Patents

Literature

65results about How to "Realize simultaneous processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing additives by combining selective laser melting and laser cutting

InactiveCN109047762AEliminate cracksEliminate spheroidizationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

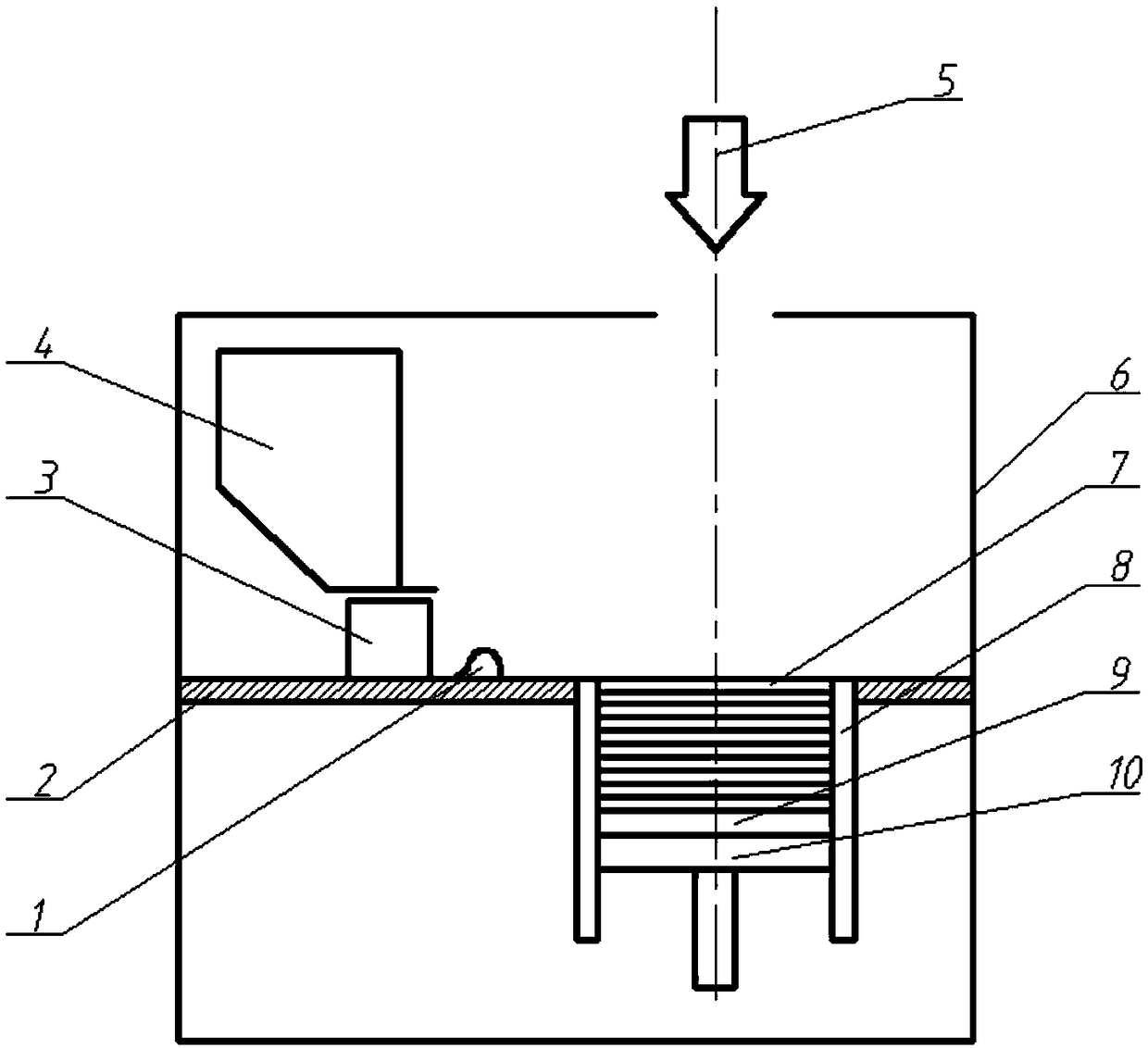

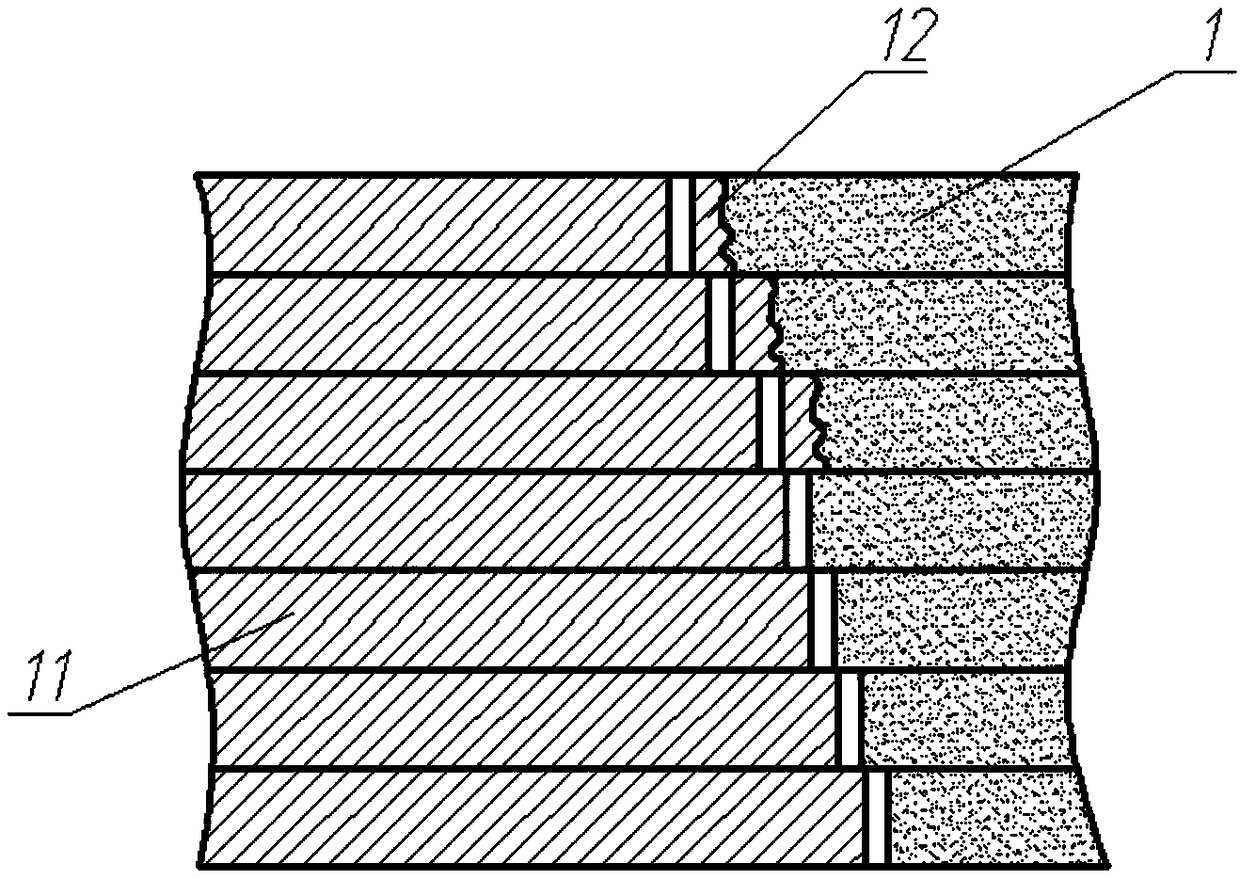

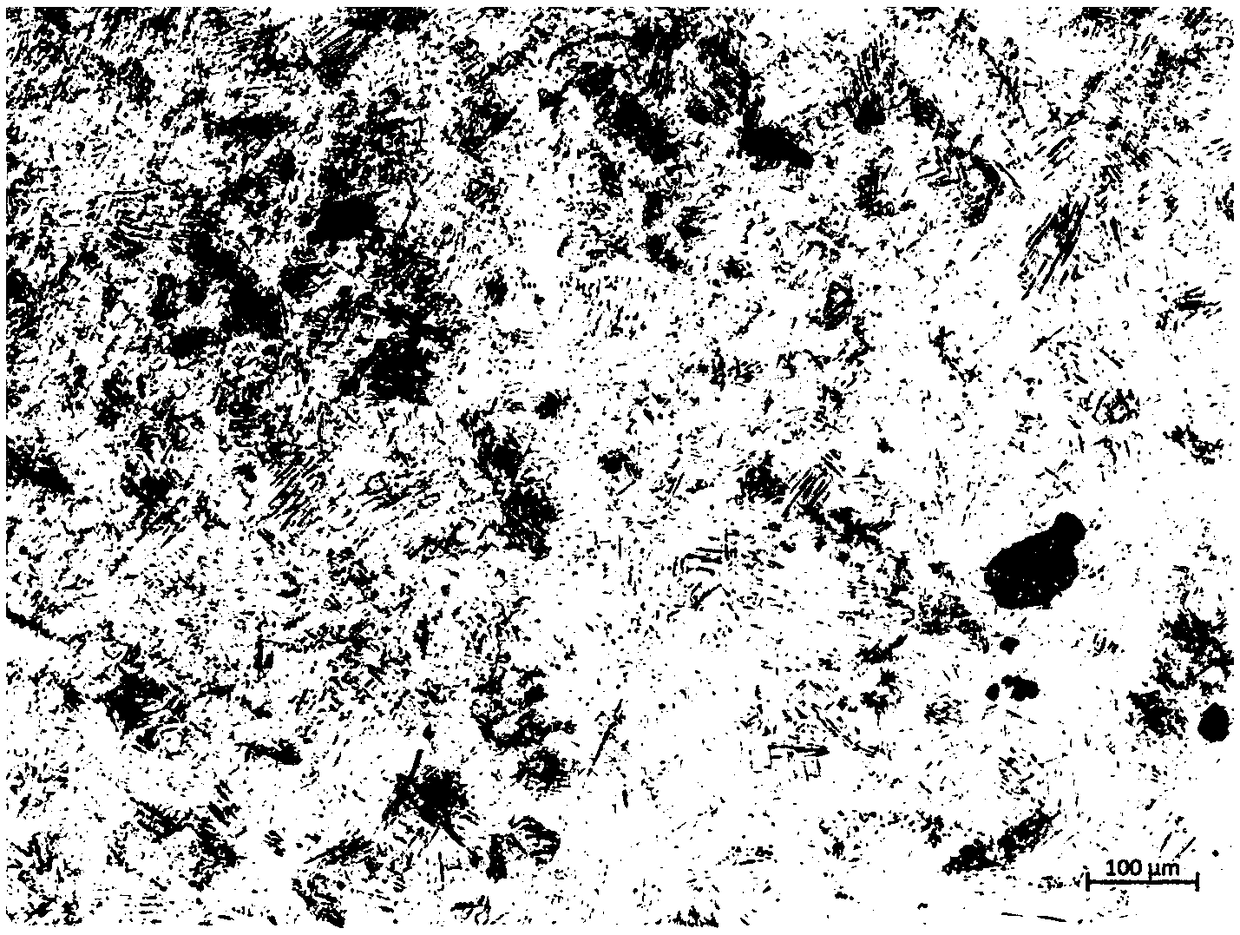

The invention relates to the technical field of additive manufacturing, in particular to a method for manufacturing additives by combining selective laser melting and laser cutting. The method for manufacturing additives by combining selective laser melting and laser cutting comprises the following steps that (1) the surface of a substrate is cleaned with an alkaline solution to remove oil stains,then an oxide film on the surface of the substrate is polished and removed, and the surface of the substrate is wiped with acetone; (2) firstly, a laser beam in a heating mode is emitted to scan andpreheat a powder bed, so that a powder material is heated to a micro-sintering temperature to generate micro-sintering; (3) then a laser beam in a selective melting mode is emitted to scan and melt the preheated powder bed to form a required workpiece cross-sectional layer; (4) finally a laser beam in a laser cutting mode is emitted to perform one or more times of cutting scan on the inner and outer contours of the workpiece cross-section to remove or cut rough edges and welding powder on the contours so as to obtain accurate and smooth inner and outer contours of the part cross-section; and (5) the heating, selective melting and cutting processes are repeated to finally obtain a required three-dimensional solid workpiece.

Owner:JIANGSU UNIV

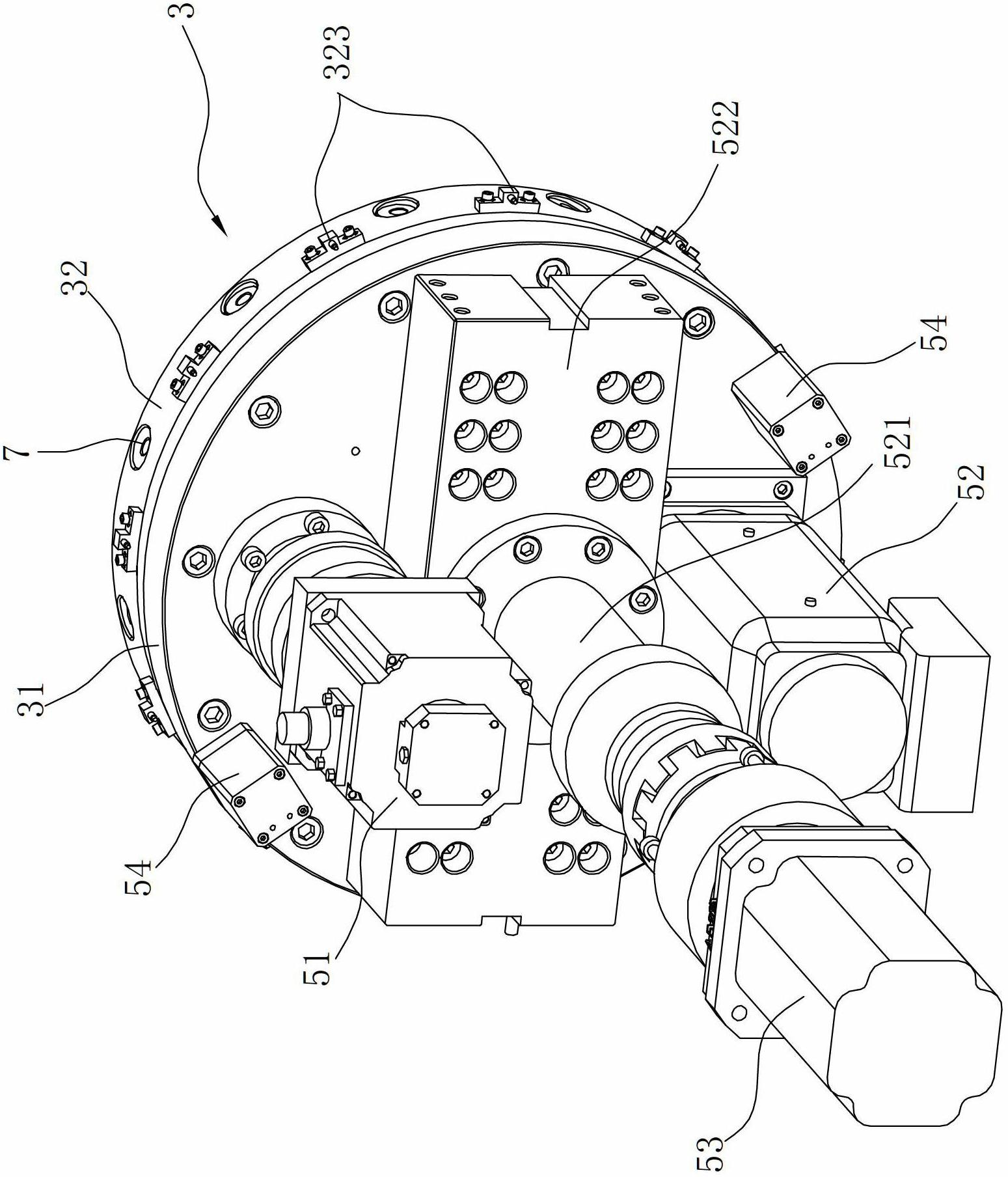

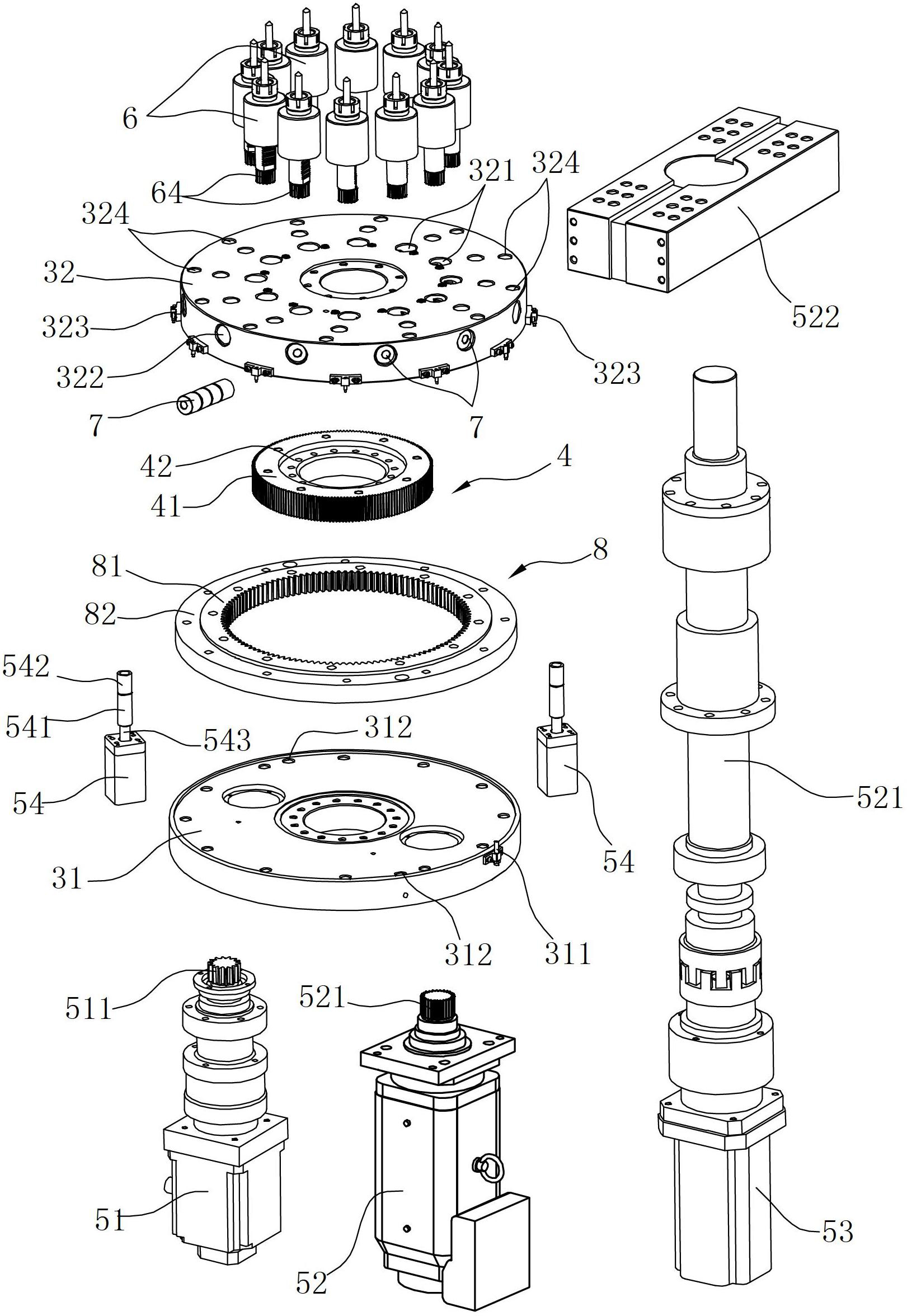

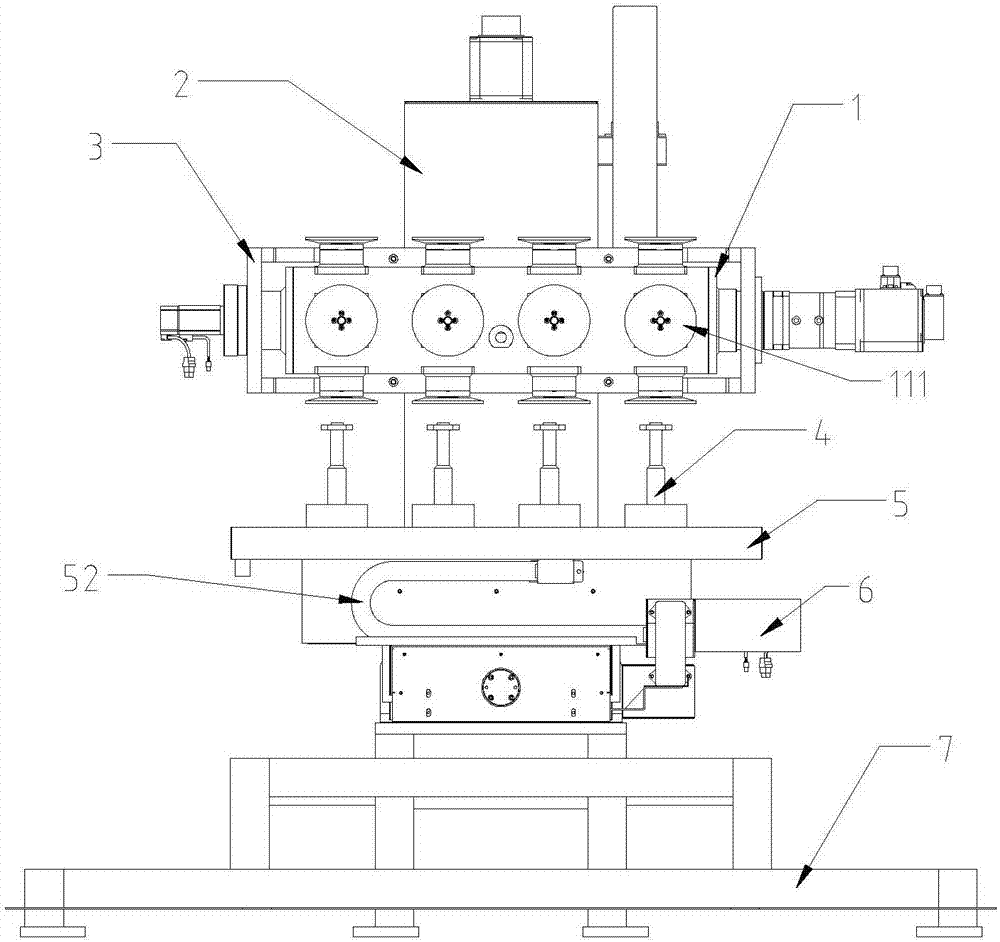

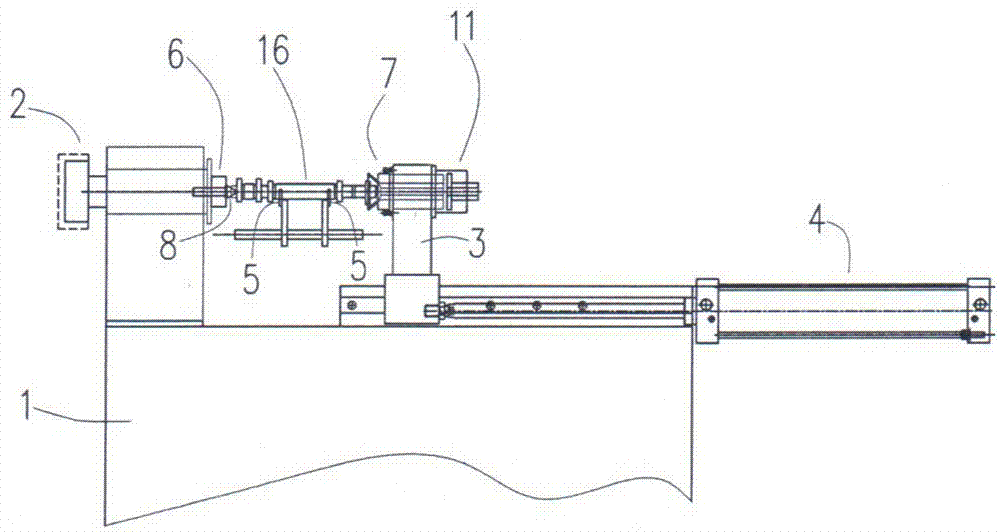

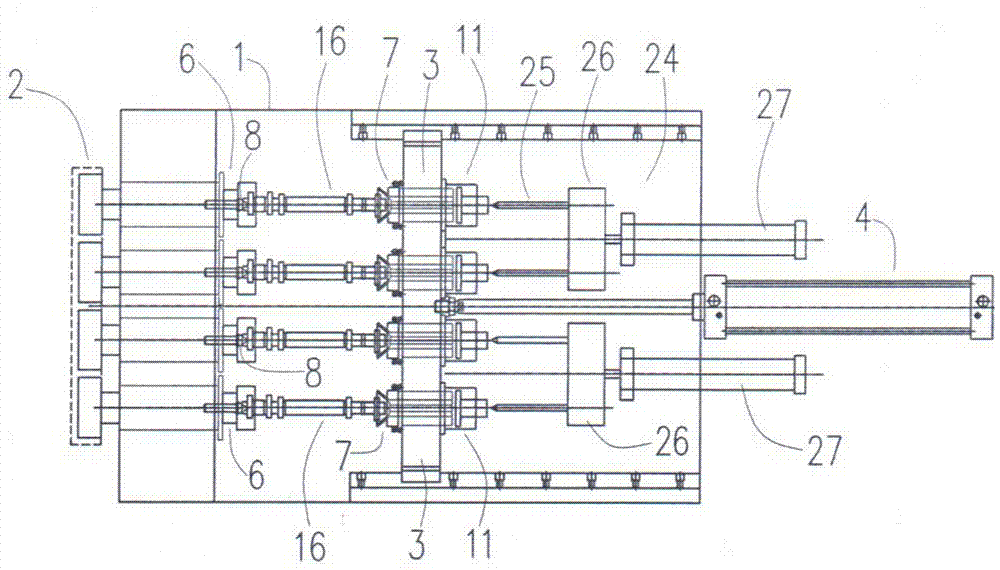

Multi-station pipe end machining equipment

ActiveCN102689235AEasy loading and unloadingReduce replacement timeTool holdersDriving apparatusPipe fittingEngineering

