Integrated valve for tunnel construction

A technology of tunnel construction and integrated valves, which is applied in tunnels, tunnel linings, valve details, etc., can solve the problems of material backflow into air ducts, nozzle vibration, difficult accelerators, etc., and achieve the effect of uniform wind diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

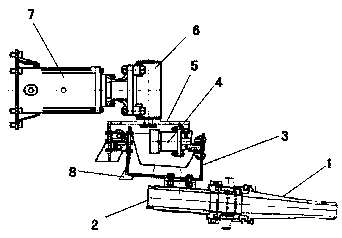

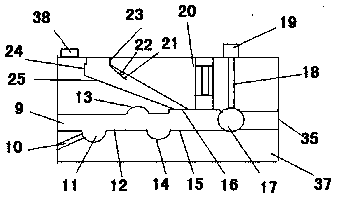

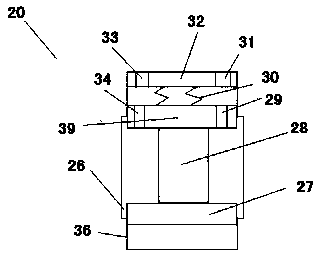

[0038] As shown in the figure: an integrated valve for tunnel construction, including concrete inlet, accelerator inlet, mixing part, diameter shrinkage part, diameter expansion part, direction change part, confluence pipe, buffer convex cavity, valve core, valve stem, Valve driver, pressure relief valve, air valve plate, bump, air duct connection port, air duct sinking part, inclined air duct, integrated valve outlet, integrated block body, integrated block connector; the pressure relief valve includes the following Piston, piston rod, upper piston, upper piston hole, spring, bonnet, bonnet hole, pressure relief valve cavity, expansion cavity;

[0039] As shown in the figure: the concrete inlet is set below the centerline of the left wall of the integrated block, the accelerator inlet is arranged below the concrete inlet, the right end of the concrete inlet is connected to the mixing part, and the upper end of the mixing part is flush with the upper end of the concrete inlet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com