Horizontal double-tool embroidery machine

A turning and horizontal technology, which is applied in the direction of turning equipment, turning equipment, tool holder accessories, etc., can solve the problems of low processing efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

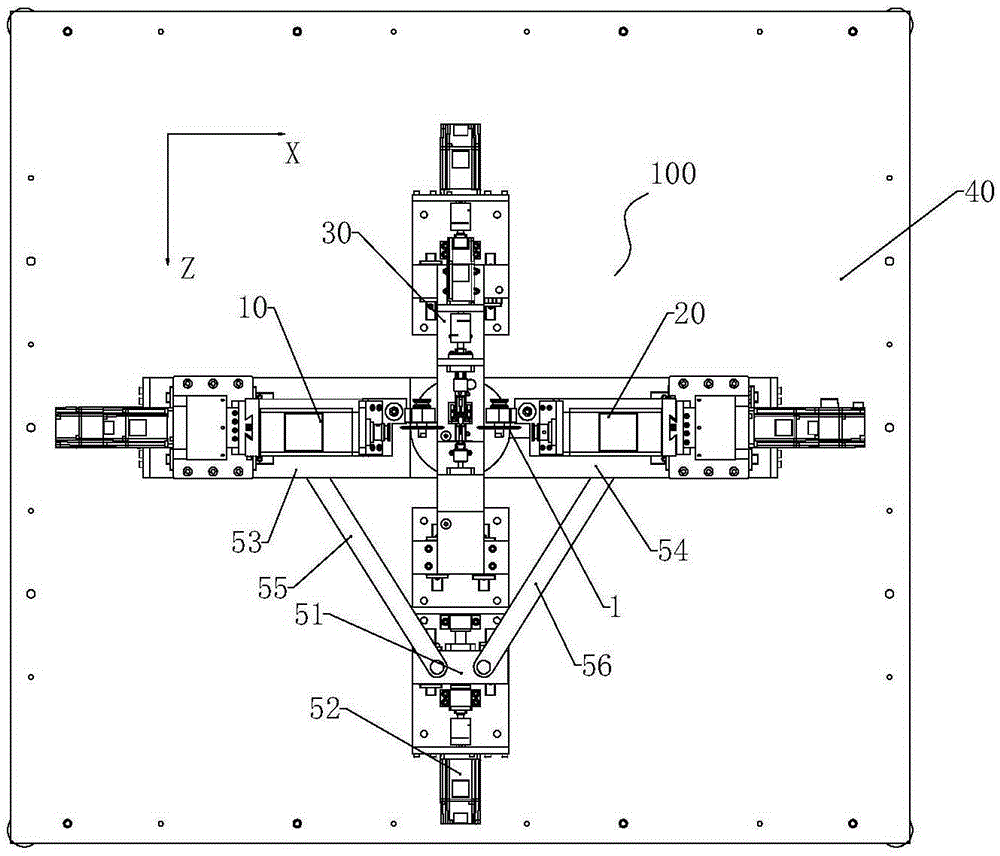

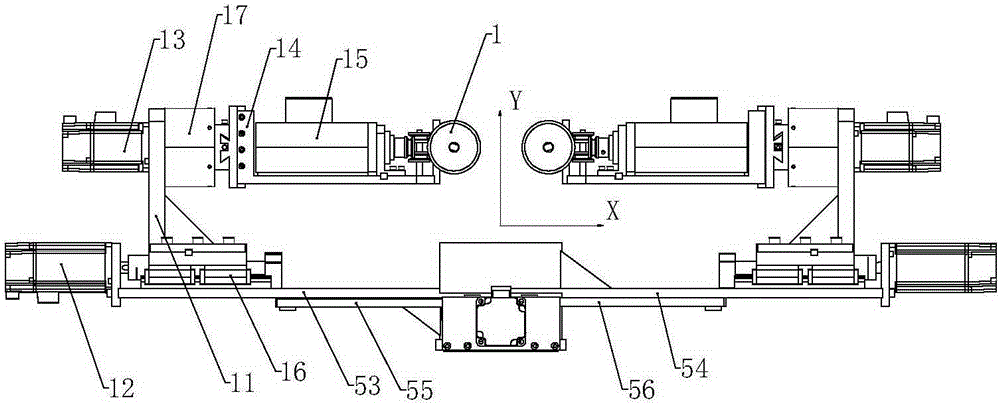

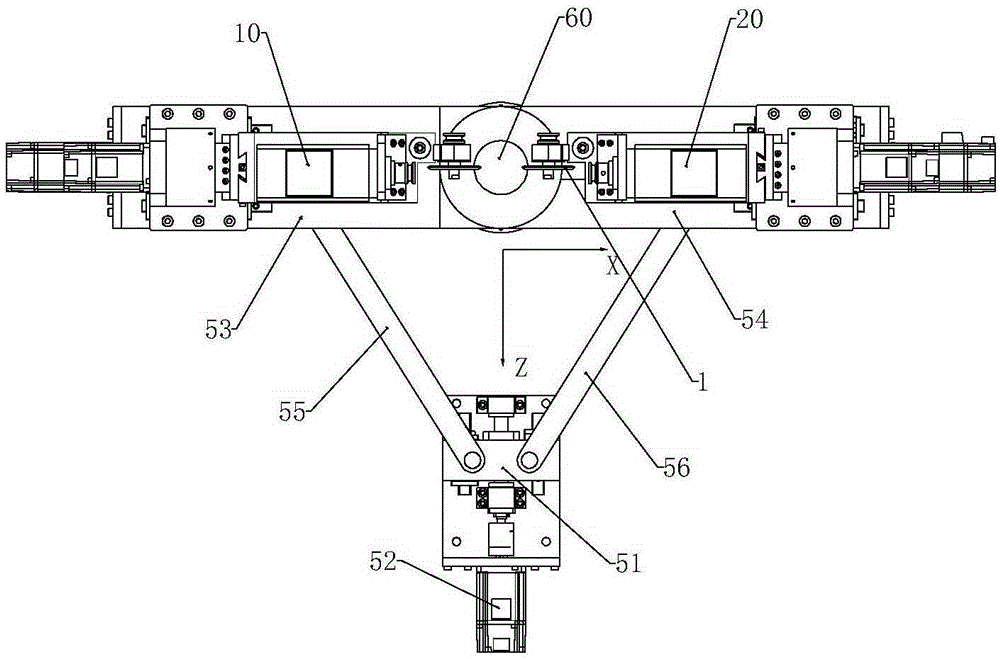

[0036] Such as figure 1 As shown, the present invention provides a horizontal double-knife turning machine 100, which is used for turning and turning jewelry. The inventor fully analyzed the pattern styles of jewelry currently on the market, and took advantage of the fact that most of the jewelry is a rotating body and each circle of patterns around the rotating body is symmetrical, and studied the realization of the double-knife machining of the car and flower machine. The horizontal double-knife turning machine 100 utilizes the offset crank-slider mechanism to design the motion trajectory of the tool-feeding module, so as to realize the simultaneous machining of two knives during the machining process, thereby greatly improving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com