Patents

Literature

37results about How to "Blanking is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

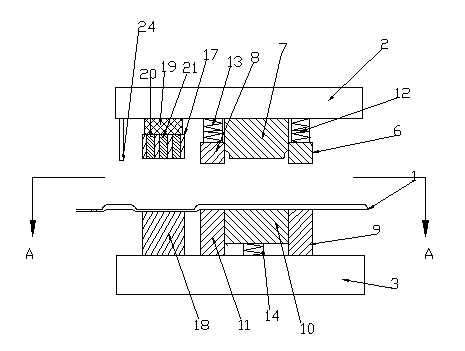

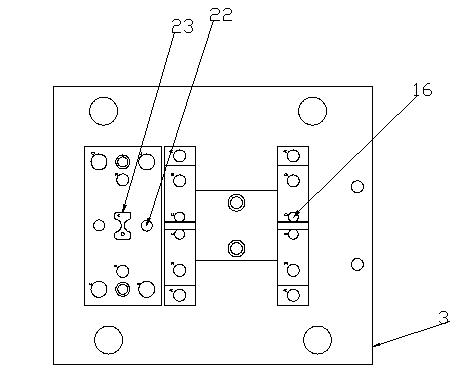

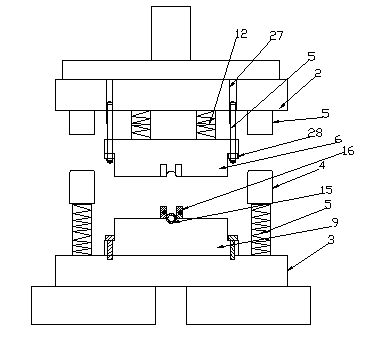

Wiring terminal progressive stamping die

ActiveCN104014659AIncrease productivityBlanking is accurateShaping toolsContact member manufacturingPunchingEngineering

The invention relates to a wiring terminal progressive stamping die. According to the wiring terminal progressive stamping die, a wiring terminal is manufactured through copper tubes, the die comprises an upper die plate, a lower die plate and a guide pillar and guide sleeve structure arranged between the upper die plate and the lower die plate; a leveling station and a punching cutting station are sequentially arranged between the upper die plate and the lower die plate in the horizontal direction, the lower end face of an upper die plate part of the leveling station is sequentially provided with a first upper movable die, a first upper stamping die and a second upper movable die from front to back, and correspondingly, the upper end face of a lower die plate part is sequentially provided with a first lower stamping die, a lower movable die and a second lower stamping die from front to back; the lower end face of an upper die plate part of the punching cutting station are sequentially provided with a third upper movable die, and correspondingly, a third lower stamping die is arranged on the upper end face of the lower die plate. The wiring terminal progressive stamping die has the advantages that operation on the leveling station and operation on the punching cutting station are completed synchronously, only one time of stamping is needed, the production efficiency of products is improved, and raw materials can be saved.

Owner:江苏华兴通讯科技有限公司

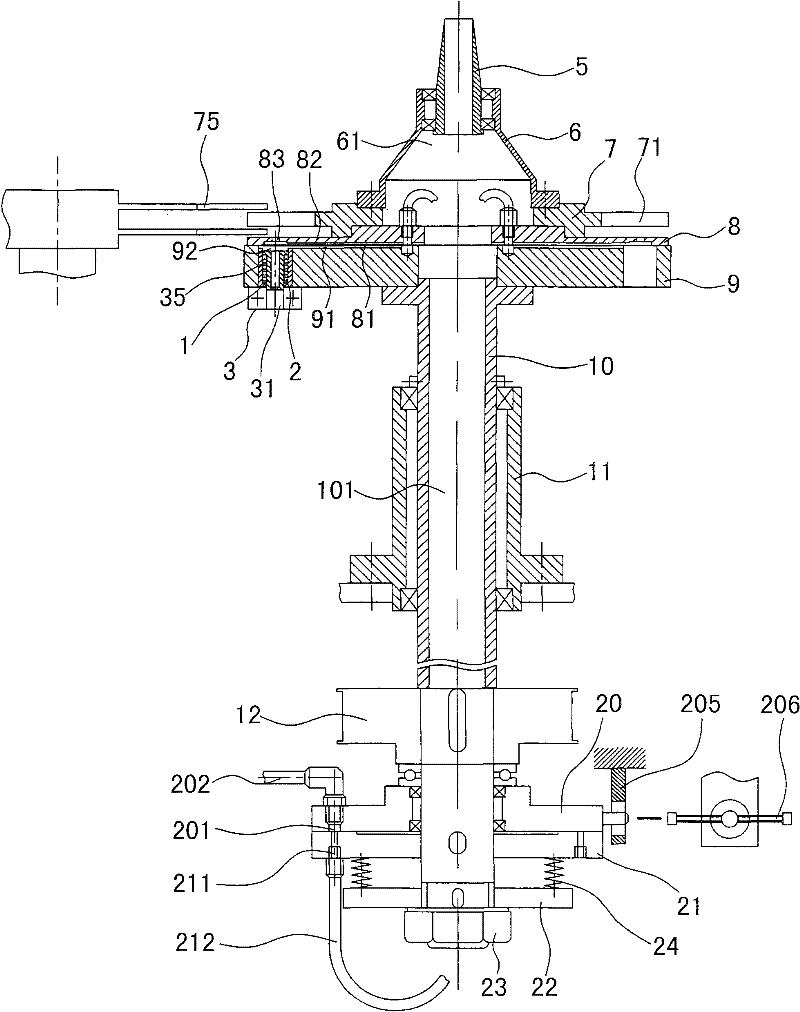

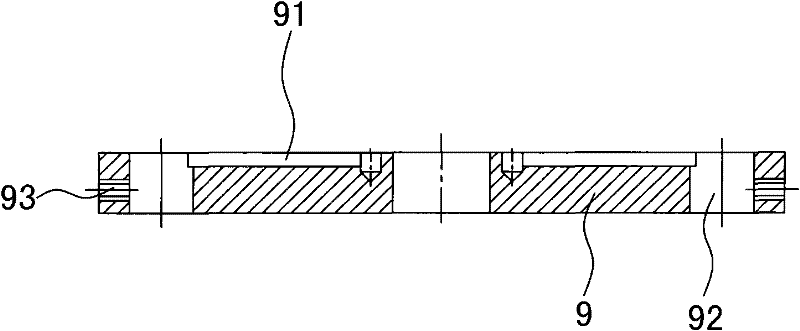

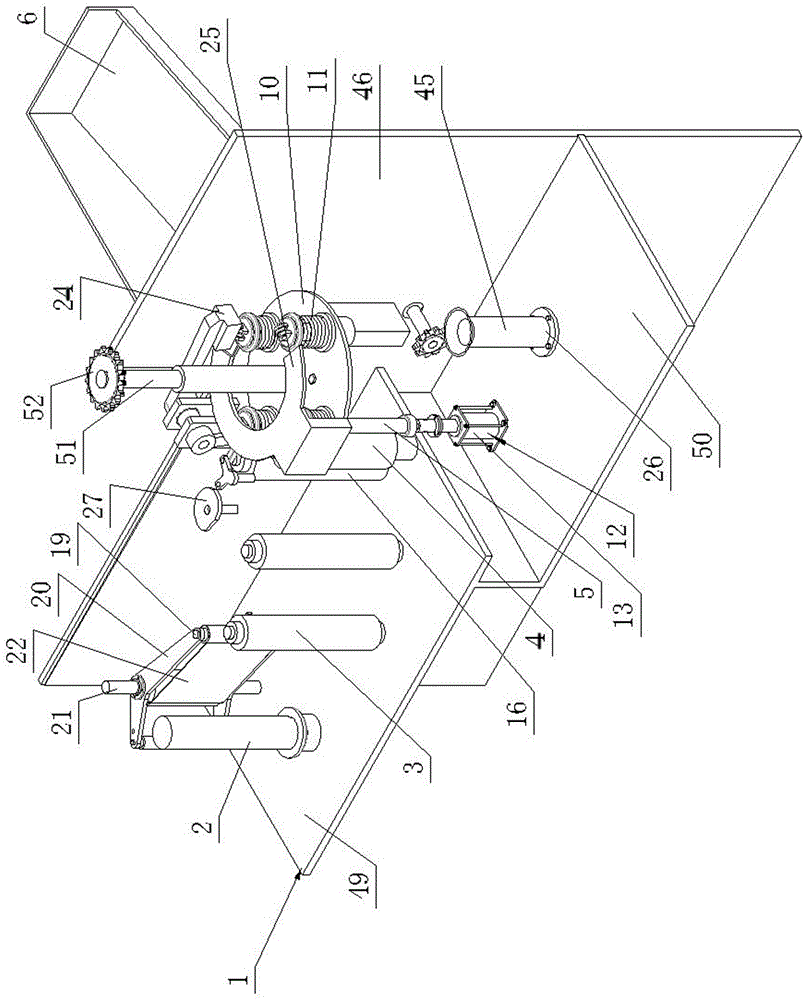

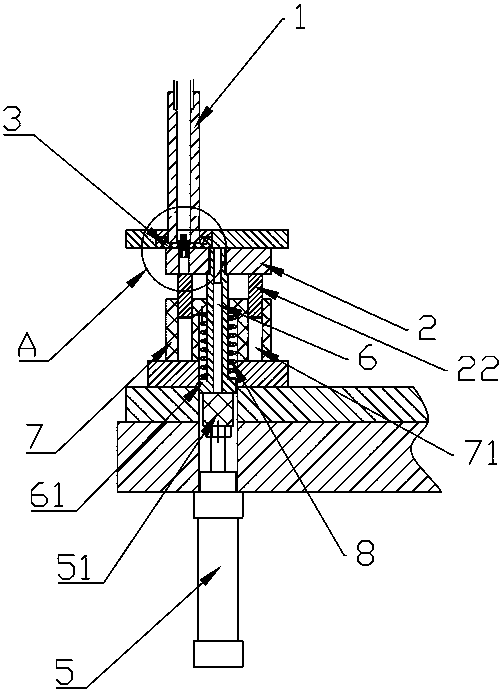

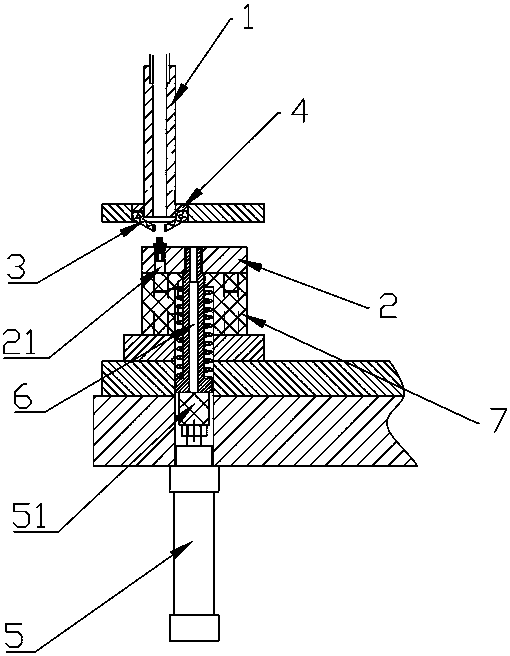

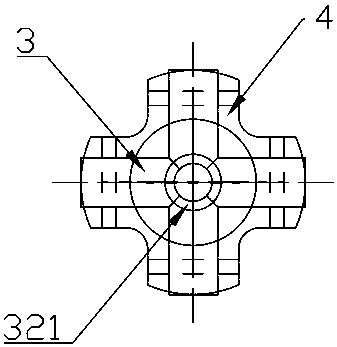

Feed and discharge mechanism for plastic bottle cap extruding machine

The invention discloses a feed and discharge mechanism for plastic bottle cap extruding machine, which comprises a spindle mounted in a spindle seat, a rotating wheel mounted outside the spindle, a gas circuit distributor mounted below the spindle as well as a feed disc and a discharge flying disc mounted on the spindle. The feed and discharge mechanism for plastic bottle cap extruding machine ischaracterized in that: the gas circuit distributor comprises an intake disc and an exhaust disc; an intake hole is arranged in the intake disc and is connected with the gas source of a gas compressorby an intake pipe; an exhaust hole is arranged in the exhaust disc and is connected with a gas pipe; a hollow cavity of the gas pipe in which the spindle is inserted is connected with a gas conveyingchannel of the feed disc; the gas conveying channel of the feed disc is provided with a pneumatic port; a material cutter holder and a material cutter are mounted below the feed disc aiming at the pneumatic port; a plunger is mounted in the pneumatic port; the plunger is provided with a return spring; a suction disc is arranged below the discharge flying disc; a division plate is arranged betweenthe suction disc and the feed disc; a vacuum hood is arranged on the suction disc; a vacuum joint is mounted on the vacuum hood; a vacuum pipe is connected with a vacuum pump by the vacuum joint; thesuction disc is provided with a vacuum channel and a vacuum suction hole; a vacuum gas chamber in the vacuum hood is communicated with the vacuum channel; and the edge of the discharge flying disc isprovided with a poking tooth and a bottle cap console.

