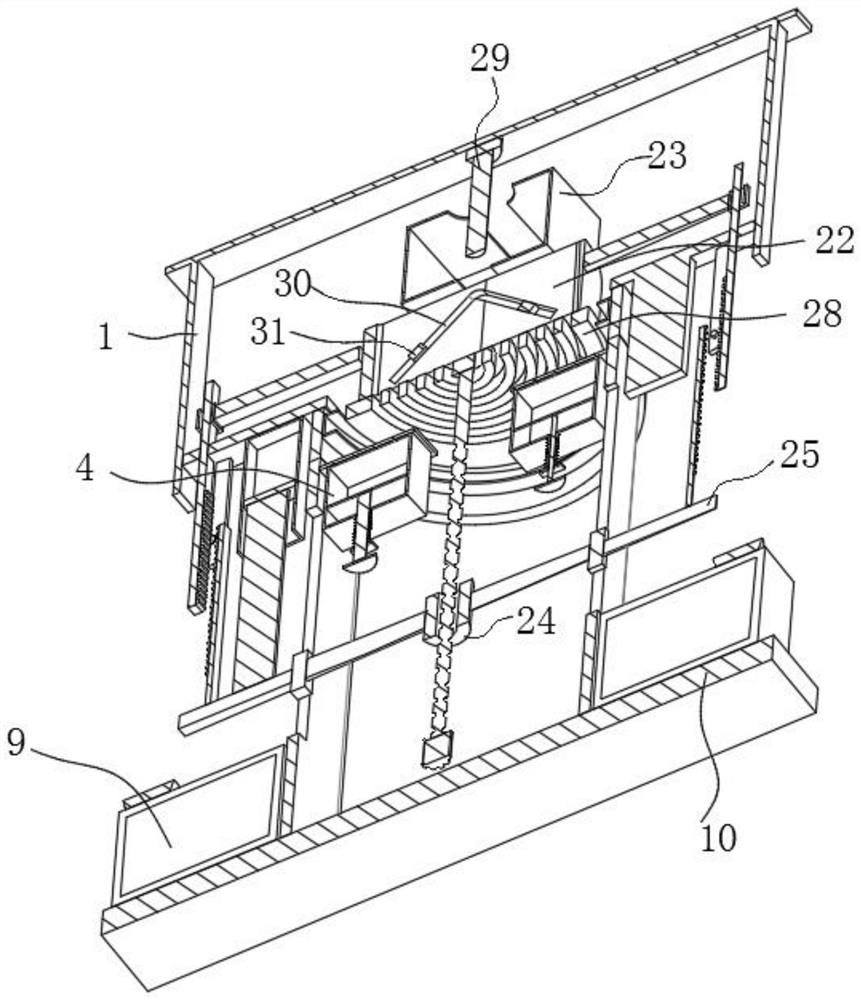

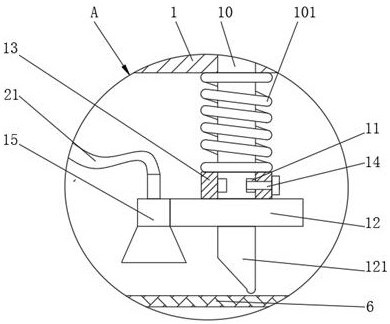

Laser fused deposition modeling device and running method thereof

InactiveCN106975750AReduce deliveryImprove molding efficiencyAdditive manufacturing apparatusFused deposition modelingCarbon dioxide

The invention discloses a laser fused deposition modeling device and a running method thereof. The device comprises a carbon dioxide laser generator, a composite printing head and a multi-way wire feeding mechanism, wherein the carbon dioxide laser generator is connected with the composite printing head through an optical fiber and is connected with a moving lens set and a focusing lens in the composite printing head by means of optical paths; the lower end of the composite printing head is of a tapered structure, and a plurality of wire guide channels are distributed along the outer circumferential wall of the tapered structure; a wire supplied by the multi-way wire feeding mechanism passes through the corresponding wire guide channel; the carbon dioxide laser generator is used as a heat source for fusing the wires, and laser focus points focus the end parts of the wires so as to fuse the wires; an X- and Y-directional moving mechanism is used for carrying the composite printing head, and the fused wires are fused and deposited on a hot bed according a planned path. According to the device, the carbon dioxide laser generator and the composite printing head are organically integrated; the wires are fused at the outside of the composite printing head, so that the problem that a spray head of an existing printing head is easily blocked during printing can be solved.

Owner:SOUTH CHINA UNIV OF TECH

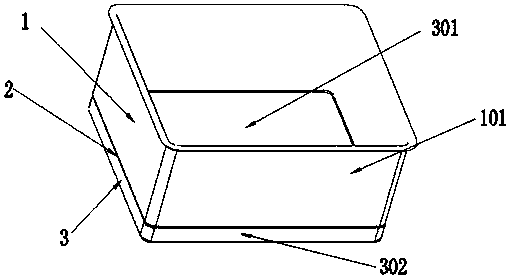

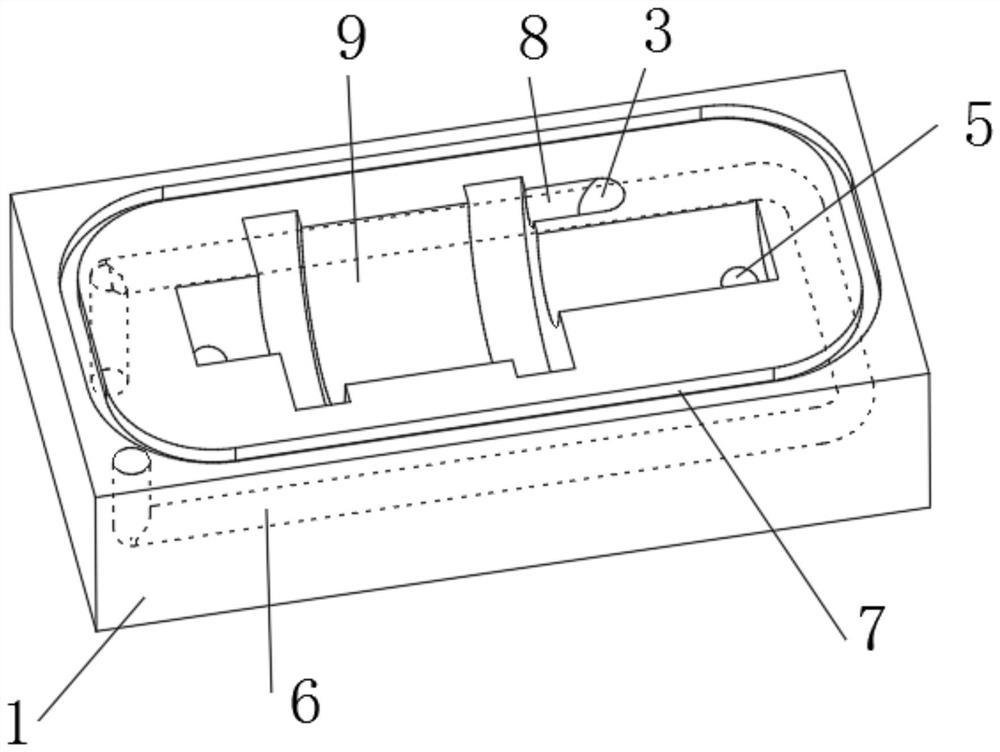

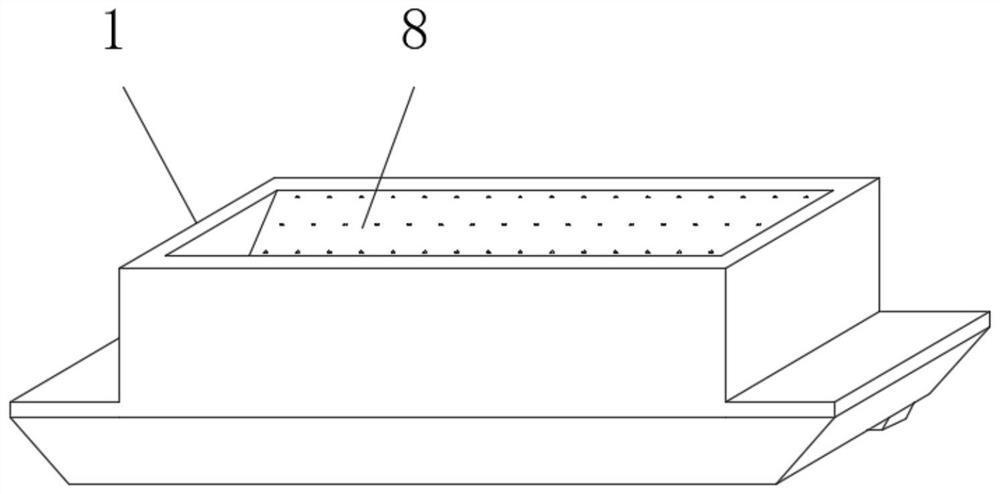

Inner container of drawer dishwasher and forming process of inner container

PendingCN107854096AReduce mold costIncrease molding rateTableware washing/rinsing machine detailsWaste productIndustrial engineering

The invention relates to the field of dishwasher equipment, in particular to an inner container of a drawer dishwasher and a forming process of the inner container; the inner container comprises an inner container upper body and an inner container lower body; the inner container upper body is provided with a holding cell for holding bowls and chopsticks, and the holding recess is extended from theinner container upper body and the inner container lower body. A traditional inner container is segmented into at least two segments; single stretching height of sheet metal of the inner container isnever too great owning to such design, forming rate of the sheet metal of the inner container can be increased, scrap rate of the sheet metal of the inner container due to stretching is decreased, the inner container forming cost is partly reduced, and industrial production is benefited.

Owner:WUHU GUANGYING IND CO LTD

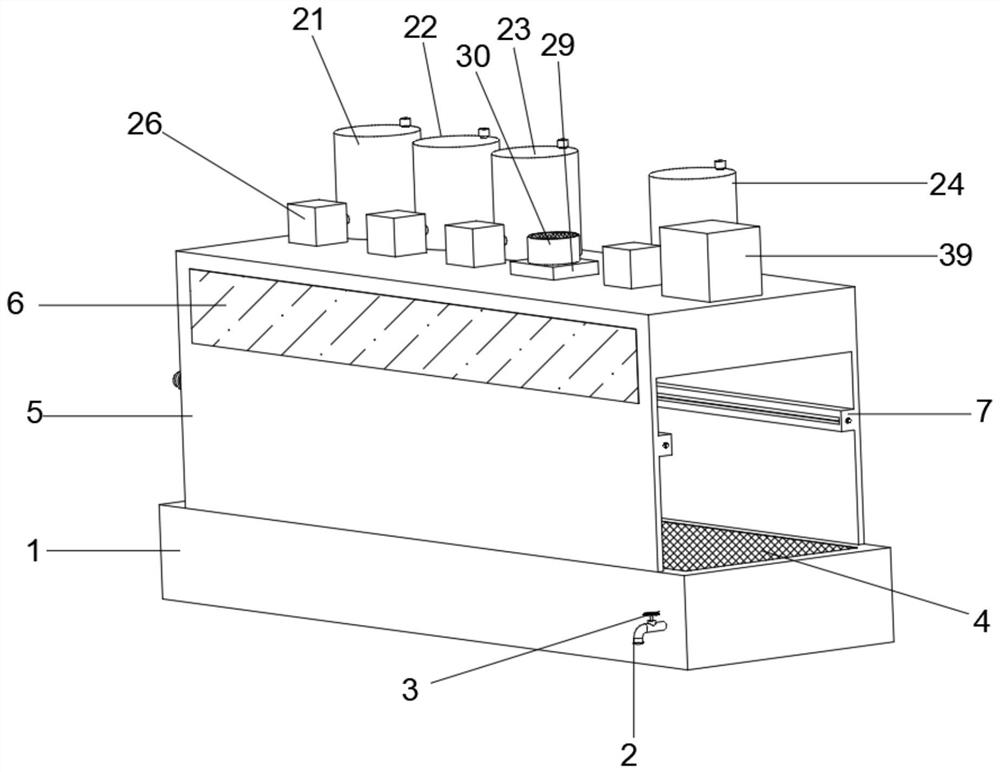

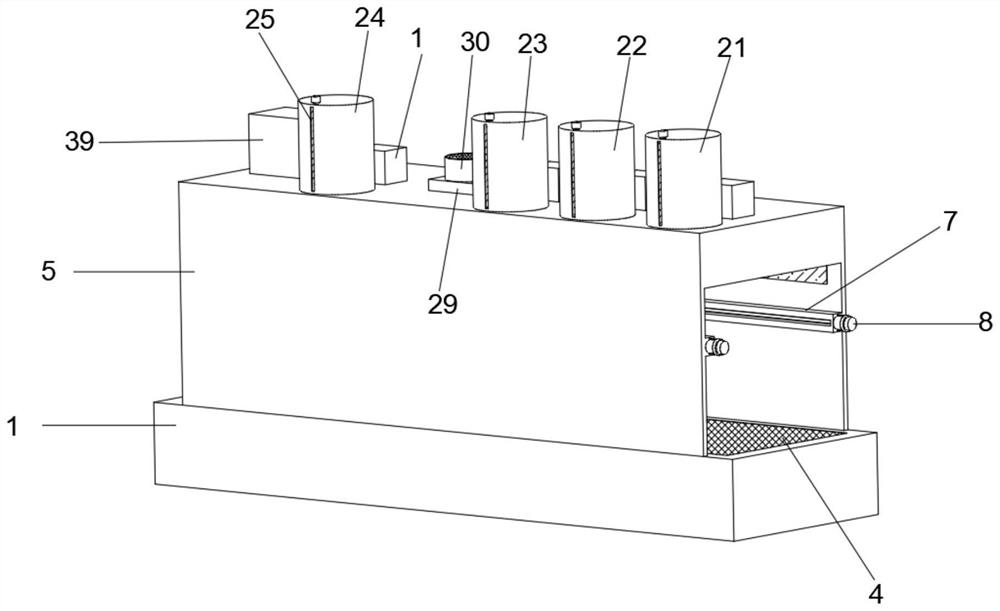

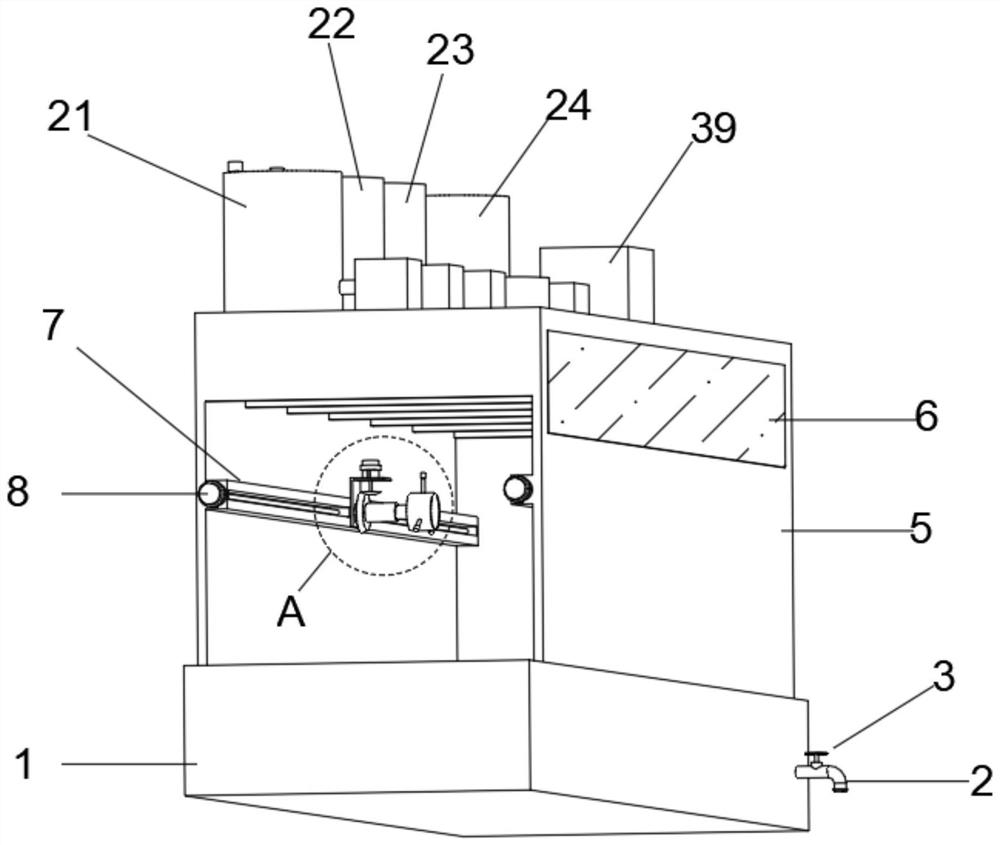

Axle paint spraying device

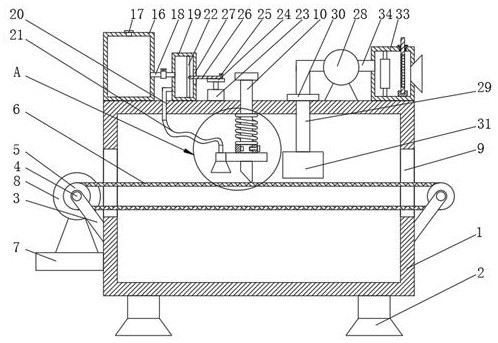

InactiveCN112452606AEasy to fixPrevent movementPretreated surfacesCoatingsElectric machineHeater Rod

The invention belongs to the field of automobile manufacturing, and relates to an axle paint spraying device. The axle paint spraying device comprises a base, wherein a shell is fixedly connected to the top of the base, two sliding rails are fixedly connected to the front end wall and the rear end wall in the shell, a hydraulic rod is rotatably connected to a fixing plate, a fixing sleeve is fixedly connected to the other end of the hydraulic rod, and a clamping plate is fixedly connected to the other end of each adjusting screw rod; a driven bevel gear fixedly sleeves the hydraulic rod, a driving bevel gear is fixedly connected to the output end of a second driving motor, four pumps are fixedly connected to the top of the shell, a nozzle fixedly communicates with the output end of each ofthe four pumps, a heating box fixedly communicates with the top of the shell, a ventilation pipe fixedly communicates with the top of the heating box, and an electric heating wire fixedly sleeves a heating rod; and an induced draft fan is fixedly connected to the output end of a third driving motor, and an air cooler is fixedly connected to the top of the shell. The device can fix axles of different sizes, degreasing, rust prevention, cleaning, drying and other treatment can be performed on the axles, and besides, turned-over multi-directional paint spraying can be performed on the axles in the paint spraying process.

Owner:SHANDONG HENGTAI AXLE

Three-dimensional printing formation method based on induction heating and used for metal nanopowder

ActiveCN108380871ALow molding temperatureEliminate molding thermal stress problemsMaterial nanotechnologyAdditive manufacturing apparatusNanometreUltra fine

The invention provides a three-dimensional printing formation method based on induction heating and used for metal nanopowder. The three-dimensional printing formation method based on induction heating and used for the metal nanopowder comprises the steps that CAD data files, a formed substrate, the metal nanopowder and a nanopowder jet array plate for three-dimensional printing formation of a part are prepared; internal block-by-block filling is conducted on each closed outline pattern of each layer of slice; the formed substrate and a formed part are kept at a preset temperature through heating in a vacuum formation cavity; and slice data of the current slice are obtained, corresponding powder delivery nozzle jet valves are controlled to be opened according to corresponding small blocksformed after the current slice is cut, solidification occurs while the metal nanopowder is molten and molten metal is leveled, and the thicknesses of the corresponding small blocks are increased by acertain degree. According to the three-dimensional printing formation method based on induction heating and used for the metal nanopowder, the process thinking that the temperature of the formed substrate and the formed part is kept below the melting point of the blocks and above the melting point of the metal nanopowder is ingeniously utilized, a high-energy beam for assisting melting is not needed, and three-dimensional formation of ultra fine and ultra-high-speed parts is achieved based on the metal nanopowder.

