Squeezing dewatering equipment

A technology of extrusion dehydration and equipment, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., can solve the problems of not considering the equal-diameter structure, unable to realize manual connection, and single function, etc., to achieve Improve space utilization and avoid effects that cannot be driven by manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

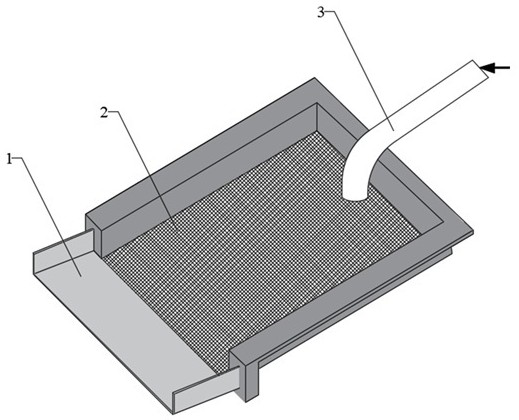

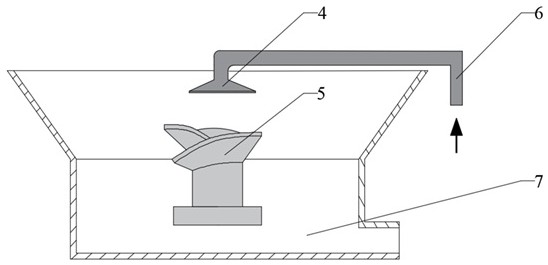

[0042] As shown in the figure: a extrusion dehydration equipment, including the main body, mud outlet regulating valve, upper plate, filter screen, sludge dewatering chamber, screw extrusion column, separated water collection tank, water collecting plate, separated water outlet, Demineralized block outlet, closing plate, manual drive device, first guide plate, second guide plate, sewage outlet, impact plate, right side wall, left side wall, inner cylinder, motor, outer cylinder; The port regulating valve includes a driving part, a valve stem and a valve core.

[0043] Wherein the upper part of the main body is provided with an upper plate, the right side of the upper plate is provided with a sludge inlet, the middle part of the main body is provided with a filter screen, and the sludge dehydration chamber is provided between the filter screen and the upper plate, and the sludge The dewatering chamber is provided with the spiral extruding column, and the right side of the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com