Clamp device used for electric spark pulse discharging and synchronous rotating machining for multiple fine holes

A technology of pulse discharge and fixture device, which is applied to electric processing equipment, manufacturing tools, accessories, etc., can solve the problems of short-circuited fine electrodes burning, limited depth of processing holes, and difficulty in making group electrodes, so as to improve the chip removal effect and the manufacturing process. The effect of low cost and small equipment cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

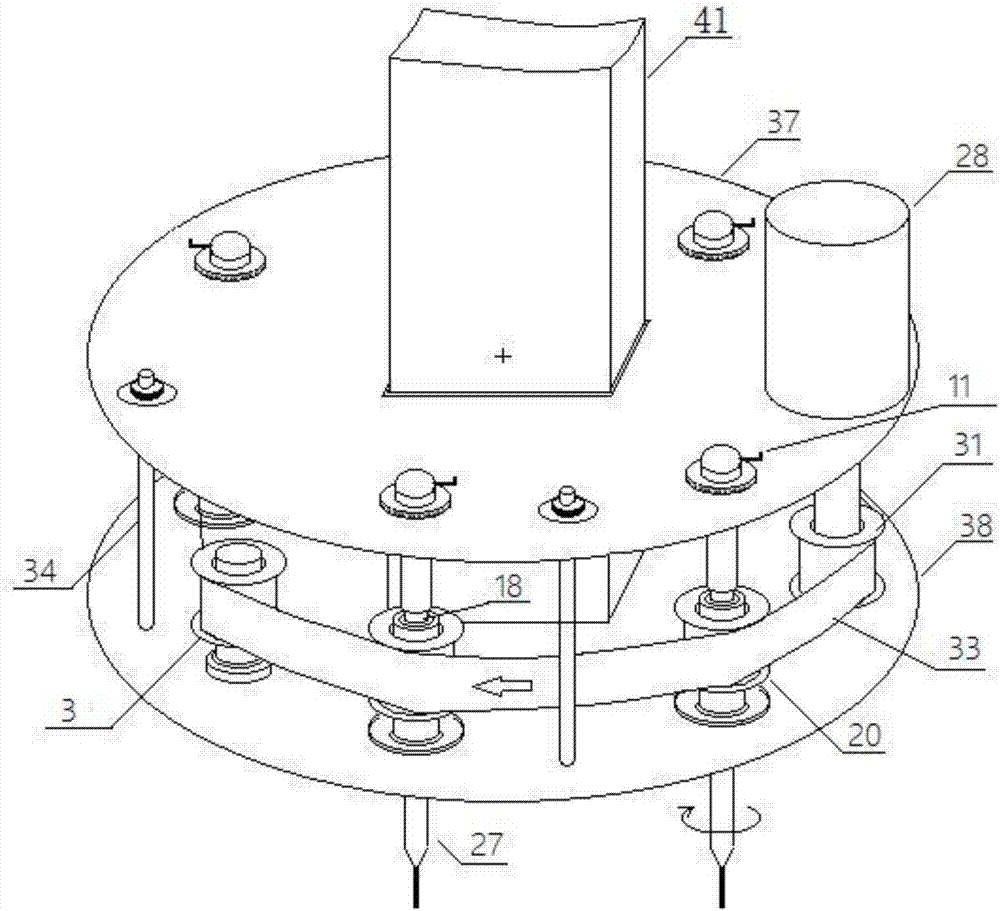

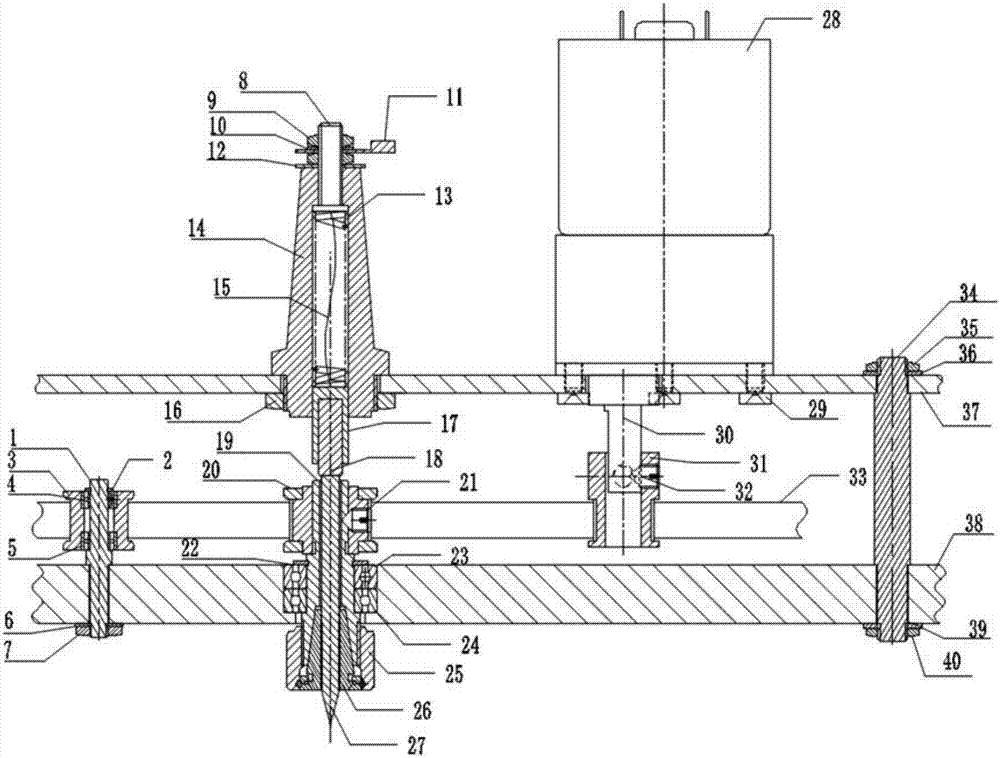

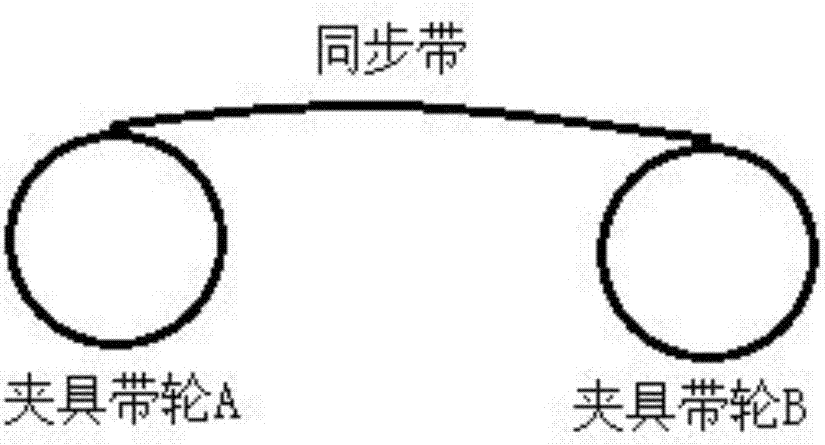

[0033] This embodiment provides a fixture device for multi-micropore EDM pulse discharge synchronous rotary machining, including a fixture plate 38, a brush plate 37, a tool electrode fixture, a brush, a motor and a timing belt 33; the brush plate 37 is located at Above the fixture plate 38, the tool electrode fixture is installed on the fixture plate 38, the brush and the motor are installed on the brush plate 37, the brush corresponds to the tool electrode fixture up and down, and the output shaft 30 of the motor drives the tool electrode fixture to rotate through the timing belt 33 .

[0034] Wherein, the brush plate 37 and the fixture plate 38 are connected up and down by three bolts 34, and the three bolts 34 are all long-axis stud bolts, and the two ends respectively pass through the fixture plate 38 and the brush plate 37 and pass through the washers (36, 39 ), nuts (35, 40) to connect.

[0035] The DC gear motor 28 is selected as the motor, and the DC gear motor 28 is...

Embodiment 2