Owner:山东承坤信息科技有限公司

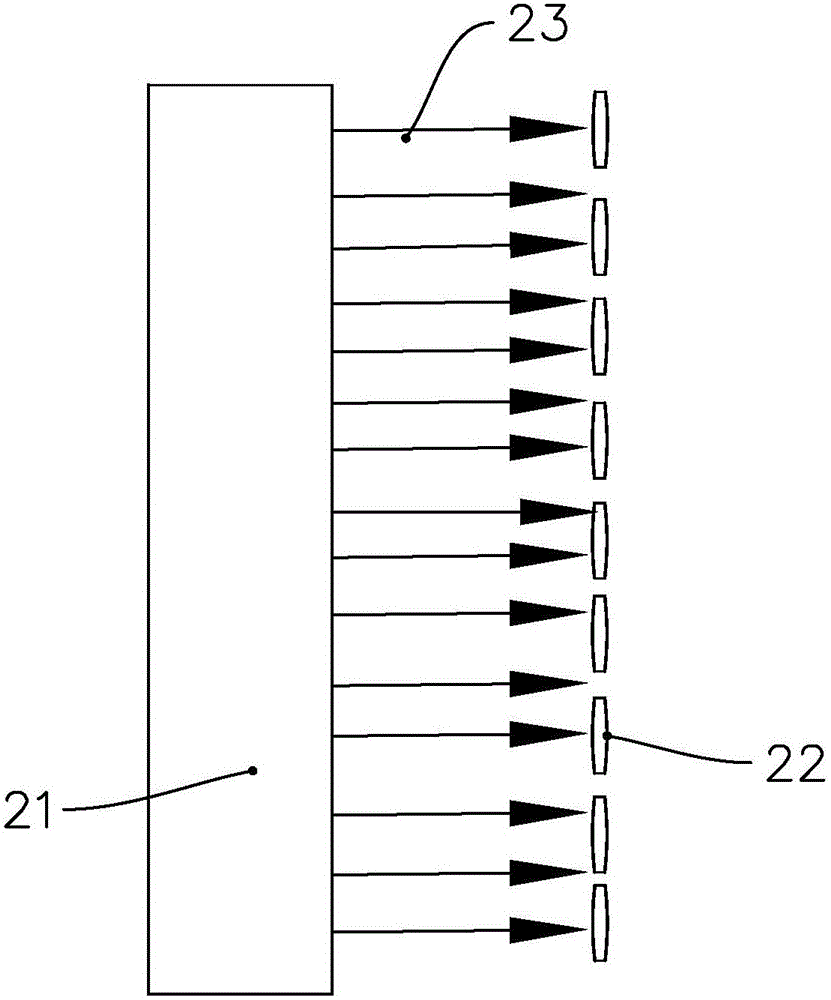

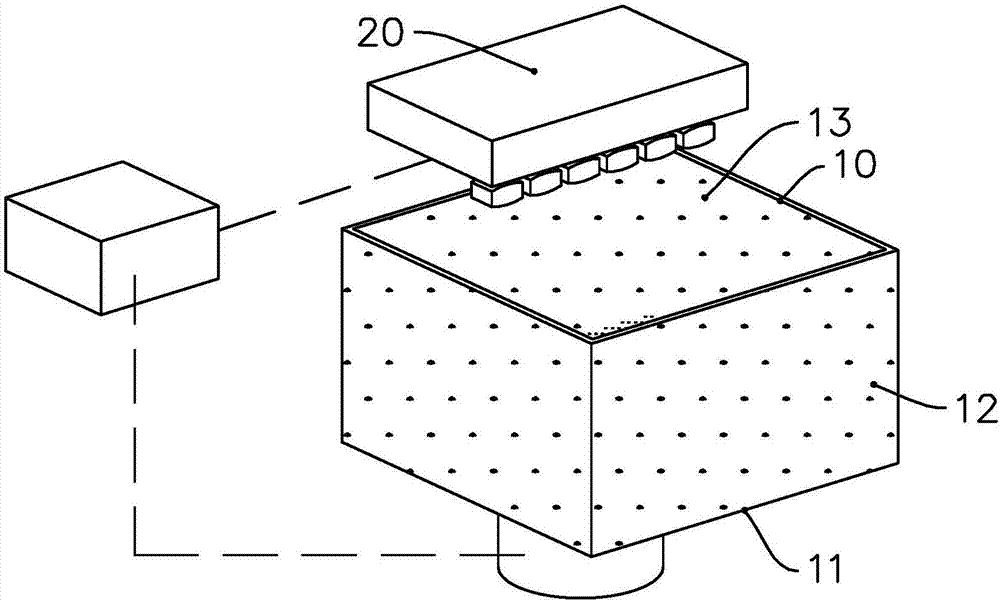

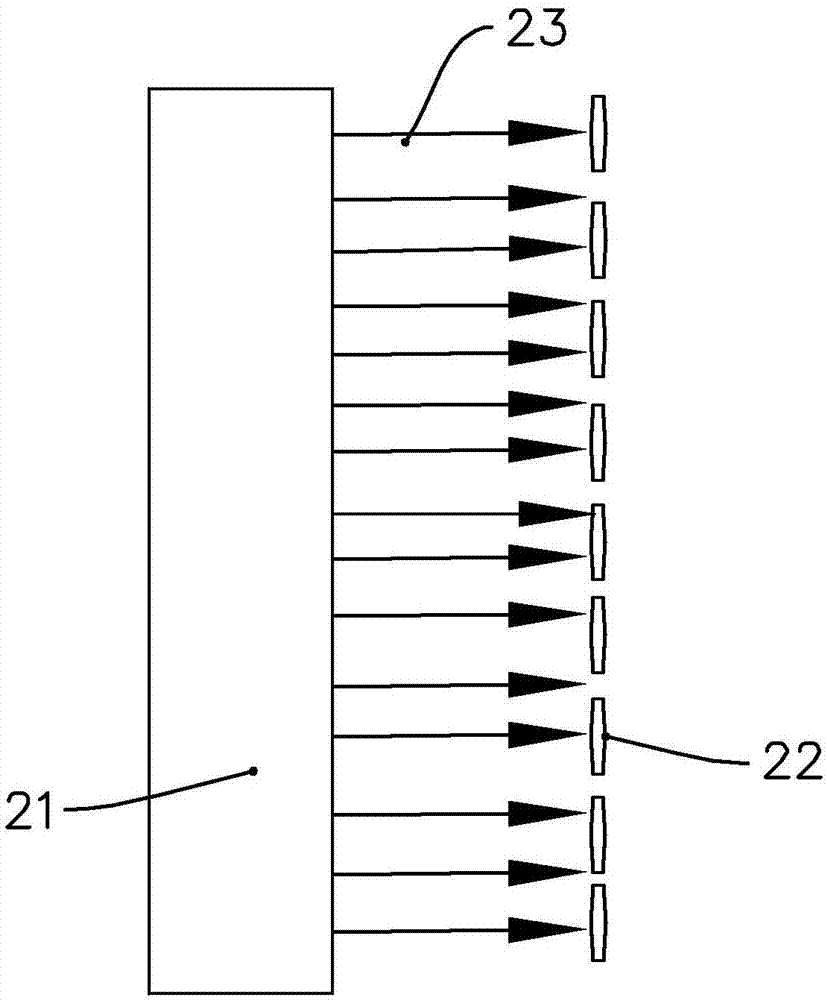

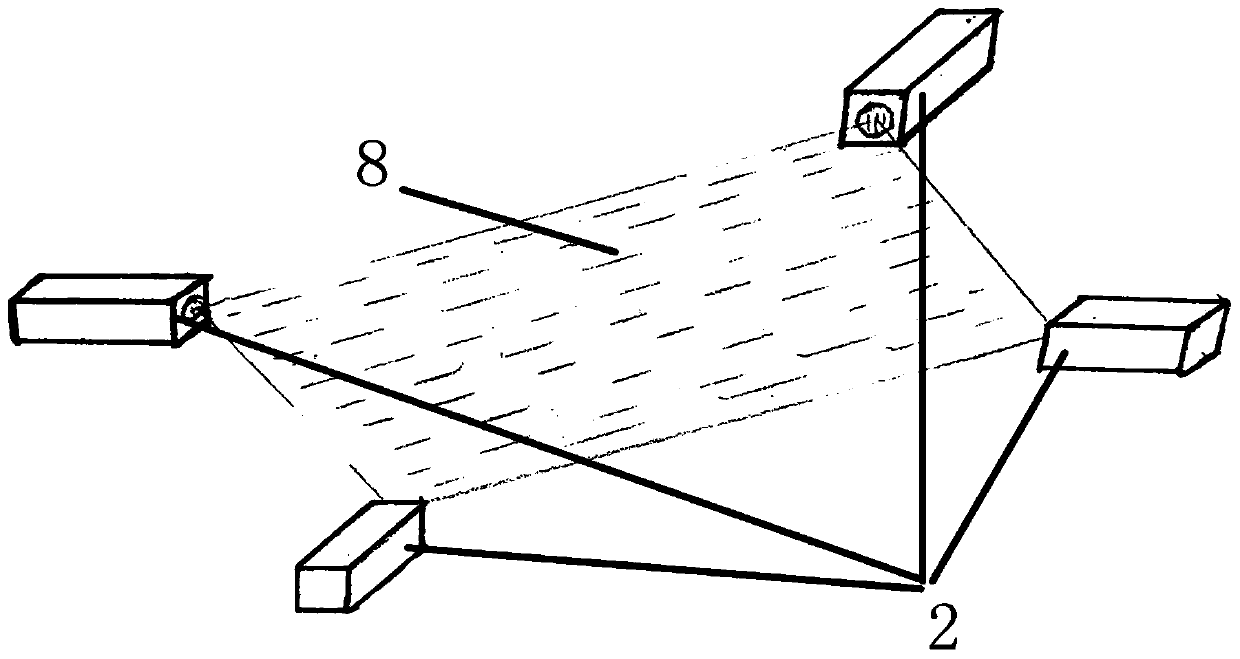

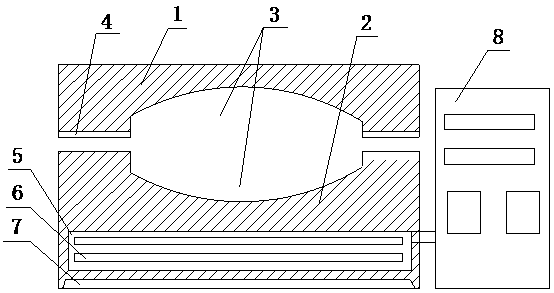

Photocuring three-dimensional printer and three-dimensional object molding method

InactiveCN105922595AAchieve layer-by-layer curingImprove molding efficiencyAdditive manufacturing apparatusLaser beamsLight sensitive

The invention relates to a photocuring three-dimensional printer and a three-dimensional object molding method. The photocuring three-dimensional printer comprises a photosensitive resin groove; plane laser units are respectively arranged in at least two side surface directions of the photosensitive resin groove; the photosensitive resin groove has a transparent part; the plane laser units have lasers and focusing lenses; the lasers can generate plane laser beams; the focusing lenses are arranged on optical paths of the lasers; and focusing positions of the plane laser beams in the photosensitive resin groove are adjustable. The photocuring three-dimensional printer realizes the layer-by-layer curing of photosensitive resins, so that the molding efficiency is improved; and the control process of the plane laser beams is simpler and easy to operate.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

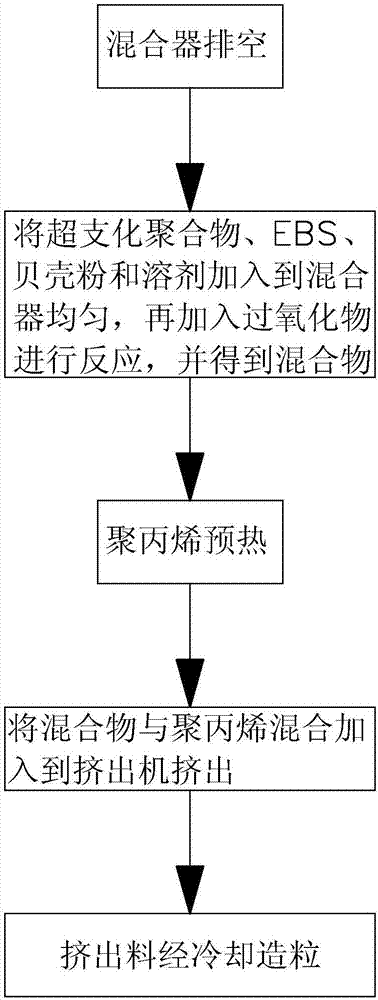

High-fluidity polypropylene for production of folding stools and preparation method of high-fluidity polypropylene

High-fluidity polypropylene for production of folding stools is prepared from components in parts by weight as follows: 60-70 parts of polypropylene, 14-18 parts of a superbranched polymer, 12-16 parts of EBS, 2-4 parts of peroxide, 10-20 parts of shell powder and 20-30 parts of a solvent. According to the technical scheme, EBS is a plastic dispersant and used as a carrier, the superbranched polymer can be combined with EBS, the mixture is added to polypropylene, and EBS can be dispersed better. Additionally, with increase of the added superbranched polymer, the viscosity of polypropylene is reduced, and the fluidity of polypropylene can be improved. Besides, when polypropylene is cooled, cured and formed, the superbranched polymer has a three-dimensional branched structure, the clean structure of a polypropylene macromolecular chain can be affected and is more difficult to damage, and accordingly, the mechanical performance of polypropylene is guaranteed.

Owner:慈溪市赛斯特金属制品有限公司

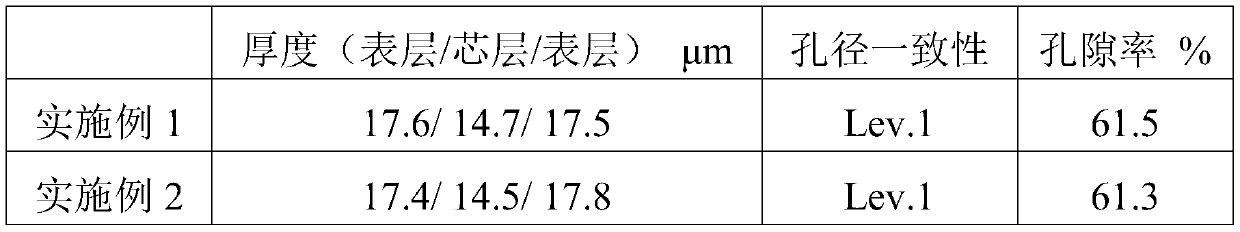

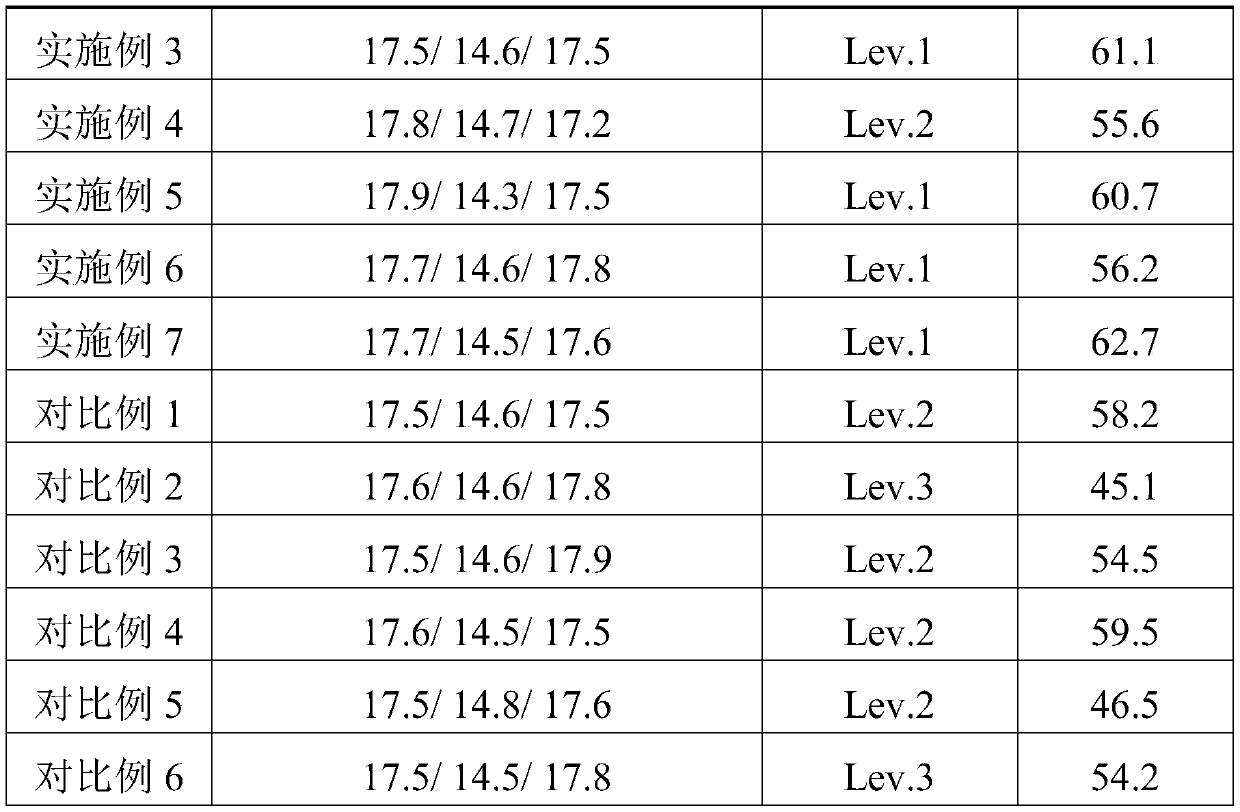

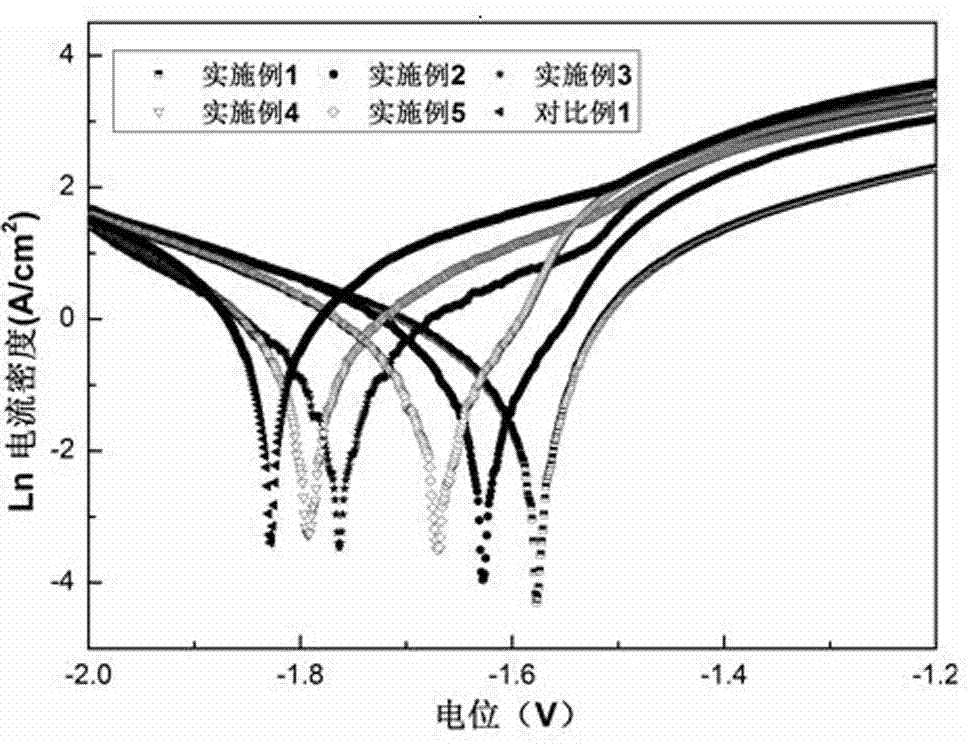

Lithium battery diaphragm with uniform pore diameter and preparation method thereof

ActiveCN109728234AUniform pore sizeGood pore size consistencyLi-accumulatorsCell component detailsEpoxyLow-density polyethylene

The invention belongs to the technical field of lithium battery diaphragms, and particularly relates to a lithium battery diaphragm with a uniform pore diameter and a preparation method thereof. The lithium battery diaphragm comprises a core layer and surface layers disposed on both sides of the core layer. The core layer comprises, 91 to 96.5% of polyethylene, 2.5 to 6% of epoxy resin, 1 to 3% iflinear high-density polyethylene. Each surface layer includes, by weight percentage, 98.5 to 99.5% of polypropylene and 0.5 to 1.5% of polypropylene copolymer. By adding a small amount of linear high-density polyethylene and epoxy resin to the polyethylene composition of the core layer, and by adding a small amount of polypropylene copolymer to the polypropylene composition of the surface layers,the molding rate of the crystal can be increased and the crystal integrity can be improved during the crystallization process of casting a cast piece, thereby forming a lithium battery diaphragm witha uniform pore diameter in a process of longitudinal stretching and transverse stretching pore formation.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

