Chip cleaning device in nc processing machine

A technology of cleaning device and chip, applied in machine tool parts, metal processing machinery parts, maintenance and safety accessories, etc., to achieve the effect of improving chip removal ability, expanding cleaning range, and expanding reachable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

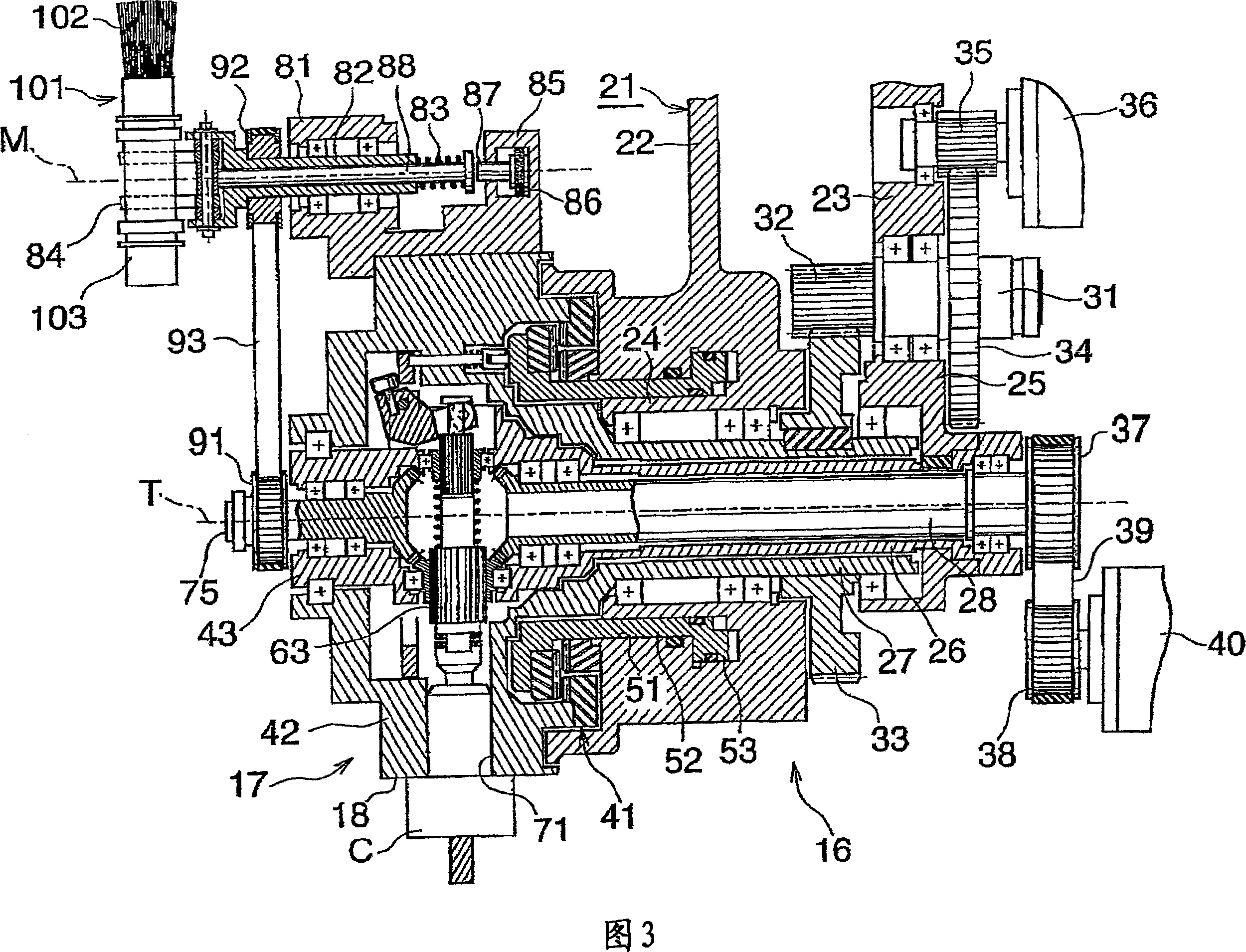

[0022] Embodiments of the present invention will be described below with reference to the drawings.