Owner:蒋乐庆

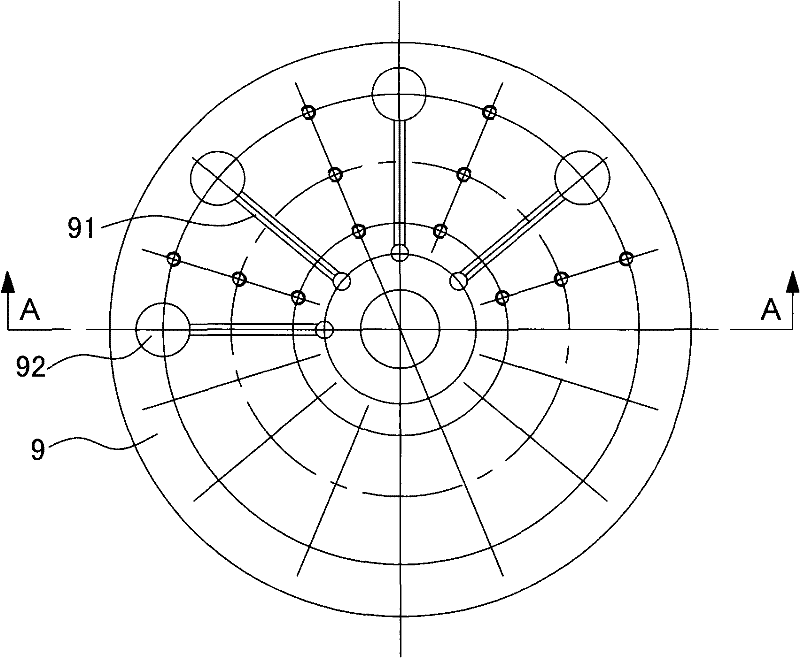

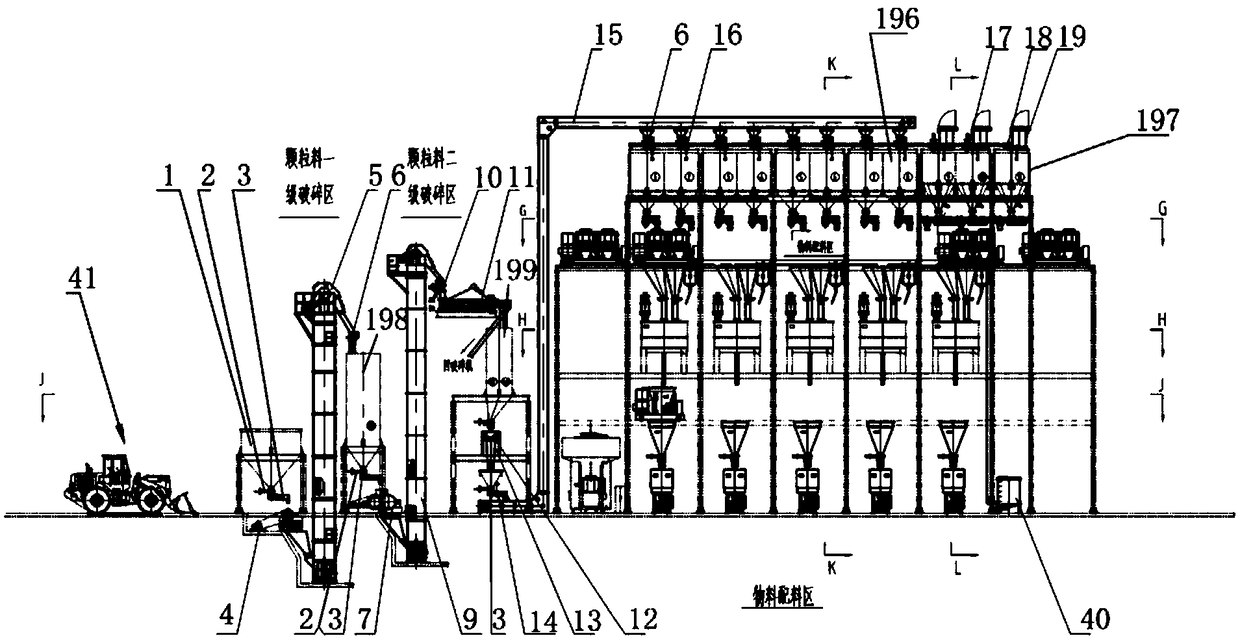

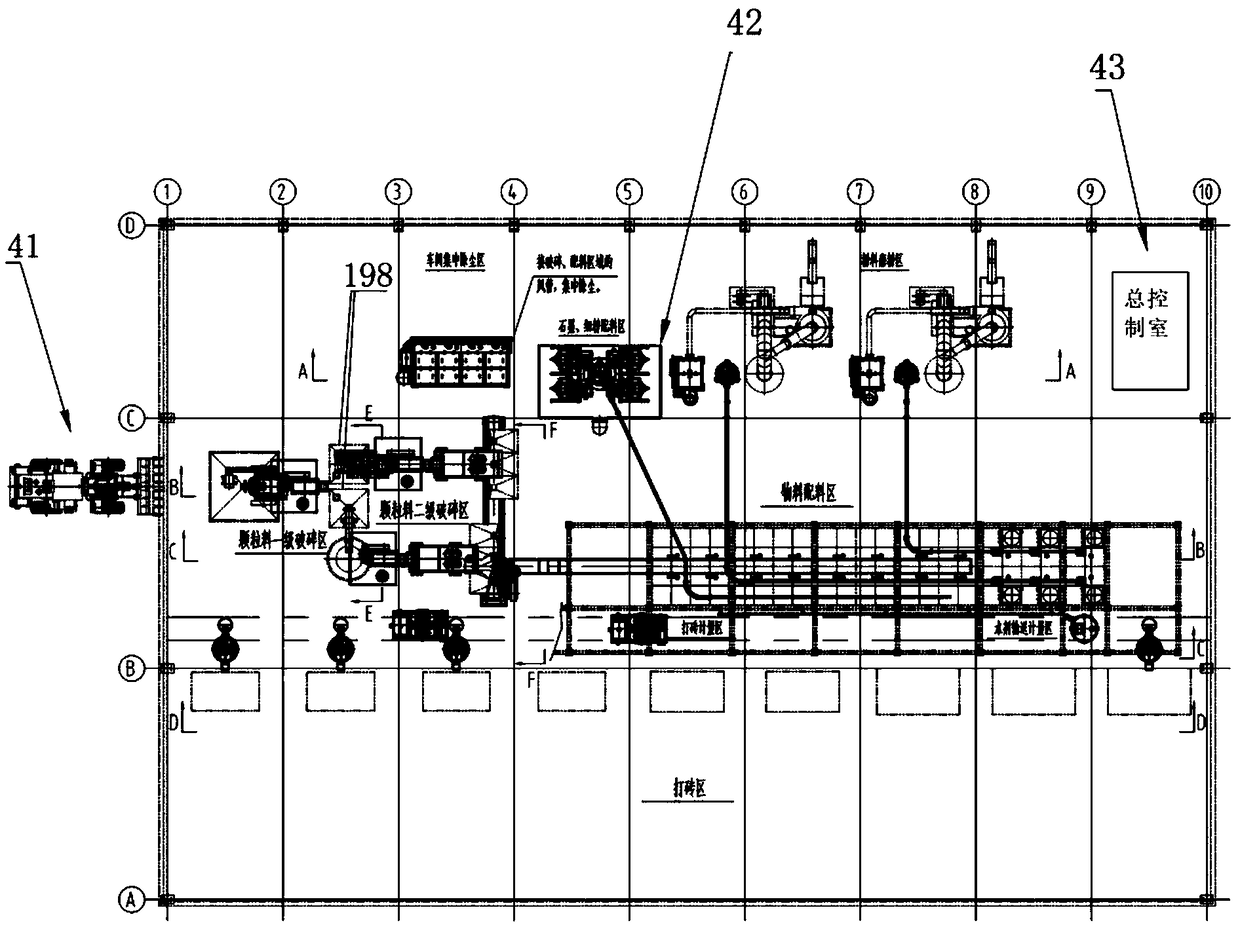

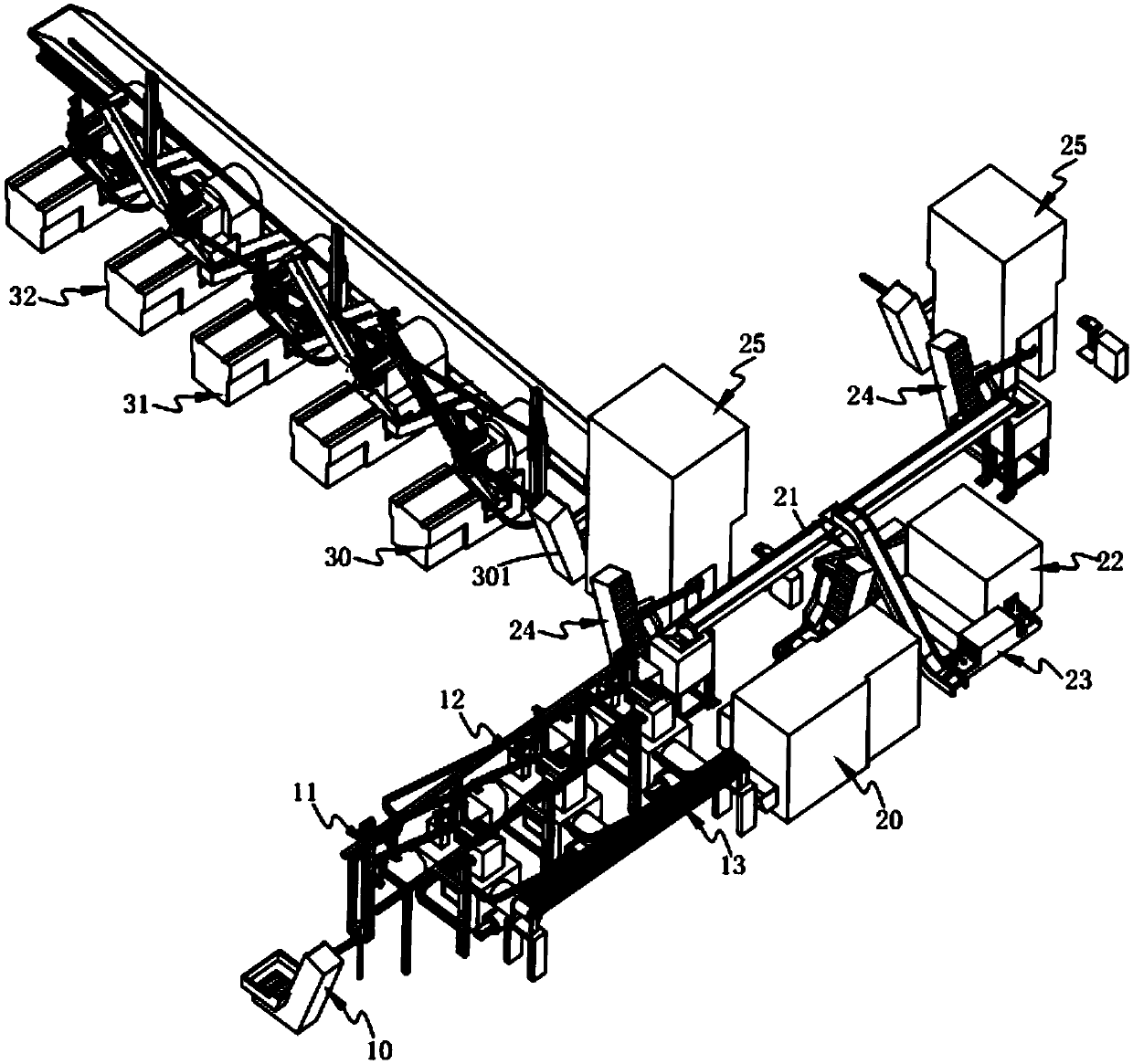

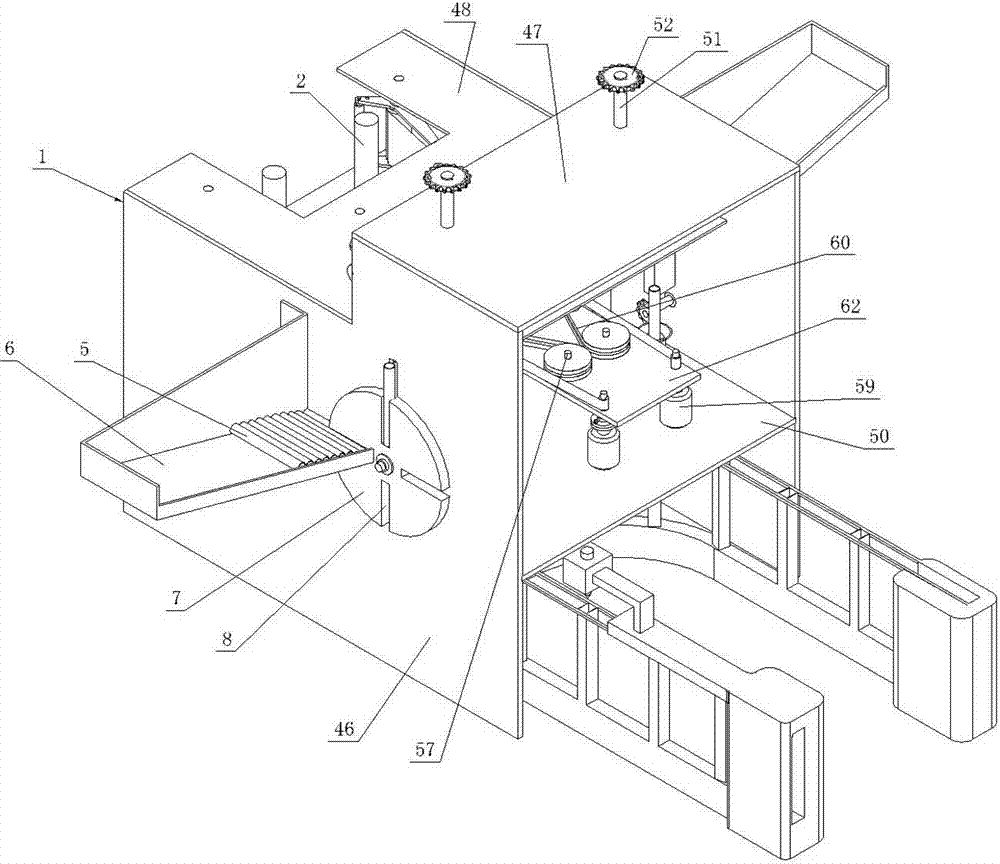

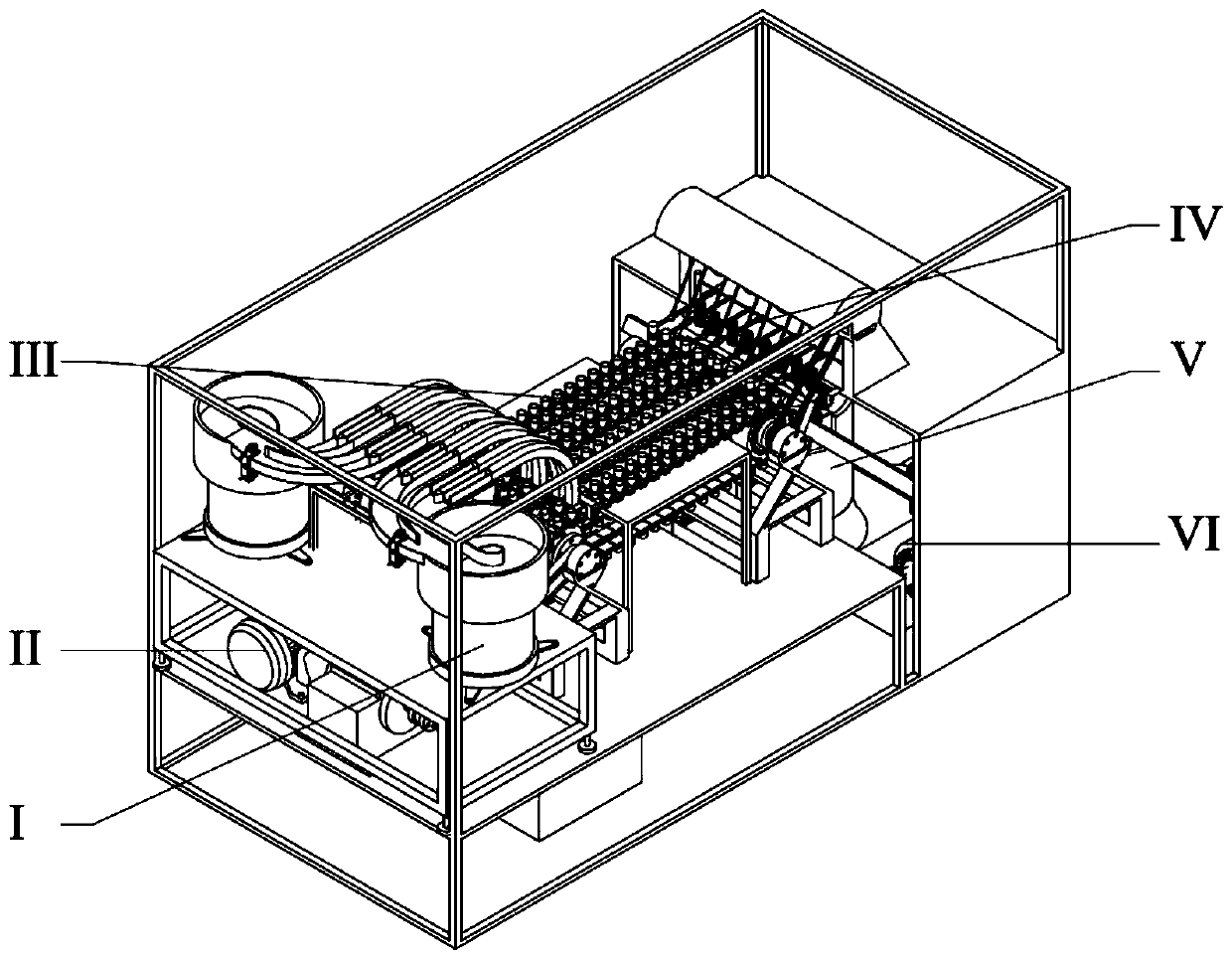

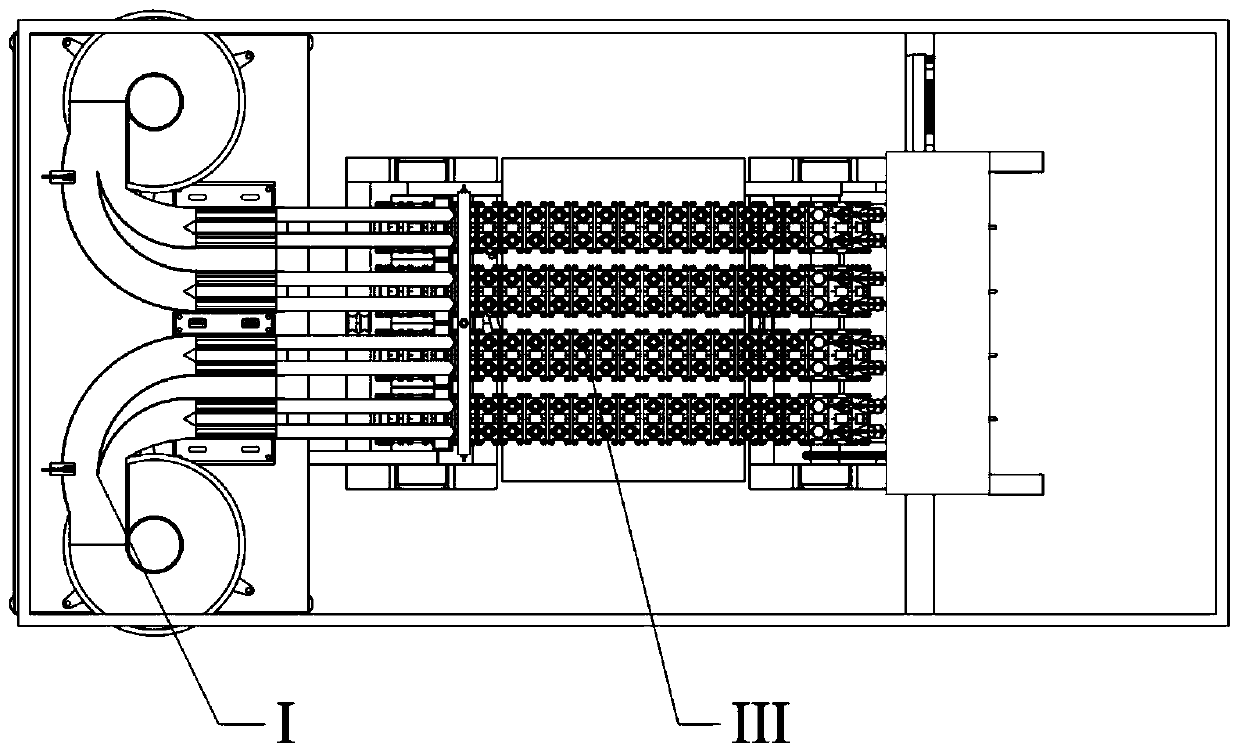

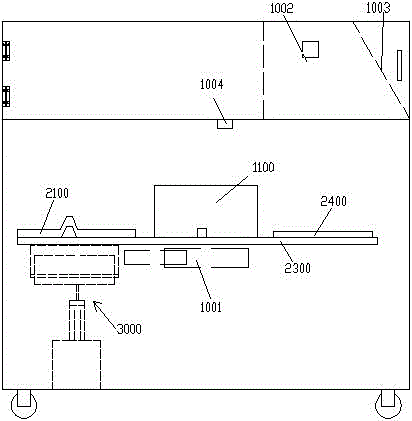

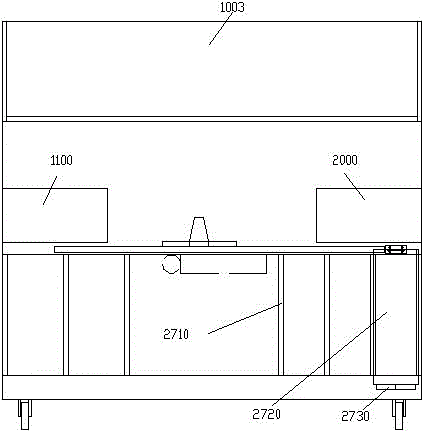

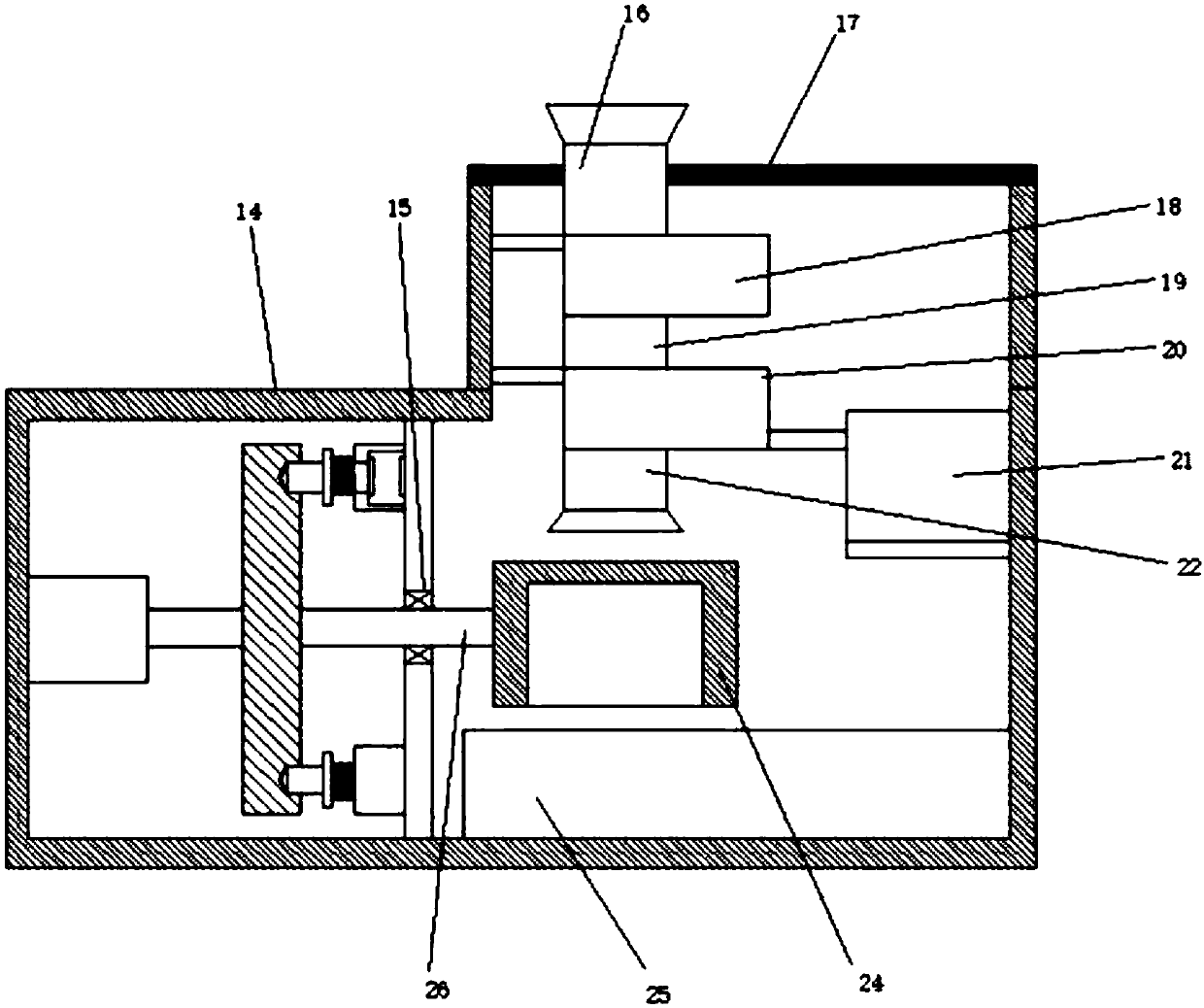

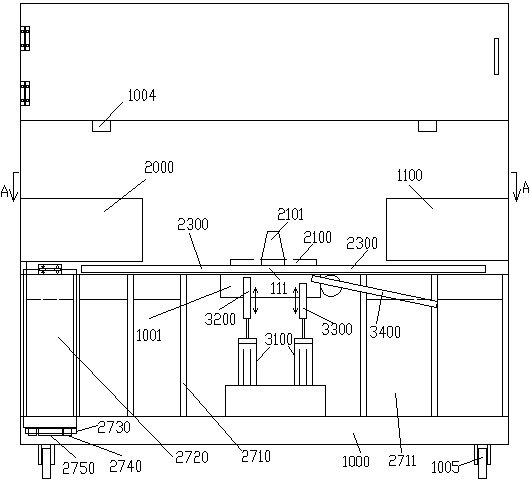

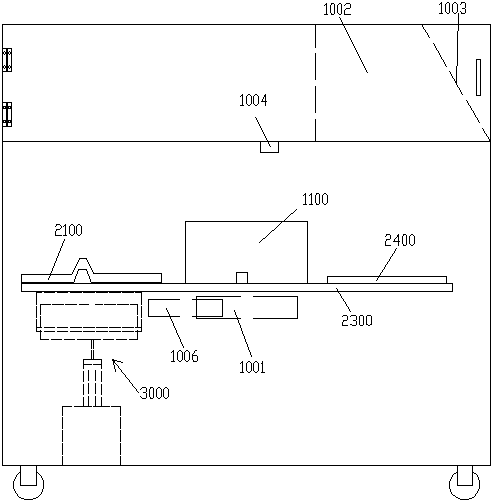

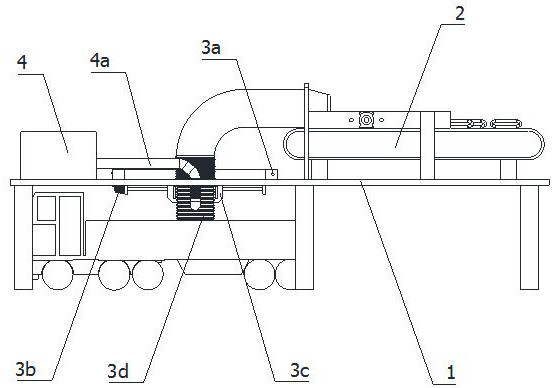

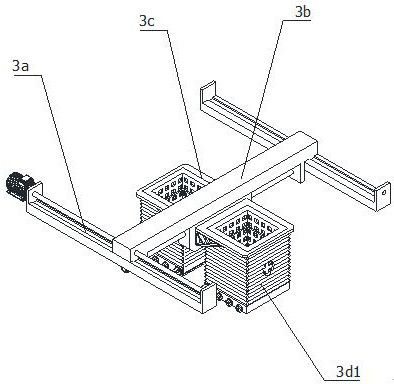

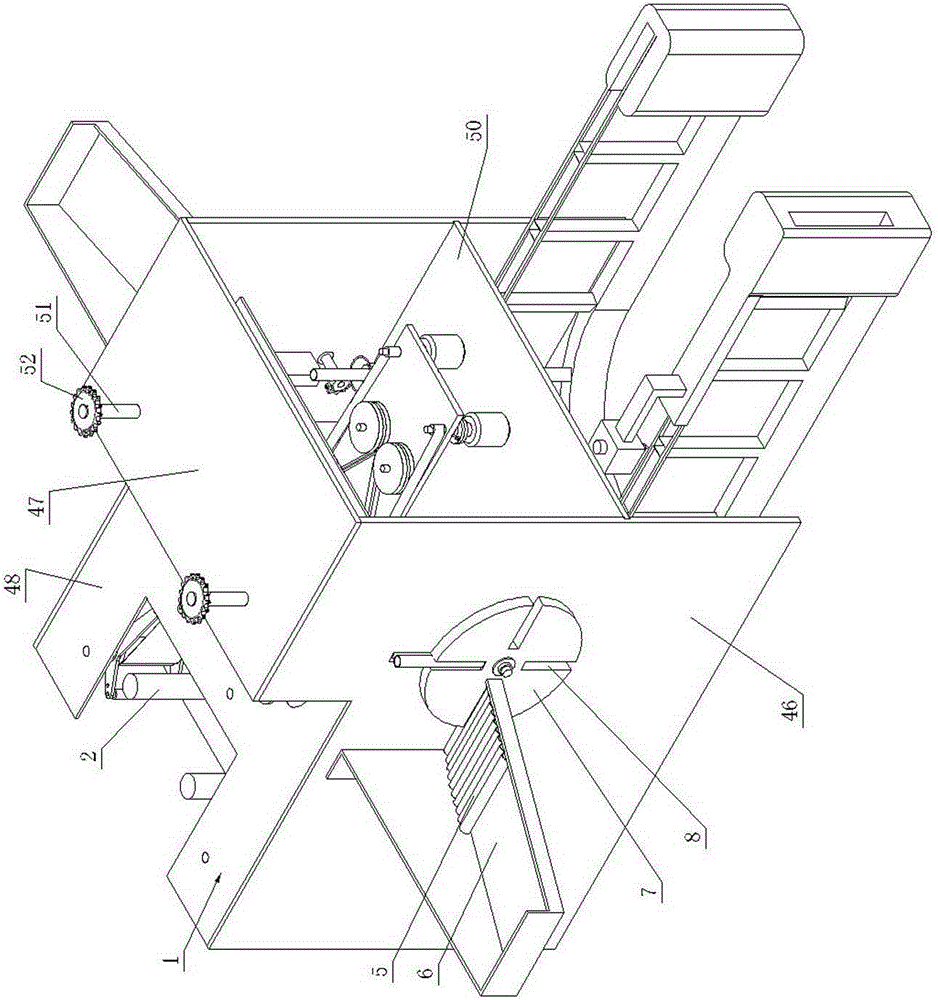

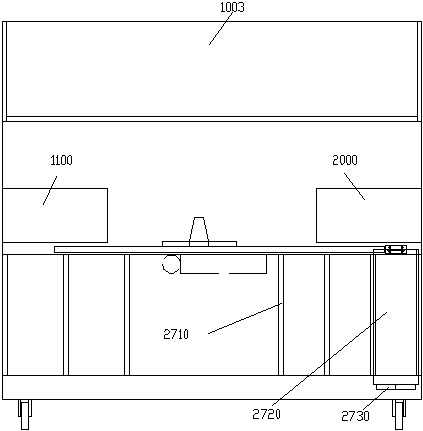

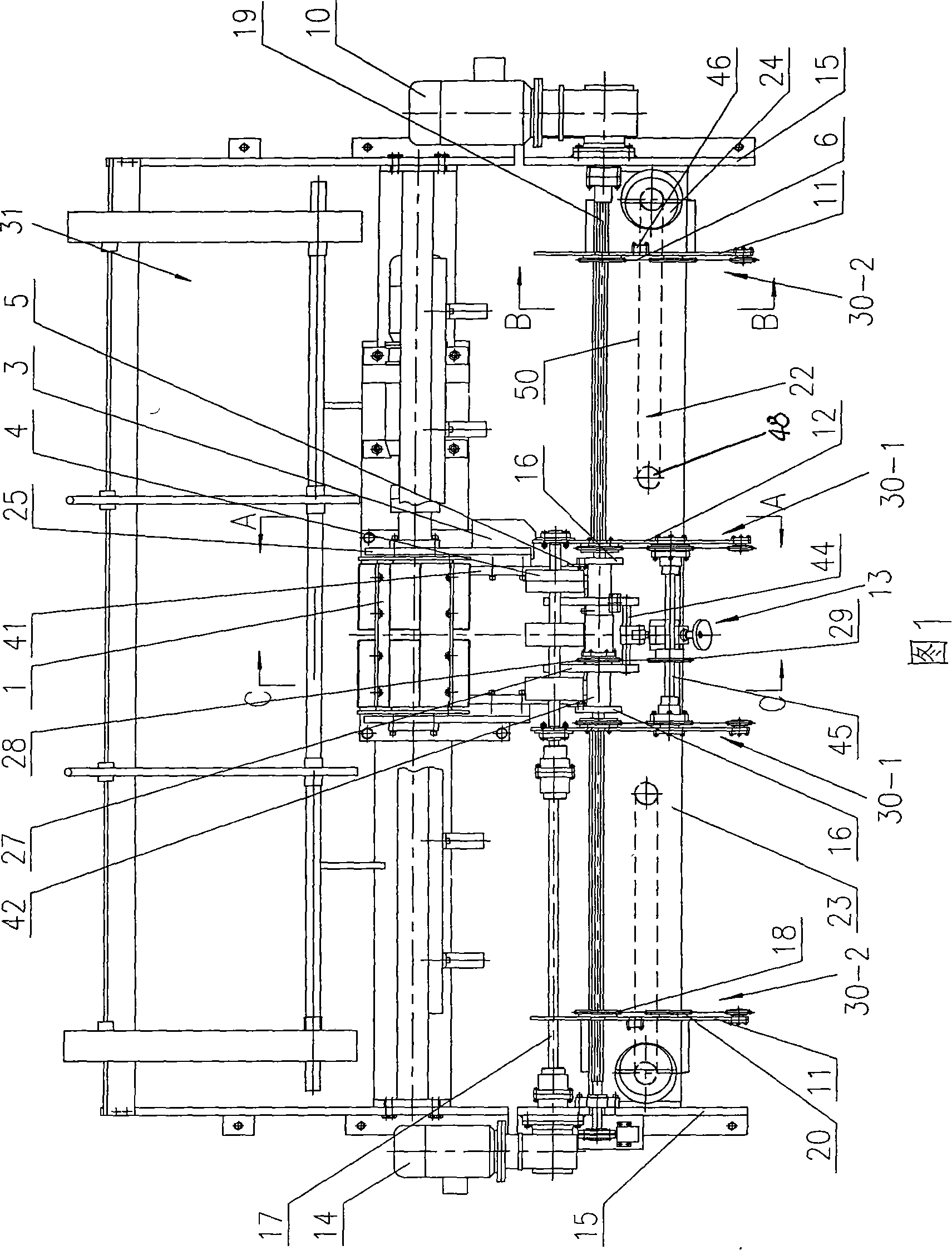

Production line used for magnesia carbon brick products and technology thereof

PendingCN108858722ARealize automatic deliveryOptimize layoutCeramic shaping plantsFeeding arrangmentsProduction lineBrick

The invention relates to a production line used for magnesia carbon brick products and a technology thereof. The production line comprises a granule crushing unit, a plurality of powder grinding units, a graphite or fine powder automatic burden charging and conveying system and a liquid metering and conveying unit, and further comprises a material burden charging unit, a material mixing unit and abrickmaking metering unit. Burden charging carriages are arranged between the material burden charging unit and the mixing unit and between the mixing unit and the brickmaking metering unit. By meansof the production line, the whole set of automatic procedures including automatic feeding treatment, automatic burden charging, automatic mixing, automatic weighing and calculating and automatic brickmaking of granules, powder, graphite and fine powder raw materials and liquid raw materials can be achieved, automatic conveying, burden charging and dust recovery of the powder industry are achieved, the whole working process conforms to environment-friendly requirements, the workshop internal environment and an operating environment of workers are effectively guaranteed, and safe production isachieved.