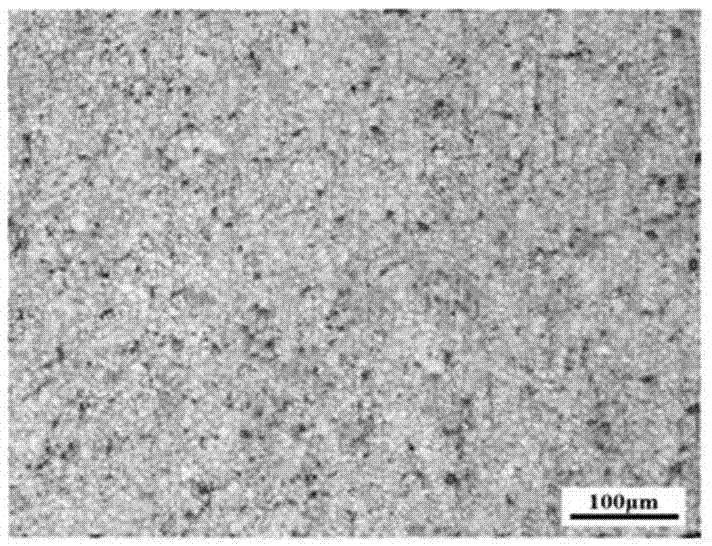

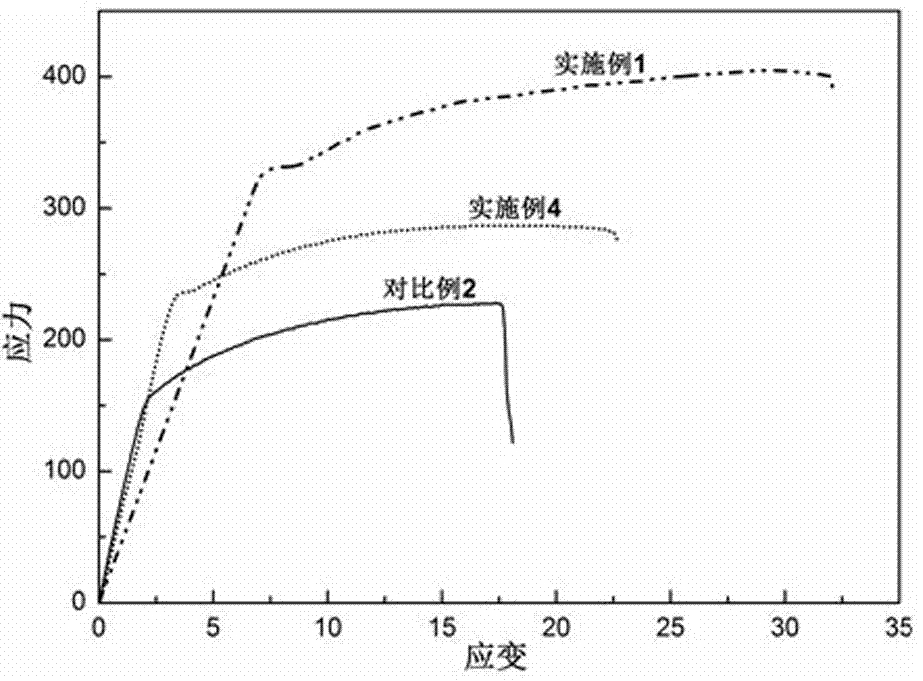

Warm pressing deformation biological magnesium alloy and preparation method thereof

ActiveCN107058838AImprove microstructureImprove mechanical propertiesCardiovascular stentInsertion stent

The invention relates to a warm pressing deformation biological magnesium alloy and a preparation method thereof. The warm pressing deformation biological magnesium alloy is composed of, by mass, 0.1-6.5% of Zn, 0.1-1.8% of Mn, 0.1-1.2% of Gd and the balance Mg. The preparation method of the biological magnesium alloy comprises the steps that as-cast magnesium alloy according with the composition proportion is subjected to a series of pre-treatment operations before being pressed, and is put into an extrusion machine for first upsetting when the temperature of a sample is lower than the recrystallization temperature, then warm pressing is conducted, the sample temperature of warm pressing is 150-250 DEG C, and the warm pressing speed is 130-200 mm / s; and after warm pressing is completed, a series of subsequent heat treatment operations are carried out on the alloy, and the warm pressing deformation biological magnesium alloy is prepared. According to the magnesium alloy, crystal particles are fine and uniform, excellent physical performance and corrosion resistance are achieved, the problems that magnesium alloy is low in intensity and plasticity and too high in degradation velocity when in human bodies can be effectively solved, the number of degradation products of the alloy is small, the pre-pressure can be discharged out of the human bodies in time and cannot cause toxicity to the human bodies, and the alloy can be applied to medical fields such as bone lamellas, bone nails and cardiovascular stents.

Owner:UNIV OF JINAN

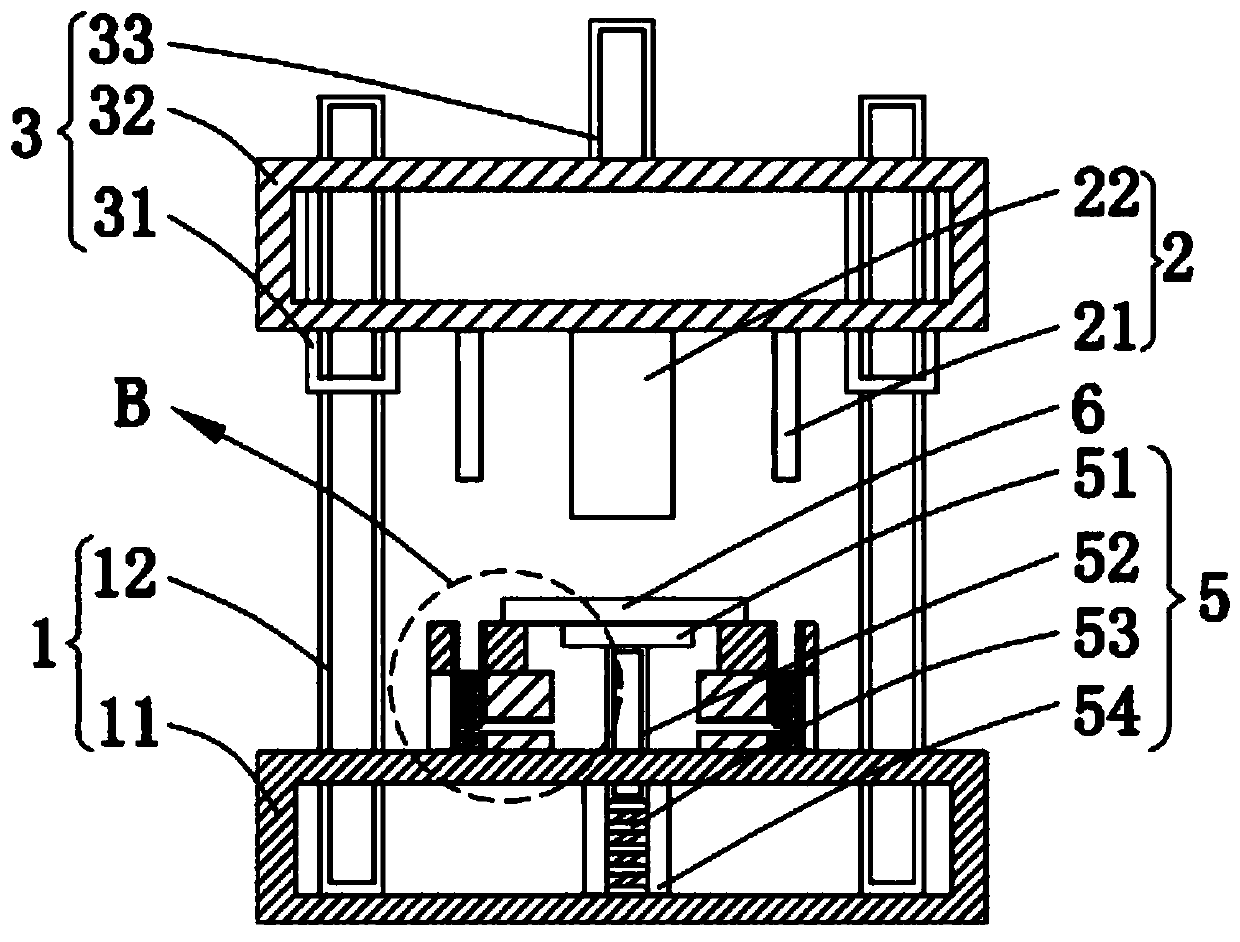

Stamping metal casting mold

ActiveCN109773050APlay a buffer roleImprove cooling effectShaping toolsCasting moldMaterials science

The invention relates to the mold field, specifically a stamping metal casting mold. The stamping metal casting mold comprises a fixing structure, a stamping structure, a sliding structure, a castingstructure, a reset structure and a metal workpiece; sliding slots are arranged in a supporting plate and a lower die are; limiting plates and second springs are fixed in the sliding slots; a through pipeline is arranged in the lower die; a ventilation pipe communicates with the sliding slots and stamping grooves, so that the lower die slides into the sliding slots through the limiting blocks whenthe metal workpiece is pressed down, and the limiting blocks press down the limiting plates and the second springs to play a buffering role, so that the lower die has a certain buffering force, the impact force when the stamping head stamps the metal workpiece is buffered, and the stamping head is not easy to damage. At the same time, the air in the sliding slots is pressed down into the ventilation pipe through the limiting plates in the sliding slots, so that the air is blown to the outside of the metal workpiece in the stamping groove, and the stamping metal casting mold is beneficial to heat dissipation of the metal workpiece and improving the quality of the metal workpiece.

Owner:上海雷祥压铸有限公司

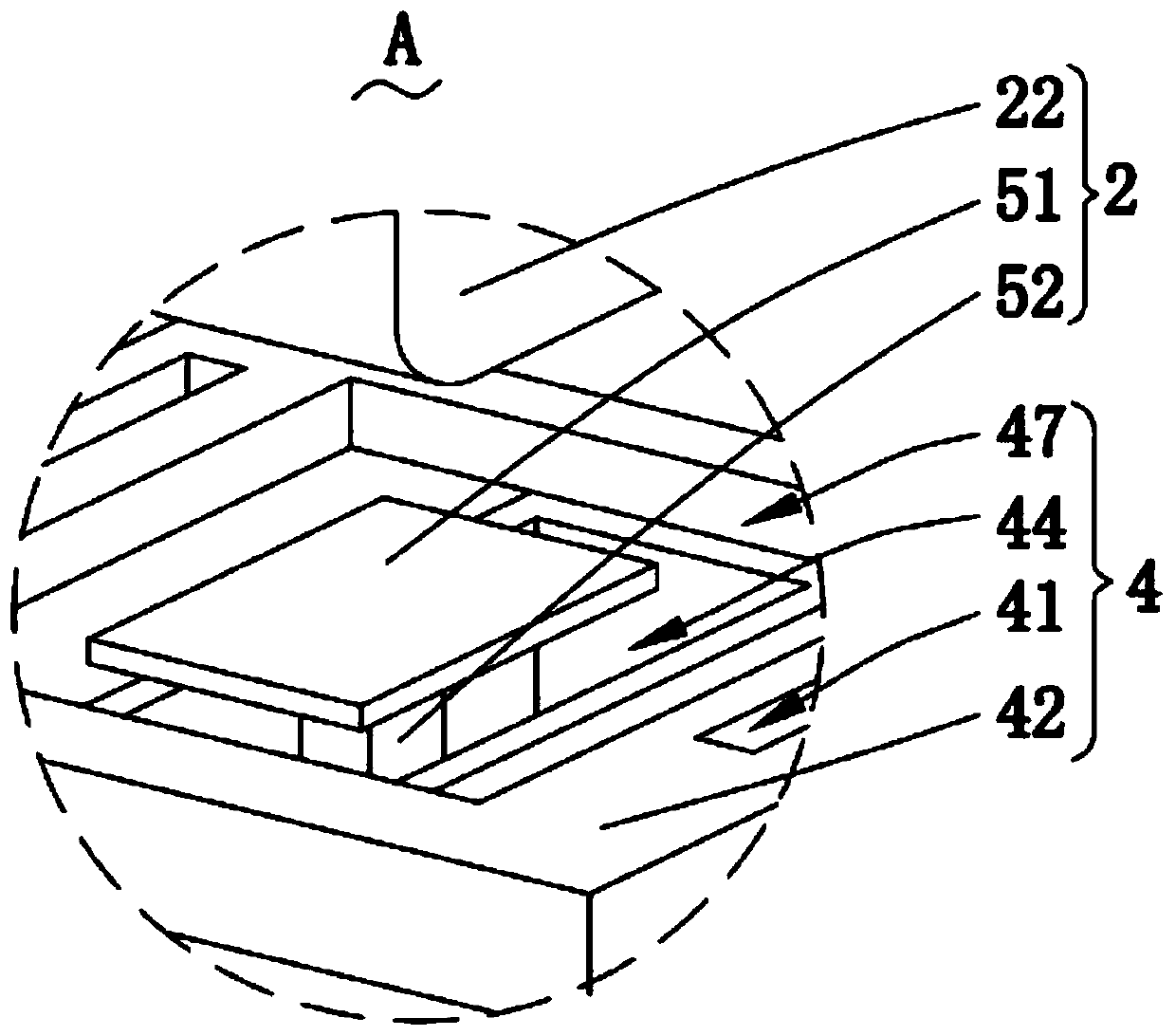

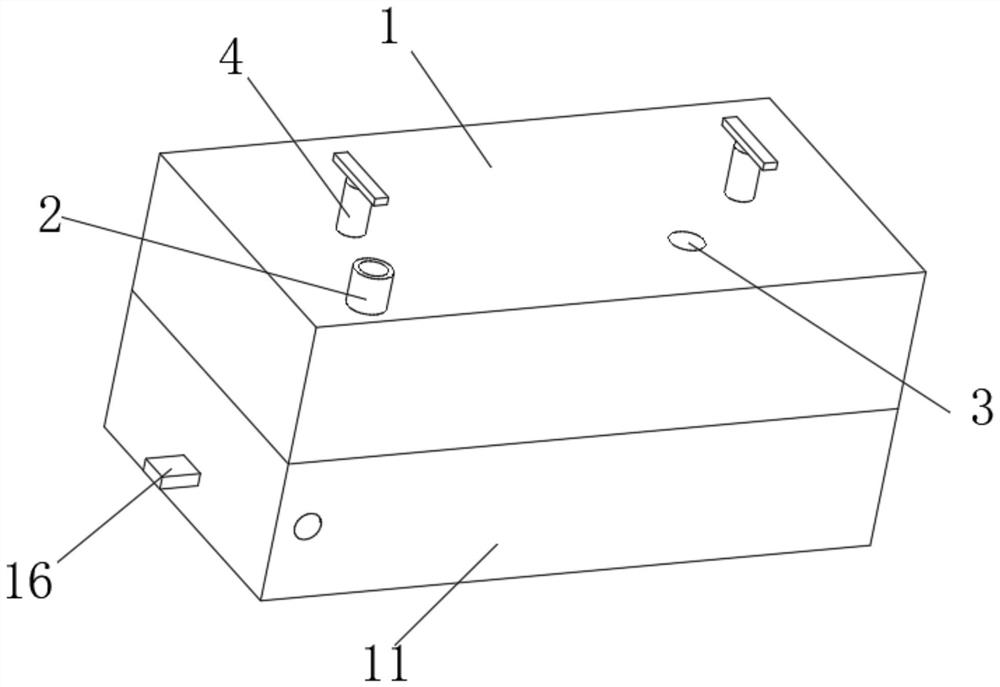

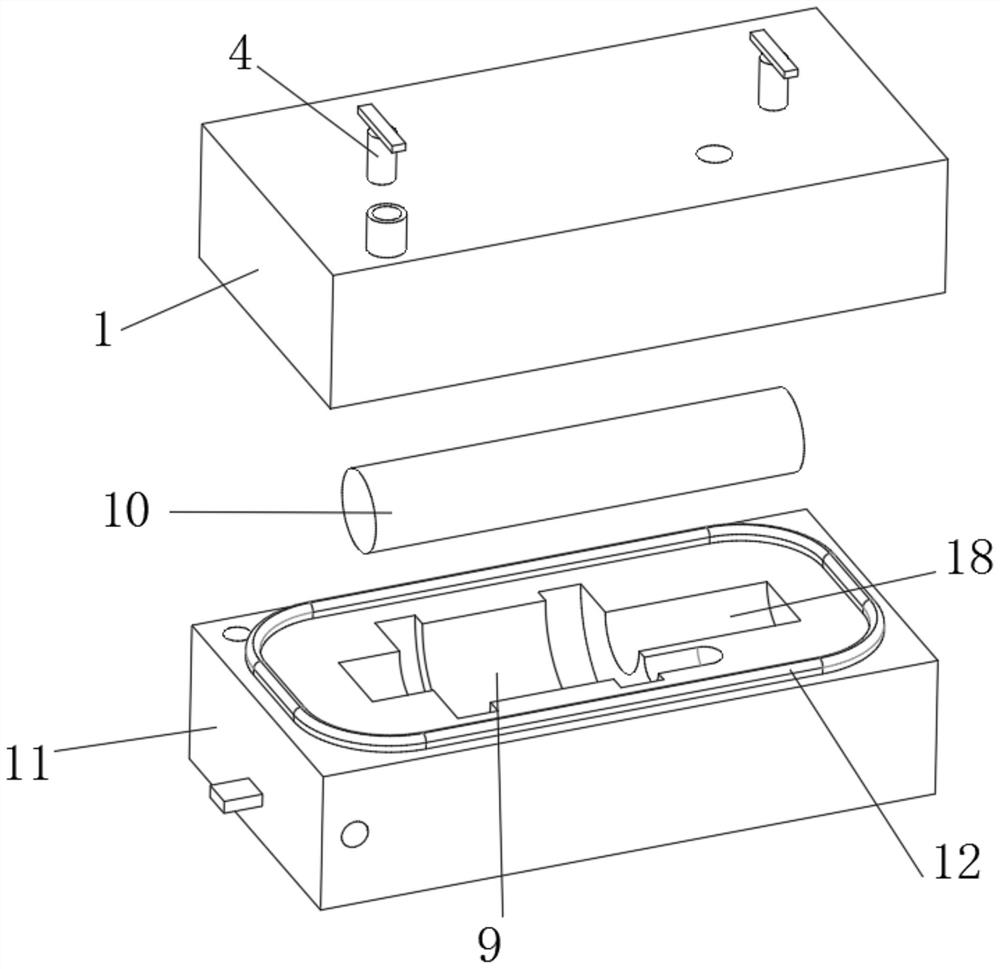

Copper bush casting mold

The invention relates to the technical field of casting molds, in particular to a copper bush casting mold. The copper bush casting mold comprises an upper mold body, a lower mold body and a sand core, wherein the bottom face of the upper mold body is attached to the top face of the lower mold body, and part grooves and sand core grooves are formed in the central positions of the bottom face of the upper mold body and the top face of the lower mold body; and the inner wall outline of the part grooves is half of the outer outline of a part, and the inner wall outline of the sand core grooves ishalf of the outer wall outline of the sand core. According to the copper bush casting mold, through the arrangement of an upper cooling channel and a lower cooling channel, the upper mold body and the lower mold body are cooled at the same time, so that consolidation molding and cooling of the part are accelerated, meanwhile, the cooling process is conveniently controlled, cooling water is conveniently collected, and secondary utilization of the cooling water is facilitated; through the arrangement of a threaded rod, the upper mold body is conveniently moved out; and through the arrangement of an extrusion sliding block and a jacking sliding block, the lower mold body is conveniently separated from the part, so that demolding of the part is facilitated.