Owner:ZHEJIANG MOTORBACS TECH

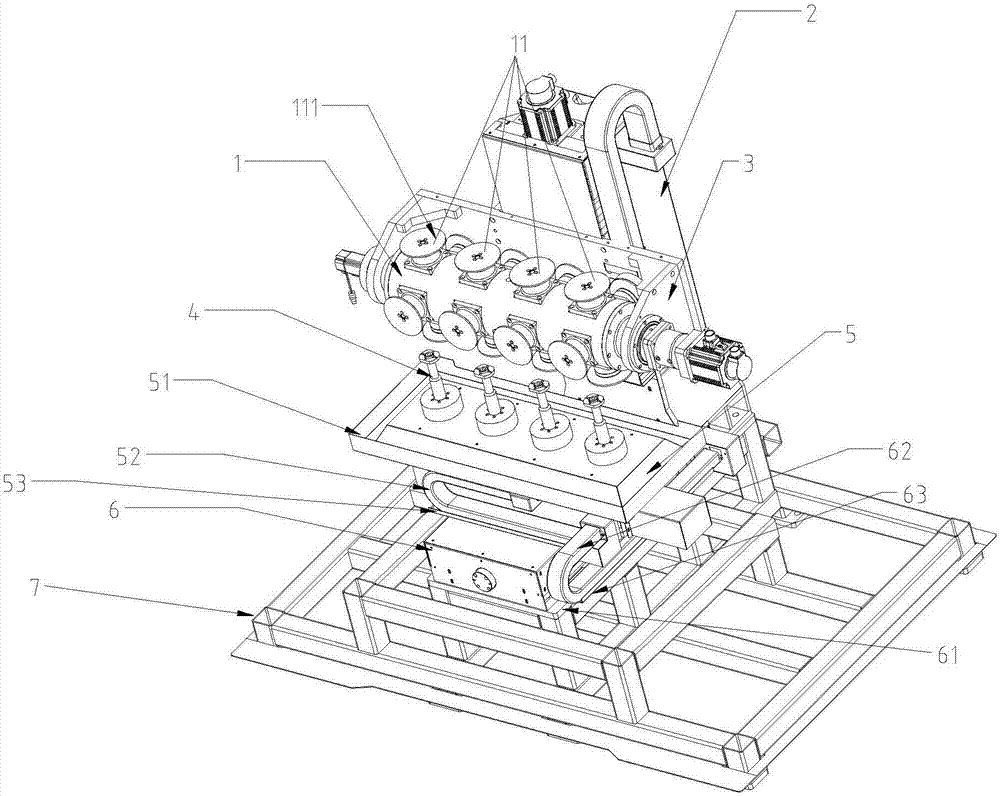

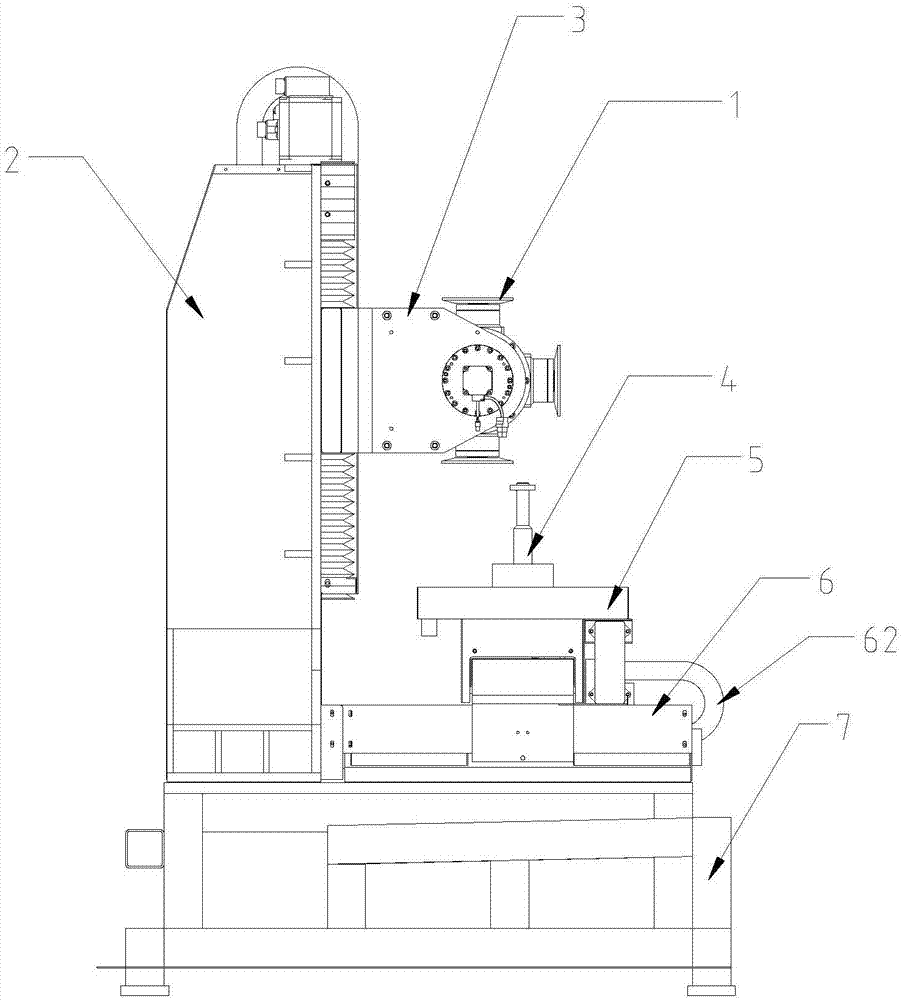

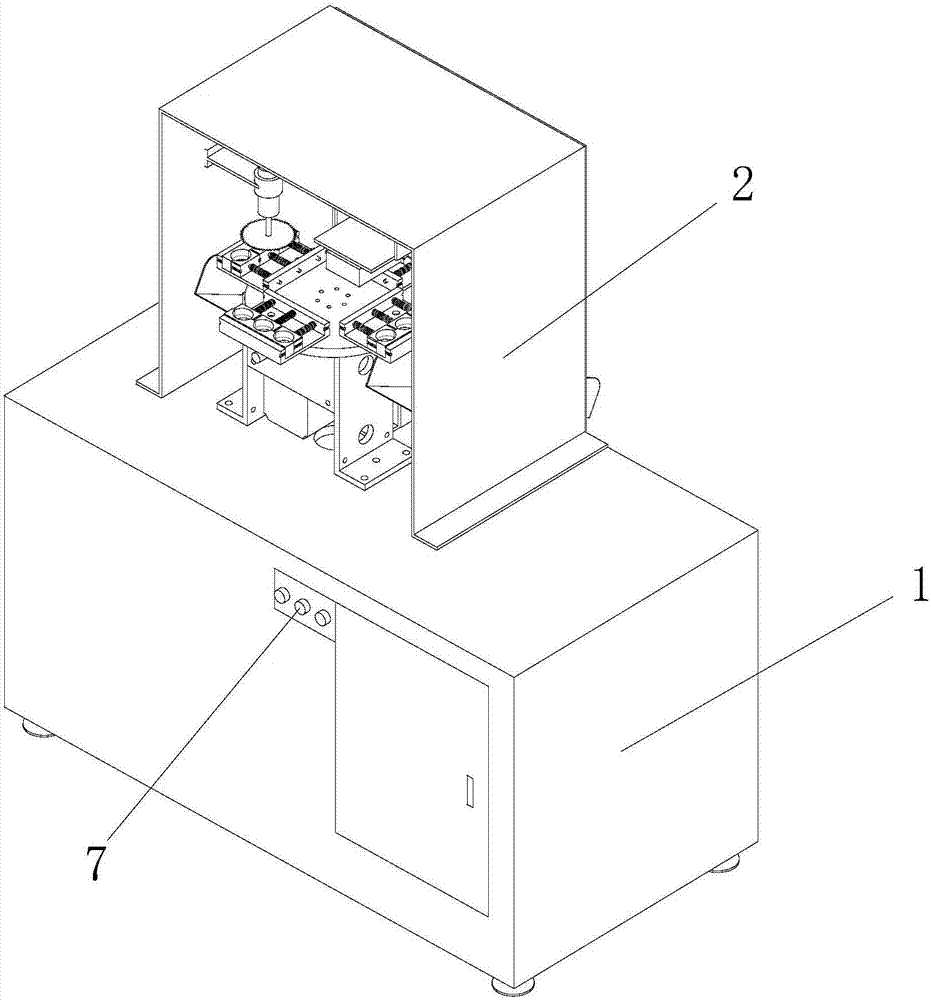

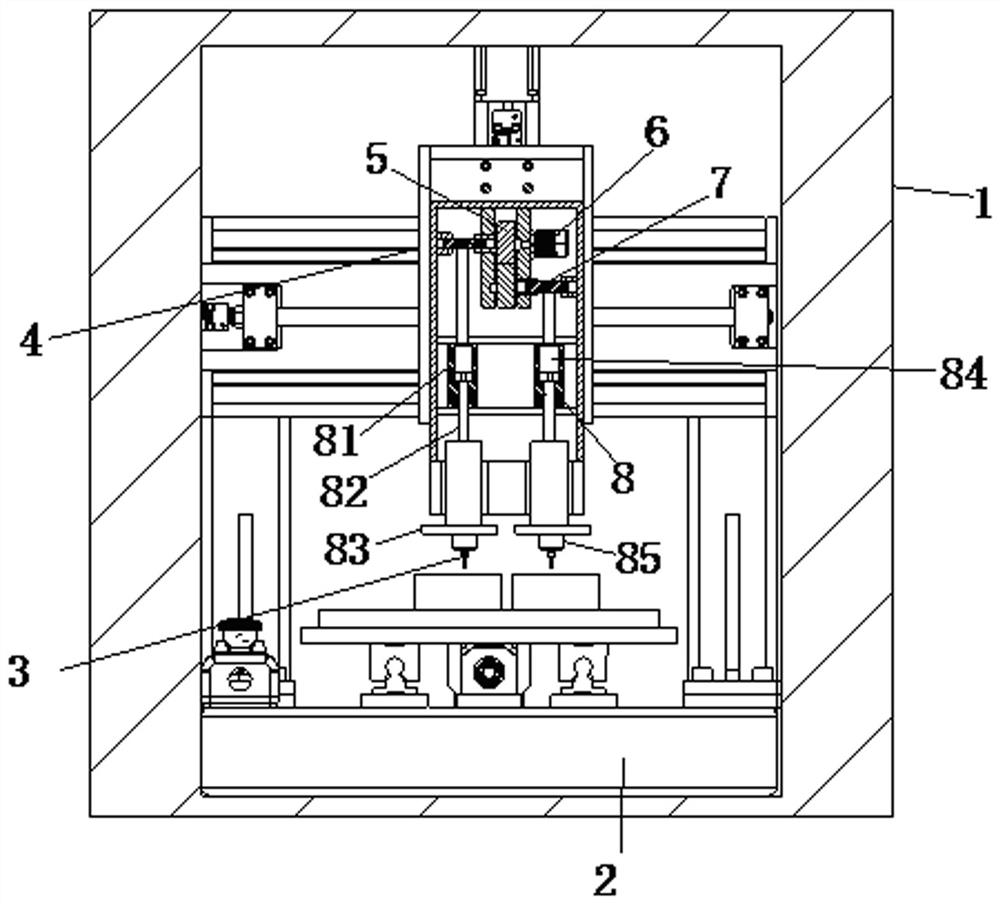

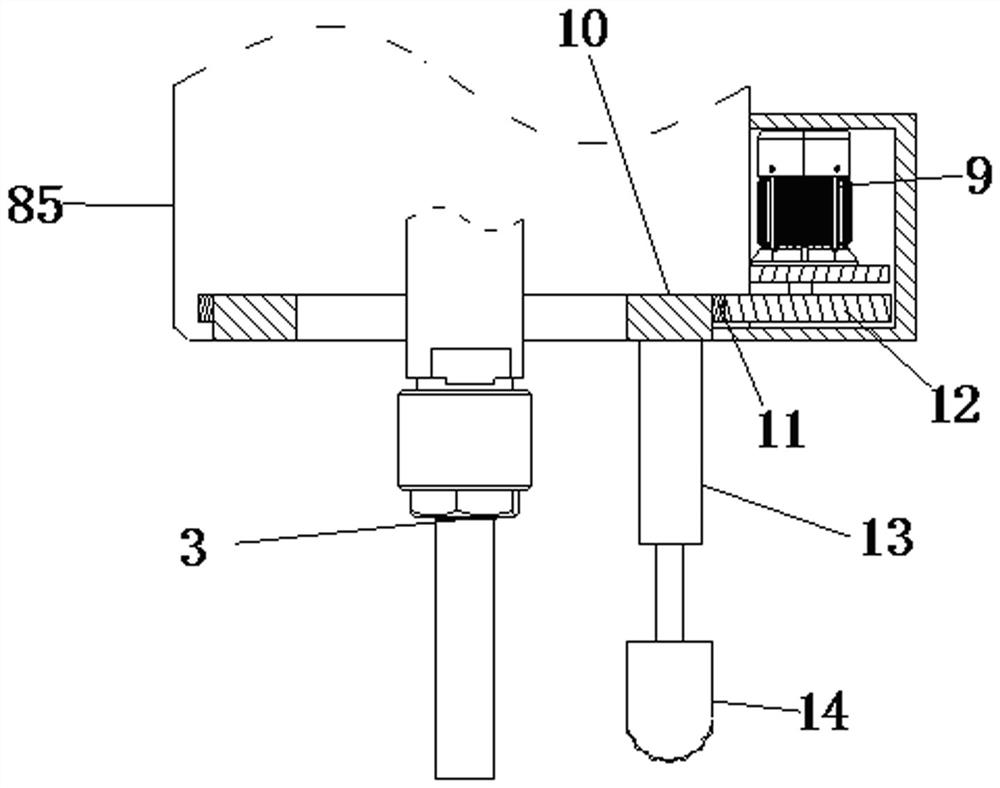

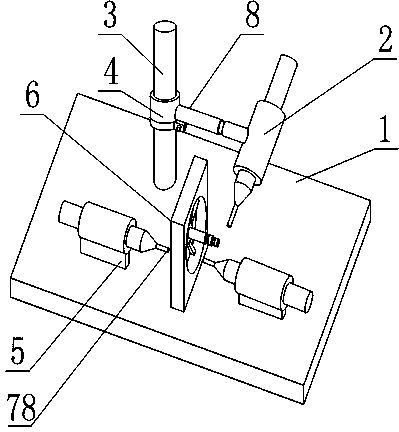

All-directional automatic polishing machine and polishing method

PendingCN107097131AAchieve rotationRealize simultaneous processingGrinding carriagesGrinding drivesMechanical engineering

The invention discloses an all-directional automatic polishing machine and a polishing method. The polishing machine comprises a polishing frame, a lifting mechanism, a grinding disc power mechanism, a tool mechanism and a translation mechanism; the tool mechanism is arranged on the translation mechanism; the translation mechanism is arranged on the polishing frame; the bottom of the lifting mechanism is connected to the polishing frame; the translation mechanism comprises an X-axle slide table mechanism and a Y-axle slide table mechanism; the grinding disc power mechanism is connected to the side surface of the lifting mechanism through a support frame; the grinding disc power mechanism comprises a grinding disc group, a grinding disc fixing module and a transmission module; the grinding disc group is assembled on a grinding disc bearing base; the grinding disc group consists of multiple grinding disc sets; and the grinding disc sets consist of multiple unit grinding discs. Multiple grinding disc sets with different specifications are provided; rotating angles of grinding disc fixed pipes are adjusted; the grinding disc sets are used for polishing bent surfaces of workpieces; and the all-directional polishing of the surfaces of the workpieces by multiple grades of precision through the grinding disc sets with different specifications is achieved.

Owner:广东遂联智能装备制造有限公司

On-line preparation method of line electrode of minuteness group lines

ActiveCN103521864AEasy to installEasy to disassembleElectrical-based machining electrodesElectrolytic agentWire cutting

The invention discloses an on-line preparation method of a line electrode of minuteness group lines, and belongs to the field of precise minuteness electrochemical machining. The on-line preparation method of the line electrode of minuteness group lines is characterized in that the following steps are included: (1) a micron-order tungsten filament is mounted on a clamp of the line electrode of the minuteness group lines, a cathode tool is mounted in an electrolytic cell, and the cathode tool is provide with a cathode hole corresponding to a wire electrode, and is of a sandwich butt joint structure formed by a metal layer and insulating layers on the two sides of the metal layer; (2) an alkaline electrolyte is added into the electrolytic cell to immerse the cathode tool completely; (3) a tool cathode and the line electrode are connected to the positive electrode and the negative electrode of a direct current power source respectively to achieve the enlargement of the diameter of the cathode hole of the metal layer in the tool cathode to form an inward concave structure; (4) the line electrode of the minuteness group lines and the tool cathode are connected to the positive electrode and the negative electrode of the direct current power source respectively, and the line electrode is made to carry out straight reciprocating motion; (5) the electrolyte is replaced by an acid electrolyte, the tool cathode is replaced by workpieces, the line electrode of the minuteness group lines and the workpieces are made to be connected with the positive electrode and the negative electrode of an ultrahigh-frequency narrow-pulse power source to achieve minuteness electrolytic wire-electrode cutting machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

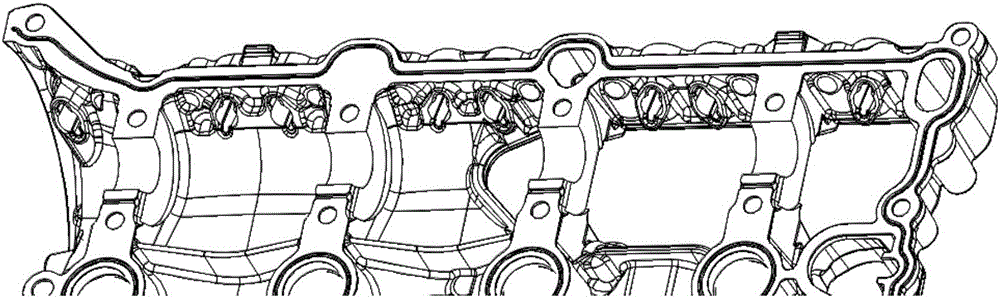

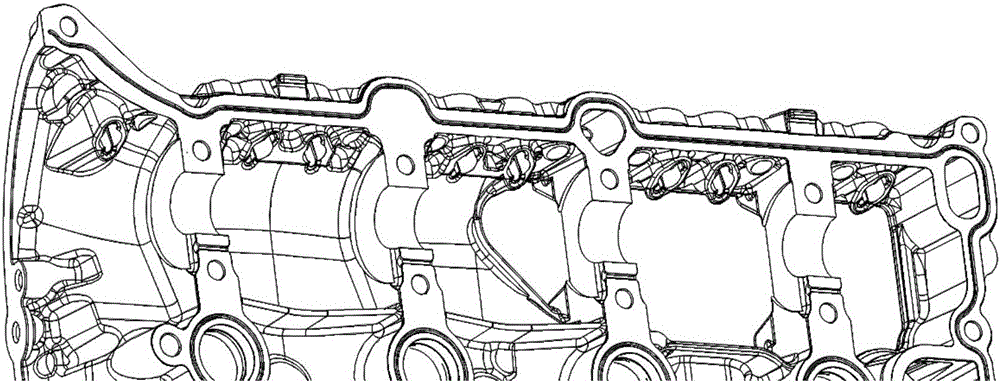

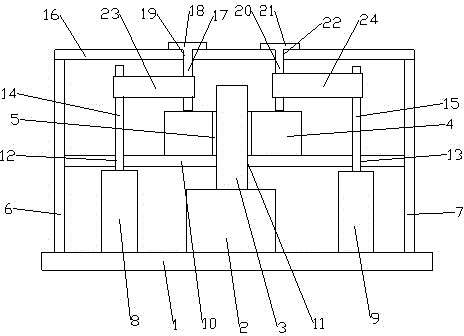

Device for machining multiple surfaces of part

PendingCN106378477ARealize simultaneous processingIncrease productivityMilling equipment detailsDriving apparatusMilling cutterMachine tool

The invention provides a device for machining multiple surfaces of a part. The device comprises a combination type cutter and a part fixing clamp, wherein the combination type cutter is mounted on a machine tool, and the part fixing clamp is mounted on the table surface of the machine tool. When the combination type cutter is fed, a milling cutter disc (124) and a cutter handle shaft (110) are inserted into a hollowed opening (48) of the clamp. The device provided by the invention has the advantages that the simultaneous machining of a plurality of parallel machining surfaces is realized, the machining precision is high, and the device is suitable for parts with complicated shapes.

Owner:CITIC DICASTAL

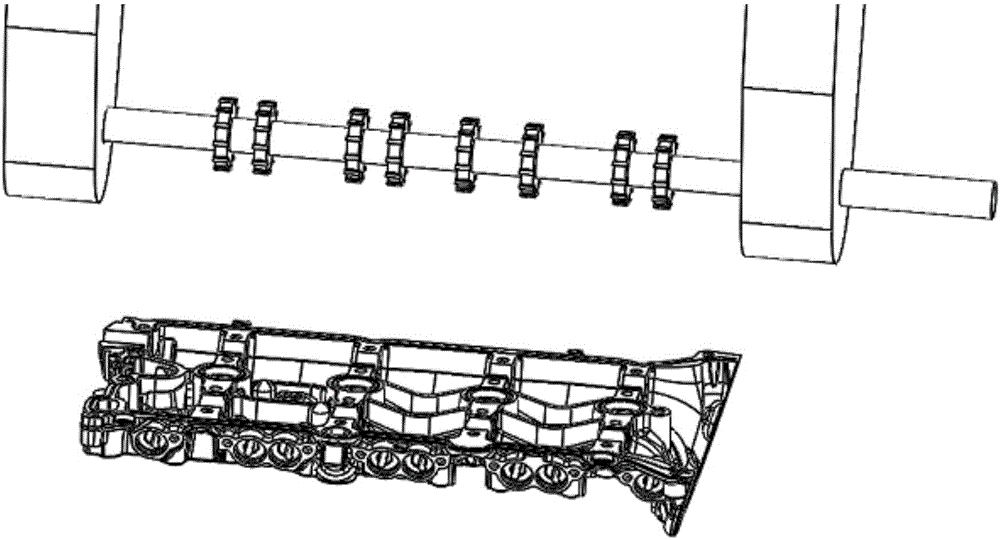

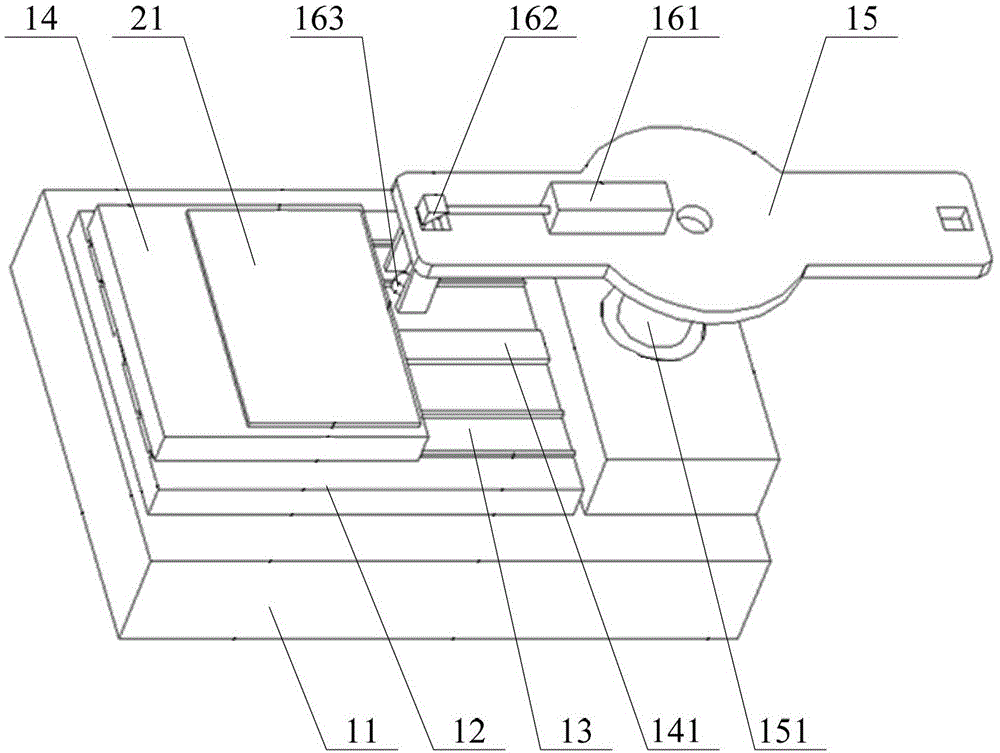

Clamping mechanism capable of synchronously machining axial holes of multiple shaft parts

PendingCN107350846AIncrease productivityCool down in timePositioning apparatusMetal-working holdersBatch productionDrill bit

The invention discloses a clamping mechanism capable of synchronously machining axial holes of multiple shaft parts. The clamping mechanism comprises a base; a motor, a first sliding seat, a first air cylinder and a plurality of parallel working units are arranged on the base; each working unit comprises a pair of V-shaped locating blocks, a front center mechanism and a counter center mechanism; the front center mechanisms are provided with rotatable center bodies; each counter center mechanism comprises a seat sleeve, a counter center body and a second air cylinder; the first air cylinder can drive the counter center bodies to initially push against the shaft parts and to precisely center; and the second air cylinders can adjust the pushing pressure. Matched with a drill mechanism, synchronous drilling can be realized. Synchronous machining on the multiple shaft parts can be realized; by being matched with a control system, automatic production can be realized, and the clamping mechanism is suitable for batch production; and if the structure provided with four working units is adopted, the production efficiency is raised by more than 4-5 times compared with that of a traditional machining method, and the production efficiency is improved significantly.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

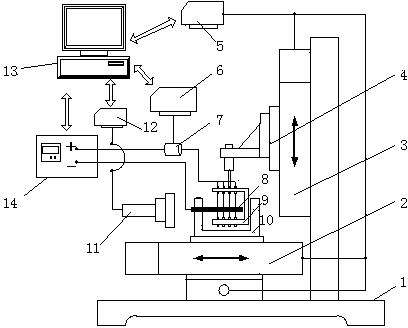

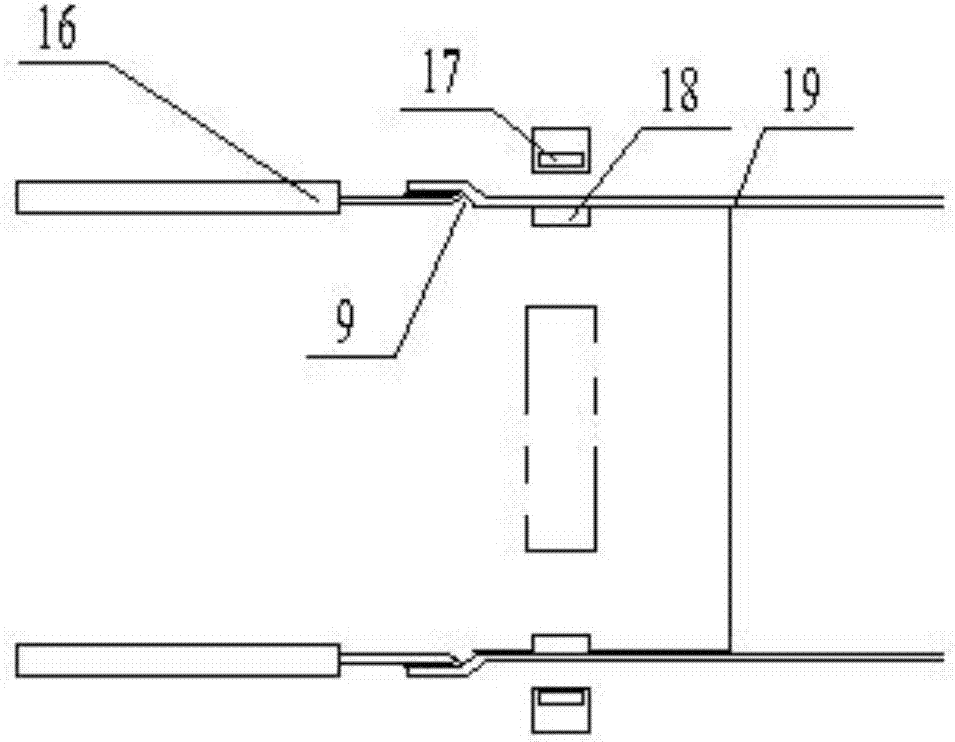

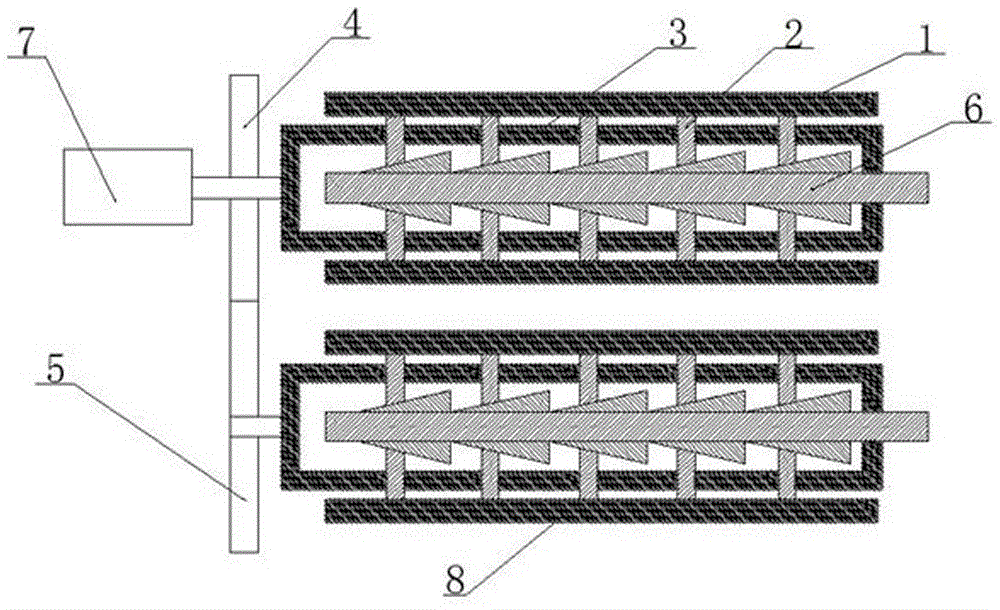

Light guide plate pattern machining equipment

ActiveCN103331522ARealize simultaneous processingImprove processing efficiencyLaser beam welding apparatusLaser transmitterLight guide

The invention discloses light guide plate pattern machining equipment. The top of a rack of the equipment is provided with a supporting plate; a guide rail is arranged on the supporting plate and is movably provided with a movable platform which is matched with a light guide plate; the rack is provided with a first driving device which can drive the movable platform to move along the extension direction of the guide rail; one end of the guide rail is provided with a rotary plate; the rotary plate is provided with a laser emitter; the edge of the upper surface of the rotary plate is provided with an optical reflector which is matched with the laser emitter; the optical reflector is positioned on an optical path of the laser emitter; a light collecting lens which is matched with the optical reflector and the light guide plate respectively is arranged below the optical reflector and is positioned on a reflecting optical path of the optical reflector; the rack is provided with a second driving device capable of driving the rotary plate to perform fixed-axis rotation; and the rotary plane of the rotary plate is parallel to the upper surface of the movable platform. The light guide plate pattern machining equipment has higher machining accuracy and machining efficiency.

