Patents

Literature

341results about How to "Differences and Significant Improvements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

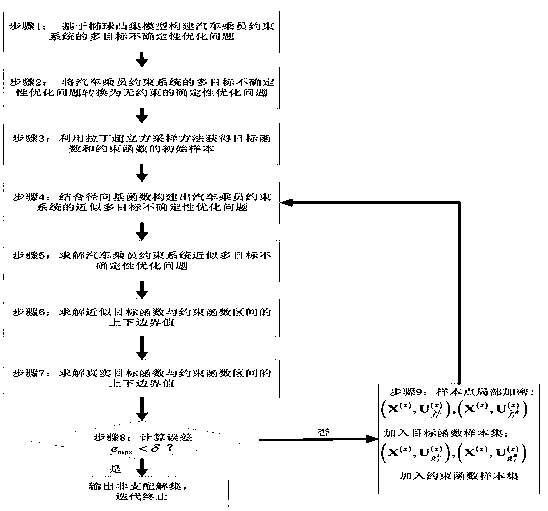

Multi-objective uncertainty optimization method for vehicle occupant restraint system

ActiveCN108647429AAvoid conservative designOptimization optimization selectionGeometric CADDesign optimisation/simulationOptimization problemAutomotive safety

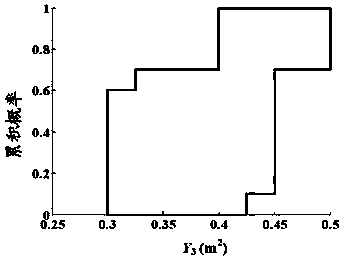

The invention discloses a multi-objective uncertainty optimization method for a vehicle occupant restraint system. The method describes the correlation of uncertainty variables of the vehicle occupantrestraint system by using an ellipsoidal convex set model, and uses the interval order relationship and the interval possibility degree to transform the multi-objective uncertainty optimization problem into a deterministic optimization problem. In order to improve the computational efficiency, a local encryption approximation model method is introduced into the iterative solution process, and anapproximation model is reconstructed multiple times to ensure the accuracy of the approximation model and the computational result; and the multi-objective uncertainty optimization method is used forsolving the non-dominated solution set that satisfies the protection performance of the vehicle occupant restraint system, thereby ensuring the safety of the vehicle occupant. The multi-objective uncertainty optimization method for the vehicle occupant restraint system in the invention can not only effectively improve the protection performance of the vehicle occupant restraint system, but also can substantially improve computational efficiency and solution quality of optimization and has a wide range of engineering applications in the field of automotive safety.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

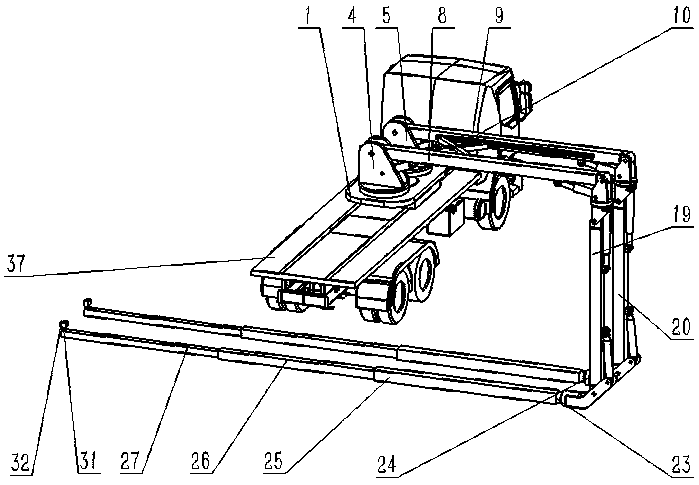

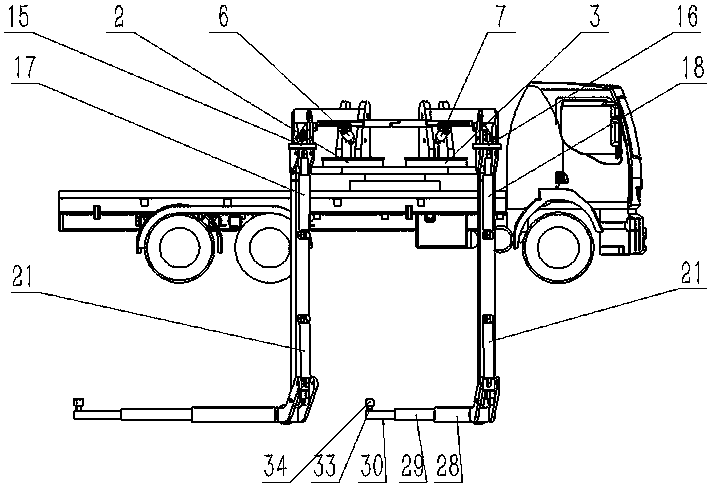

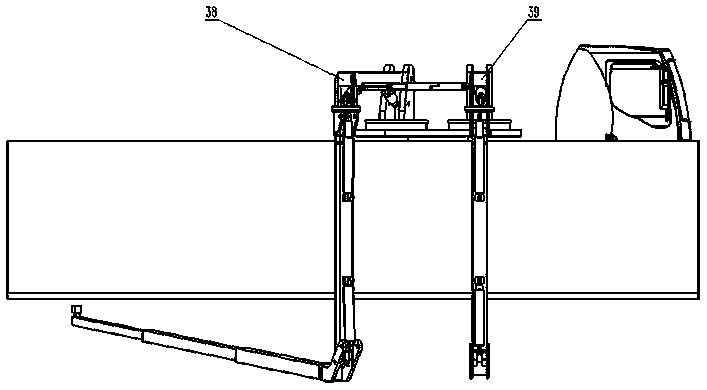

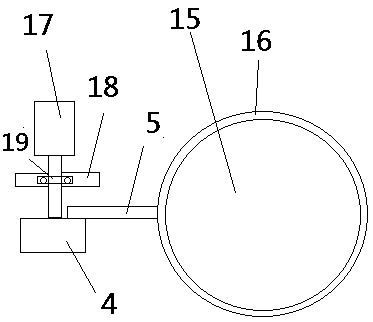

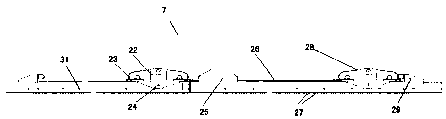

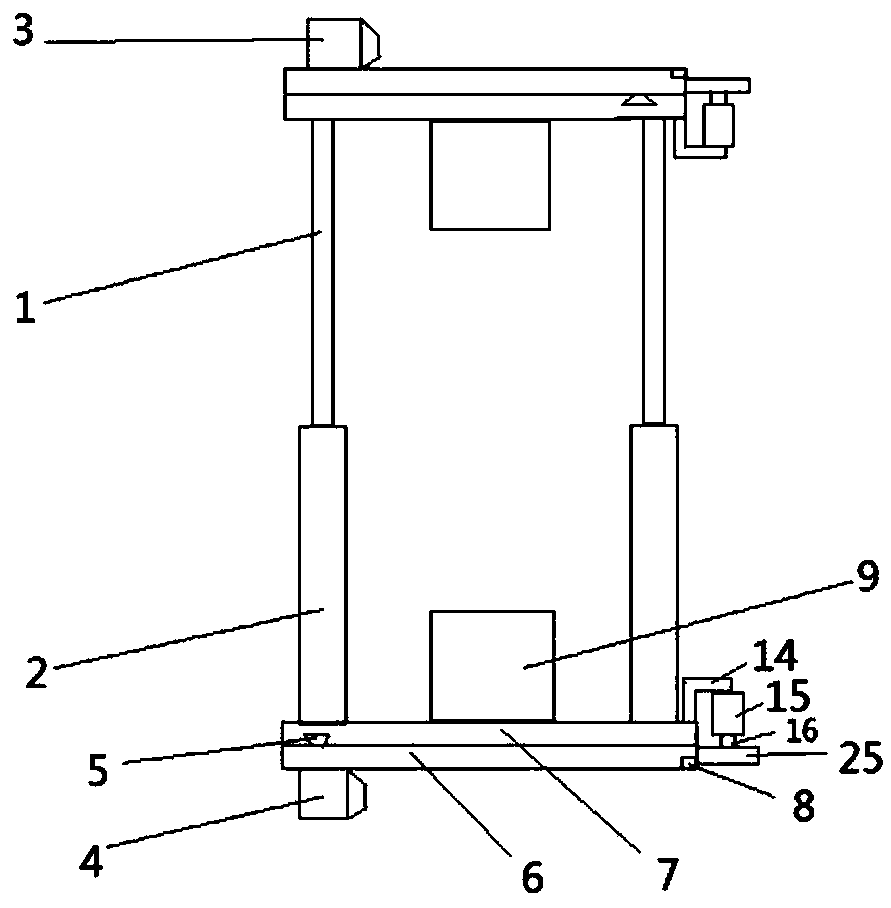

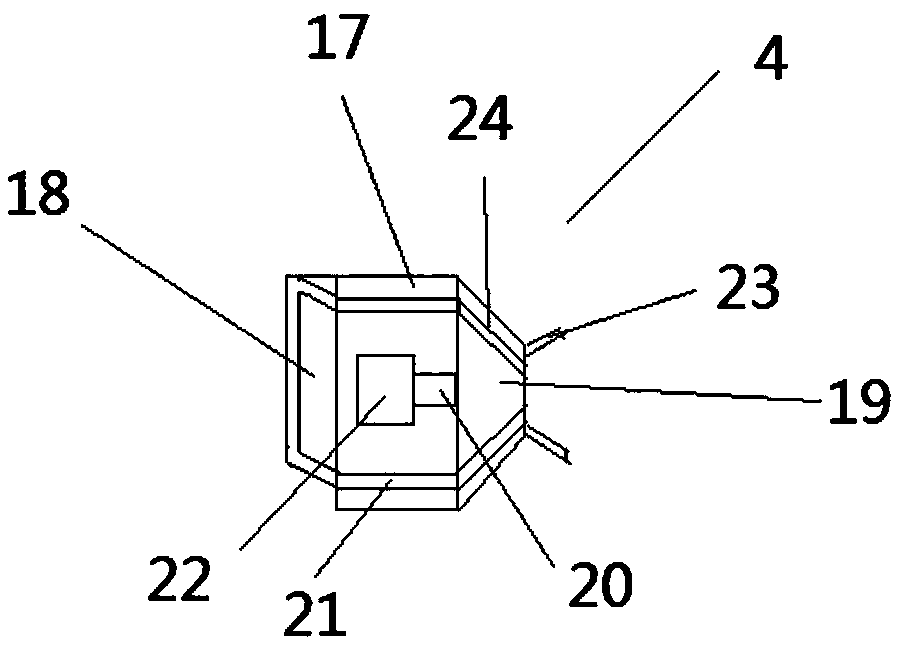

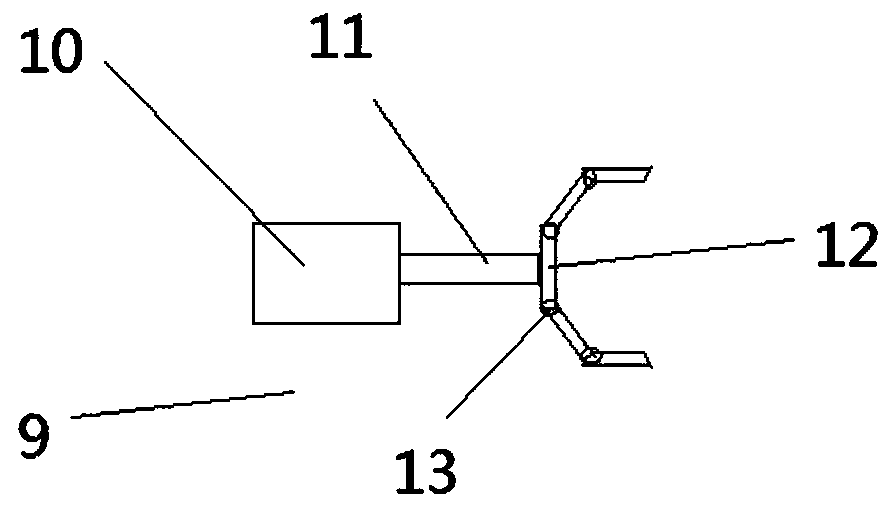

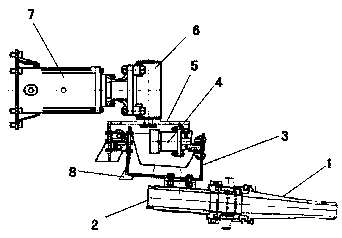

Control method of folding arm type dual-arm bridge detecting vehicle

ActiveCN109468949AImprove stabilityFlexible adjustmentBridge structural detailsRotary stageHydraulic cylinder

The invention discloses a control method of a folding arm type dual-arm bridge detecting vehicle. The control method includes the dual-folding-arm unfolding control method, the dual-folding-arm folding control method, the two-horizontal-arm included angle control method, and the telescopic arm control method. The dual-folding-arm unfolding control method and the dual-folding-arm folding control method include the step of driving a first rotating mechanism, a second rotating mechanism, a first hydraulic cylinder, a second hydraulic cylinder, a third hydraulic cylinder, a fourth hydraulic cylinder, a fifth hydraulic cylinder, a sixth hydraulic cylinder and telescopic arm hydraulic cylinders so as to fold and unfold the dual folding arms. The two-horizontal-arm included angle control method includes the steps of driving the folding or unfolding amount of a first telescopic arm and the second telescopic arm so as to control the angles of two main arms. The telescopic arm control method includes the steps of controlling the swing amplitude of the telescopic arms by driving a fourth rotating mechanism and a fifth rotating mechanism, controlling the movements of the telescopic arms by driving ball hinge mechanisms, controlling the rotation movements of detecting devices by driving rotating tables, and controlling the working radius of the telescopic arms by driving stroke hydraulic cylinders of the telescopic arms.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