Owner:马鞍山楚锐科技信息咨询有限公司

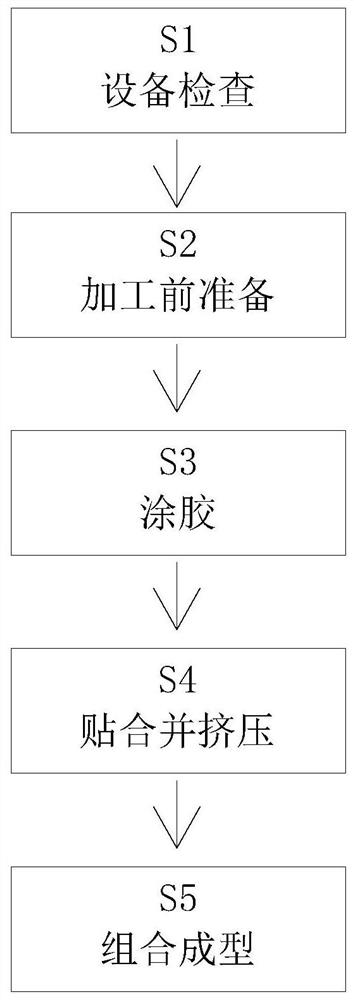

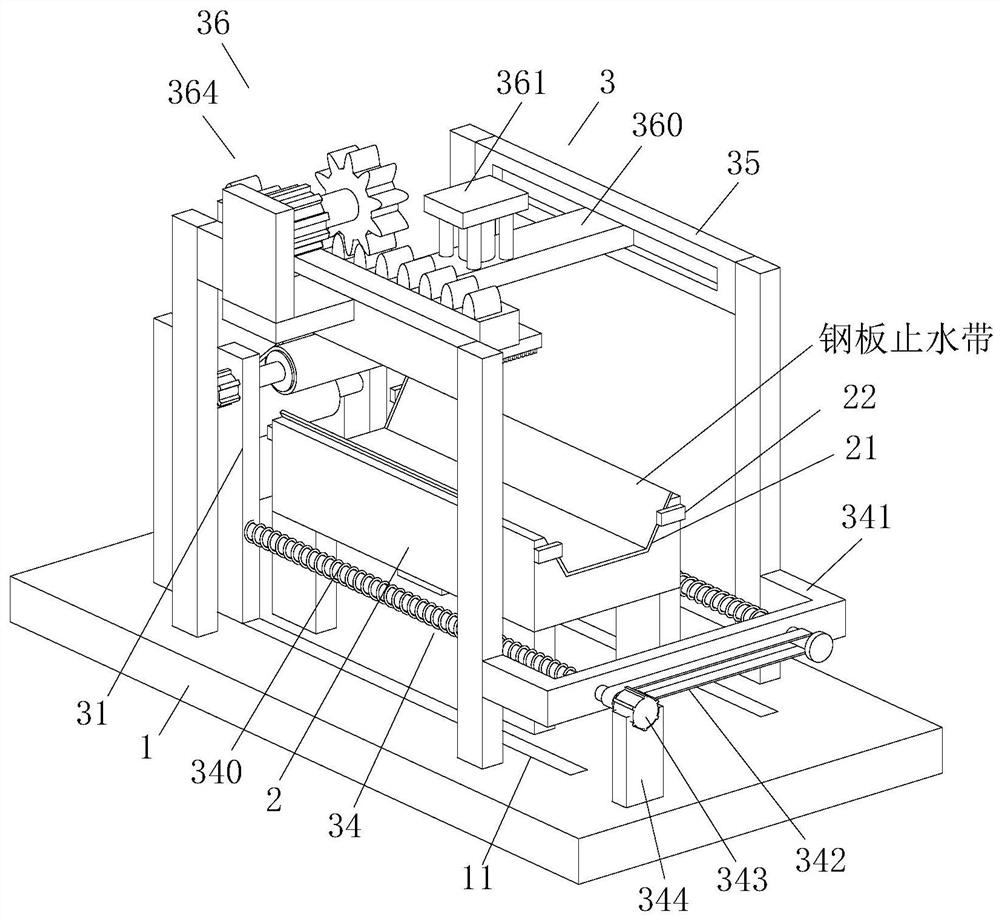

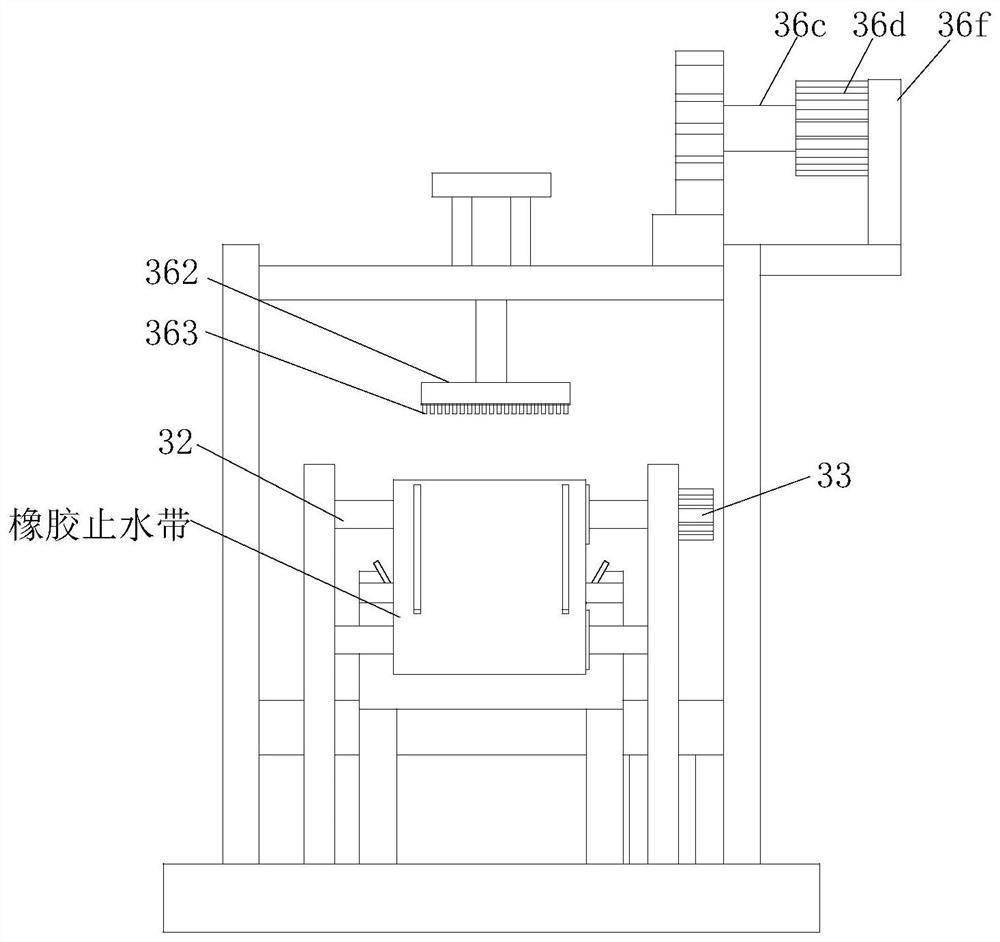

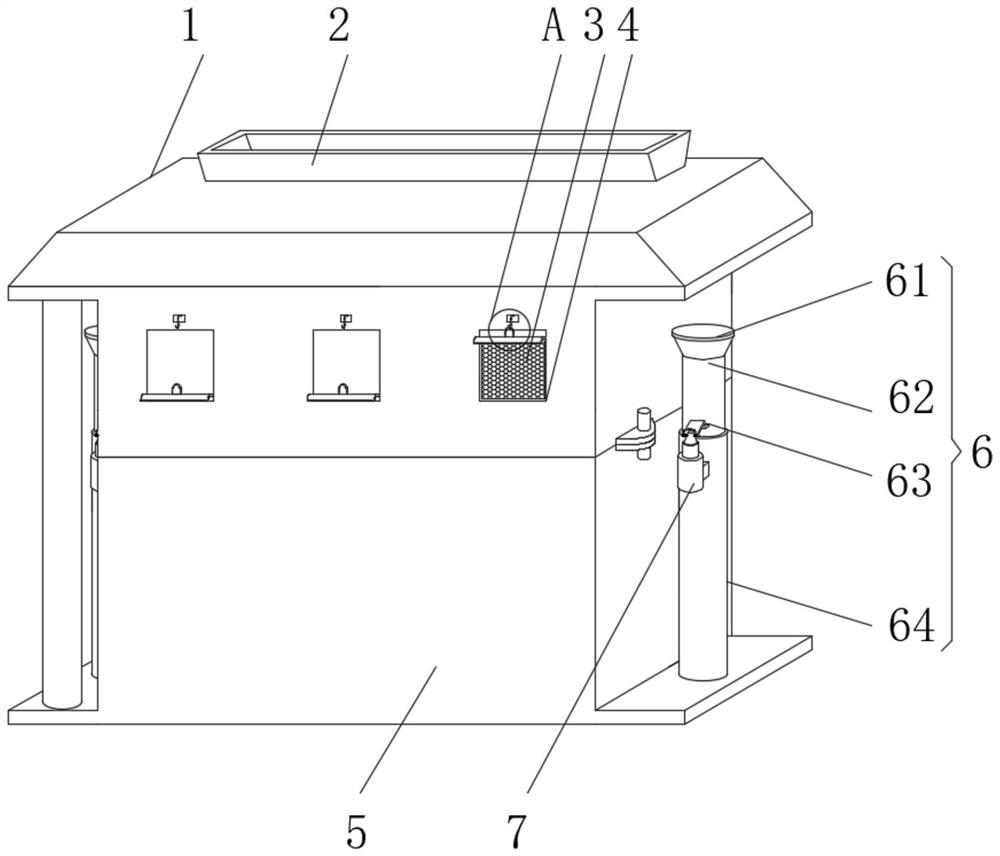

Combined waterproof material processing and forming method

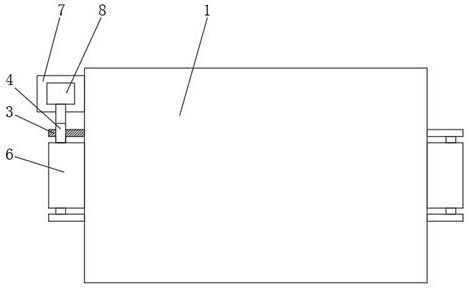

InactiveCN112917934ARealize the function of automatic combination moldingQuick and automatic fittingElectric machineryStructural engineering

The invention provides a combined waterproof material processing and forming method. The combined waterproof material processing and forming method adopts the following equipment for processing. The equipment comprises a base, a supporting table and a laminating device, wherein the lower end of the base is connected with the existing ground, the supporting table is mounted at the upper end of the base, and the laminating device is arranged above the supporting table. A rubber waterstop can be wound and unwound through a round roller through a first motor, then a second fixing plate drives the round roller to do synchronous linear motion through a moving module, so that the round roller drives the rubber waterstop to do stretching motion till the rubber water-stop belt is unwound and attached to the steel plate water-stop belt, so that the function of automatically combining and forming the rubber water-stop belt and the steel plate water-stop belt is achieved.

Owner:纪萍

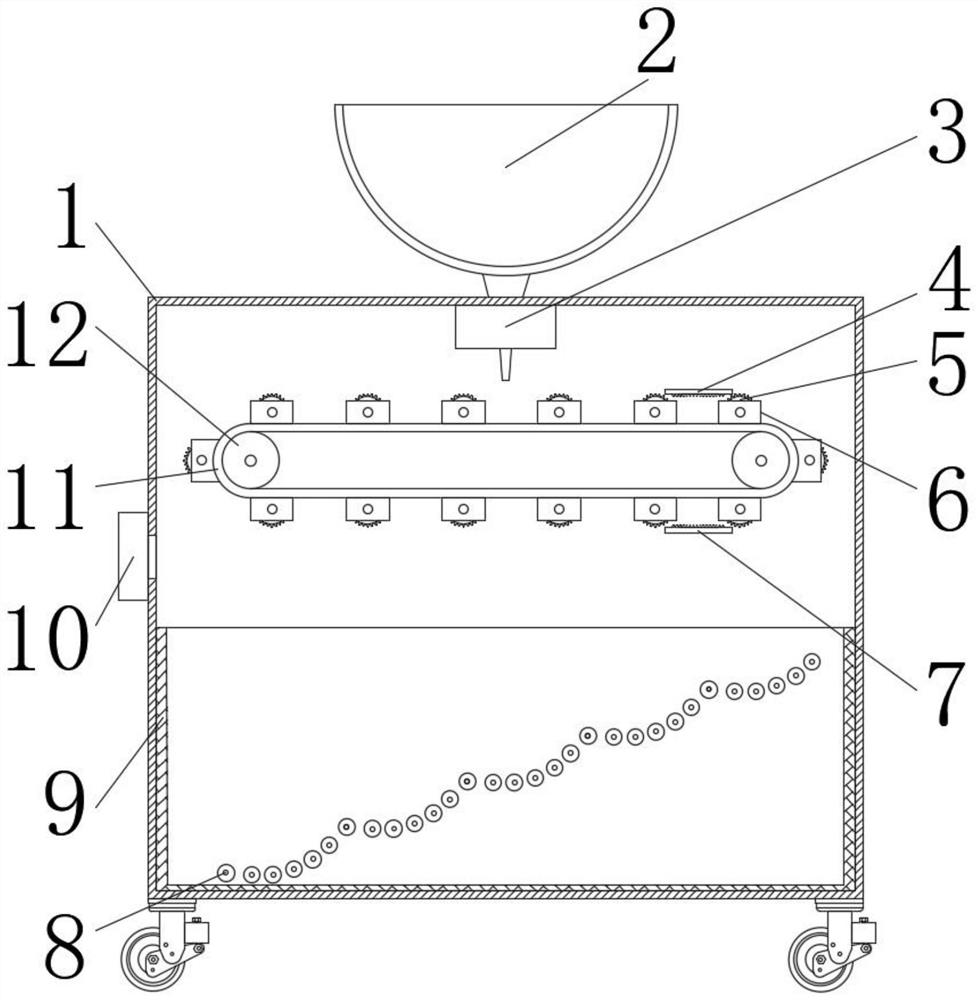

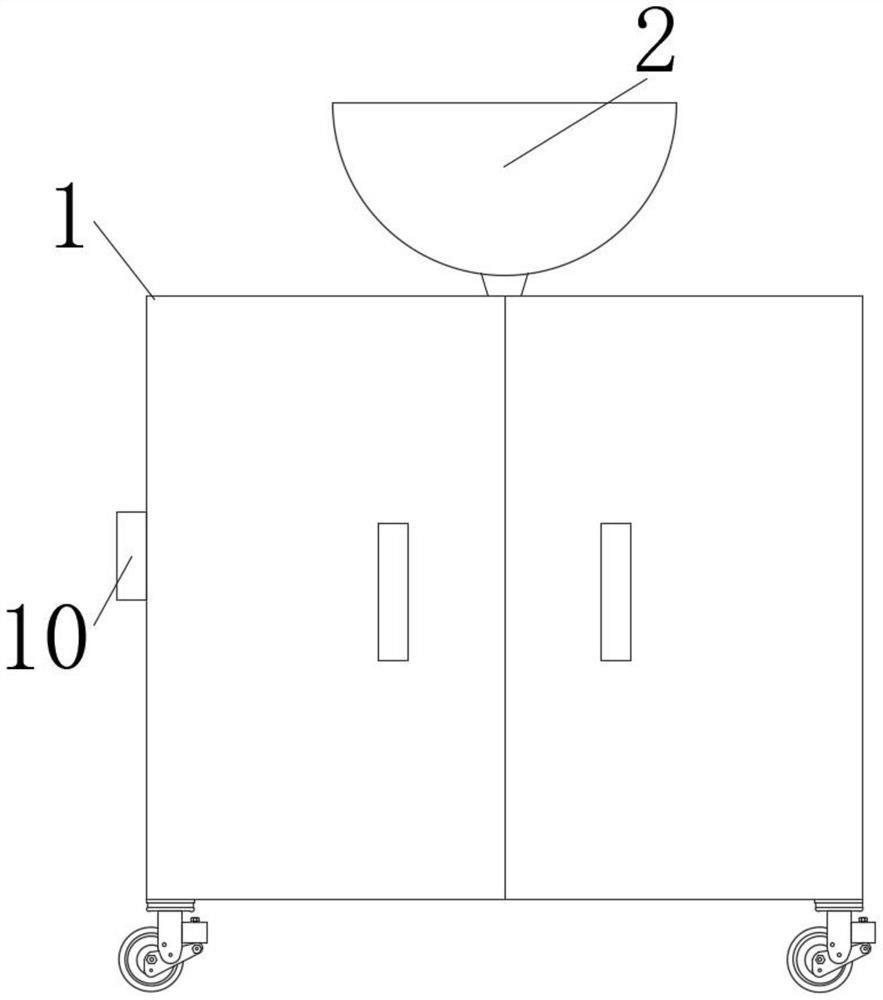

Injection molding production equipment for instrument plastic cover

The invention provides injection molding production equipment for an instrument plastic cover, and belongs to the technical field of instrument part production and machining equipment. The injection molding production equipment for the instrument plastic cover comprises a box body, a storage box, an injection molding machine and a servo motor, and two transmission wheels are arranged in the box body; the outer surfaces of the two transmission wheels are sleeved with a transmission belt, and the two transmission wheels are in transmission connection through the transmission belt; and the outersurface of the transmission belt is fixedly connected with a plurality of placing racks; the distances between every two adjacent placing racks are the same, and limiting mechanisms are arranged in the multiple placing racks; and each limiting mechanism comprises a transmission threaded rod. According to the equipment, the production rate of the instrument plastic cover is greatly increased, and the equipment flexibility is further greatly improved, namely that when plastic covers of different models need to be produced, only corresponding molds need to be placed between two adjusting frames,and the plastic covers of different models can be further produced in the same batch; and the equipment applicability is greatly improved.

Owner:马鞍山市求是仪表厂

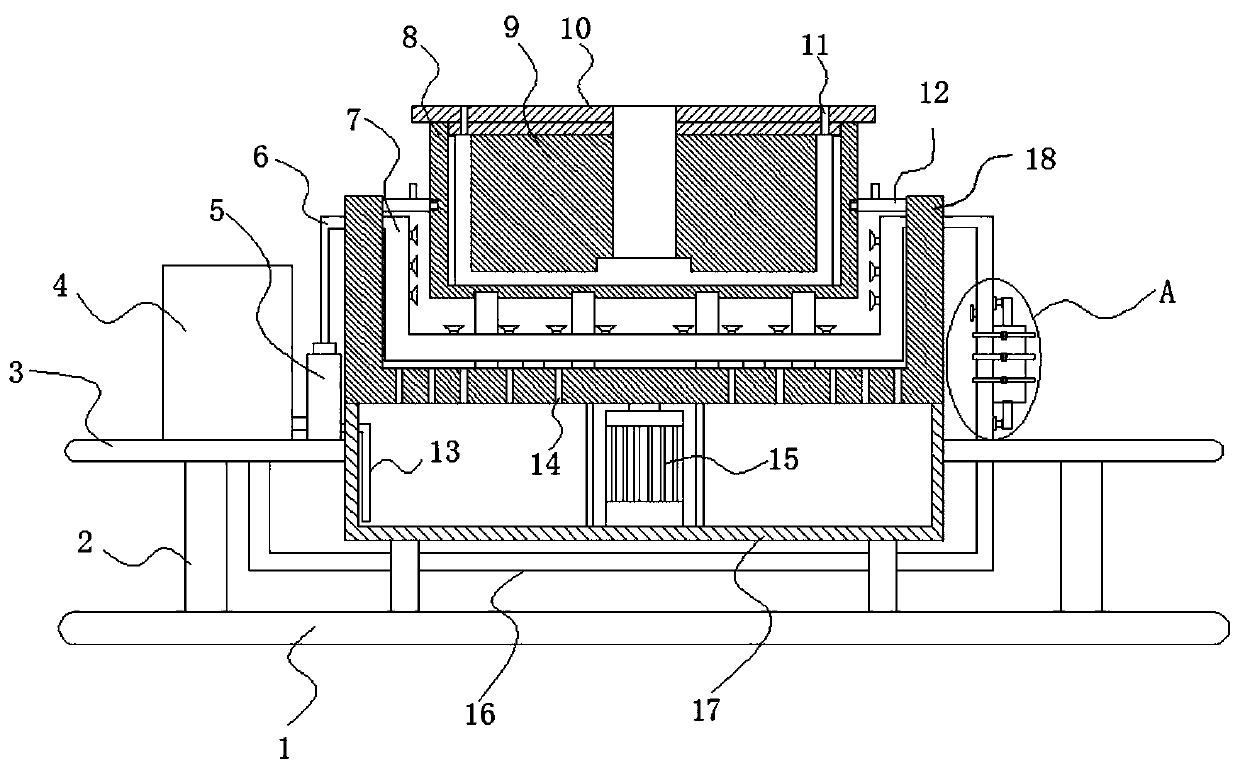

Aluminum casting motor casting equipment

The invention discloses aluminum casting motor casting equipment which comprises a bottom plate, a transverse plate, a base, a rotary seat, a lower die, a die core and an upper die plate. The transverse plate is horizontally fixed above the bottom plate through a supporting column, the base is fixed on the transverse plate, the rotary seat is movably arranged above the base, a motor for driving the rotary seat to rotate is fixed in the base, the top end of the rotary seat is opened, the lower die is detachably arranged in the rotary seat, the upper die plate is arranged above the lower die, the die core is fixed on the bottom surface of the upper die plate, a cavity is formed between the die core and the lower die, a heat dissipation gap is reserved between the outer wall of the lower dieand the inner wall of the rotary seat, draining holes are distributed at the bottom of the shell of the rotary seat, a cooling water channel is arranged in the heat dissipation gap, and a plurality ofatomizing nozzles are distributed on the cooling water channel. According to the aluminum casting motor casting equipment, raw materials can be uniformly distributed in the cavity by rotating the rotary seat, and the cooling water channel and the atomizing nozzles are arranged, so that products in the cavity can be rapidly cooled, and product forming is accelerated.

