Surface microstructure-forming system based on coherent laser

A microstructure forming and laser technology, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that cannot be adjusted, etc., and achieve the effect of simple and easy technical means, easy promotion and application, and reduction of steps and instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

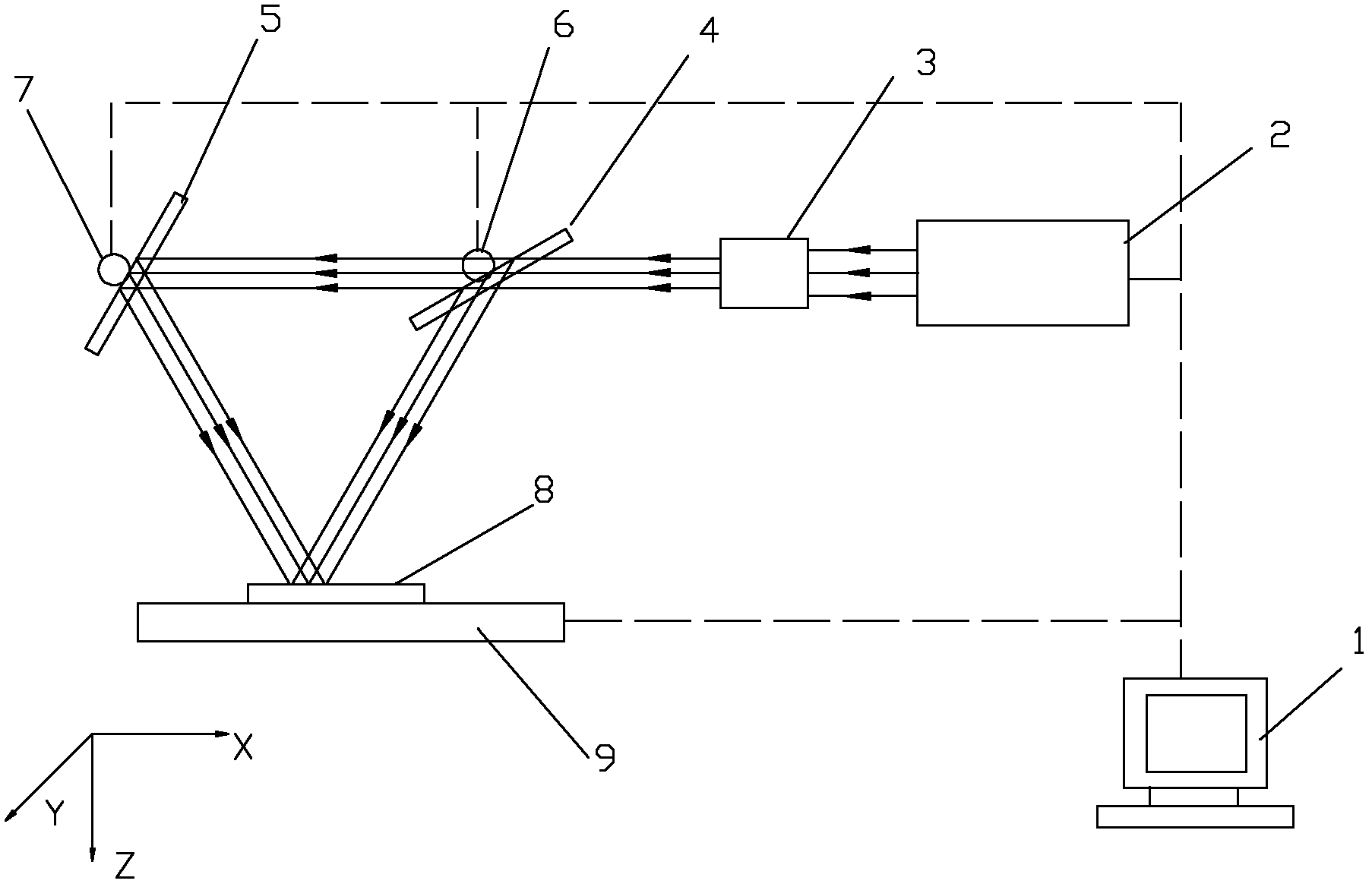

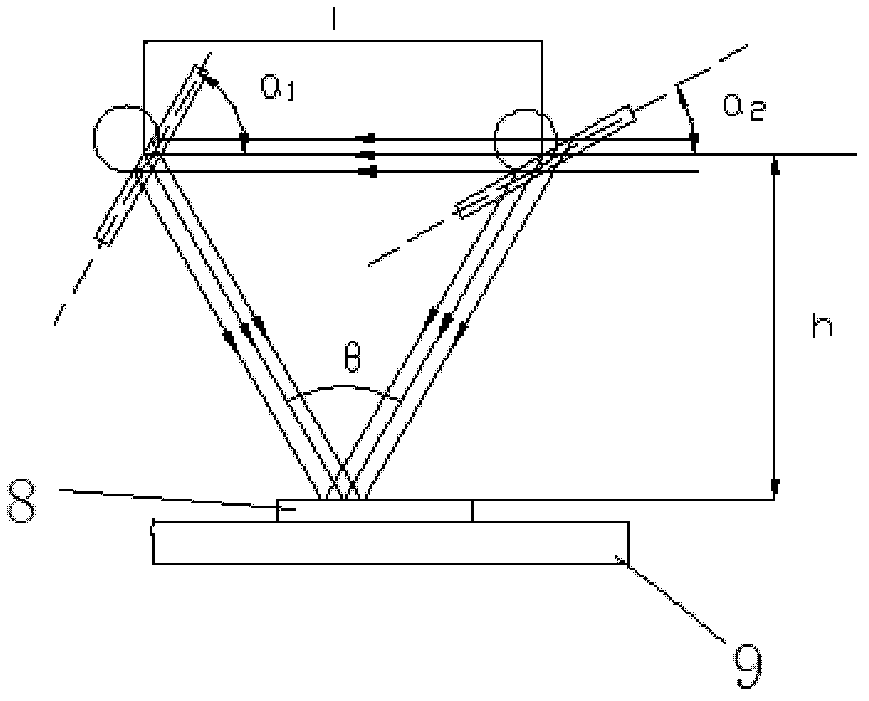

[0019] Such as figure 1 As mentioned above, the surface microstructure forming system based on coherent laser in the present invention includes a laser generator 2, a beam shaping module 3, a first half reflection mirror 4, and a second total reflection mirror 5 arranged in sequence on the optical path, and the