Tool electrode clamp for multi-micropore electric spark discharge synchronous machining

A tool electrode and spark discharge technology, which is applied in the direction of electric processing equipment, manufacturing tools, electrode manufacturing, etc., can solve the problems of short-circuit micro-electrode burnt, electrodes cannot be electrically insulated, and group electrodes are difficult to manufacture, so as to improve chip removal effect and manufacture The effect of low cost and small equipment cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

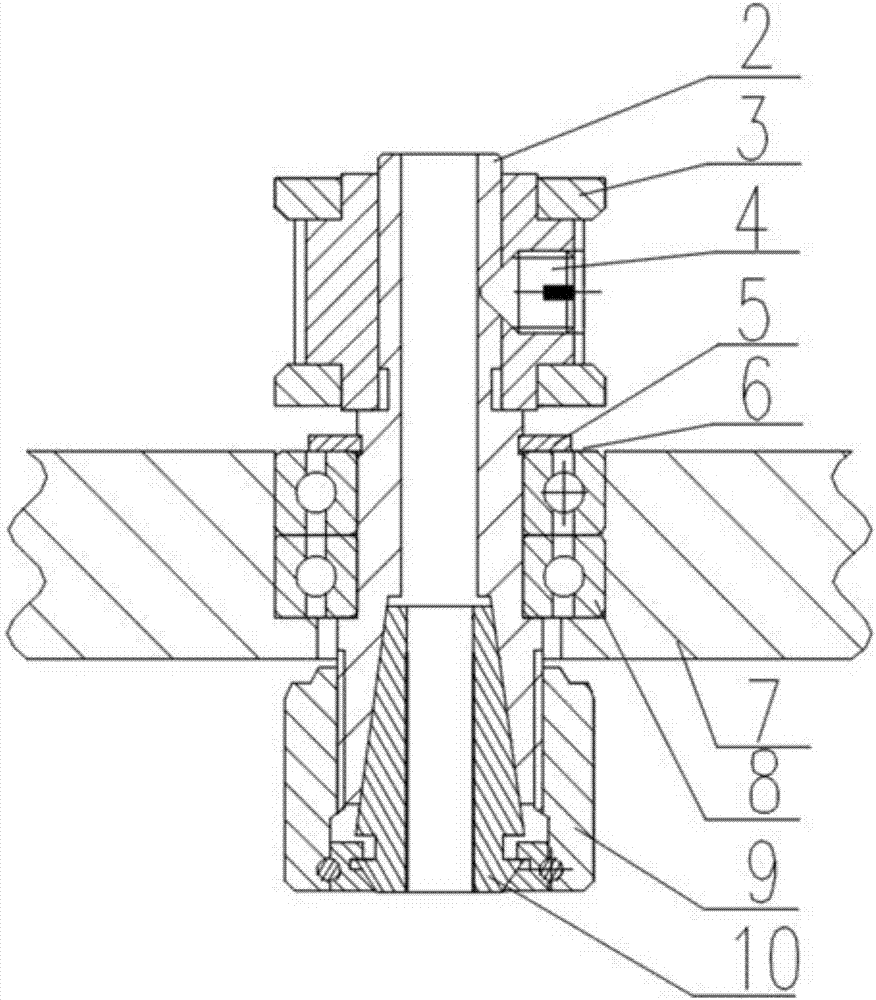

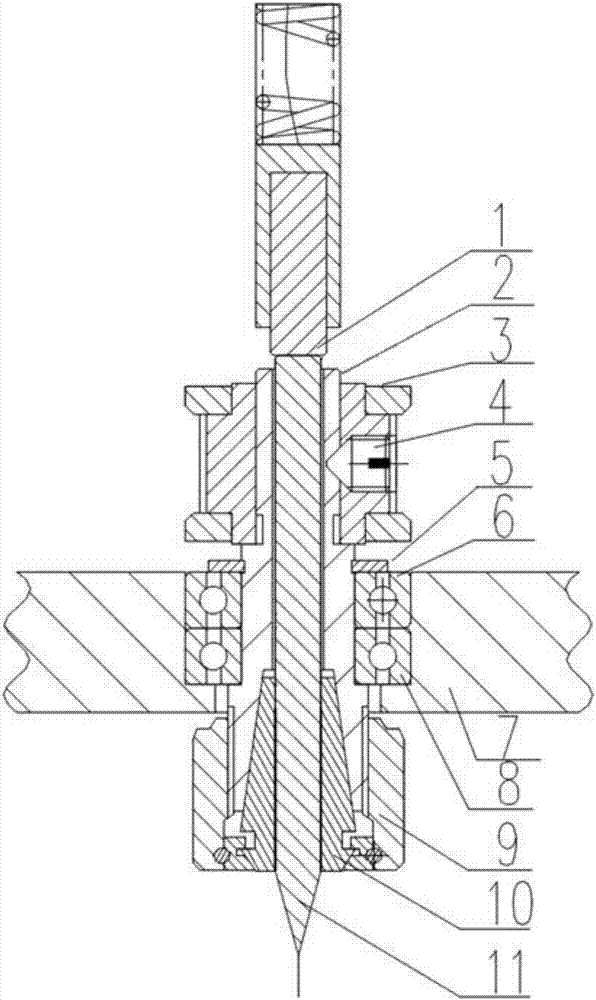

[0038] Such as Figure 1 to Figure 9 As shown, this embodiment provides a tool electrode fixture for synchronous EDM machining with multiple pores, including:

[0039] - hollow stepped shaft 2 for placing the tool electrode 11;

[0040] —The pulley 3 is connected with the upper part of the hollow stepped shaft 2, and is used to drive the rotation of the hollow stepped shaft 2;

[0041] - Collet 10 and nut 9 , the collet 10 is connected to the bottom of the hollow stepped shaft 2 and locked by the nut 9 , the collet 10 is used to fix the tool electrode 11 .

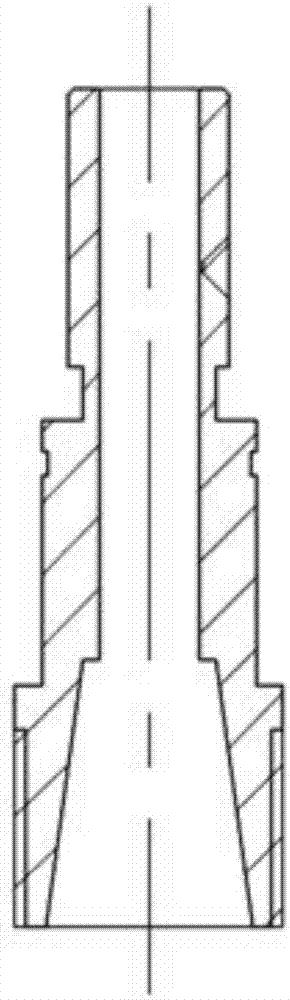