Owner:中擎电机有限公司

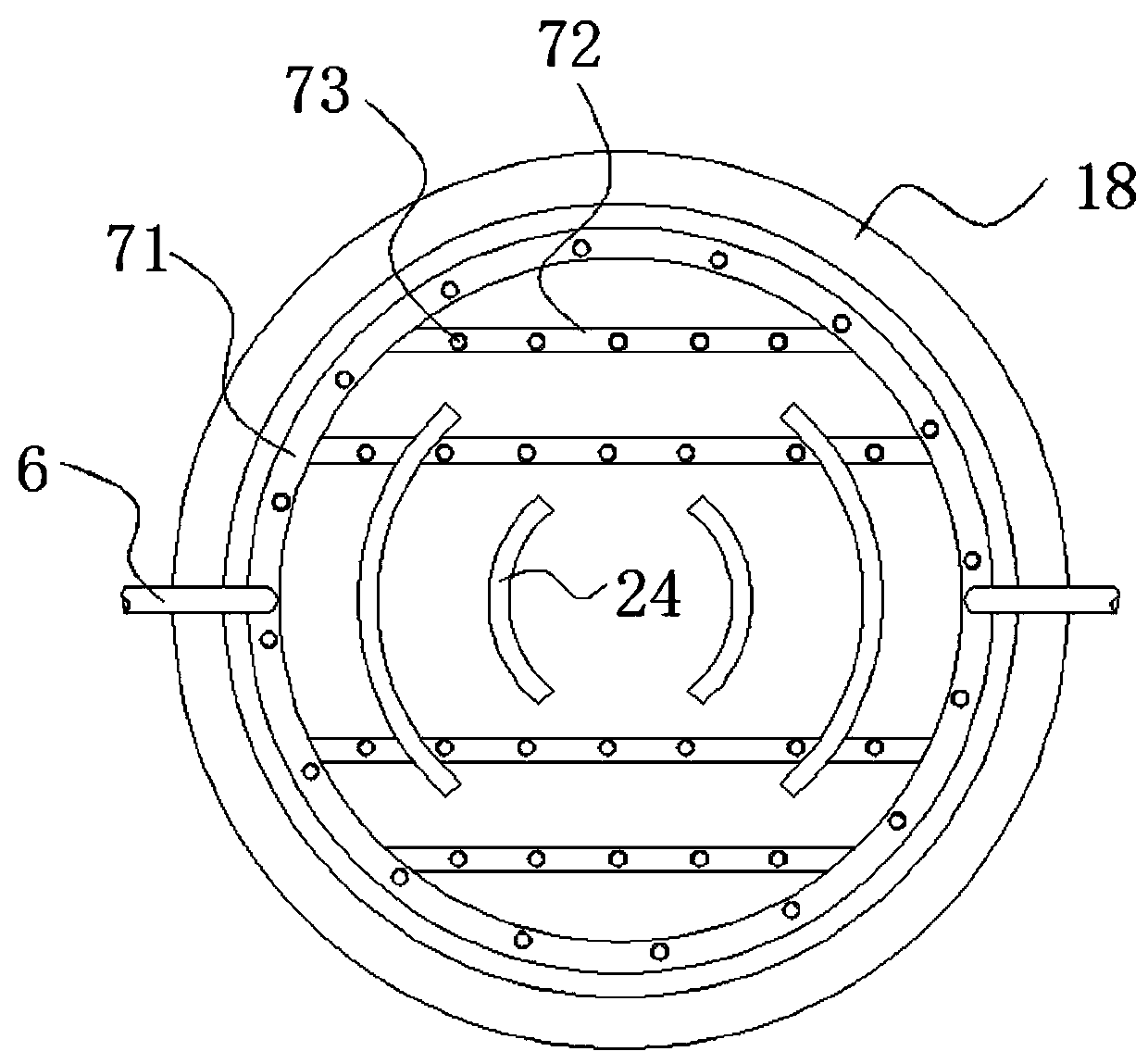

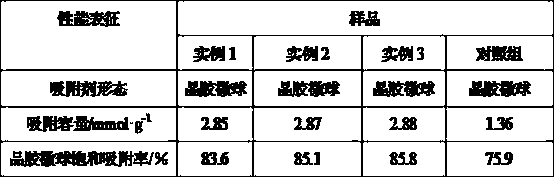

Method for preparing high-adsorption-capacity crystal glue microsphere particles

InactiveCN107617426APromotes aromatizationImprove adsorption efficiencyOther chemical processesAlkali metal oxides/hydroxidesCross-linkSludge

The invention discloses a method for preparing high-adsorption-capacity crystal glue microsphere particles and belongs to the technical field of adsorption materials. Semi-coke and sludge are taken asraw materials to prepare high-adsorption particles, and under the dehydration, wetting-expansion and condensation functions in the preparation process, aromatization of a carbon skeleton is promoted,and the carbon content and the adsorption performance are improved; and during filling of a crystal glue material, the adsorption efficiency of the material is effectively improved, and the adsorption capacity of the crystal glue material is improved. As a carbon material with a porous structure is added into the crystal glue material, a cross-linking agent in a polymerization system is adsorbedby the carbon material; when the temperature of a reaction system is reduced to be lower than the solvent crystallization temperature, a solvent starts to crystallize, and at the moment, polymer monomers and the cross-linking agent are enriched nearby the adsorption material; and therefore, the forming rate and the pore forming ratio of the crystal glue material are improved, and the adsorption capacity of the crystal glue material is further improved.

Owner:常州市宇科不绣钢有限公司

Centrifugal automatic forming mold for plastic processing

The invention discloses a centrifugal automatic forming mold for plastic processing. The centrifugal automatic forming mold for plastic processing comprises a bottom plate, a supporting frame is fixed to the upper surface of the bottom plate, an annular frame is fixed to the top of the supporting frame, a circular plate is connected to the interior of the annular frame through a rotating mechanism, a mounting column is connected to the upper surface of the circular plate, a V-shaped groove is formed in the mounting column, two opposite movable blocks are slidably installed in the V-shaped groove, vertical rods are fixed to the two movable blocks, the bottom ends of the two vertical rods extend into a spiral groove formed in the circular plate, the top ends of the two vertical rods are fixedly connected with forming die cavities, and the top of the annular frame is connected with a limiting mechanism used for time-limited locking of the mounting column. Through the arrangement of the structure, when the forming die cavity drives a formed product to rotate reversely, a core rod and the formed product are rapidly separated, adhesion between the formed product and the surface of the core rod is avoided, and therefore the working efficiency is greatly improved.

Owner:张秀兰

Photo-cured three-dimensional printer and forming method of three-dimensional object

ActiveCN107263873AIncrease molding rateReasonable shapeAdditive manufacturing apparatus3D object support structuresEngineeringLaser beams

The invention relates to a photo-cured three-dimensional printer and a forming method of a three-dimensional object. The photo-cured three-dimensional printer comprises a photosensitive resin tank; plane laser units are arranged on the outer sides of at least two side surfaces of the photosensitive resin tank; at least a part of each side wall, corresponding to one plane laser unit, of the photosensitive resin tank is a transparent part; each plane laser unit is provided with a laser and a focusing lens; the lasers generate plane type laser beams; the focusing lenses are arranged in light paths of the corresponding lasers; and focusing positions of plane type laser beams in the photosensitive resin tanks can be adjusted. The forming method of the three-dimensional object adopts the photo-cured three-dimensional printer to print and realizes the effect of photocuring. The photo-cured three-dimensional printer realizes the effect of layer-by-layer curing of photosensitive resin, the forming efficiency is improved, a control process of the plane type laser beams is simple, and the operation is easy.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

