Working method of rigid-flexible coupling airborne loading combined buffer device

A cushioning device, rigid-flexible coupling technology, applied in the direction of launching devices, transportation and packaging, aircraft parts, etc., can solve problems such as equipment damage, airbag explosion, large rebound, etc., to meet the requirements of reducing landing attitude, improve accuracy, and enhance The effect of airborne ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

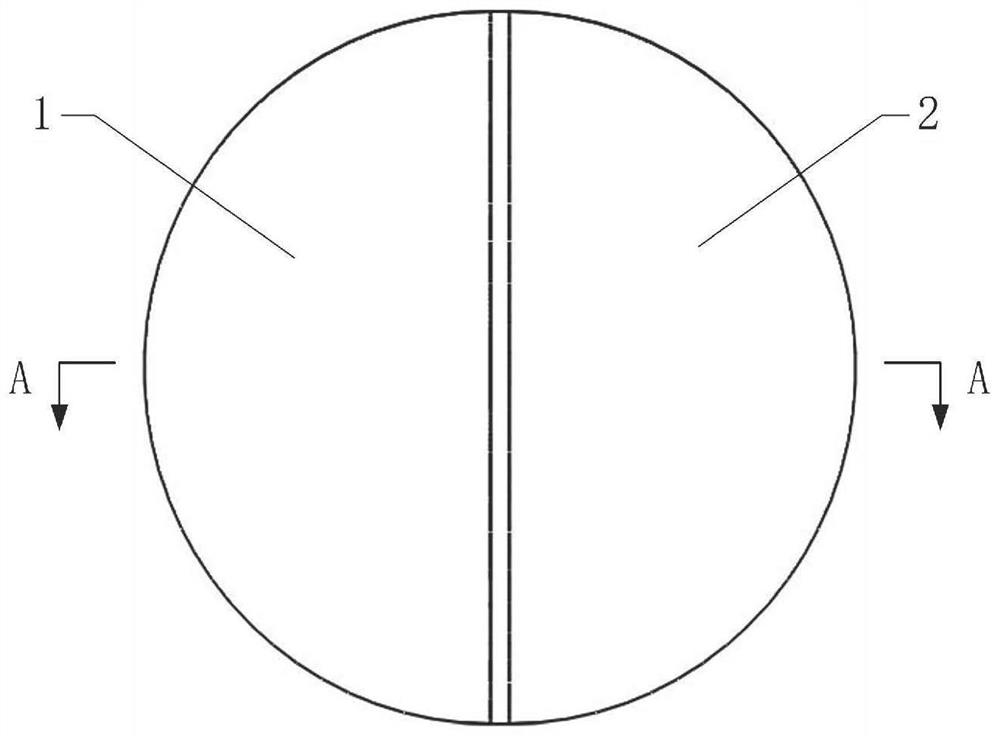

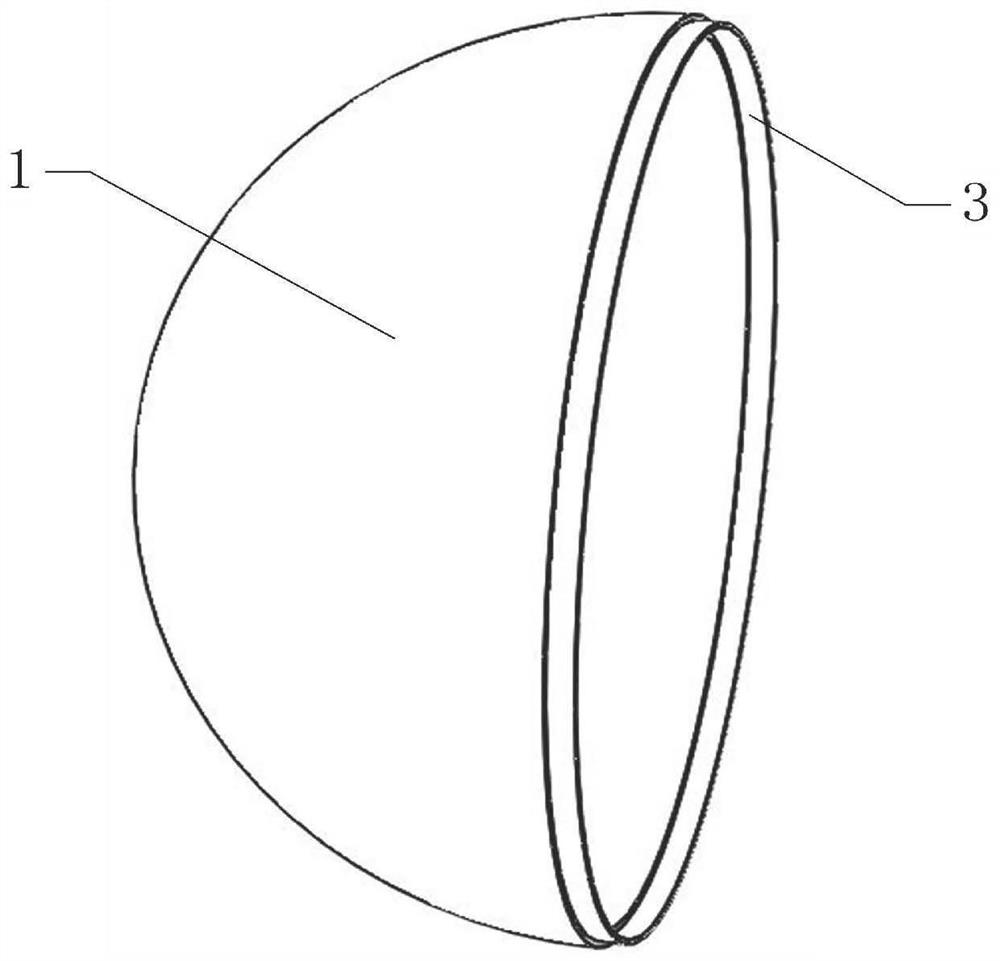

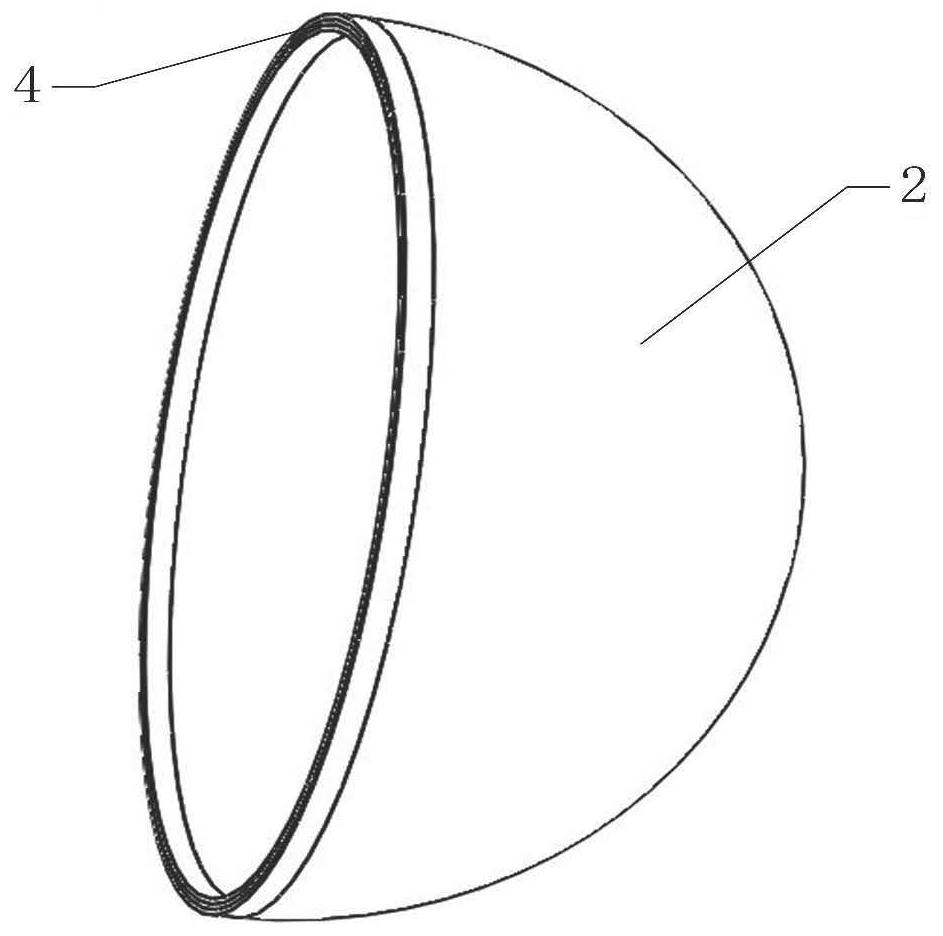

[0042] As shown in the figure: a working method of a rigid-flexible coupled airborne loading combined buffer device, the overall shape of the rigid-flexible coupled airborne loaded combined buffering device is spherical, including an airborne material storage box 5 and an inner buffer airbag 7 , inner spherical shell, outer cushioning airbag 14 and outer spherical shell; described airborne material storage box 5, inner buffering airbag 7, inner spherical shell, outer buffering airbag 14 and outer spherical shell adopt the method of wrapping airborne materials layer by layer from inside to outside arrangement; the surface of the airborne material storage box 5 and the inner surface of the inner spherical shell are evenly arranged with eight connecting rings 16; the connecting rings 16 arranged on the described airborne material storage box 5 and the inner surface of the inner spherical shell The connecting rings 16 arranged in one-to-one correspondence, and the middle section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com