Owner:江苏万衡智能科技有限公司

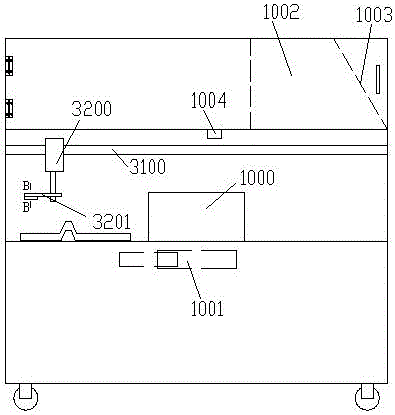

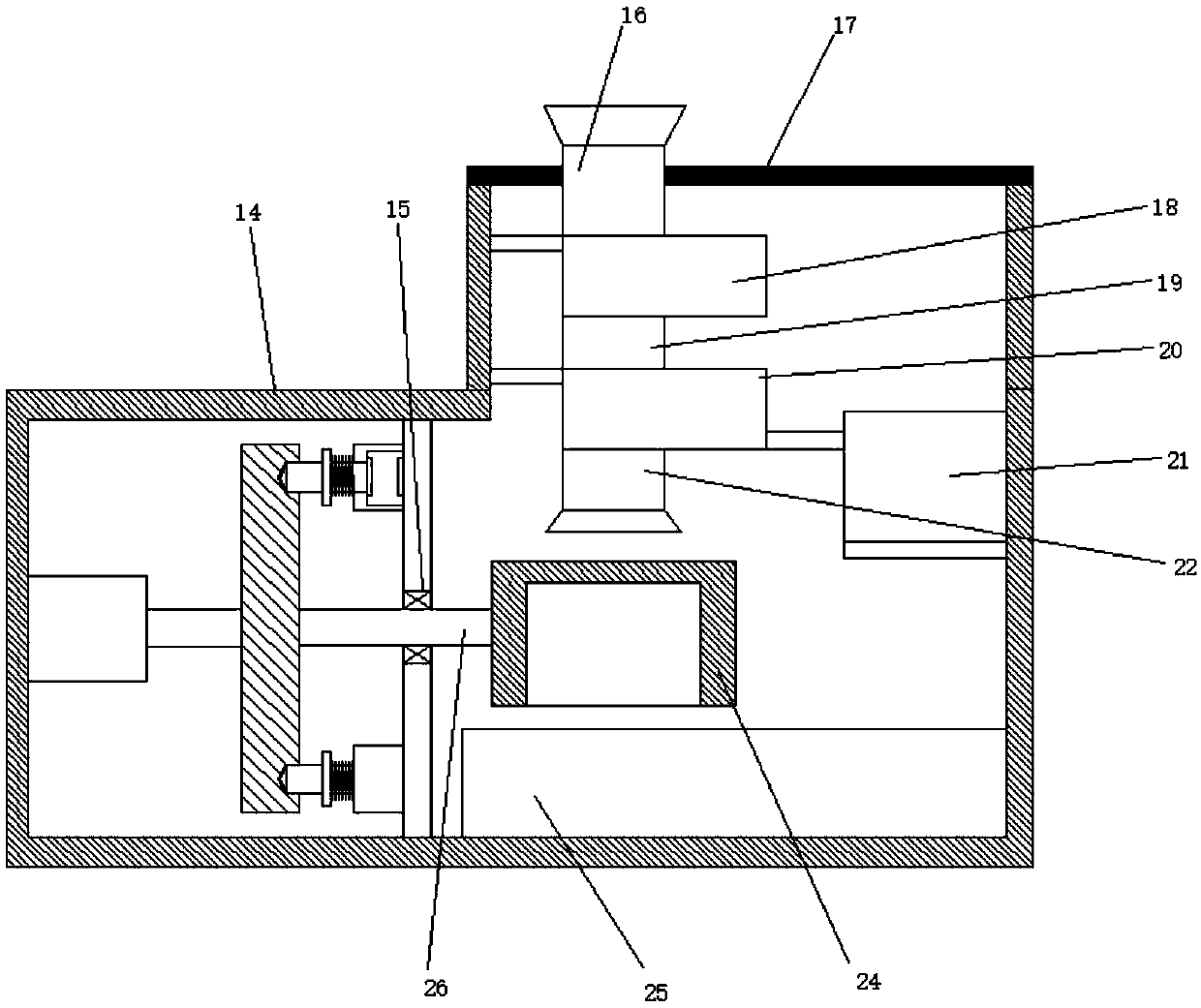

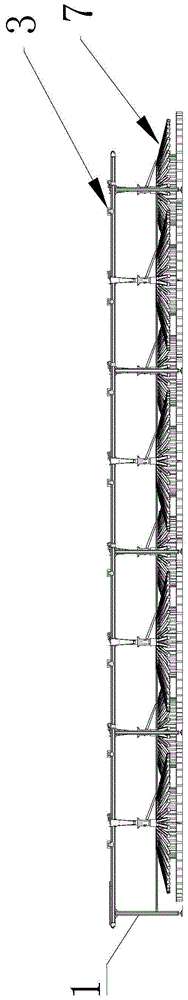

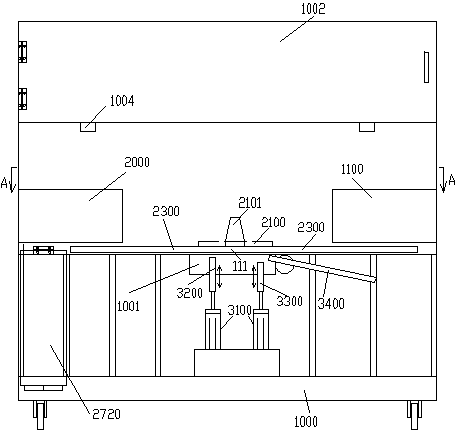

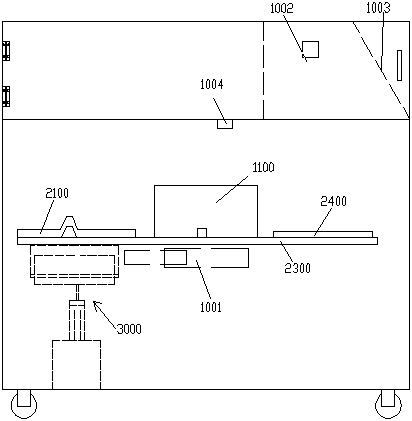

Intelligent rotary disc metal casting and nozzle separation integrated machine and operating method thereof

The invention relates to an intelligent rotary disc metal casting and nozzle separation integrated machine and an operating method thereof. The integrated machine comprises a cabinet. An annular rotary disc driven by an electric dividing plate is arranged in the middle of the cabinet. A positioning rod for containing a metal casting is arranged at the front portion of the annular rotary disc. A metal casting and nozzle separation device for allowing the metal casting to rotate to the position to achieve water gas separation is arranged on one side of the annular rotary disc. A metal casting separation device for allowing the metal casting to rotate to the position to achieve product separation of the metal casting is arranged on the other side of the annular rotary disc. A clamping mechanism for clamping waste of the metal casting to the rear portion of an annular disc body to be discharged after rotating to the front portion is further arranged at the portion, located above the annular rotary disc, of the cabinet. Blanking grooves are further formed in the front portion and the rear portion below the annular disc body respectively. The separation integrated machine is compact in structure and high in automation degree, and is conveniently used for nozzle separation of the metal casting and separation of the metal casting, and the operating method is easy and convenient.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

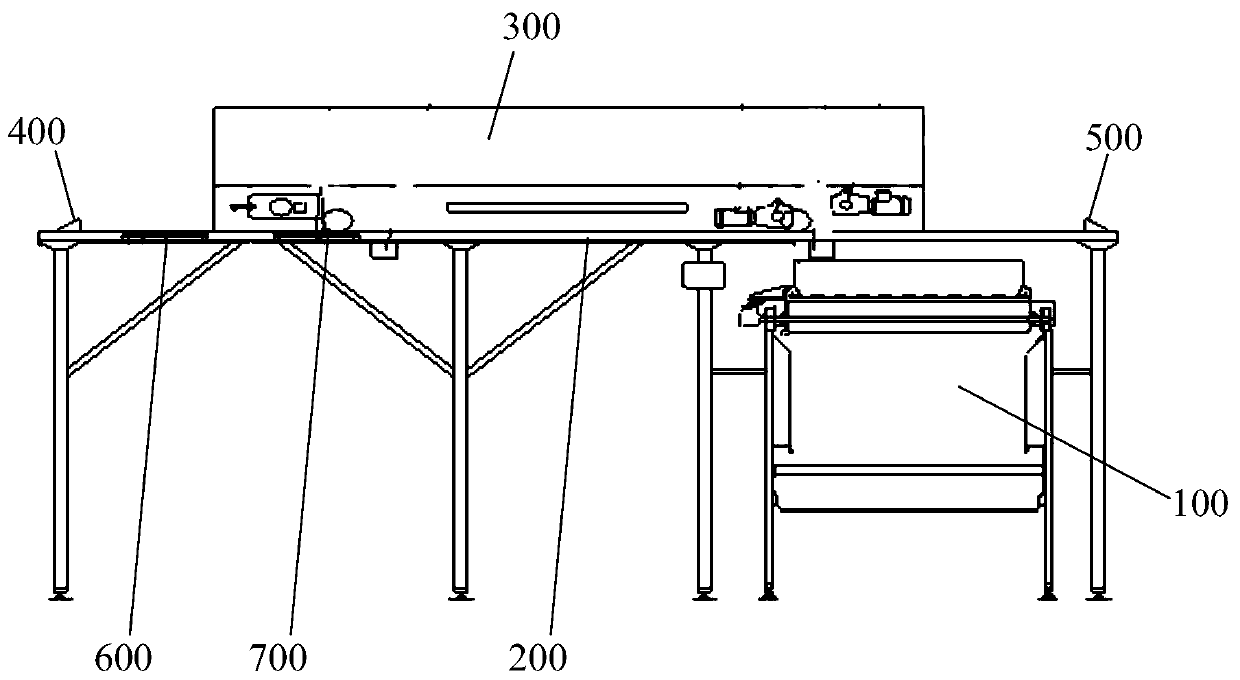

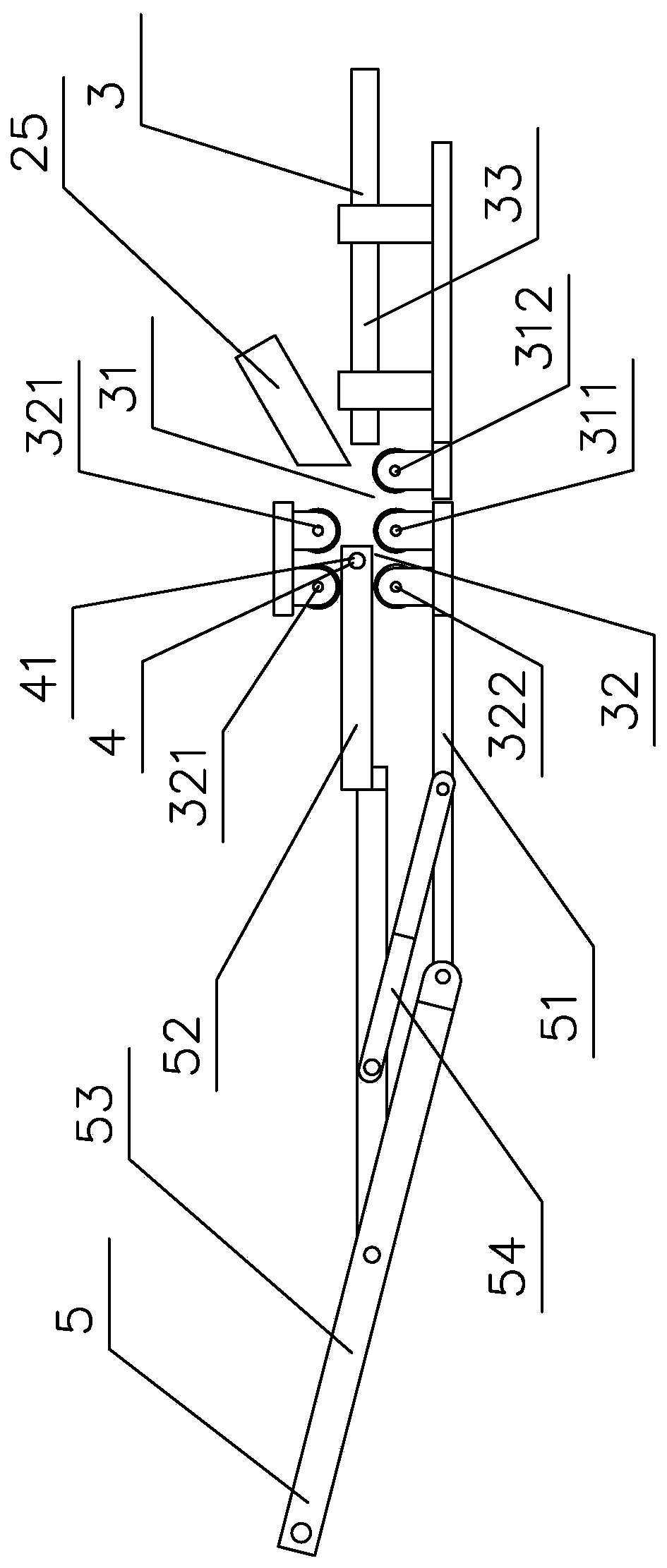

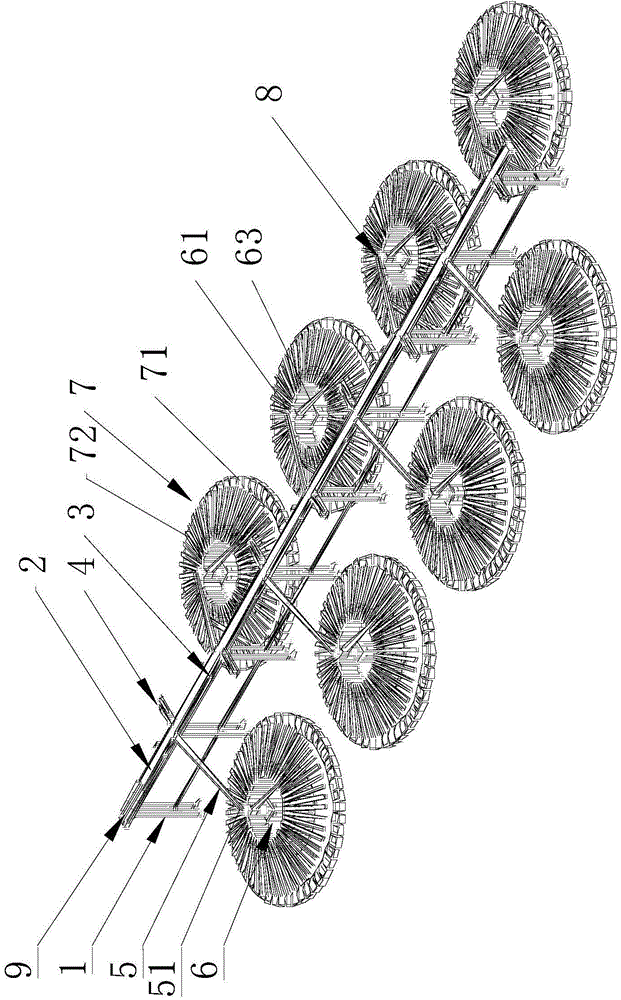

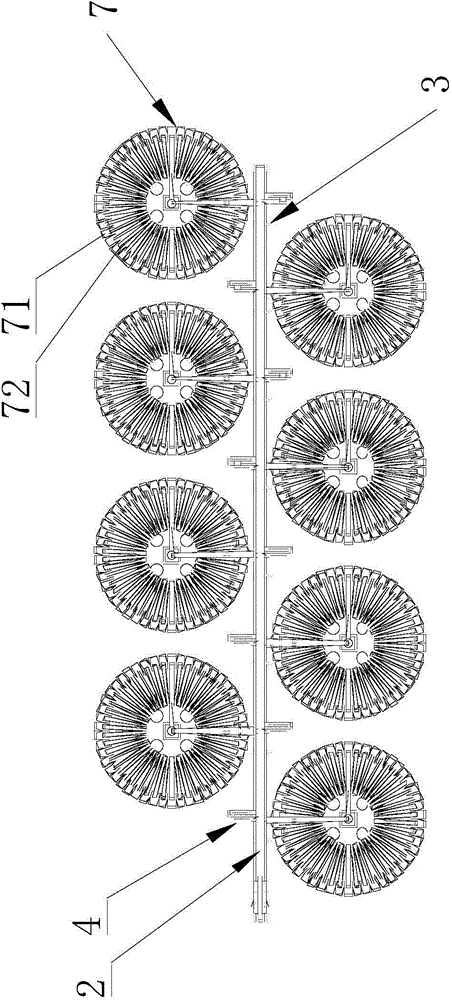

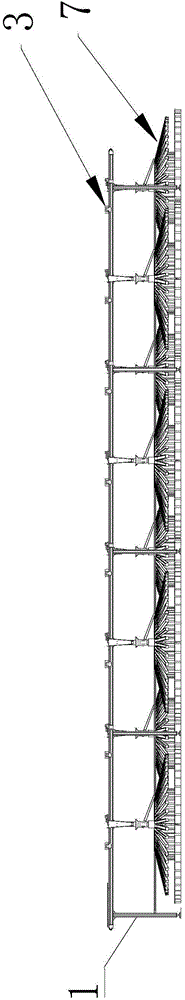

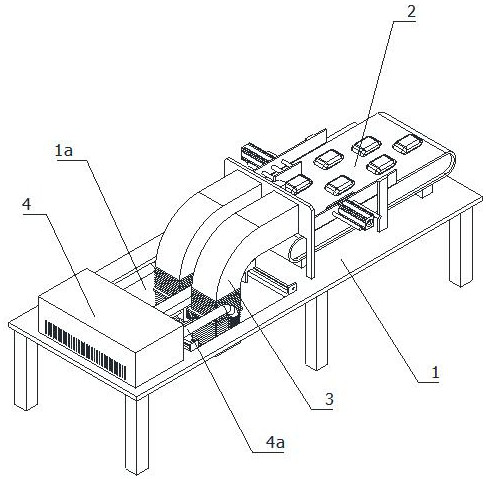

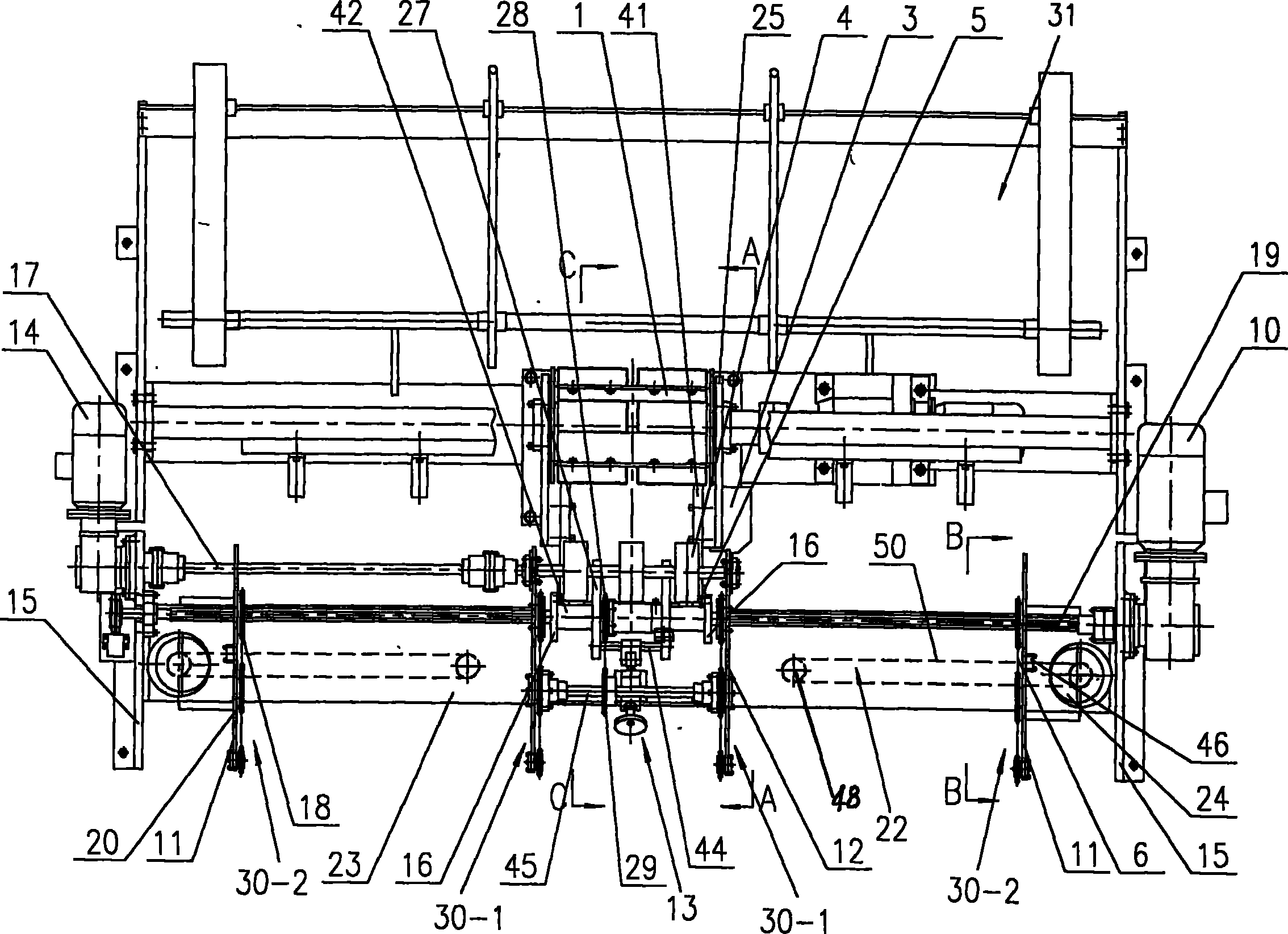

Feeding machine provided with reciprocating distribution cart

PendingCN110403224ARealize limitBlanking is accurateTobacco treatmentLoading/unloadingReciprocating motionAgricultural engineering

The invention discloses a feeding machine provided with a reciprocating distribution cart. The feeding machine comprises a feeding bin, a rack, a first limit switch arranged on the rack, a second limit switch arranged on the rack, the distribution cart and an induction mechanism, wherein a first limit mechanism and a second limit mechanism are arranged at the two ends of the rack respectively; thefirst limit switch is arranged between the first limit mechanism and the second limit mechanism; the second limit switch is arranged between the first limit switch and the second limit mechanism; thedistribution cart reciprocates on the rack; and the induction mechanism is arranged on the distribution cart, and the distance between the induction mechanism and the second limit mechanism is smaller than the distance between the second limit switch and the second limit mechanism. According to the feeding machine, through reciprocating motion of the distribution cart on the rack, uniform distribution of materials is realized; besides, through cooperation of the limit switches, the induction mechanism and the limit mechanisms, limiting of the distribution cart is realized; and meanwhile accurate falling and stable conveying of the materials are guaranteed.

Owner:CHINA TOBACCO HENAN IND

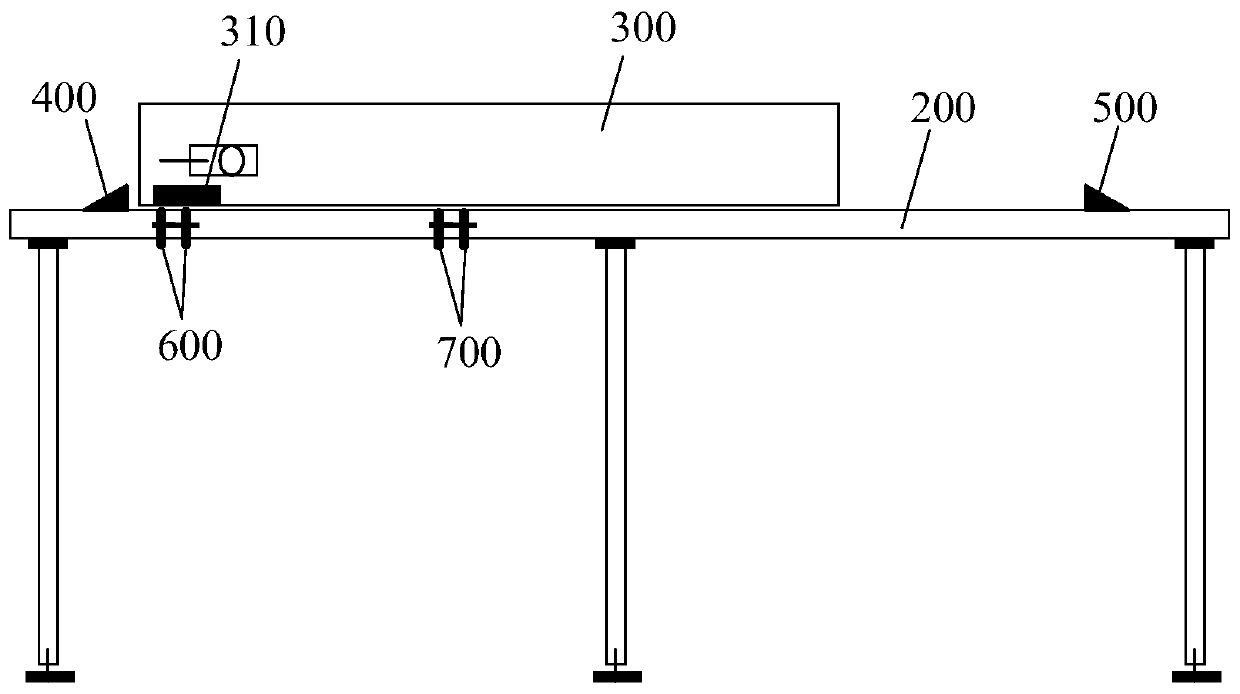

Stamping die capable of facilitating unloading

InactiveCN110899500AEasy to remove the moldPrecise positioningShaping toolsStripping-off devicesEngineeringStructural engineering

The invention belongs to the technical field of stamping die design and discloses a stamping die capable of facilitating unloading. The stamping die comprises a fixed base and an upper die holder; thetop surface of the fixed base is fixedly connected with the bottom of a lower die plate waste cutter; the top of the lower die plate waste cutter is fixedly connected with the bottom of a female diefixing plate; the top of the lower die plate waste cutter is fixedly connected with the bottom of a female die; a die shank is installed at the top of the upper die holder; and the upper die holder isfixedly connected with a male die fixing plate through positioning pins. According to the stamping die, with the positioning pins mounted, a male die and the die shank can be accurately positioned; with the lower die plate waste cutter adopted, the female die can be more accurate during blanking, and the situation that a material is stuck in the female die is avoided; with a stuck material unloading device adopted, a material plate which is attached to the male die can be unloaded conveniently.