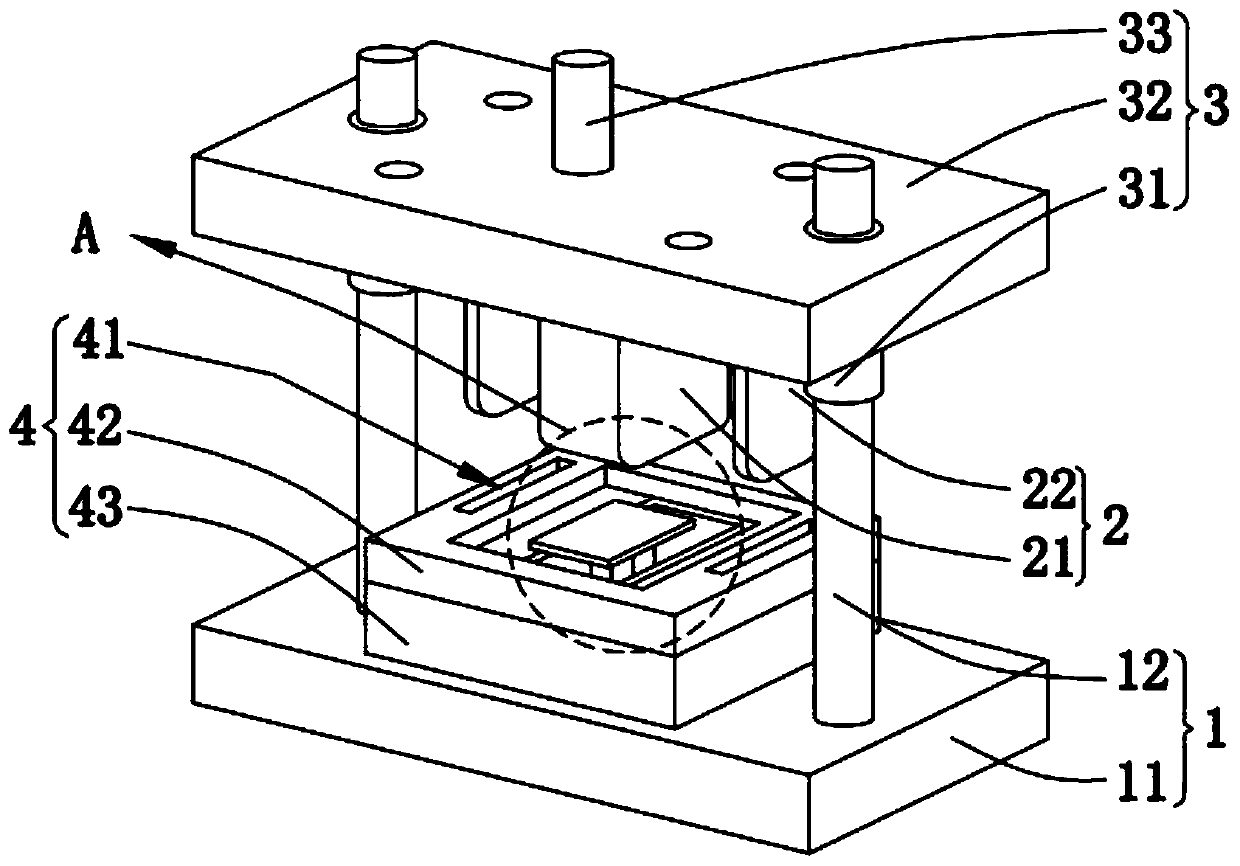

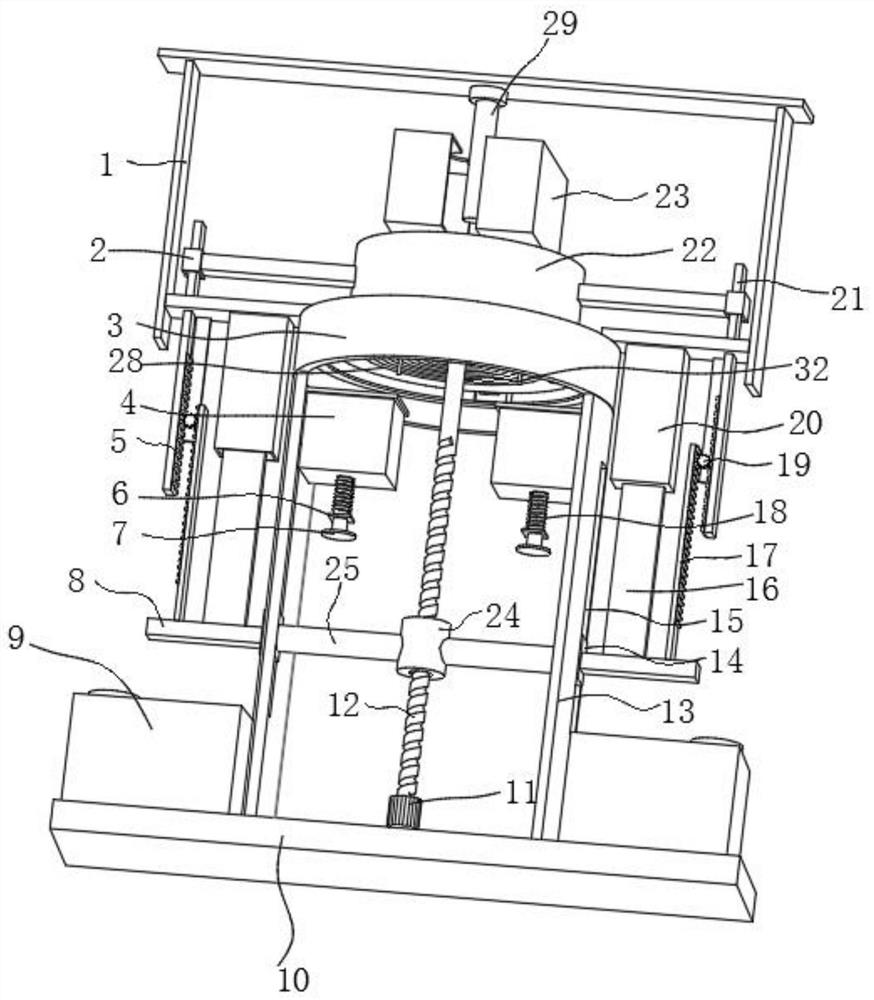

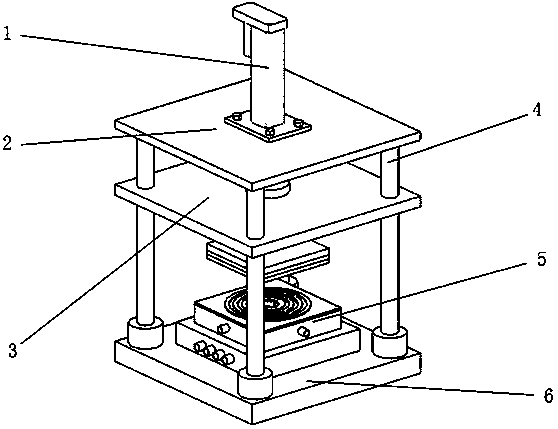

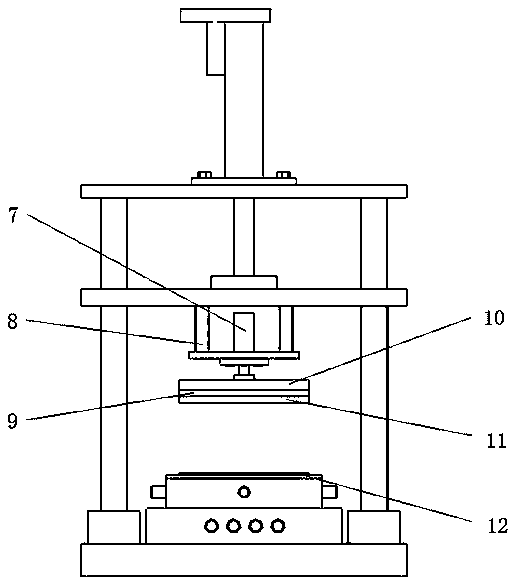

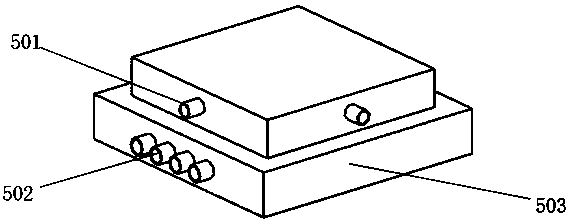

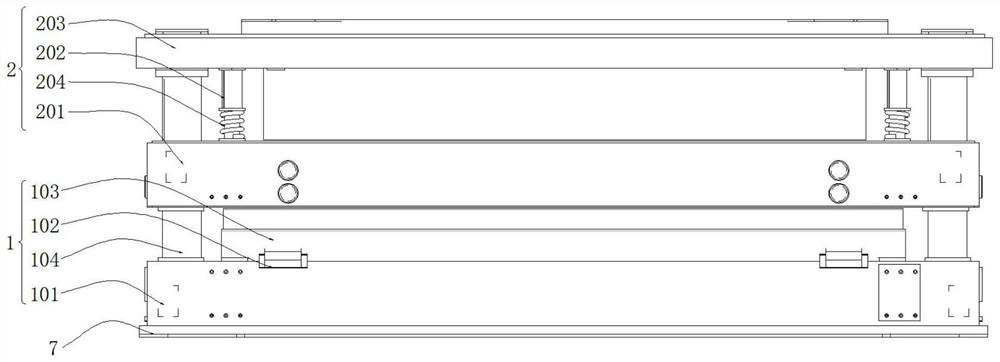

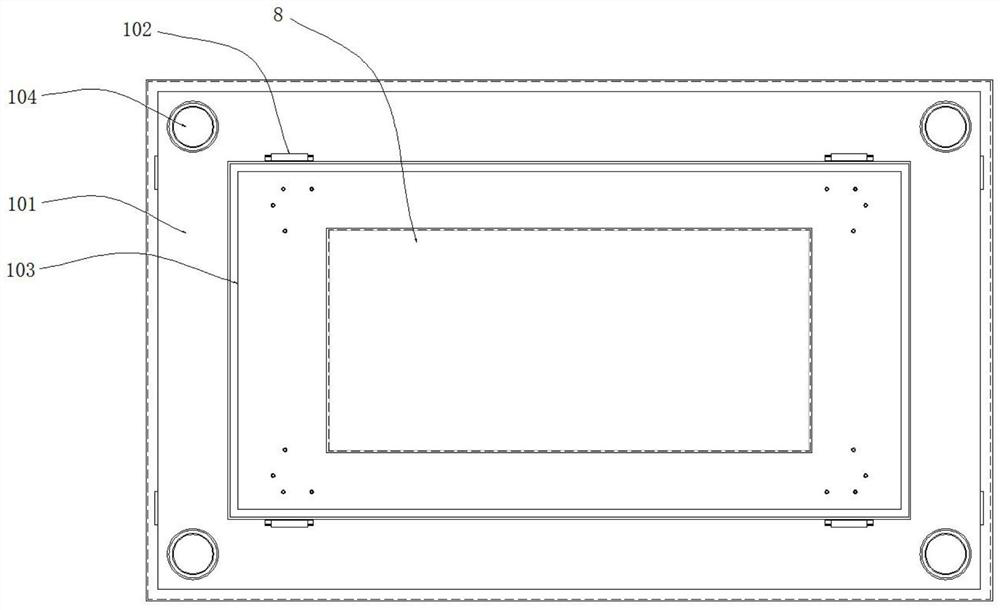

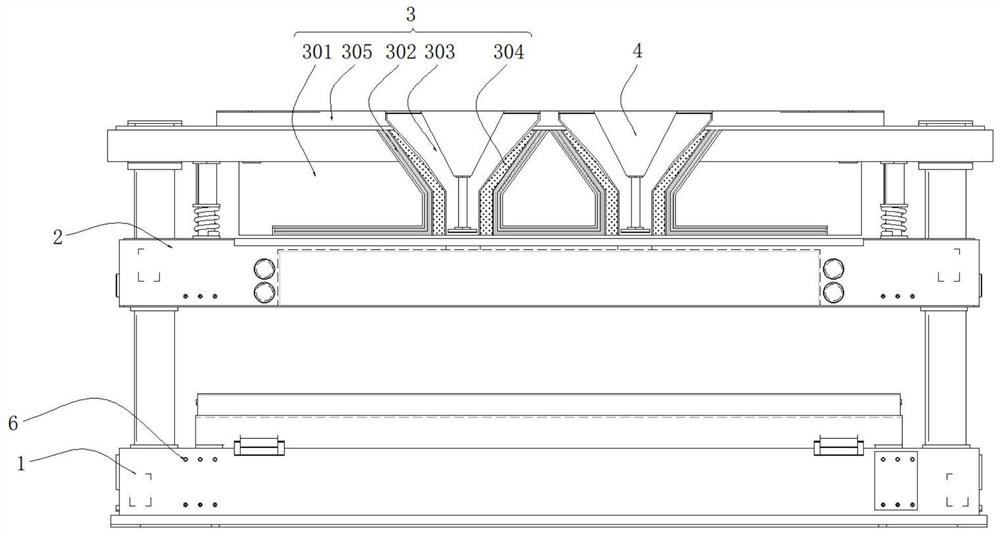

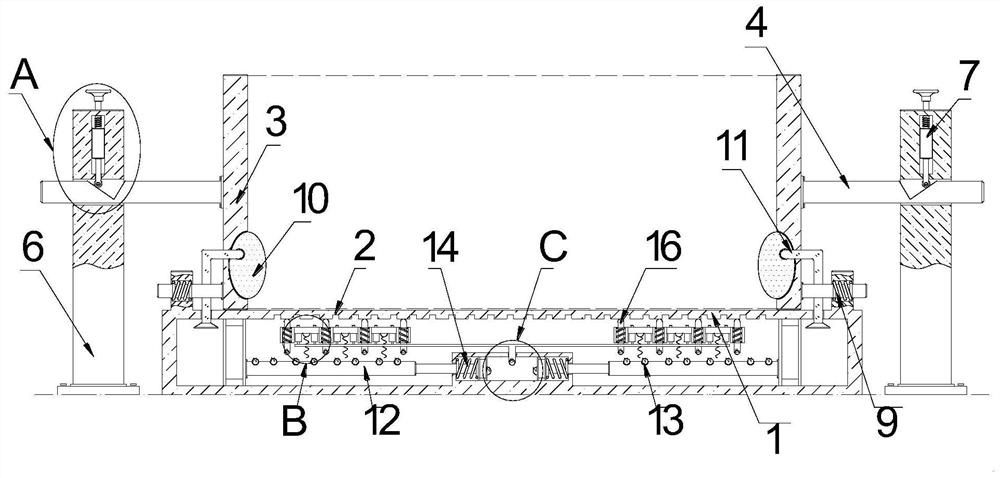

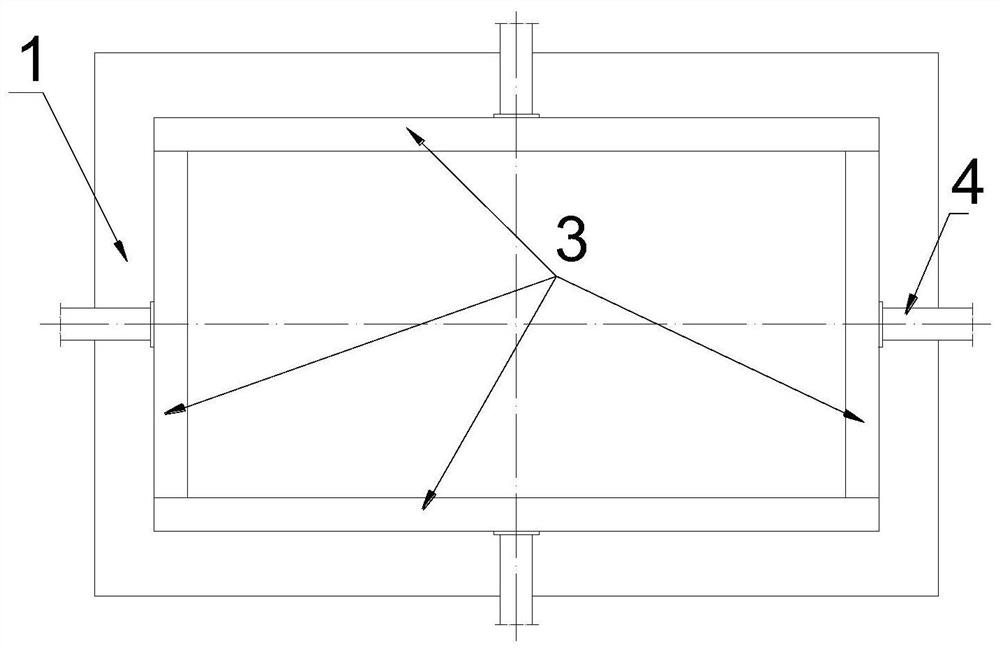

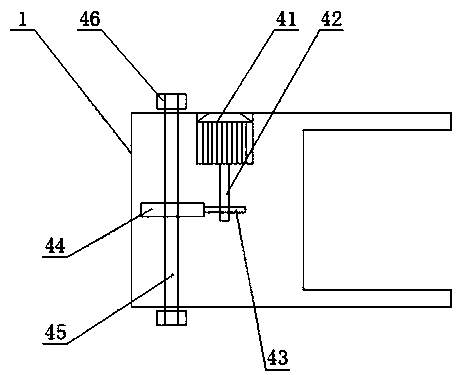

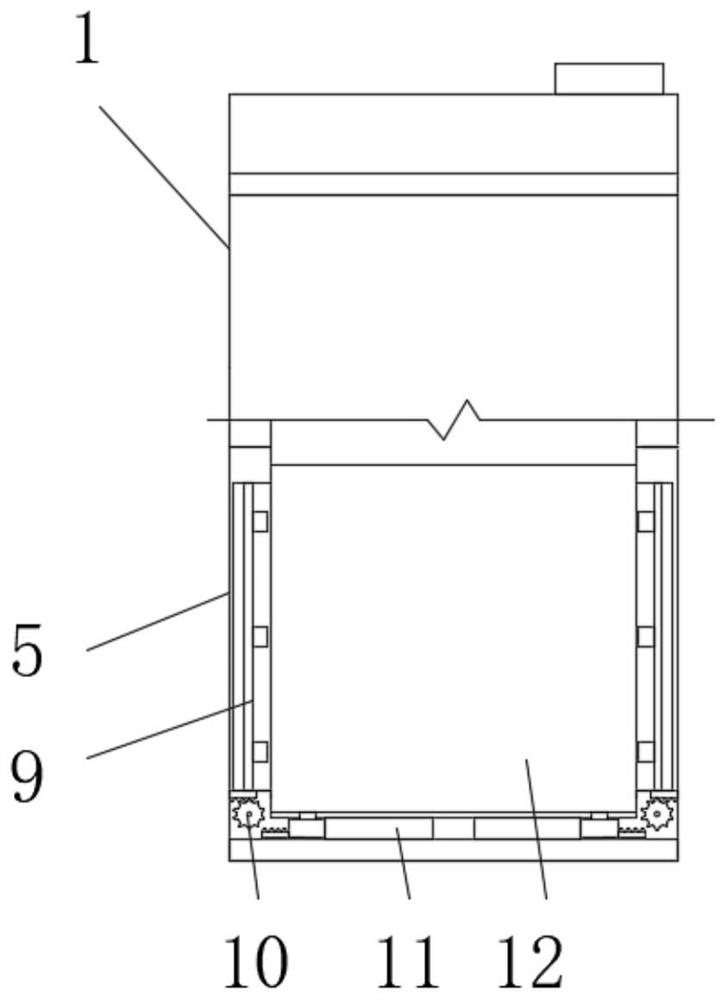

Device and method for vibration assisting of hot embossing

PendingCN109501216AIncrease molding rateAvoid damagePhotomechanical apparatusUltrasonic vibrationSlide plate

The invention discloses a device and method for vibration assisting of hot embossing. The device is composed of an electric control rod, an upper bottom plate, a sliding plate, guide rods, a temperature regulation and control device, a lower bottom plate, a supporting frame, an ultrasonic generation device, a load bearing plate, a heating plate, a first vacuum suction cup and a second vacuum suction cup. A template is fixed to the first vacuum suction cup. A substrate is fixed to the second vacuum suction cup. The template and the substrate are preheated, and pre-pressing is conducted after heating is conducted to the assigned temperature. An ultrasonic vibrator is used for applying ultrasonic vibration, the temperature regulation and control device is coordinated to heat a polymer on thesubstrate to the glass transition temperature, then, embossing is conducted, and after embossing is finished, the temperature regulation and control device is used for cooling and curing, and demoulding is finished. According to the device and method for vibration assisting of hot embossing, the polymer forming rate is increased, template and substrate damage is reduced, and the needed cost is reduced.

Owner:CHANGCHUN UNIV OF TECH

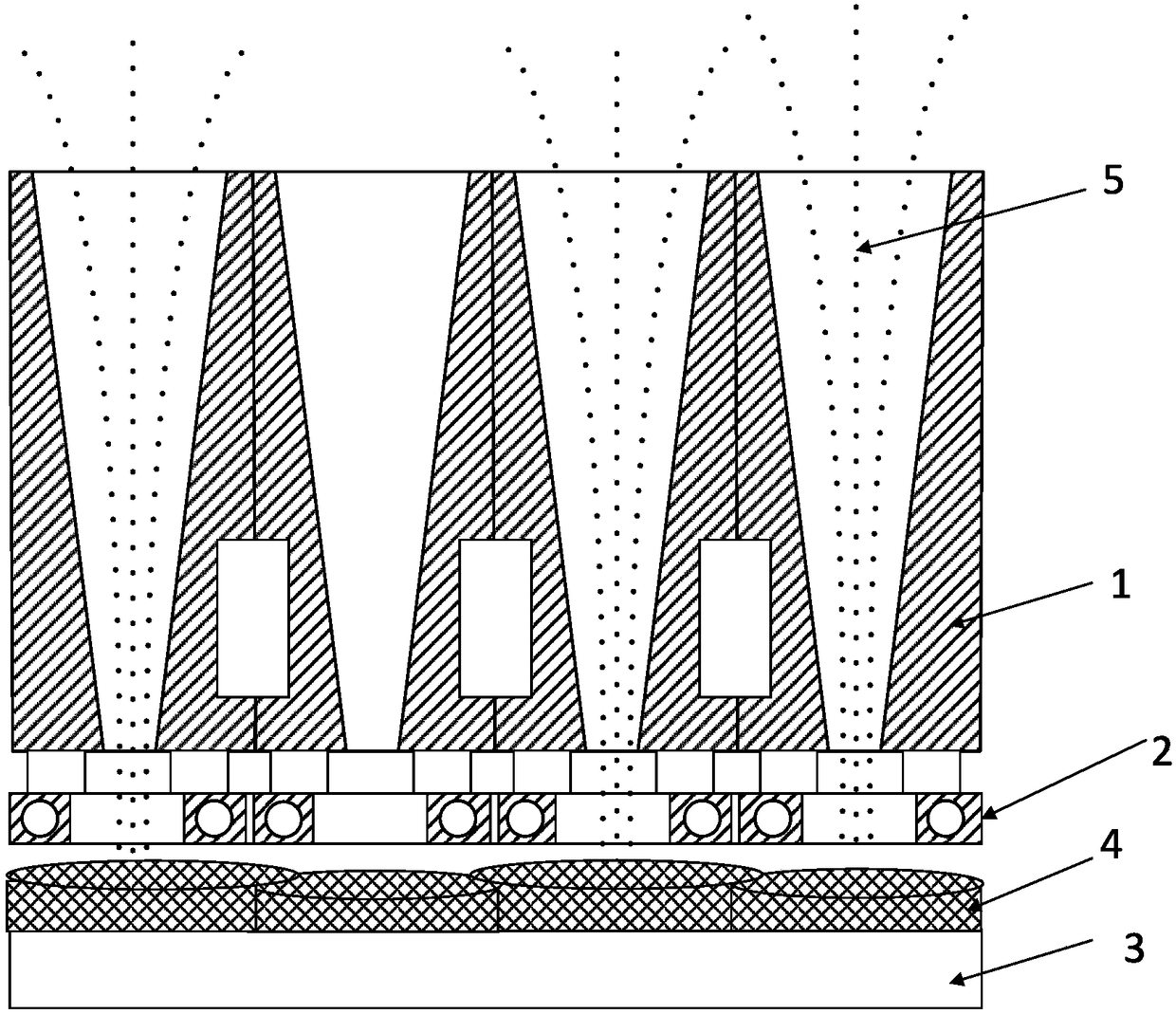

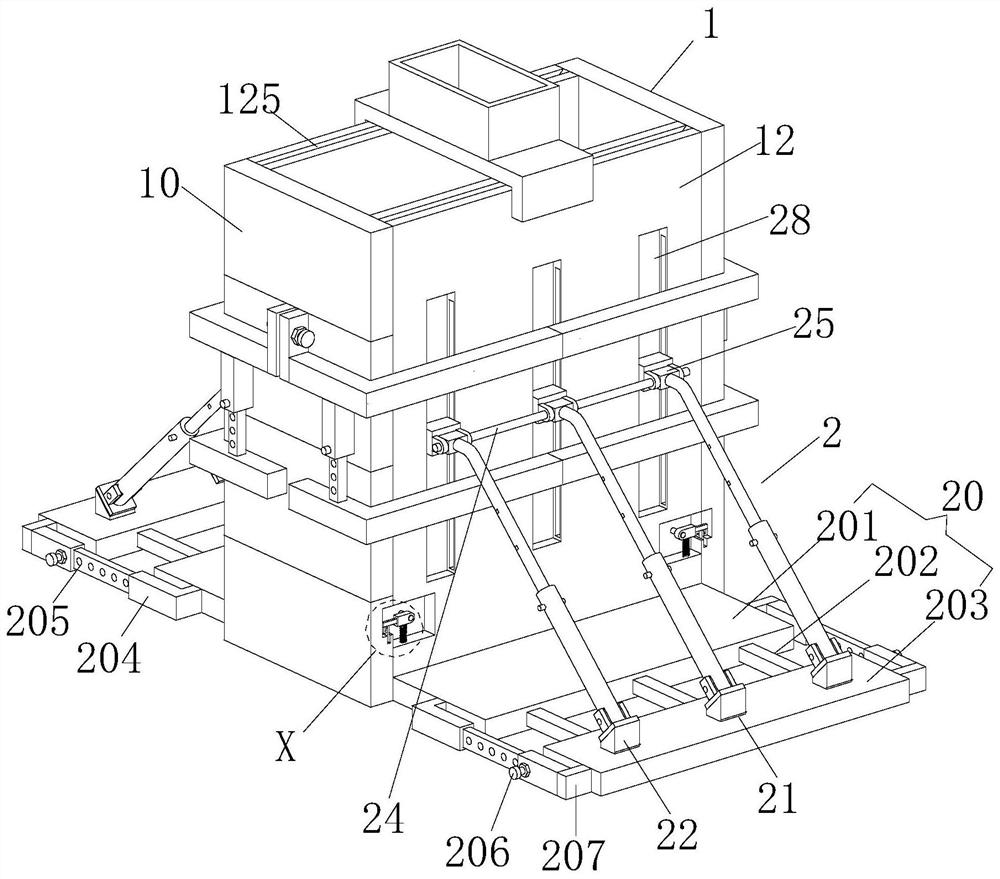

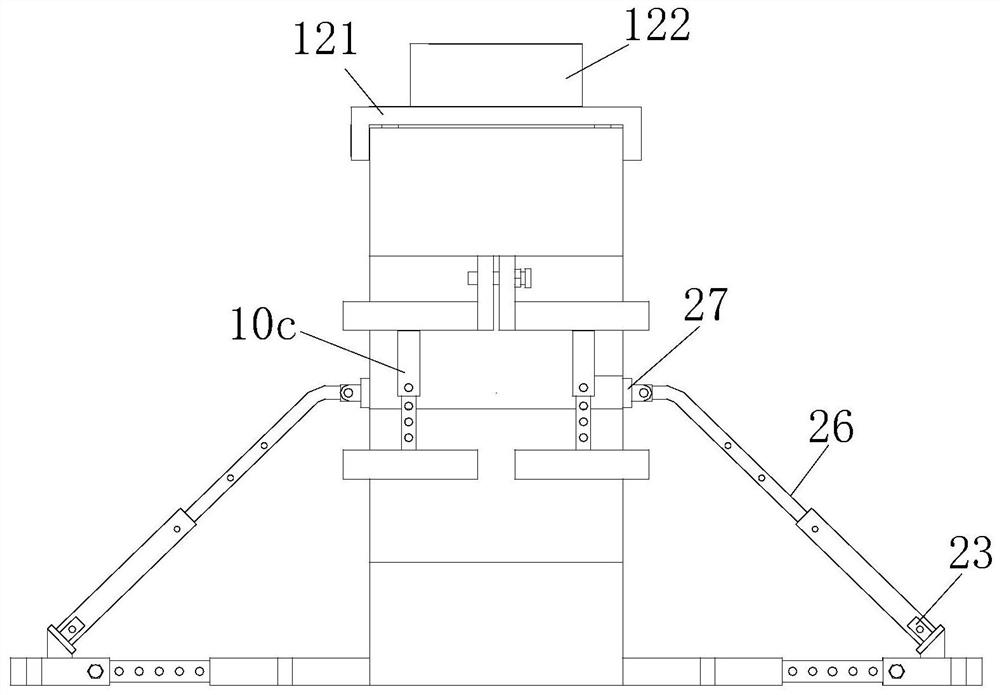

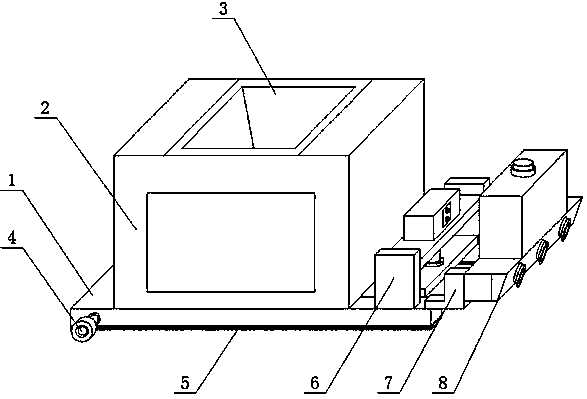

Cast-in-place construction method for low-energy-consumption assembly type steel mould net rack concrete thermal insulation wall

InactiveCN113235778APrevent slidingQuick lockWallsClimate change adaptationThermal insulationArchitectural engineering

The invention provides a cast-in-place construction method for a low-energy-consumption assembly type steel mould net rack concrete thermal insulation wall. The cast-in-place construction method for the low-energy-consumption assembly type steel mould net rack concrete thermal insulation wall adopts the following equipment for cast-in-place construction, and the equipment comprises a forming device and supporting devices, wherein the supporting devices are symmetrically arranged at the left end and the right end of the forming device. When the equipment is used for conducting cast-in-place construction on the low-energy-consumption assembly type steel mould net rack concrete thermal insulation wall, the following steps are specifically included, S1, the equipment is assembled and checked; S2, reinforcement is conducted; S3, concrete slurry is poured; and S4, forming and mould removing are conducted. According to the construction method, supporting rods can be limited and fixed by clamping trapezoidal blocks into limiting grooves, so that the supporting rods are more stable, and the situation that the supporting rods slide backwards due to the pressure of concrete in the concrete slurry pouring process can be avoided.