[0043] A fixture device for synchronous rotary machining of multi-micropore EDM pulse discharge, the structure is as described in Embodiment 1, the difference is that the fixture device also includes a tension guide wheel 3, and the tension guide wheel 3 passes through the fixed shaft 1 is installed on the fixture disk 38, the bottom end of the fixed shaft 1 is fixedly connected to the fixture disk 38 through the washer 6 and the nut 7, two upper and lower bearings (4, 5) are arranged between the tensioning guide wheel 3 and the fixed shaft 1 and The bearing retaining ring 2 is fixedly installed, and the synchronous belt 33 is wound around the tension guide wheel 3 .

[0044] The tension guide wheel 3 adopts a small size design to reduce the occupied space of the clamp disc 38 . The tension guide wheel 3 is a smooth wheel of MXL16 size, with a pitch diameter of Φ9.8mm, a width of 7mm, a total thickness of 10mm, and a pitch of 2.032mm. Two ball bearings 4 and 5 are installed in...

Embodiment 3

[0051] The installation method of the fixture device for multi-micropore EDM pulse discharge synchronous rotary machining described in Embodiment 2, the specific operation process is as follows:

[0052] (1) Confirm the direction of the timing belt 33 according to the position of the machining hole, and calculate and confirm the installation position of the tension guide wheel 3;

[0053] (2) Preliminarily draw up the shape and outline of the fixture disc 38;

[0054] (3) Determine the hole position of the bolt 34 for installing the fixed brush plate 37, Figure 5 Three-point positioning is used in this method, that is, three through holes will be drilled on the fixture plate 38 for installing the bolts 34 connected to the brush plate;

[0055] (4) Taking account of the center of gravity of the brush plate 37 to calculate the clamp plate 38, the center of gravity is drawn up as the installation position of the vibration connecting rod 41; Adjust the shape and profile of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com