Owner:王煜

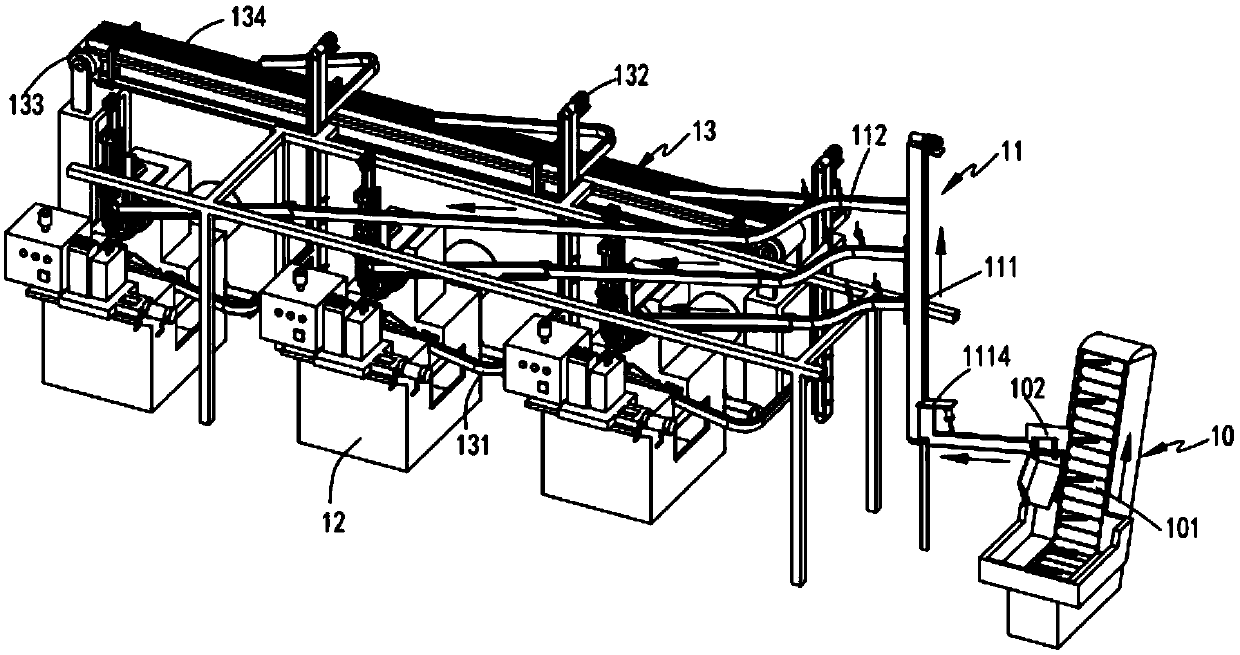

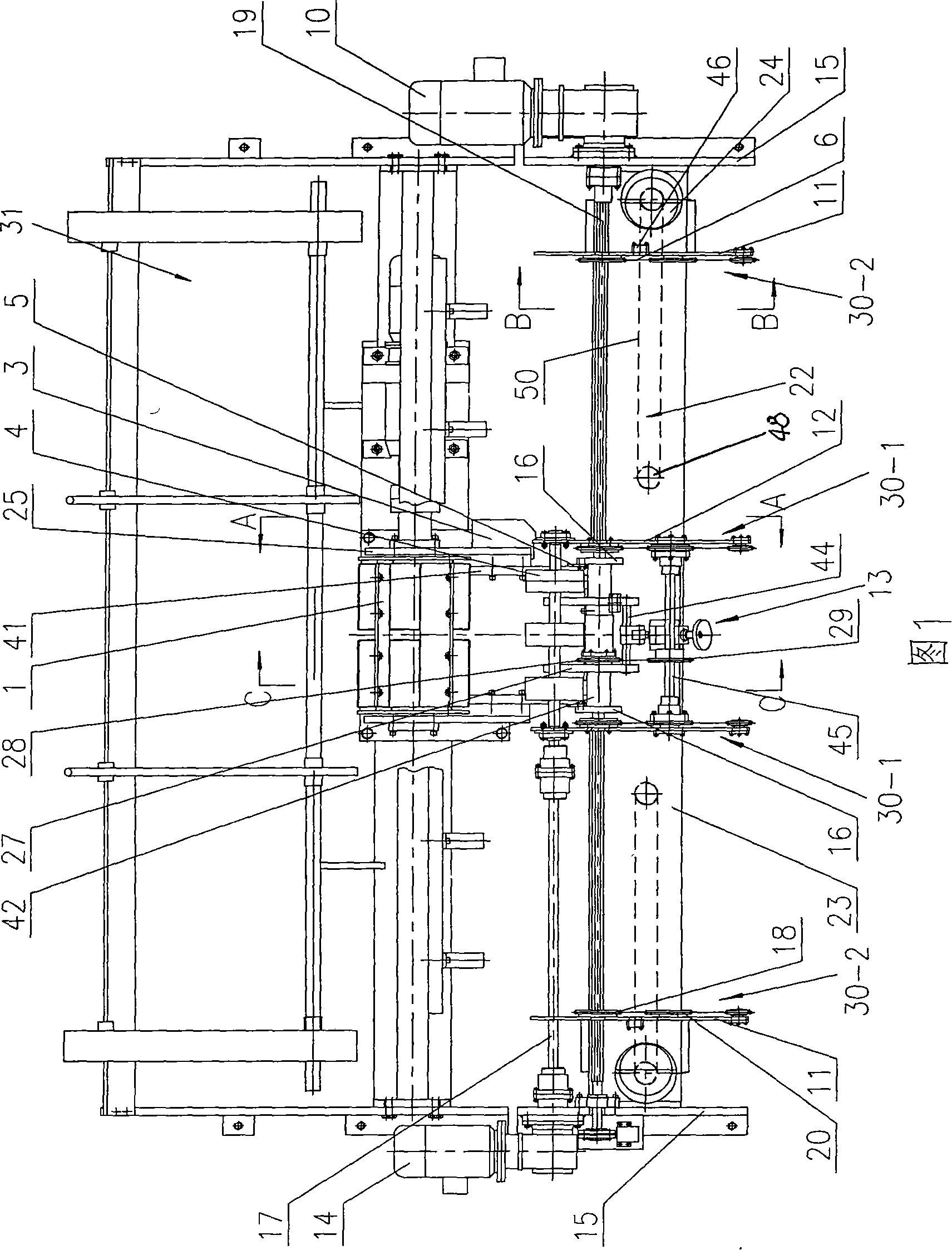

Bearing full-automatic production assembly line and technology

ActiveCN108673069ASolve the technical problems of fully automatic off-line processingAvoid cumbersomeMetal working apparatusAssembly lineMachining system

The invention provides a bearing full-automatic production assembly line and technology. The bearing full-automatic production assembly line comprises a rough machining system, a cold forging system and a finish machining system. The rough machining system, the cold forging system and the finish machining system are subjected to automatic line connection, thus annular blanks are automatically fedand machined, stations are automatically transferred, and rough turning machining, shot blasting machining, phosphorus saponification machining, cold forging machining, slitting machining and finish turning machining of bearing inner and outer sleeve rings are completed sequentially; and the technical problem of full-automatic loss line machining of inner and outer bearing sleeve ring machining equipment is solved, single machining equipment is subjected to automatic line connection to become the full-automatic production assembly line, the machining speed is increased, the tedious process ofworkpiece transferring is omitted, the labor intensity is lowered, and occupied areas of workpieces and the bearing full-automatic production assembly line are reduced.

Owner:浙江信石轴承有限公司

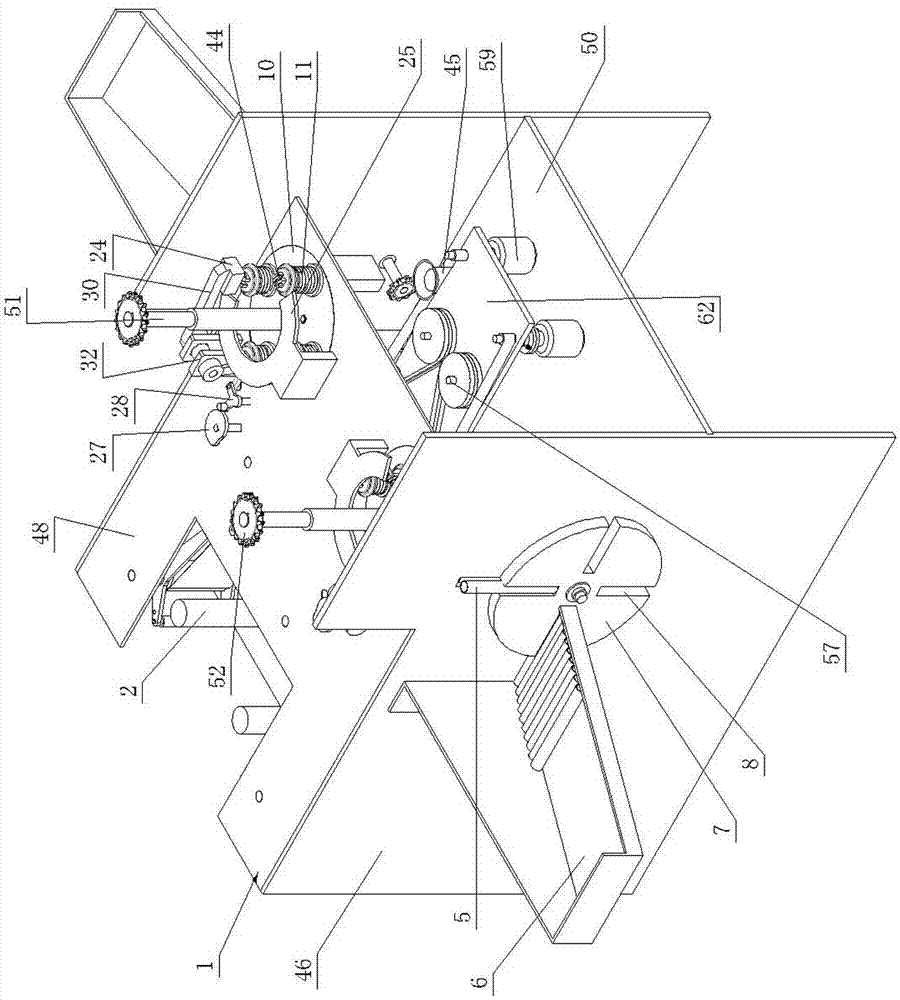

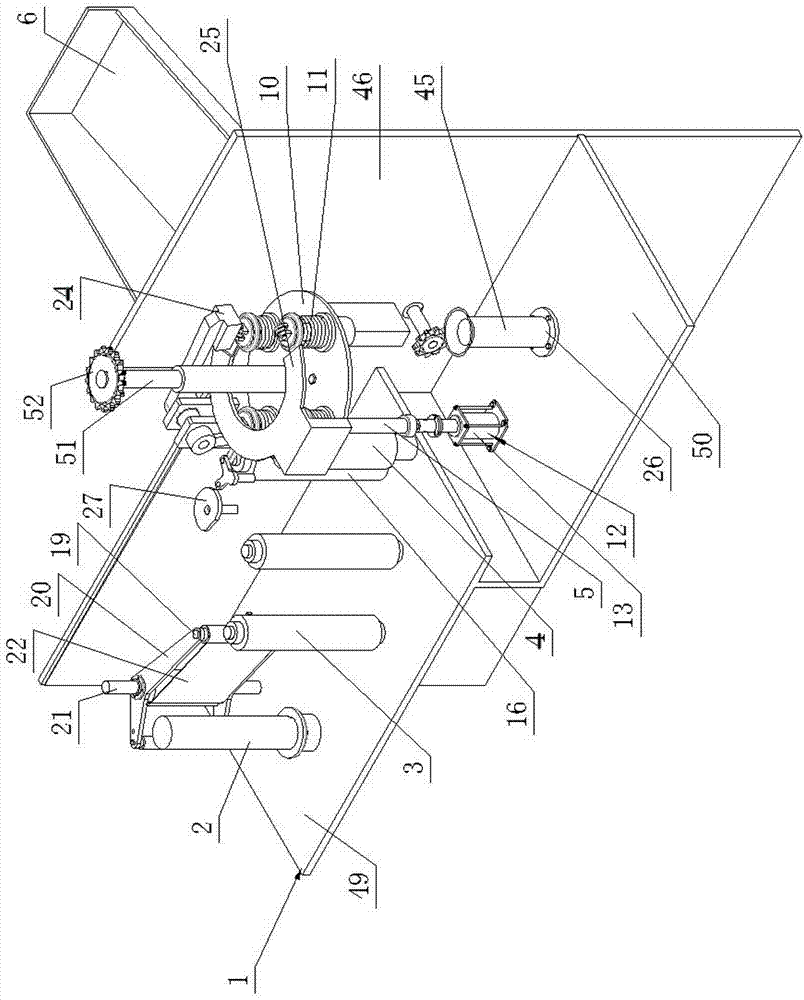

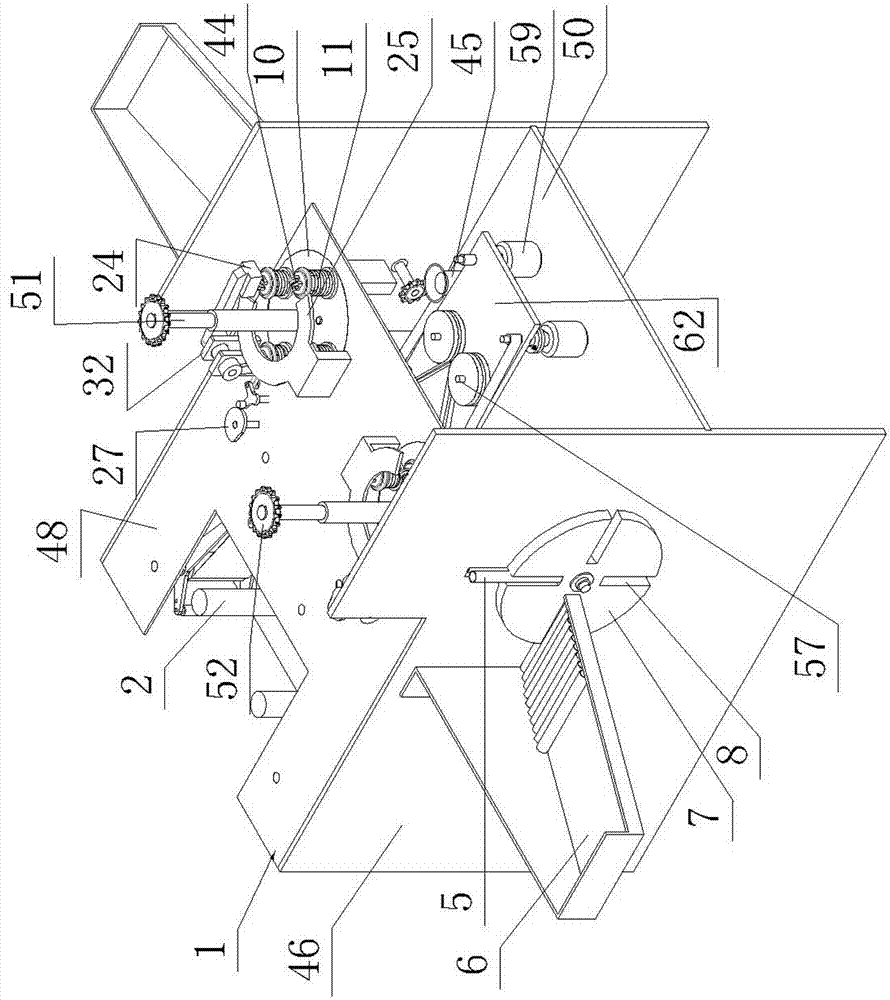

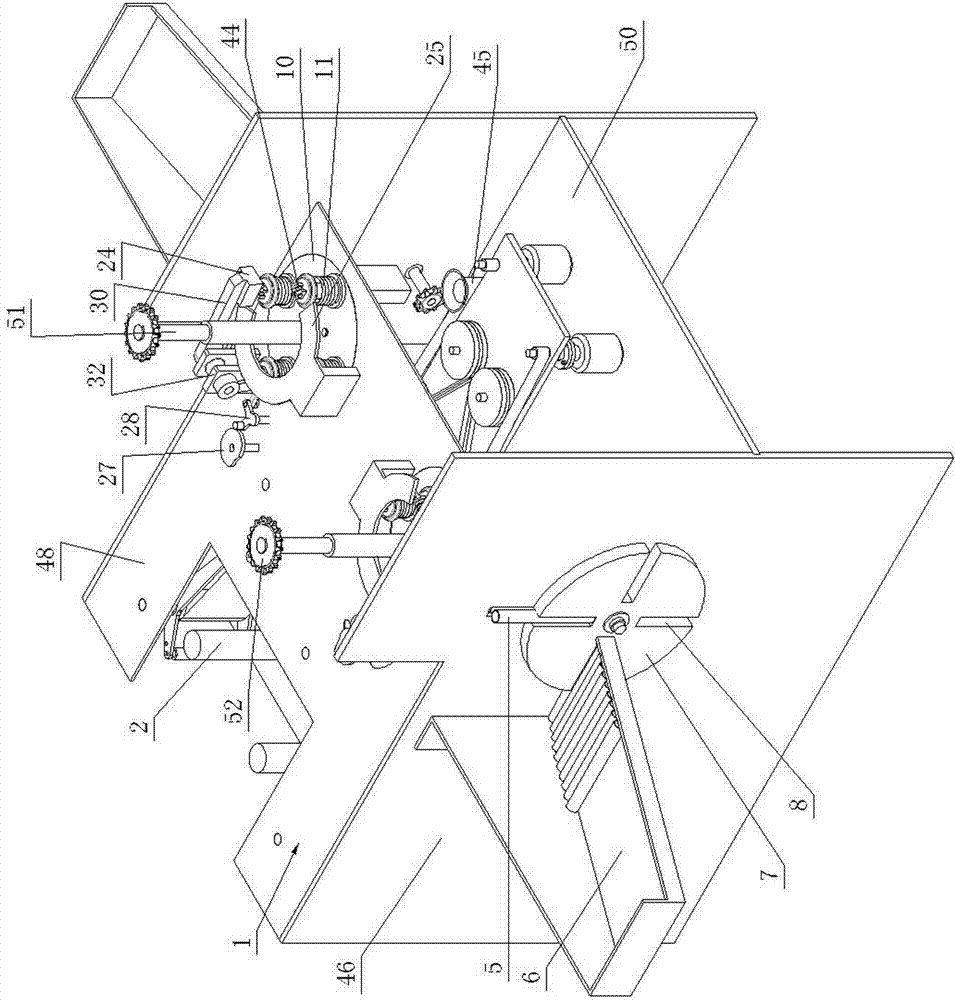

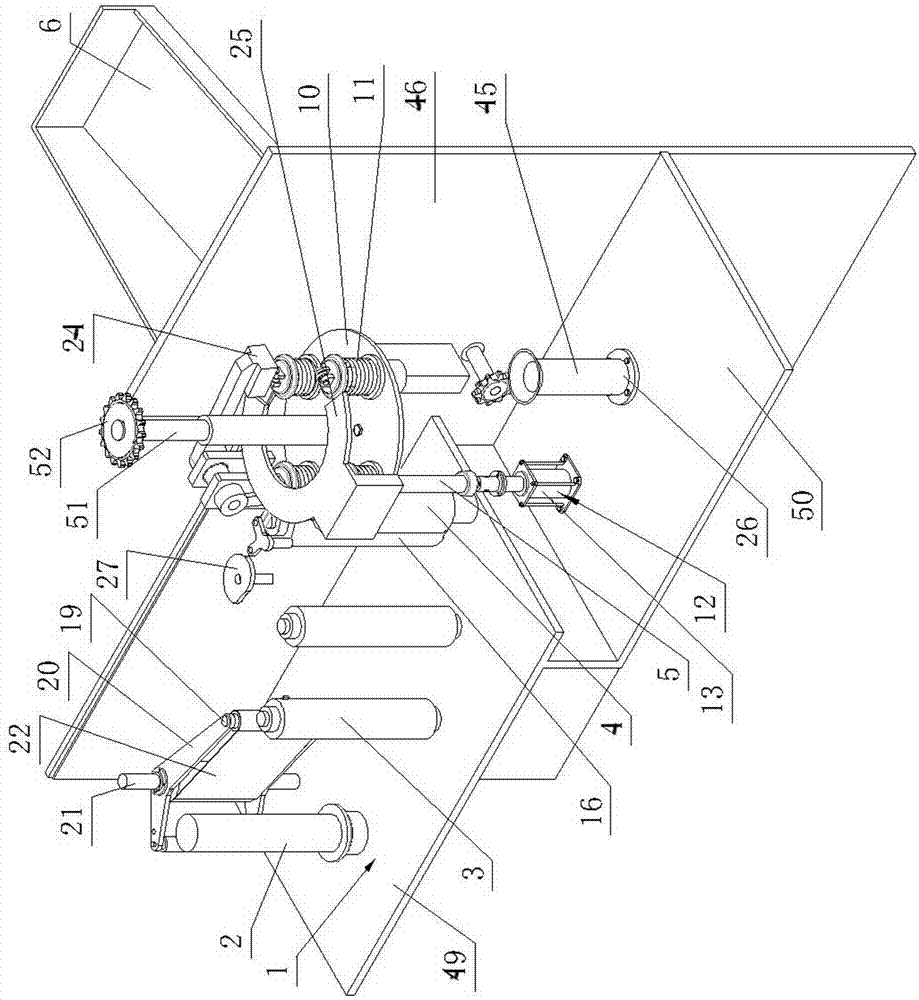

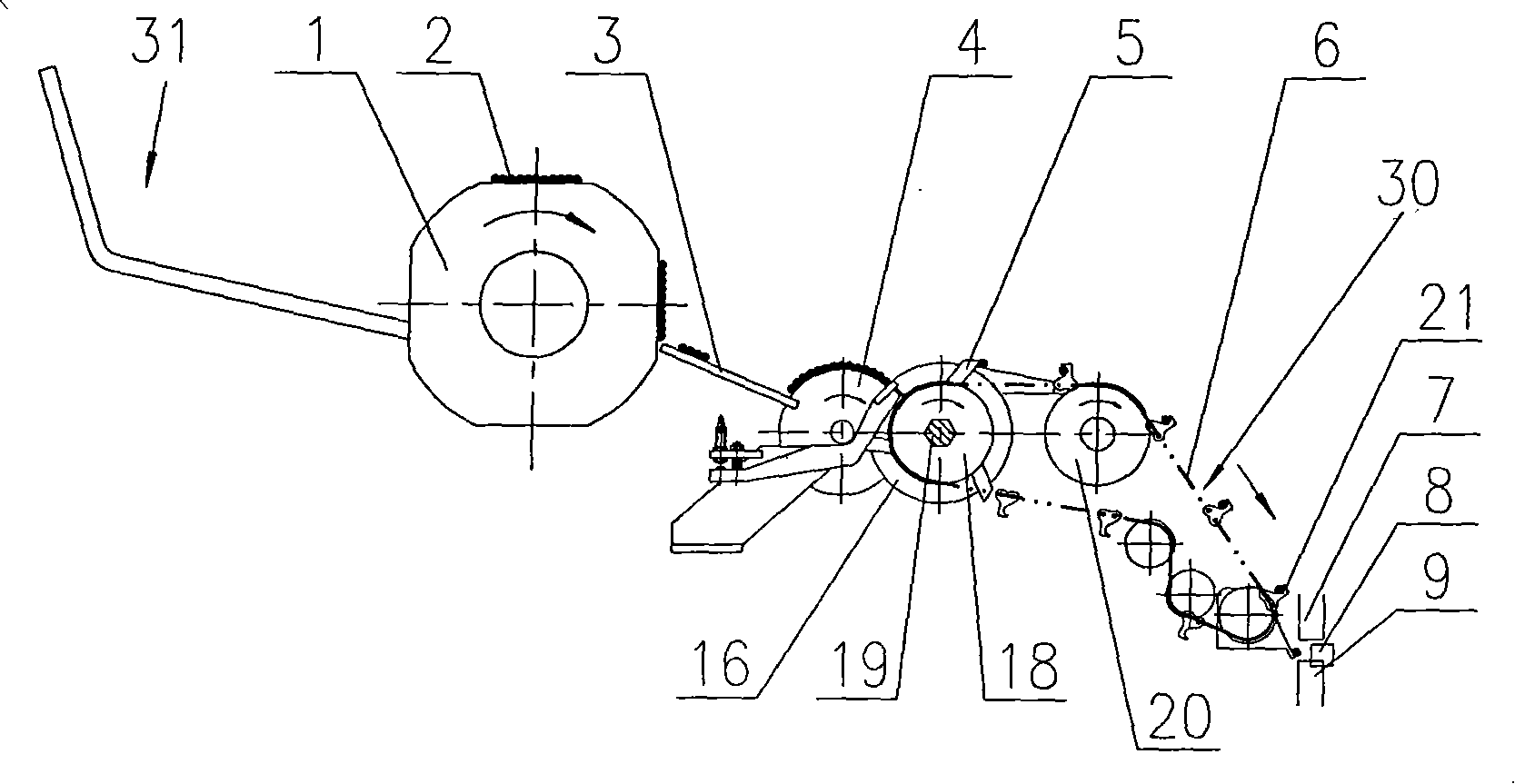

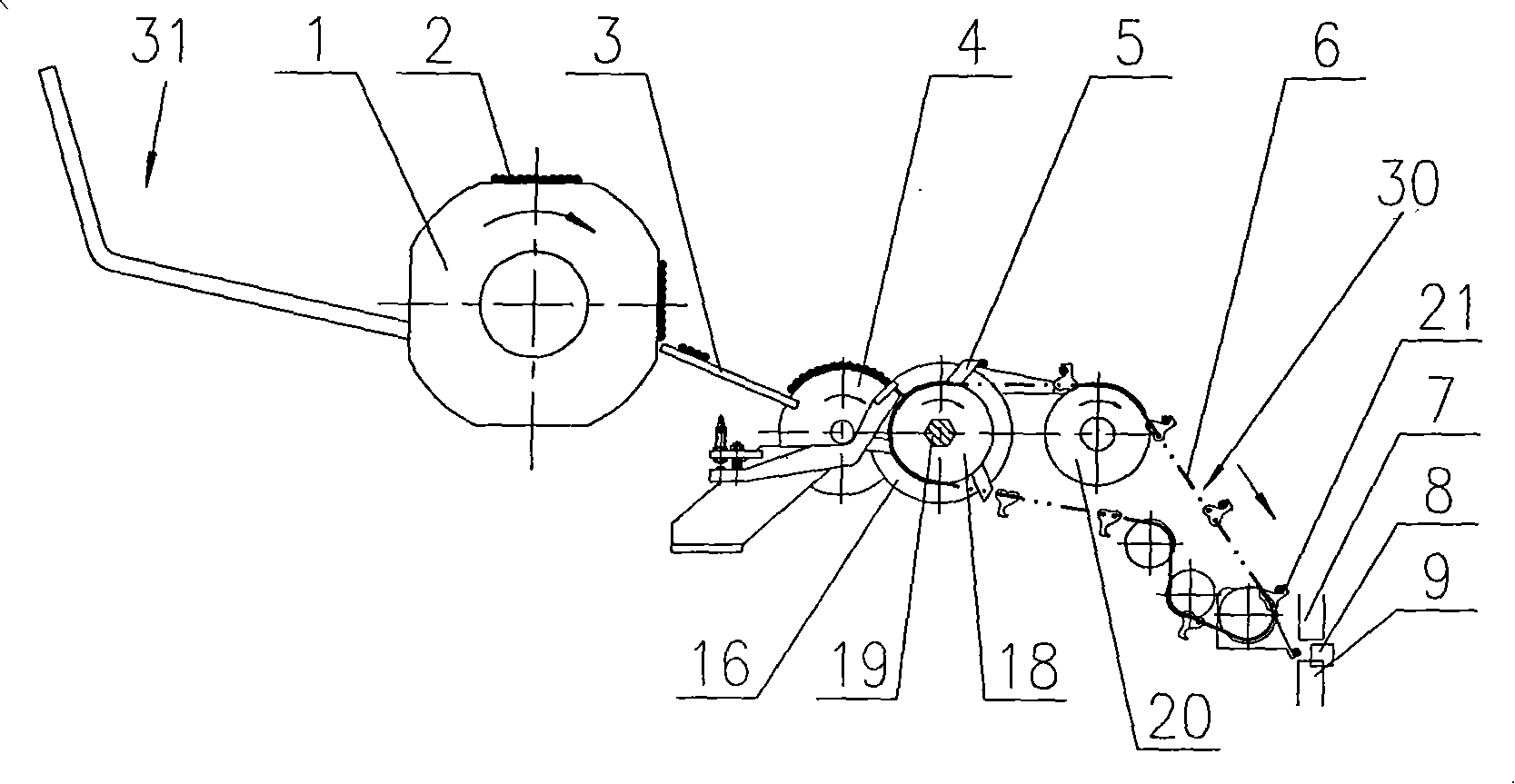

Aluminum foil packaging machine

ActiveCN103935797AThe feeding process is convenientHigh accuracy of operation and positioningWebs handlingPipe supportEngineering

