Three-gear four-waveform valve easy to disassemble and assemble

An easy-to-assemble, wave-shaped technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of difficult processing, inability to simulate one by one, sealing structure processing and installation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

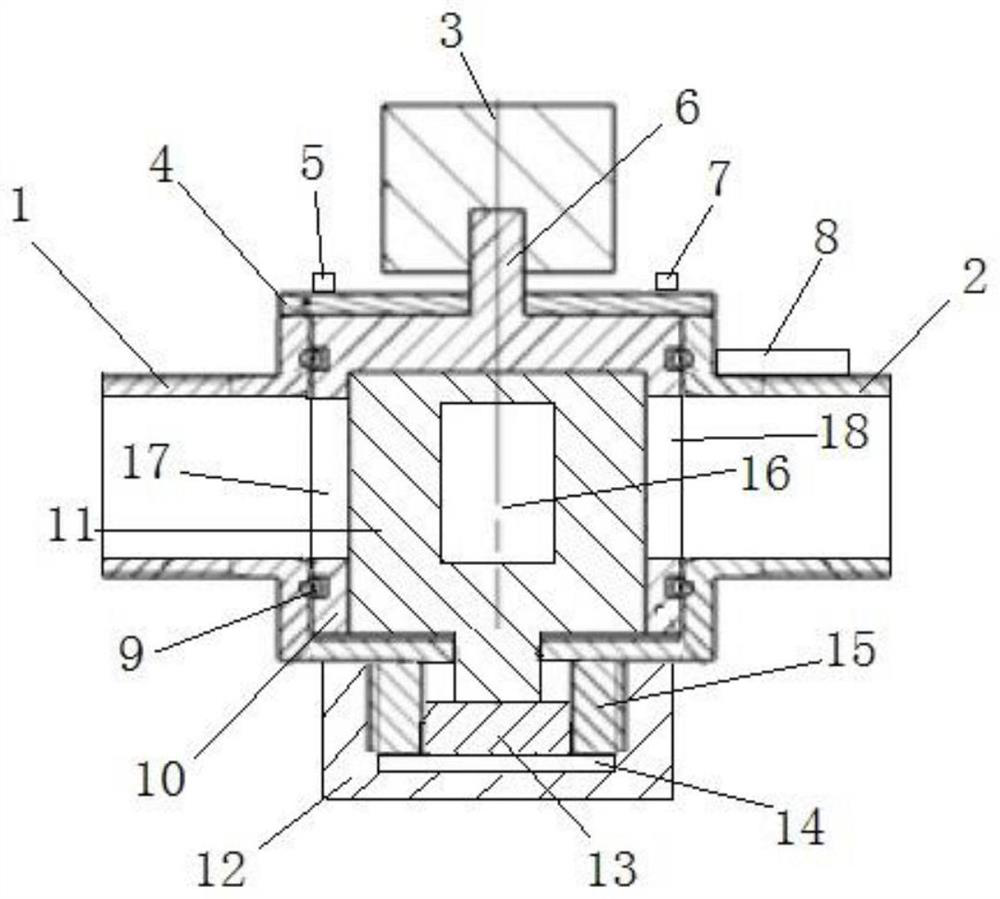

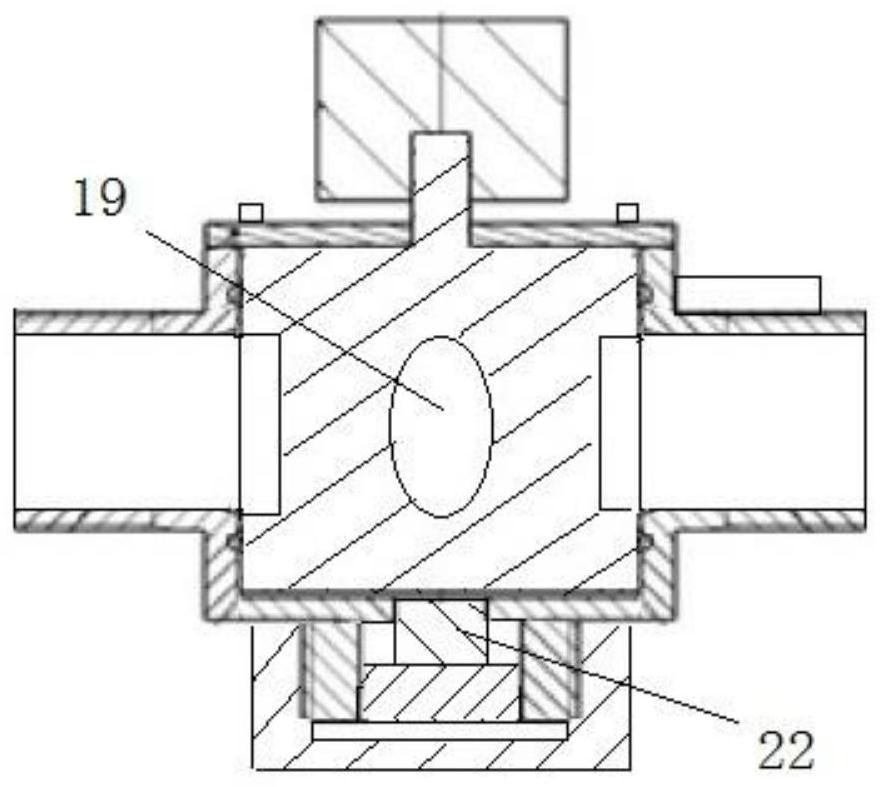

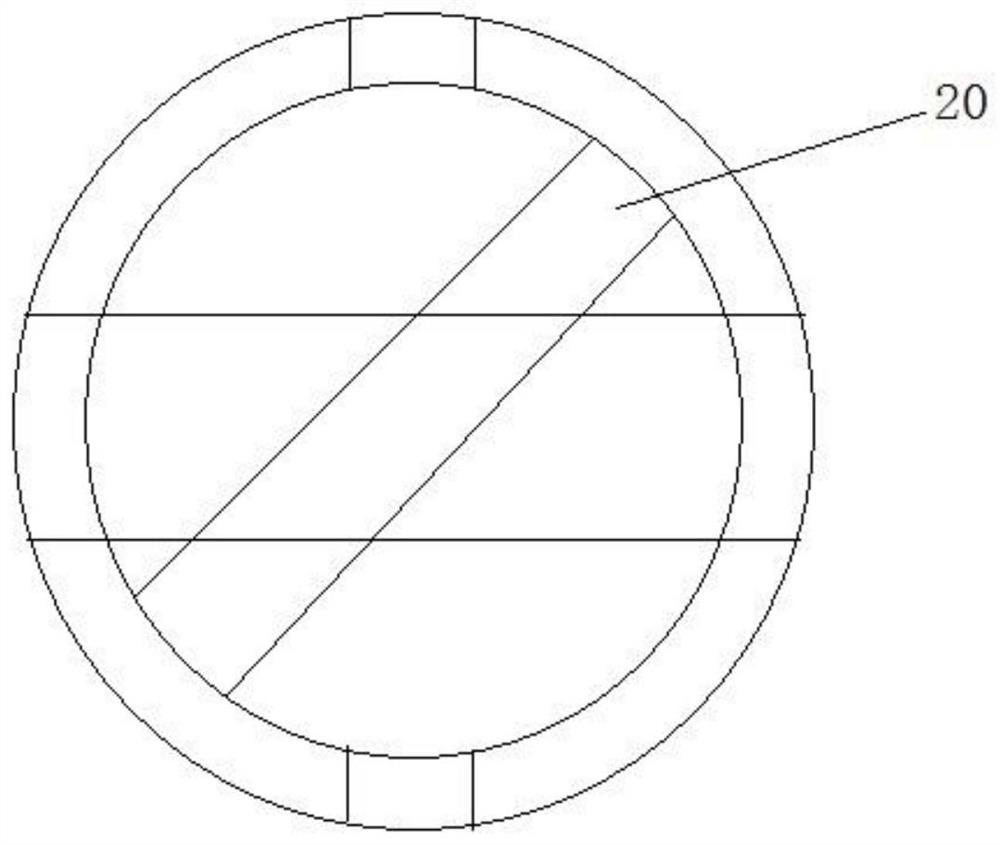

[0044] As shown in the figure: a three-speed four-wave waveform easy-to-install valve, including a left valve body, a right valve body, a servo motor, a lifting cover, a left pull ring, a motor shaft, a right pull ring, a sensing module, and a seal , waveform control sleeve, main spool, threaded cover, lower drive piece, shock absorber, threaded pipe, lower output shaft; wherein the waveform control sleeve includes outer square hole one, outer square hole two, outer oval hole one 1. Outer oval hole two; the main valve core includes an inner square channel and an inner elliptical channel;

[0045] Wherein the lifting cover plate is detachably connected to the left valve body and the right valve body, the servo motor outputs power to the motor shaft, and the motor shaft is connected to the waveform control sleeve, the The wave control sleeve includes an upper plate and a sleeve part, the motor shaft is connected to the upper plate, the upper plate is located under the lifting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com