Owner:SUZHOU DONGSHAN PRECISION MANUFACTURING CO LTD

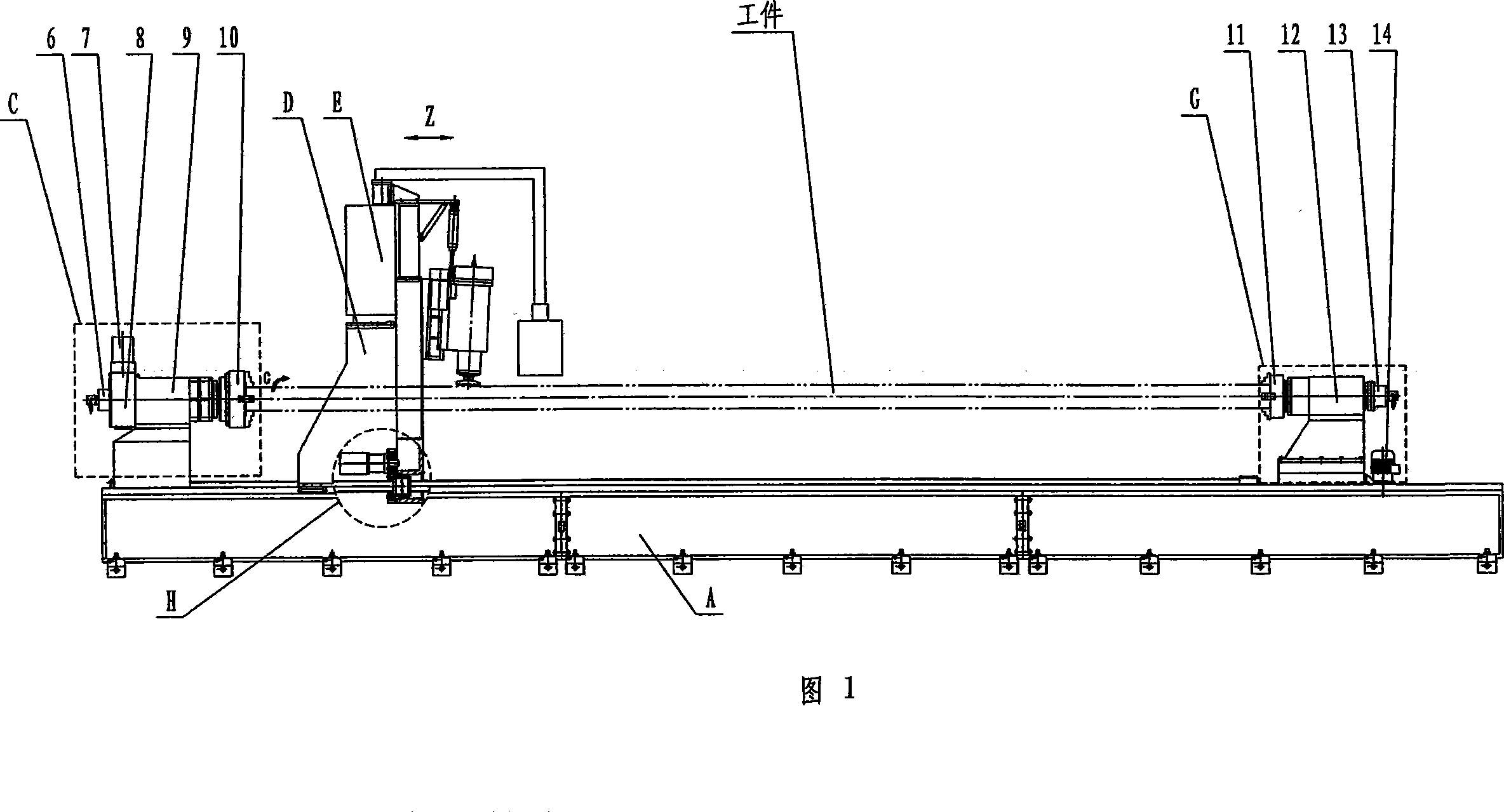

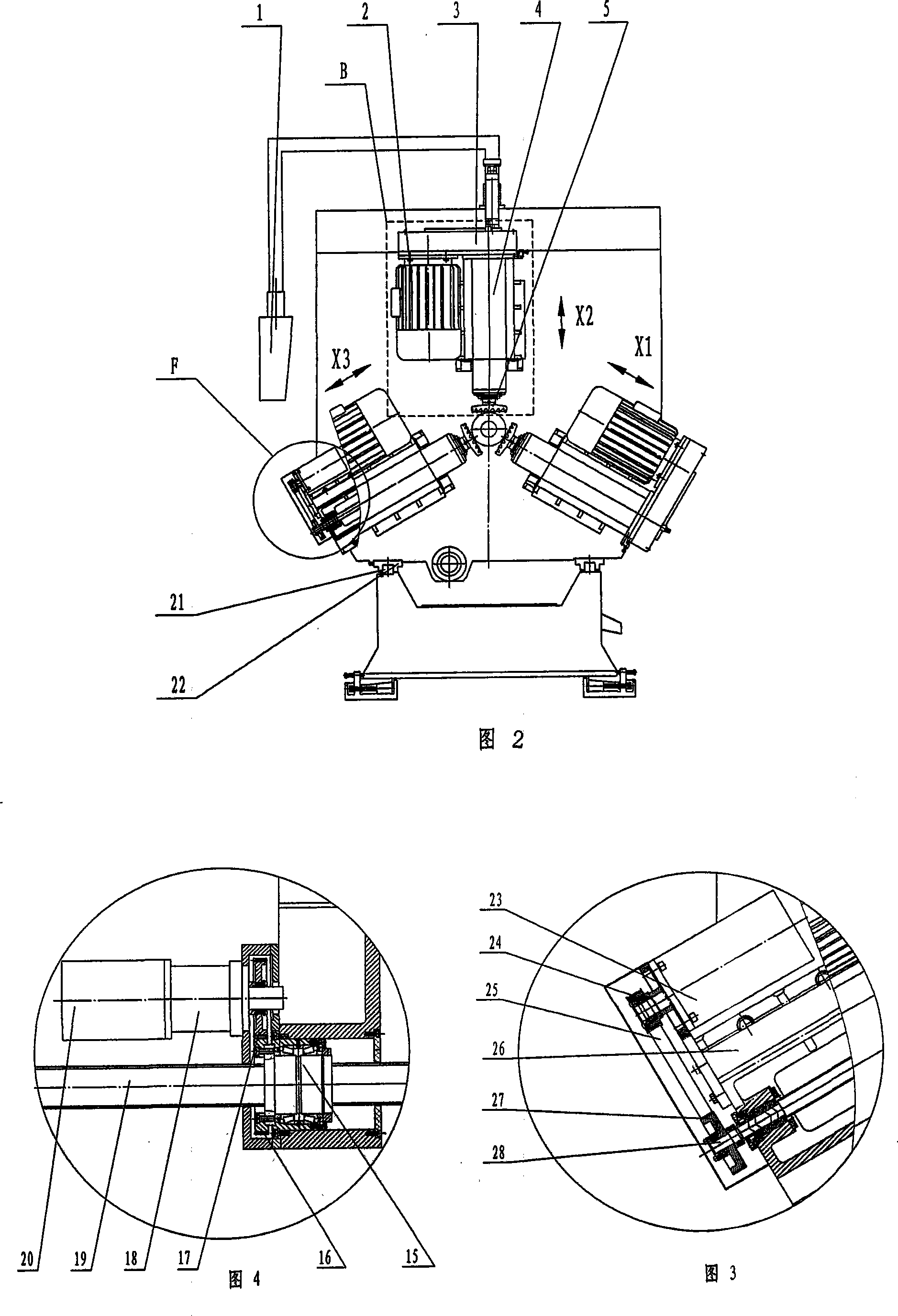

Three-head helix milling machine

InactiveCN101134248ARealize simultaneous processingImprove work efficiencyTailstocks/centresLarge fixed membersMilling cutterElectric machinery

The present invention discloses one kind of triple-thread screw miller, which includes one Z-direction skid platform capable of sliding in Z direction under the drive of the Z-direction drive unit; three milling heads with milling cutter on the Z-direction skid platform and capable of sliding separately in X1, X2 and X3 directions under the drive of the motor; one rotating spindle holding the workpiece; and one tail stock supporting the tail end of the workpiece and rotating with the spindle. The triple-thread screw miller machines the three spiral grooves of triple-thread screw rod or pipe simultaneously and has the advantages of high work efficiency, suitability to batch production, high machining quality and improved production environment.

Owner:NANJING CNC MACHINE TOOL

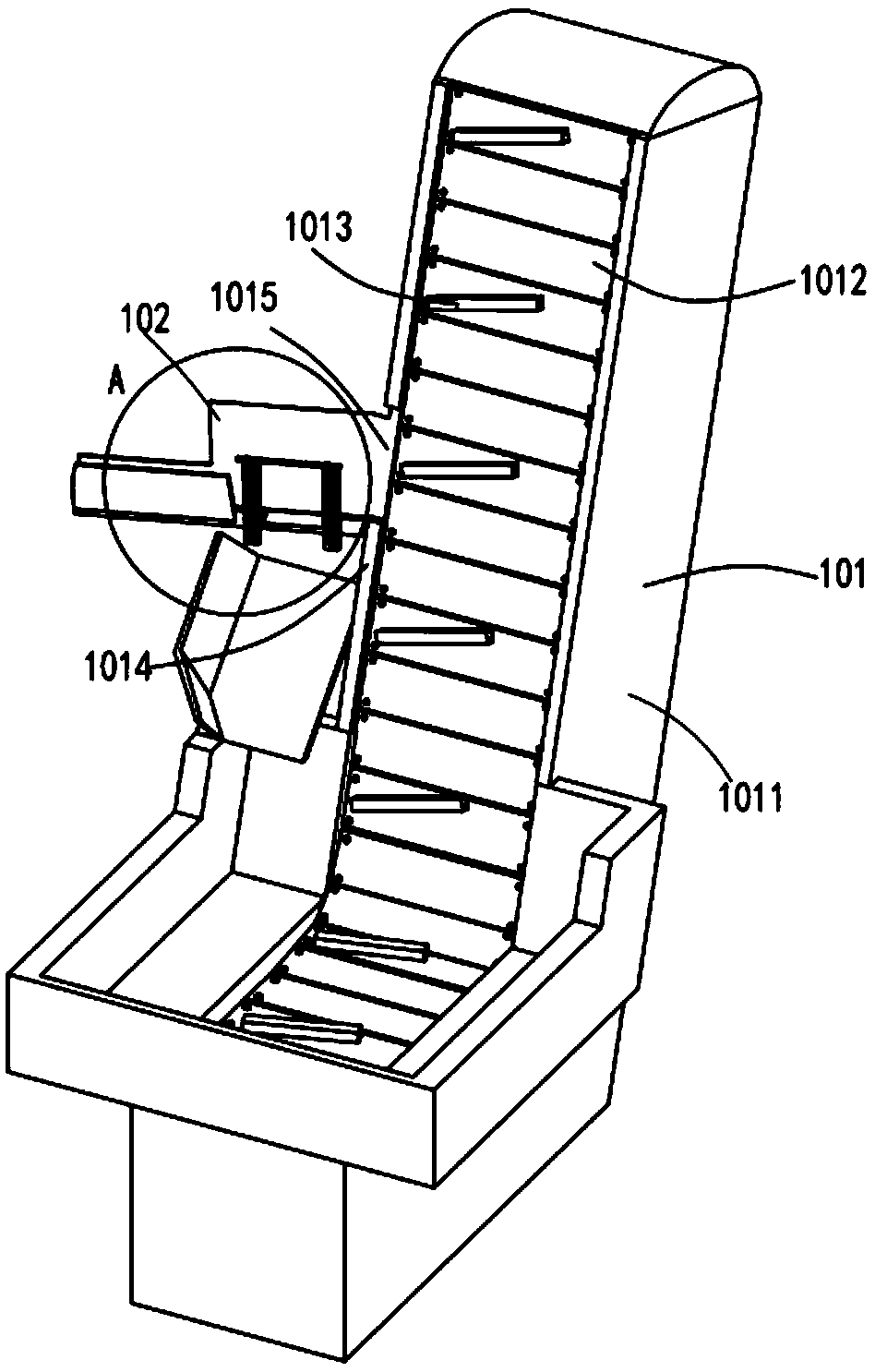

Multi-stage processing, coring and peeling machine with flexible feeding mechanism

ActiveCN107319591ASimple structureEasy to operateClimate change adaptationFruit stoningCircular discEngineering

The invention discloses a multi-stage processing, coring and peeling machine with a flexible feeding mechanism. The machine comprises a box body, a gantry, the flexible feeding mechanism, a controller, a pre-cutting mechanism, a coring and peeling mechanism and a waste-material removing mechanism, wherein the gantry and the flexible feeding mechanism are arranged on the box body, and the pre-cutting mechanism, the coring and peeling mechanism and the waste-material removing mechanism are installed on the gantry. Firstly, fruits are put into flexible locating holes in a disc manually, then, the multi-stage flexible feeding mechanism carries the three fruits to turn to a pre-cutting station, and round blades cut the pedicels of the fruits off; secondly, an intermittent cutting machine drives a rotating disc to turn to a coring and peeling position, a coring cutter moves downwards to push fruit cores out, and a peeling cutter moves upwards and cooperates with a shell-flesh separation baffle to extrude fruit flesh out; thirdly, a push plate moves forwards to push the fruit flesh forwards into a fruit flesh box; finally, the multi-stage flexible feeding mechanism turns to a waste-material station, a rolling brush carries fruit shells out of a feeding hole through rotating movement. The multi-stage processing, coring and peeling machine with the flexible feeding mechanism is simple in structure, convenient to operate and good in processing effect, the obtained fruit flesh is good in integrity and low in loss, and the processing efficiency reaches 5-6 times of manual processing efficiency.

Owner:SOUTH CHINA AGRI UNIV

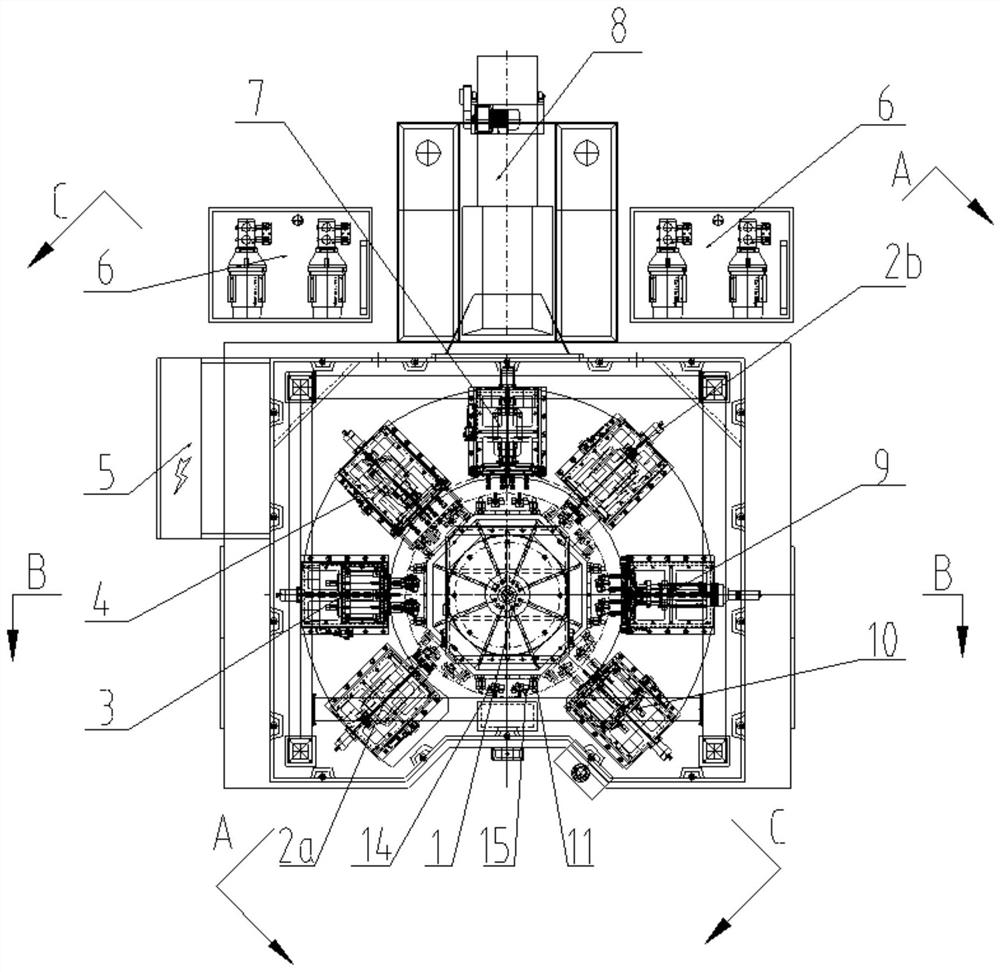

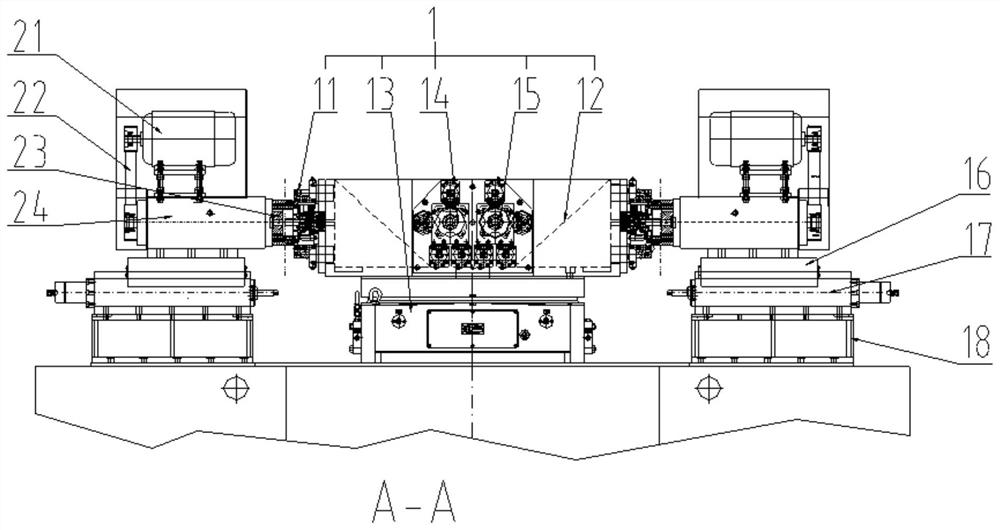

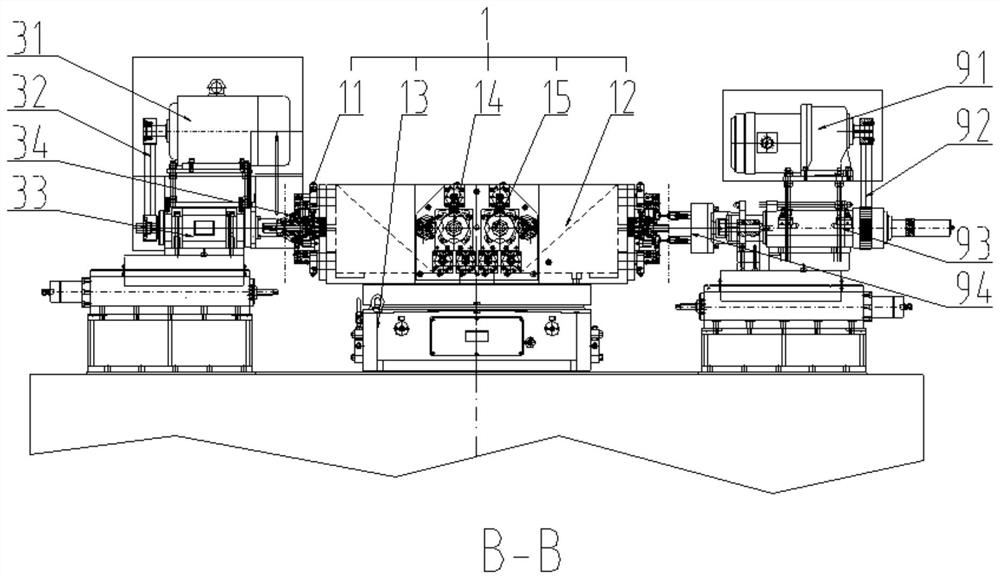

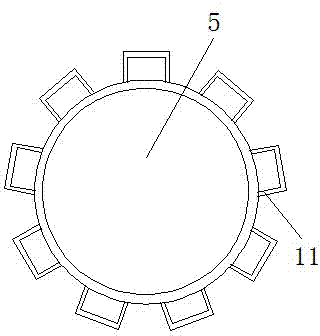

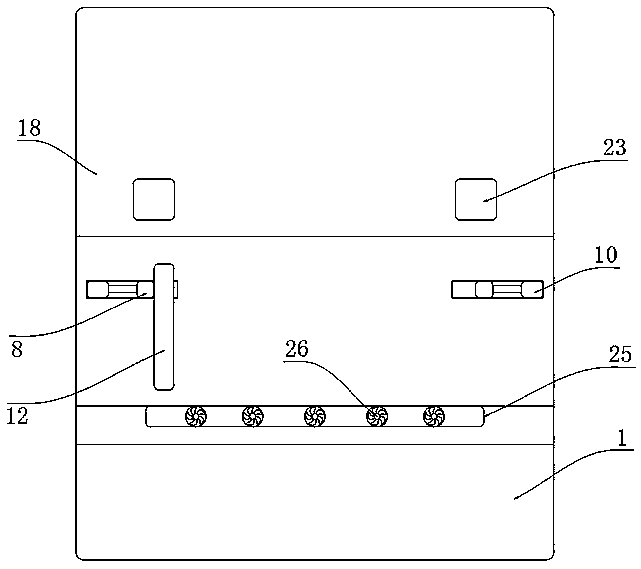

Eight-station crankcase stator combination machining device

PendingCN111673479ARealize multiple quantizationQuality assuranceOther manufacturing equipments/toolsPositioning apparatusCrankcaseControl theory

The invention discloses an eight-station crankcase stator combination machining device. The eight-station crankcase stator combination machining device comprises an eight-station rotating disc mechanism, crankcase stator combination machining mechanisms, moving sliding table mechanisms, a cooling mechanism and a control mechanism. The eight-station rotating disc mechanism comprises a rotating frame and a rotating disc arranged on the rotating frame. The rotating disc is rotationally connected with the rotating frame. Workpiece tools are arranged on the rotating disc in the circumferential direction in an array manner. The workpiece tools are used for fixing workpieces. The crankcase stator combination machining mechanisms are arranged in the circumferential direction of the rotating disc in an array manner. The moving sliding table mechanisms are arranged at the bottoms of the crankcase stator combination machining mechanisms and used for driving the crankcase stator combination machining mechanisms to move in the radial direction of the rotating disc. The cooling mechanism is used for cooling the crankcase stator combination machining mechanisms and the workpieces. By the adoptionof the eight-station crankcase stator combination machining device, simultaneously continuous machining of multiple workpieces and multiple processes can be achieved, and the machining efficiency andprecision are high.

