On-line preparation method of line electrode of minuteness group lines

A wire electrode, micro technology, applied in the field of precision micro electrochemical machining, can solve problems such as clamping and positioning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

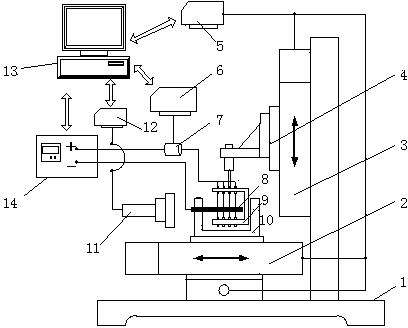

[0021] according to figure 1 As shown, the online preparation and device of micro-group wire electrodes of the present invention mainly include PCI motion control card 5 and industrial computer 13; also include active vibration isolation platform 1, X-Y axis precision mobile platform 2 on active vibration isolation platform 1, machine tool The column and the Z-axis precision mobile platform 3 located on the machine tool column, the group line installation fixture 9 is installed on the workpiece fixture 4 located on the Z-axis precision mobile platform 3; the cathode tool 8 installed horizontally in the electrolytic cell 10, and the DC power supply 14 The positive and negative poles are respectively connected to the group line electrode on the group line installation fixture 9 and the cathode tool 8, and the current value change in the process is measured and monitored by the current sensor 7; in addition, a CCD11 and a video acquisition card 12 are also included.

[0022] fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com