The invention discloses an aluminum foil packaging machine. The aluminum foil packaging machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism and a labeling mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel, a feed channel and a feed rotary disc (7). The feed channel is communicated with a long notch (8) of the feed rotary disc (7). The vertical long notch (8) of the feed rotary disc (7) is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel are vertically arranged. The discharge station of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil packaging machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, convenience, high efficiency and energy conservation are achieved in discharging and unloading processes, and automatic labeling is achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG +1

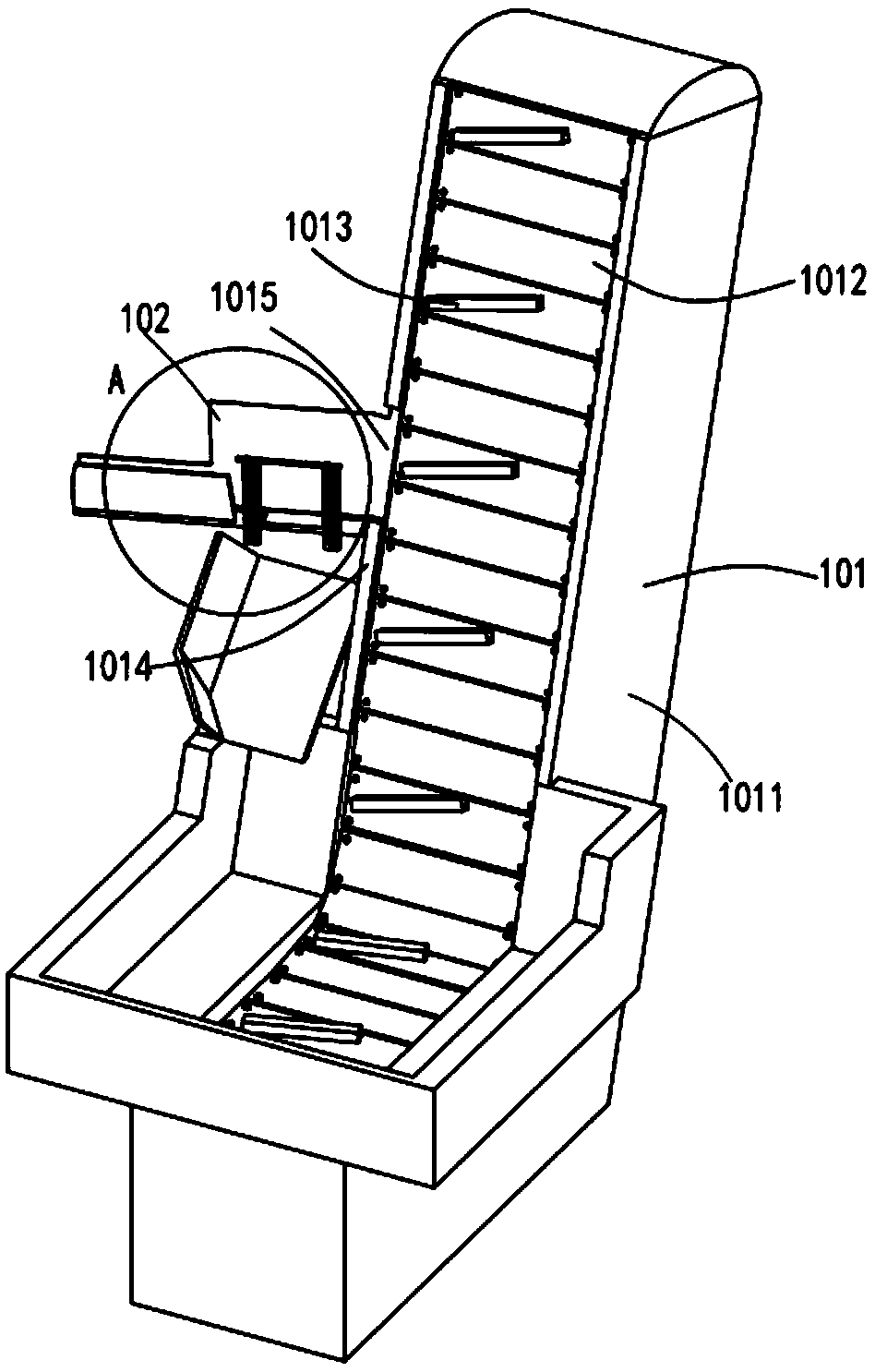

Indent self-positioning long-diameter striking type shell breaking and whole kernel taking equipment and method for high-exposed-kernel walnuts

InactiveCN111567817AImprove shell breaking rateStrong controllabilityHuskingHullingEngineeringMechanical engineering

The invention provides indent self-positioning long-diameter striking type shell breaking and whole kernel taking equipment and method for high-exposed-kernel walnuts. The equipment comprises a feeding positioning device used for discharging the walnuts in a long-diameter posture, a chain plate feeding device used for fixing the discharged long-diameter walnuts through indents and conveying the walnuts to a primary shell breaking device, the primary shell breaking device used for simulating manual knocking type shell breaking to realize a shell breaking action, a secondary shell breaking device that comprises a spiral slideway, and a shell and kernel separation device for separating shells and kernels by utilizing air pressure power generated by pressure difference, wherein the spiral slideway can rotate, so that the walnuts treated with the primary shell breaking device roll downwards along the spiral slideway under the action of gravity.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

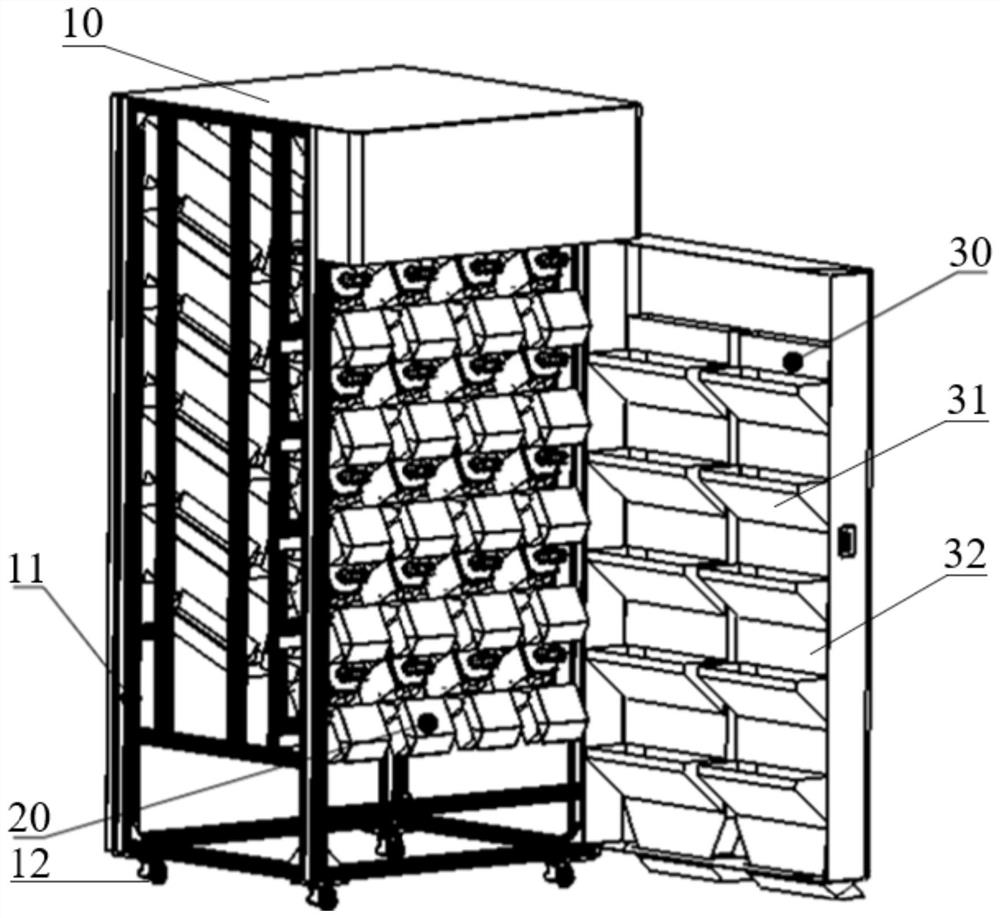

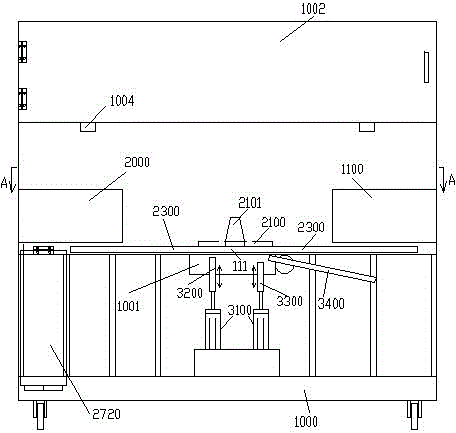

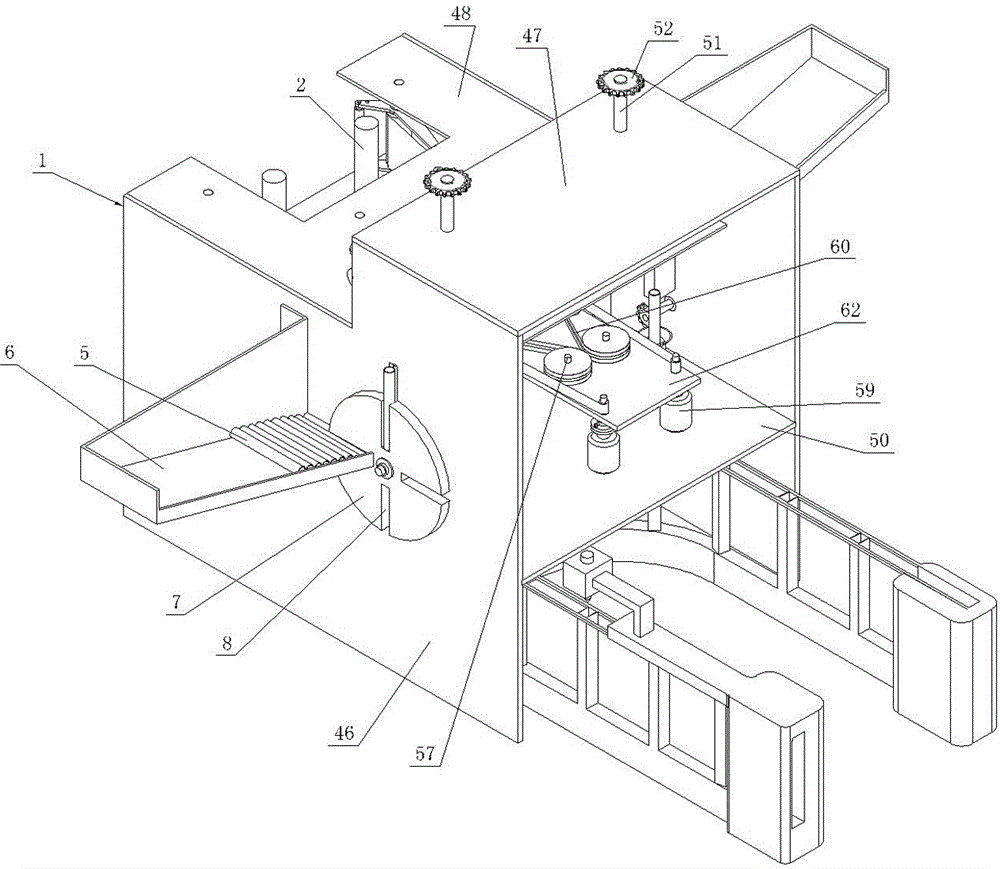

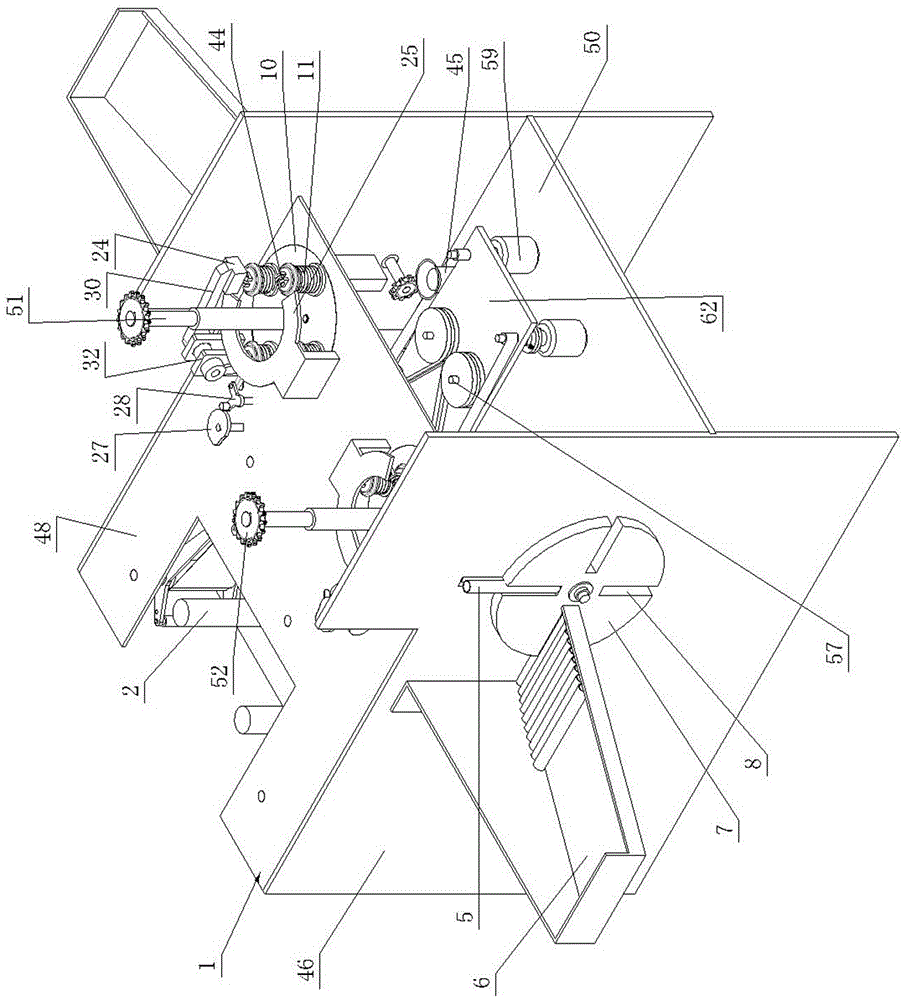

Granular traditional Chinese medicine decoction piece dispensing cabinet

PendingCN112808150AImprove efficiencyEasy to assemble and disassembleRotary stirring mixersTransportation and packagingSurgeryMechanical engineering

The invention relates to a granular traditional Chinese medicine decoction piece dispensing cabinet, which comprises a cabinet main body, a granular medicine dispensing unit and a discharging unit, wherein the cabinet main body is hollow, more than one granular medicine dispensing unit is obliquely arranged in the cabinet main body, the interior of each granular medicine dispensing unit is hollow, one side of each granular medicine dispensing unit is provided with an upper opening, the top of the other side of each granular medicine dispensing unit is provided with a scattering port, more than one dispensing screw rod is arranged in each granular medicine dispensing unit in a penetrating manner, the dispensing screw rods rotate, medicines are conveyed from bottom to top along the dispensing screw rods and are scattered from the scattering ports, the discharging unit is fixedly arranged on the cabinet main body, the upper end of the discharging unit is communicated with the scattering ports, the lower end of the discharging unit is a mixed medicine discharging port, and more than one granular medicine dispensing unit is integrated in the same cabinet main body, so that the use efficiency is high, the disassemble and assemble are convenient, the space utilization rate is increased, the blanking amount per unit time is controlled, and material falling is more accurate; and the dispensing screw rod rotates to be matched with the bending structure so as to reduce the material falling impact, and the material falling channels correspond to the material falling units one to one so as to effectively improve the integration level of the equipment.

Owner:上海观道生物科技有限公司

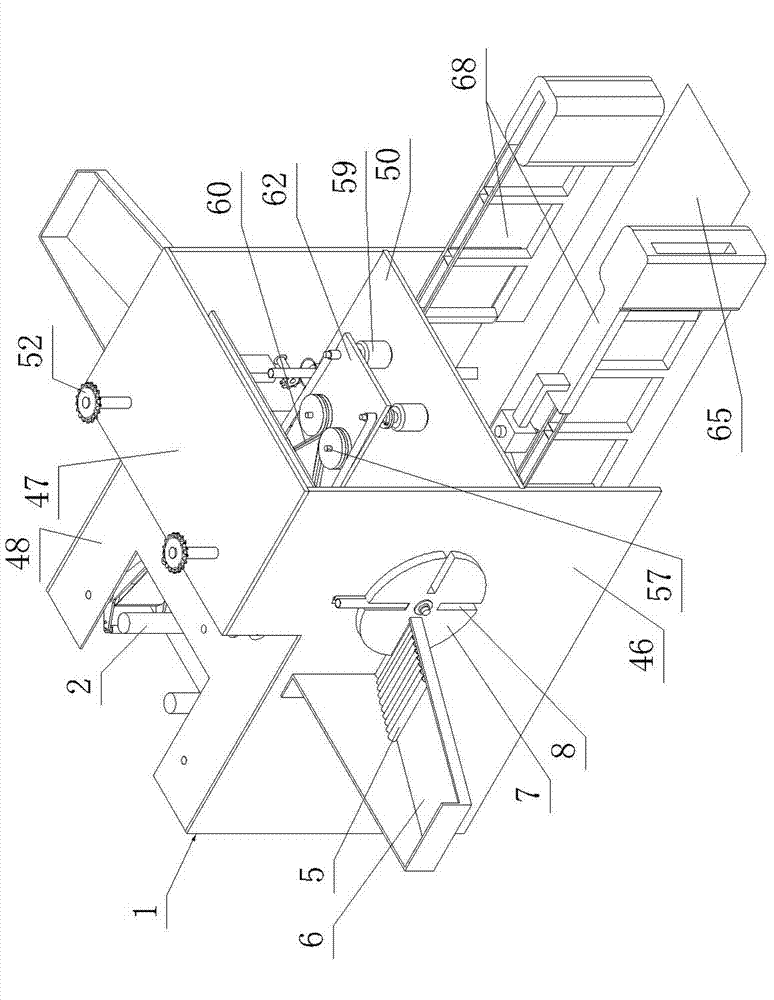

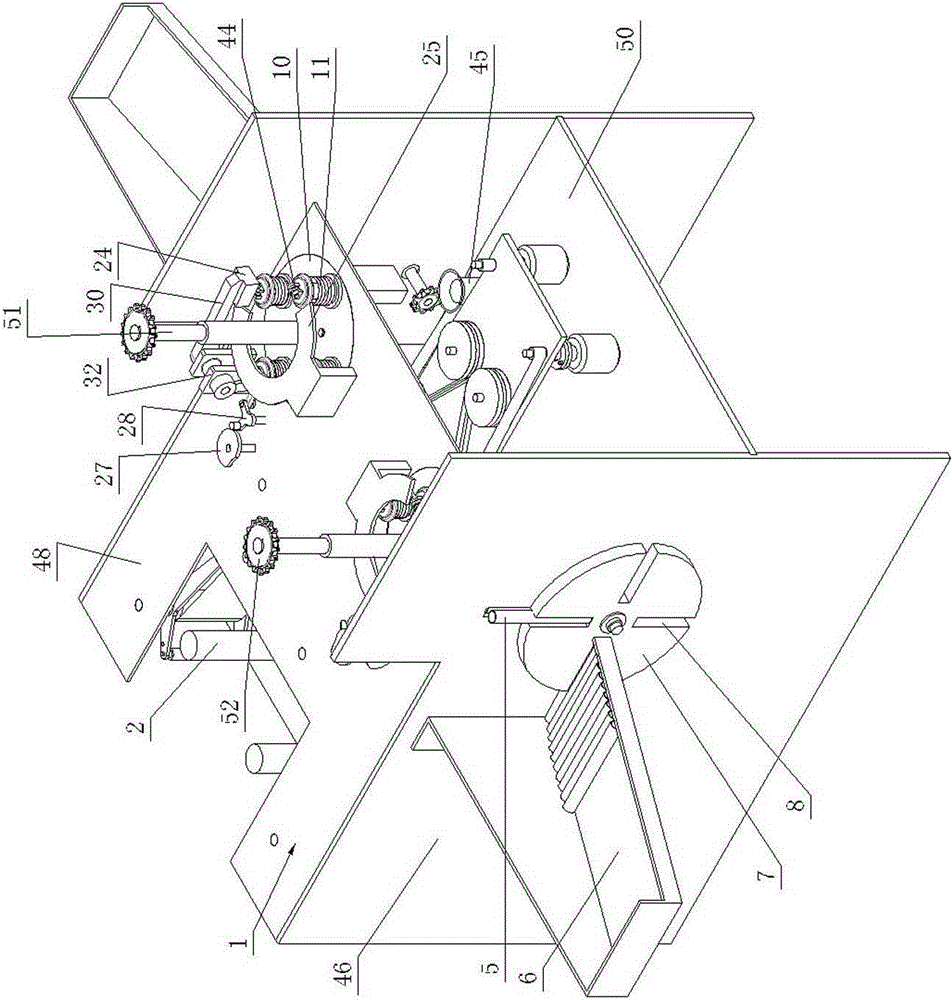

Multifunctional aluminum foil packaging machine

ActiveCN103935798AThe feeding process is convenientHigh accuracy of operation and positioningIndividual articlesPackaging machinesPipe supportAutomation

The invention discloses a multifunctional aluminum foil packaging machine which comprises a machine frame (1). A reeling mechanism and a labeling mechanism are arranged on the machine frame (1). The reeling mechanism comprises a primary reeling shaft (2), tensioning wheels (3), an auxiliary reeling wheel, a feeding channel and a feeding rotary disc (7), the feeding channel is communicated with long notches (8) of the feeding rotary disc (7), the vertical long notches (8) of the feeding rotary disc (7) are communicated with a clamping station, a station switching rotary disc (10) is installed on the machine frame (1), pipe supporting mechanisms (11) are installed on the station switching rotary disc (10), inner supporting structures are installed on the pipe supporting mechanisms (11), a conveying belt is arranged below a discharging opening of the machine frame (1), and a mechanism for folding a box cover is further arranged on the conveying belt. The multifunctional aluminum foil packaging machine is efficient and convenient to use in the feeding process, compact in structure and small in occupied space, discharging and unloading are convenient to achieve and efficient and save energy, and automation labeling and automatic box packaging can be achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG +1