Owner:HUANGSHI HUADAN MACHINE MFG

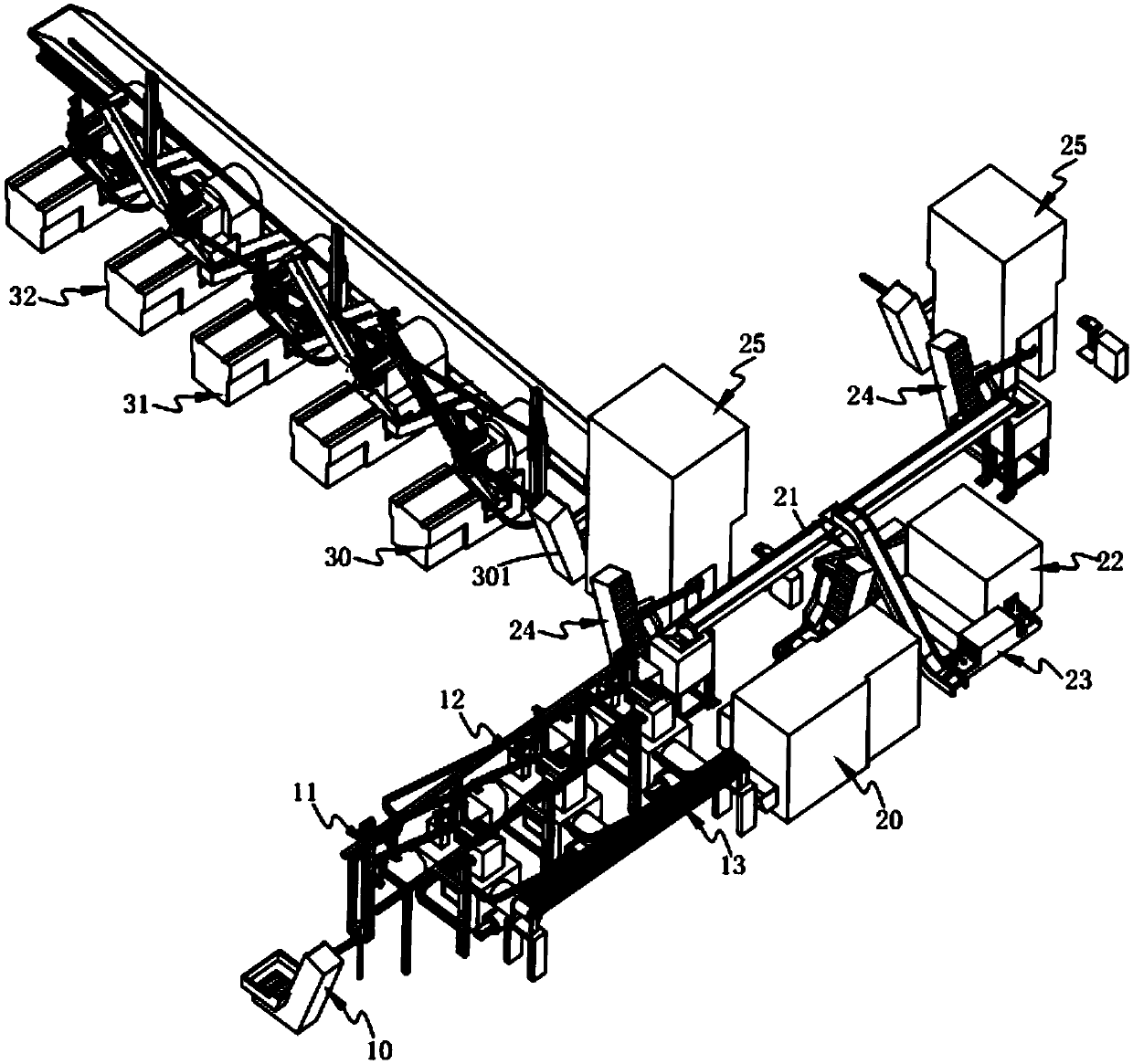

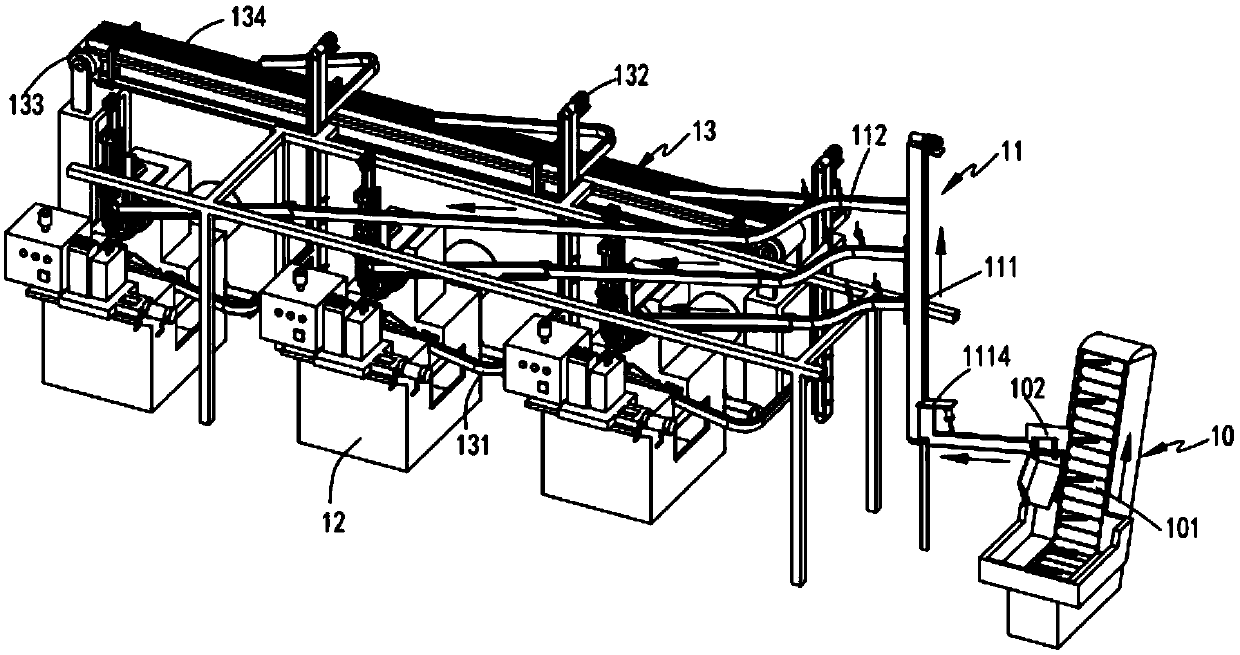

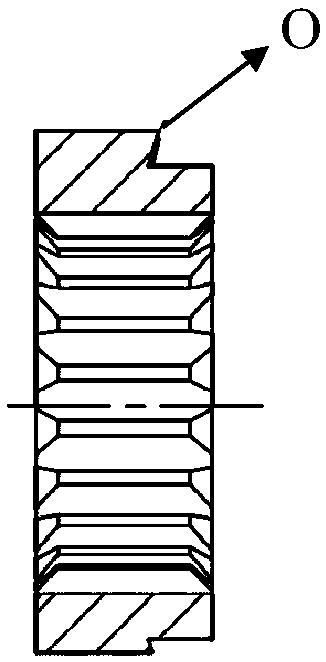

Bearing full-automatic production assembly line and technology

ActiveCN108673069ASolve the technical problems of fully automatic off-line processingAvoid cumbersomeMetal working apparatusAssembly lineMachining system

The invention provides a bearing full-automatic production assembly line and technology. The bearing full-automatic production assembly line comprises a rough machining system, a cold forging system and a finish machining system. The rough machining system, the cold forging system and the finish machining system are subjected to automatic line connection, thus annular blanks are automatically fedand machined, stations are automatically transferred, and rough turning machining, shot blasting machining, phosphorus saponification machining, cold forging machining, slitting machining and finish turning machining of bearing inner and outer sleeve rings are completed sequentially; and the technical problem of full-automatic loss line machining of inner and outer bearing sleeve ring machining equipment is solved, single machining equipment is subjected to automatic line connection to become the full-automatic production assembly line, the machining speed is increased, the tedious process ofworkpiece transferring is omitted, the labor intensity is lowered, and occupied areas of workpieces and the bearing full-automatic production assembly line are reduced.

Owner:浙江信石轴承有限公司

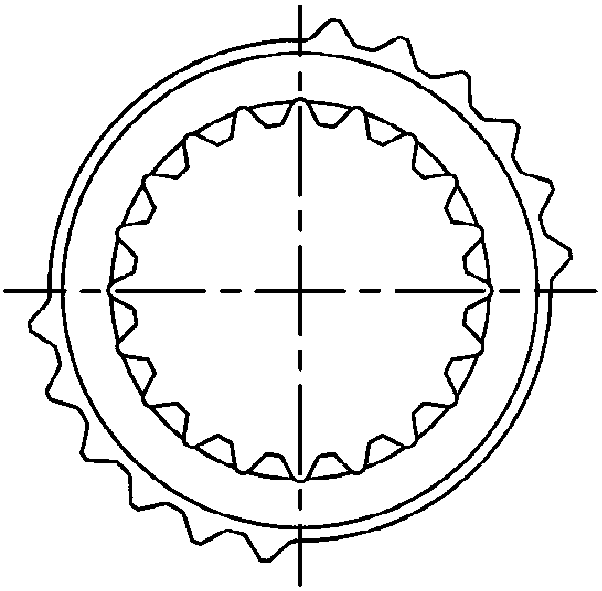

Internal-and-external tooth structure machining device of tooth-shaped linings

ActiveCN108406021AEasy to installWon't get stuckElectrical-based machining electrodesElectrical-based auxillary apparatusWire cuttingEngineering

The invention provides an internal-and-external tooth structure machining device of tooth-shaped linings. The internal-and-external tooth structure machining device comprises a pressing plate, a mainbody, a positioning ring and a positioning clamp. The positioning ring can move axially in a central through hole of the main body and can be detachably fixed to the side wall of the main body. The pressing plate is detachably fixed to the top of the main body and used for pressing tooth-shaped lining blanks. The main body can be detachably fixed into the positioning clamp. According to the internal-and-external tooth structure machining device, clamping is convenient, positioning is accurate, linear cutting machining of large-batch and small-batch flexible adjusting of the tooth-shaped linings can be achieved.

Owner:AEROSPACE PRECISION PROD INC LTD

Paper tube dividing and cutting machine capable of achieving synchronous processing

InactiveCN103934841ARealize simultaneous processingImprove processing efficiencyMetal working apparatusDrive motorPulp and paper industry

The invention relates to a paper tube dividing and cutting machine capable of achieving synchronous processing. The paper tube dividing and cutting machine comprises a machine frame. A first locating roller, a second locating roller and a plurality of cutting blades are arranged on the machine frame. Each cutting blade is at least perpendicular to the axis of one locating roller. The cutting blades perpendicular to the axis of any locating roller make contact with the locating roller. The locating rollers comprise drive ends and non-drive ends. The drive end of the first locating roller and the drive end of the second locating roller are connected with a first drive motor and a second drive motor respectively. According to the technical scheme, the paper tube dividing and cutting machine capable of achieving synchronous processing can process a plurality of paper tubes synchronously, and therefore the processing efficiency is remarkably improved; meanwhile, the two locating rollers rotate oppositely to control meshing gears of the ends of the two locating rollers to rotate so that mechanical vibration in the processing process can be balanced out, and therefore the processing precision is improved; due to the fact that the cutting blades are designed to be telescopic, the precision of cutting the paper tubes can be improved.

Owner:QUANJIAO HAIFENG PRINTING PACKAGING

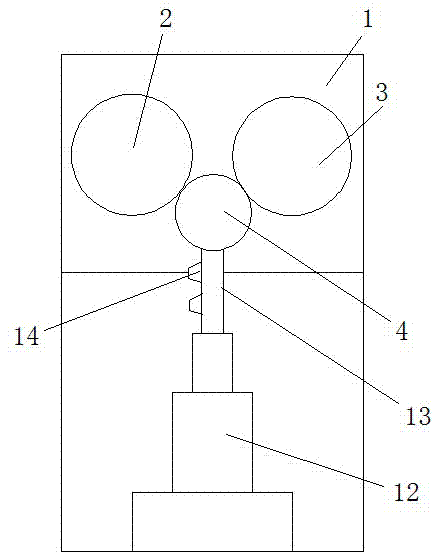

Wallpaper printing device

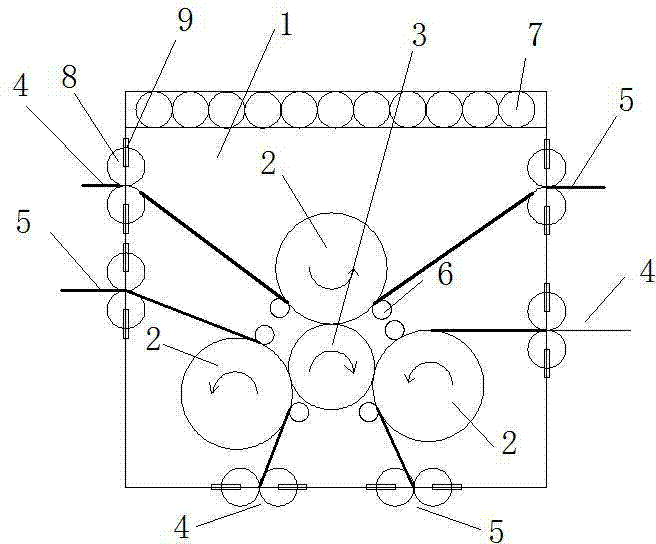

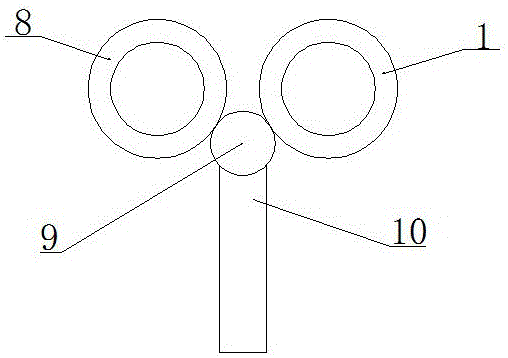

ActiveCN103692839ATake advantage ofRealize simultaneous processingEmbossing decorationsTextile printerWallpaper

The invention relates to the field of wallpaper equipment, in particular to a wallpaper printing device which comprises a box. Three printing rolls are arranged in the box and triangularly distributed, a rubber roll is arranged among the three printing rolls, the rotating directions of the three printing rolls are the same, the rotating direction of the rubber roll is opposite to that of each printing roll, and a feed port and a discharge port are formed in the box. By the aid of the structure, the three printing rolls and the rubber roll arranged in the box mutually move, three bolts of wallpaper are simultaneously machined, the rubber roll is sufficiently used, efficiency is greatly improved, the three printing rolls are structurally triangular, so that the structure is more compact, and space and cost are saved.

Owner:WUJIANG WALLMATE DECORATION MATERIALS

Numerical control multi-station milling machine

PendingCN112935354ARealize simultaneous processingImprove matchFeeding apparatusLarge fixed membersNumerical controlMilling cutter

The invention relates to the field of engraving machines, in particular to a numerical control multi-station milling machine which comprises a shell, a bedplate and milling cutters; the bedplate is arranged on the inner bottom surface of the shell; a first shoe mold is arranged on the top surface of the bedplate; the top surface of the bedplate is fixedly connected with a second shoe mold; an adjusting plate is arranged at the top of the bedplate; a pair of first gears is rotationally connected into the adjusting plate; one first gear is fixedly connected with a first motor; screw rods are arranged on the side surfaces of the two first gears; moving assemblies are arranged at the bottoms of the two screw rods; and the milling cutters are arranged at the bottoms of the two moving assemblies. Synchronous machining of the pair of shoe molds is effectively achieved, in the machining process, a set of control program is adopted, the pair of milling cutters moves symmetrically through a linkage structure, then the pair of shoe molds obtained through machining can be guaranteed to be completely symmetrical on the premise that special treatment is not conducted, and compared with two sets of control systems, the matching degree of the obtained shoe molds is higher.