Owner:郭良红

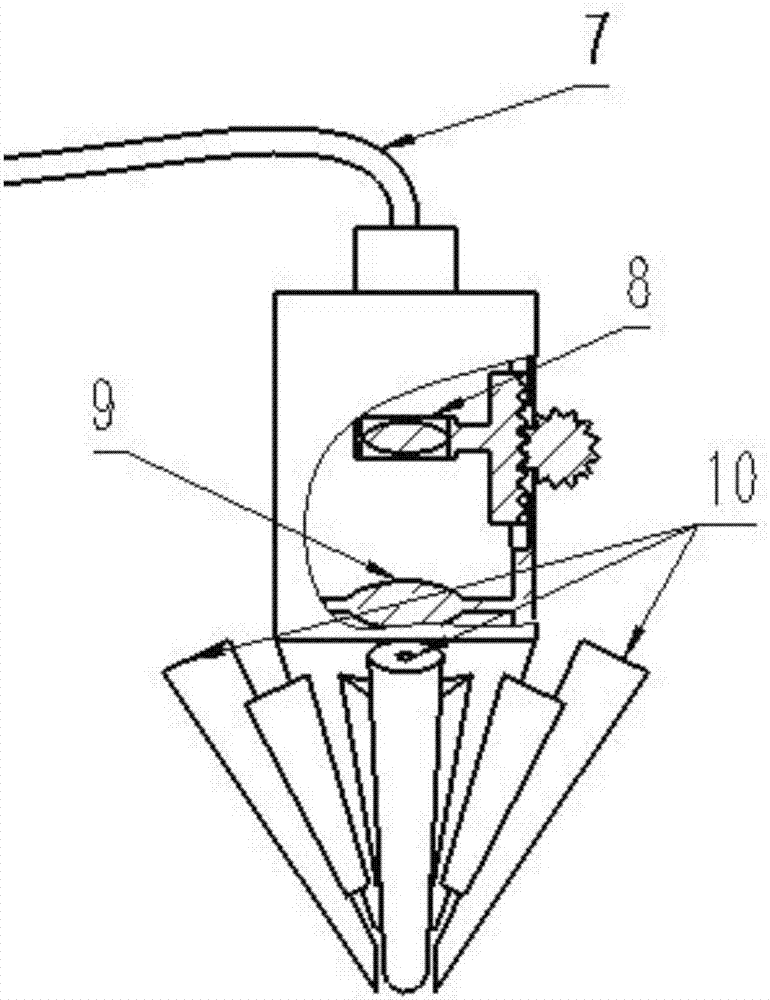

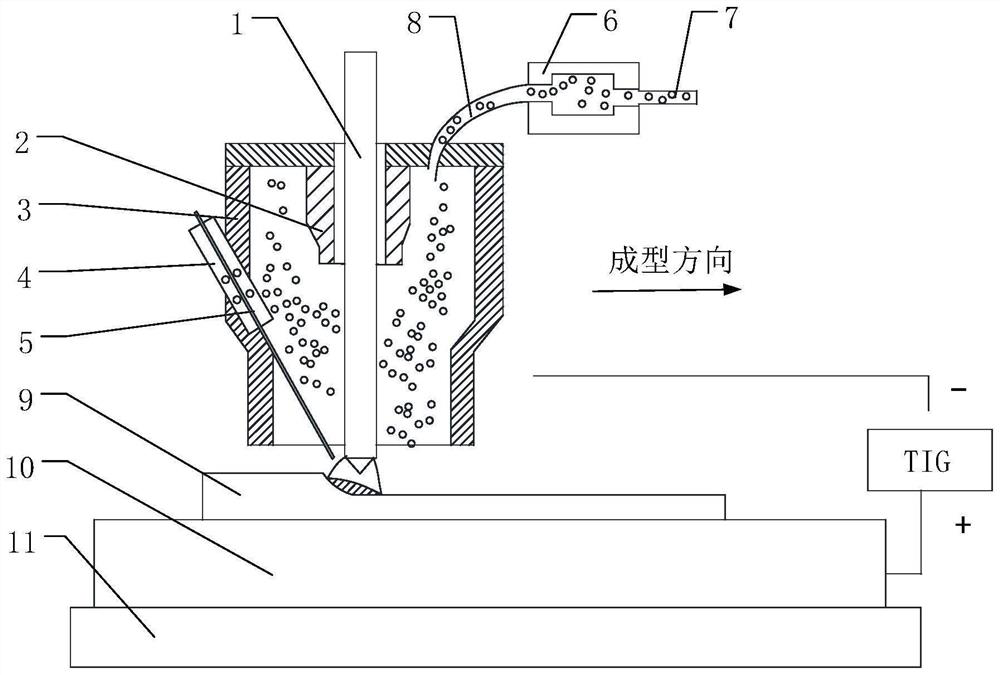

TOPTIG electric arc material increasing device and method for modifying aluminum alloy

PendingCN114769796AOptimize chemical compositionImproved metallurgical propertiesAdditive manufacturing apparatusArc welding apparatusAdditive layer manufacturingAluminium alloy

The invention discloses a TOPTIG electric arc additive material device for modifying aluminum alloy. The TOPTIG electric arc additive material device comprises a nozzle, a clamping sleeve is arranged on a nozzle sleeve, a tungsten electrode is located in the clamping sleeve, the nozzle is located over a workpiece, the nozzle is connected with a powder feeder through a powder feeding pipe, and a powder heating box for heating powder is arranged on the powder feeding pipe; a wire feeder is arranged on the side wall of the nozzle, and the bottom end of the wire is located at the front end of the tungsten electrode. The invention further discloses a material adding method of the TOPTIG electric arc material adding device for modifying the aluminum alloy. By the adoption of the TOPTIG electric arc material increasing device and method for modifying the aluminum alloy, the problems that the forming efficiency of existing material increasing manufacturing is low, and the performance of the formed aluminum alloy is poor can be solved.

Owner:河北金融学院

Round pin-point gate pouring molding structure

The invention discloses a round pin-point gate pouring molding structure. The structure comprises a supporting mechanism, a mold closing mechanism is arranged at the top of the upper end of the supporting mechanism, a base plate is arranged at the bottom of the lower end of the supporting mechanism, screws are arranged on the periphery of the outer side of the supporting mechanism, and a lower mold cavity is formed in the top of the upper end of the supporting mechanism. A molding mechanism is arranged on the inner side of the upper end of the mold closing mechanism. Auxiliary feeding mechanisms are arranged on the two sides of the interior of the molding mechanism. According to the structure, a heating wire layer is used for heating the upper mold cavity, so that the situation that the temperature in the mold cavity is too low, water vapor is generated due to direct contact with melt, even the water vapor is accumulated in the mold cavity, flowing and molding pressure of the melt are affected, and bubbles are generated in a product is avoided. Through the heating of the heating wire layer, preheating operation can be carried out before molding, so that the situation that melt flows discontinuously in the mold cavity due to too large mold temperature difference is avoided.

Owner:深圳市华中思明通科技有限公司

Assembly type building template with firm structure for engineering construction

PendingCN114525922AReduce the presence of air bubblesFast formingNon-rotating vibration suppressionAuxillary members of forms/shuttering/falseworksArchitectural engineeringMachining

The invention discloses an assembly type building template with a firm structure for engineering construction, which comprises a bottom plate, a connecting groove and a building template main body, the inner wall of the bottom plate is provided with the connecting groove, and the upper end of the bottom plate is provided with the building template main body; the transverse rod is arranged on the outer side of the building formwork body, an extrusion groove is formed in the transverse rod, and the transverse rod is arranged on the supporting frame in a penetrating mode; the movable rod is arranged in the bottom plate, a first magnetic ball is installed at the upper end of the movable rod, and the movable rod and the bottom plate are connected through a built-in spring; and the stop lever is fixedly installed at the lower end of the vertical rod, and magnets are installed at the lower end of the middle of the stop lever and the inner end of the movable rod. According to the assembly type building formwork with the firm structure for engineering construction, bubbles existing between concrete can be reduced in the pouring process, meanwhile, after pouring is completed, the concrete can be heated so that the concrete can be rapidly formed, and the working efficiency of overall machining is improved.

Owner:新疆兵团城建集团有限公司

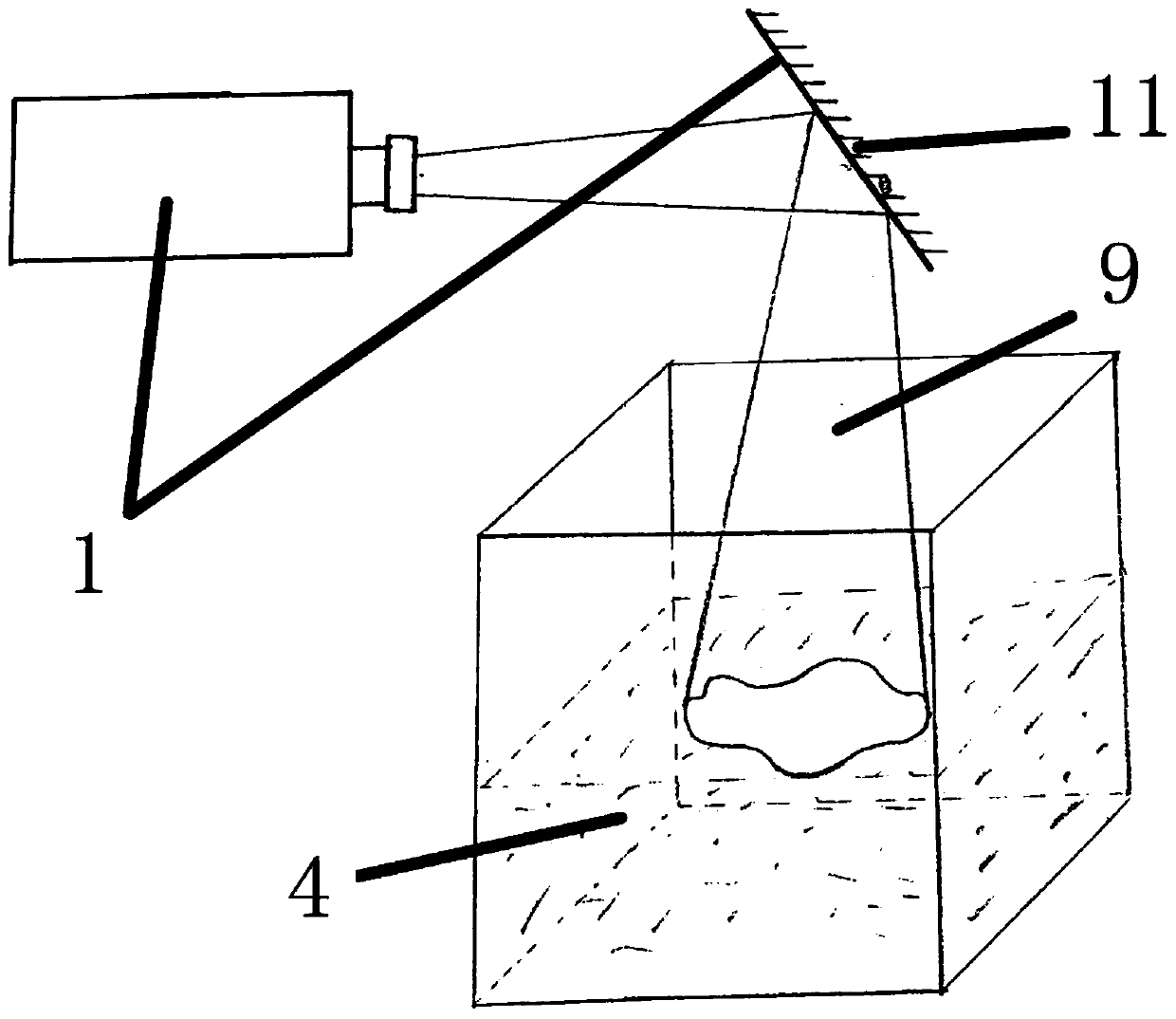

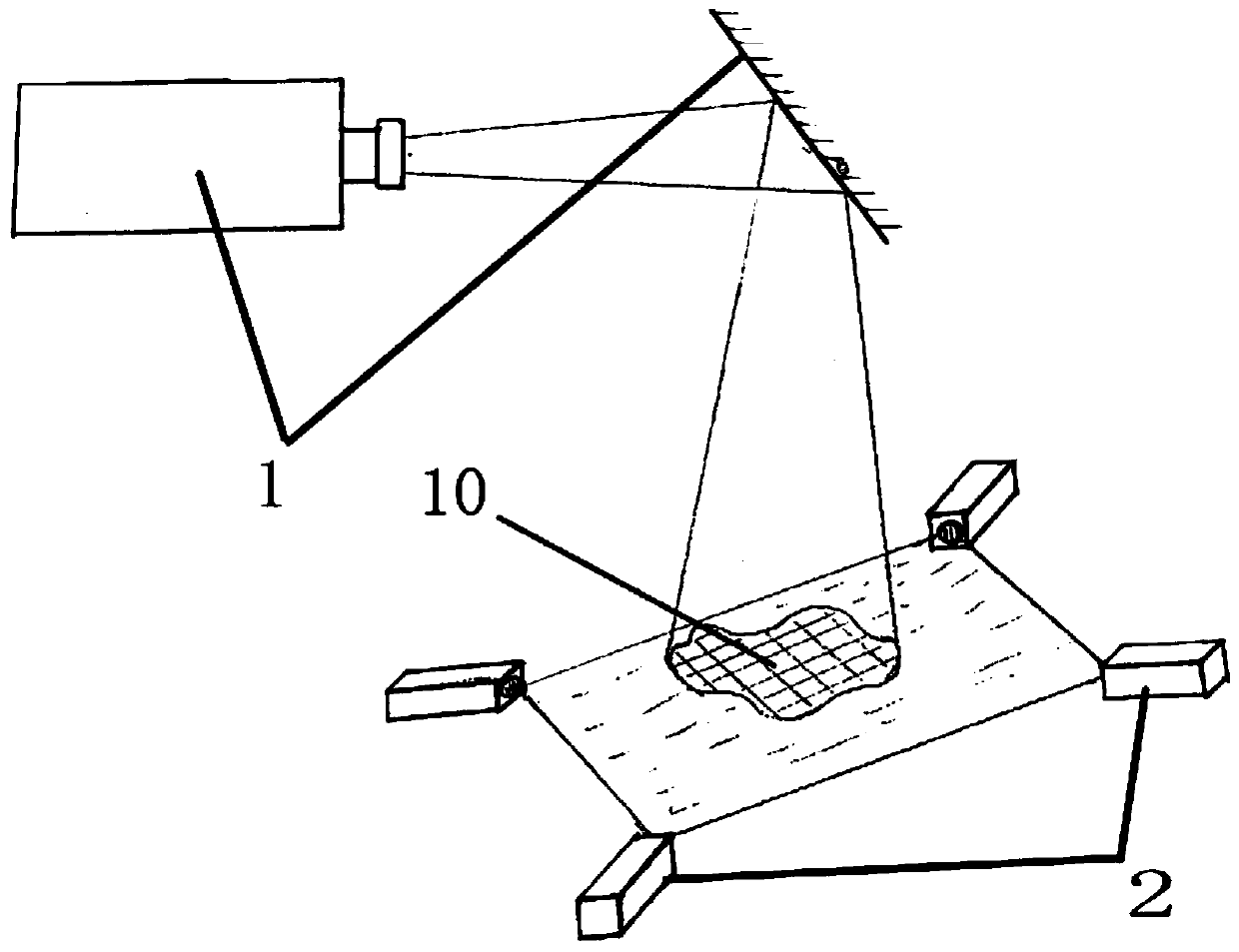

Inner stereoscopic light projection curing forming 3D printing equipment and forming method thereof

PendingCN110014647AHigh precisionImprove surface smoothnessManufacturing platforms/substratesManufacturing enclosuresControl systemComputer module

Inner stereoscopic light projection curing forming 3D printing equipment mainly comprises a laser projection module, a light reference plane module, a light reference plane module lifting system, a resin tank, a forming platform, a forming platform lifting system, a control system, a power supply system and a body framework. Curing forming is carried out in liquid resin. Multiple beams of light with specific wavelength are used for irradiating photosensitive resin, the unit light strength of each beam of light is lower than that of light required for photosensitive resin curing, but the unit irradiation strength generated after several beams of light coincide is higher than that required for photosensitive resin curing. When the irradiation strength reaches the light intensity required when the photosensitive resin is subjected to a curing reaction, the liquid photosensitive resin of this part can generate a polymerization reaction so as to be cured into solids, and the liquid resin iscontinuously cured from bottom to top according to the cross section of an objected needing to be formed so that a practical object of a model can be obtained.

Owner:匡津永

Preparation method for rapidly-formed light-cured resin

The invention discloses a preparation method for a rapidly-formed light-cured resin, and belongs to the field of the material preparation. The preparation method comprises the following steps: pouringan epoxy resin into a flask with a stirrer and a temperature control device, and feeding nitrogen for protection, heating, adding a hydroquinone polymerization inhibitor, and uniformly stirring; weighing an acrylic acid according to the molar weight of the epoxy resin, adding tetrabutylammonium bromide, and stirring until all are completely dissolved, pouring into a constant pressure dropping funnel, dropwise adding mixed solution, wherein each drop is about 2 s, and slowly warming; and interval-sampling after the reaction is stable, and measuring an acid value, stopping heating while the acid value is less than 5 mg / g KOH, to obtain a product which is the prepared resin. Through the effective improvement of a technology, the preparation method for the light-cured resin is simplified, andthe prepared resin has the low viscosity, so the resin can be rapidly leveled. The operation is easy, the curing rate is high, the forming speed is improved, the preparation process is simplified, and the preparation cost is saved. The preparation method is suitable for popularization and application in the related field.