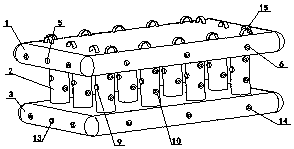

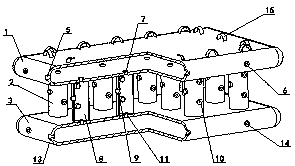

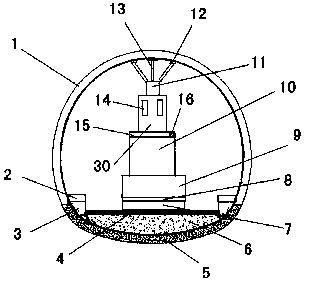

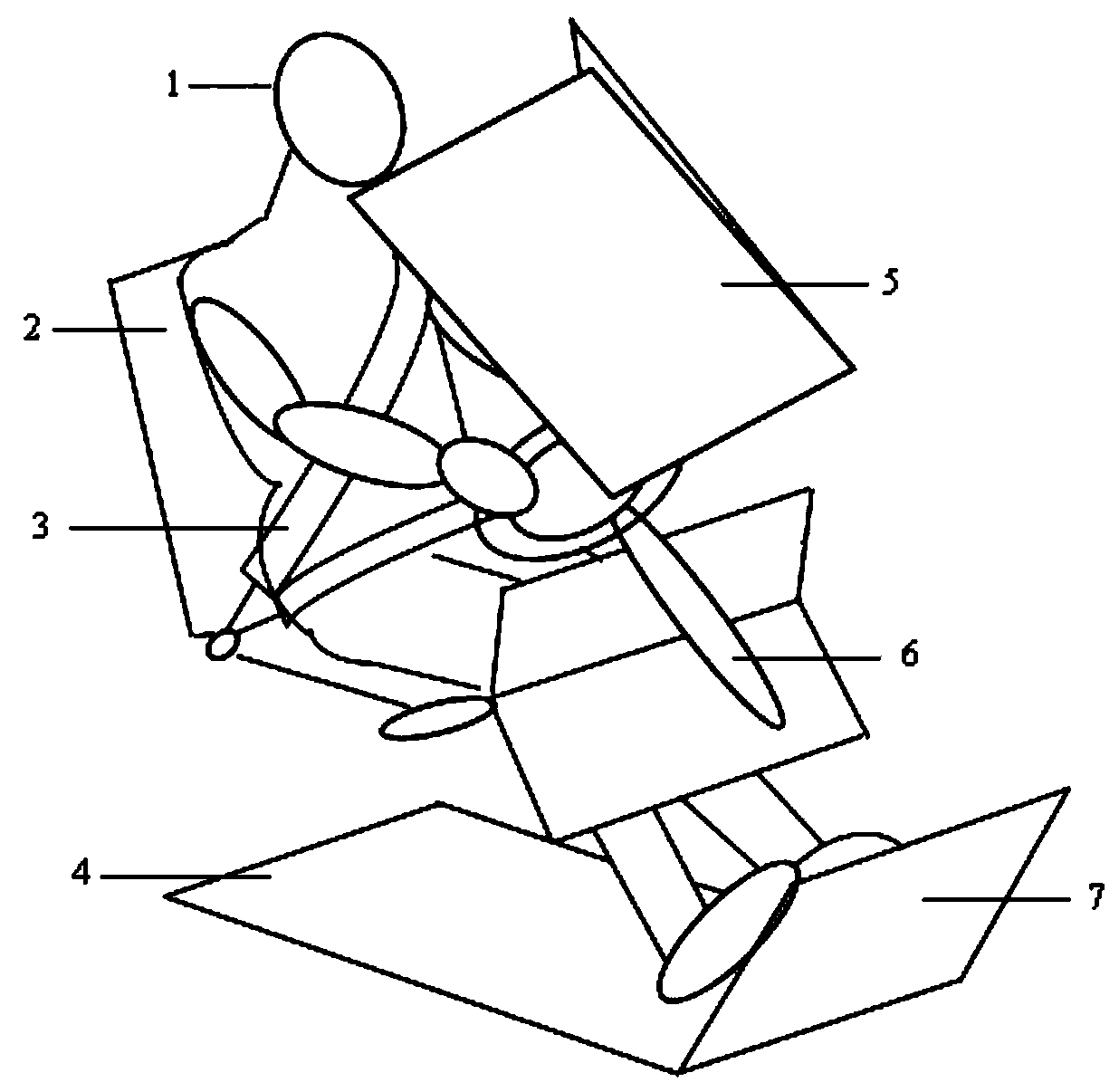

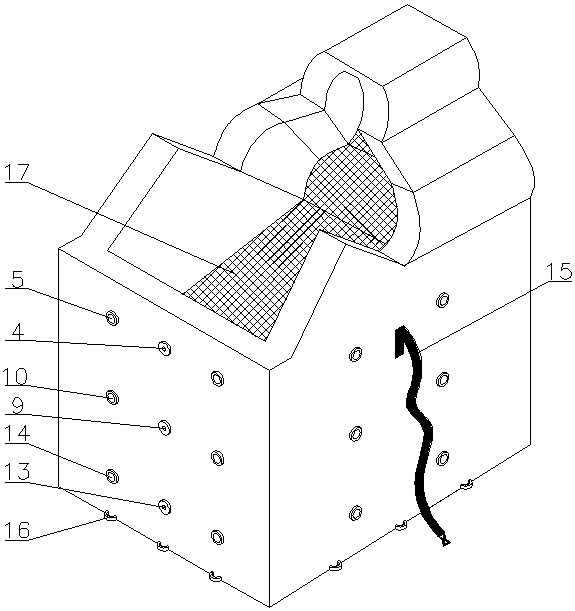

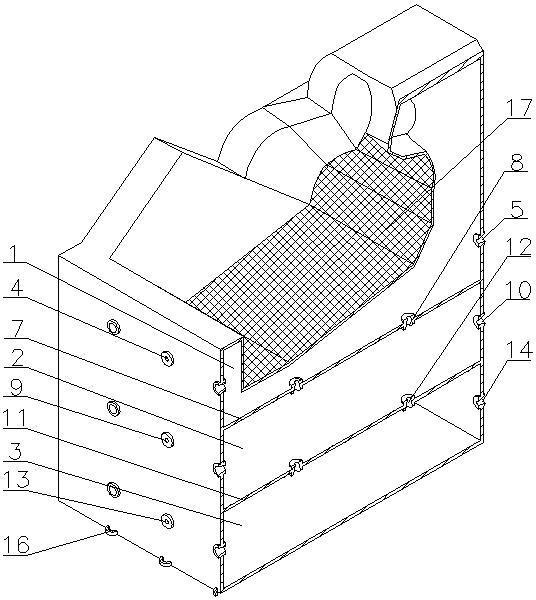

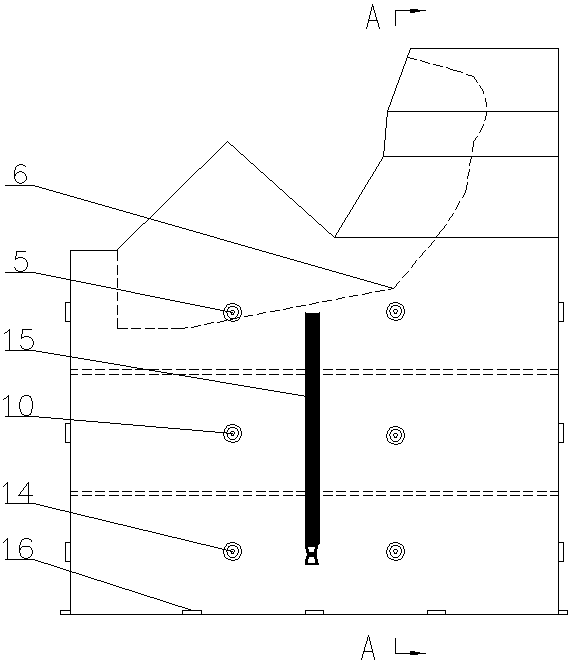

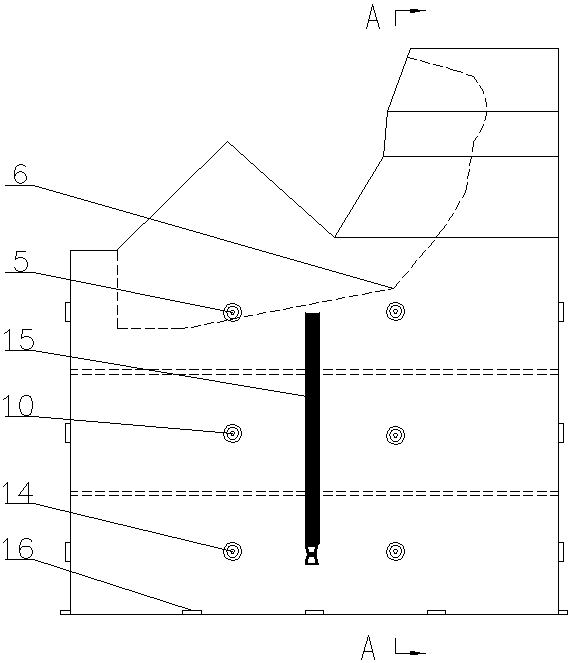

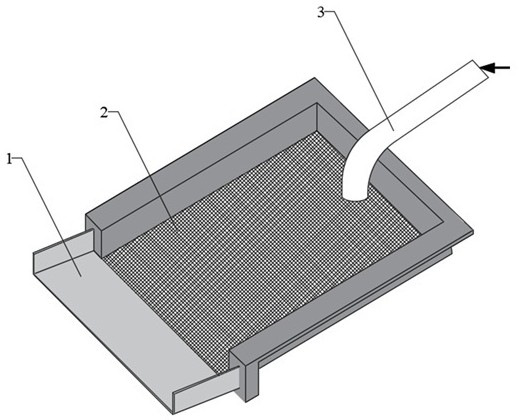

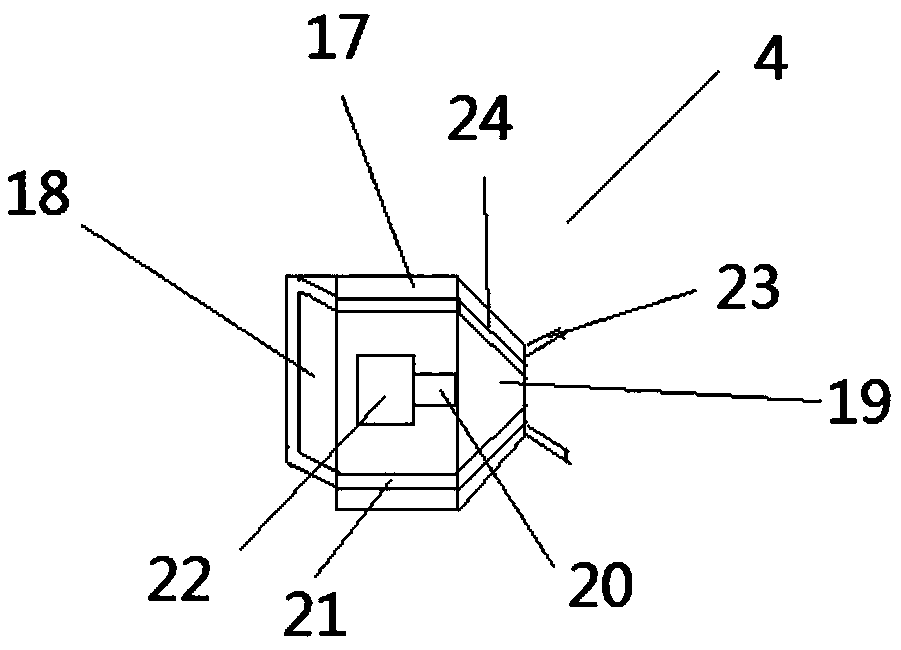

Operating method of equipment airborne multistage airbag cooperative shock absorber

ActiveCN108327907AImplement bufferingPrevent blastingAircraft componentsLaunching weaponsInternal pressureExhaust valve

The invention discloses an operating method of an equipment airborne multistage airbag cooperative shock absorber. The multistage airbag cooperative shock absorber comprises an upper airbag, an airbagtube column and a lower airbag. In an equipment airborne landing process, the upper airbag can discharge gases and relieve pressure outside by virtue of an upper airbag exhaust valve, gases can be discharged to the airbag tube column by virtue of a combined exhaust valve I, and the airbag tube column expands to realize first-stage shock absorption; the airbag tube column can discharge gases and relieve pressure outside by virtue of an airbag tube column exhaust valve, gases can be discharged to the lower airbag by virtue of a combined exhaust valve II, and the lower airbag expands to realizesecond-stage shock absorption; the lower airbag can discharge gases and relieve pressure outside by virtue of a lower airbag exhaust valve to realize third-stage shock absorption; after equipment airborne safe landing, the airbag device can be vented and is convenient to contain and store. According to the multistage shock absorption method of the multistage airbag cooperative shock absorber, airborne equipment can be prevented from directly contacting with the ground, multistage release of the pressure inside the airbag can also be realized, airbag blasting is avoided, and safe landing of theairborne equipment is ensured.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

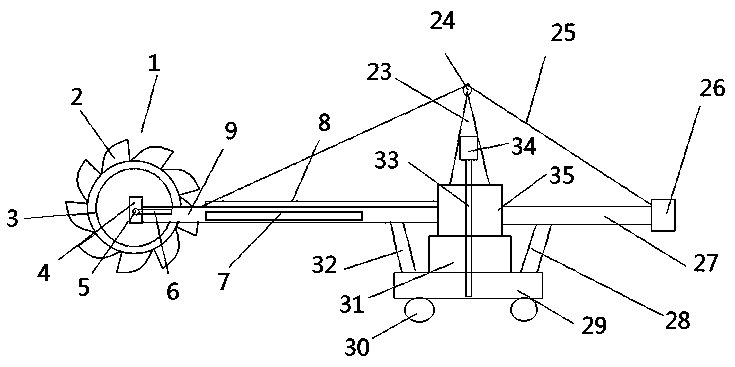

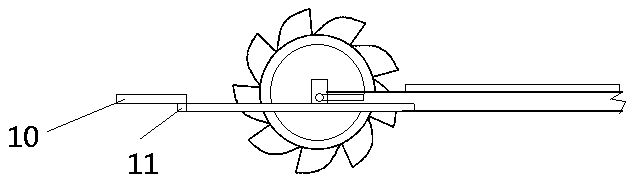

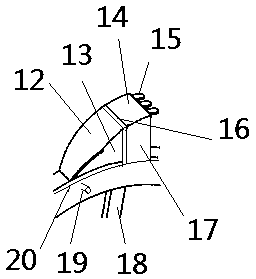

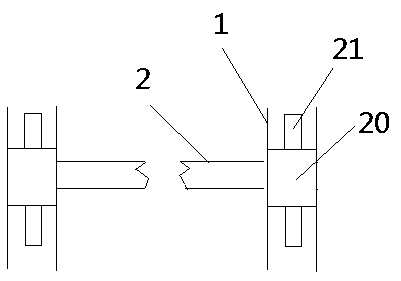

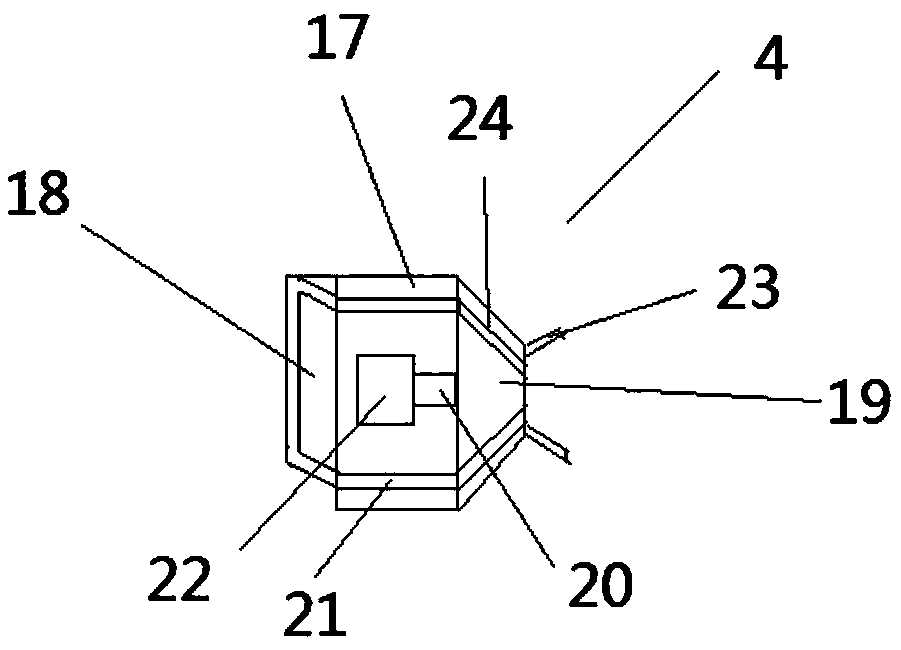

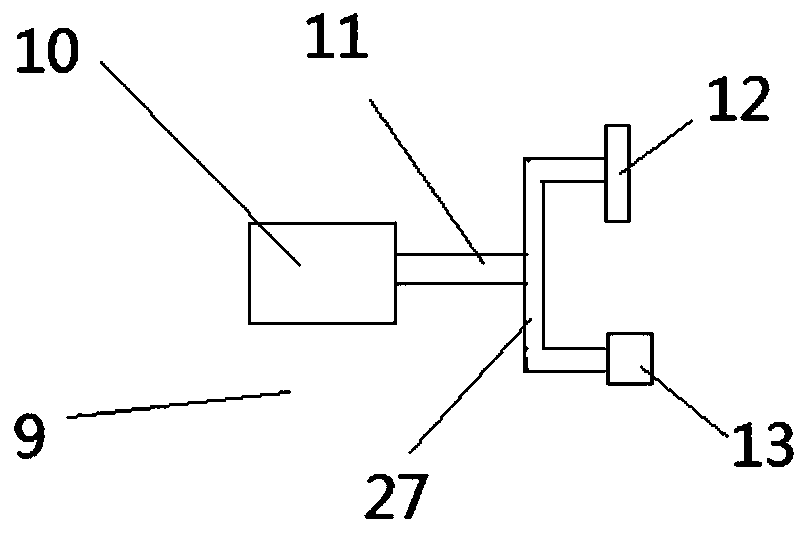

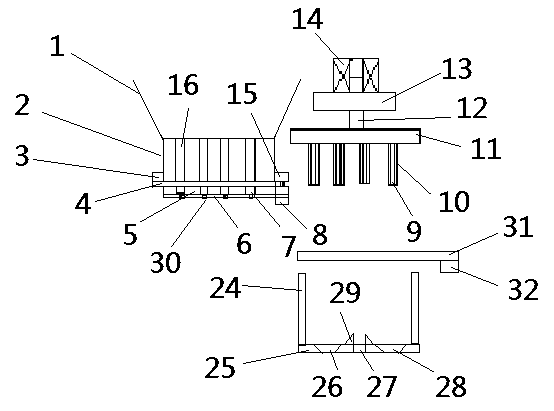

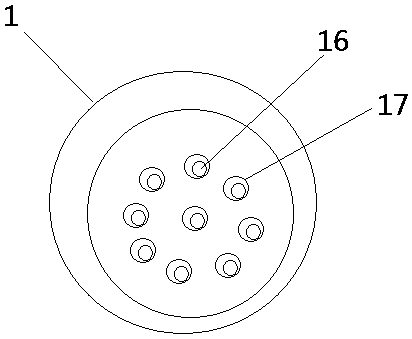

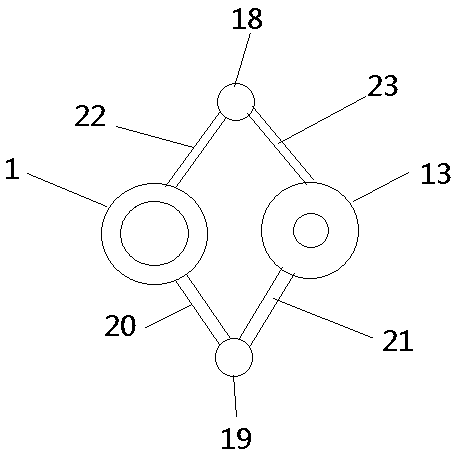

Bucket wheel stacker-reclaimer

The invention discloses a bucket wheel stacker-reclaimer. The bucket wheel stacker-reclaimer comprises a portal frame, a pulley, a steel wire rope, a counterweight, a counterweight arm, a counterweight driving cylinder, a base, a trundle, a circular base, a pitching mechanism, a ladder, a cockpit, a revolving mechanism, a bucket wheel, a motor frame, a slide piece, a chute, a storage leveling rod,a conveying belt, a bracket, a leveling plate and a leveling motor, wherein the bucket wheel comprises a wheel bucket, a wheel bucket frame, a spoke, a rotating handle and a rotating ring; the wheelbucket comprises a large wheel bucket, a small wheel bucket, wheel teeth and a bundle hoop; the bundle hoop comprises a main body layer and a sealing layer; the circular base is arranged on the base,and is provided with the revolving mechanism; the portal frame is arranged on the revolving mechanism; the cockpit is arranged beside the portal frame; the ladder is arranged on the bucket wheel stacker-reclaimer, and communicates to the cockpit; one end of the revolving mechanism is connected with the bracket, and the other end is connected with the counterweight arm; the counterweight is connected to the counterweight arm; the pulley is arranged at the top end of the portal frame; the steel wire rope is bypassed through the pulley, and the two ends are connected with the bracket and the counterweight arm; the pitching mechanism and the counterweight driving cylinder are symmetrically arranged on the edge of the base; the pitching mechanism is connected with the bracket; and the counterweight driving cylinder is connected with the counterweight arm.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

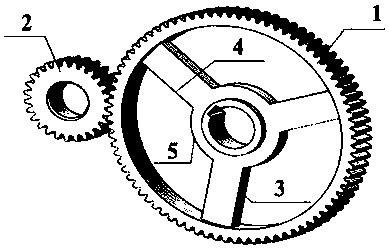

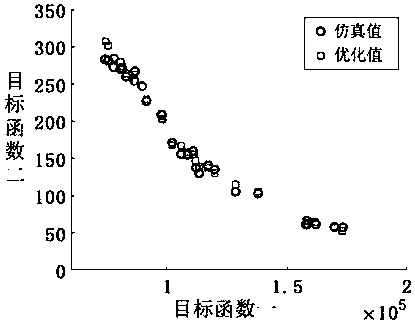

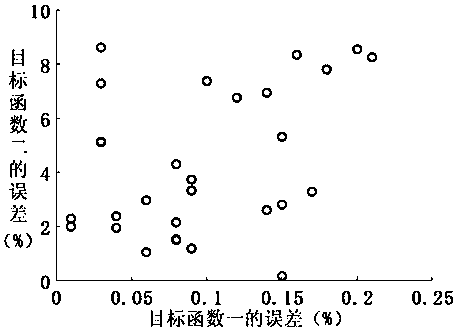

Gear transmission device multi-objective optimization design method based on self-adaptive agent model

InactiveCN110889202AImprove computing efficiencyOptimization optimization selectionGeometric CADDesign optimisation/simulationGear driveGear wheel

The invention discloses a gear transmission device multi-objective optimization design method based on a self-adaptive agent model. According to the method, sample points are sampled through a Latin hypercube experiment design method, meanwhile, optimal shape parameters corresponding to the sample points are solved through a radial basis function, and the solved optimal shape parameters are combined with the sample points to construct an agent model of the gear transmission device; in order to improve the calculation efficiency, a local encryption approximation model method is introduced intoan iterative solving process, meanwhile, the precision of the agent model and a calculation result is ensured by reconstructing the agent model for multiple times, and a non-dominated solution set meeting the structural characteristics of the gear transmission device is solved through a multi-objective optimization method; according to the method, the structural characteristics of the gear transmission device can be effectively improved, the optimized calculation efficiency and solving quality can be essentially improved, and the method has wide engineering application value in the field of gear transmission device design.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