Owner:陈明川

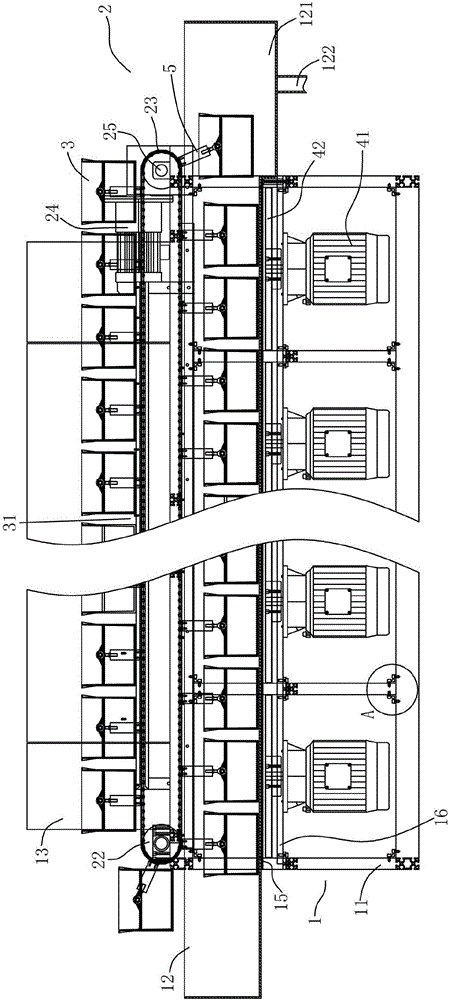

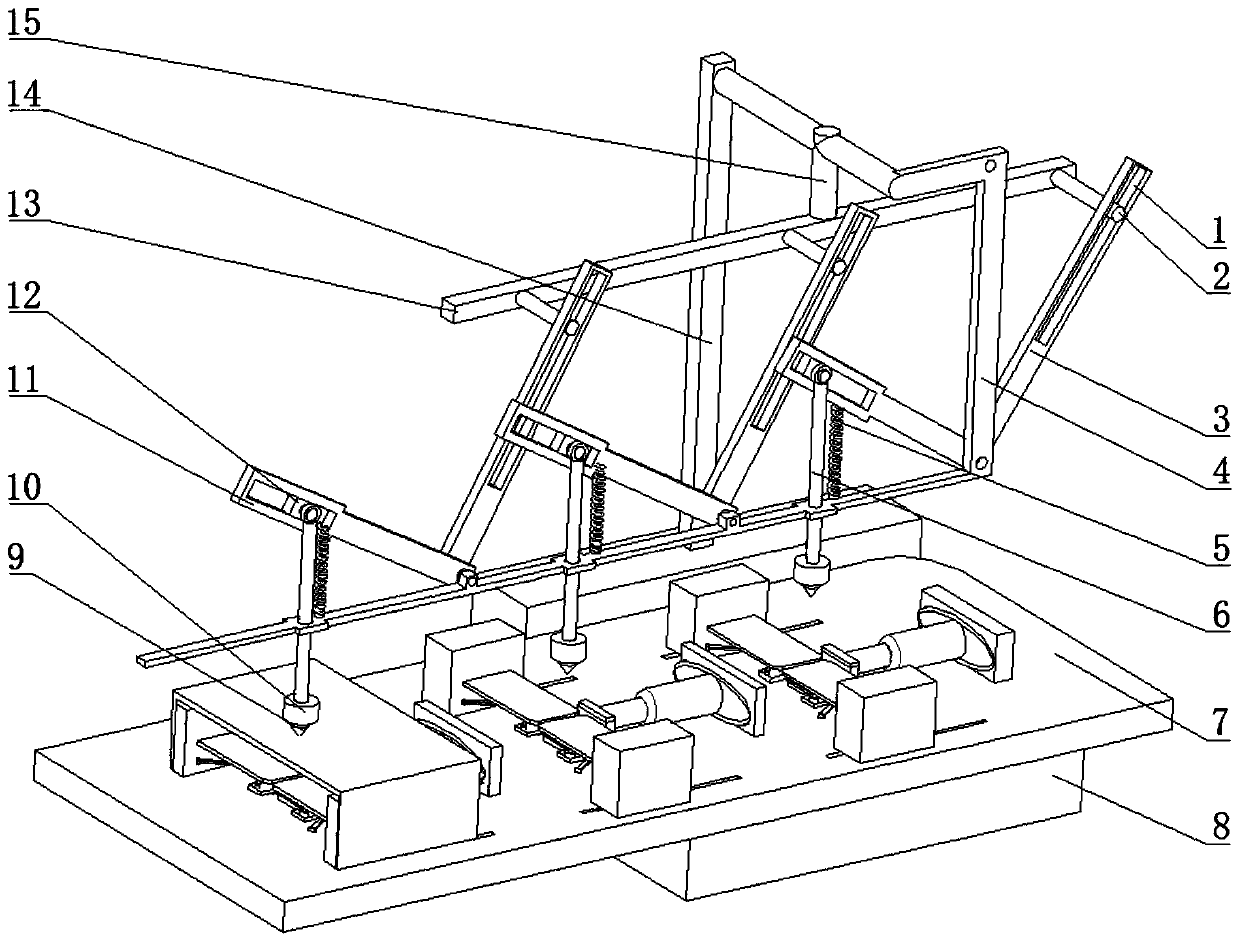

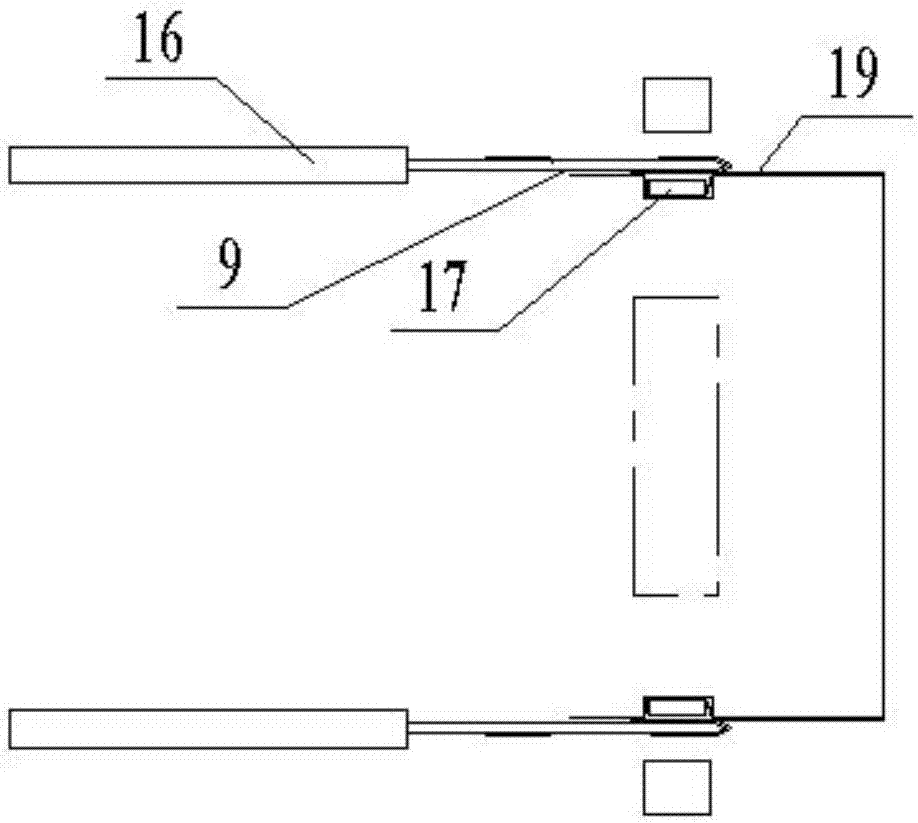

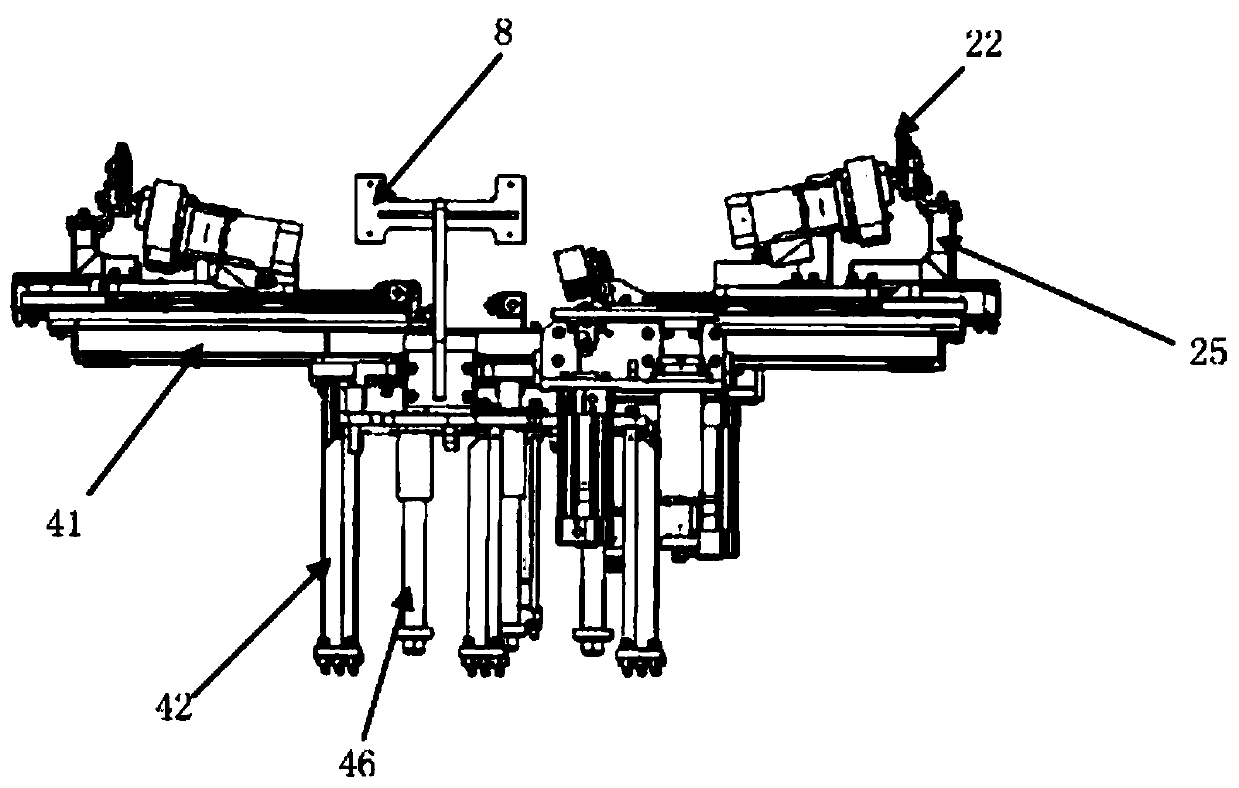

Horizontal double-tool embroidery machine

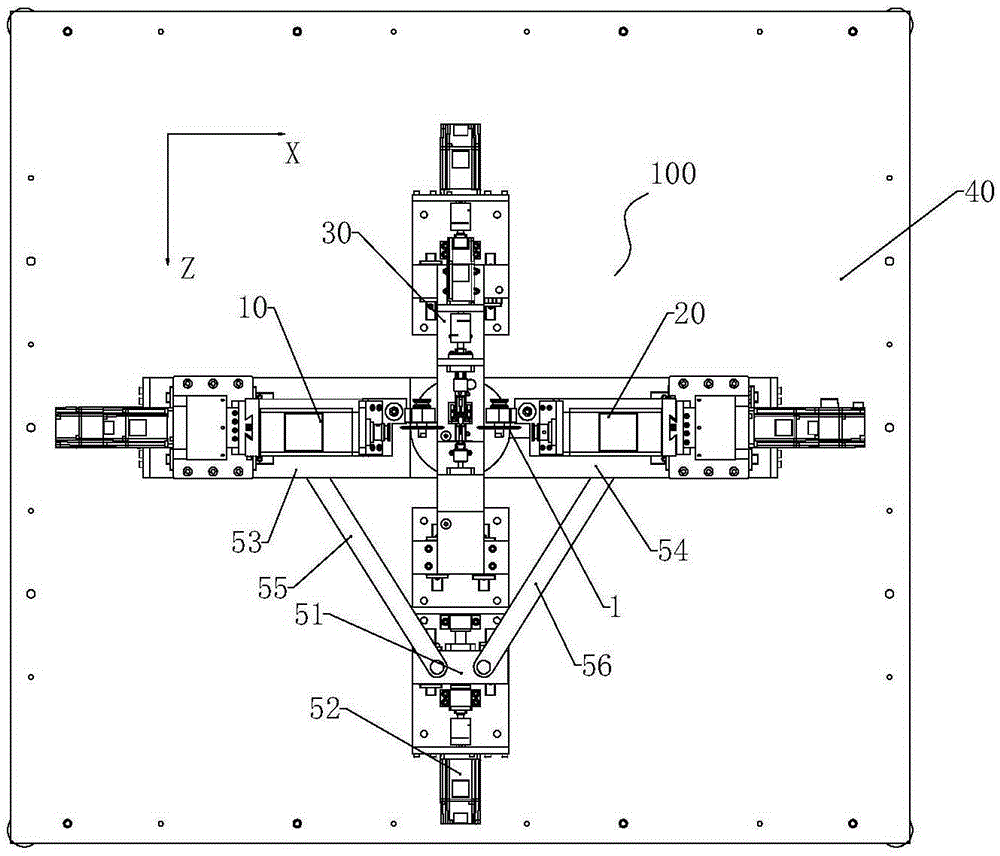

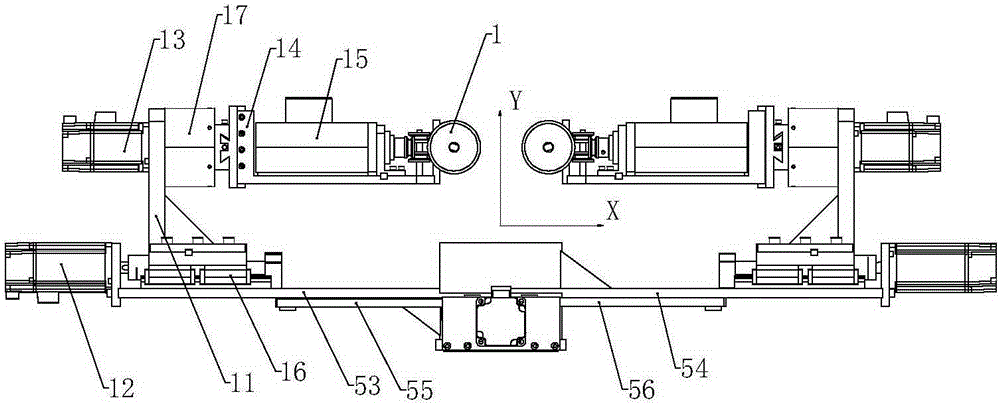

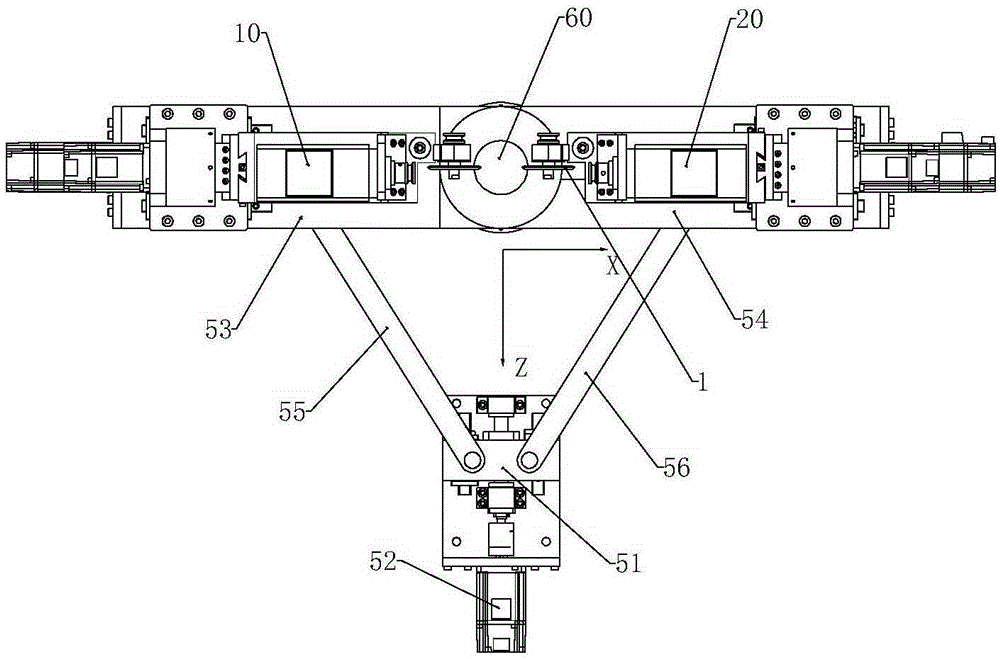

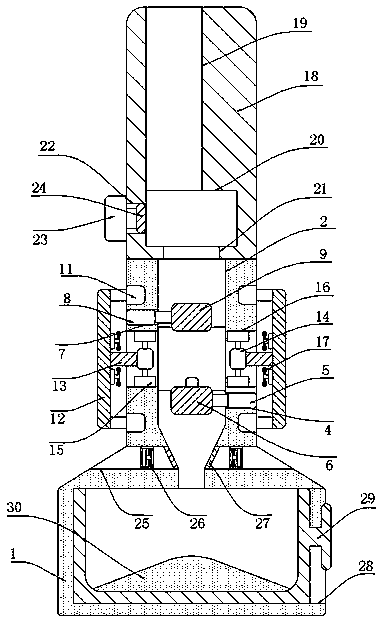

ActiveCN105171002AAchieving synchronous deflectionRealize simultaneous processingAutomatic/semiautomatic turning machinesAuxillary equipmentEngineeringMachining

The invention relates to a horizontal double-tool embroidery machine. The horizontal double-tool embroidery machine comprises tool feeding modules and a fixture module. The fixture module can be arranged on a workbench by horizontally moving in the Z-axis direction. A workpiece can be clamped to the fixture module by rotating in the Z-axis direction. The tool feeding modules comprise the first tool feeding module and the second tool feeding module. The first tool feeding module and the second tool feeding module can be both arranged on the workbench by swinging around the Y-axis direction. The first tool feeding module and the second tool feeding module are arranged on the two sides of the fixture module in symmetry about the rotation axis of the workpiece. The first tool feeding module and the second tool feeding module are each provided with a tool. The first tool feeding module and the second tool feeding module drive the tools to synchronously swing around the Y-axis direction under driving of a crank-slider mechanism. The included angle between the tool feeding direction of one tool and the rotation axis of the workpiece is equal to the included angle between the tool feeding direction of the other tool and the rotation axis of the workpiece. According to the horizontal double-tool embroidery machine, synchronous eccentric rotation of the tool feeding modules is achieved through the crank-slider mechanism, so that simultaneous machining by the two tools is achieved, and machining efficiency is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

Full-automatic groove broacher for wood processing

ActiveCN110815412AAvoid wasting manpowerAvoid duplicate joinsProfiling/shaping machinesWood mortising machinesElectric machineryStructural engineering

The invention discloses a full-automatic groove broacher for wood processing. The full-automatic groove broacher for wood processing comprises a processing table, wherein the upper end of the processing table is provided with a processing groove, the side wall of the processing groove is provided with an outlet groove in a penetrating mode, the inner wall of the processing groove is provided witha plurality of conveying grooves, the inner wall of each conveying groove is welded with a conveying motor, and an output shaft of each conveying motor is welded with a conveying rotating wheel; and two groups of clamping push rods are symmetrically welded on the outer walls of the two sides of the processing table, and a clamping plate is welded at one end, far away from the processing table, ofeach group of clamping push rods. The full-automatic groove broacher for wood processing has the advantages that through the crossed arrangement of a material storage tank and a temporary storage tank, raw materials can be blocked by the temporary storage tank to be stored in the material storage tank, one-time large material feeding can be realized, manpower waste caused by repeated feeding is avoided, the raw materials in the temporary storage tank are pushed and redirected through a redirection push rod, and the raw materials can gradually fall into the processing groove under a controllable state to realize cyclic processing.

Owner:梁山常青树板材有限公司

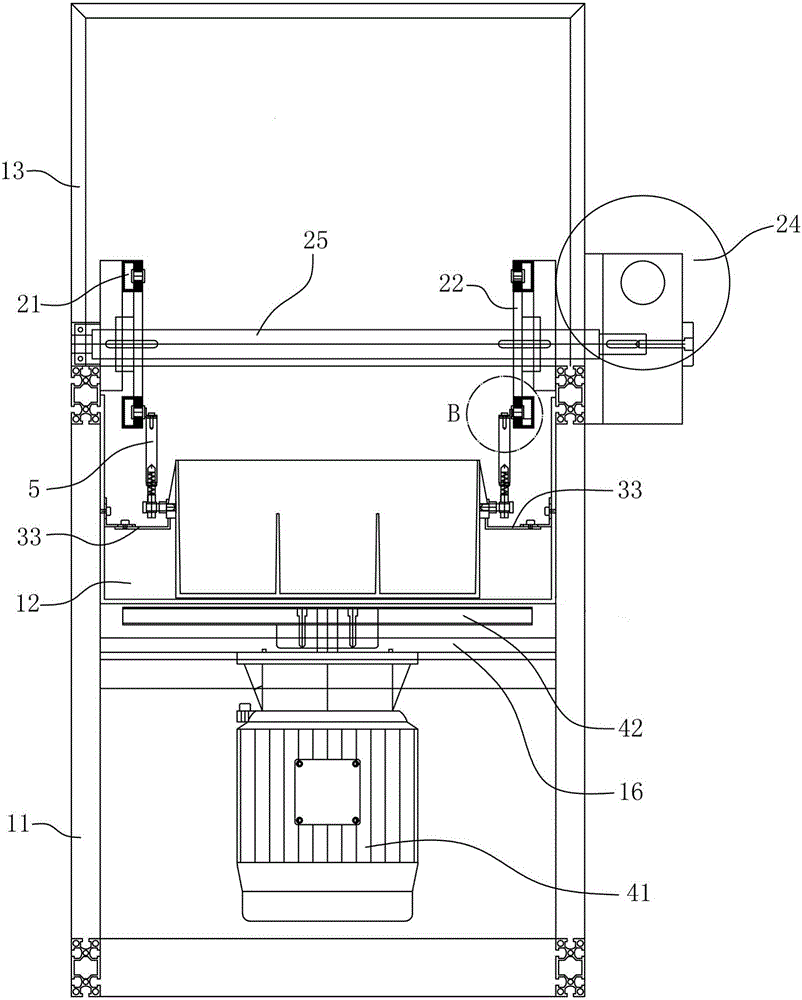

Automatic magnetic grinding machine

ActiveCN102729128BGuarantee processing qualityRealize simultaneous processingEdge grinding machinesPolishing machinesEngineeringAssembly line

The invention relates to the technical field of grinding and polishing equipment and discloses a full-automatic magnetic force grinder. The full-automatic magnetic force grinder comprises a grinder body, a transmission mechanism for circular transmission, a plurality of grinding containers for containing materials and a magnetic force generating device for grinding, wherein the transmission mechanism is arranged at the upper end of the grinder body; the grinding containers are connected to the transmission mechanism through a movable bracket to form an assembly line structure in circular transmission; and the magnetic force generating device is arranged below the grinding containers and is arranged at the lower end of the grinder body through a fixing plate. During operation, according to the transmission mechanism in circular transmission, the grinding containers uninterruptedly pass through a high-speed rotating powerful magnetic disc at a low speed, so that abrasive materials such as stainless steel needles in the grinding containers rotate, flow, vibrate, reverse and turn at high frequency, and the surface of the workpiece is rubbed so that grinding and polishing treatment on the workpiece is achieved; and moreover, uninterrupted assembly line type production is realized, the machining efficiency is improved, the machining quality is guaranteed, and manpower and material resources are saved.

Owner:罗泽波

Automatic punching machine and control system thereof

ActiveCN110340406AAchieve positioningSame positioningFeeding apparatusPositioning apparatusPunchingControl system

The invention discloses an automatic punching machine and a control system thereof. The automatic punching machine comprises an L-shaped plate, and is characterized in that the upper side of a transverse plate of the L-shaped plate is fixedly connected with a motor I, the upper side of a vertical plate of the L-shaped plate is fixedly connected with a vertical rod, the upper side of the vertical rod is fixedly connected with one end of a round rod II, the middle of the round rod II is fixedly connected with a hollow round rod, the other end of the round rod II is fixedly connected with one endof an upper side transverse rod of a U-shaped rod, an output shaft of a motor II is hinged to one corner of a supporting plate, a group of vertical plates are fixedly connected to the supporting plate, a group of symmetrically-distributed grooves are formed in the supporting plate, a punching mechanism is arranged on the U-shaped rod, and a fixing mechanism is arranged on the supporting plate. The invention relates to the field of grinding equipment, in particular to the automatic punching machine and the control system thereof. According to the automatic punching machine and the control system thereof, positioning and punching of a plate are facilitated.

Owner:广州沃迪森汽车零部件有限公司

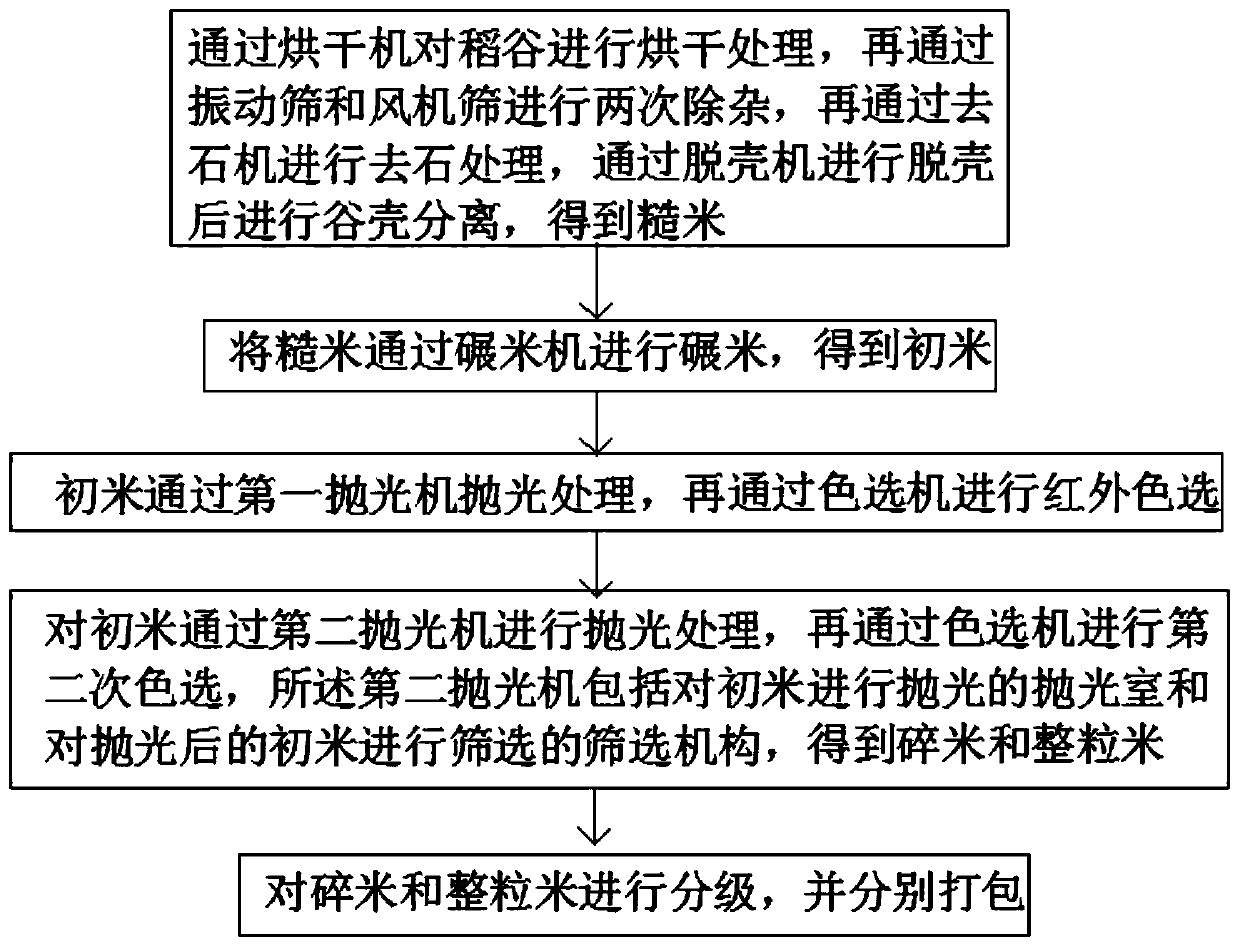

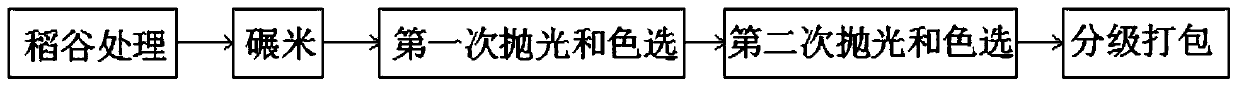

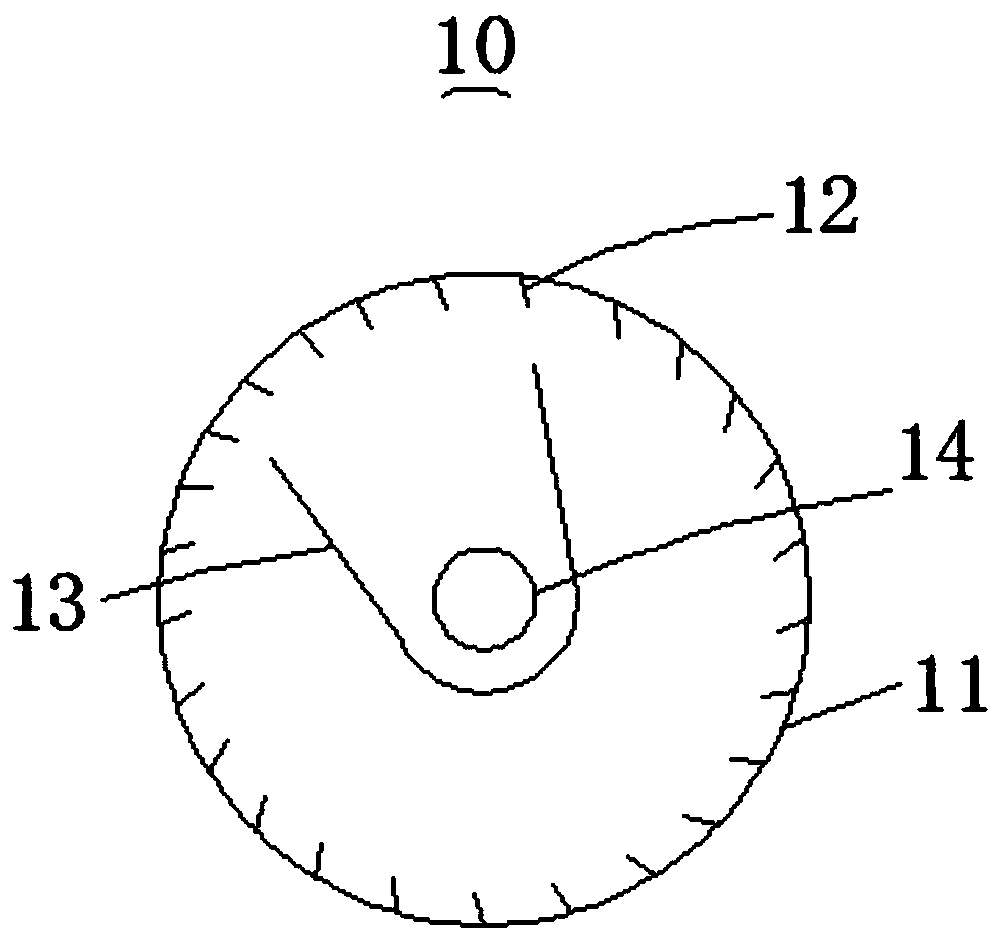

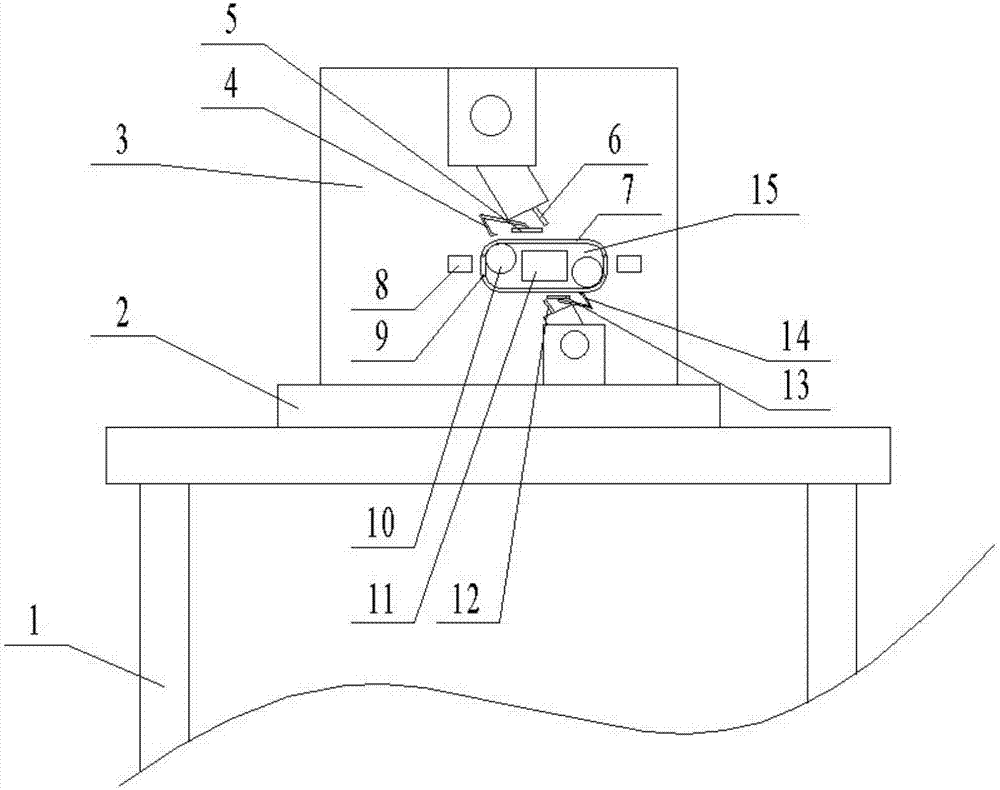

High-quality graded rice production and processing method

ActiveCN111185256AEasy to undertakeEasy dischargeGrain treatmentsAgricultural engineeringBroken rice

The invention discloses a high-quality graded rice production and processing method. The high-quality graded rice production and processing method comprises the following steps: S1, unhusked rice treatment: a step of drying unhusked rice through a drying machine, removing impurities twice through a vibrating screen and a draught fan screen, removing stones through a stone removing machine, carrying out husking through a husking machine, and separating husks so as to obtain brown rice; S2, rice milling: a step of milling the brown rice through a rice mill so as to obtain primary rice; S3, polishing and color sorting for the first time; S4, polishing and color sorting for the second time: a step of polishing the primary rice through a second polishing machine, and performing secondary colorsorting through a color sorter so as to obtain broken rice and whole-grain rice; and S5, grading and packaging: a step of grading the broken rice and the whole-grain rice from a screening mechanism, and carrying out packaging respectively. The high-quality graded rice production and processing method provided by the invention can realize simultaneous processing of the broken rice and the whole-grain rice, avoids the waste of grains, and can realize screening of the whole-grain rice and the broken rice through the screening mechanism to facilitate separate packaging.

Owner:靖州县振宏米业有限责任公司

Glove lock edge and trademark sewing device

PendingCN107460644AAchieve valgusRealize simultaneous processingMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention discloses a glove lock edge and trademark sewing device, and belongs to the field of glove making. The sewing device includes a main support, a platform is arranged on the main support, a lock edge machine head is arranged on the platform, a lock edge platform is arranged on the lock edge machine head, a lock edge needle is arranged above the lock edge platform, a lock edge pressing lower plate and a lock edge line cutter are arranged on one side of the lock edge; a trademark platform is arranged on the front end of the lock edge platform, a trademark needle is arranged on the bottom of the trademark platform, a trademark pressing lower plate and a trademark line cutter are arranged on one side of the trademark needle, a transition slope is arranged between the lock edge platform and the trademark platform, needle holes are formed in the transition slope, and outward pushing needles are arranged inside the needle holes; electromagnet is arranged on the interior of the trademark platform, two grooves are formed in two sides of the trademark platform, and a magnet channel is arranged on the position, corresponding to the position of the grooves, of the lock edge machine head, the electromagnet is arranged inside the magnet channel, and the electromagnet is connected with power to attract the magnet into the grooves or to repel the magnet into the magnet channel, and two rolling wheels are arranged on the interior of the trademark platform to drive gloves to rotate.

Owner:山东孚润机械科技有限公司

Internal screw thread processing mechanism

InactiveCN104801788AImprove processing efficiencyEasy to processThread cutting feeding devicesThread cutting machinesScrew threadDrill

The invention discloses an internal screw thread processing mechanism, which comprises a work table, wherein a fixing plate used for wheel hub fixation is arranged on the work table, the upper surface of the work table is a horizontal plane, the internal screw thread processing mechanism also comprises an axial drill and a radial drill, screwdrivers are respectively and fixedly arranged on the axial drill and the radial drill, the axial line of the screwdriver arranged on the axial drill is parallel to the horizontal plane, the axial line of the screwdriver arranged on the radial drill is inclined relative to the horizontal plane, the axial drill and the radial drill are respectively and fixedly arranged on the work table, the axial drill braking corresponds to the screwdriver rotation and the reciprocating movement along the axial direction of the screwdriver, and the radial drill braking corresponds to the screwdriver rotation and the reciprocating movement along the axial direction of the screwdriver. The internal screw thread processing mechanism has the advantages that the structure is simple, and the wheel hub thread tapping processing efficiency can be favorably improved.

