Bearing full-automatic production assembly line and technology

A production line, fully automatic technology, applied in the field of bearing processing, can solve the problems of high labor intensity in manual handling, slow workpiece transfer speed, low processing efficiency, etc., to reduce the number of feeding machines, increase processing speed, and facilitate blanking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

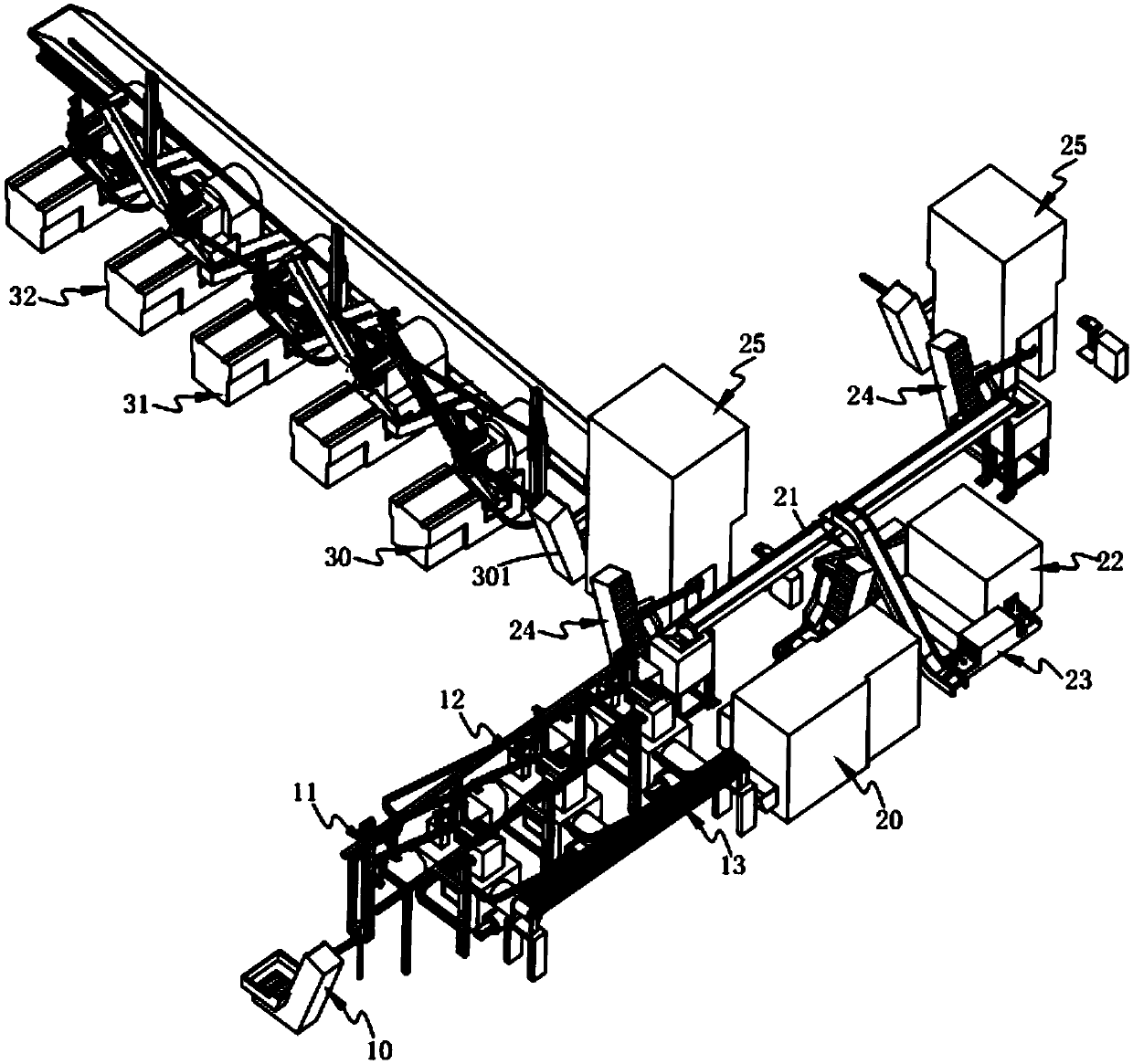

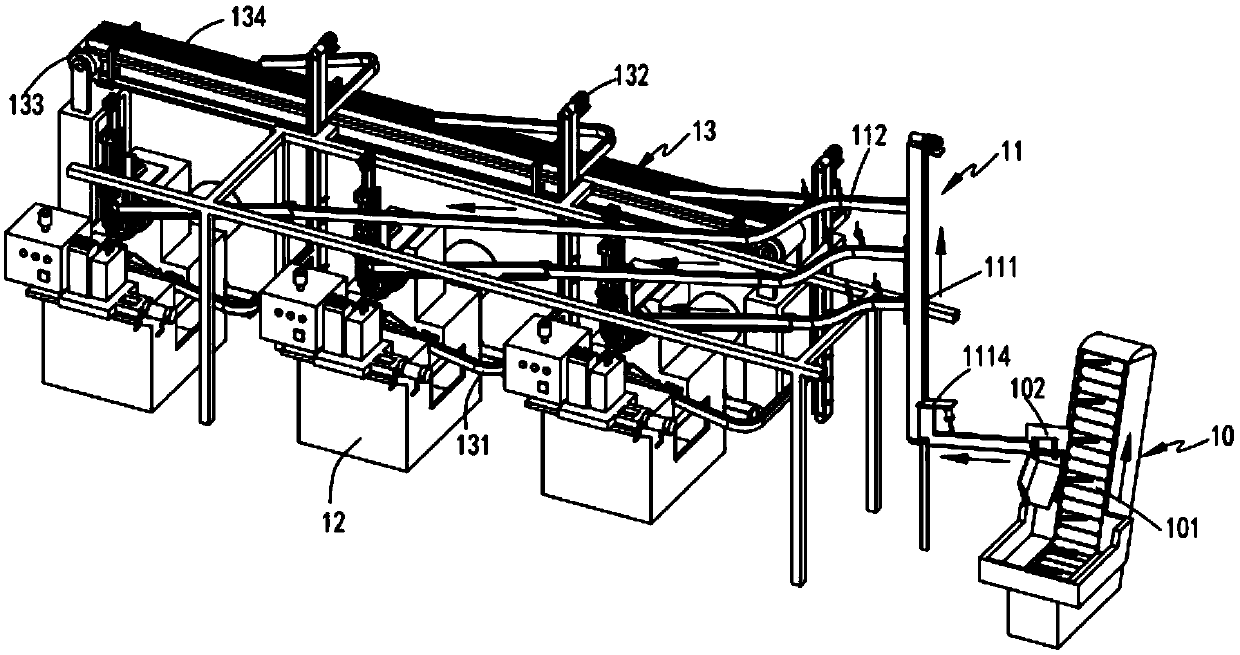

[0086] Such as figure 1 As shown, a fully automatic production line for tapered bearings, including rough machining system I, cold forging system II and finishing system III:

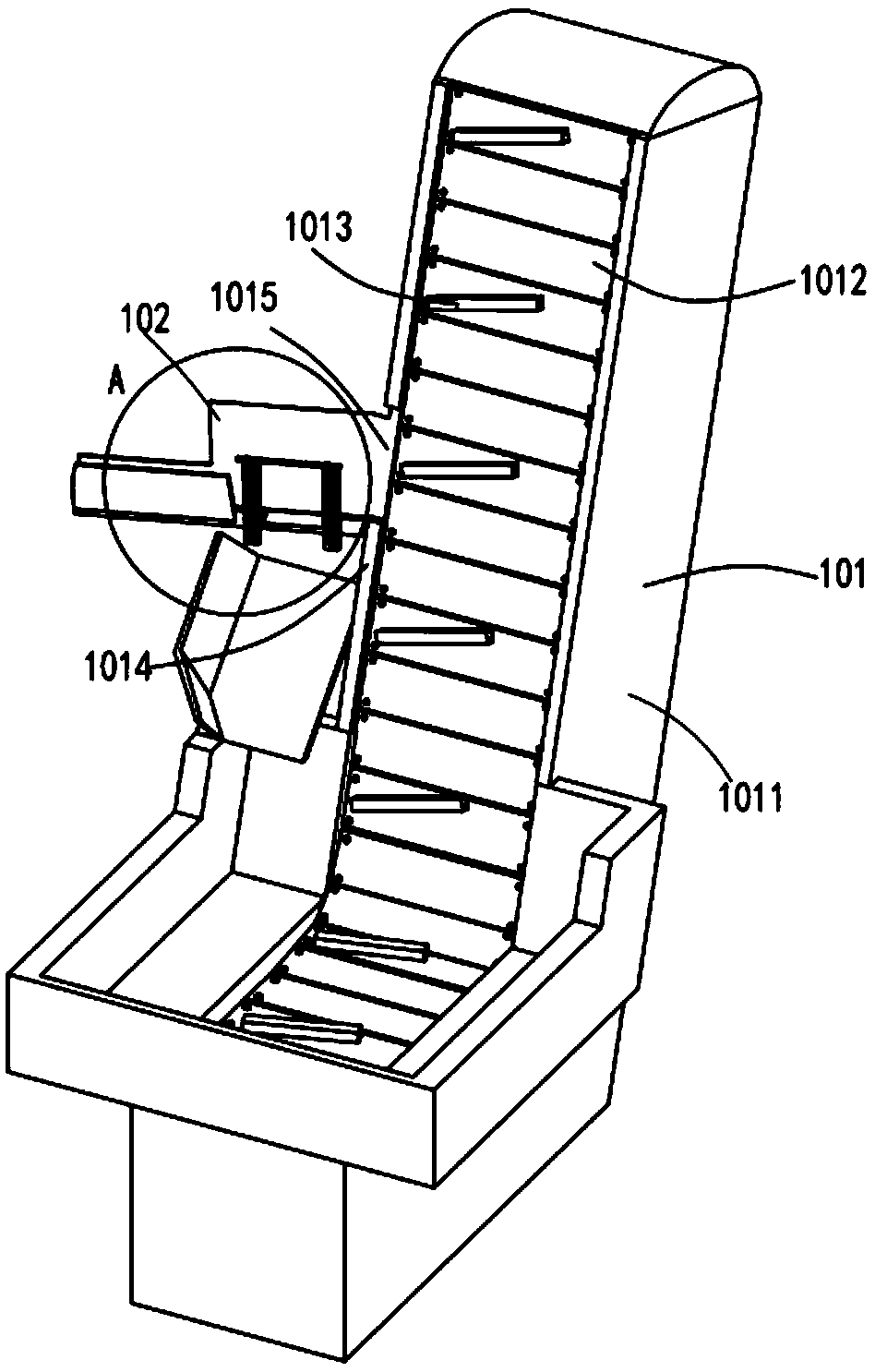

[0087] Described rough processing system 1 comprises sorting feeding device 10, distributing device 11, some rough processing devices 12 and centralized output device 13, and described sorting feeding device 10 is to described distributing device 11 one by one, orderly transport ring Blank 1, the distribution device 11 respectively supplies the ring blank 1 to the rough processing device 12, and the centralized output device 13 collects the ring blank 1 output by the rough processing device 12, wherein, in the present invention The roughing device 12 is preferably a roughing lathe, but is not limited to a roughing lathe, and any equipment used for roughing the bearings falls within the protection scope of this embodiment;

[0088] The cold forging system II includes a shot blasting device 20, a first c...

Embodiment 2

[0153] Figure 27 It is a structural schematic diagram of Embodiment 2 of a fully automatic bearing production line of the present invention; Figure 27 As shown, the components identical or corresponding to the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. This embodiment two and figure 1 The differences of the shown embodiment one are:

[0154] Such as Figure 27 As shown, according to the inventor’s reflection, in the actual production layout process, due to the limitation of the production site, the distribution cannot be carried out according to the optimal layout scheme in Example 1, so in the rough machining system I, cold forging system II and finishing system III It is necessary to set up an automatic conveying track for short-term temporary storage and transfer transportation.

Embodiment 3

[0156] A fully automatic production process of a tapered bearing according to Embodiment 3 of the present invention will be described with reference to Embodiment 1.

[0157] Such as Figure 28 As shown, a fully automatic production process for tapered bearings, including:

[0158] Step 1, the rough machining process, the ring blank 1 is transported one by one by the sorting feeding device 10 to a plurality of rough machining devices 12 through the distribution device 11 for rough turning;

[0159] Step 2, the shot blasting process, the rough-processed ring blank 1 is delivered to the shot blasting device 20, and the ring blank 1 is shot blasted by the shot blasting device 20 to remove the oxide skin on the ring blank 1 surface;

[0160] Step 3, the phosphorus saponification process, the ring blank 1 that has completed the shot blasting process is input into the metal surface lubrication device 22 for washing, and the surface lubrication treatment is carried out after washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com