Internal-and-external tooth structure machining device of tooth-shaped linings

A processing device, internal and external gear technology, applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc., can solve the problems of poor dimensional consistency, easy out-of-tolerance coaxiality, difficult product assembly, etc., to achieve improved consistency, High processing efficiency and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with specific drawings.

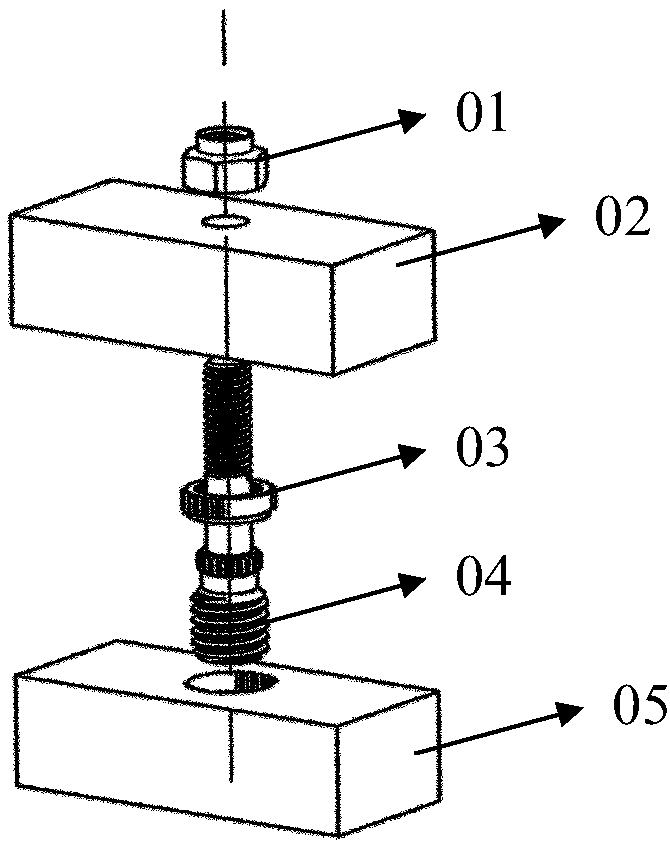

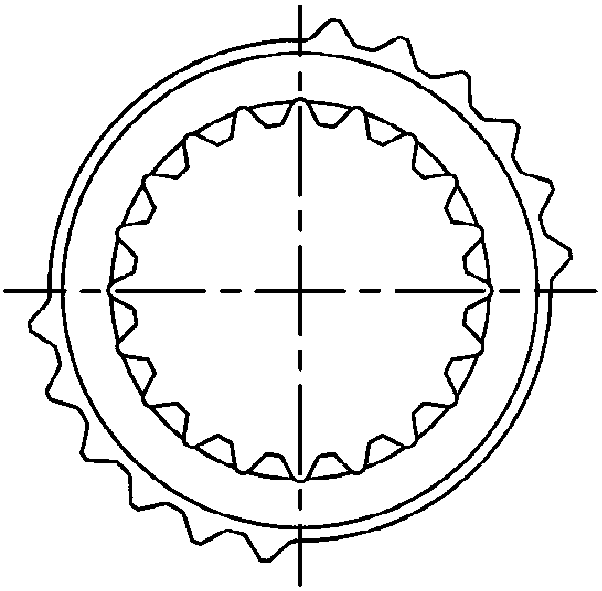

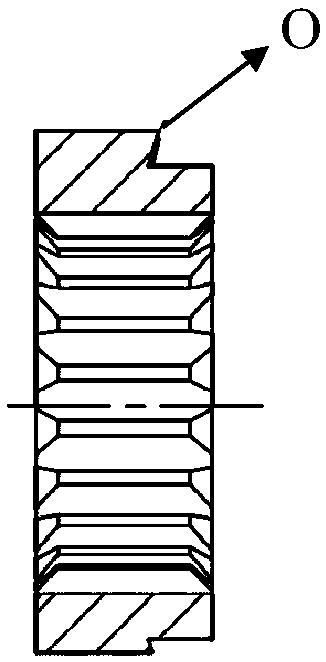

[0026] The internal and external gear structure processing device of the toothed bush of the present invention, such as Figure 7-8 , including a pressing plate 100, a main body 200, a positioning ring 300 and a positioning pincer 400; the main body 200 is in the shape of a rectangular parallelepiped column, and the middle part is provided with a central passage capable of accommodating a toothed bushing blank 500 along the axial direction (the extending direction of the rectangular parallelepiped columnar body). hole 201, one side of the main body 200 is also axially provided with a slot 202 communicating with the central through hole 201, the positioning ring 300 can move axially in the central through hole 201 of the main body 200, and It can be detachably fixed on the side wall of the main body 200, the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com