Owner:CHENGDU LINGCHUAN SPECIAL IND

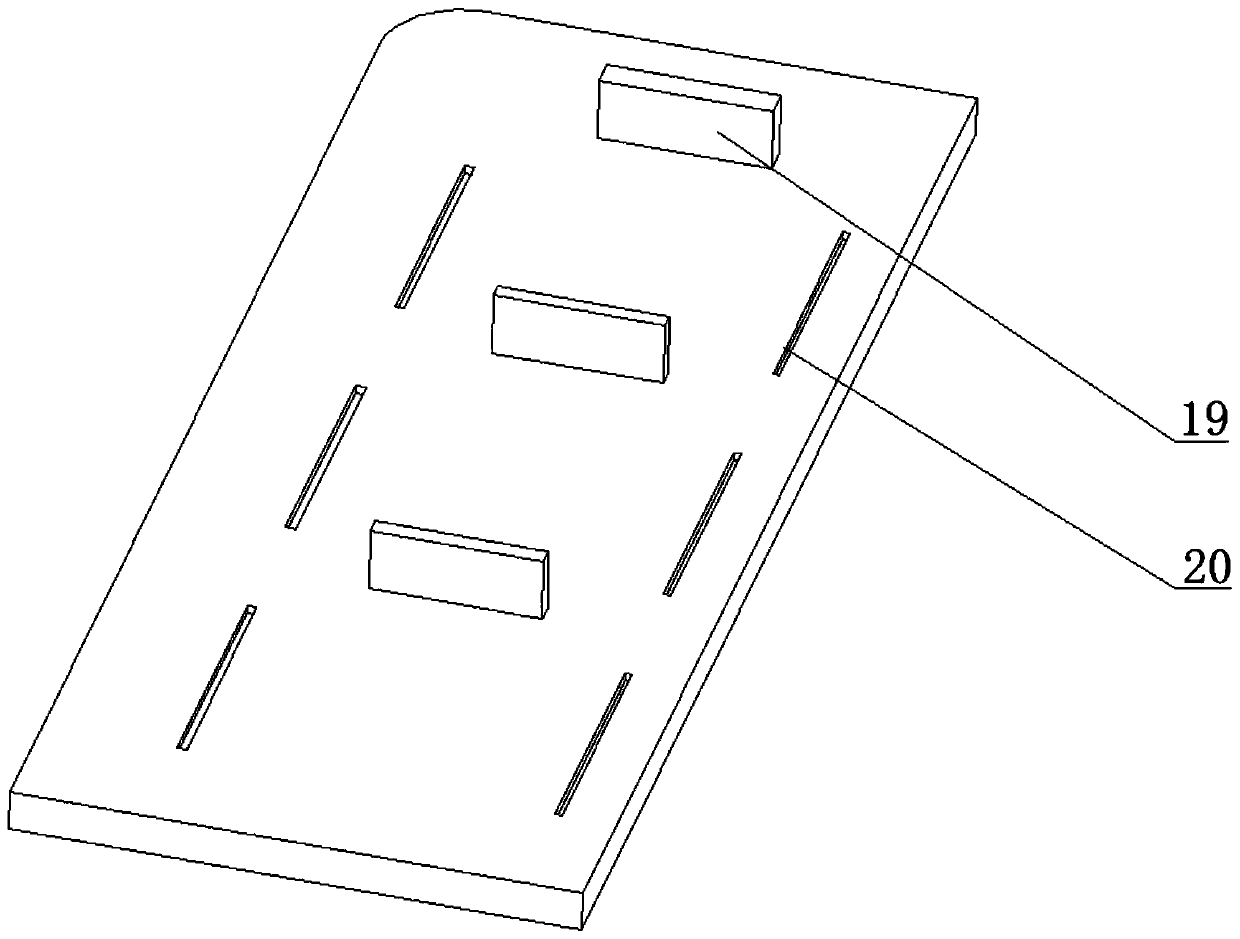

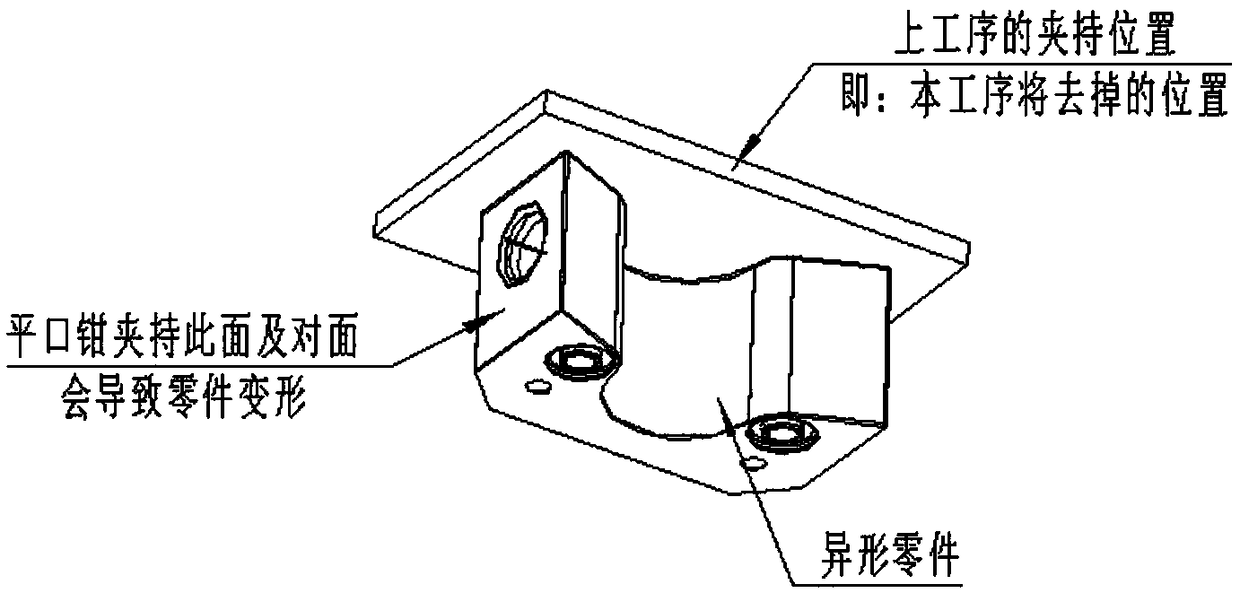

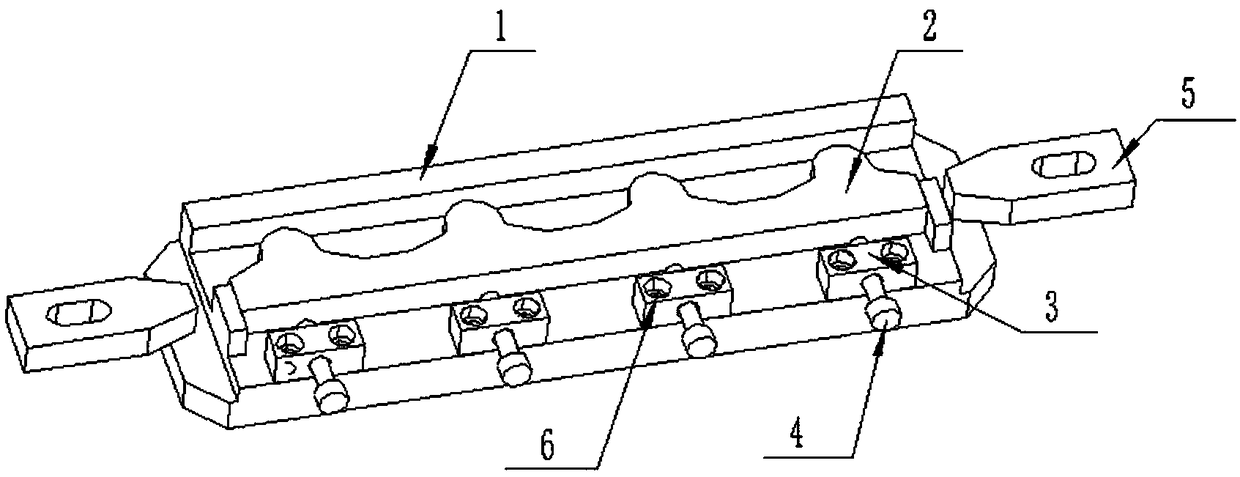

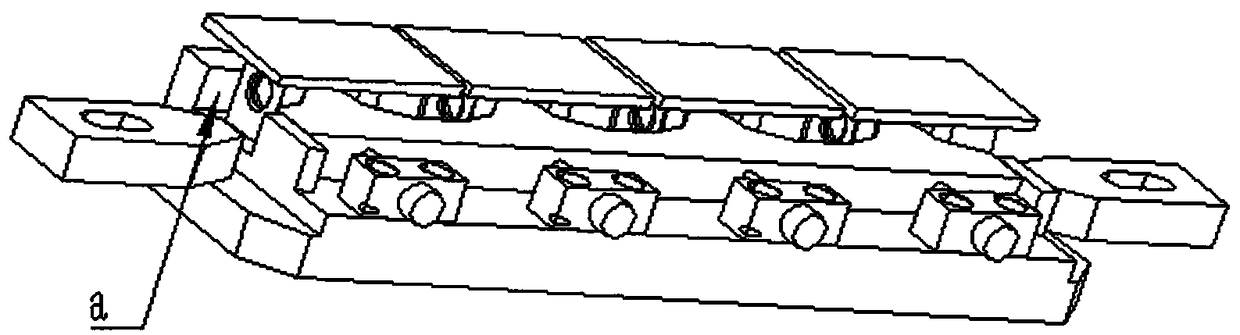

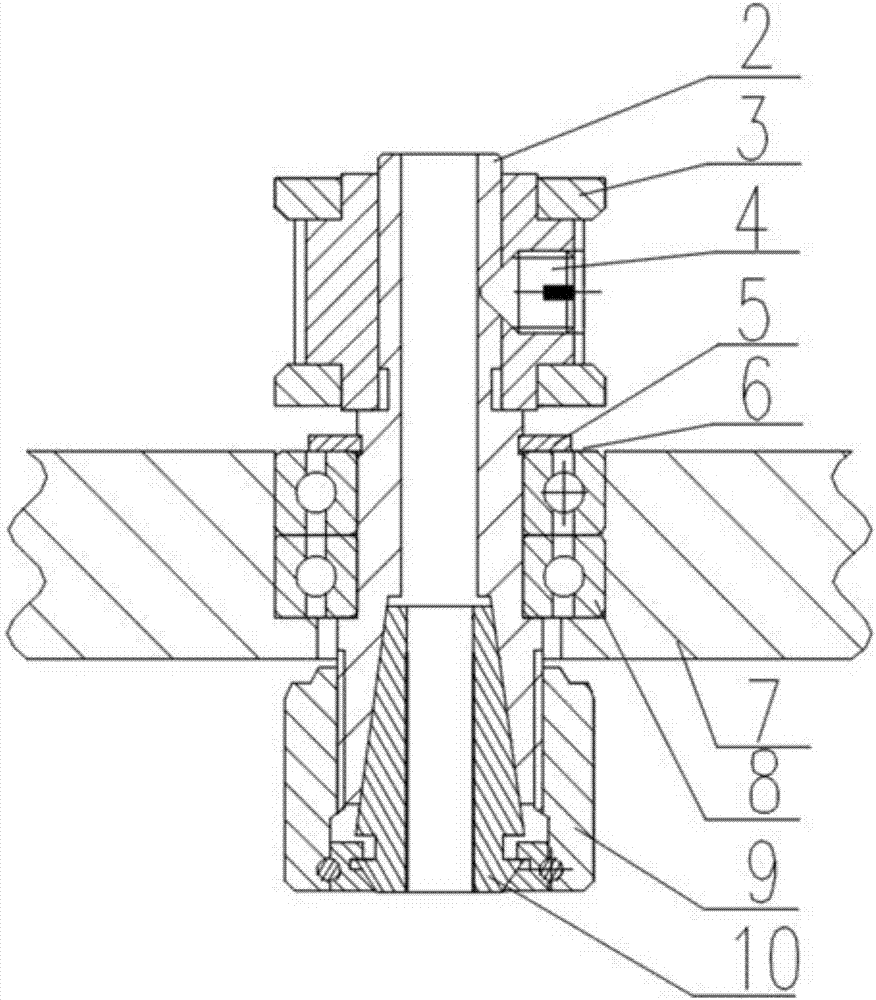

Clamped position removal process of special-shaped aluminum alloy workpiece

InactiveCN108747895AGuaranteed stabilityImprove processing efficiencyWork holdersDeformation ProblemSlide plate

The invention discloses a clamped position removal process of a special-shaped aluminum alloy workpiece. A profiled side jacking tool is manufactured according to the appearance of an irregular part,the part is clamped, and part deformation is avoided in the clamped position removal process. The profiled side jacking tool manufactured according to the appearance of the irregular part comprises abase, a side jacking sliding plate, jackscrew fixing blocks, jackscrews, pressing plates and screws. The base is fixed to a machining platform through the pressing plates, the side jacking sliding plate is arranged on the base and connected with the jackscrews, and the jackscrews are fixed to the base by the jackscrew fixing blocks through the screws. The base is provided with a protruding block,the end face of the special-shaped part is limited, the side jacking sliding plate is provided with profiled end faces on the same face with the special-shaped part, and the special-shaped part is pushed by the jackscrews to be fixed between the side jacking sliding plate and the protruding block of the base. The multiple profiled end faces are arranged, multiple parts can be machined at the sametime, and the clamped position removal efficiency of the special-shaped part is greatly improved. The multiple parts are subjected to side jacking at the same time, and clamped position removal is achieved efficiently without deformation. According to the process, the deformation problem of the workpiece after common clamped position removal is relieved.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