Owner:SHAANXI SHENGMAI PETROLEUM

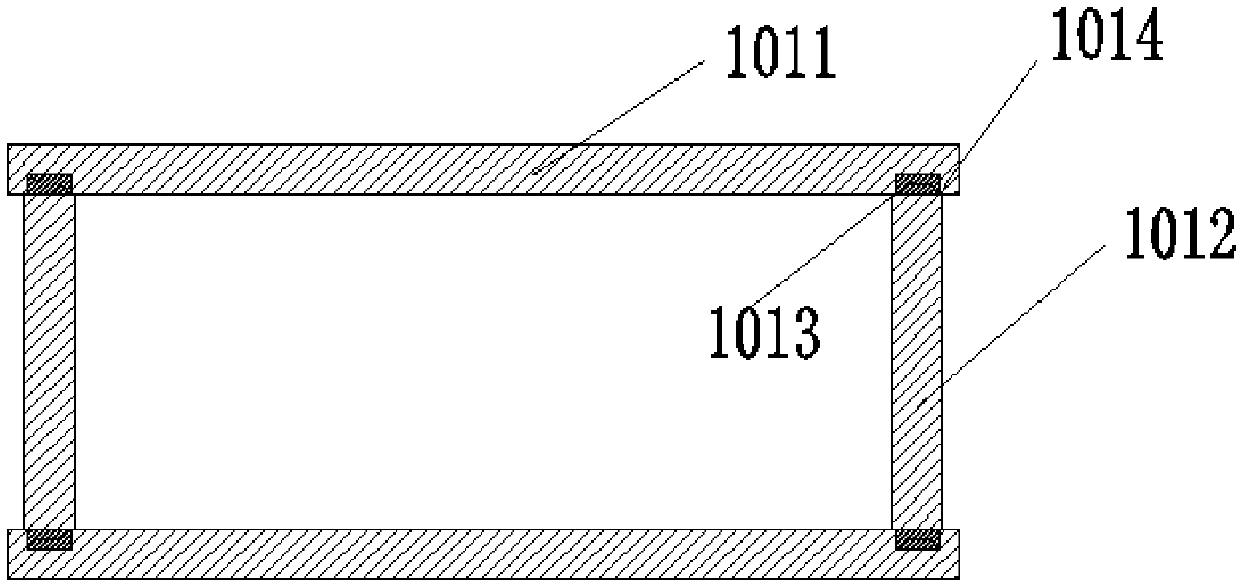

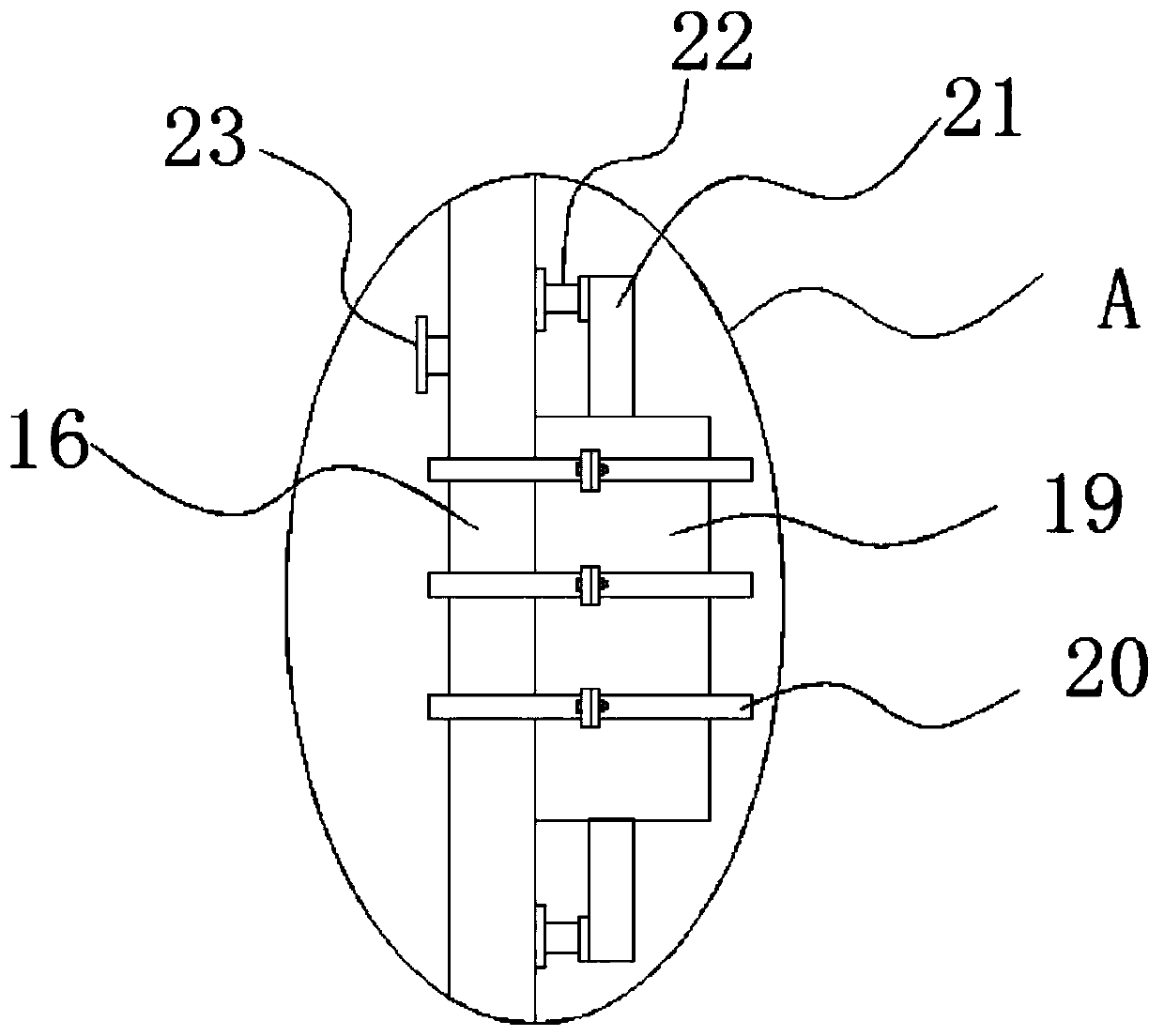

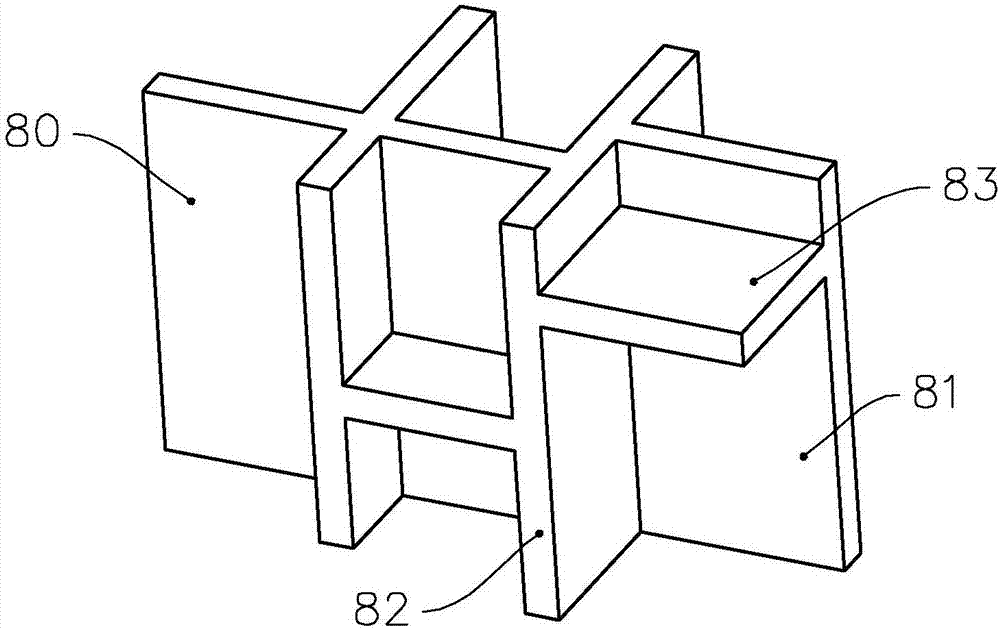

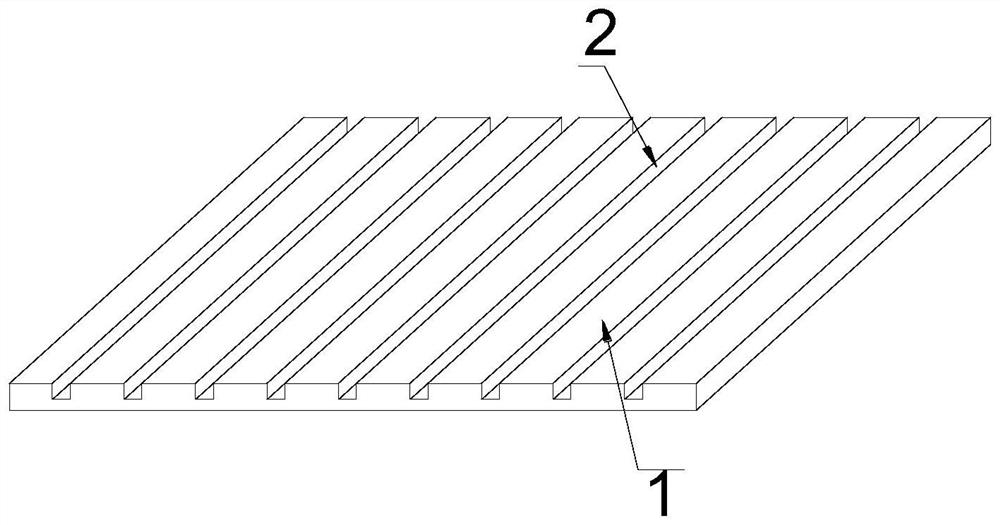

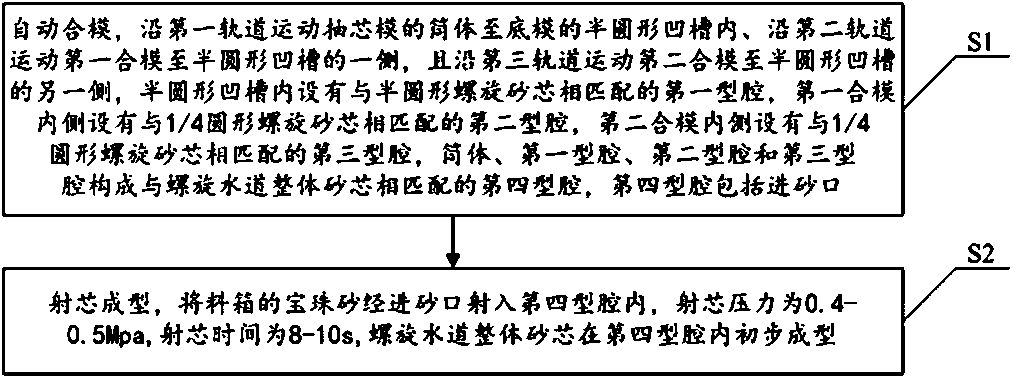

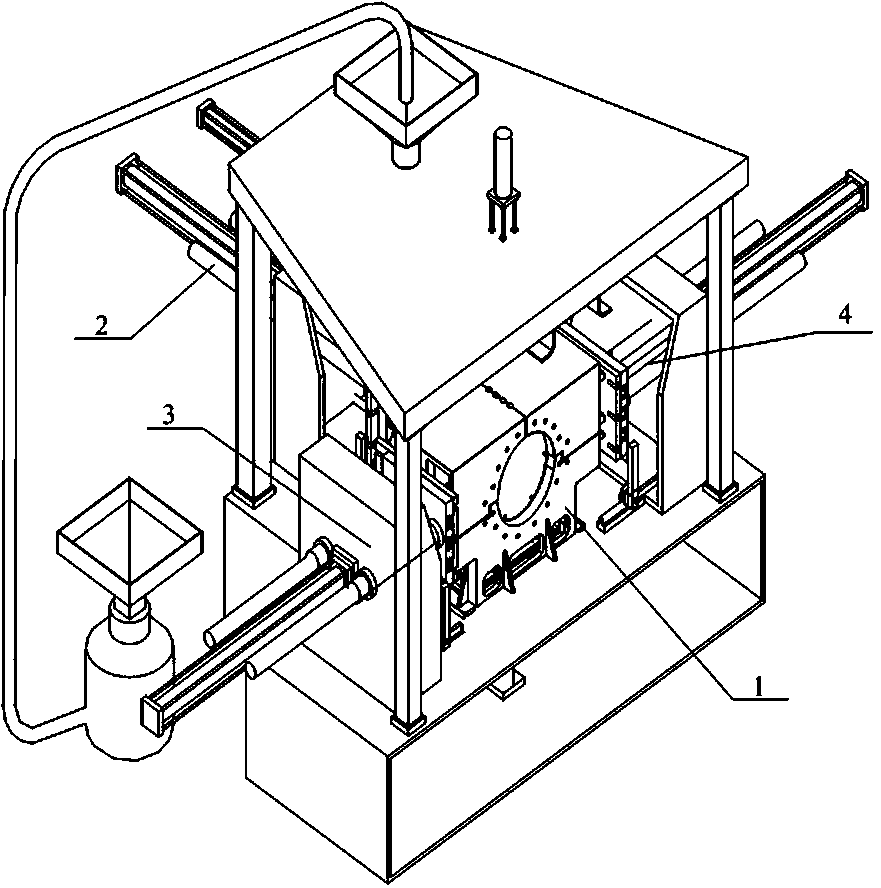

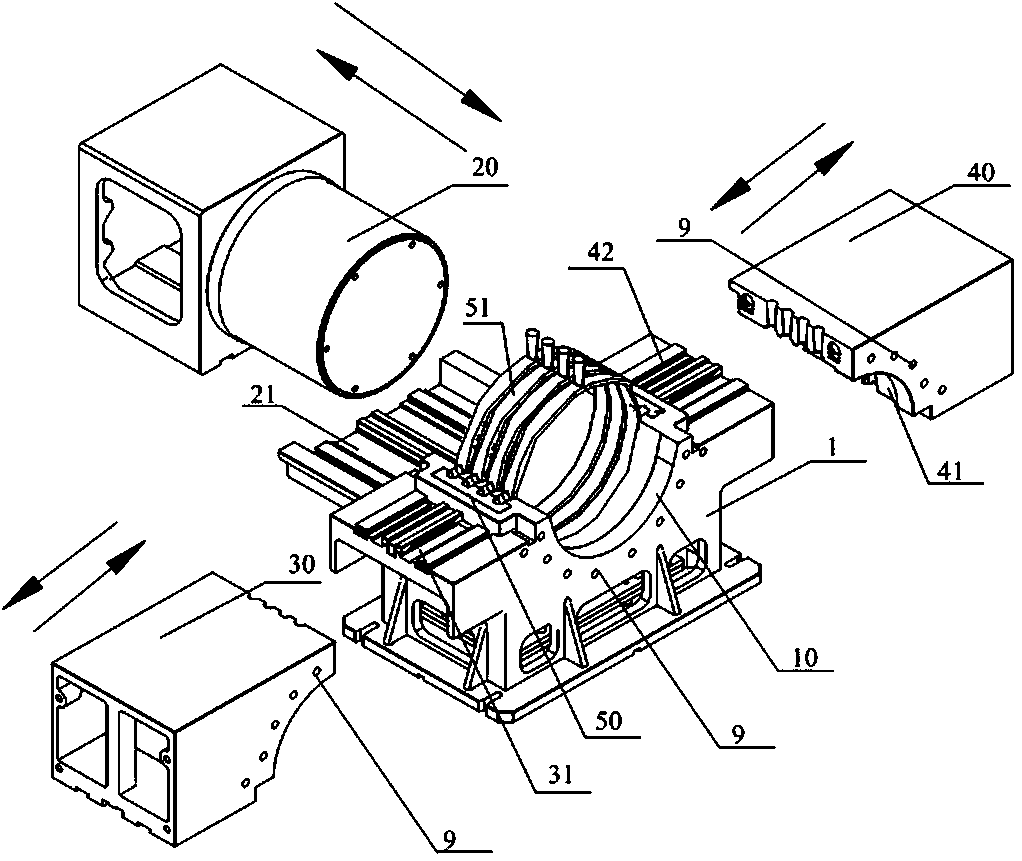

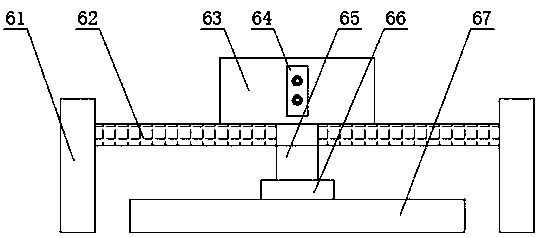

Integral sand core casting method for spiral waterway of new-energy automobile motor casing and sand core structure

InactiveCN108723331AEasy to operateIncrease molding rateFoundry mouldsFoundry coresNew energyAlternative fuel vehicle

The invention discloses an integral sand core casting method for a spiral waterway of a new-energy automobile motor casing and a sand core structure. The integral sand core casting method comprises the steps of automatic mold closing and core injection molding. In the step of automatic mold closing, a core pulling mold, a bottom mold, a first mold closing and a second mold closing are closed automatically; a fourth mold cavity matched with the integral sand core of the spiral waterway is formed by a cylinder body of the core pulling mold, a first mold cavity located in the semi-circle groove of the bottom mold, a second mold cavity of the first mold closing, a third mold cavity of the second mold closing; and the fourth mold cavity comprises a sand inlet. In the step of core injection molding, ceramsite in a workbin is injected into the fourth mold cavity through the sand inlet; and the integral sand core of the spiral waterway is molded preliminarily in the fourth mold cavity. According to the integral sand core casting method for the spiral waterway of the new-energy automobile motor casing, by means of automatic mold closing, the fourth mold cavity matched with the integral sandcore of the spiral waterway is formed; then the ceramsite is injected into the fourth mold cavity, and the integral sand core of the spiral waterway is acquired in an integrally-molded manner; the molding operation of the integral sand core of the spiral waterway is simplified; and thus the molding rate of the sand core is improved, and the molding quality of the sand core is also improved.

Owner:HUIZHOU WEISHENG IND

Mainboard coating device based on artificial intelligence

PendingCN112756173AImprove applicabilityIncrease molding rateDispersed particle filtrationPretreated surfacesElectric machineryAlgorithm

The invention discloses a mainboard coating device based on artificial intelligence. The mainboard coating device comprises a box body and a connecting plate, wherein supporting legs are fixedly connected to the bottom of the box body, four evenly-distributed supporting frames are fixedly connected to the outer portion of the box body, a rotating shaft is jointly and rotationally connected between every two supporting frames, guide rollers are fixedly connected to the outer portion of each rotating shaft, and the guide rollers are fixedly connected to the outer portion of the box body; a conveying belt is jointly arranged between every two guide rollers, a motor base is welded to the outer portion of the box body, a first motor is installed at the upper end of the motor base, an output shaft of the first motor is fixedly connected with the rotating shaft at the left side, two symmetrically-distributed open windows are formed in the box body, and the conveying belts penetrate through the open windows; and the interior of the box body is connected with a threaded rod through threads, and the threaded rod is provided with an annular groove. The mainboard coating device based on artificial intelligence has the characteristics that the product quality is improved, and the product forming rate is increased.

Owner:许强

Production device of multi-size prefabricated floor slab

InactiveCN110948666AImprove evaporation efficiencyIncrease molding rateMould fastening meansFloor slabWater discharge

The invention discloses a production device of a multi-size prefabricated floor slab, which comprises a bottom framework, a floor slab machine body, a feeding groove, a moving assembly, a wear-resisting plate, a compaction assembly, a rack and a spraying assembly, wherein the floor slab machine body is fixedly mounted at the top of the bottom formwork through bolts, the moving assembly is arrangedin the bottom formwork, the compaction assembly is arranged at the position, which is close to the edge, of the top of one side of the bottom formwork, the rack is fixedly mounted at the edge of oneside of the bottom formwork through bolts, and the spraying assembly is arranged on the outer side of the rack; and the spraying assembly comprises a water storage tank, a water injection base, a filter head, a spraying box, a water conveying pump, a water pumping pipe, a water discharging pipe, a water distributing pipe and an atomizing nozzle. The production device of the multi-size prefabricated floor slab is convenient to move and good in wear resistance. When the device is used, the prefabricated floor slab can be compacted so as to enable the floor slab to be firmer. Meanwhile, water mist can be sprayed to the fabricated floor slab, so that the forming time of the floor slab can be shortened.

Owner:徐州恭乐橡塑机械有限公司

Blowing mold with heater

The invention relates to a blowing mold with a heater, which comprises a mold body. The blowing mold is characterized in that the mold body comprises a female module and a male module, wherein the female module and the male module are in closed fitting; mold cavities are formed in middles of the female module and the male module; a plurality of runners downwards recessed are evenly formed in the two ends of the mold cavity of the female module; a hollow cavity is formed below the mold cavity of the male module; the heater is arranged in the hollow cavity; a cooling device is arranged at the bottom of the heater; and the heater is controlled through an external intelligent controller. The blowing mold has the advantages of simple structure, convenience for use, low production cost, satisfaction of demands of small enterprises, small land occupation and reduction of production cost; the arrangement of the heater can quicken the object forming speed; when the mold is not operated, the heat is dissipated through cooling chips; and the intelligent degree is high.

Owner:KUNSHAN JUYUANSHENG MACHINERY DESIGN

Constant-temperature mold with multi-limiting function for switch injection molding

PendingCN113276355ARapid synchronization of multiple limit actionsImprove stabilityEngineeringInjection molding process

The invention discloses a constant-temperature mold with a multi-limiting function for switch injection molding, and belongs to the technical field of injection molds. The constant-temperature mold comprises a first combined mold, a second combined mold, a mold opening assembly, a positioning assembly, a multi-limiting assembly, a trigger assembly and a separation blade, wherein the second combined mold is installed below the first combined mold, the mold opening assembly is fixedly installed on a bottom plate installed at the bottom of the second combined mold, and limiting pieces are fixedly installed on the outer wall of one side of the first combined mold and the outer wall of one side of the second combined mold. According to the mold, the trigger assembly and the multi-limiting assembly are installed inside, so that when an inner mold is installed at ordinary times, only the inner mold needs to be directly placed in the second combined mold, through the linkage structure design, the design is ingenious, and when the inner mold is placed and mounted, the inner mold is subjected to a rapid and synchronous multi-limiting effect, so that the stability of the inner mold in the injection molding process can be greatly improved, and the injection molding quality is effectively improved.

Owner:杭州程意电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com