Full-automatic groove broacher for wood processing

A fully automatic groove processing technology, which is applied in wood processing equipment, slotting machines, special forming/shaping machines, etc., can solve the problems of low processing efficiency and difficult disposal of waste materials, so as to avoid waste of manpower, effectively collect and avoid The effect of repeated joins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

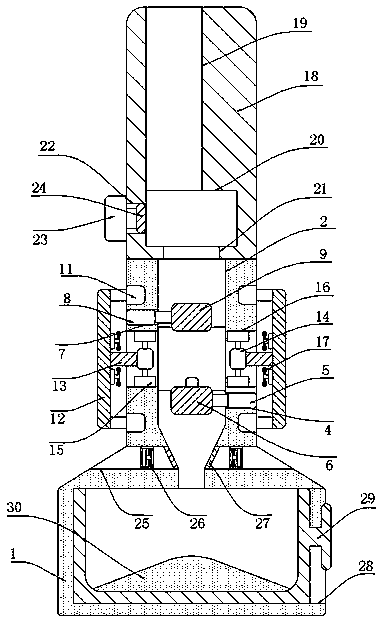

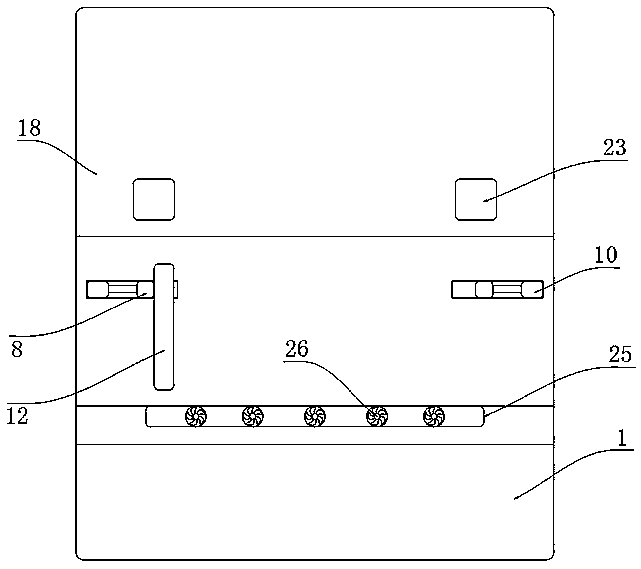

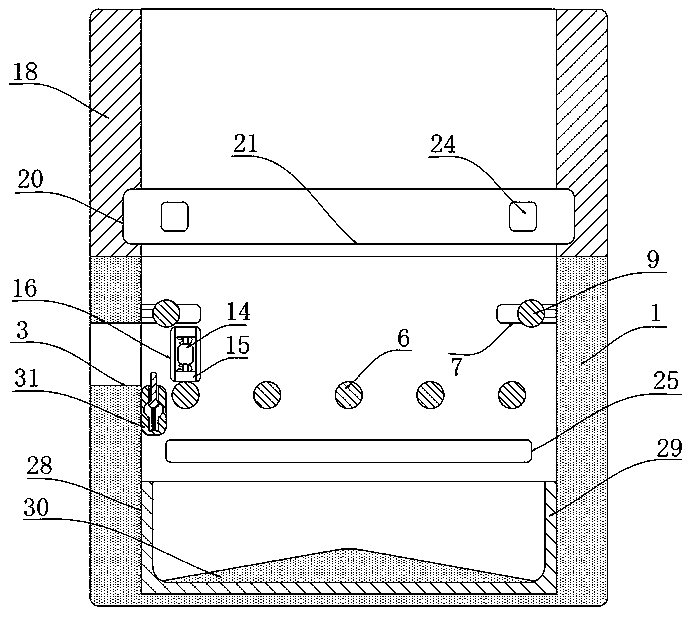

[0026] refer to Figure 1-5 , a fully automatic slotting machine for wood processing, comprising a processing table 1, the upper end of the processing table 1 is provided with a processing slot 2, the side wall of the processing slot 2 is provided with an outlet slot 3, and the inner wall of the processing slot 2 is provided with a A plurality of transport troughs 4, the inner wall of each transport trough 4 is welded with a conveying motor 5, the output shaft of each conveying motor 5 is welded with a conveying runner 6, and the outer walls of both sides of the processing table 1 are symmetrically welded with two sets of clamping Push rods 11, each group of clamping push rods 11 is welded with a clamping plate 12 at the end far away from the processing table 1, and a plurality of fans 17 are fixed on the side of the clamping plate 12 close to the processing table 1, and the fans 17 flow to the inside of the processing tank 2. The blowing makes the waste material produced in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com