Semiconductor device and method for fabricating same

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of high manufacturing cost and slow coating rate of epoxy resin layer, and achieve improved thickness uniformity, high production rate, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Examples of the present invention are described below. The purpose of this description is to provide a general concept of the present invention and not to limit the scope of the present invention. The protection scope of the present invention should be determined by the claims.

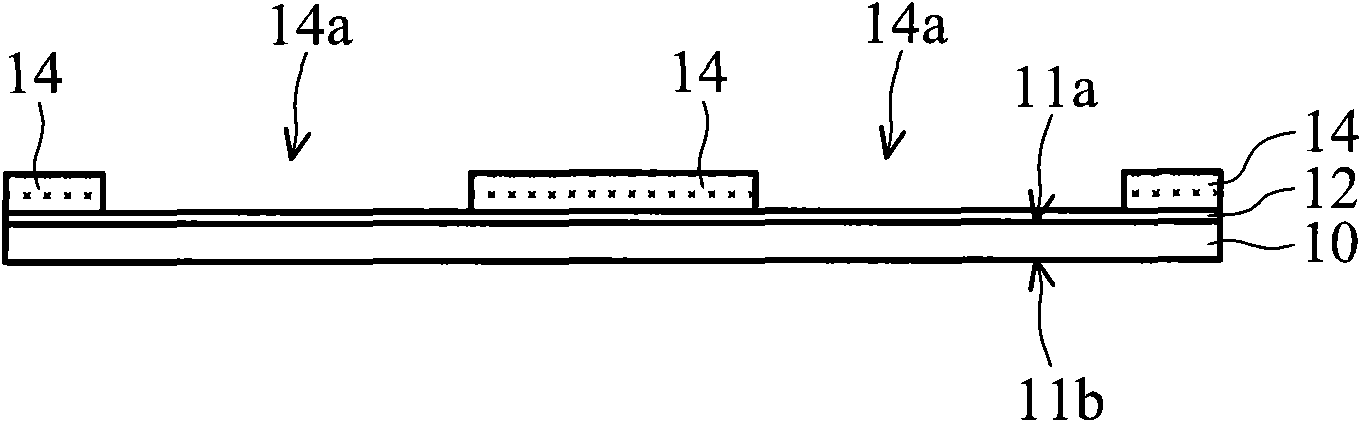

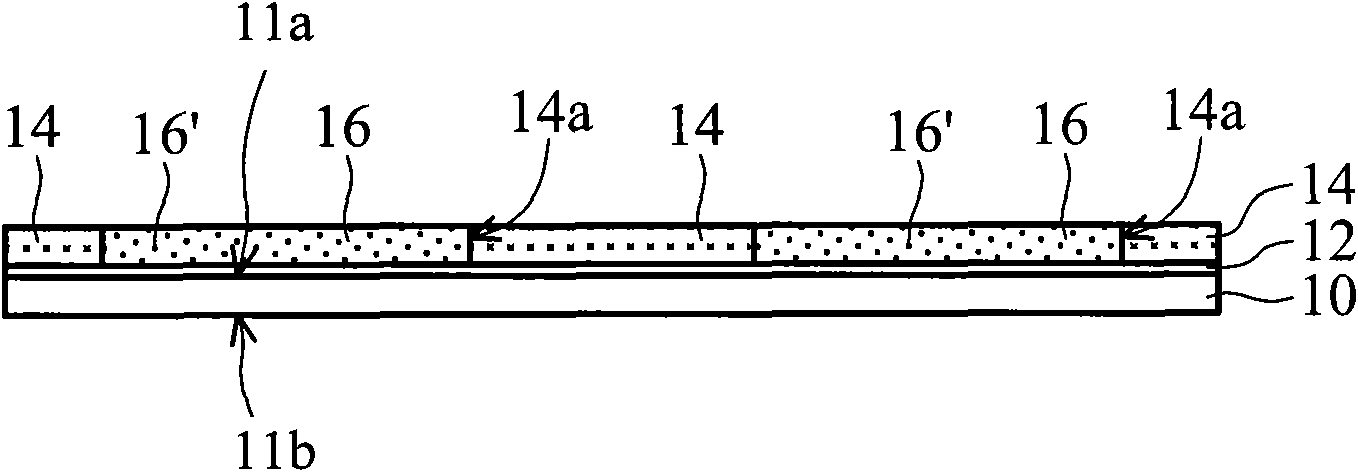

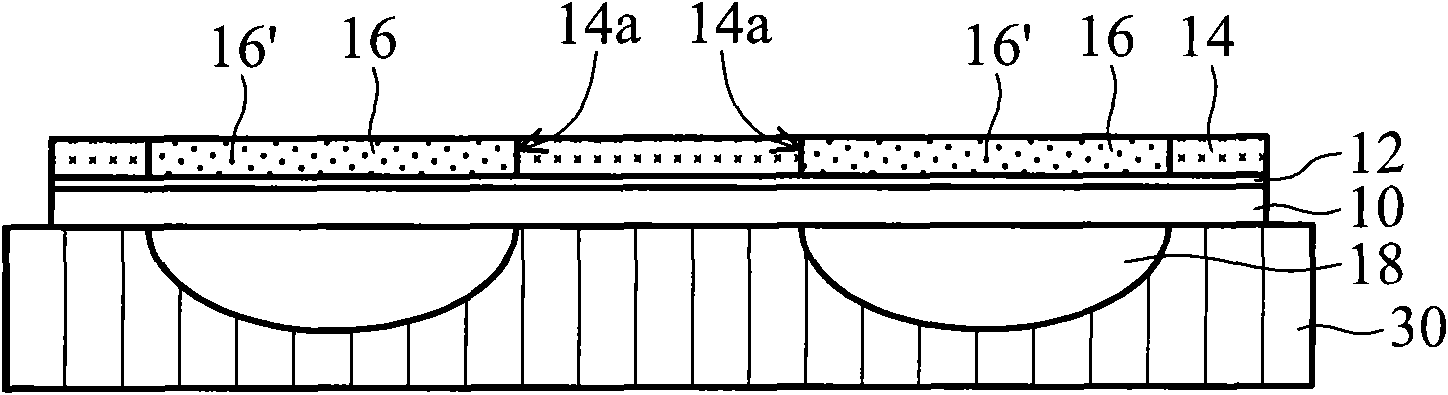

[0019] Figure 2D , 3D , 4D respectively show the cross-sectional schematic diagrams of LED devices according to different embodiments of the present invention, wherein Figure 3D and 4D and Figure 2D The same parts are used in , and the relevant descriptions are omitted. Please refer to Figure 2D , the LED device includes a semiconductor substrate 200, such as a silicon substrate or other known semiconductor substrates, which has a cavity 100a. The semiconductor substrate 200 may include various components such as transistors, resistors and other known semiconductor components. In order to simplify the drawings, individual components are not shown here.

[0020] At least two separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com