Control method of sludge treatment system

A technology of treatment system and control method, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as difficult collection, damage, large size, etc., and achieve volume saving Space, avoid accumulation and solidification, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

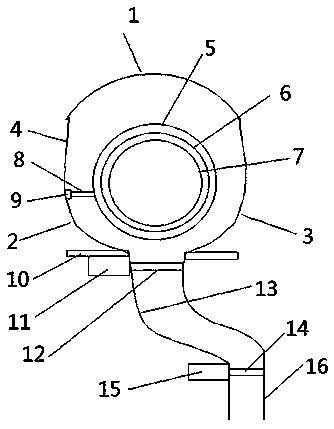

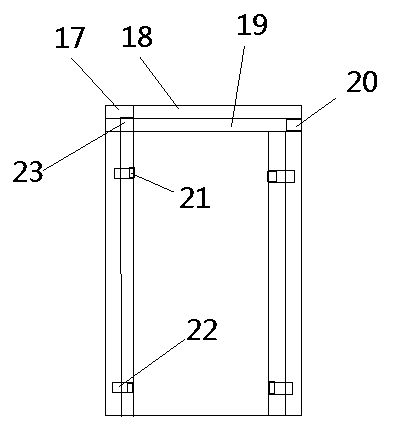

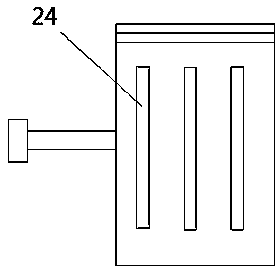

[0040] As shown in the figure: a control method for a mud treatment system, the mud treatment system includes a liquid collection tank, a delivery pipeline, a centrifuge, a centrifuge motor, a control valve, a mixing cylinder, a flocculant pump, a mud pump, a mud tank, Mixing drum motor, conveyor belt, mud inlet pipe, discharge valve, bracket; the centrifuge includes the first arc, second arc, third arc, connecting section, outer wall, middle wall, inner wall, scraper rod, scraper, multi-function Groove, outer maintenance plate, inner maintenance plate, liquid discharge purge port, top wall of liquid discharge pipe, liquid discharge pipe, auxiliary purge port, mud discharge grid; the control method includes mud entry control method, centrifugal control method, Unloading and conveying control method;

[0041] As shown in the figure: the mud inlet control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com