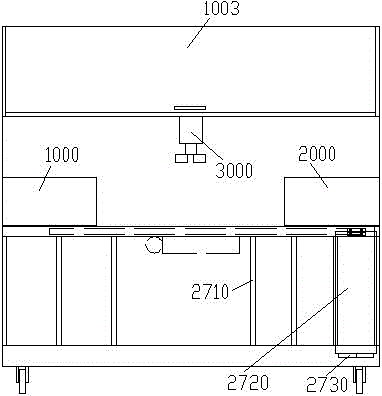

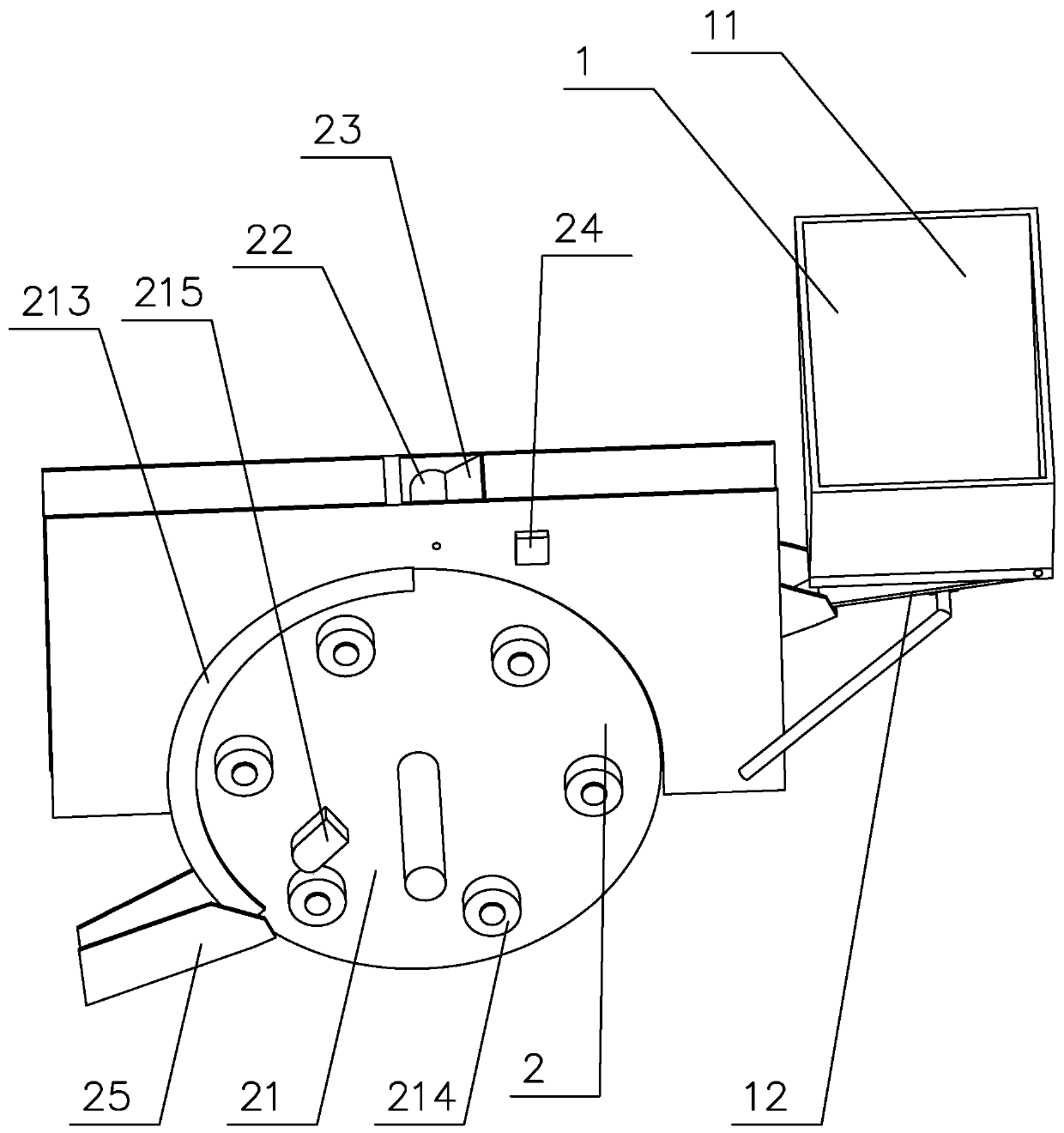

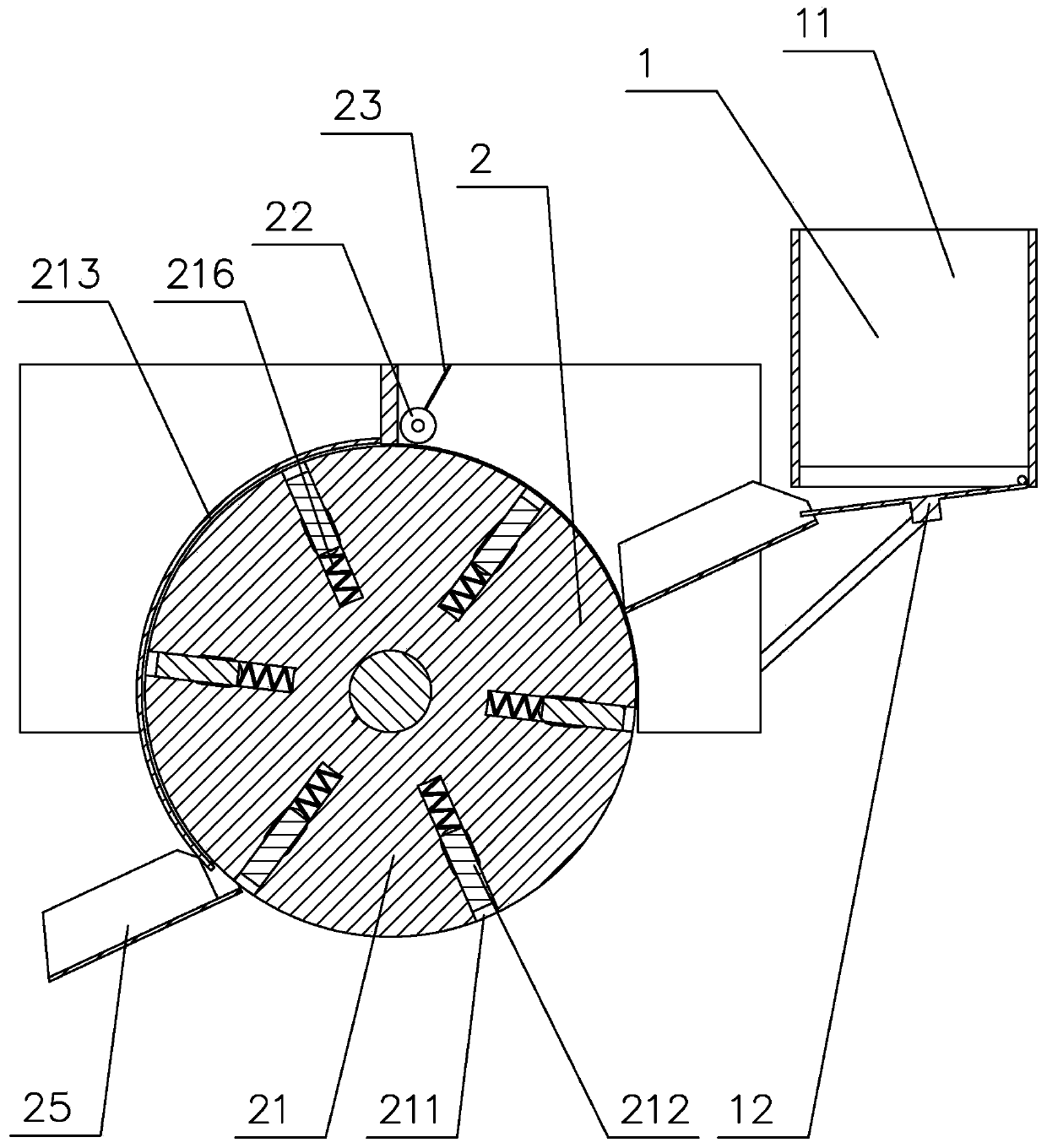

Intelligentized rotary table metal casting sprue separating integrated machine and method thereof

The invention relates to an intelligentized rotary table metal casting sprue separating integrated machine and a method thereof. The intelligentized rotary table metal casting sprue separating integrated machine comprises a machine cabinet. An annular rotary table driven by an electric index plate is arranged in the middle of the machine cabinet. Positioning poles used for placing metal castings are arranged on the annular rotary table at intervals. A metal casting sprue separating device used for achieving sprue waste separation after the metal castings are rotated to the position is arranged on one side of the annular rotary table. A metal casting separating device used for achieving metal casting product separation after the metal castings are rotated to the position is arranged on the other side of the annular rotary plate. An ejection mechanism used for ejecting metal casting wastes after the metal casting wastes are rotated to the position along with the annular rotary plate is further arranged on the lower side of the annular rotary table and on the front portion of the machine cabinet. The intelligentized rotary table metal casting sprue separating integrated machine is compact in structure; metal casting sprue separation and metal casting separation are convenient; the automation degree is high, and the operation method is simple and convenient.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

Vegetable and fruit kernel removing device

ActiveCN110613149AIncrease productivityEnsure consistencyFruit stoningAutomatic processingEngineering

The invention discloses a vegetable and fruit kernel removing device. The vegetable and fruit kernel removing device comprises a feeding part, a conveying part, a positioning part and a processing part, wherein the feeding part is used for storing and outputting to-be-processed materials; the conveying part is used for conveying materials output by the feeding part to the positioning part; the positioning part is used for adjusting positions and postures of the to-be-processed materials; the processing part is used for processing the materials positioned by the positioning part; and through ordered feeding of the feeding part, the conveying part can sequentially output the materials to the positioning part, then the materials are positioned through the positioning part, and the proper positions and the proper postures of the materials are determined; and core parts of the materials are removed through the processing part, so that automatic processing of kernel removal of vegetable andfruit can be completely carried out, and thus, the production efficiency is improved, and the processing consistency is ensured.

Owner:廖邹婧

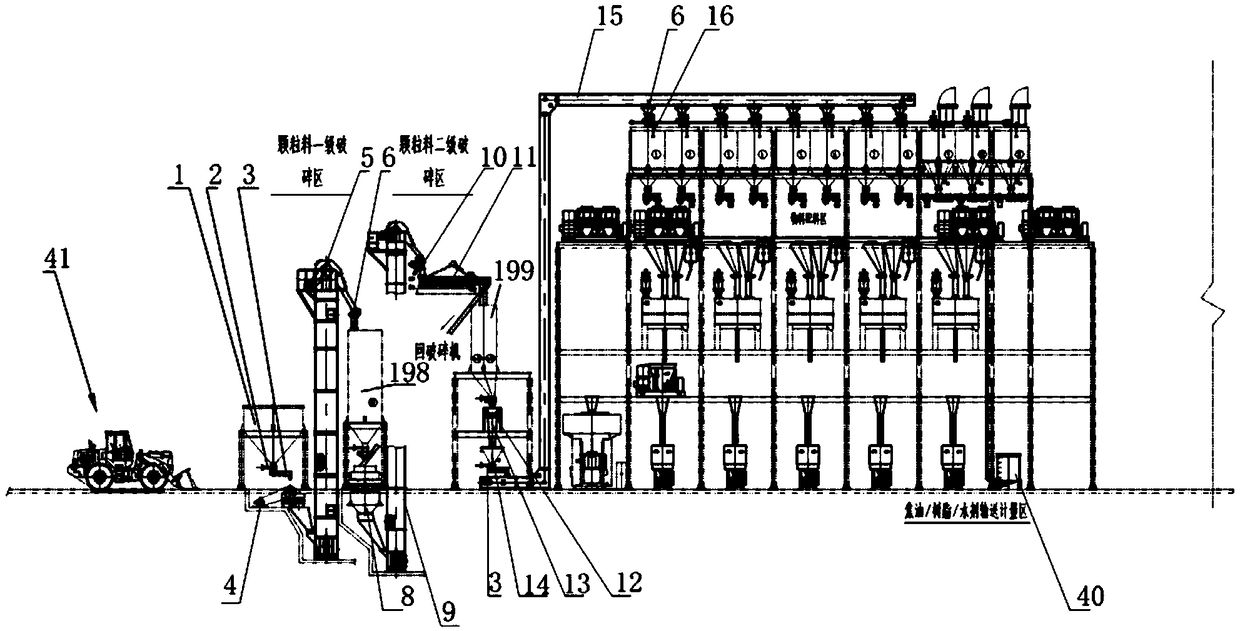

Kitchen waste disposer and kitchen waste treatment method thereof

ActiveCN109530407AStop precisePrecise Control of Rotational ContinuitySolid waste disposalDomestic plumbingElectromagnetic shieldingEngineering

The invention discloses a kitchen waste disposer and a kitchen waste treatment method thereof. The kitchen waste disposer comprises a motor, a rotating disc, a first limiting device, a second limitingdevice and a fixing plate, wherein the rotating disc is arranged at the tail end of an output shaft of the motor, the output shaft of the motor is perpendicular to the surface of the rotating disc, an annular sliding groove is formed in the side edge, away from the motor, of the rotating disc, the cross section of the sliding groove is conical, a first positioning hole and a second positioning hole which are symmetrical are formed in the bottom of the sliding groove, the side, far away from the motor, of the rotating disc is provided with the fixing plate, the side edge, close to the rotatingdisc, of the fixing plate is provided with the first limiting device and the second limiting device, the first limiting device comprises a positioning pin, a shaft shoulder, a spring, a first electromagnetic disc, a base and a second electromagnetic disc, wherein the base is of a hollow structure with one end open, one end of an upper opening of the base is installed on the fixing plate, and a guide through hole is formed in the side edge, away from the fixing plate, of the base. According to the kitchen waste disposer and the kitchen waste treatment method thereof, the accuracy of the rotating position of a drying chamber can be ensured, so that falling is accurate, pollution to a box body and repeated drying are avoided, and the efficiency is very high.

Owner:徐州川珉建设工程有限公司

Automatic sorting device of wire drawing die

ActiveCN104525509AImprove sorting efficiencyReduce sorting error rateSortingControl systemEngineering

The invention discloses an automatic sorting device of a wire drawing die. The automatic sorting device comprises a machine frame, a conveying belt and at least one sorting unit. Each sorting unit comprises a supplied-material detection sensor, a pushing device, a discharging guide tank, a rotating separating device and a sorting disc, and the conveying belt, the supplied-material detection sensors, the pushing devices and discharging guide tanks are installed on the machine frame. Each rotating separating device comprises an installation base, a support, a hopper, a separating tank and a rotating separating power device, wherein the support is installed on the installation base in a rotary mode and driven by the rotating separating power device, the hopper and the separating tank are installed above and below the support respectively, the separating tank is communicated with the hopper, and the hopper is located below the corresponding discharging guide tank. Each sorting disc is located below the corresponding separating tank and comprises a base and a plurality of sorting boxes, wherein the sorting boxes are installed on the base and annularly distributed, and the rotating centers of the separating tanks are coincident with the annular centers of the sorting boxes. The supplied-material detection sensors, the pushing devices and the rotating separating devices are connected with a control system. By means of the automatic sorting device, the sorting efficiency is improved.

Owner:严格防务科技集团有限公司

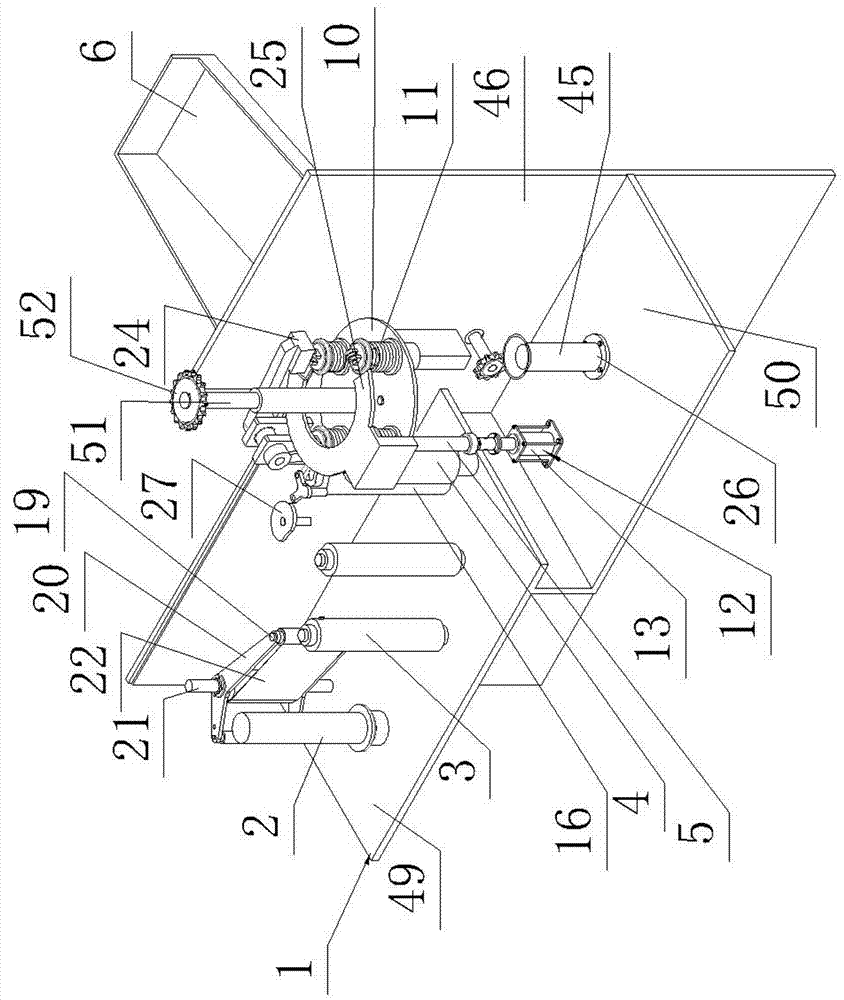

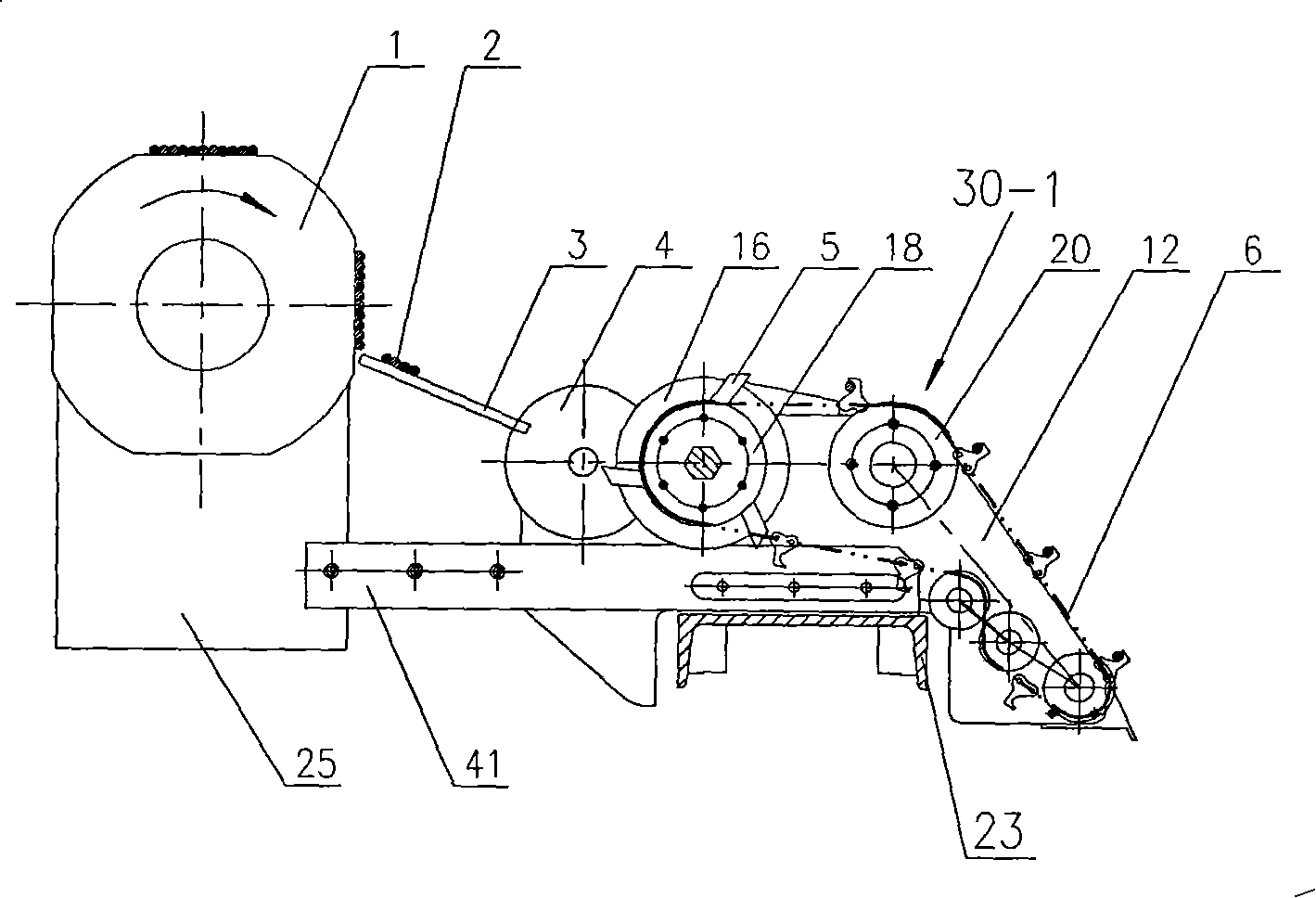

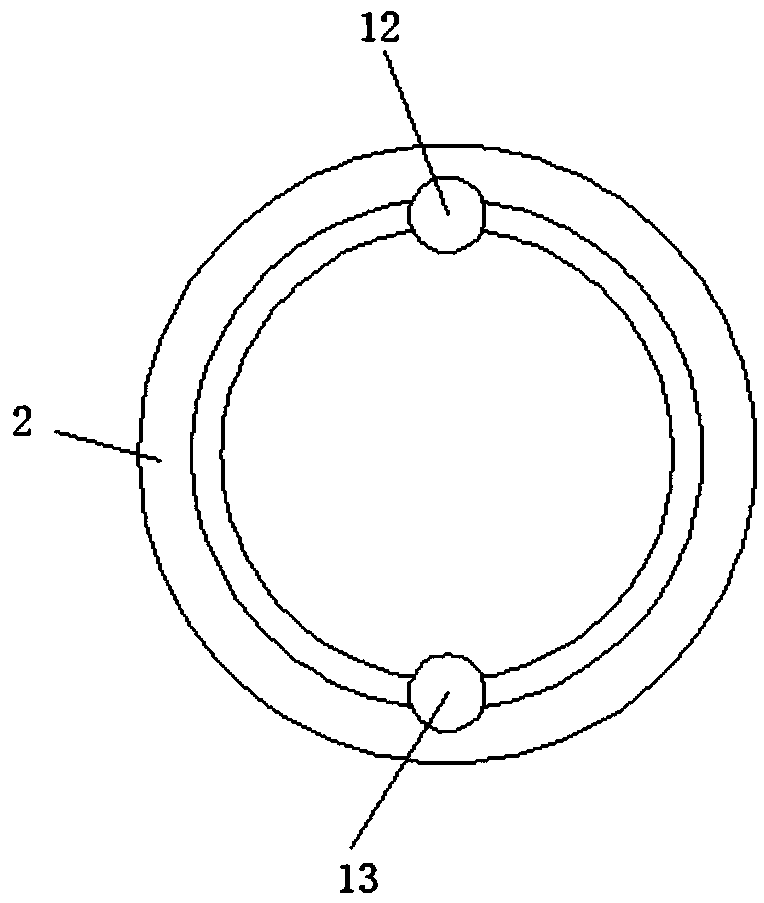

Aluminum foil rewinding machine

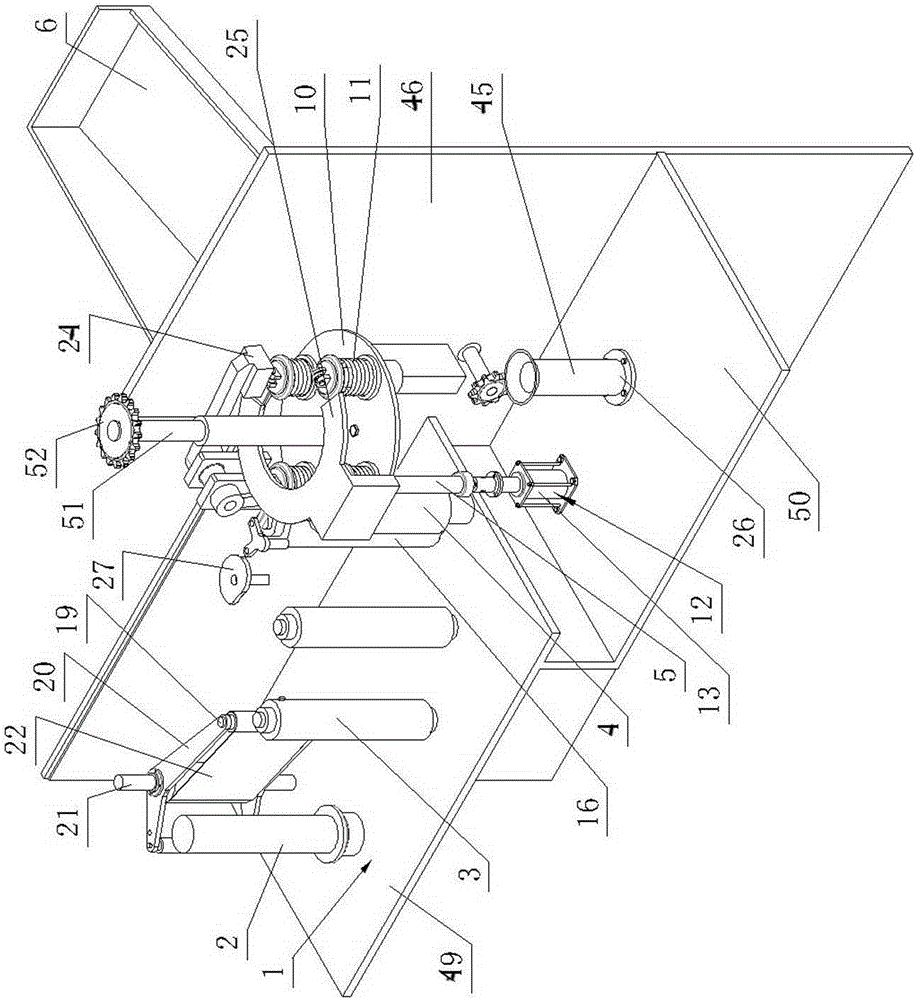

ActiveCN103935803AThe feeding process is convenientHigh accuracy of operation and positioningWebs handlingPipe supportEngineering

The invention discloses an aluminum foil rewinding machine. The aluminum foil rewinding machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel (4), a feed channel (6) and a feed rotary disc. The feed channel (6) is communicated with a long notch of the feed rotary disc. The vertical long notch of the feed rotary disc is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel (4) are vertically arranged. The discharge station (26) of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil rewinding machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, the packaging effect of sub rolls is good, and convenience, high efficiency and energy conservation are achieved in discharging and unloading processes.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

Aluminum foil packaging machine

The invention discloses an aluminum foil packaging machine. The aluminum foil packaging machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism and a labeling mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel, a feed channel and a feed rotary disc (7). The feed channel is communicated with a long notch (8) of the feed rotary disc (7). The vertical long notch (8) of the feed rotary disc (7) is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel are vertically arranged. The discharge station of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil packaging machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, convenience, high efficiency and energy conservation are achieved in discharging and unloading processes, and automatic labeling is achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG +1

