Tram silk chain manner material dropping mechanism of welding machine of mesh

The technology of blanking mechanism and mesh welding machine is applied in the field of mesh welding machine, which can solve the problems of difficult to control weft, affecting welding speed, and disordered accumulation, so as to eliminate jamming phenomenon, improve productivity, and have good balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

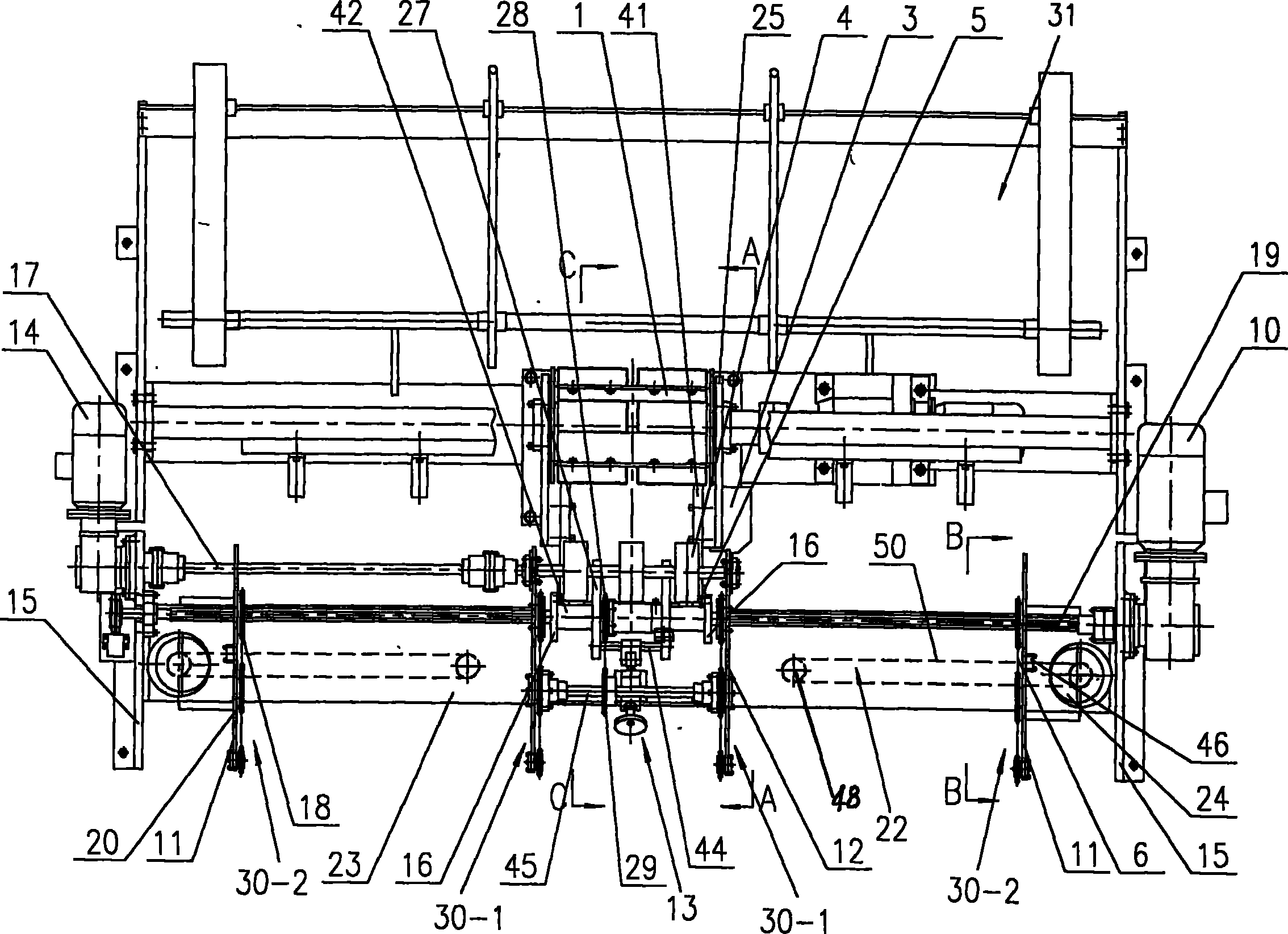