[0042] Among them, the hollow step shaft 2 is a non-standard part, which is processed from bar stock, with a total length of 38.5mm, a maximum outer diameter of Φ10.0mm, and a central hole (cavity) diameter of Φ3.3mm, such as image 3 shown. The hollow stepped shaft 2 includes two shaft shoulders, the two shaft shoulders are the first shaft shoulder and the second shaft shoulder respectively, the pulley 3 is located at ...

Embodiment 2

[0049] Using the method of using the tool electrode fixture for multi-micropore EDM synchronous machining described in Example 1, the tool electrode fixture needs to be used with a specially designed fixture plate, and a plurality of tool electrode fixtures are provided on the fixture plate The step hole, the specific use process is as follows:

[0050](1) Assemble the bearings 6 and 8 into the stepped holes of the fixture disc 7 in an interference fit manner;

[0051] (2) Put the middle step of the hollow step shaft 2 into the inner rings of the two bearings 6 and 8 in the step hole of the fixture disc 7 in an interference fit manner, and then install the bearing retaining ring 5;

[0052] (3) Fix the pulley 3 to the first shoulder of the upper stepped shaft of the hollow stepped shaft 2 by using the set screw 4 .

[0053] Next, the process of installing the tool electrode 11, such as figure 2 shown.

[0054] (4) Clip the collet 10 into the nut 9;

[0055] (5) Insert the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter φ | aaaaa | aaaaa |

| Outer diameter φ | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com