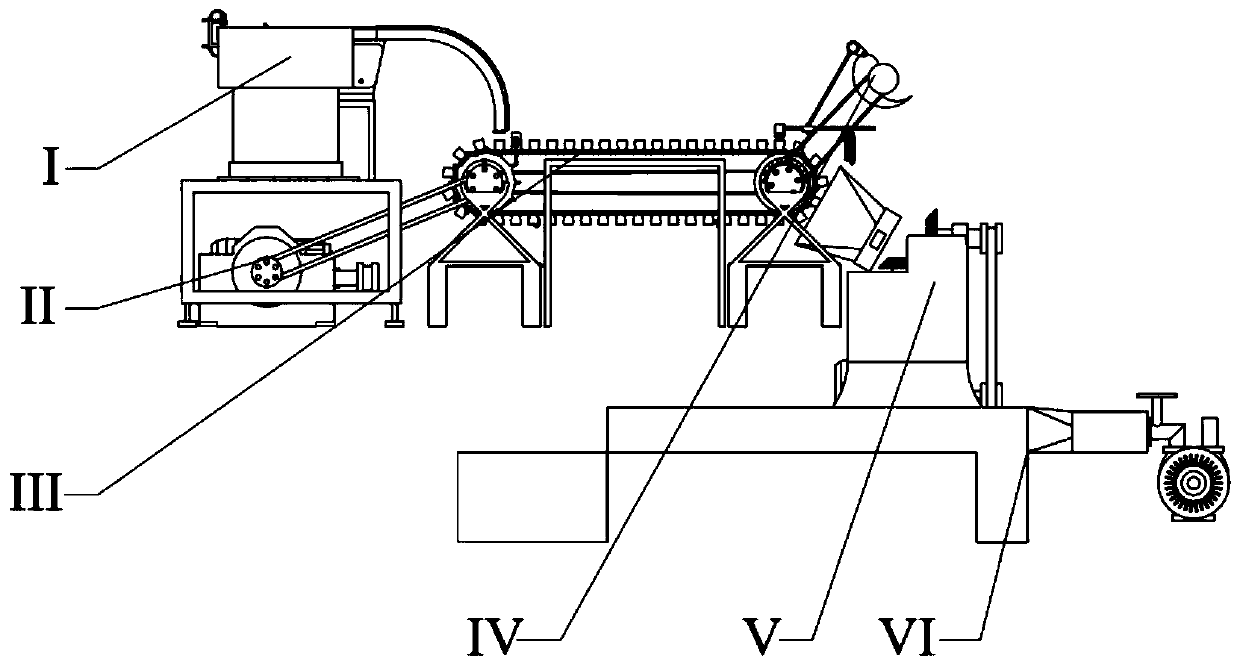

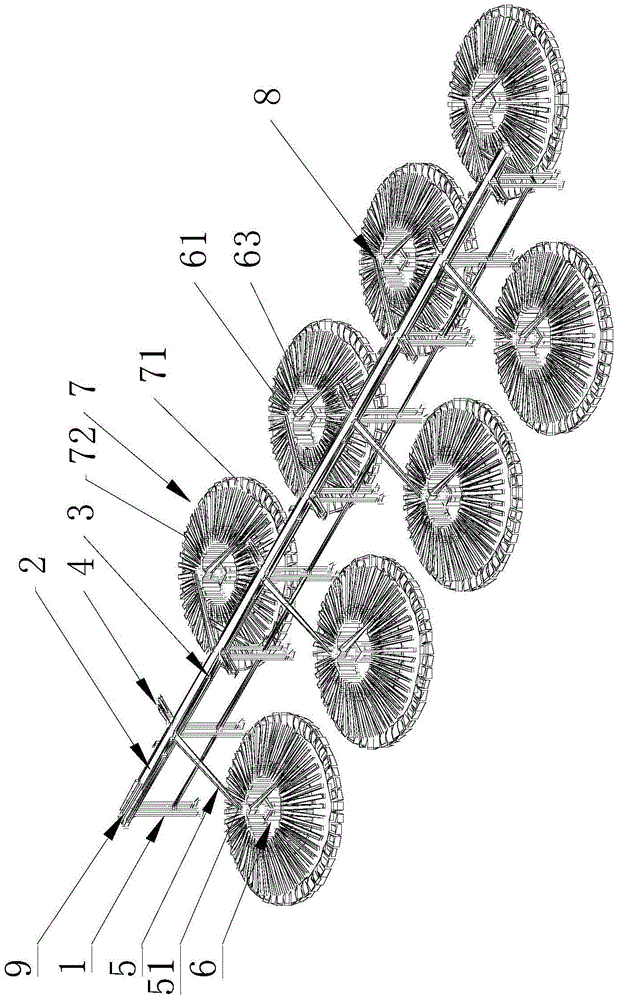

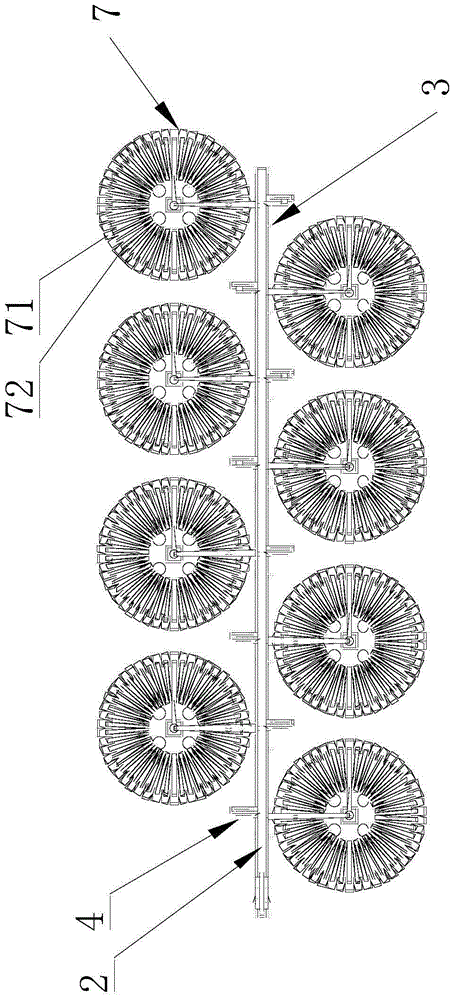

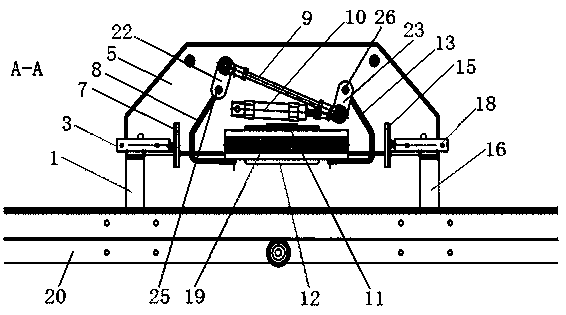

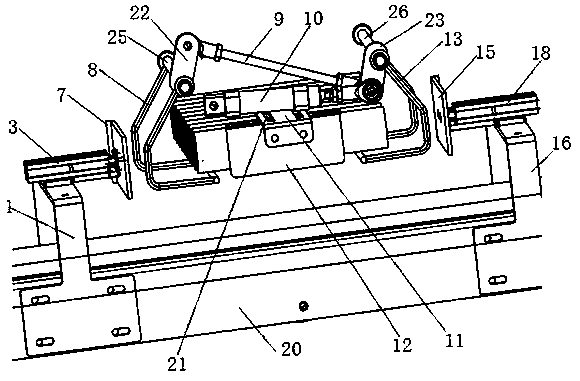

Tram silk chain manner material dropping mechanism of welding machine of mesh

ActiveCN101244501AStable blankingHigh speedWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftEngineering

The invention discloses a chain blanking device of tram for a welding machine of mesh, wherein, a round magnetic drum is arranged below a square magnetic drum; a slide carriage is arranged between the square magnetic drum and one side of the round magnetic drum; the first drive sprockets of a fixed chain transport device and a shift chain transport device are fixed on the same drive shaft; one end of the drive shaft is connected with the driving motor of a carrier chain and the other end is hold by a frame; the first driven sprockets of two fixed chain transport devices are arranged on the drive shaft; a pusher dog disk and the second driven sprocket are arranged on the pusher dog shaft; an inner hole of the pusher dog shaft is intermittently sleeve-arranged on the drive shaft; the second drive sprocket connected to the second driven sprocket is arranged on the pusher dog shaft. The chain blanking device of tram has the advantages that the tram blanking can be steady, orderly and accurate with the transport hook of the transport device; the shift chain transport device can shift synchronously in lateral direction, so as to adapt to the tram with different lengths; the blanking process has good balance performance, and the productivity of the welding mesh is improved.

Owner:TJK MACHINERY TIANJIN

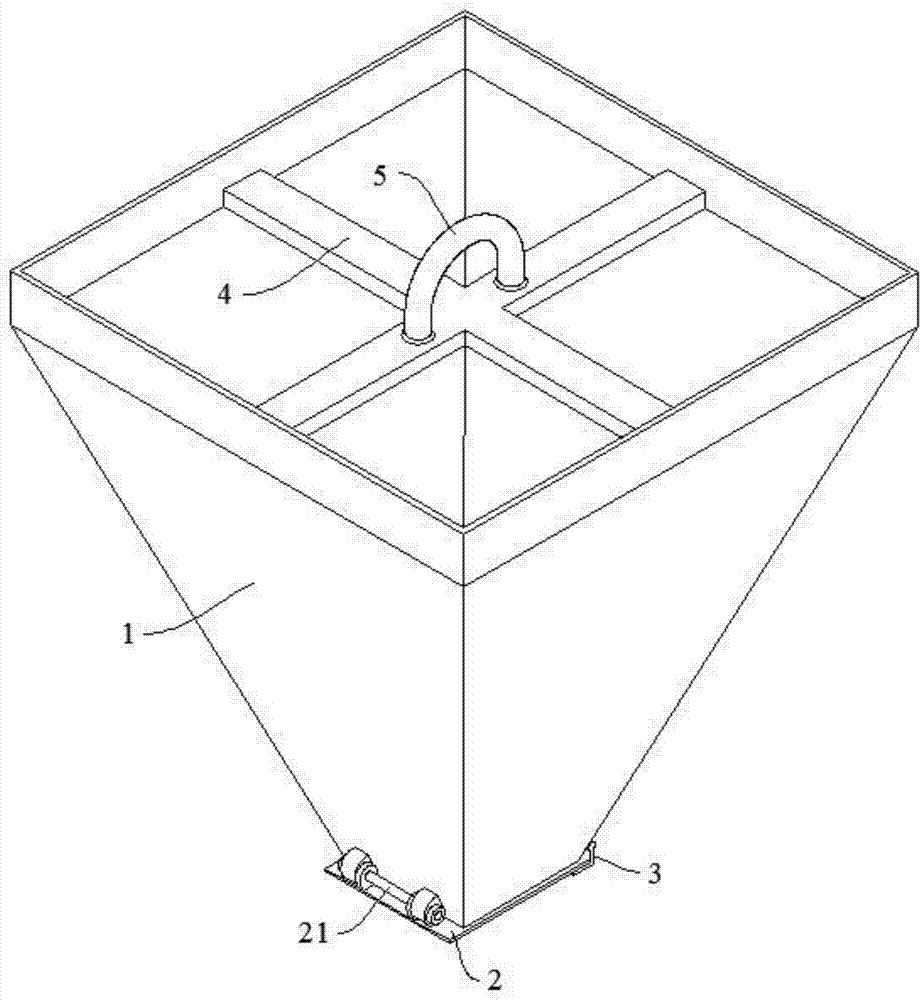

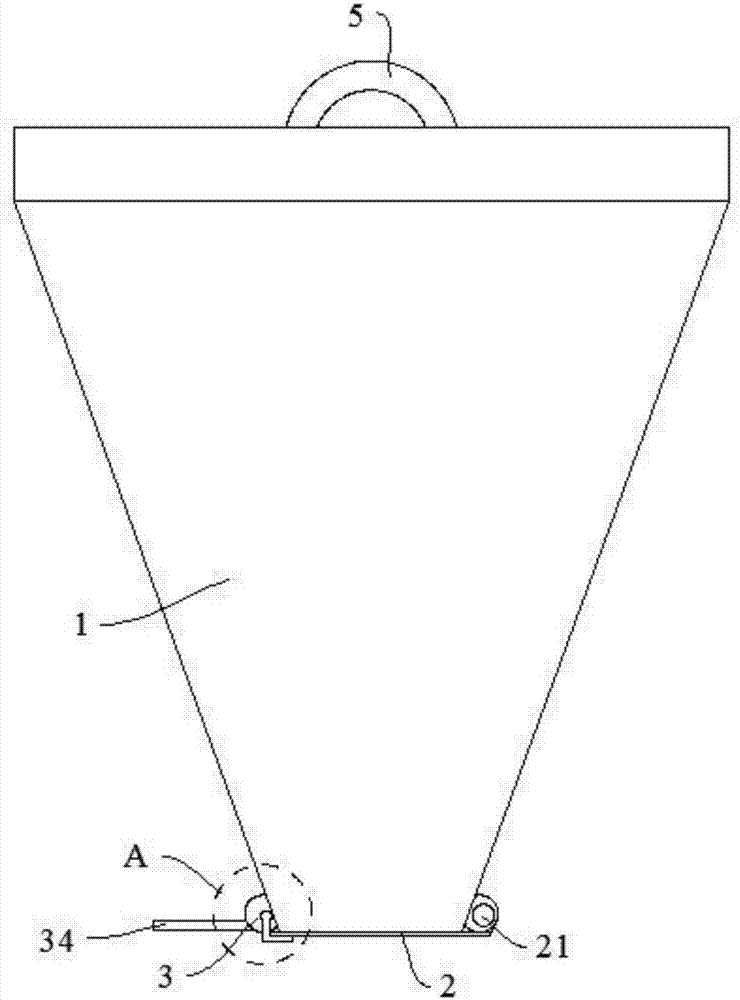

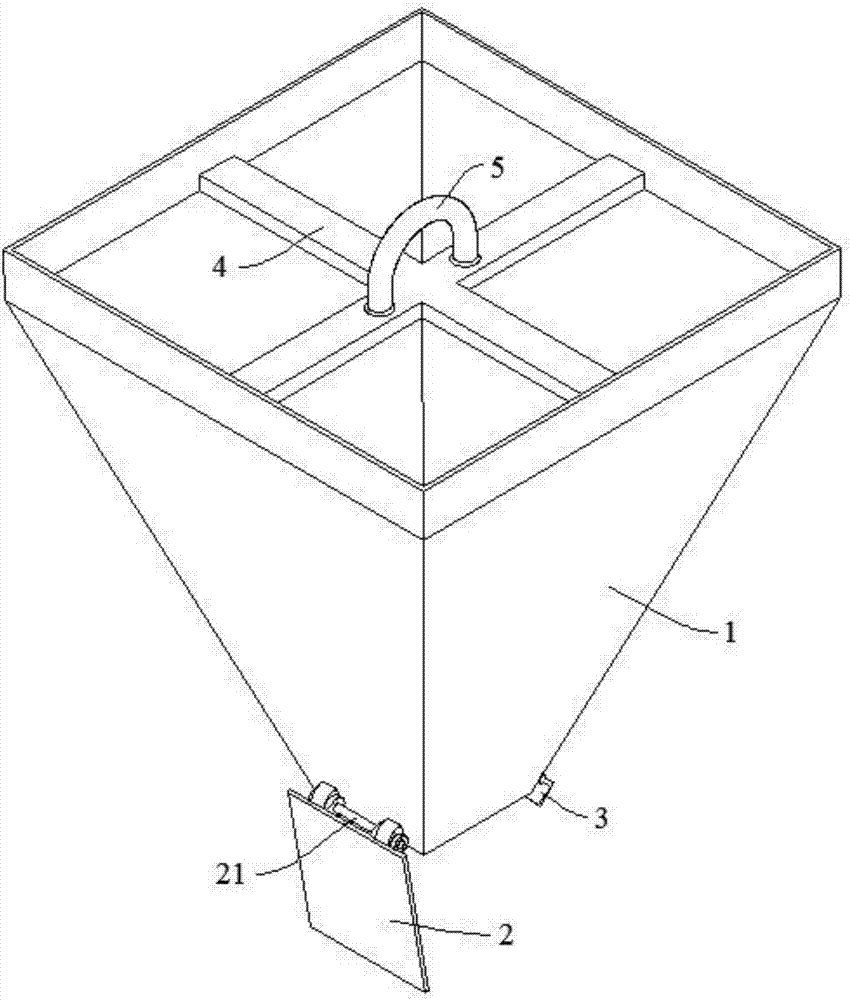

Bottom discharging type metal smelting feeding hopper

ActiveCN107120973AEasy to openSimple structureCharge manipulationProcess efficiency improvementStructural engineeringMechanical engineering

The invention discloses a bottom discharging type metal smelting feeding hopper. The top and the bottom of a hopper body are opened. A hopper bottom door is hinged to the outer wall of the lower end of the hopper body. A locking mechanism is also hinged to the outer wall of the lower end of the hopper body. A hinge shaft of the locking mechanism is parallel with a hinge shaft of the hopper bottom door. A top beam is fixed to an upper opening of the hopper body. A hanging ring is fixed to the center of the top beam. The locking mechanism comprises a table portion, a connection portion and a foot-operated balance weight lever. The table portion is a belt-shaped flat plate and located below the hinge shaft of the locking mechanism. One side wall of the table potion extends upwards, so that the connection portion is formed. The other side of the connection portion is fixed to the hinge shaft of the locking mechanism. The foot-operated balance weight lever is parallel with the table portion and protrudes in the direction opposite to the table portion. The table portion, the connection portion and the hopper bottom door is required to meet the condition that when the hopper bottom door is closed, the table portion is level, and a force arm of force which is applied to the hinge shaft of the locking mechanism by the hopper bottom door is smaller than 2 cm. The bottom discharging type metal smelting feeding hopper is simple, reliable and reasonable in structure; and when the bottom discharging type metal smelting feeding hopper is used, an operator only needs to conduct simple lifting with a foot, and a discharging opening can be opened easily and material dropping can be achieved precisely.

Owner:宁夏铸峰特殊合金有限公司

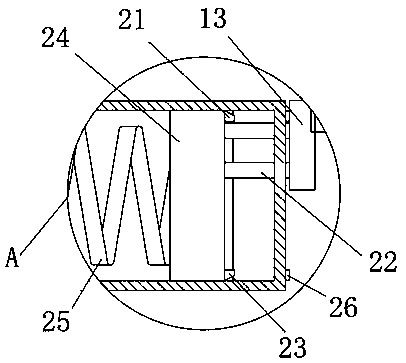

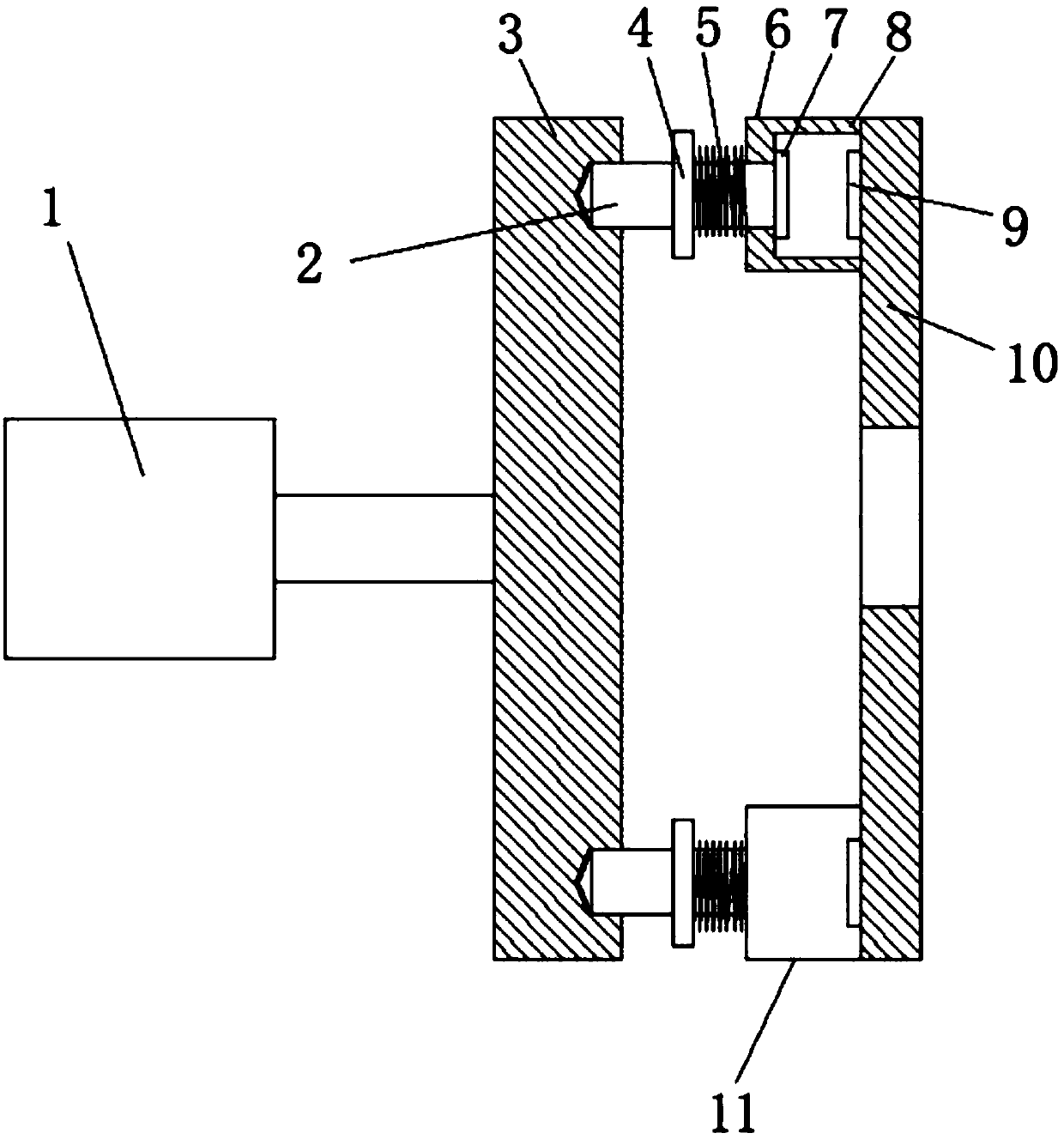

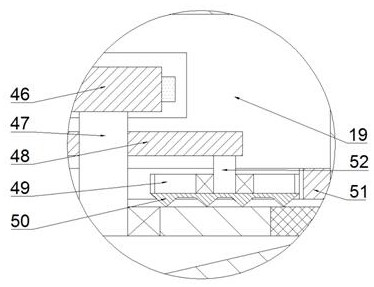

A motor rotation positioning structure and kitchen waste disposer

ActiveCN106836401BStop precisePrecise Control of Rotational ContinuitySolid waste disposalDomestic plumbingElectric machineEngineering

The invention discloses a motor rotation positioning structure and a kitchen waste disposer. The output shaft is perpendicular to the surface of the turntable. The side of the turntable away from the motor is provided with an annular chute, and the cross section of the chute is tapered. The bottom of the chute is provided with symmetrical first and second positioning holes. The turntable The side away from the motor is provided with a fixed plate, and the side of the fixed plate close to the turntable is equipped with a first limiting device and a second limiting device. The first limiting device includes a positioning pin, a shaft shoulder, a spring, a first electromagnet, The base and the second electromagnetic disk, the base is a hollow structure with one end open, the open end of the base is installed on the fixing plate, and the side of the base away from the fixing plate is provided with a guide through hole. The invention can ensure the accuracy of the rotating position of the drying chamber, so that the blanking is accurate, the box body can be avoided from being polluted, and the drying can be repeated, and the efficiency is very high.

Owner:LINYI ENTREPRENEURSHIP TECH SERVICE CO LTD

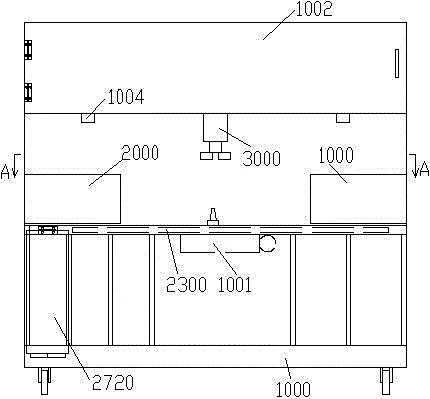

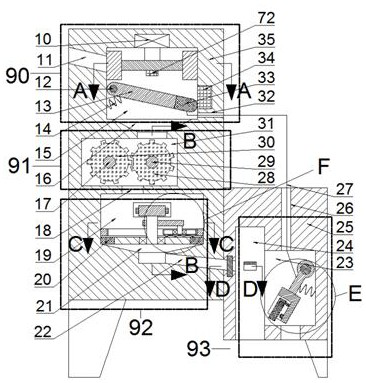

Intelligent anti-deformation metal casting nozzle separation machine and its control method

The invention relates to an intelligent deformation-resistant metal casting water gap separating integrated machine and an operation method thereof. The intelligent deformation-resistant metal casting water gap separating integrated machine comprises a cabinet with casters, wherein an annular rotary table driven by an electric dividing plate is arranged in the middle of the cabinet, positioning mechanisms which rotate with the annular rotary table and are used for mounting metal castings are arranged on the circumference of the annular rotary table at an interval of 90 degrees, a first work station positioned on the front side, a second work station and a fourth work station, positioned on the two sides and a third work station positioned on the rear side are arranged in the cabinet along the circumferential side of the annular rotary table at intervals, the first work station is a metal casting loading and unloading work station, the second work station is a metal casting water gap waste material separating work station, the fourth work station is a metal casting product separating work station, and an electric cabinet in which an industrial personal computer is mounted is arranged at the upper part of the rear side of the cabinet. The integrated machine not only is compact in structure and convenient for separating metal casting water gaps from metal casting products, but also is simple in operation method.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

Automatic packaging bag stacking device with dust collection function

ActiveCN114803529AReduce workloadAvoid damageStacking articlesCleaning using gasesPalletizerWorking environment

The invention relates to the technical field of cement production, in particular to an automatic packaging bag stacking device with a dust collection function, which comprises a rack, a conveyor belt, a stacking mechanism, a dust collection mechanism and a rectangular groove, the stacking mechanism comprises a first driving assembly, a second driving assembly, a mounting frame and a stacking assembly, and the stacking assembly comprises a stacking box and a guide pipe. A baffle in sliding fit with the stacking box is arranged at the bottom of the stacking box, through the arrangement of the stacking box, packaging bags can be stacked in advance in the height direction of the stacking box, meanwhile, through the arrangement of a dust suction pipe, raised dust of falling materials in the stacking box is sucked by the dust suction pipe and finally collected by a dust suction mechanism, and the packaging bags are stacked in advance. According to the packaging bag stacking device, packaging bags can fall into the compartment in order through limiting of the stacking box, stacking is more orderly, so that the packaging bags do not need to be manually straightened, the working burden of workers is relieved, meanwhile, the situation of secondary dust raising caused by falling is avoided, dust raising in the working environment is reduced, and damage to the workers is reduced.