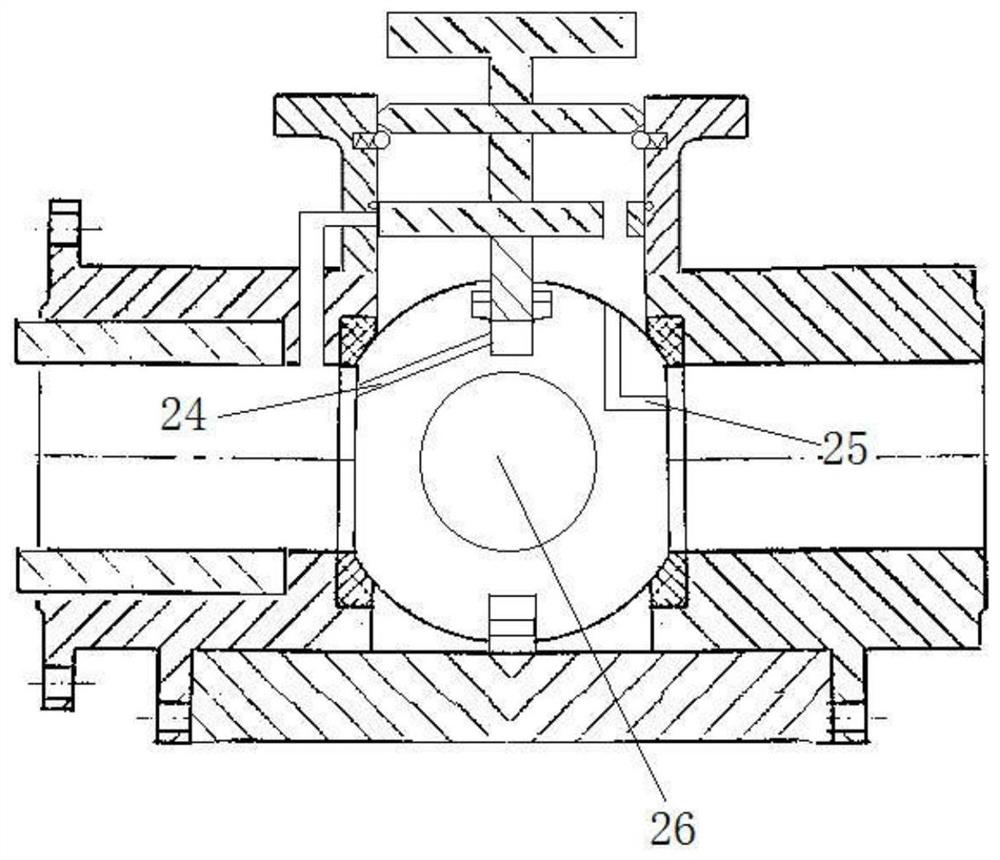

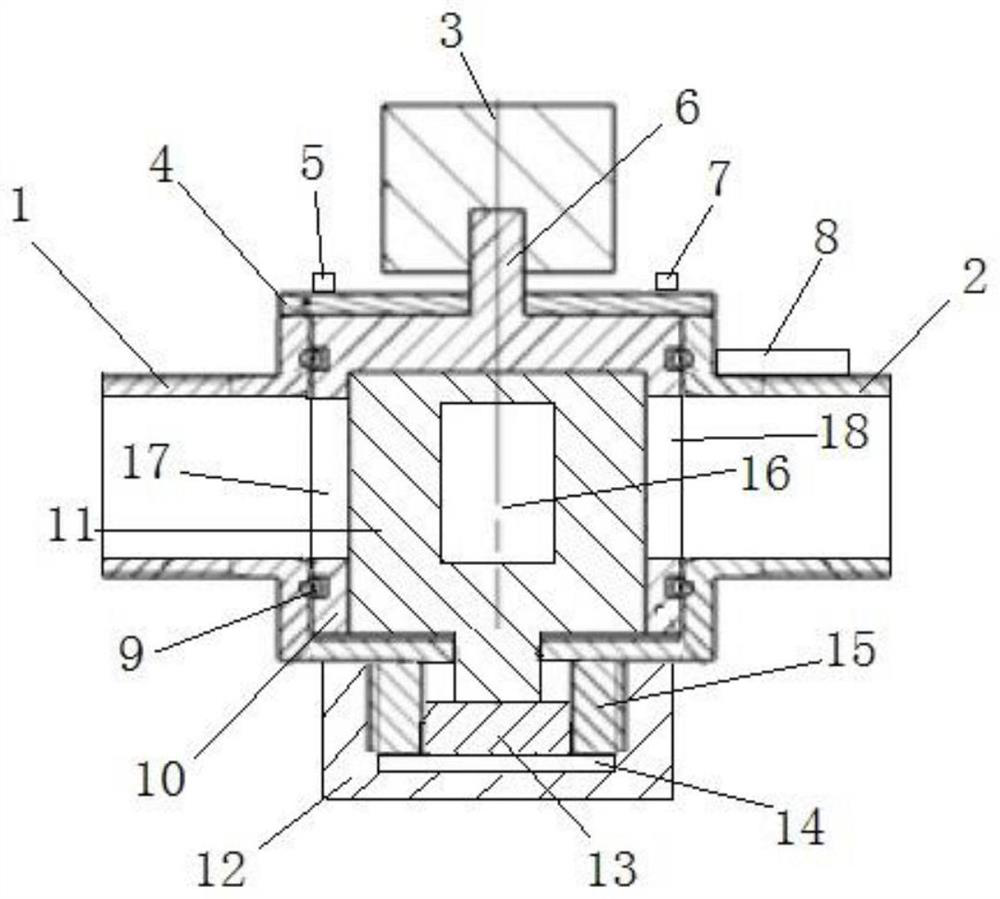

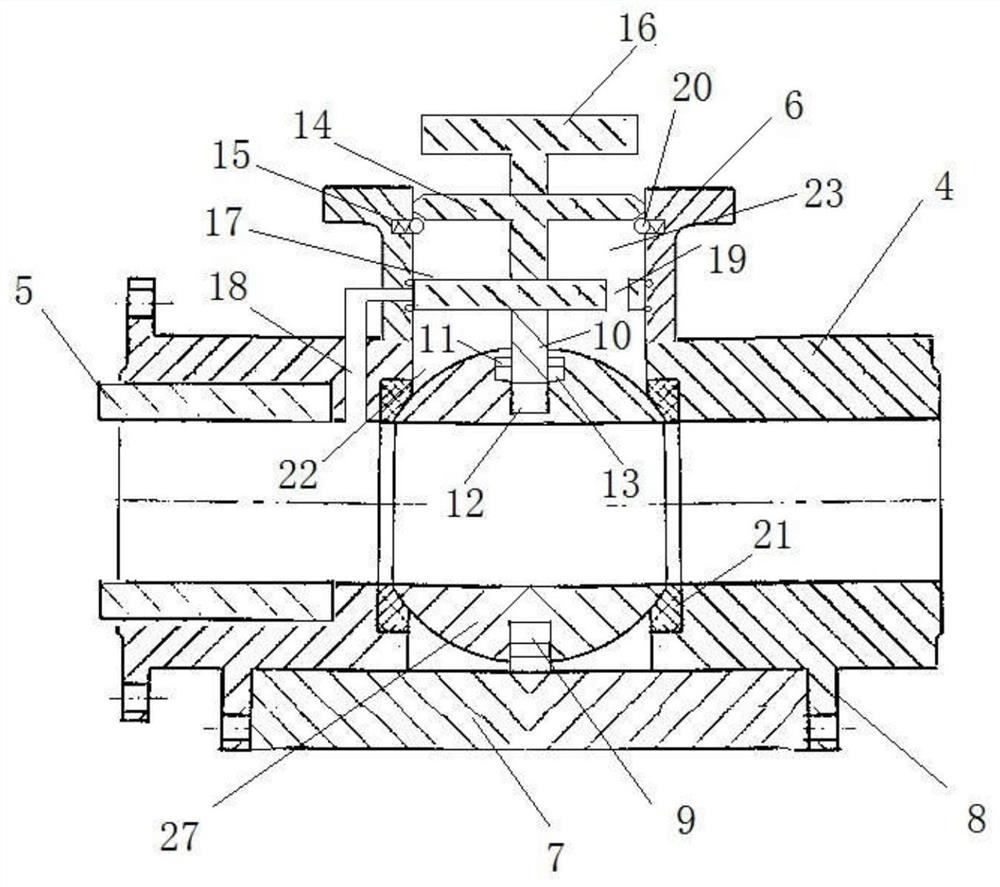

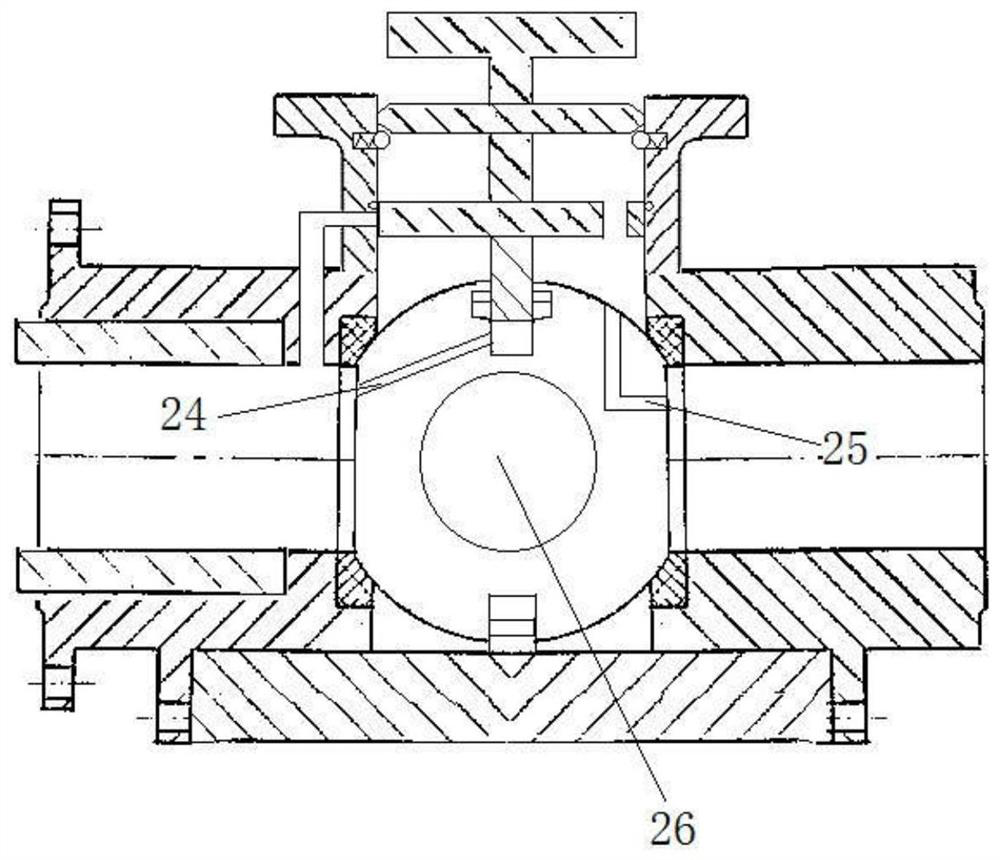

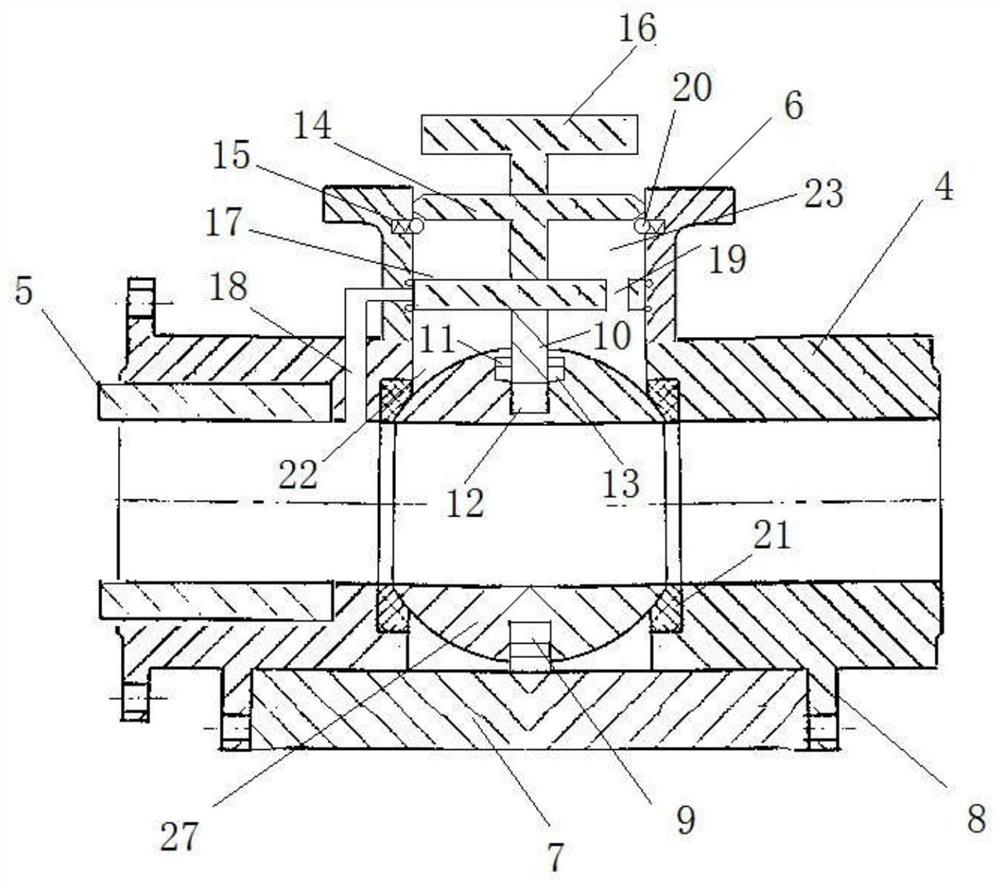

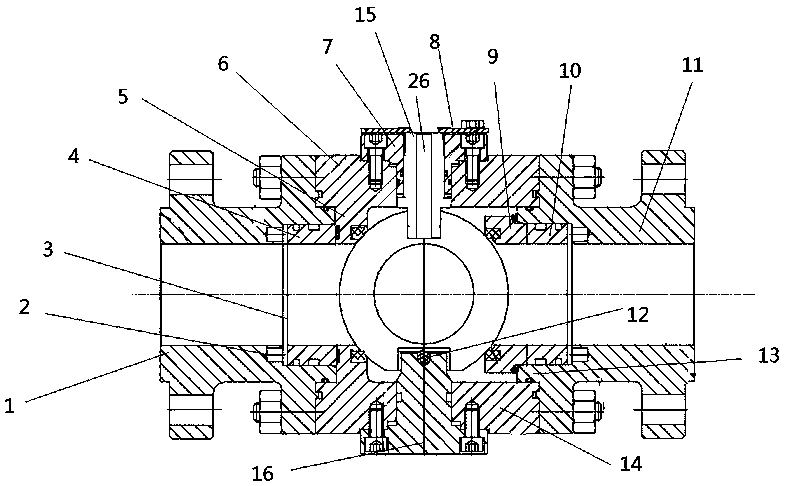

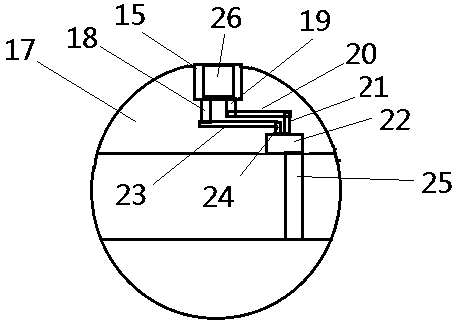

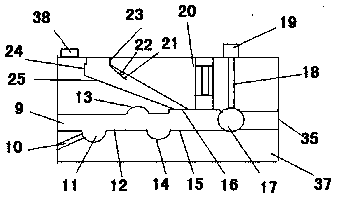

Fluid control equipment for square cabin

ActiveCN111810670AWon't wasteRealize the delay functionPlug valvesFluid-delivery valvesFluid controlStructural engineering

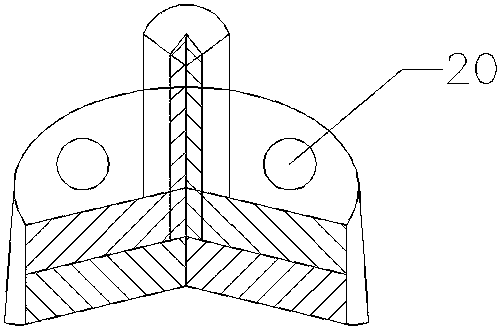

The invention discloses fluid control equipment for a square cabin. The fluid control equipment comprises a valve body, a pipe joint, a valve neck, a support block, a lug, a lower valve shaft, a firstT-shaped part, a second T-shaped part, a third T-shaped part, a lower cavity, a middle cavity, an upper cavity, a clamping block, a sliding chute, an avoiding groove, an avoiding ball, a small-flow conduit, a small hole, a sealing base and a valve ball, wherein the first T-shaped part comprises an upper valve shaft and an enclosing plate; and a pressure-keeping channel, a small-flow draining channel and a pass-through hole are formed inside the valve ball.