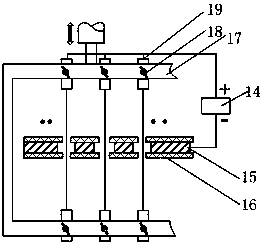

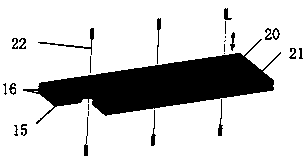

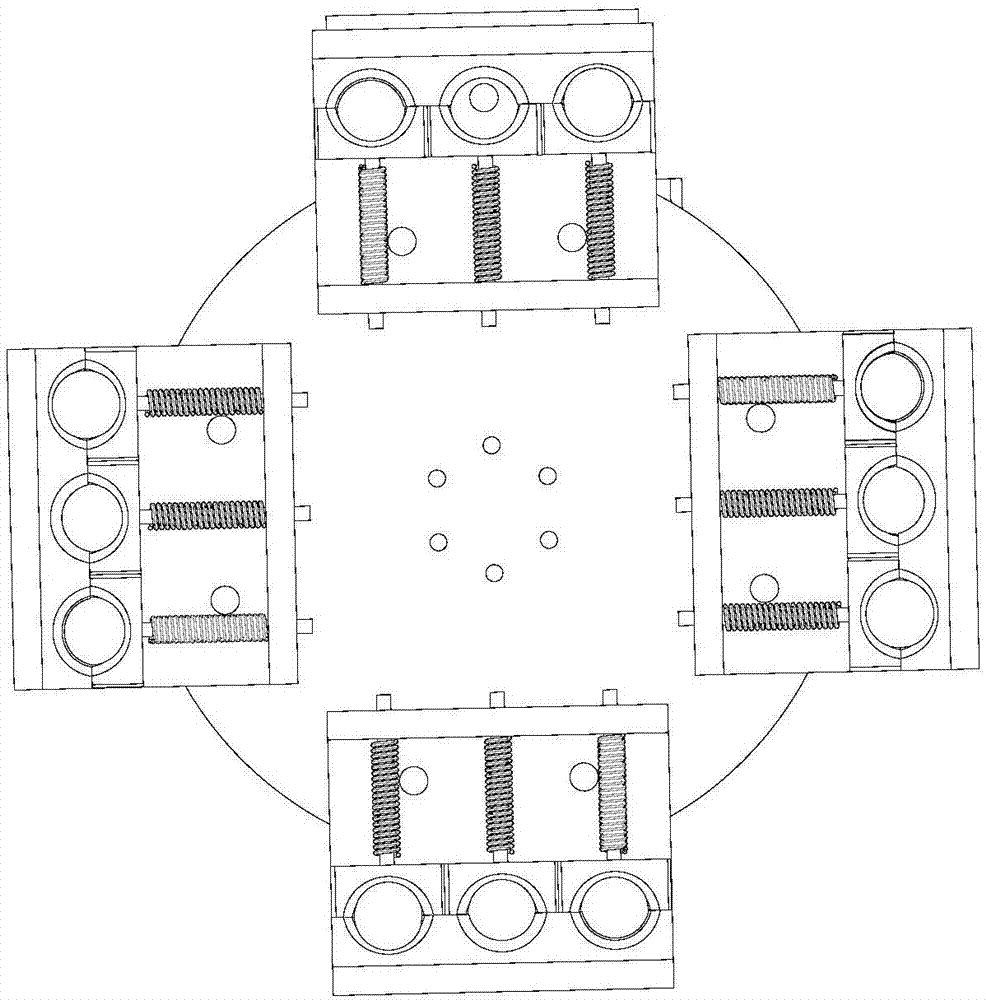

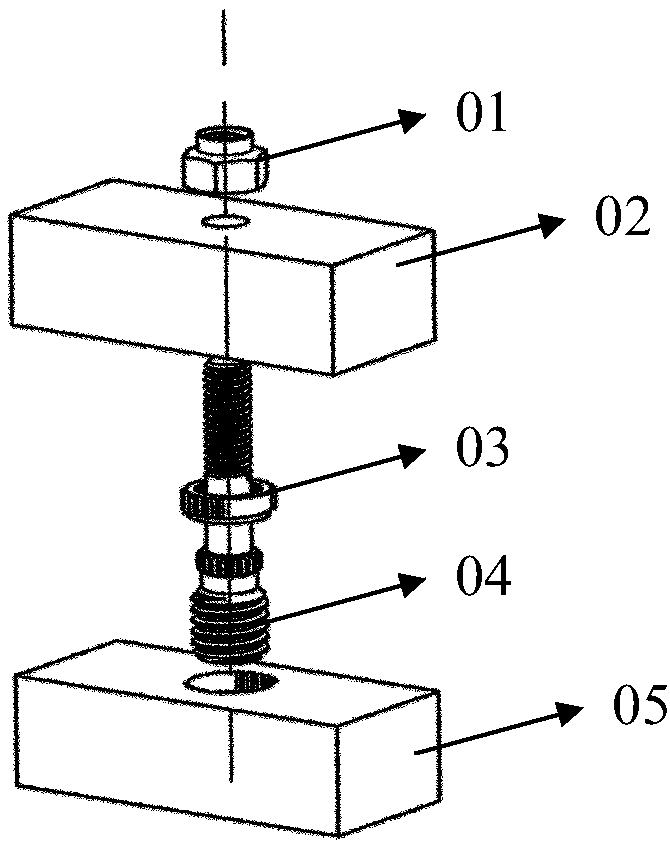

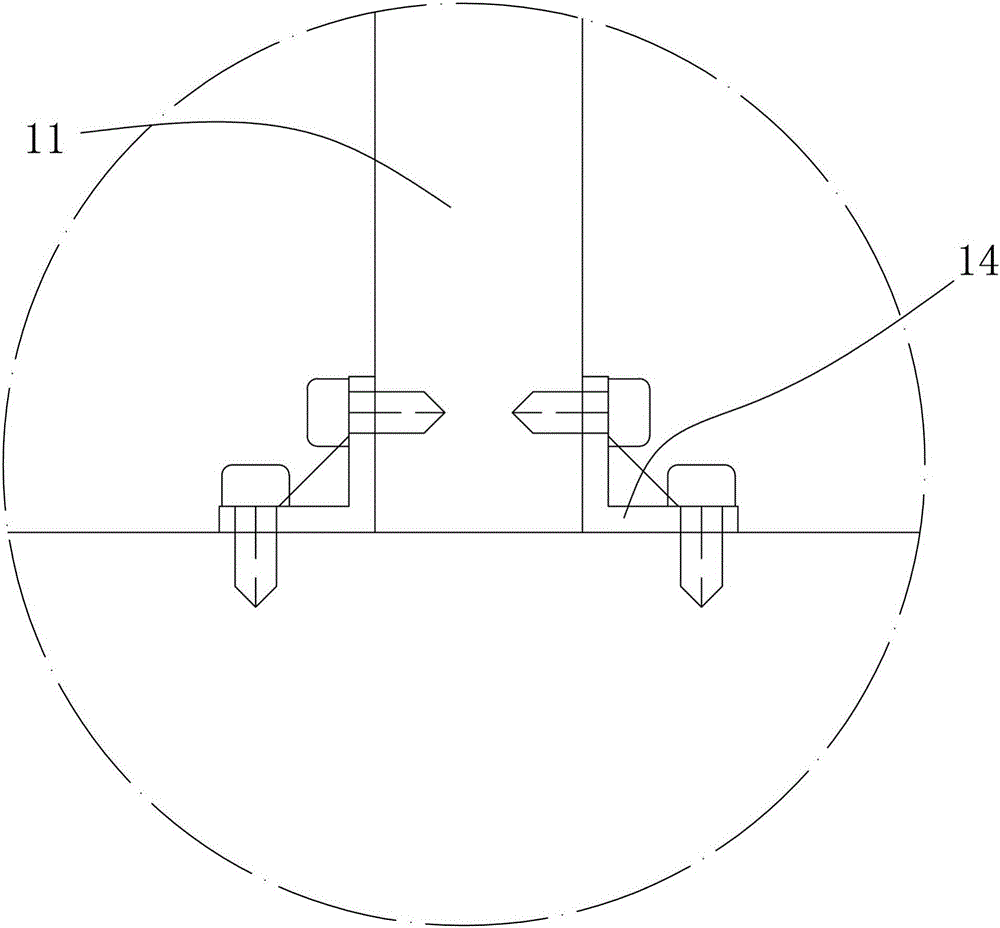

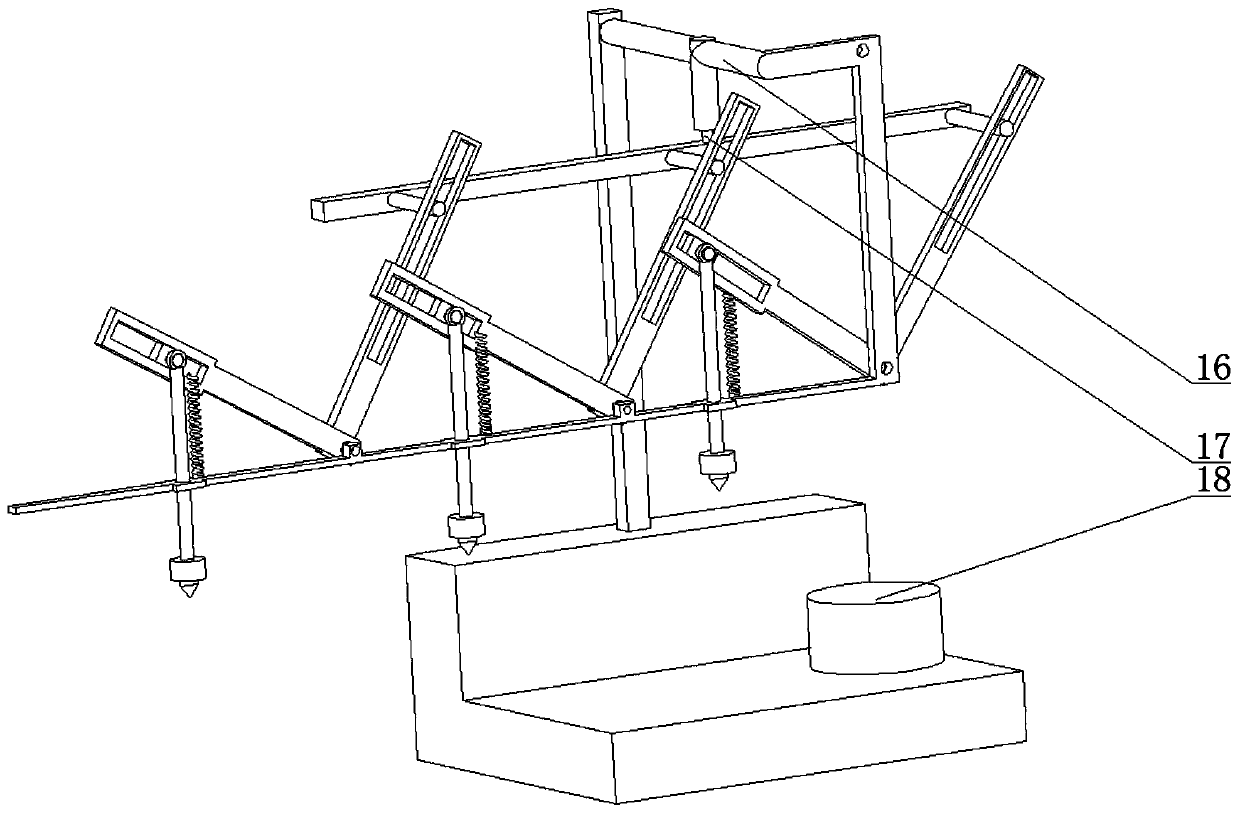

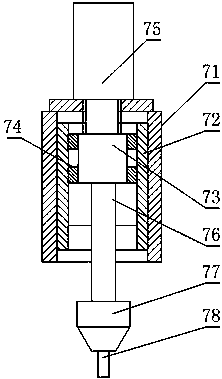

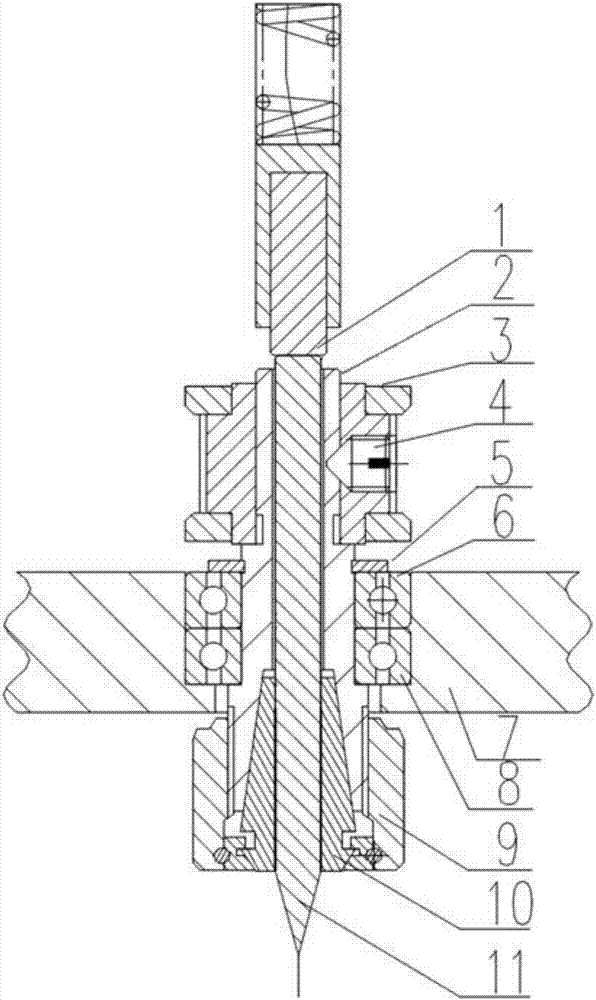

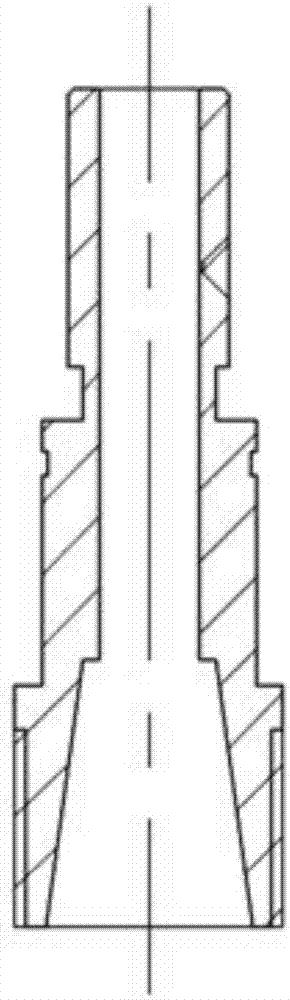

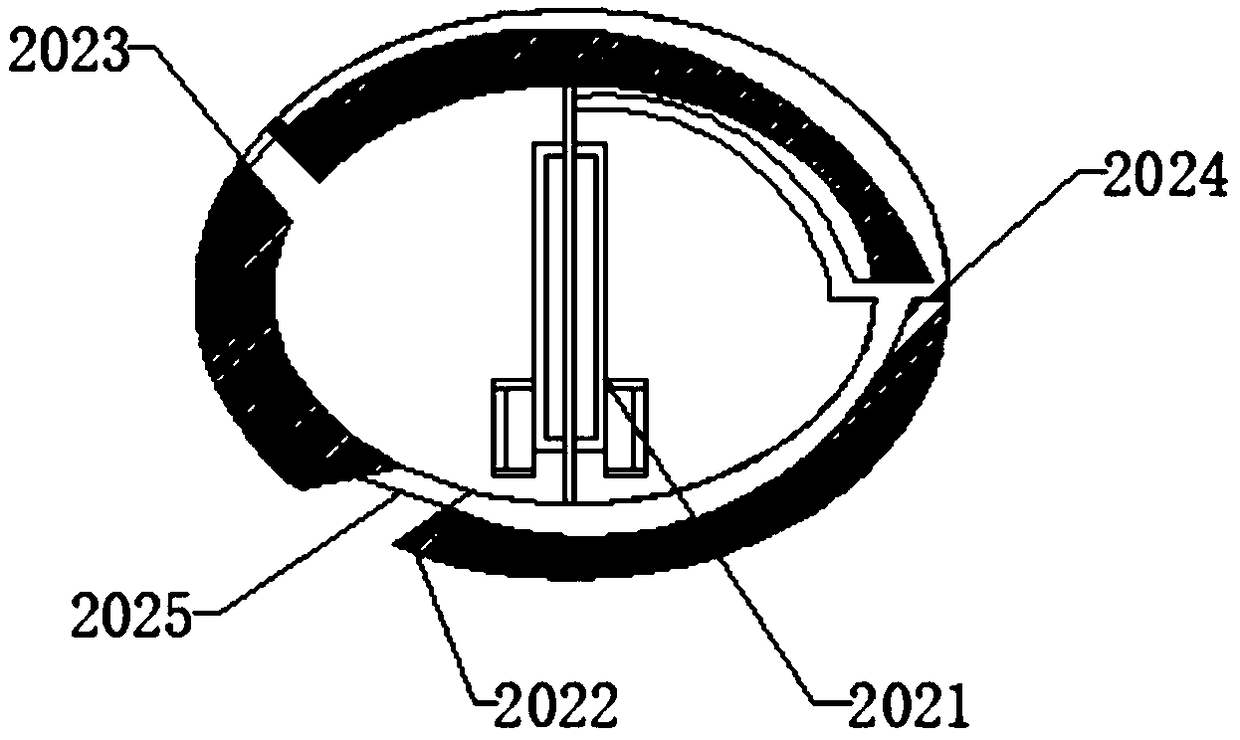

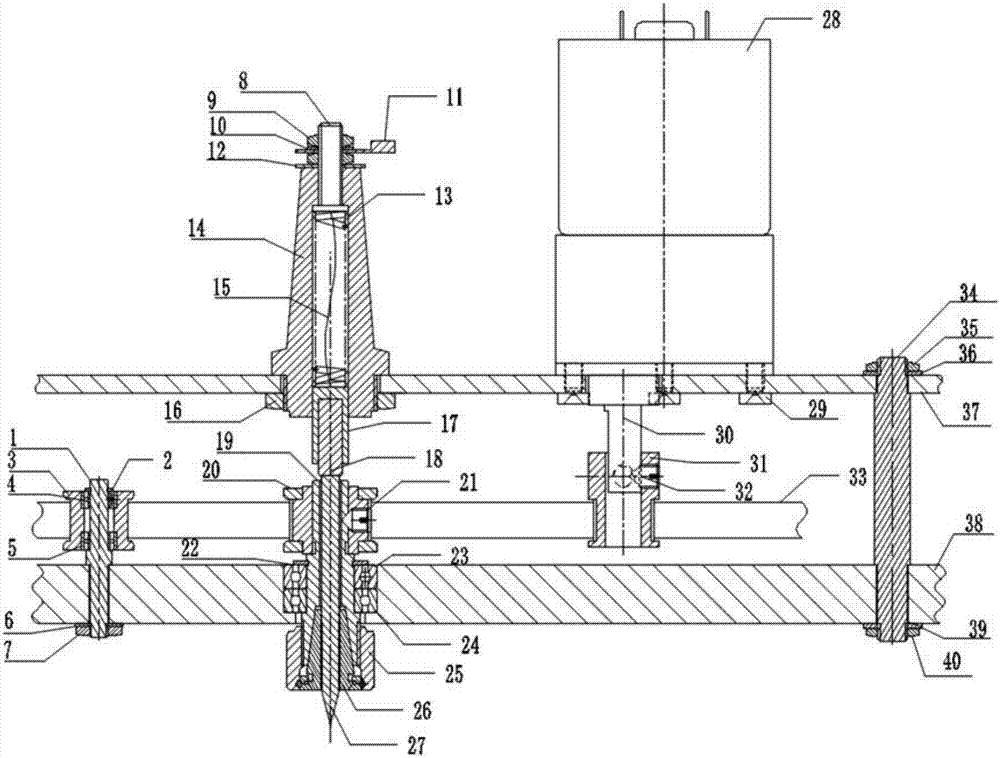

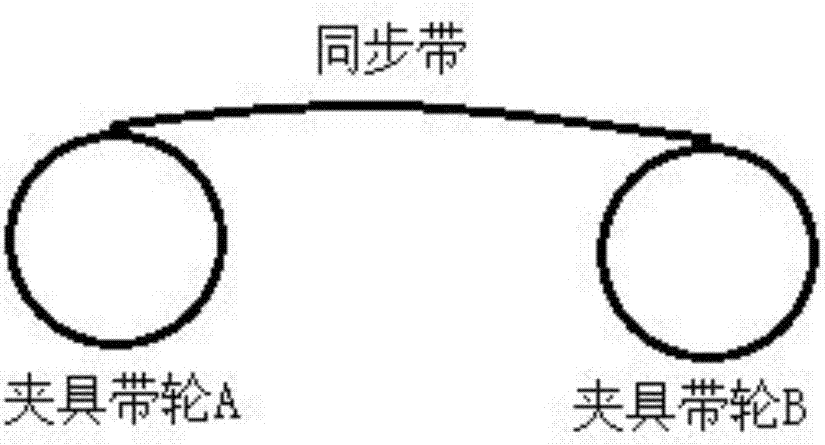

Tool electrode clamp for multi-micropore electric spark discharge synchronous machining

PendingCN107138815AImproved chip removalAdd depthElectrical-based machining electrodesElectrical-based auxillary apparatusPhysicsElectric spark

The invention relates to a tool electrode clamp for multi-micropore electric spark discharge synchronous machining. The tool electrode clamp comprises a hollow step shaft, a belt wheel, a clamp head and a nut. The hollow step shaft is used for containing a tool electrode. The belt wheel is connected with the upper portion of the hollow step shaft and used for driving the hollow step shaft to rotate. The clamp head is connected with the bottom of the hollow step shaft, used for fixing the tool electrode and locked through the nut. According to the tool electrode clamp, in combination with a special clamp disc, multiple tool electrode clamps can be mounted on the same clamp disc, among the tool electrode clamps, belt wheels and hollow step shafts are driven by synchronous belts to rotate, and the consistency of all the tool electrodes on the clamp disc in work can be guaranteed in the following processes; and the tool electrodes work at the same time, the working efficiency of machining multiple micropores is improved, meanwhile electric insulation among all the tool electrodes is achieved in work, independent discharge energy control can be conducted, and thus the phenomena of the short circuit and electrode burnout can be avoided.

Owner:SHANDONG UNIV

Flexible feeding and discharging mechanism

InactiveCN110525889AMeet the widthTransmission moreConveyorsControl devices for conveyorsEngineeringMachining

The invention is applicable to the field of product transportation, and provides a flexible feeding and discharging mechanism. The flexible feeding and discharging mechanism comprises a lifting driving device, transmission mechanisms, adjusting mechanisms and a supporting mechanism, the lifting driving device is arranged at the lower end of the supporting mechanism, and the adjusting mechanisms are symmetrically arranged at the two ends of the top of the supporting mechanism. The transmission mechanisms are arranged on the adjusting mechanisms, and each adjusting mechanism comprises a bottom plate, an adjusting driving device, a first sliding rail and a second sliding rail. The adjusting driving device is connected with the middle of the bottom plate, the first sliding rail is arranged atone side of the bottom end of the bottom plate, and the second sliding rail is arranged at the other side of the bottom end of the bottom plate. One side of the bottom plate is connected with a sliding block of the first sliding rail, and the other side of the bottom plate is connected with a sliding block of the second sliding rail. The distance between the transmission mechanisms is changed through the adjusting mechanisms, the widths of rolling window frames and non-rolling window frames of different vehicle types are met, the simultaneous machining of the products of various vehicle typesis achieved, and the working efficiency is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

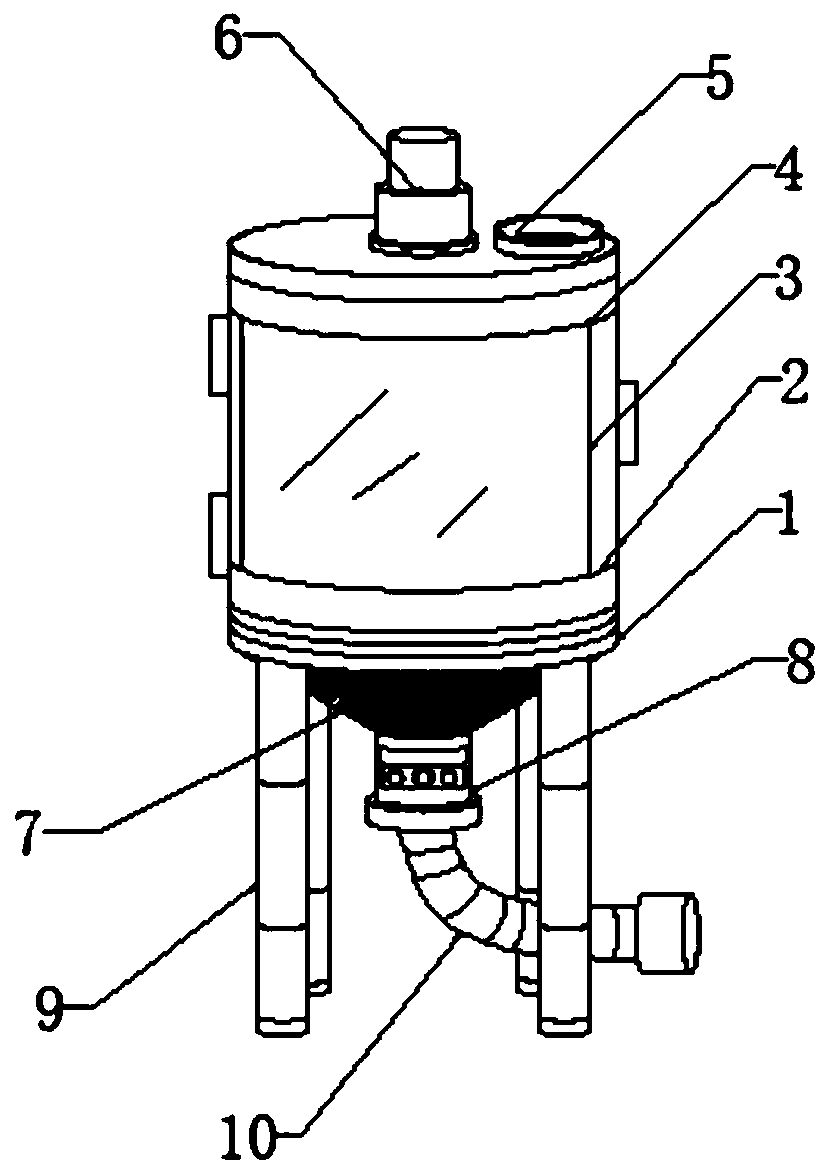

Electric mixer for industrial manufacturing

InactiveCN109126596ARealize simultaneous processingImprove stirring efficiencyTransportation and packagingMixer accessoriesEngineeringIndustrial engineering

The invention discloses an electric mixer for industrial manufacturing, comprising a mixer body. A tank is arranged at the top of the mixer body; the front of the tank is fitted with an observation window; an upper cover is mounted at the top of the tank; the top of the upper cover is provided with a first feed port and a second feed port; the bottom of the first feed port is provided with an auxiliary conveying pipe; the bottom of the second feed port is connected with a main conveying pipe. The electric mixer for industrial manufacturing has a valve and a slideway; after materials are mixed,the mixture may slip to an outlet under the action of the slideway arranged obliquely; workers may operate operating keys on an operating panel according to actual needs so as to change the opening state of the valve, it is convenient for the workers to control the outflow speed of the mixture, and the mixture is better for the workers to collect.

Owner:新沂城北新区城市建设发展有限公司

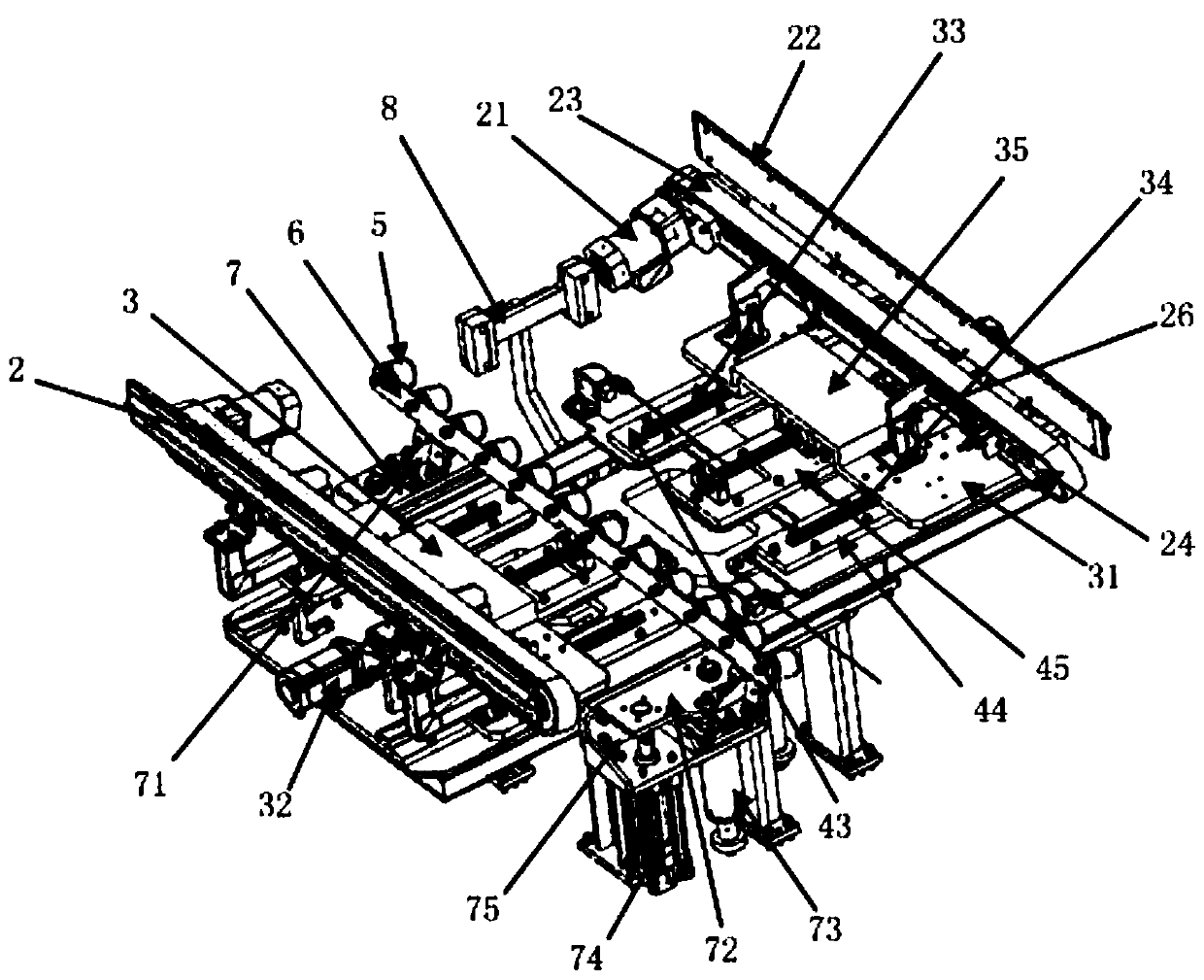

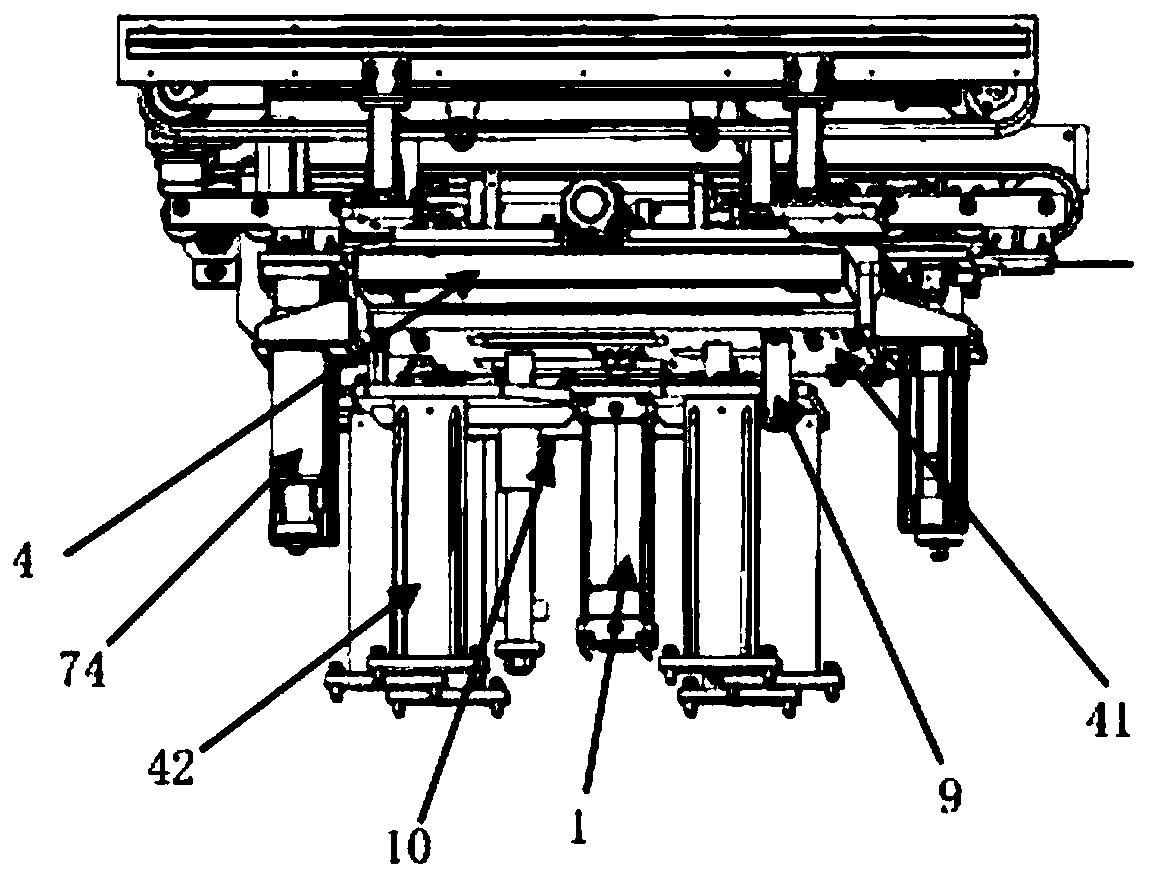

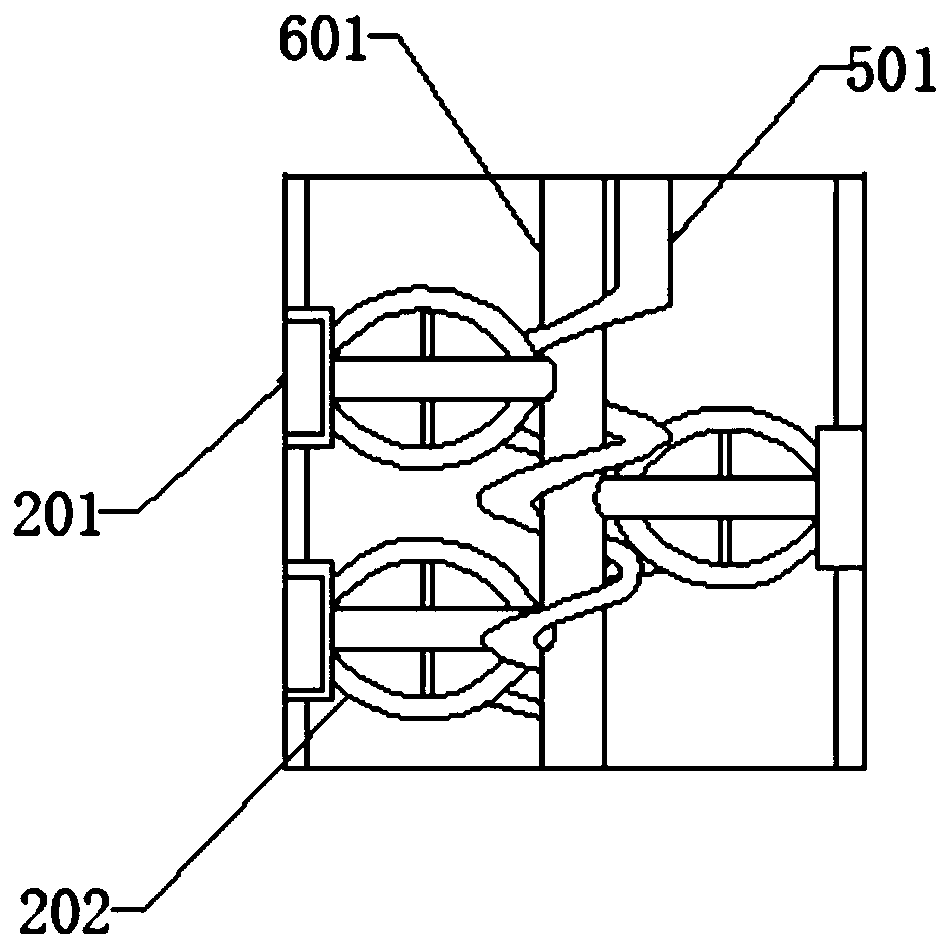

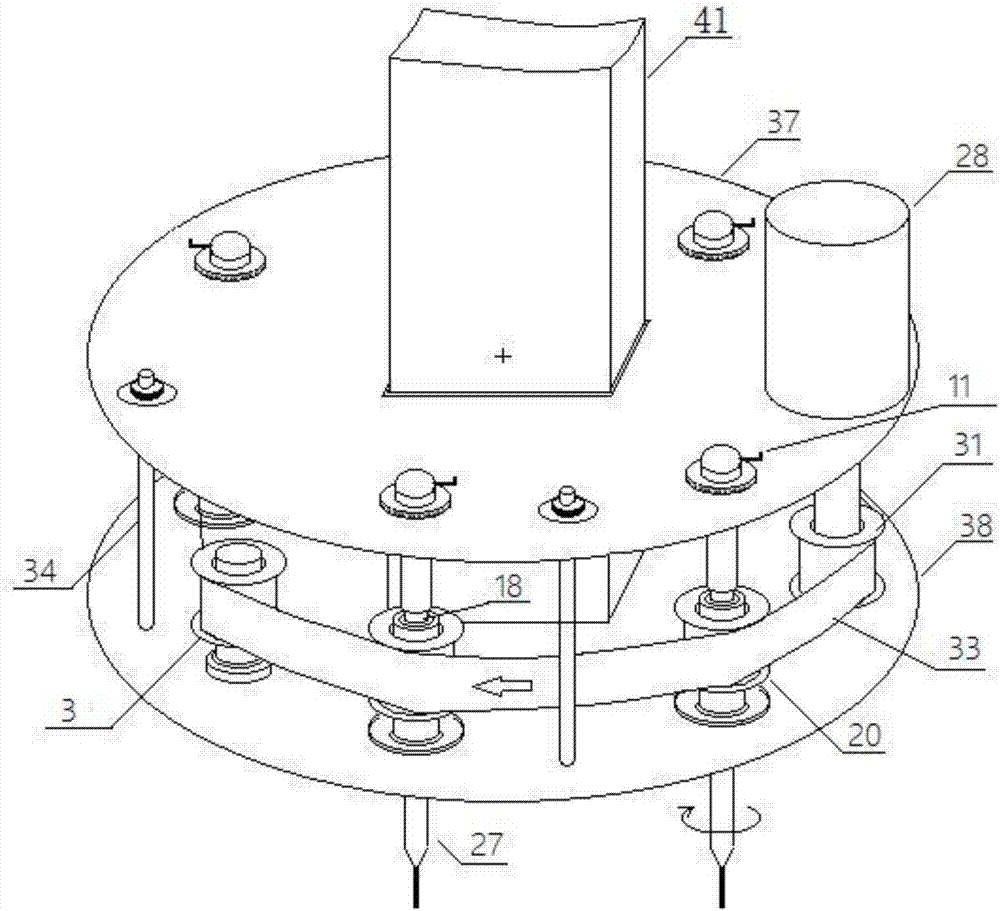

Clamp device used for electric spark pulse discharging and synchronous rotating machining for multiple fine holes

ActiveCN107159981ARealize simultaneous processingRealize batch processingElectrical-based auxillary apparatusElectric machineEnergy control

The invention relates to a clamp device used for electric spark pulse discharging and synchronous rotating machining for multiple fine holes. The clamp device comprises a clamp disc, an electric brush disc, tool electrode clamps, electric brushes, a motor and a synchronous belt. The electric brush disc is located above the clamp disc. The tool electrode clamps are mounted on the clamp disc. The electric brushes and the motor are mounted on the electric brush disc. The electric brushes and the tool electrode clamps are arranged in an up-down corresponding mode. An output shaft of the motor drives the tool electrode clamps to rotate through the synchronous belt. By means of the specially-made clamp disc, the corresponding tool electrode clamps and the electric brush disc, multi-fine-hole workpieces can be machined in a synchronous mode; and meanwhile, during operation, all tool electrodes are mutually electrically insulated, independent discharging energy control can be conducted, and accordingly the phenomenon that short-circuit electrodes are burnt can be avoided. The clamp device provided by the invention is small in equipment cost input, synchronous machining of the multiple fine holes is achieved, the machining efficiency is improved by multiples, and the labor and time cost is lowered by multiples.