first half reflection mirror 4 and the second total reflection mirror 5 are provided with an electric control mobile workbench 9, which is used to place the substrate 8, and the first half reflection mirror 4 and the second total reflection mirror 5 are provided with servo motors 6, 7, the electric control mobile workbench 9, the servo motors 6, 7 and the laser generator 2 are connected with the computer 1. The servo motors 6 and 7 are digital control servo motors.

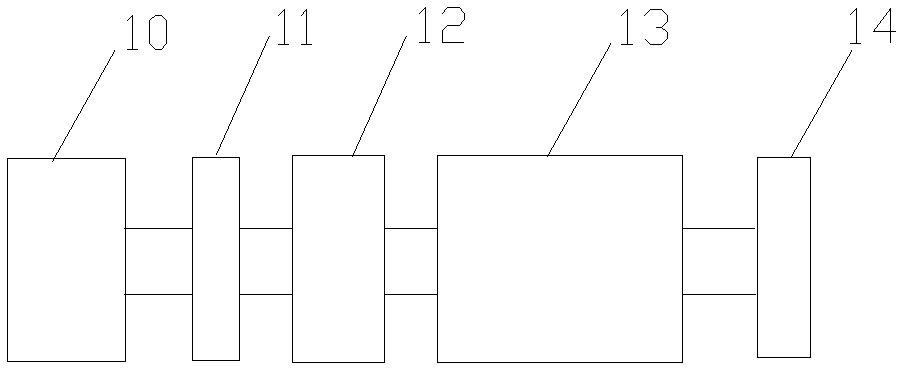

[0020] Such as figure 2 As shown, the laser generator 2 includes a beam expander mirror 10 , a partial reflection mirror 11 , a Q-switch 12 , a condenser cavity 13 , and a total reflection mirror 14 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com