High-efficiency paper tube dividing and cutting machine

A paper tube slitting machine, high-efficiency technology, applied in the direction of metal processing, etc., can solve the problems of low production efficiency, low processing efficiency, high cost, etc., and achieve the effect of improving processing efficiency, uniform force, and synchronous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

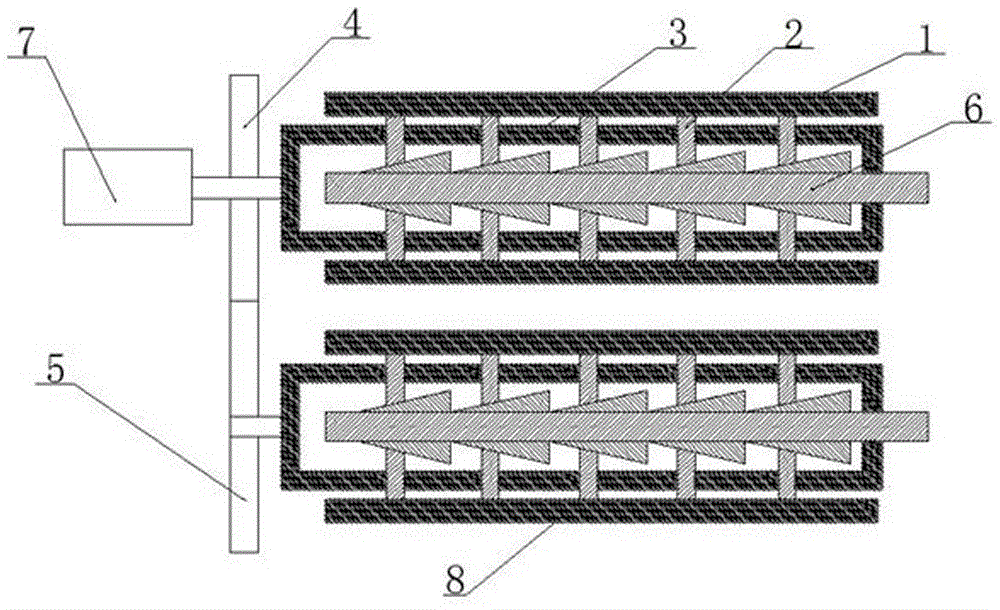

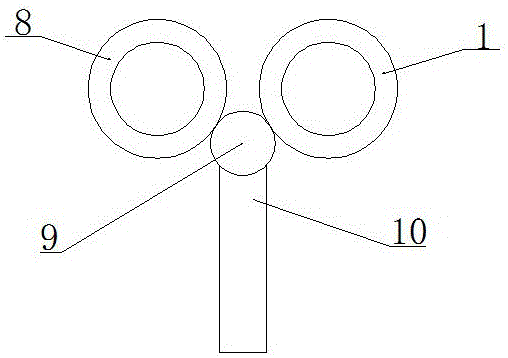

[0013] Figure 1-2 Shown is the high-efficiency paper tube slitting machine provided by the present invention, including slider 2, roller 3, first paper tube 1, driving gear 4, pull rod 6, motor 7, second paper tube 8, blade 9, telescopic Rod 10 and driven gear 5. The clamping device is connected with the output shaft of the motor 7; the clamping device is two, and the two clamping devices are respectively provided with a driving gear 4 and a driven gear 5; the two clamping devices are arranged side by side, and The distance between the two clamping devices is consistent with the radial dimension of the blade 9; the clamping device includes a drum 3, the inside of the drum 3 is a cavity, and the outer circular surface of the drum 3 is provided with a plurality of through hole groups, the through hole groups It in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com