Automatic sorting device of wire drawing die

An automatic sorting and wire drawing die technology, applied in sorting and other directions, can solve the problems of reducing sorting error rate, low sorting efficiency, and labor-intensive, etc., to reduce sorting error rate, improve sorting efficiency, reduce The effect of human involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific examples.

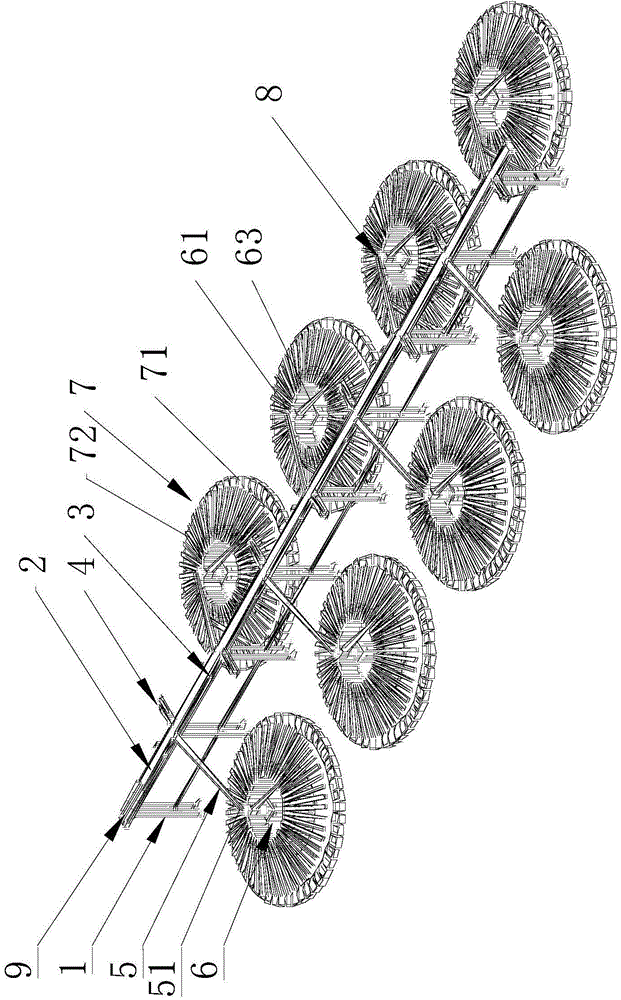

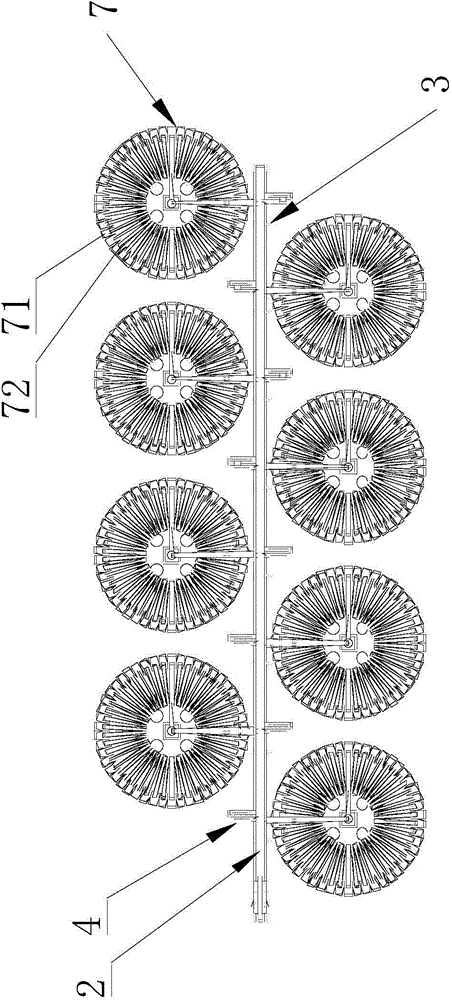

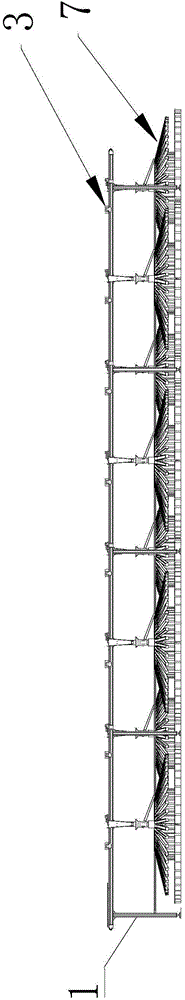

[0033] Such as Figure 1-6As shown, a wire drawing die automatic sorting device includes a frame 1, a conveyor belt 2 and at least one group of sorting units, and each group of sorting units sequentially includes an incoming material detection sensor 3, a push material Device 4, unloading guide trough 5, rotating material distributing device 6, sorting tray 7, conveyor belt 2 is driven by a conveying drive device, conveyor belt 2 and incoming material detection sensor 3, material pushing device 4, and unloading guide trough 5 are all Installed on the frame 1, the pushing device 4 and the blanking guide groove 5 are respectively installed on the opposite sides of the frame 1, and the pushing device 4 and the blanking guide groove 5 cooperate to complete the pushing and blanking of the wire drawing die; Distributing device 6 comprises mounting base 65, support 62, hopper 61, mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com