Owner:南通罗纳尔包装材料有限公司

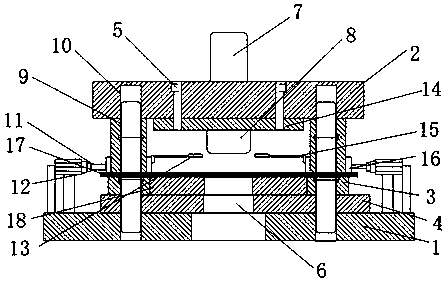

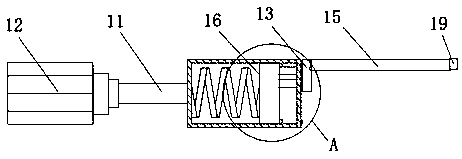

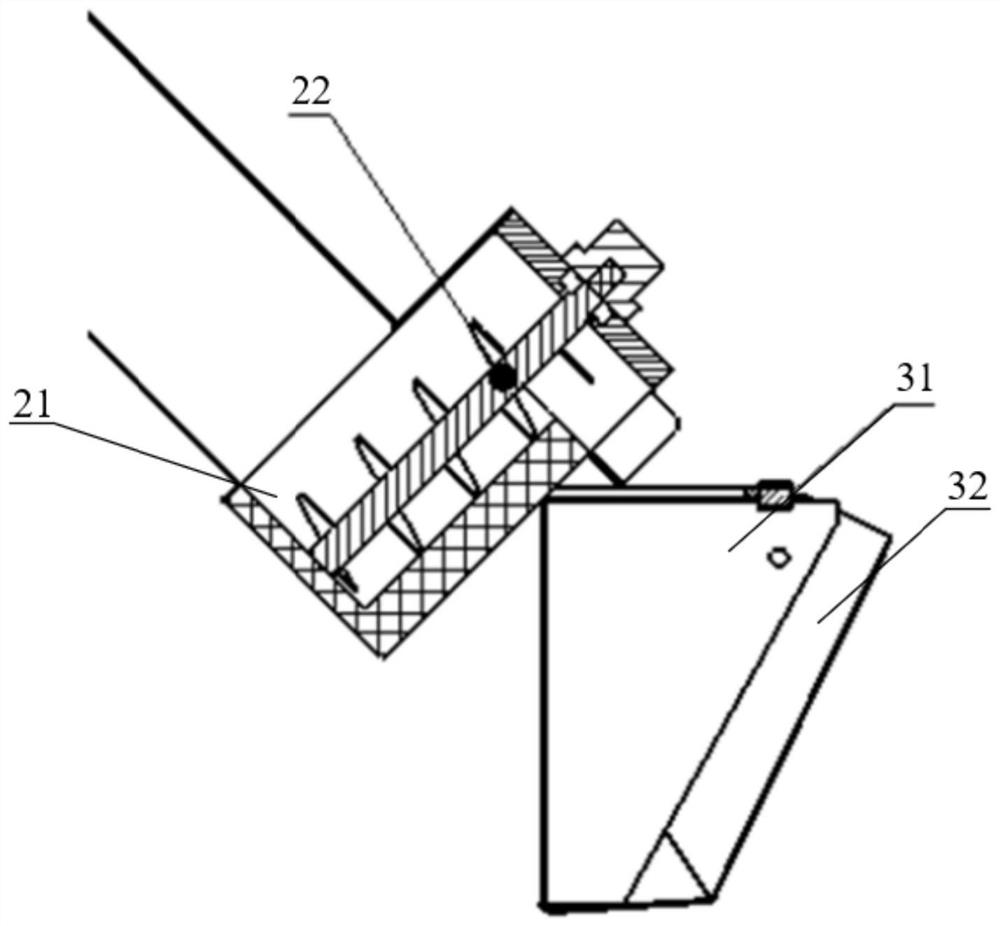

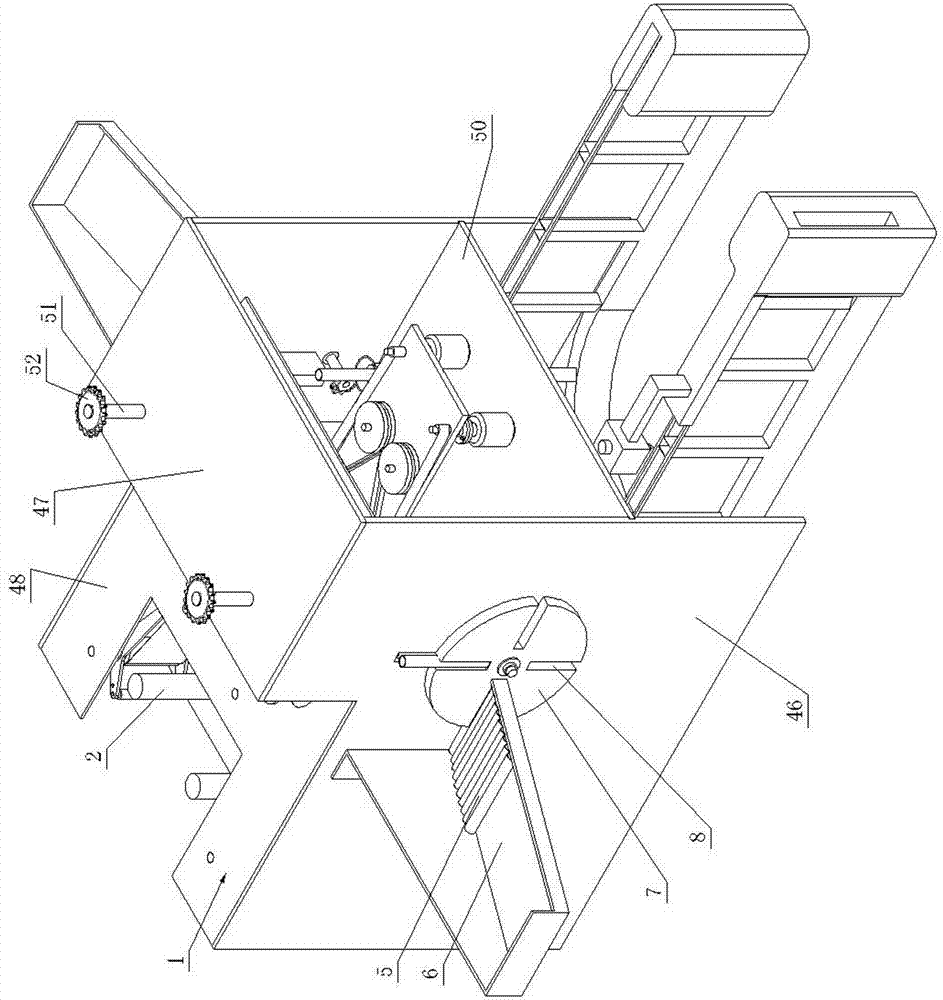

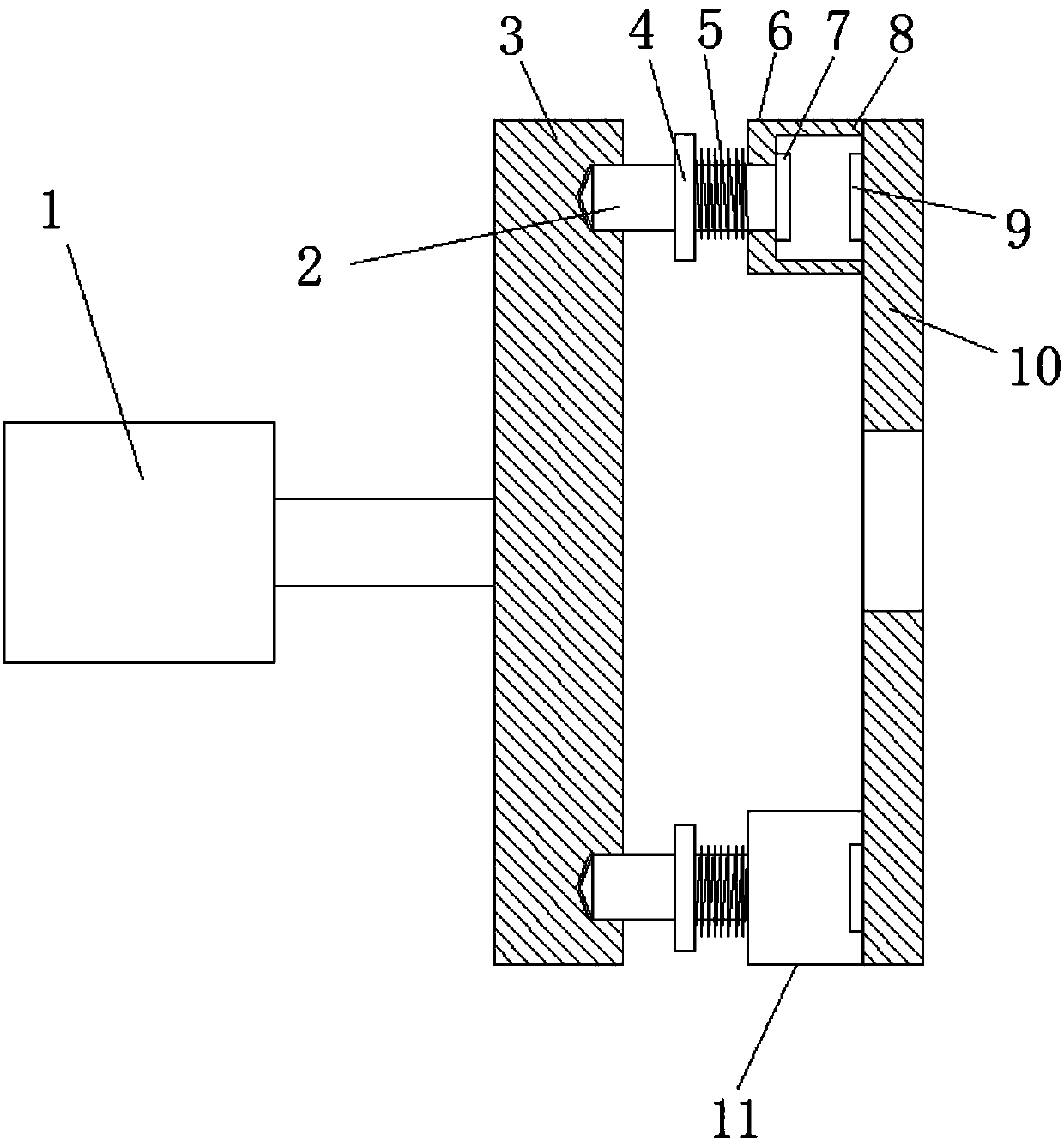

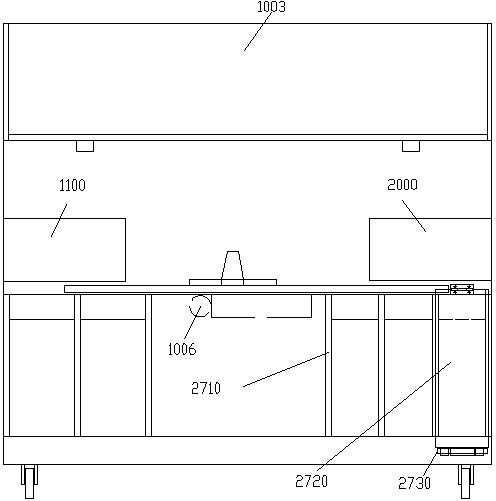

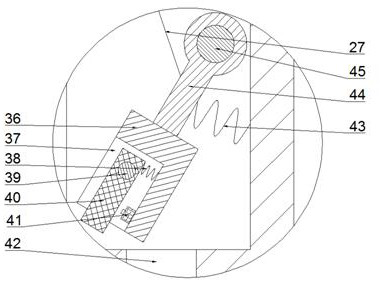

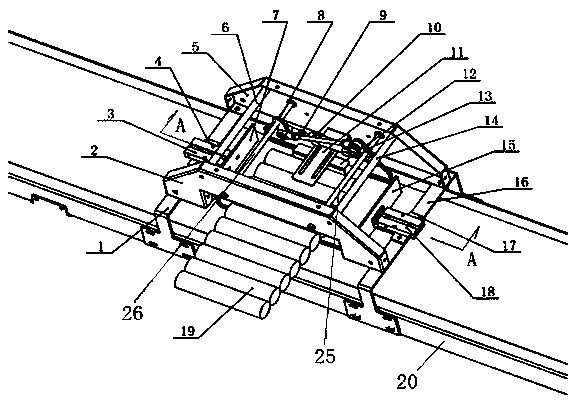

A precise blanking mechanism

ActiveCN106938306BBlanking is accurateSimple structureMetal-working feeding devicesPositioning devicesEngineeringFunnel shape

The invention discloses a precise blanking mechanism and relates to the field of blanking equipment. The precise blanking mechanism comprises a material distributing pipe and a base plate, wherein a hole site corresponding to the material distributing pipe is formed in the base plate, the width dimension of the hole site is less than that of an inner bore of the material distributing pipe; an elevator mechanism which drives the base plate to do up-and-down motion is arranged below the base plate; a plurality of turning sheets which can turn over a certain angle and circle around an axle center of the material distributing pipe are arranged at the lower end of the material distributing pipe; the turning sheets are provided with first positions which are contacted with the base plate and close an outlet of the material distributing pipe and second positions which are opened to form a funnel shape to allow a to-be-processed part in the material distributing pipe to precisely enter the hole site after being separated from the base plate. The precise blanking mechanism disclosed by the invention has the advantages of high in work efficiency and blanking accuracy rate and simple in structure.

Owner:揭阳市锦欣电器有限公司

Aluminum foil rewinder

The invention discloses an aluminum foil rewinding machine. The aluminum foil rewinding machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel (4), a feed channel (6) and a feed rotary disc. The feed channel (6) is communicated with a long notch of the feed rotary disc. The vertical long notch of the feed rotary disc is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel (4) are vertically arranged. The discharge station (26) of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil rewinding machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, the packaging effect of sub rolls is good, and convenience, high efficiency and energy conservation are achieved in discharging and unloading processes.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

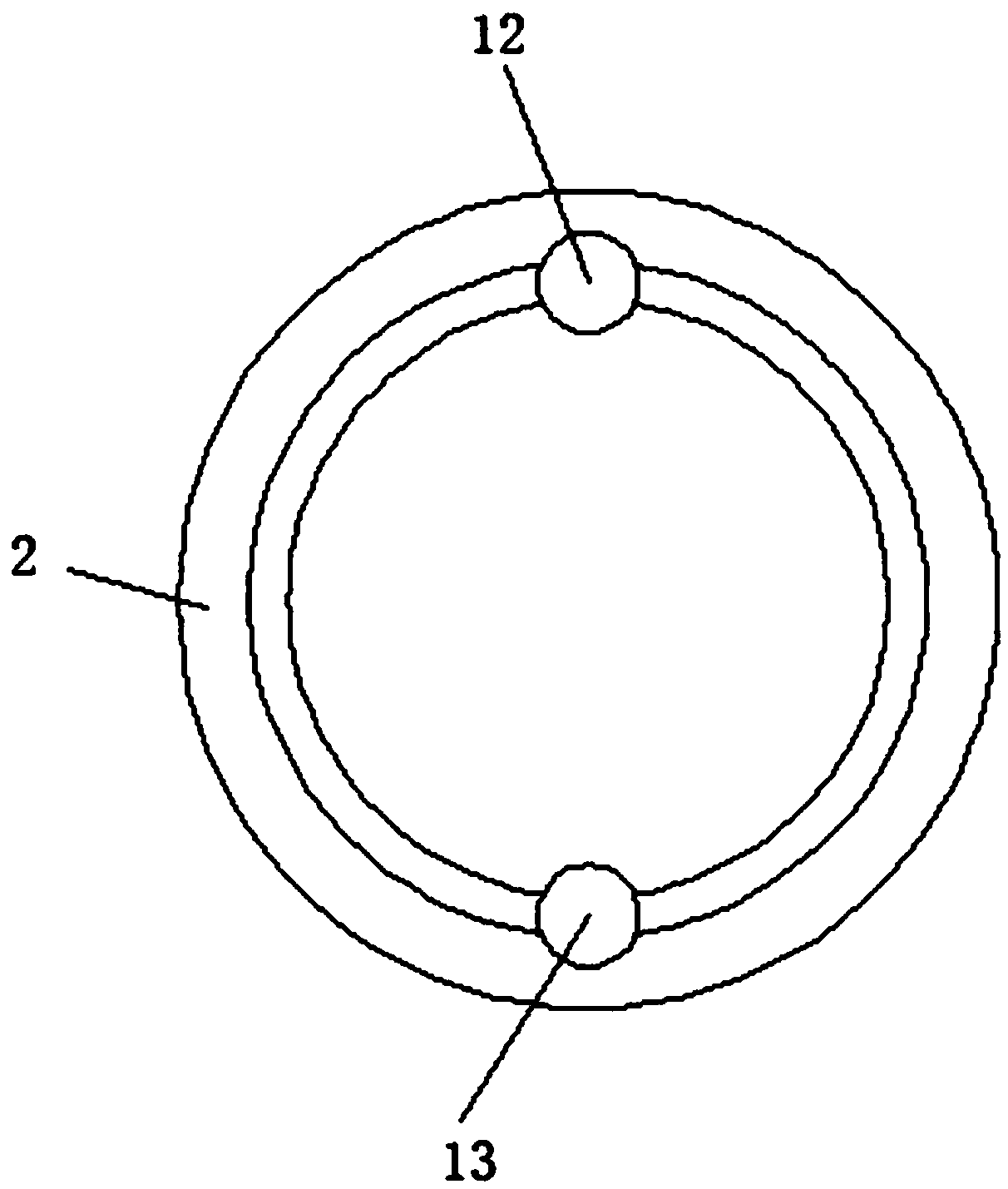

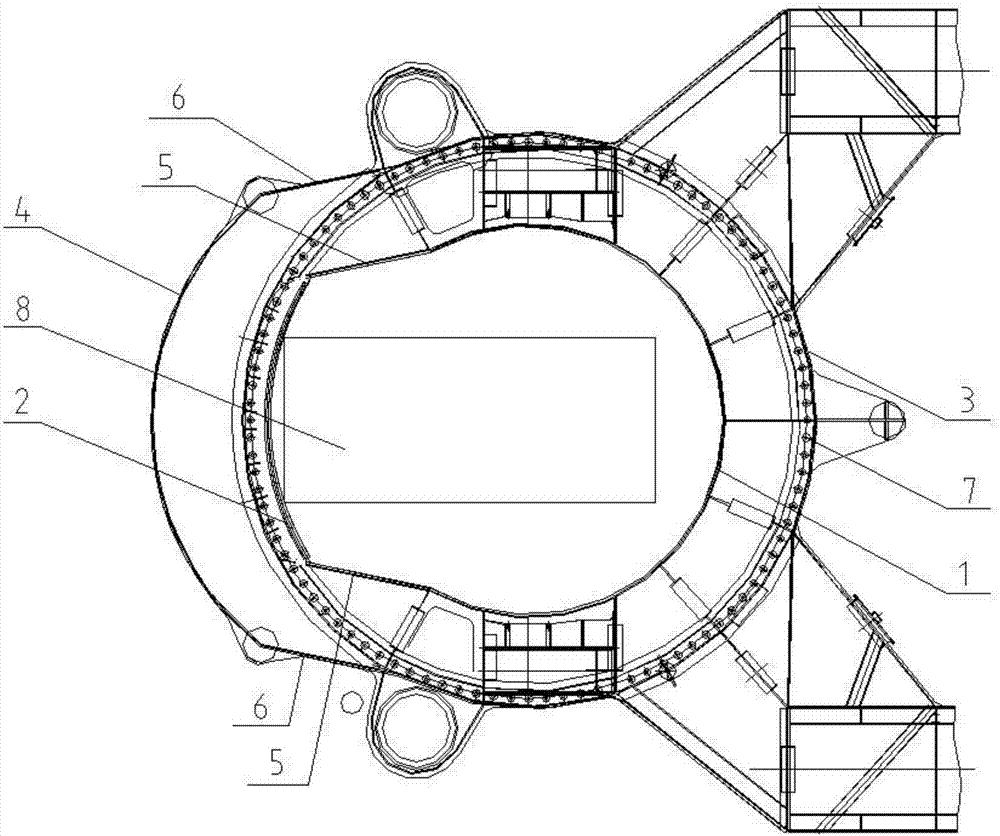

Stacker and reclaimer and its rotary platform

ActiveCN105621114BImprove delivery capacityAvoid cloggingConveyorsLoading/unloadingSlewing bearingStacker

The invention discloses a material piling and taking machine and a revolving platform thereof. The revolving platform of the material piling and taking machine comprises a ring-shaped body, wherein the inner side outline of the ring-shaped body forms a hollow mounting cavity of a center hopper, which is adaptive to the inner side outline; the bottom end of the ring-shaped body can be rotatably connected above a gate seat rack through a slewing bearing; and the inner side outline and an outer side outline of the ring-shaped body form a similar dual-ring structure. According to the material piling and taking machine and the revolving platform thereof provided by the invention, the mounting cavity of the center hopper of the revolving platform is large is size, so that cost is not increased much, and therefore, the revolving platform is suitable for being popularized and applied.

Owner:HUADIAN HEAVY IND CO LTD

An automatic sorting device for wire drawing dies

ActiveCN104525509BImprove sorting efficiencyReduce sorting error rateSortingControl systemEngineering

The invention discloses an automatic sorting device of a wire drawing die. The automatic sorting device comprises a machine frame, a conveying belt and at least one sorting unit. Each sorting unit comprises a supplied-material detection sensor, a pushing device, a discharging guide tank, a rotating separating device and a sorting disc, and the conveying belt, the supplied-material detection sensors, the pushing devices and discharging guide tanks are installed on the machine frame. Each rotating separating device comprises an installation base, a support, a hopper, a separating tank and a rotating separating power device, wherein the support is installed on the installation base in a rotary mode and driven by the rotating separating power device, the hopper and the separating tank are installed above and below the support respectively, the separating tank is communicated with the hopper, and the hopper is located below the corresponding discharging guide tank. Each sorting disc is located below the corresponding separating tank and comprises a base and a plurality of sorting boxes, wherein the sorting boxes are installed on the base and annularly distributed, and the rotating centers of the separating tanks are coincident with the annular centers of the sorting boxes. The supplied-material detection sensors, the pushing devices and the rotating separating devices are connected with a control system. By means of the automatic sorting device, the sorting efficiency is improved.

Owner:严格防务科技集团有限公司

Intelligent Turntable Metal Casting Nozzle Separation Integrated Machine and Method

The invention relates to an intelligentized rotary table metal casting sprue separating integrated machine and a method thereof. The intelligentized rotary table metal casting sprue separating integrated machine comprises a machine cabinet. An annular rotary table driven by an electric index plate is arranged in the middle of the machine cabinet. Positioning poles used for placing metal castings are arranged on the annular rotary table at intervals. A metal casting sprue separating device used for achieving sprue waste separation after the metal castings are rotated to the position is arranged on one side of the annular rotary table. A metal casting separating device used for achieving metal casting product separation after the metal castings are rotated to the position is arranged on the other side of the annular rotary plate. An ejection mechanism used for ejecting metal casting wastes after the metal casting wastes are rotated to the position along with the annular rotary plate is further arranged on the lower side of the annular rotary table and on the front portion of the machine cabinet. The intelligentized rotary table metal casting sprue separating integrated machine is compact in structure; metal casting sprue separation and metal casting separation are convenient; the automation degree is high, and the operation method is simple and convenient.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

A multi-stage recovery device for steelmaking slag

ActiveCN110280336BImprove finenessHigh recovery rateMagnetic separationGrain treatmentsSteelmakingMaterials science

Owner:日照泰东环保科技有限公司

Tram silk chain manner material dropping mechanism of welding machine of mesh

ActiveCN101244501BStable blankingHigh speedWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftDrive motor

The invention discloses a chain blanking device of tram for a welding machine of mesh, wherein, a round magnetic drum is arranged below a square magnetic drum; a slide carriage is arranged between the square magnetic drum and one side of the round magnetic drum; the first drive sprockets of a fixed chain transport device and a shift chain transport device are fixed on the same drive shaft; one end of the drive shaft is connected with the driving motor of a carrier chain and the other end is hold by a frame; the first driven sprockets of two fixed chain transport devices are arranged on the drive shaft; a pusher dog disk and the second driven sprocket are arranged on the pusher dog shaft; an inner hole of the pusher dog shaft is intermittently sleeve-arranged on the drive shaft; the seconddrive sprocket connected to the second driven sprocket is arranged on the pusher dog shaft. The chain blanking device of tram has the advantages that the tram blanking can be steady, orderly and accurate with the transport hook of the transport device; the shift chain transport device can shift synchronously in lateral direction, so as to adapt to the tram with different lengths; the blanking process has good balance performance, and the productivity of the welding mesh is improved.

Owner:TJK MACHINERY TIANJIN

Counting, positioning and feeding device

PendingCN111332552AAchieve positioningAdjust orientationPackaging automatic controlRod-shaped articlesControl theoryMechanical engineering

The invention discloses a counting, positioning and feeding device. The counting, positioning and feeding device comprises a front side plate and a rear side plate which are arranged in parallel, a left discharging support shaft and a right discharging support shaft are rotationally supported on the left side and the right side of the upper portion between the front side plate and the rear side plate correspondingly, and the left discharging support shaft and the right discharging support shaft are connected with the L-shaped left discharging support, one end of a left swing arm, one end of the right discharging support and one end of a right swing arm correspondingly; a left aligning plate and a right aligning plate which can move relatively are mounted on the left side of the left discharging support and the right side of the right discharging support correspondingly; the left discharging support shaft and the right discharging support shaft are in transmission connection with a driving device used for driving the left discharging support shaft and the right discharging support shaft to synchronously and reversely rotate; and a surface blocking plate is arranged on the front sideof the rear side plate. The counting, positioning and feeding device has the advantages that materials can be positioned, so that the purposes of direction adjustment and accurate blanking are achieved; an air cylinder and a connecting rod are matched and linked, so that blanking and surface aligning are carried out without intervals, the blanking and surface aligning process is completed, and high-efficiency operation is realized; and the structure is simple, space utilization rate is high, and cost is low.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com