Owner:衡阳泰豪通信车辆有限公司

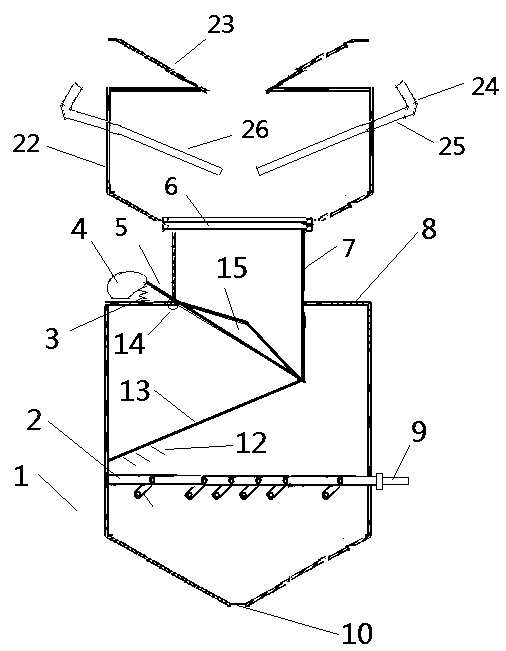

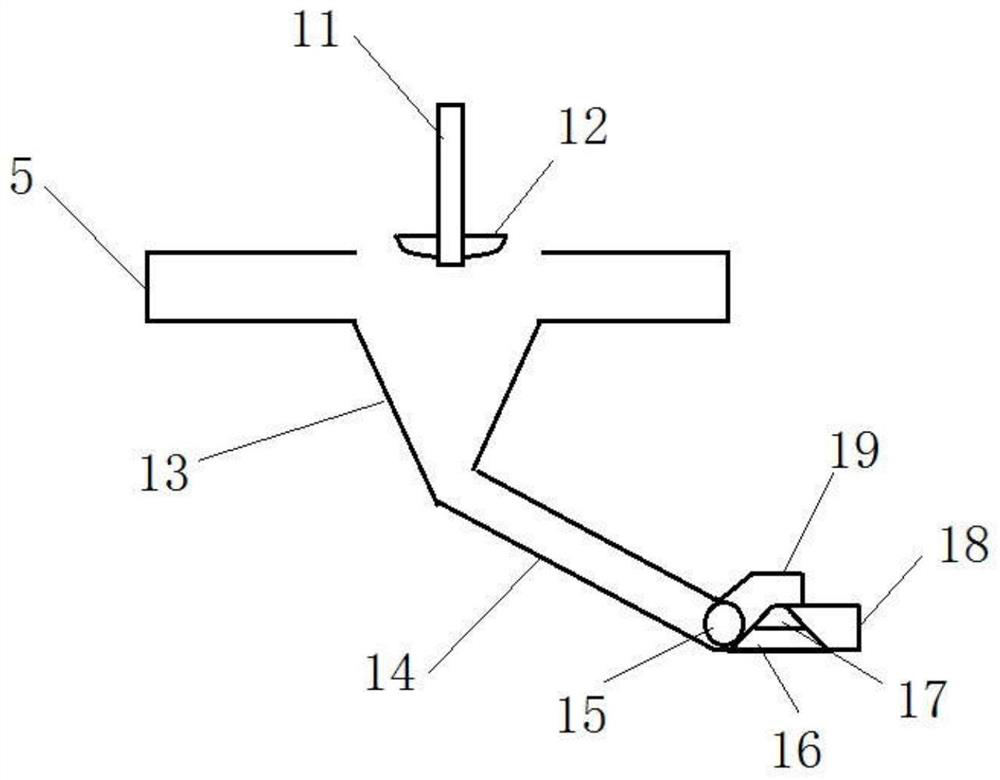

Double-layer combination flap valve

The invention relates to a double-layer combination flap valve which includes a first falling valve and a second falling valve. The first falling valve is located on the upper layer, the second falling valve is located on the lower layer, the first falling valve comprises an upper layer barrel body, a funnel, bends, levers and left and right flapping plates, the bends can control the levels to rotate, thus the left and right flapping plates are driven to rotate, and then the first falling valve is opened or closed; and the funnel is arranged on the upper portion of the upper layer barrel bodyfor receiving materials conveniently, the second falling valve comprises a lower layer barrel body, a partition plate, a spring, a wheel disc, a supporting rod, a flange, a straight barrel, a barrel shoulder, an air cylinder, a discharging port, a blade plate, comb teeth, telescopic rods, a fulcrum, a conical disc, a damping ring, a servo motor, a support, a hoop, rotating rings and bulges, the lower portion of the upper layer barrel body contracts, and the first falling valve and the second falling valve are mutually connected by an end port formed by contraction through the flange.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

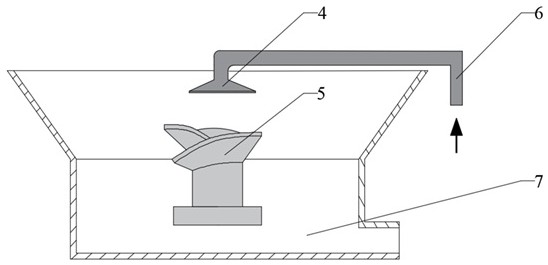

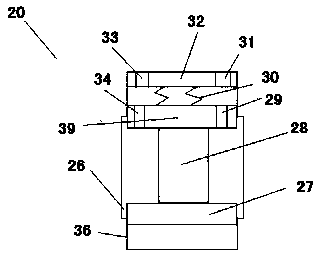

Equipment airborne multi-stage airbag cooperative buffering device

PendingCN108382598AImplement bufferingImprove buffering effectAircraft componentsLaunching weaponsInternal pressureExhaust valve

The invention discloses an equipment airborne multi-stage airbag cooperative buffering device. The equipment airborne multi-stage airbag cooperative buffering device comprises an upper airbag, an airbag tube column and a lower airbag; the upper airbag can exhaust air to the outside to reduce pressure by using an upper airbag exhaust valve and can also exhaust air to the airbag tube column by usinga combined exhaust valve I, and the airbag tube column expands to realize primary buffering; the airbag tube column can exhaust air to the outside to reduce the pressure by using an airbag tube column exhaust valve and can also exhaust air to the lower airbag by using a combined exhaust valve II, and the lower airbag expands to realize secondary buffering; and the lower airbag can exhaust air tothe outside to the reduce the pressure by using a lower airbag exhaust valve to realize three-stage buffering. According to the equipment airborne multi-stage airbag cooperative buffering device, through multi-stage buffering of the airbag cooperative buffering device, airborne equipment can be prevented from directly touching the ground multi-stage releasing of the pressure in the airbag can alsobe realized; and therefore, the airbag is prevented from exploded and safely landing of the airborne equipment is guaranteed.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Working method for sewage treatment fluid control device

ActiveCN111928121AImprove mixing efficiencySpeed up the mixingWater treatment parameter controlPlug valvesFluid controlStream flow

The invention discloses a working method for a sewage treatment fluid control device. The sewage treatment fluid control device comprises a rotational flow disc, a first charging pipe, a second charging pipe, a control ball valve, a flow collection conical pipe, a stirring rod, a stirring blade, a funnel, an inclined flow channel, a one-way valve ball, a drainage channel, a blockage block, a flowinlet pipe, a yielding pipe end, a liquid level sensor and a controller, wherein the control ball valve comprises a valve body, a ball body, a valve rod, a sealing valve base and a valve neck; the ball body comprises a small-flow channel, a large-flow channel, a first area, a second area, a third area, a fourth area, a fifth area, a sixth area, a seventh area and an eighth area; the large-flow channel comprises a first port and a second port; and the small-flow channel comprises a third port and a fourth port. The working method comprises a ball valve circulation control method and a linkage control method.

Owner:RAILWAY NO 5 BUREAU GRP FIRST ENG CO LTD +2

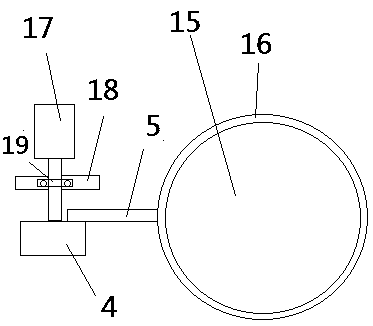

Linkage type discharging valve

ActiveCN109230624AThe blanking range is controllable and adjustableApplicable to the needs of different working conditionsLoading/unloadingEngineeringSupport point

Disclosed is a linkage type discharging valve. The discharging valve comprises a cylinder, a partition plate, a spring, a wheel disc, a supporting rod, a flange, a straight cylinder, a cylinder shoulder, a cylinder, a discharging outlet, a vane plate, broaches, a stretchable rod, a supporting point, a conical disc, a damping ring, a servo motor, a support, a hoop, a rotating ring and a protrusion;the cylinder shoulder is arranged above the cylinder, the middle of the cylinder shoulder extends upwards to form the straight cylinder, the flange is arranged above the straight cylinder, a part ofthe straight cylinder extends downwards along the horizontal line of the cylinder shoulder to form an inclined opening, the conical disc closes or opens the opening, the supporting rod is arranged above the left part of the conical disc, the supporting point is arranged at the intersection of the cylinder shoulder and the straight cylinder, and the supporting rod drives the conical disc to rotatethrough the supporting point to open or close the opening.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

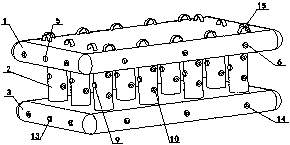

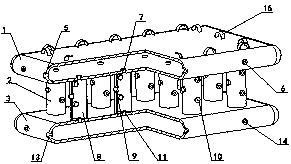

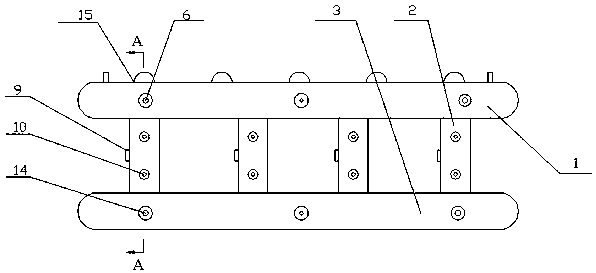

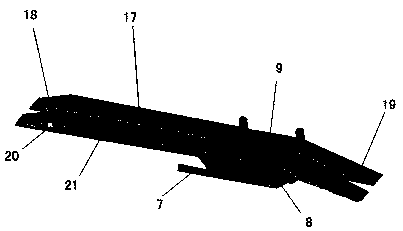

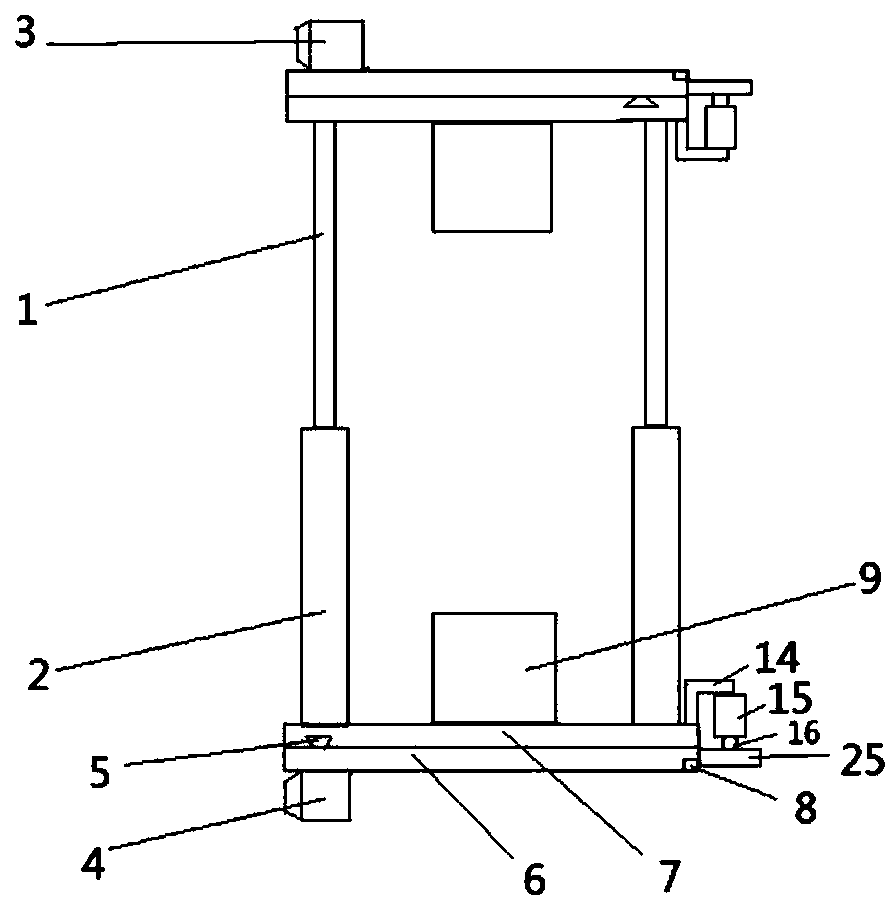

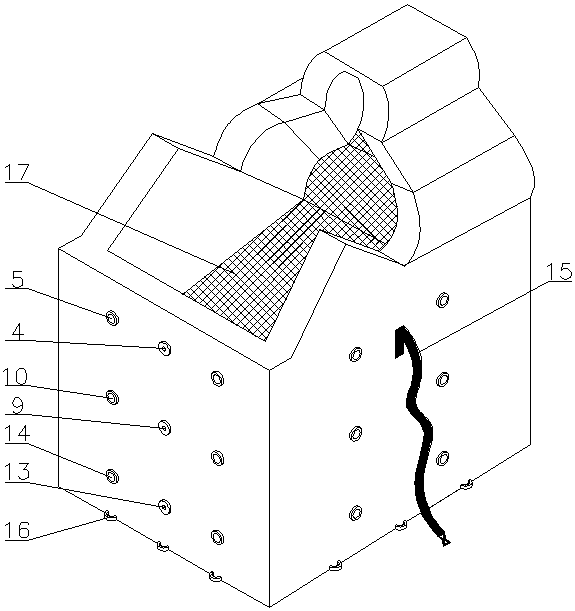

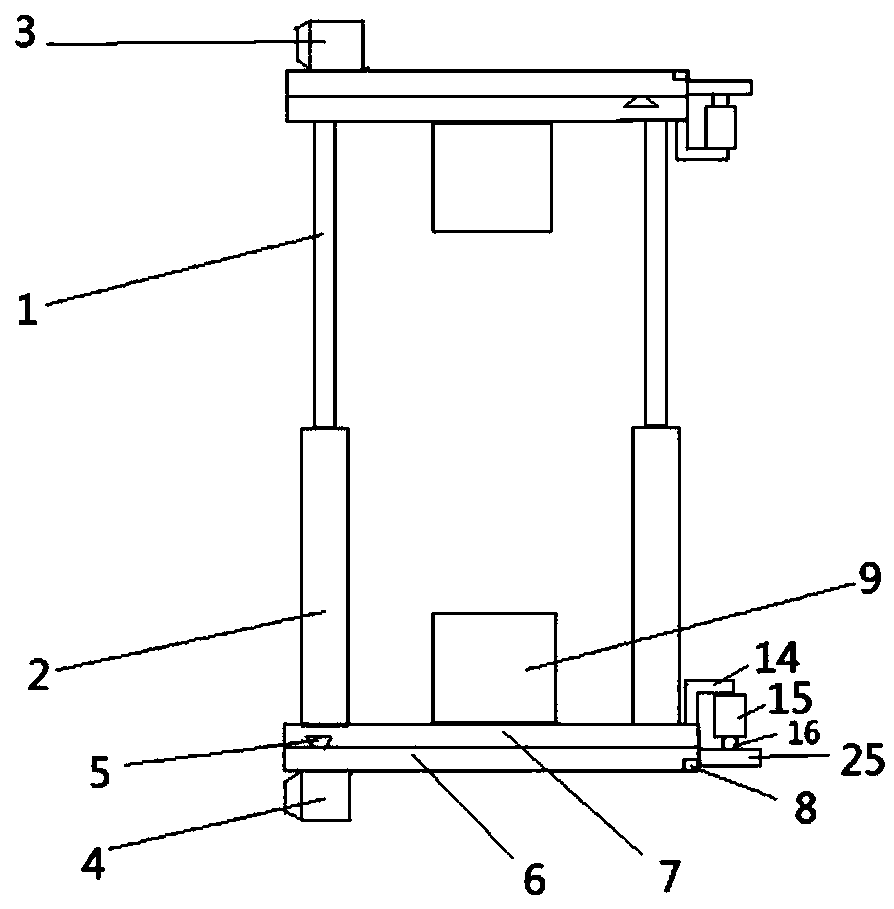

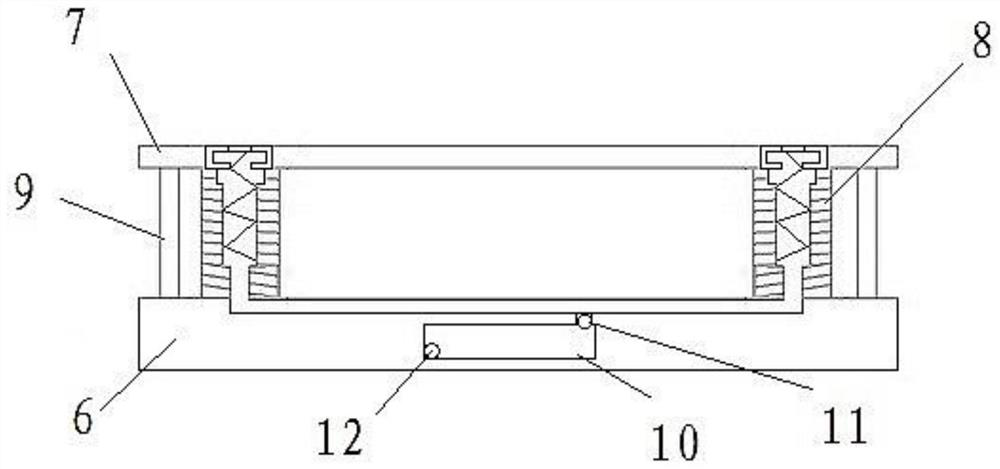

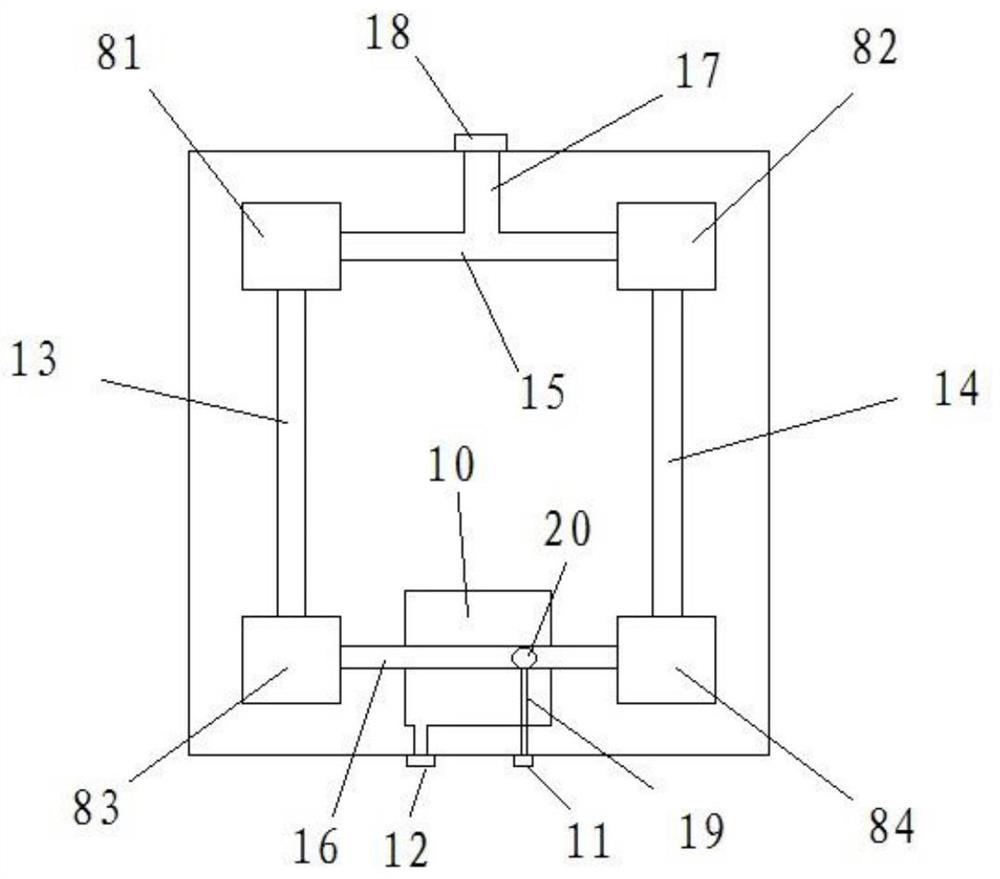

Stable construction device

ActiveCN110656958ARelieve stressImprove securityUnderground chambersTravelling bridgesTraction cordStructural engineering

A stable construction device comprises a formwork, a driving device, a supporting block, a connecting rod, a walking system, a base, a main bridge, a square table, a supporting column, a workbench, atraction claw, a traction rod, a traction wheel, a storage type rack, a storage type fence, a front bridge, a slope, a rear bridge, a traction rope bayonet and a concrete slab, wherein supporting legsare arranged on the lower side of the base, each supporting leg comprises a connecting frame, an installing hole, universal hinge pieces, supporting foots and rubber cushions, a bolt penetrates through each installing hole so that the corresponding connecting frame can be connected to the base, the two ends of each connecting frame are each provided with one universal hinge piece, the lower sideof each universal hinge piece is connected with one supporting foot, each supporting foot can rotate relative to the corresponding connecting frame through the corresponding universal hinge piece so as to adapt to different road conditions, and the lower side of each supporting foot is provided with one rubber cushion.