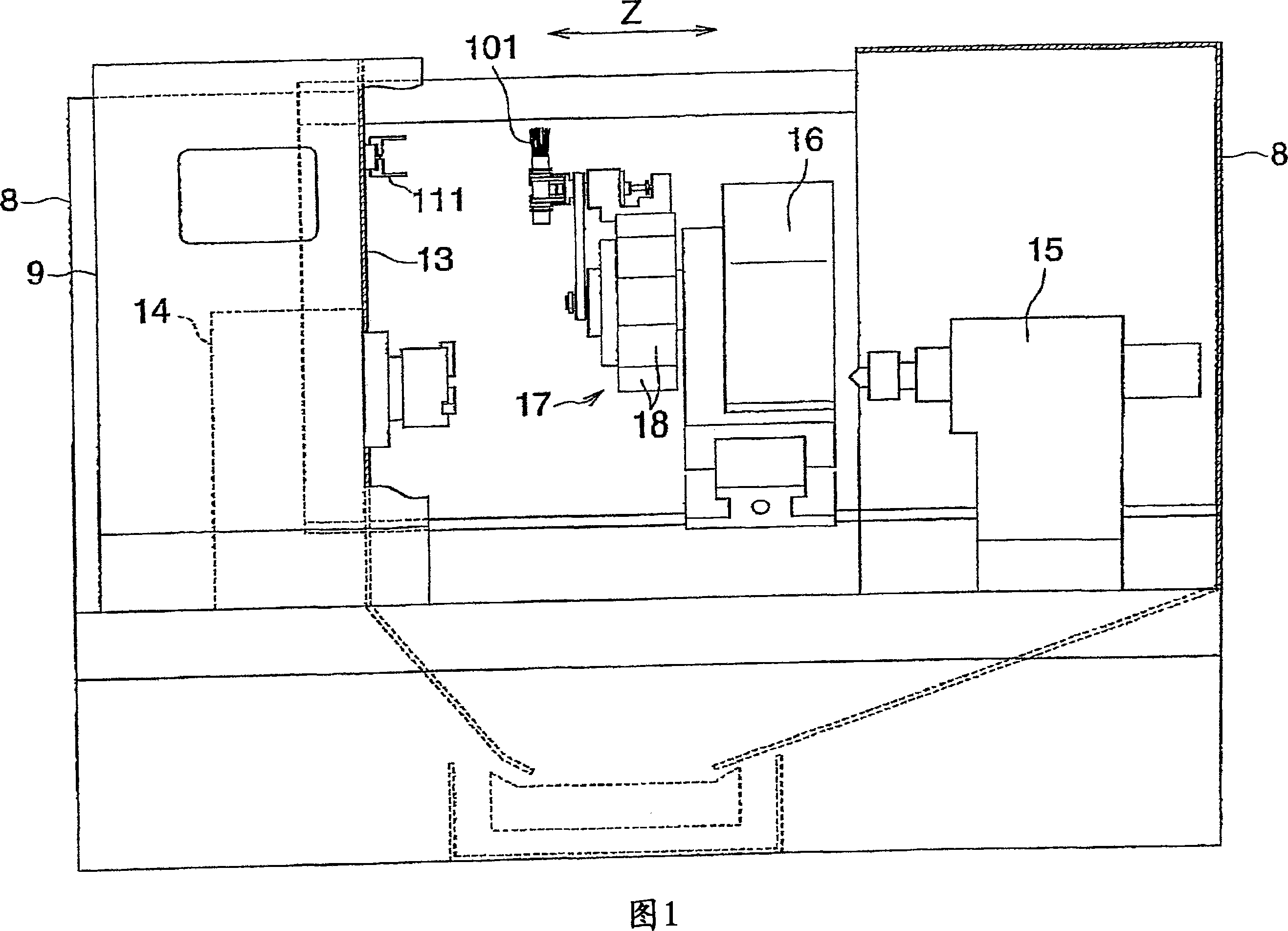

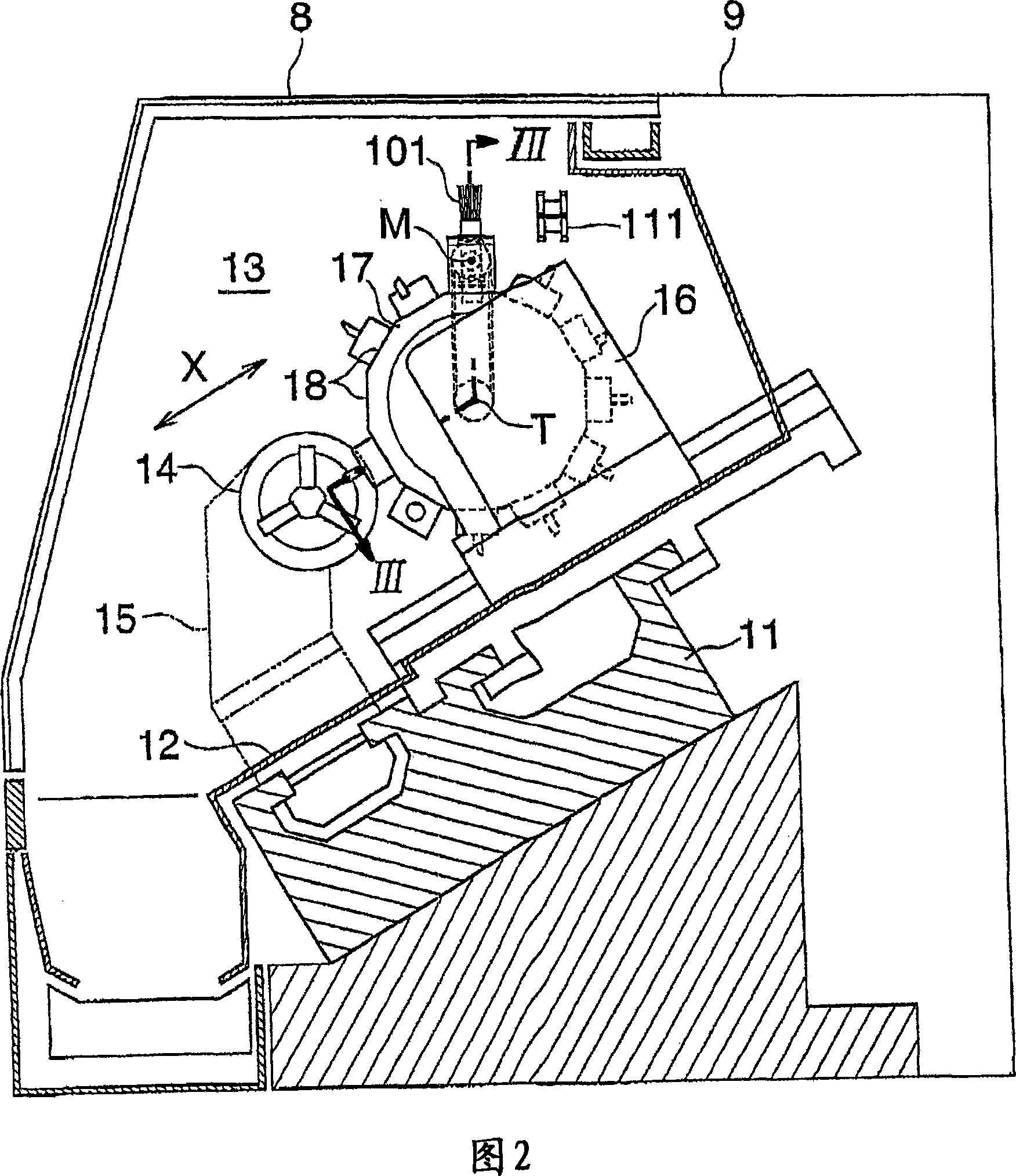

[0023] In Figure 1 and Figure 2, the overall structure of the CNC machine tool is shown. In the following description, the front-rear direction (Z-axis direction) means that the left side in FIG. left and right sides).

[0024] The bed 11 is provided with a right upper inclined top surface. The direction perpendicular to the Z direction and inclined along the top surface of the bed is the X direction. In the rear space of the partition cover 13, a processing chamber is formed by the outer cover 12 covering the right side from the top surface of the bed, the door 9 covering the integral cover 8 and a part of the notch of the integral cover, and the partition cover 13.

[0025] On the left side of the bed top surface, a headstock 14 and a tailstock 15 are mounted to face each other. The front end portion of the headstock 14 penetrates the partition cover 13 and enters the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com