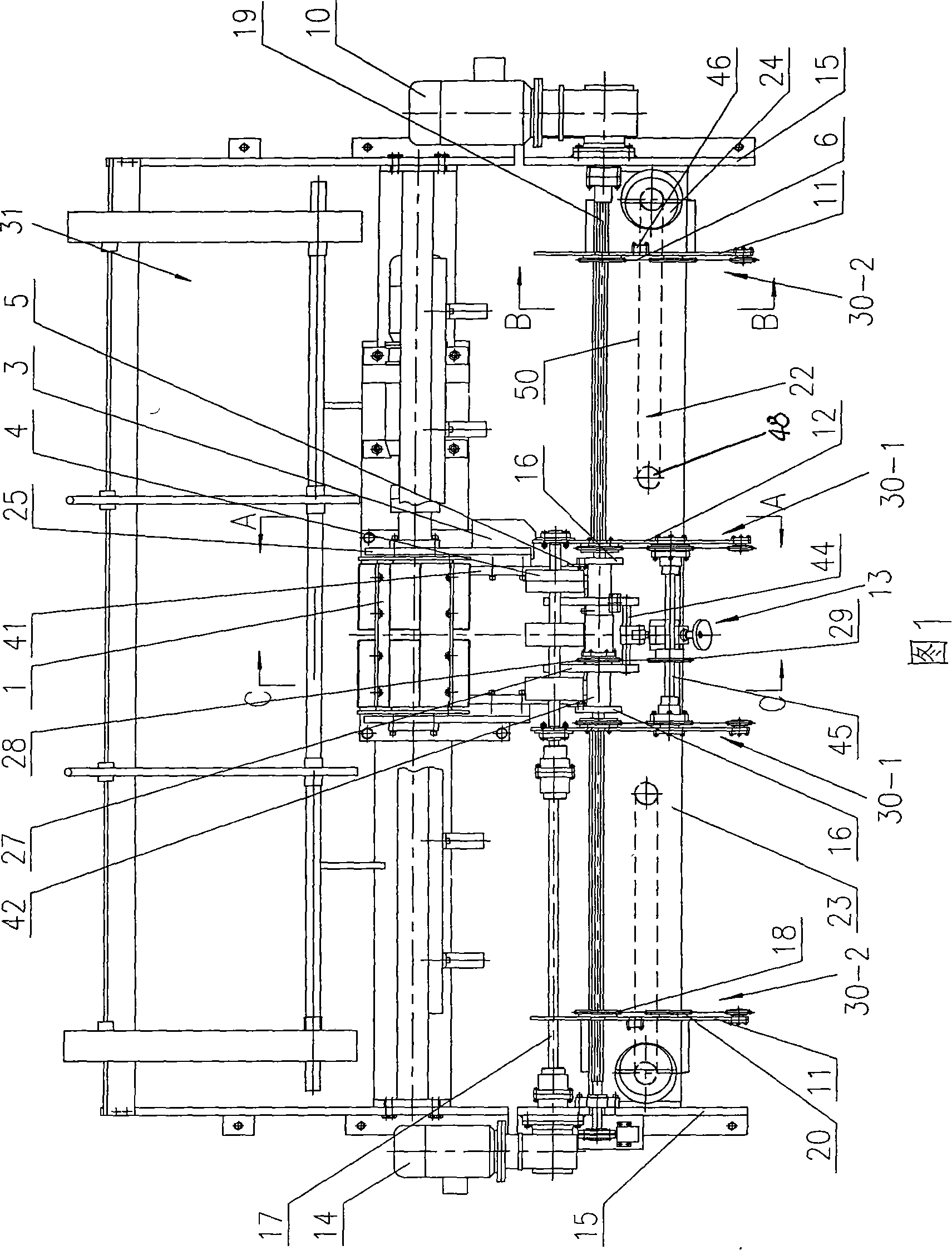

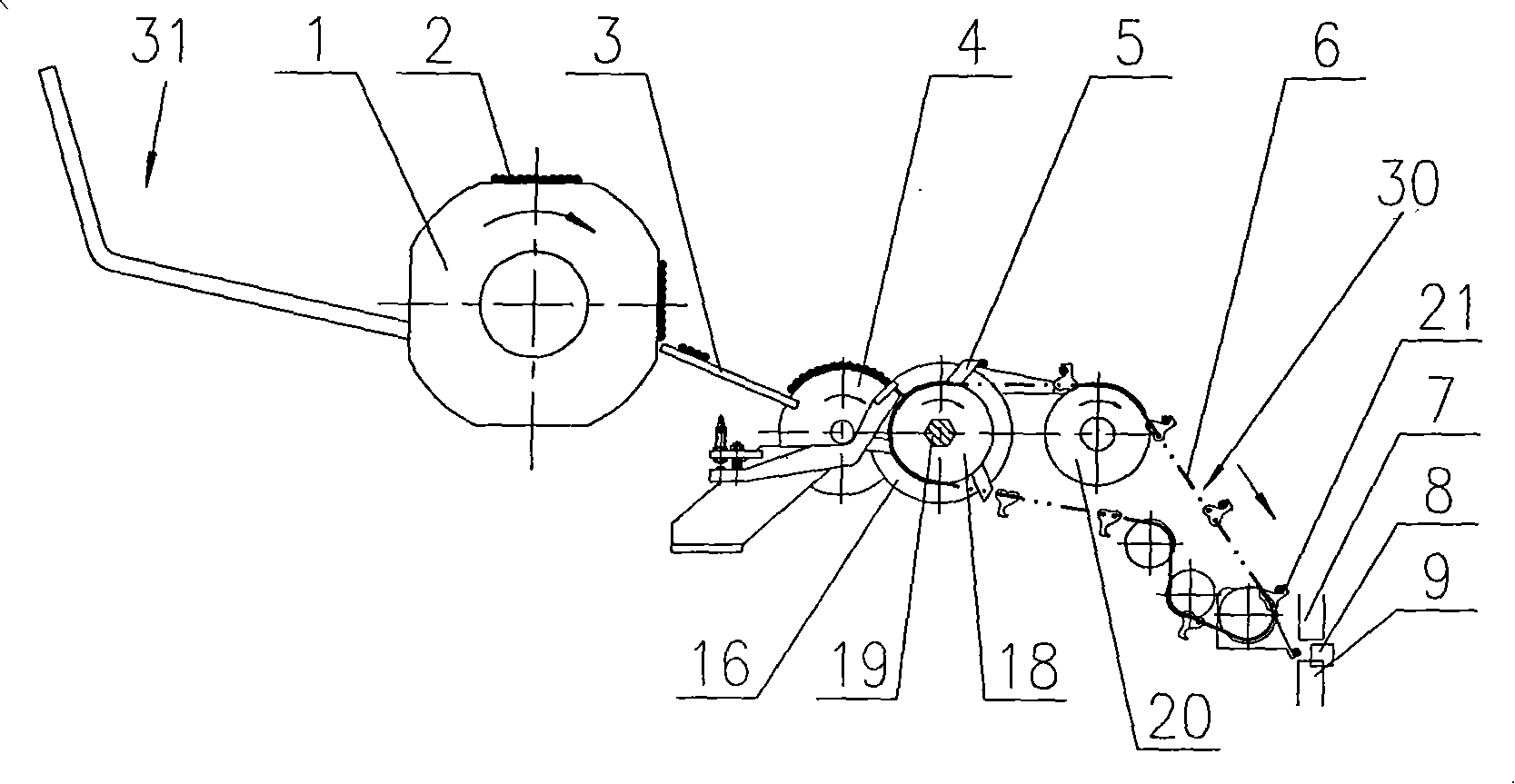

[0036] Fig. 1 is a front view of the present invention; Fig. 2 is a schematic diagram of weft yarn conveying in Fig. 1 .

[0037] As shown in Figure 1, the present invention provides a weft chain type blanking mechanism of a wire mesh welding machine. The weft wire chain type blanking mechanism of the wire mesh welding machine includes: a storage bin 31, a square magnetic drum 1, and a : more than 2 circular magnetic drums 4, a claw plate 16 equipped with claws 5, two fixed chain conveyors 30-1 and a mobile chain conveyor 30-2 with synchronous transmission motion and the same structure and the same height.

[0038] The circular magnetic drum 4 in Fig. 1 of the present invention is arranged directly below the square magnetic drum 1, and the number is three. There is a set distance between the circular magnetic drums 4 and they are fixedly connected on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com