Owner:RAILWAY NO 5 BUREAU GRP FIRST ENG CO LTD

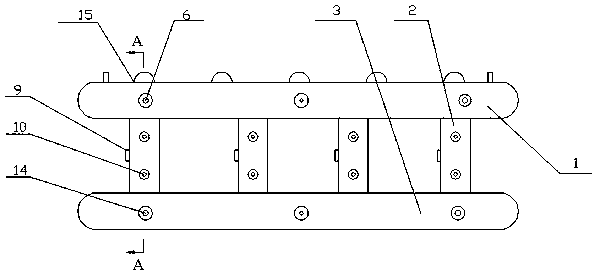

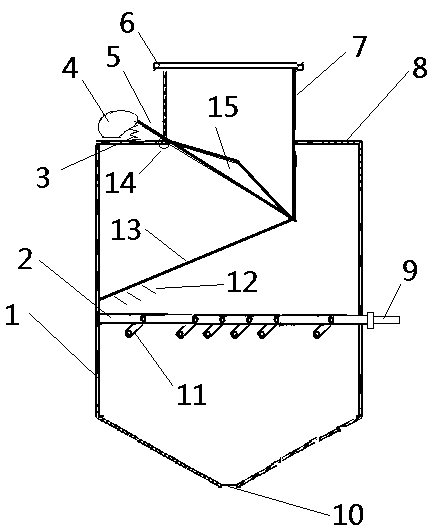

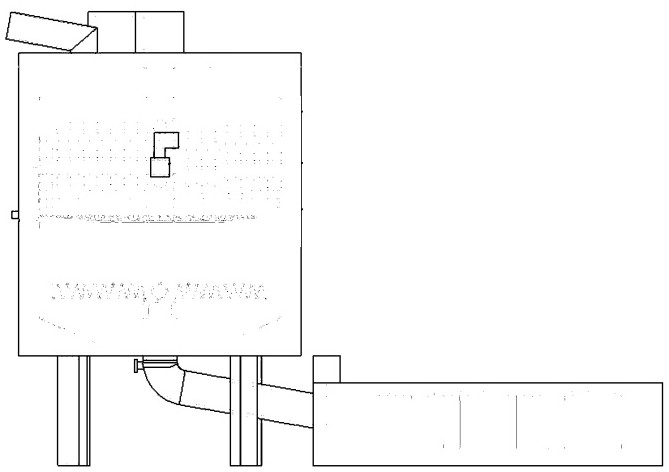

Squeezing dewatering equipment

PendingCN112499929AImprove space utilizationAvoid manpower failure to driveSludge treatmentWater dischargeWater collection

Squeezing dewatering equipment comprises a main body, a sludge outlet adjusting valve, an upper plate, a filter screen, a sludge dewatering cavity, a spiral squeezing column, a separated water collecting tank, a water collecting plate, a separated water discharge port and a dewatered sludge block outlet, wherein an upper plate is arranged above the main body, a sludge inlet is formed in the rightside of the upper plate, a filter screen is arranged in the middle of the main body, the sludge dewatering cavity is formed between the filter screen and the upper plate, the spiral squeezing column is arranged in the sludge dewatering cavity, and an impact-resistant plate is arranged at the position, corresponding to the sludge inlet, of the right side of the filter screen.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

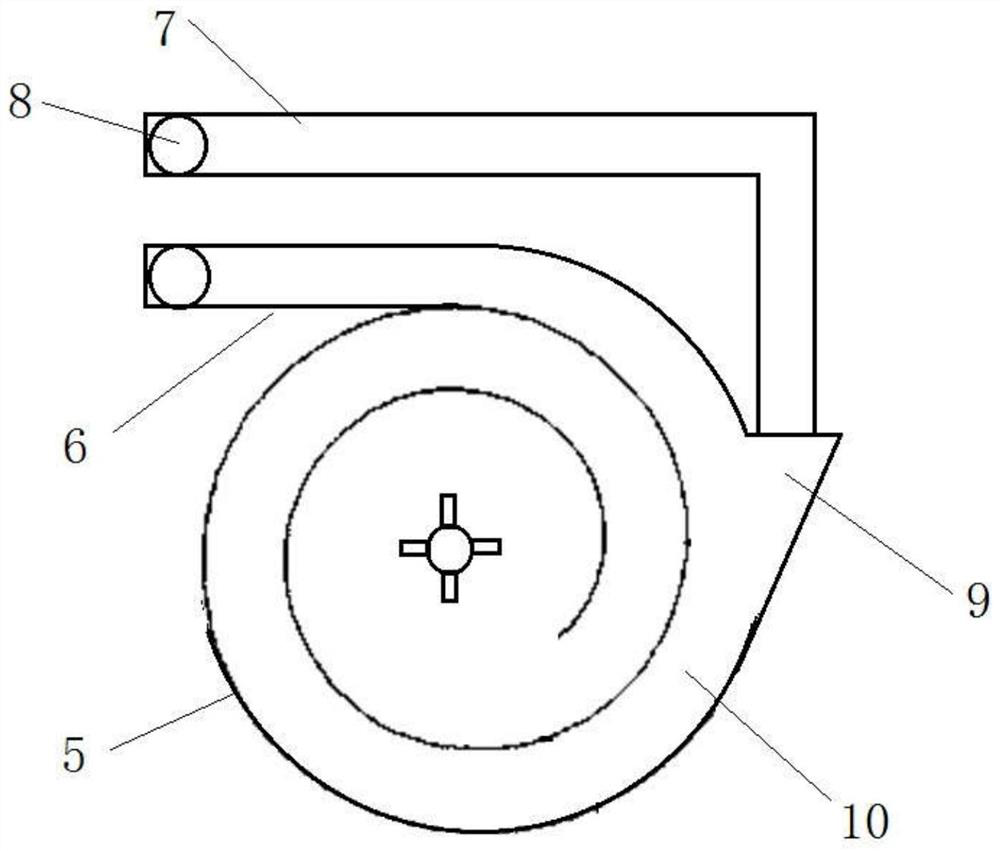

Control method of adjustable vortex ejection rod-climbing robot

PendingCN109352662AAvoid weight imbalanceEasy to sprayCleaning using liquidsManipulatorGear wheelWater flow

The invention discloses a control method of adjustable vortex ejection rod-climbing robot. The adjustable vortex ejection rod-climbing robot comprises a piston rod, a cylinder barrel, an upper cleaning structure, a lower cleaning structure, a trapezoidal sliding block, a water storage structure, a support seat, a water injection port, a clamping structure, a clamping cylinder, a clamping rod, a multi-section type clamping jaw, a pivoting node, a supporting frame, a motor, a motor output shaft, a cleaning block, a connecting block, a nozzle and a nozzle motor shaft, an annular flow channel, a nozzle motor, a nozzle turning plate, a spiral flow channel, a small gear and a clamping connection structure; the control method comprises a preparation step, a climbing rod control step and a cleaning control step; the cleaning control step comprises the following steps that a control valve is opened, so that water flows to the outlet of the nozzle through the connecting block, an annular channeland a spiral channel, rotating the nozzle motor to enable the fluid passing through the spiral channel to rotate so as to form vortex ejection.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

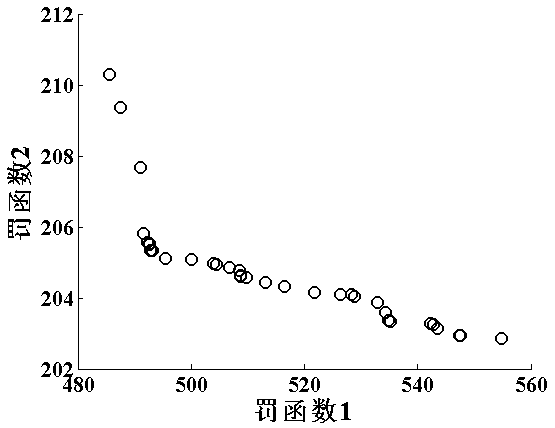

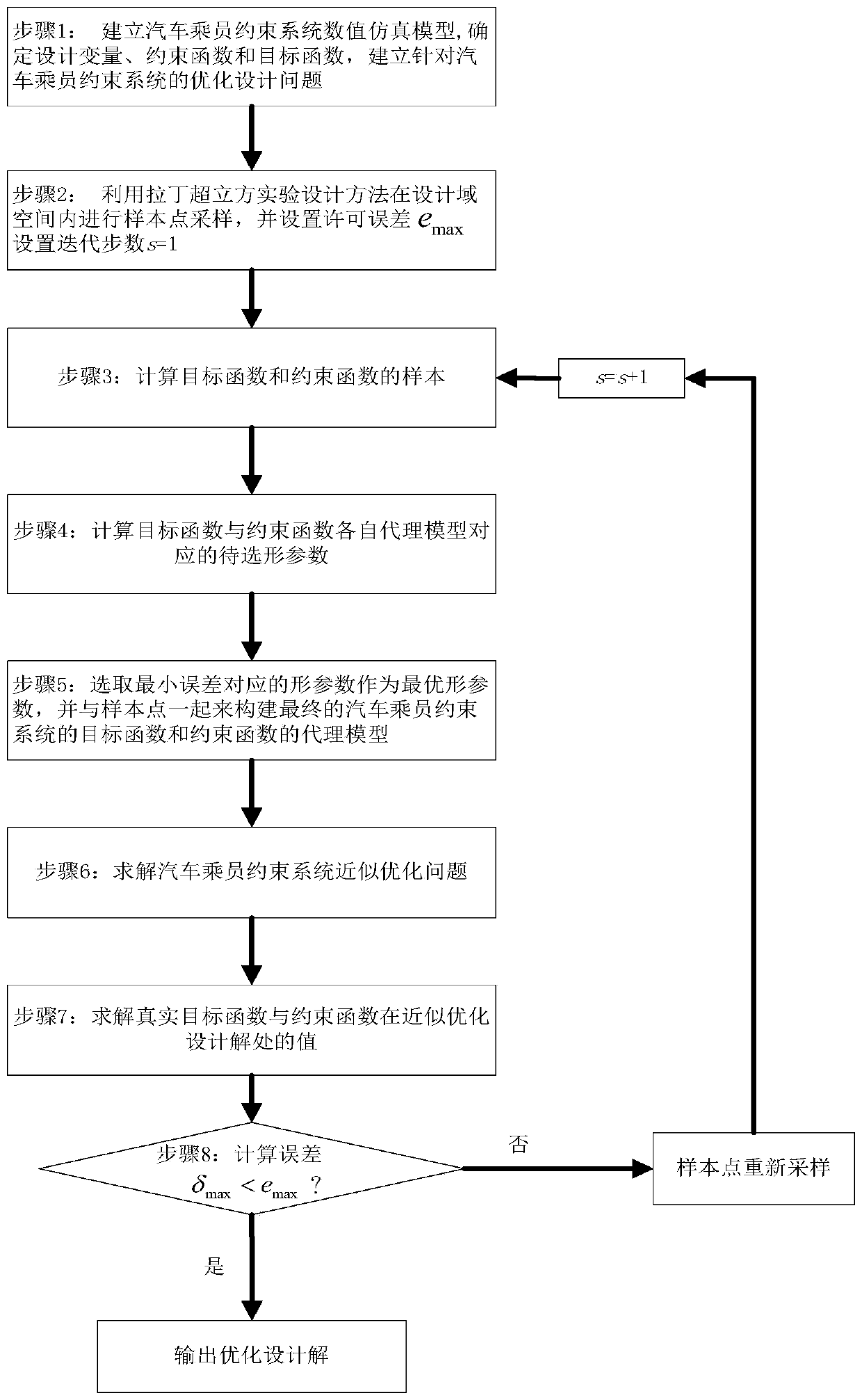

Automobile passenger restraint system optimization design method based on self-adaptive agent model

ActiveCN110889203AImprove computing efficiencyGuaranteed accuracyGeometric CADInternal combustion piston enginesGenetics algorithmsAutomobile safety

The invention discloses an automobile passenger restraint system optimization design method based on a self-adaptive agent model. According to the method, sample points are sampled through a Latin hypercube experiment design method, meanwhile, optimal shape parameters corresponding to the sample points are solved through a radial basis function, and the solved optimal shape parameters are combinedwith the sample points to construct an agent model of the automobile passenger restraint system; in order to ensure the precision of an optimization calculation result, multiple reconstruction of theagent model is realized based on error judgment, so that a final approximate optimization design problem of the automobile passenger restraint system is obtained, and an optimization solution meetingdesign requirements is solved through an intergeneration mapping genetic algorithm, so that the safety of automobile passengers is ensured. According to the method, the protection performance of theautomobile passenger restraint system can be effectively improved, the optimized calculation efficiency and solving quality can be essentially improved, and the method has wide engineering applicationvalue in the field of automobile safety.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

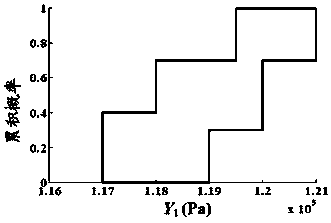

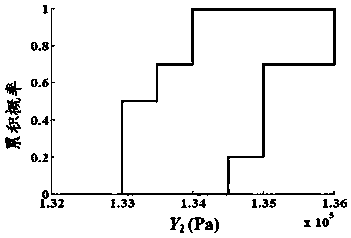

Imprecise probability reliability design method for equipment airborne airbag buffer device

InactiveCN110162898AReduce difficultyAvoid conservative designDesign optimisation/simulationComplex mathematical operationsEntropy principleReliability design

The invention discloses an imprecise probability reliability design method for an equipment airborne airbag buffer device. The method comprises the following steps: describing a random vector and a probability box vector through a probability model and a probability box model respectively; in order to effectively construct a cumulative distribution function of a probability box variable, ensuringthe consistency of the cumulative distribution function by adopting a moment condition, and ensuring the effectiveness of the cumulative distribution function by adopting a shape condition; meanwhile,in order to ensure the uniqueness of the cumulative distribution function, reconstructing the cumulative distribution function of the probability box variables based on the maximum entropy principle,and solving the reliability index of the equipment airborne airbag buffer device through an iterative mapping genetic algorithm; according to the method, the uncertain variable in the buffer processof the air bag under equipment can be effectively constructed, the calculation efficiency and the solution quality of the solution reliability index can be improved essentially, and the method has a wide engineering application value in the field of air bag under equipment safety.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

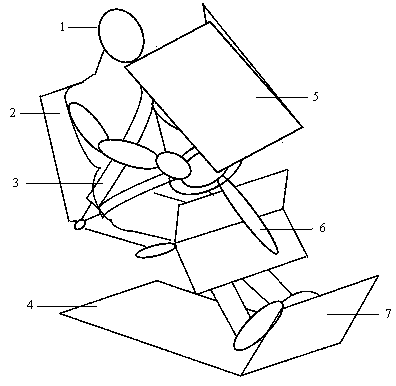

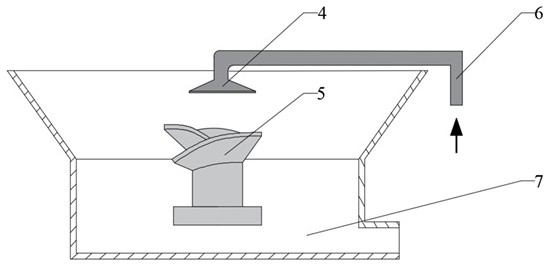

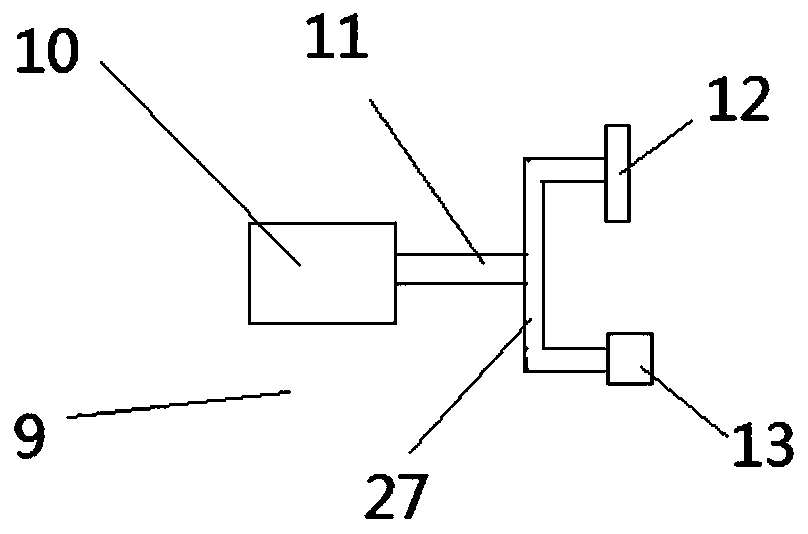

Working method of airborne occupant multi-stage airbag cooperative buffer seat

The invention discloses a working method of an airborne occupant multi-stage airbag cooperative buffer seat. The multi-stage airbag cooperative buffer seat comprises an upper air chamber, a middle airchamber and a lower air chamber; the upper air chamber, the middle air chamber and the lower air chamber are arranged by stacking from top to bottom, the upper air chamber can exhaust to the outsidethrough an upper air chamber exhaust valve for decompression, and can exhaust to the middle air chamber through a combined exhaust valve, and the middle air chamber is expanded to achieve first-stagebuffer; the middle air chamber can exhaust to the outside through a middle air chamber exhaust valve, and can further exhaust to the lower air chamber through a second combined exhaust valve, and thelower air chamber is expanded to achieve secondary buffer; the lower air chamber can exhaust to the outside through a lower air chamber exhaust valve to achieve three-stage buffer; the multi-stage buffer method of the multi-stage airbag cooperative buffer seat can prevent a human body from colliding secondly with the interior of a fighting vehicle, achieve multi-stage release of the internal pressure of the airbag buffer seat, and prevent the airbag buffer seat from blasting, thereby effectively ensuring a safe landing of an airborne occupant.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Control method of dual-clamping cyclone rope-climbing robot