Owner:SHANDONG UNIV

High-efficiency paper tube dividing and cutting machine

Disclosed in the invention is a high-efficiency paper tube dividing and cutting machine comprising a motor, a blade, and clamping devices connected with an output shaft of the motor. Two clamping devices are respectively provided with a driving gear wheel and a driven gear wheel; and the two clamping devices are arranged side by side and the distance between the two clamping device is consistent with the radial dimension of the blade. The clamping devices contain rolling cylinders; cavities are formed inside the rolling cylinders; and a plurality of through hole groups are arranged at the excircle surfaces of the rolling cylinders. Each through hole group contains four through holes that are distributed uniformly; and the plane formed by central lines of the four through holes is perpendicular to the axis of each rolling cylinder. A pull rod is arranged in each rolling cylinder; square blocks are arranged on the pull rod, wherein the number of the square blocks is consistent with the number of the through hole groups; planes, parallel to the axis of the rolling cylinder, of the square blocks are inclined ones; and sliding blocks cooperating with the inclined surfaces are arranged on all inclined surfaces, also cooperate with the through holes, and penetrate the through holes. With the machine, the working efficiency is improved and the cost is lowered.

Owner:CHENGDU BAOMIHUA INFORMATION TECH

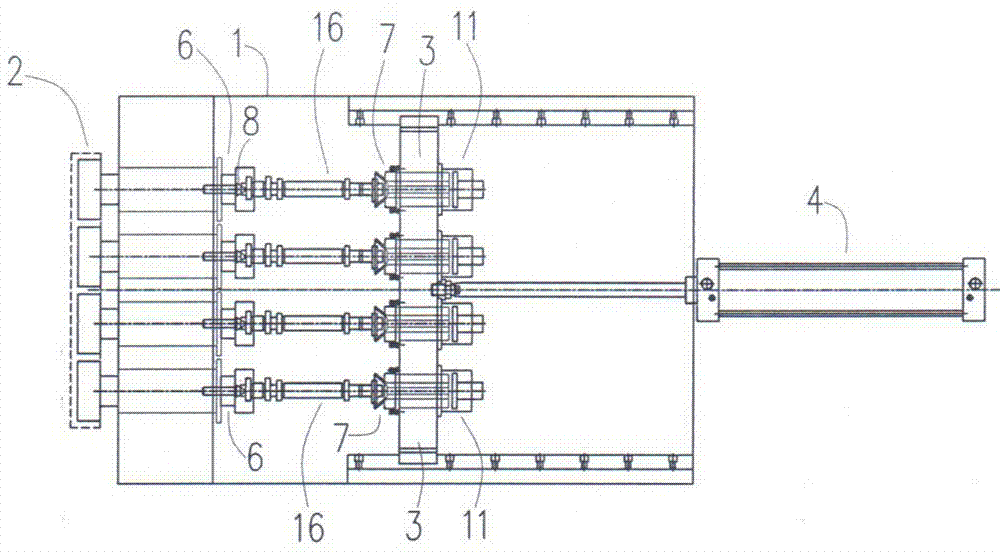

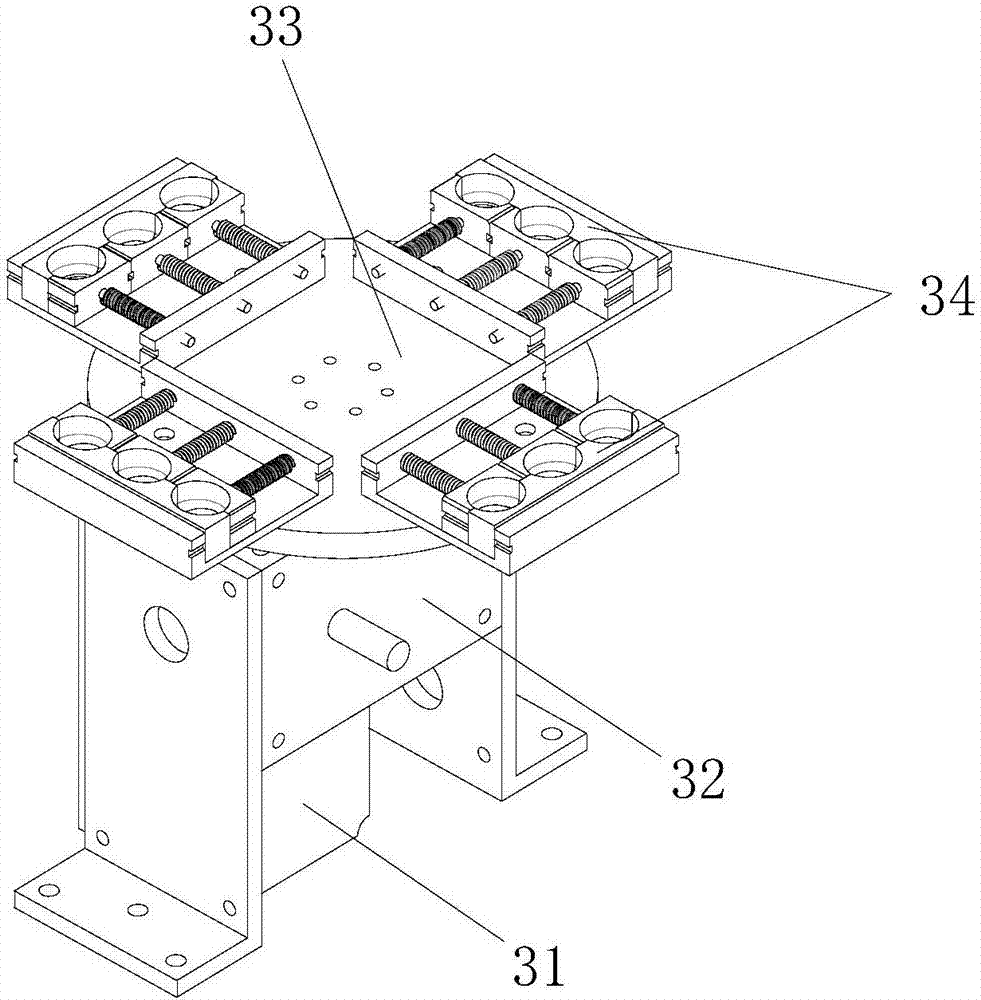

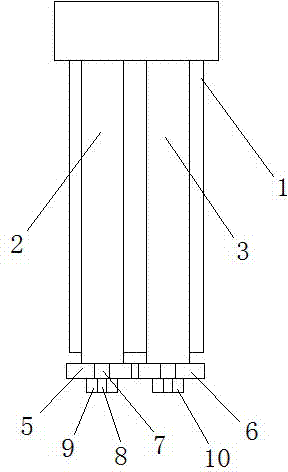

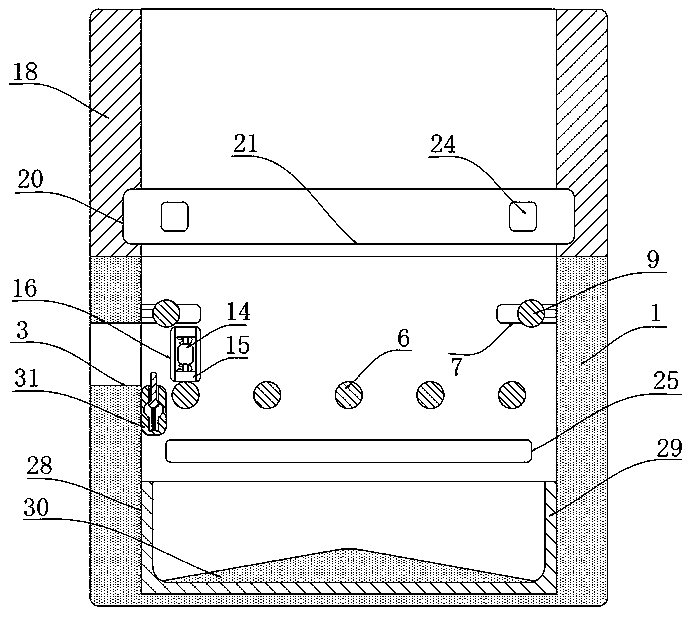

Multi-station pipe end machining equipment

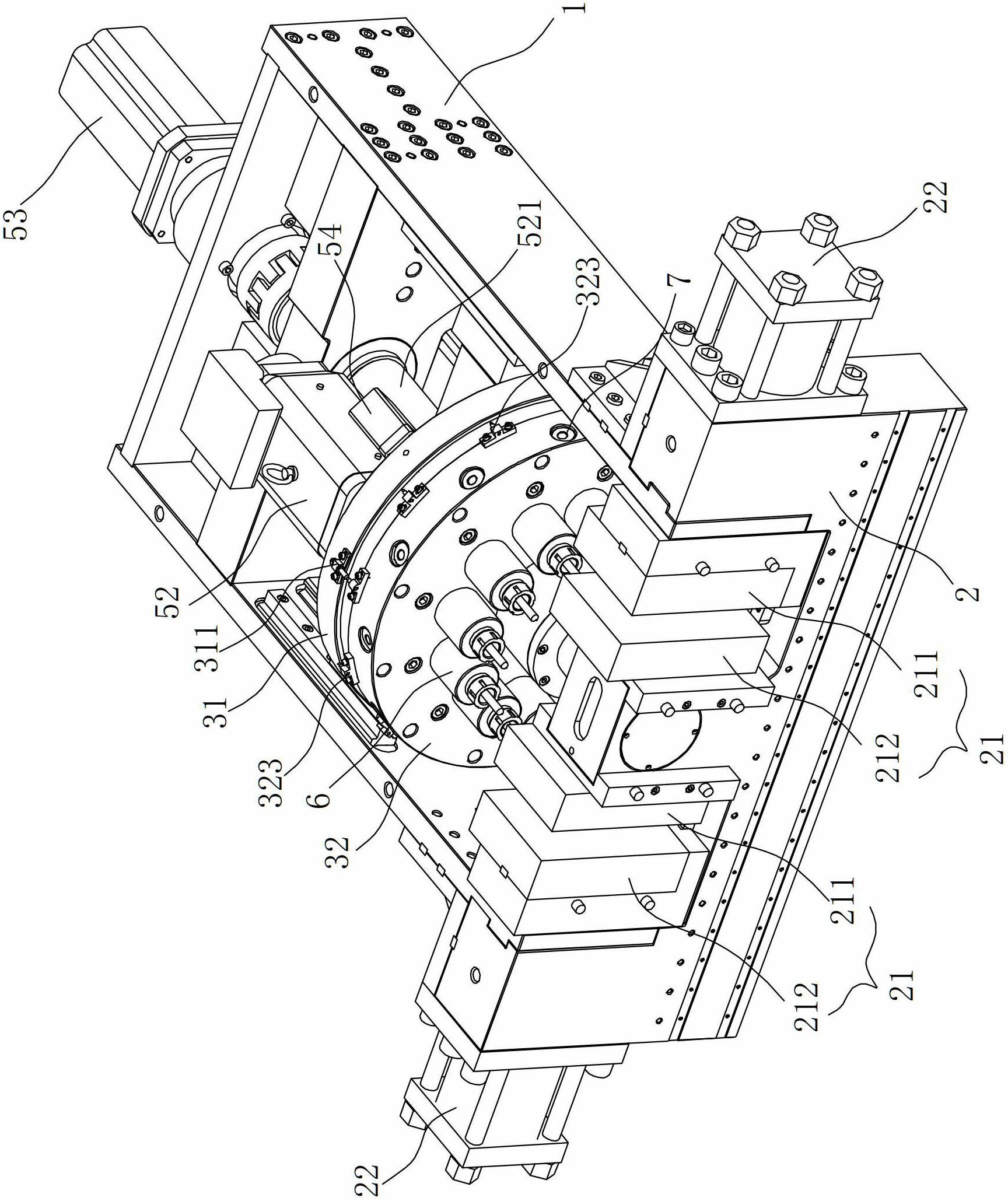

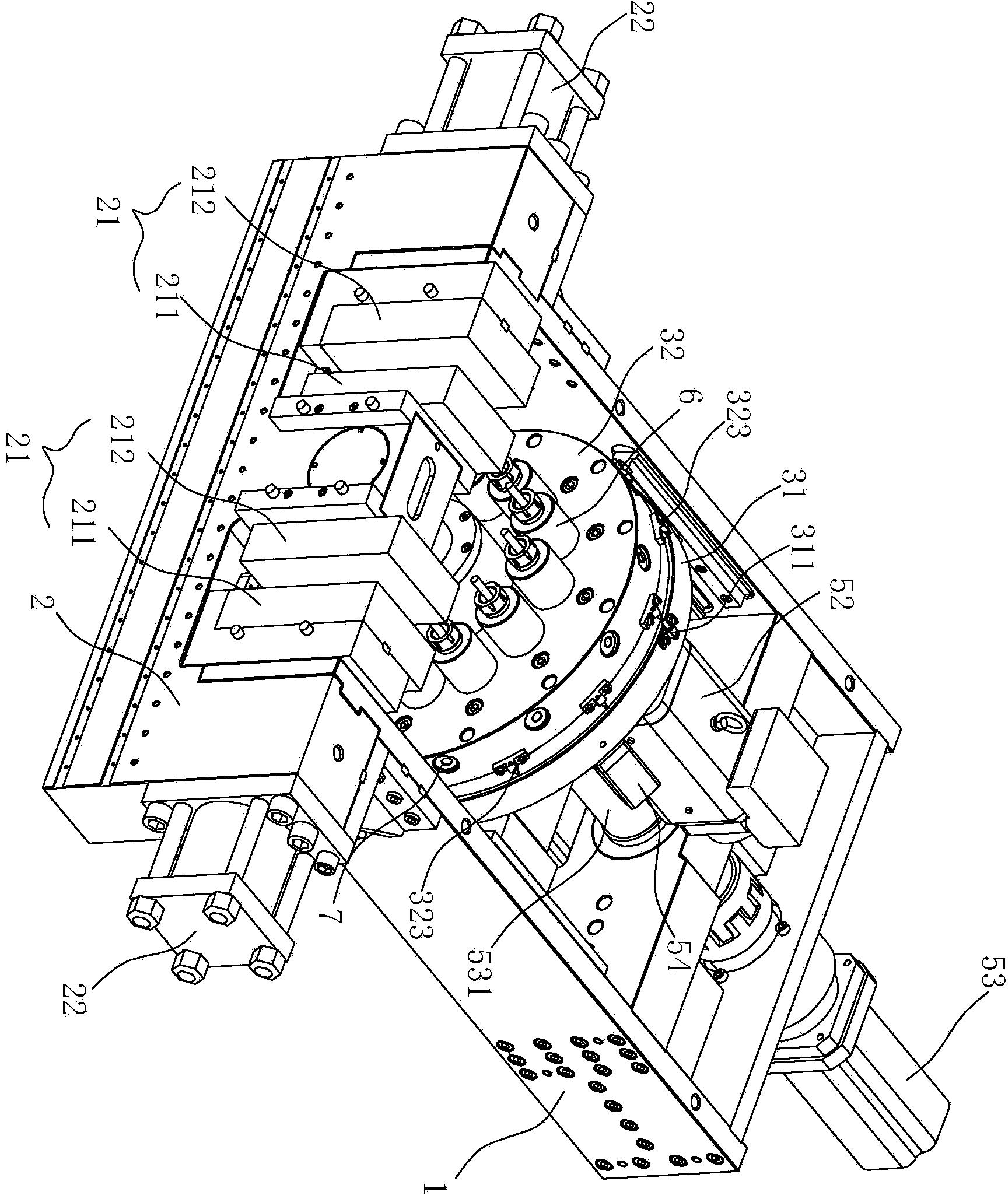

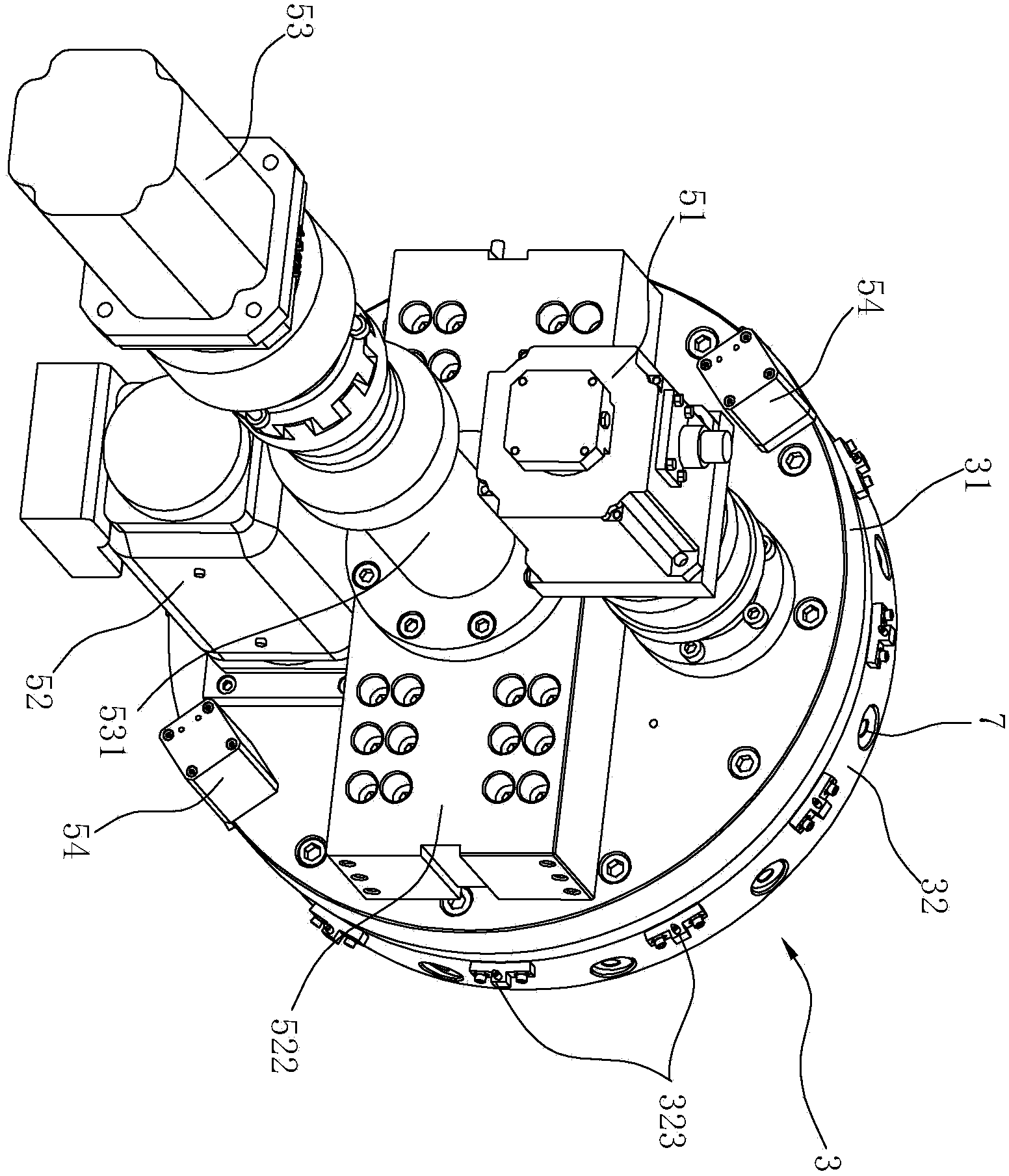

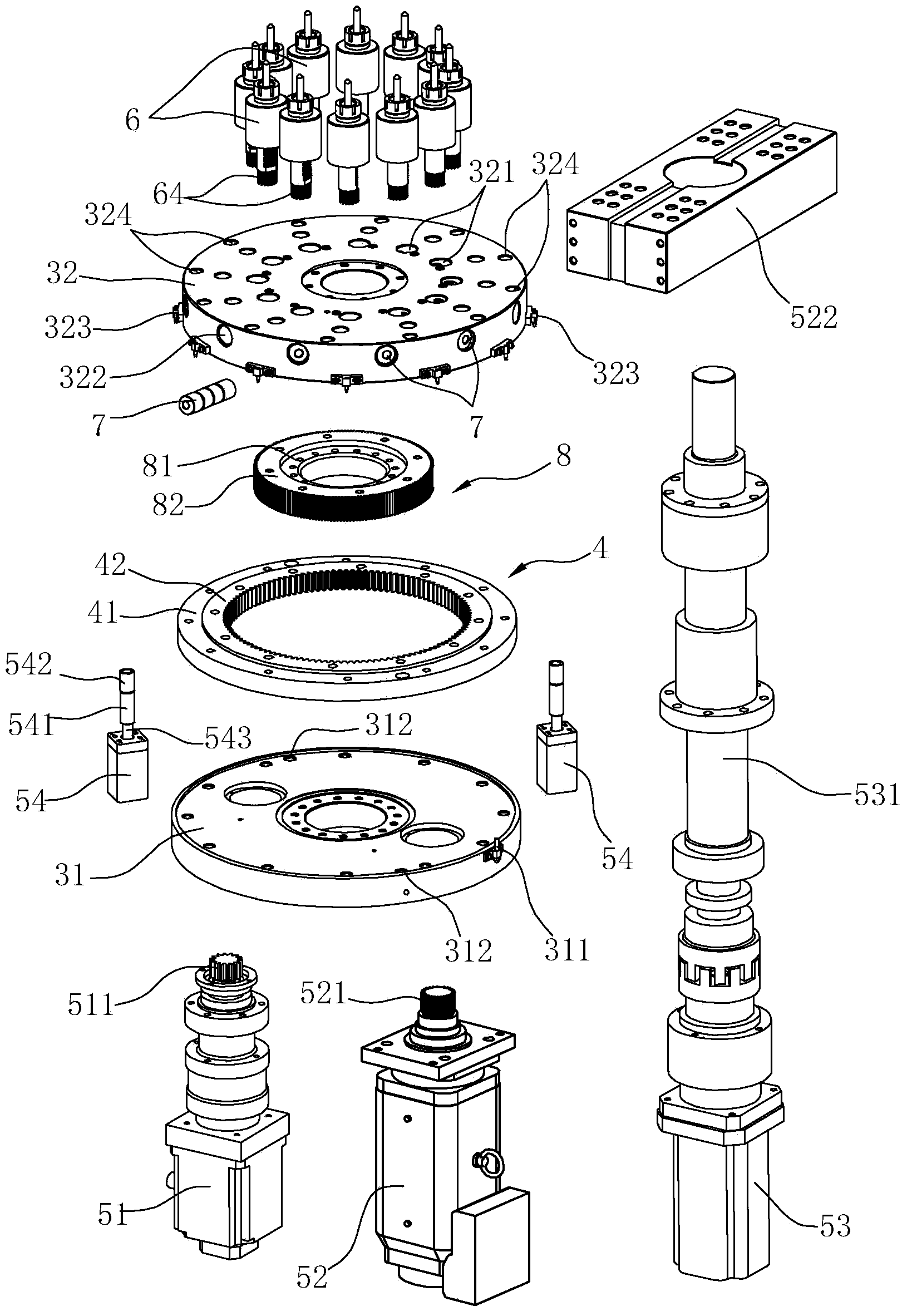

ActiveCN102689235BEasy loading and unloadingReduce replacement timeTool holdersDriving apparatusEngineeringWorkstation

Disclosed is multi-station pipe end machining equipment, comprising a machine base (1) and cutter saddle (3), wherein the cutter saddle (3) comprises a fixed plate (31) and a cutter head (32) rotatably connected to the fixed plate (31). Multiple cutters (6) are mounted circumferentially on the cutter head (32). The machine base (1) is also provided with a pipe clamping apparatus straight ahead of the cutter saddle (3). The pipe clamping apparatus comprises a workbench (2) with at least two workstations, wherein a mould (21) is provided on each workstation, and a mould cavity is provided in the moulds (21). A master driving apparatus able to move the cutter saddle (3) in a straight line is further provided on a machine frame. Multiple cutters with different functions can be mounted on the machining equipment at the same time, saving on time to replace cutters, and the multi-workstation workbench can achieve synchronous machining of multiple pipes, improving the utilization factor of the equipment.

Owner:ZHEJIANG MOTORBACS TECH

Tapping device for stop ring of clutch machine cover

InactiveCN106271624AEnables rotary machiningRealize simultaneous processingOther manufacturing equipments/toolsDriving apparatusEngineeringDrill

The invention belongs to the technical field of mechanical processing, and particularly relates to a tapping device for a stop ring of a clutch machine cover. A rotary motor is arranged on a base; a rotary shaft is arranged on the top of the rotary motor; the outer surface of the rotary shaft is sleeved by the stop ring; a first processing motor and a second processing motor are further arranged on the base; a first processing shaft is further arranged on the top of the first processing motor; a second processing shaft is arranged on the top of the second processing motor; a drill spindle and a screw tap are arranged above the stop ring; the drill spindle passes through a first circular hole; the screw tap passes through a second circular hole; a drill spindle limiting block is arranged on the top of the drill spindle; a screw tap limiting block is arranged on the top of the screw tap; the drill spindle limiting block and the screw tap limiting block are positioned on the upper surface of a supporting plate; the drill spindle and the first processing shaft are sleeved by a first synchronous belt; and the screw tap and the second processing shaft are sleeved by a second synchronous belt.

Owner:TIANJIN DINGCHENG ALUMINUM DIE CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com