Injection molding production equipment for instrument plastic cover

A technology for production equipment and plastic covers, which is applied to household components, household appliances, and other household appliances. It can solve the problems of inconvenient separation of finished products and molds, low production efficiency, and troublesome plastic covers, so as to improve flexibility and increase The rate of production, the effect of accelerating the molding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

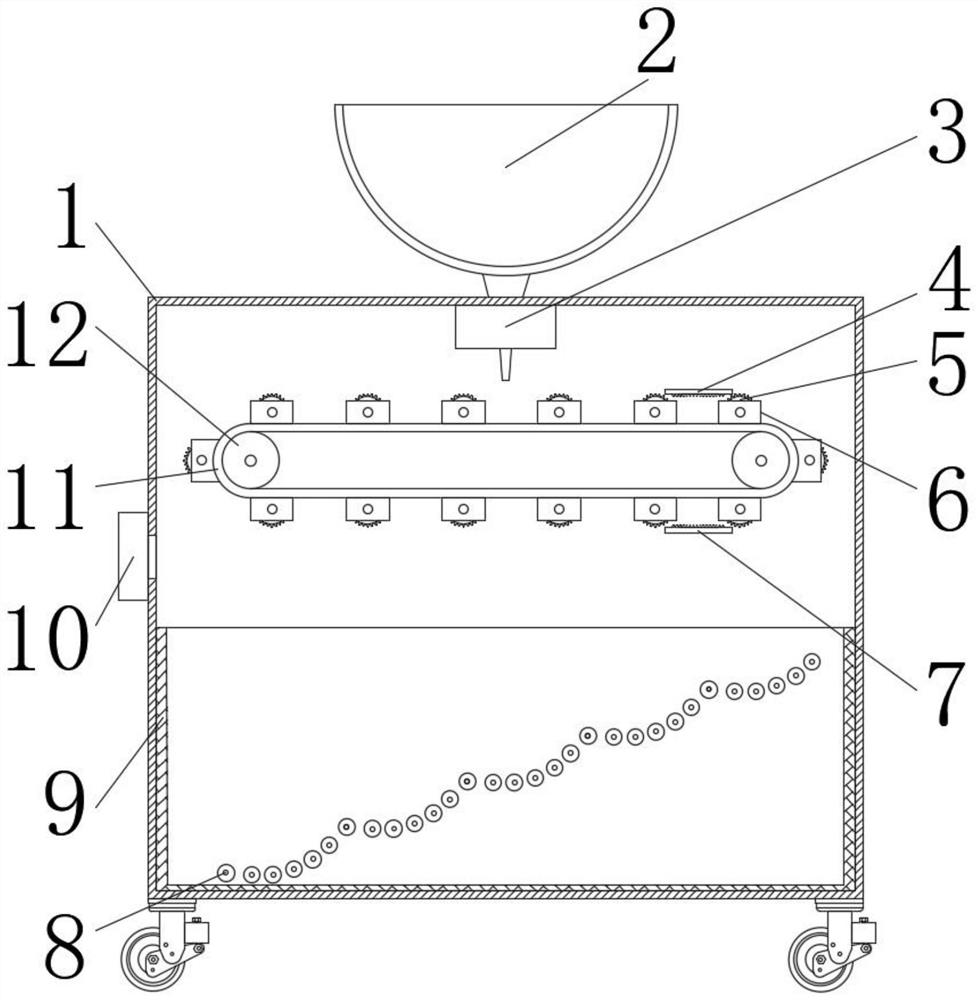

[0028] Such as Figure 1-6 As shown, the embodiment of the present invention provides an instrument plastic cover injection molding production equipment, including a box body 1, a material storage box 2, an injection molding machine 3 and a servo motor 17, and the inside of the box body 1 is provided with two transmission wheels 12, two The outer surface of transmission wheel 12 is provided with transmission belt 11, and two transmission wheels 12 are connected by transmission belt 11 transmission, and the outer surface of transmission belt 11 is fixedly connected with a plurality of placement racks 6, and between two adjacent placement racks 6 The distances are all the same, a plurality of placing frames 6 are provided with limiting mechanisms inside, and the limiting mechanisms include a transmission threaded rod 14, one end of the transmission threaded rod 14 is rotatably connected with the inner side wall of the placing frame 6, and the other end of the transmission threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com