PendingCN108890651AImprove securityLarge carrying capacityProgramme-controlled manipulatorBuilding repairsPistonSpray nozzle

A control method of a dual-clamping cyclone rope-climbing robot is provided. The dual-clamping cyclone rope-climbing robot comprises piston rods, cylinder barrels, an upper washing structure, a lowerwashing structure, a trapezoidal slider, water storage structures, support seats, a water injection port, a clamping structure, a carrier, a motor, a motor output shaft, a connection block, a nozzle,a nozzle motor shaft, a circular passage, a nozzle motor, a nozzle flap, a spiral passage, a small gear, and a fastening structure. The clamping structure includes a clamping cylinder, a clamping rod,a clamping plate, a clamping half-ring and a split support. The control method includes the steps of preparing, controlling rope climbing, and controlling washing; the washing controlling step includes opening a control valve so that flows of water pass through the connection block, the circular passage and the spiral passage and gather at a nozzle outlet, turning the nozzle motor so that a fluidpassing the spiral passage rotates to form a vortex sprayed out, controlling a motor connected with the carrier so that the small gear rotates and drives teeth at the outer edges of the water storagestructures, thereby driving the water storage structures to rotate and driving the washing structures to rotate for cleaning.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

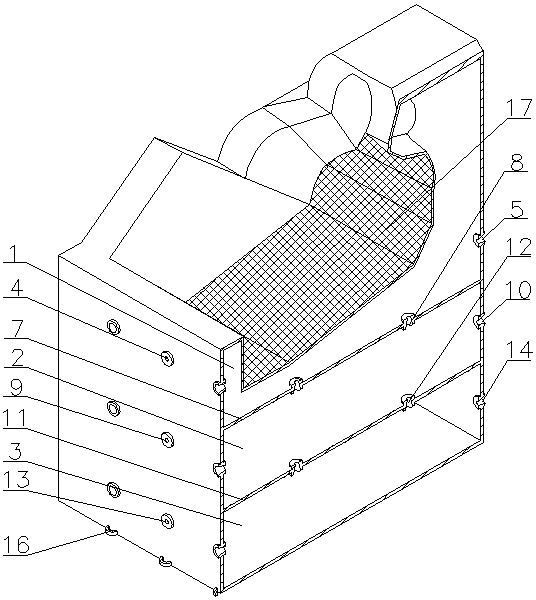

Multi-stage airbag cooperative buffering seat for airborne occupant

PendingCN108357684AReduce volumeReduce weightSupports/holding devicesAircraft ejection meansInternal pressureExhaust valve

The invention discloses a multi-stage airbag cooperative buffering seat for an airborne occupant. The seat comprises an upper air chamber, a middle air chamber and a lower air chamber which are stacked from top to bottom; the upper air chamber can discharge air and release pressure through an air discharge valve of the upper air chamber and also discharge air to the middle air chamber through a first combined air discharge valve, and the middle air chamber expands to achieve first-stage buffering; the middle air chamber can discharge air and release pressure to the exterior through an air discharge valve of the middle air chamber and also discharge air to the lower air chamber through a second combined air discharge valve, and the lower air chamber expands to achieve second-stage buffering; the lower air chamber can discharge air and release pressure to the exterior through an air discharge valve of the lower air chamber to achieve third-stage buffering. Through multi-stage buffering of the multi-stage airbag cooperative buffering seat, not only can secondary collision between the human body and chariot interior parts be prevented, but also the multi-stage release of pressure in the airbag buffering seat can be achieved, the airbag buffering seat is prevented from being blasted, and therefore safe landing of the airborne occupant is effectively ensured.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

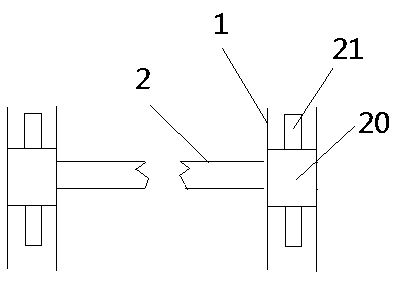

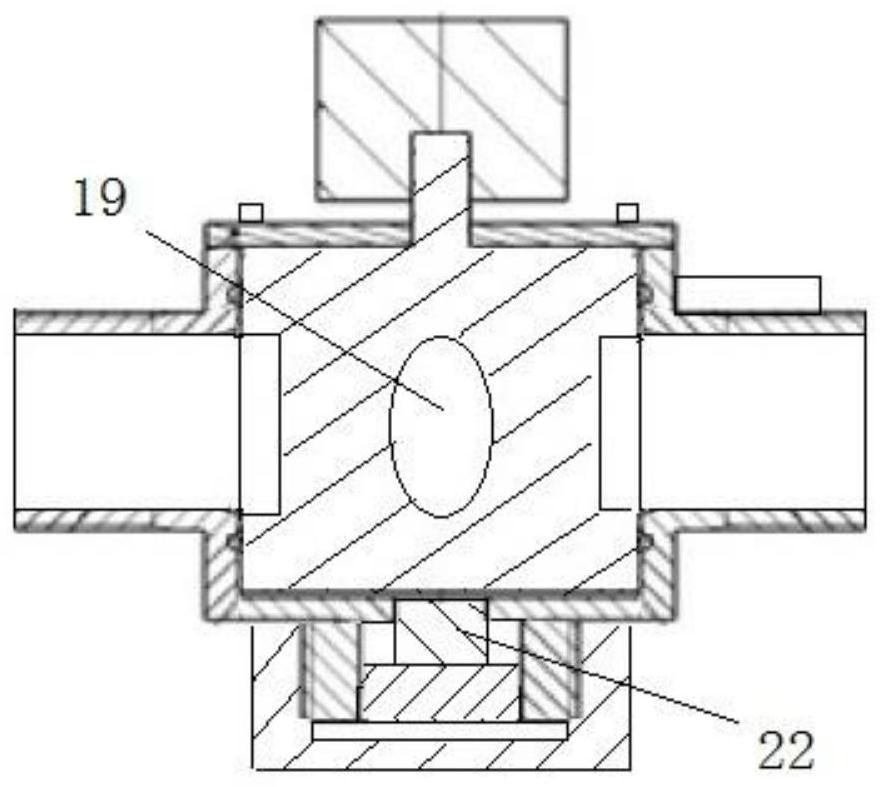

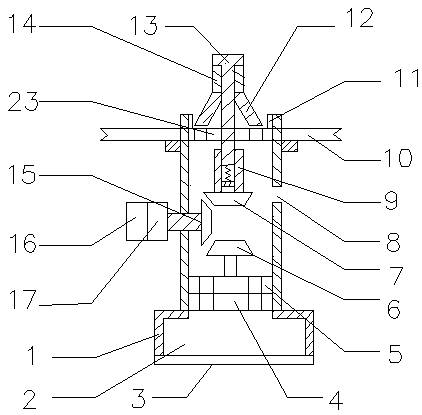

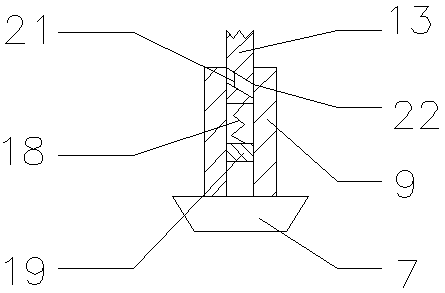

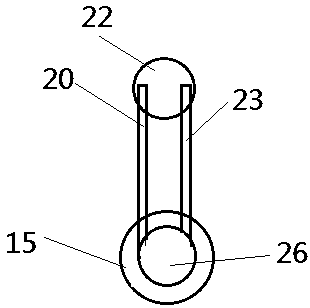

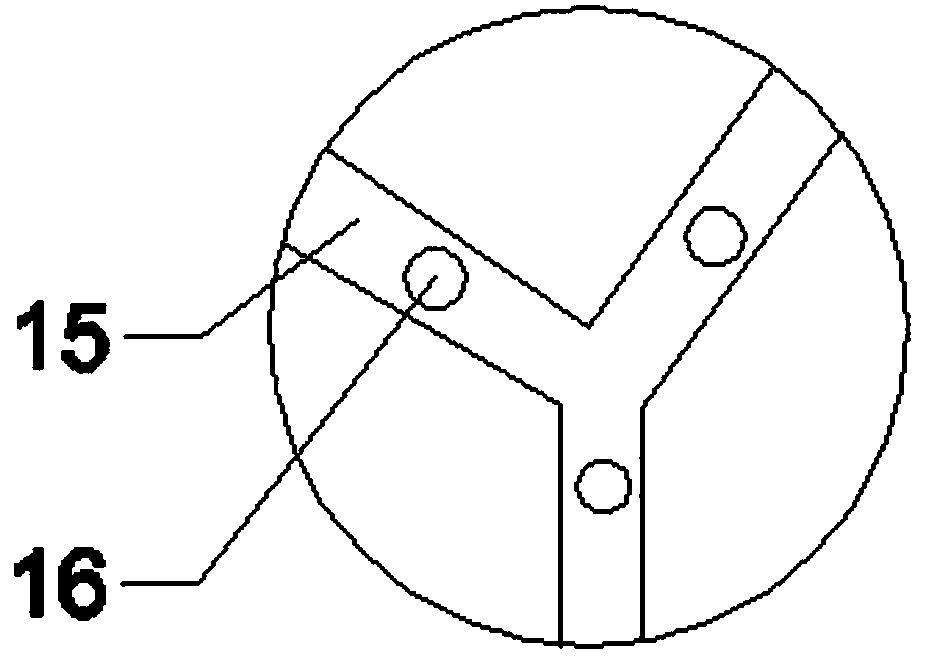

Three-gear four-waveform valve easy to disassemble and assemble

ActiveCN113357393ARich experimental wind waveformExtended via coveragePlug valvesNon-rotating vibration suppressionThreaded pipeControl engineering

A three-gear four-waveform valve easy to disassemble and assemble comprises a left valve body, a right valve body, a servo motor, a lifting cover plate, a left pull ring, a motor shaft, a right pull ring, a sensing module, a sealing piece, a waveform control sleeve, a main valve element, a threaded cover, a lower driving piece, a shock pad, a threaded pipe and a lower output shaft. The waveform control sleeve comprises a first outer square hole, a second outer square hole, a first outer elliptical hole and a second outer elliptical hole. The main valve element comprises an inner square channel and an inner elliptical channel. The lifting cover plate is detachably connected with the left valve body and the right valve body, the servo motor outputs power to the motor shaft, the motor shaft is connected with the waveform control sleeve, and the waveform control sleeve comprises an upper plate and a sleeve part.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

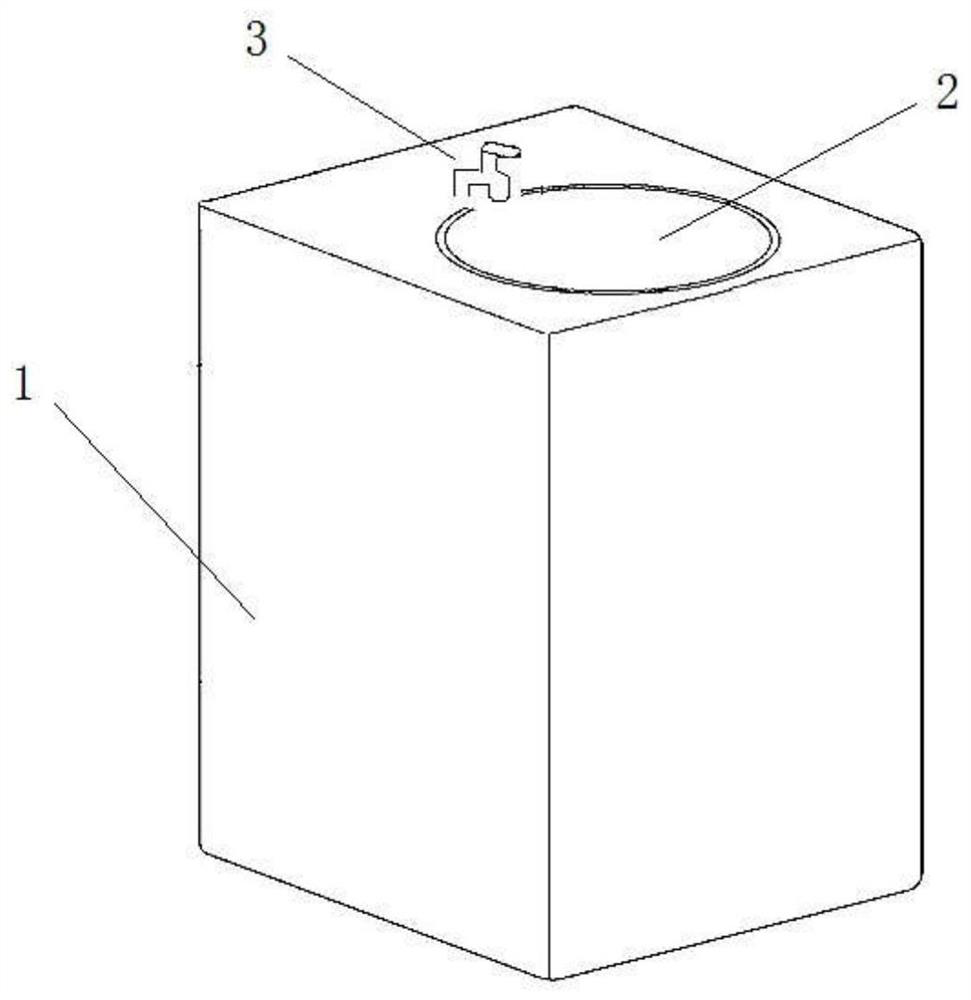

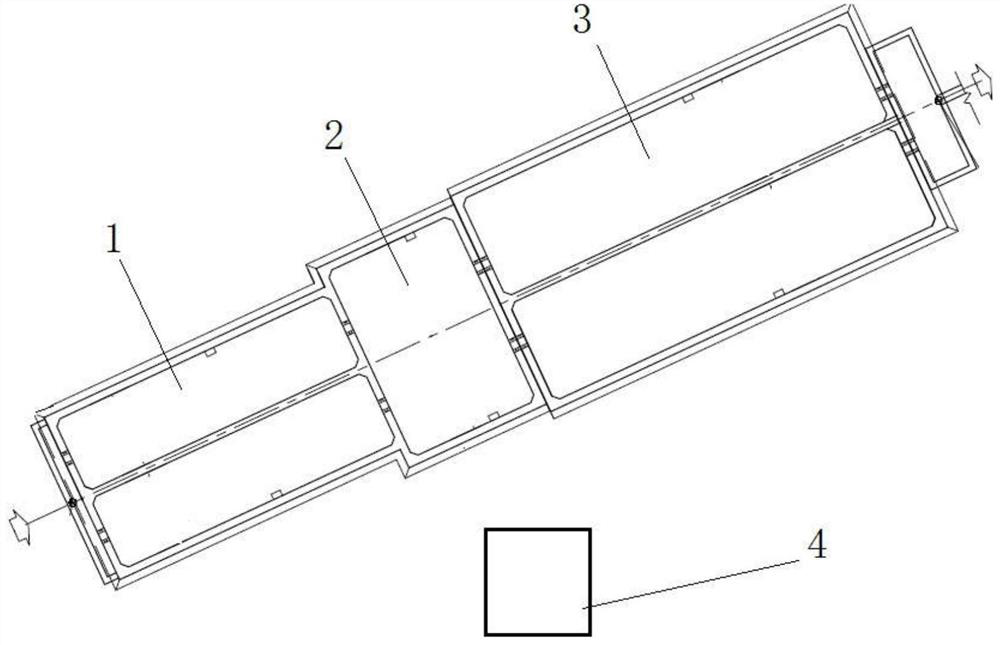

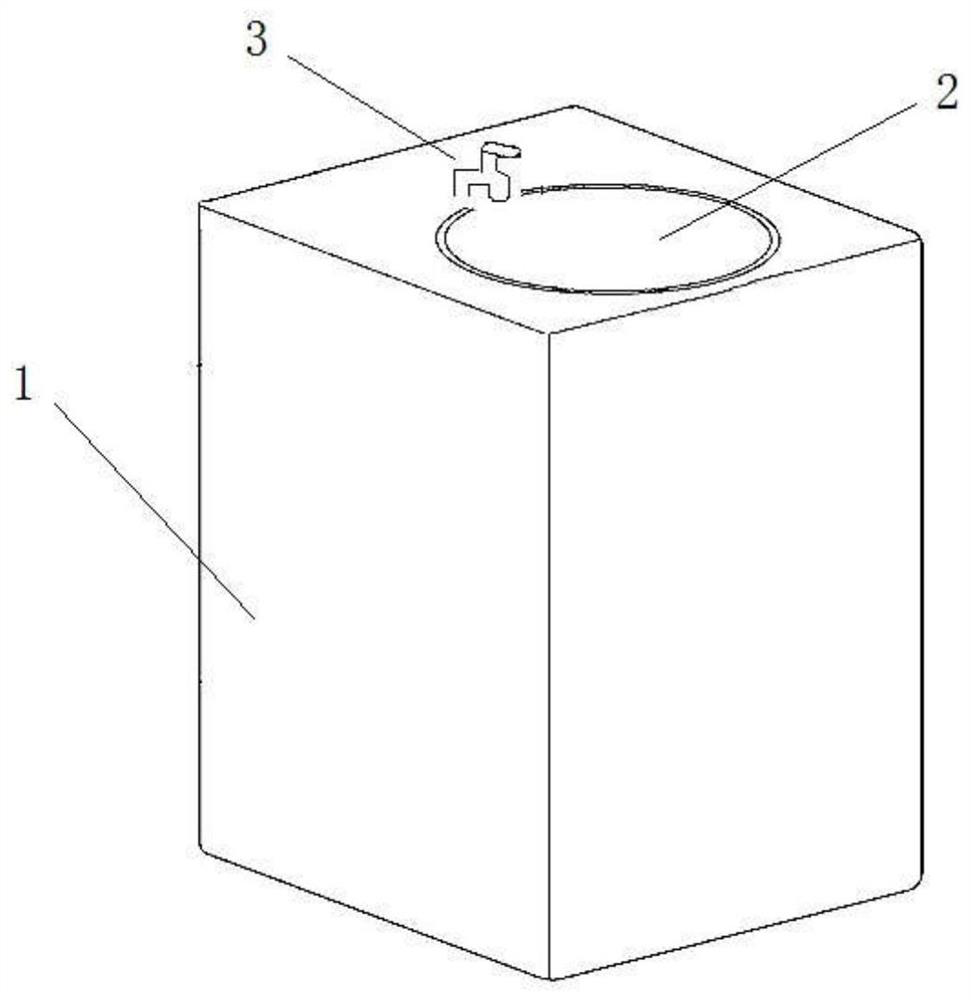

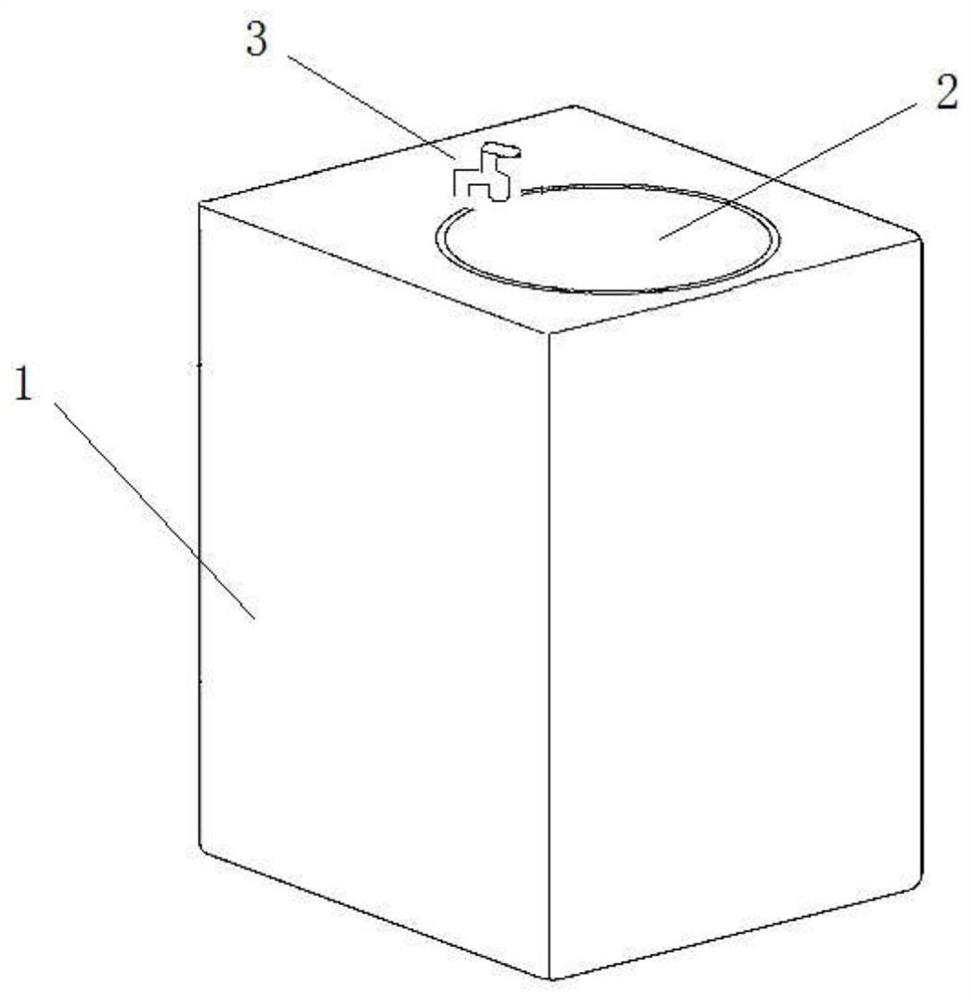

Mobile cabin system

ActiveCN111809930AWon't wasteRealize the delay functionPlug valvesDomestic plumbingWater storageTemperature control

A mobile cabin system comprises a mobile cabin body, and the mobile cabin body comprises a panel, and a water supply system, a photography bed and a temperature control sterilizer which are arranged internally, wherein the water supply system comprises a box body for water supply, a water tank, a water pump, a delivery pipeline, a water storage cavity, a wash basin, a faucet and castors; the watertank is arranged in the box body, and the water pump is arranged above the water tank; water in the water tank is supplied into the delivery pipeline through the water pump, and then supplied into the faucet; the wash basin is arranged at the upper part of the box body, and corresponds to the position of the faucet; and the water storage cavity is arranged below the wash basin, and the bottom surface of the water storage cavity is not installed at the bottom of the box body.

Owner:衡阳泰豪通信车辆有限公司

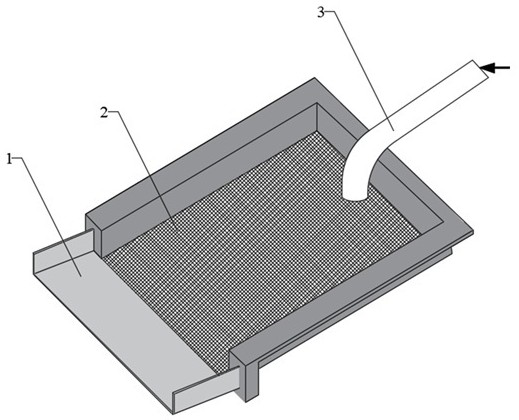

Sludge treatment system

The invention discloses a sludge treatment system. The sludge treatment system comprises a sand-stone separation module, a liquid medicine mixing module and a sludge dehydration module, wherein the sludge sequentially passes through the sand-stone separation module, the liquid medicine mixing module and the sludge dehydration module to be treated; the sand-stone separation module comprises a vibrating screen, a screen mesh and a sand-stone plate are arranged on the vibrating screen, a sludge conveying pipe conveys sludge to the screen mesh, slurry infiltrates downwards through a gap of the screen mesh, and sand-stone incapable of passing through the screen mesh enters a sand-stone collection bag through the sand-stone plate.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

a cabin system

ActiveCN111809930BWon't wasteRealize the delay functionPlug valvesDomestic plumbingWater holdingWall plate

A shelter system, comprising a shelter body, the shelter body includes a wall plate and an internal water supply system, a photography bed, a temperature-controlled sterilizer, wherein the water supply system includes a water supply box, a water tank, a water pump, Delivery pipe, water chamber, washbasin, faucet, casters, a water tank is placed inside the box, a water pump is arranged above the water tank, and the water in the water tank is provided to the delivery pipeline by the water pump and then provided to the water faucet. The upper part of the box body is provided with the washbasin, the position of the washbasin corresponds to the water tap, the water holding chamber is arranged below the washbasin, and the bottom surface of the water holding chamber is not installed on the bottom of the box body.

Owner:衡阳泰豪通信车辆有限公司

Working method of double-linkage conveyor discharge valve

InactiveCN107902435AImprove flowClear condensationLoading/unloadingConveyor partsGear wheelEngineering

A working method for a double-linkage conveyor unloading valve, the working steps are as follows: the first step is to control the rotation of the motor, drive the third angle gear to rotate through the reduction mechanism, and the third angle gear drives the first and second angle gears to rotate at the same time, The second angle gear drives the valve stem to rise through the rod sleeve, and the valve stem drives the pivot rod and the closure to rise for storage operation, the material hole is opened for discharge, and at the same time, the moving valve disc rotates to the closed position relative to the static valve disc , the weighing cavity is closed; in the second step, after discharging for a predetermined time, the motor is controlled to rotate in reverse, and the closing member is controlled to close the material hole through the transmission structure, and the movable valve disc rotates to the opposite static valve When the disc is opened, the material is dropped into the weighing cavity, and when the material in the weighing cavity reaches a predetermined weight, the first step and the second step are repeated in sequence.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

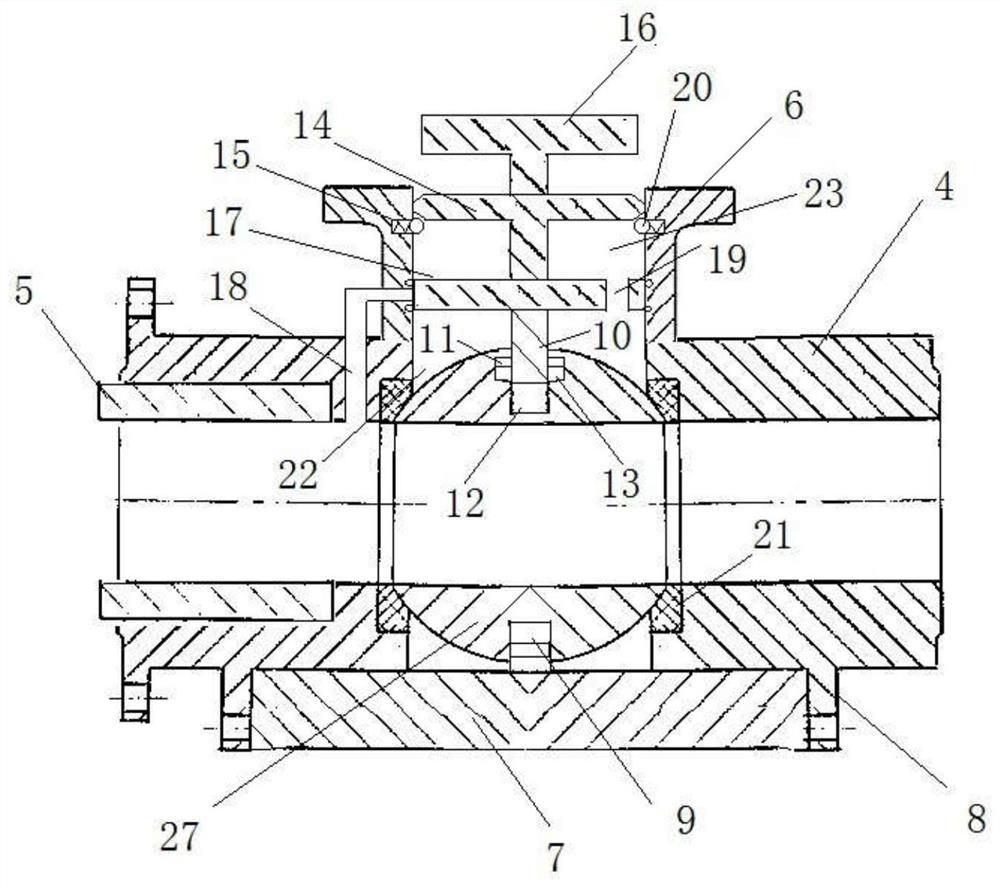

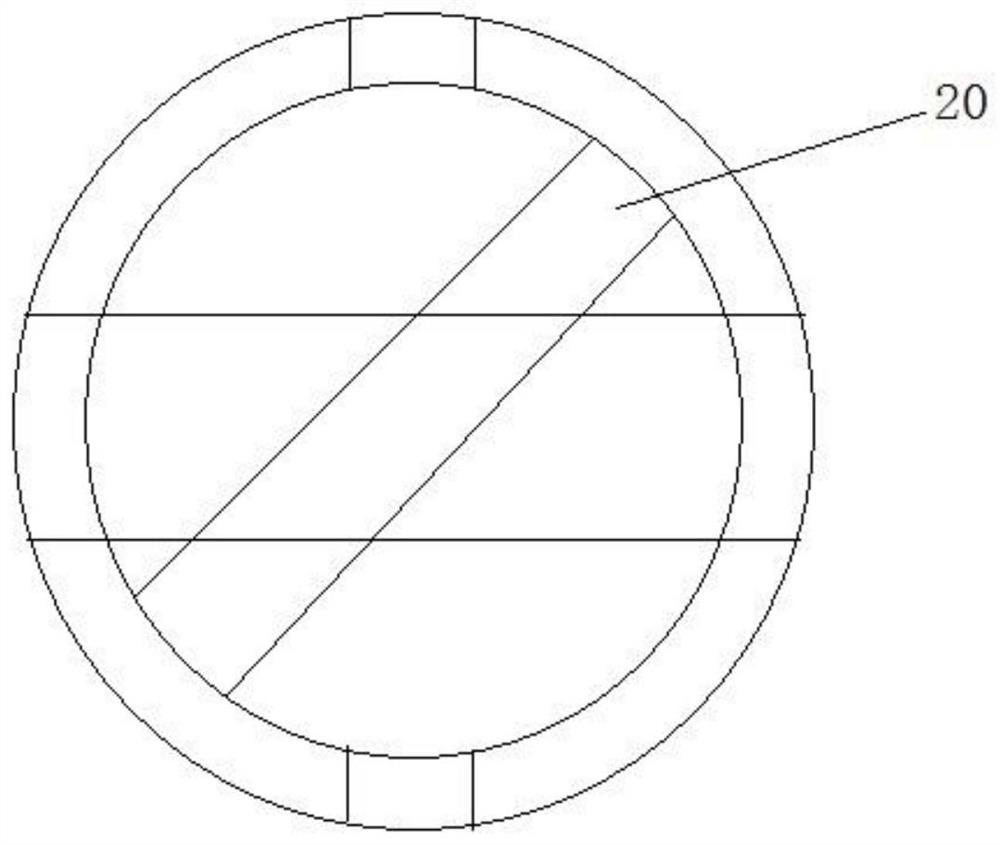

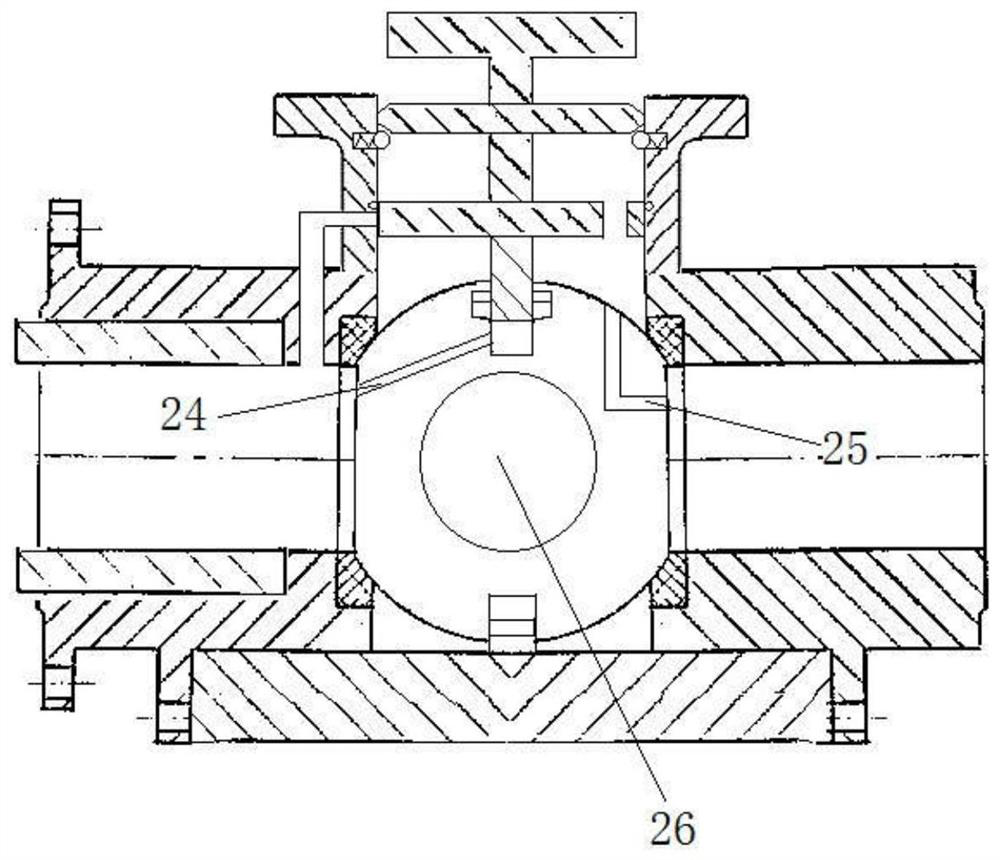

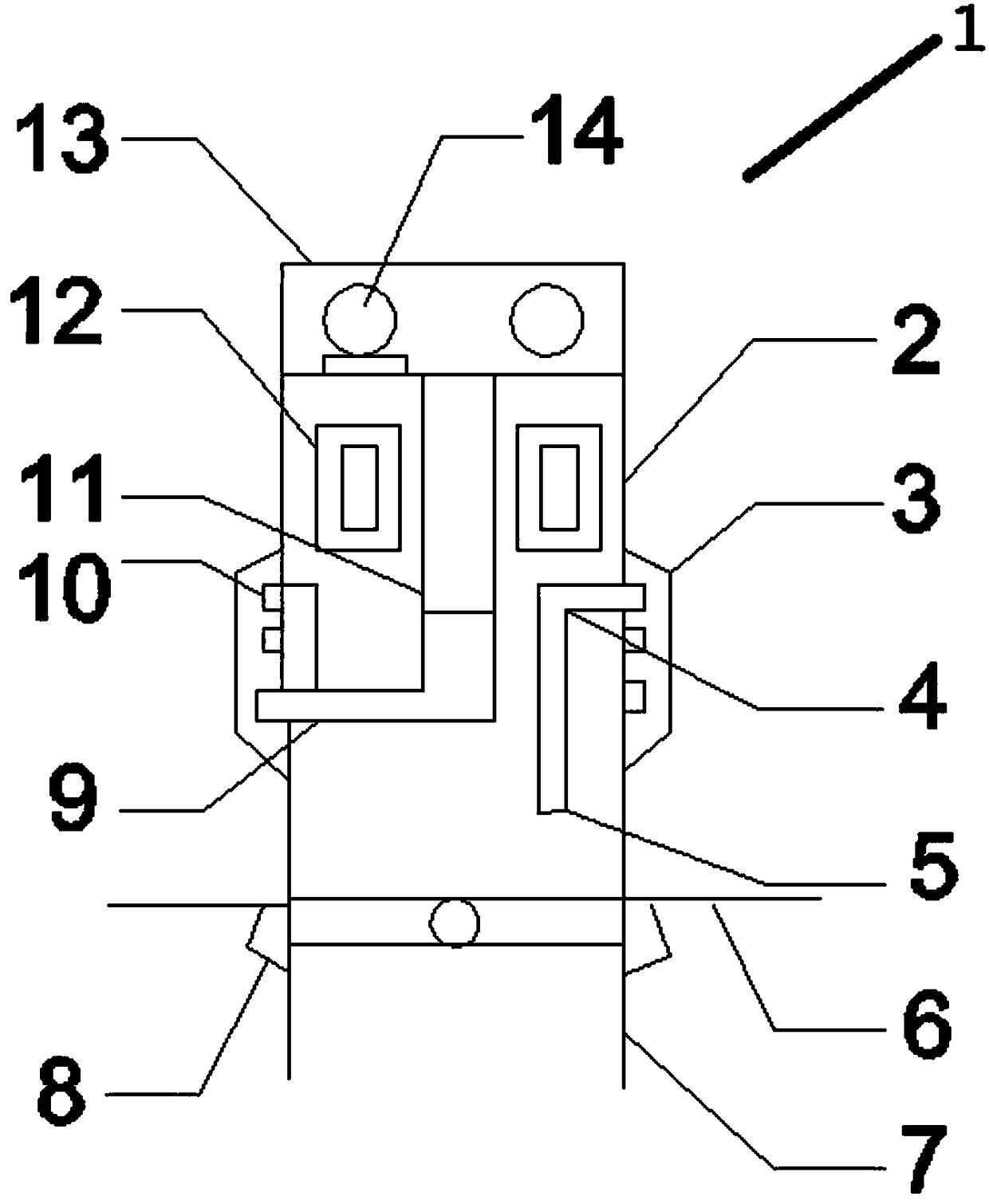

Multi-gear steady-supporting ball valve controlled by double rocker

ActiveCN108547998AGuaranteed connection formingGuaranteed to be dynamically adjustablePlug valvesOperating means/releasing devices for valvesEngineeringValve seat

The invention discloses a multi-gear steady-supporting ball valve controlled by a double rocker. The multi-gear steady-supporting ball valve comprises a left flange, a pre-tightening piece, a separation ring, a left pressing ring, a lower convex valve seat, an upper valve body, a shaft sleeve, a connecting plate, a right valve seat, a right pressing ring, a pressing plate flange, a lower spring, aleft protruding part, a lower valve body, an outer valve rod, a lower valve shaft, a ball body, a first long rod, a first short rod, an upper connecting rod, a second long rod, an auxiliary shaft, alower connecting rod, a second short rod, an auxiliary valve plate and an inner valve rod, wherein the inner valve rod is arranged in the outer valve rod, the first long rod and the first short rod are arranged at the lower end of the inner valve rod, the tail end of the first long rod is connected with the lower connecting rod, the tail end of the first short rod is connected with the upper connecting rod, the other end of the upper connecting rod is connected with the top end of the second long rod, and the other end of the lower connecting rod is connected with the top end of the second short rod; and the upper connecting rod and the lower connecting rod are located on different horizontal planes and do not interfere with each other, the lower end of the second long rod is connected with the auxiliary valve plate, and the lower end of the second short rod is connected with the auxiliary valve plate. The multi-gear steady-supporting ball valve is characterized in that the inner valverod rotates to drive the first long rod and the first short rod to rotate so as to drive the second long rod and the second short rod to rotate, and therefore the auxiliary valve plate can be drivento be opened and closed, and the auxiliary valve plate is screwed into the ball body when opened; and a groove for containing the auxiliary valve plate in the ball body is formed by injection molding.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Integrated valve for tunnel construction

ActiveCN110925464AImplement the layoutAchieve fixationOperating means/releasing devices for valvesUnderground chambersPiston rodLeft wall

An integrated valve for tunnel construction comprises a concrete inlet, an accelerator inlet, a mixing part, a reducing part, an expanding part, a turning part, a converging pipe, a buffering convex cavity, a valve element, a valve rod, a valve driving part, a pressure relief valve, an air valve plate, a convex block, an air duct connecting port, an air duct sinking part, an inclined air duct, anintegrated valve outlet, an integrated block body and an integrated block connecting part. The pressure relief valve comprises a lower piston, a piston rod, an upper piston, an upper piston hole, a spring, a valve bonnet, a valve bonnet hole, a pressure relief valve cavity and an expanding cavity. The concrete inlet is formed in the position below the center line of the left wall of the integratedblock body, the accelerator inlet is formed below the concrete inlet, the right end of the concrete inlet is communicated with the mixing part, the upper end of the mixing part is aligned with the upper end of the concrete inlet, the lower end of the mixing part protrudes downwards relative to the lower end of the concrete inlet, and the protruding part is communicated with the accelerator inlet.

Owner:RAILWAY NO 5 BUREAU GRP FIRST ENG CO LTD

Dual-clamping cyclone rope-climbing robot

ActiveCN108890667AAvoid weight imbalanceEasy to sprayGeneral water supply conservationBuilding repairsCycloneEngineering

A dual-clamping cyclone rope-climbing robot comprises piston rods, cylinder barrels, an upper washing structure, a lower washing structure, a trapezoidal slider, water storage structures, support seats, a water injection port, a clamping structure, a carrier, a motor, a motor output shaft, a connection block, a nozzle, a nozzle motor shaft, a circular passage, a nozzle motor, a nozzle flap, a spiral passage, a small gear, and a fastening structure. The clamping structure includes a clamping cylinder, a clamping rod, a clamping plate, a clamping half-ring and a split support; the cylinder barrels and the piston rods are connected between the two support seats; vertical motion is achieved through telescoping of the cylinder barrels and the piston rods; the lower portion of the upper supportseat and the upper portion of the lower support seat are connected with the clamping structure; the upper portion of the upper support seat and the lower portion of the lower support seat are connected with the water storage structure; the upper washing structure is positioned at the upper portion of the upper water storage structure; the lower washing structure is positioned at the lower portionof the lower water storage structure.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

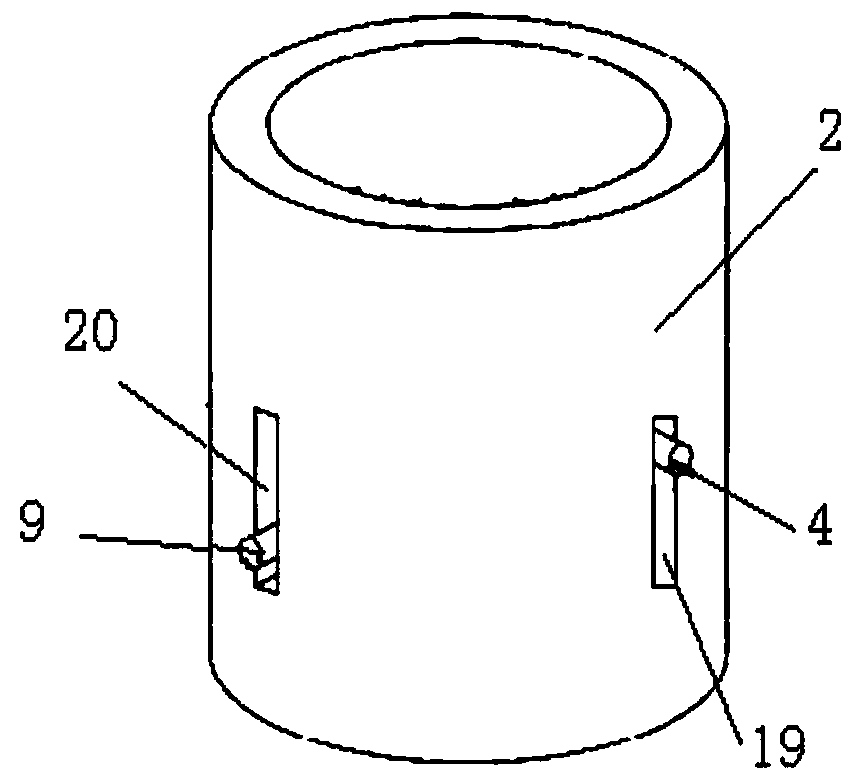

Buffer type container

ActiveCN112660635APrevent slight tiltingRealize multiple functionsLarge containersStructural engineeringContainer tops

The invention discloses a buffer type container which comprises a container outer shell. The container outer shell comprises container top corner pieces, container stand columns, a rear wall, container bottom corner pieces, container cross beams, a right wall, container longitudinal beams, a top wall, a front wall, a left wall, a bottom wall and two forklift grooves; and the top wall, the bottom wall, the front wall, the left wall, the right wall and the rear wall jointly define a container shell body, the rear wall is constructed to be a rear double-door, the right wall is constructed to be a right double-door, and the forklift grooves are located in the lower portion of the right wall.

Owner:衡阳泰豪通信车辆有限公司 +1

Reciprocating material discharging method of lotus seeds

ActiveCN110179131AImprove work efficiencySave the process of strippingFruit stoningHuskingMotor driveEngineering

The invention relates to a reciprocating material discharging method of lotus seeds. The reciprocating material discharging method comprises a material collecting method, a transferring method, a coredischarging method and a lotus discharging method, wherein the material collecting method comprises the steps that at the initial state, an upper blocking disk is located just below a fixing barrel,during discharging, an upper blocking disk motor drives the upper blocking disk to rotate to move out of the range of the fixing barrel, lotus seeds fall onto a material collecting disk through lotusseed passages, the upper blocking disk moves to return to a position just below the fixing barrel, and the lotus seed passages are blocked; the transferring method comprises the steps that four or above lotus seed holes corresponding to the lotus seed passages are formed in the material collecting disk, four or above lotus core holes corresponding to the lotus seed holes are formed in the lower blocking disk, the diameter of each lotus core hole is smaller than that of each lotus seed hole, after material collection is completed, the lower blocking disk and the material collecting disk rotateto the position under a needle disk at the same time, and the positions of cutting ring edges are aligned with those of the lotus seed holes.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

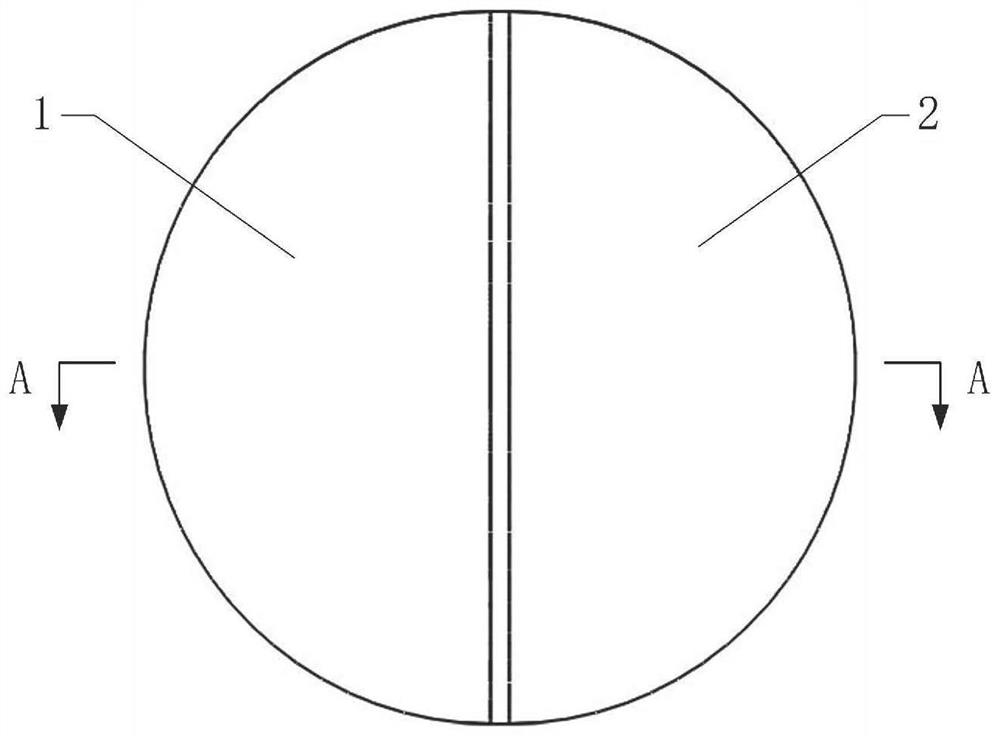

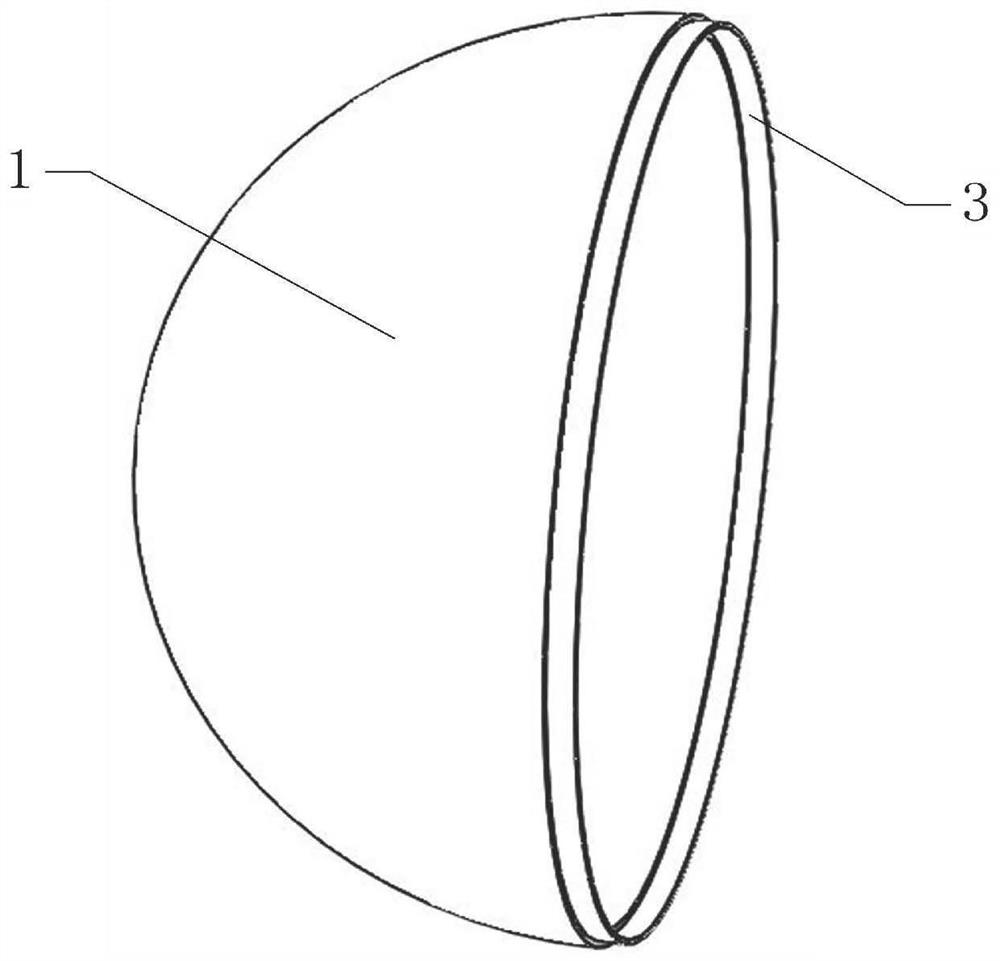

Hydrogen storage system

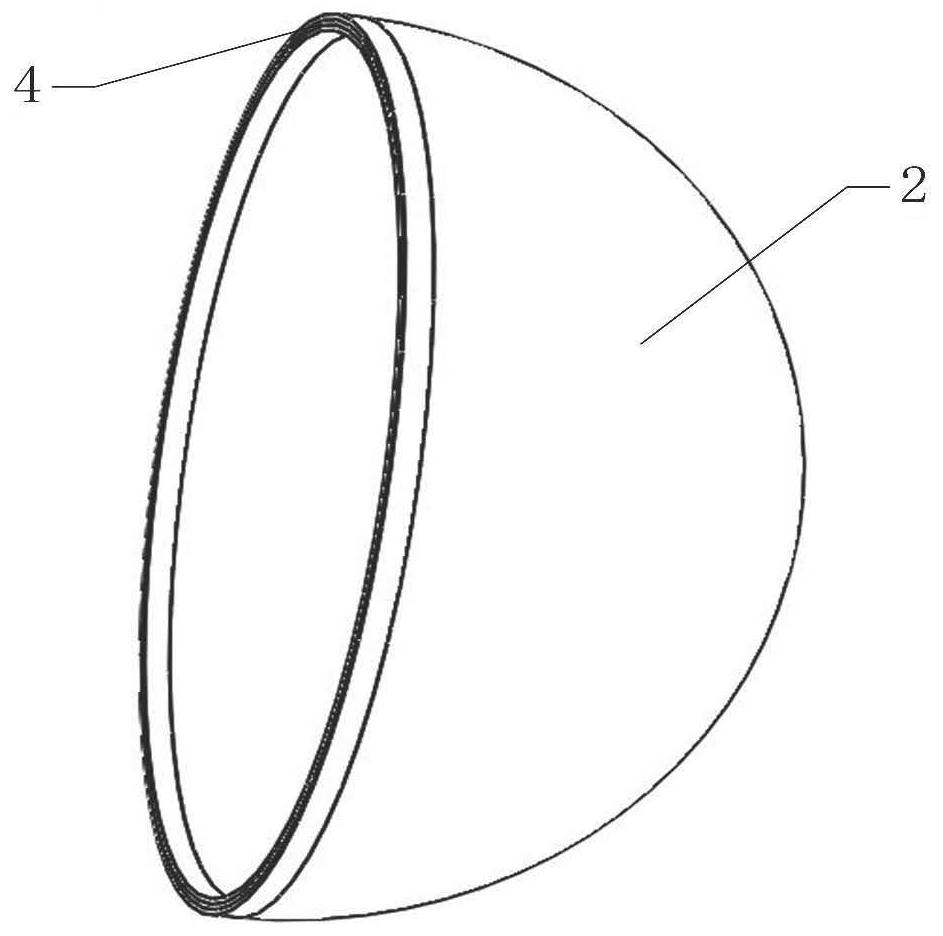

InactiveCN108626563ARealize double-layer opening and closingAchieve pioneering inventionsContainer filling methodsFluid handledFiberSurface layer

The invention discloses a hydrogen storage system, the hydrogen storage system comprises a hydrogen storage tank and a hydrogen storage valve, the hydrogen storage tank comprises a surface layer, a tank body, an inner container, a tank plug and an upper cover, the surface layer, the tank body and the inner container are sequentially arranged from outside to inside, the tank body is upwards provided with a closing-up opening, the inner container is located below the closing-up opening, in an unopened state, the tank plug is contained in the closing-up opening, the upper cover is connected to the closing-up opening in a threaded mode, the surface layer is a fiber winding layer, the inner container is made of stainless steel, and the hydrogen storage valve comprises a valve body, a hand wheel, a first supporting rod, a second supporting rod, a cylindrical connecting part, pawls, a third supporting rod, a spiral groove, an armature, an electromagnetic coil, a piston, outlets, fan rib channels, one-way valves, a valve plate, a magnetic block, a first vertical groove, a second vertical groove and an electronic drive module.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Working method of rigid-flexible coupling airborne loading combined buffer device

InactiveCN111846232AGuaranteed buffer protectionReduced landing attitude requirementsAircraft componentsNon-rotating vibration suppressionExhaust valveMaterial storage

The invention discloses a working method of a rigid-flexible coupling airborne loading combined buffer device. The device comprises an airborne material storage box, a buffer spring, an inner buffer air bag, an inner spherical shell, an outer buffer air bag and an outer spherical shell. In the loading airborne landing process, the outer spherical shell deforms firstly, and first-stage buffering isachieved; then a folding buffer connecting piece deforms, and second-stage buffering is achieved; the outer buffering air bag is compressed, and the outer buffering air bag exhausts air and relievespressure outwards through an outer buffering air bag exhaust valve so that three-stage buffering is realized; the inner spherical shell is deformed after being subjected to a load so that four-stage buffering is realized; the buffer spring contracts subsequently to realize five-stage buffering; the inner buffer air bag is finally compressed and the inner buffer air bag exhausts air and relieves pressure outwards through the inner buffering exhaust valve, and six-stage buffering is achieved; by means of the multi-stage buffering method of the airborne landing device, impact energy can be absorbed stage by stage, the internal pressure of the buffering air bag can be prevented from being sharply increased, the buffering air bag is prevented from blasting, and therefore, the integrity of materials in the airborne landing device is effectively guaranteed.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com