Working method of airborne load combination buffer device with gas liquid solid coupling

A buffer device and working method technology, applied in the direction of launching devices, transportation and packaging, aircraft parts, etc., can solve the problems of airdrop material damage, large rebound, and inability to adapt to airborne, etc., and achieve the effect of reducing requirements and enhancing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

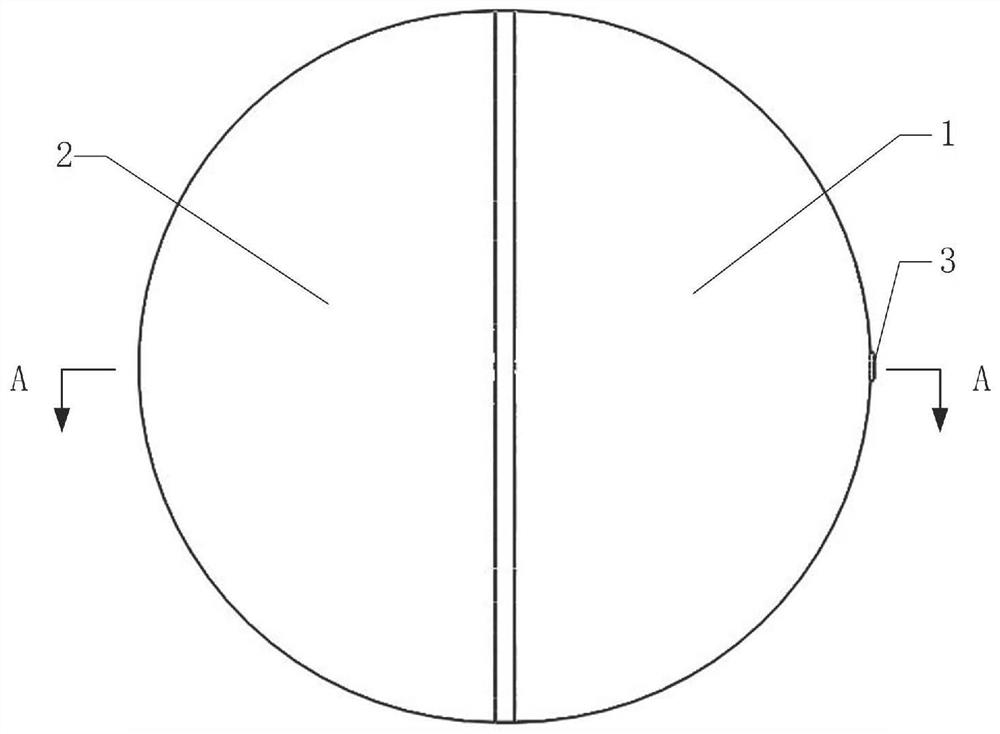

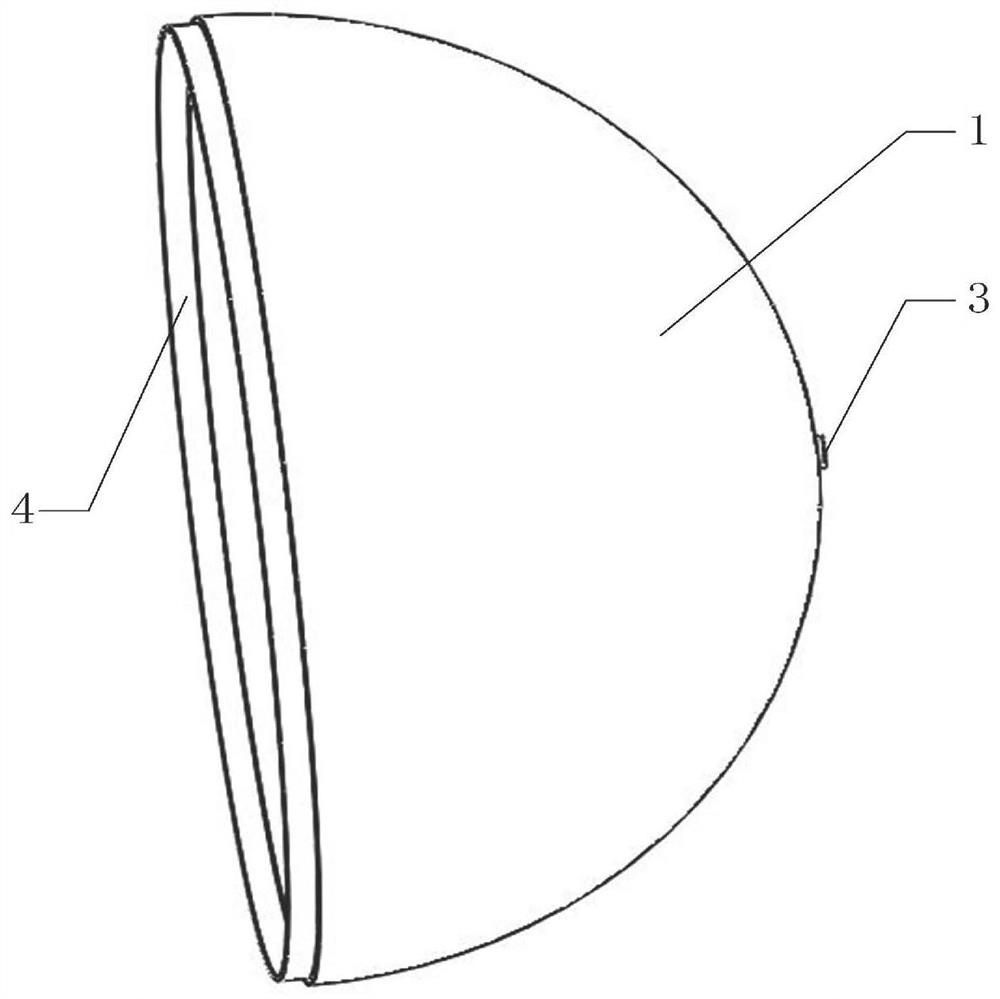

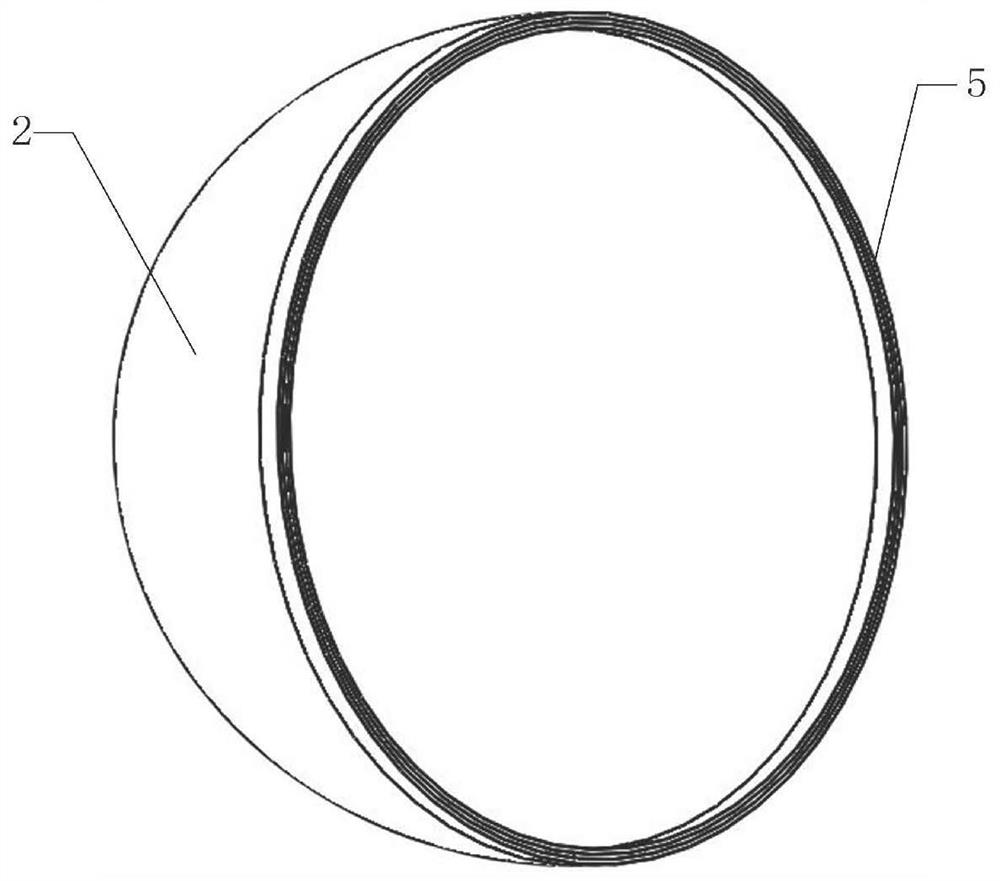

[0031] As shown in the figure: a working method of a gas-liquid-solid coupled airborne load combined buffer device, the overall shape of the gas-liquid-solid coupled airborne load combined buffer device is spherical, including an airborne material storage box 6, a buffer airbag 8. The inner spherical shell, the buffer solution and the outer spherical shell; the airborne material storage box 6, the buffer airbag 8, the inner spherical shell, the buffer solution and the outer spherical shell are arranged in a manner of wrapping the airborne material layer by layer from the inside out; The surface of the airborne material storage box 6 and the inner surface of the inner spherical shell are evenly arranged with eight connecting rings 16; One corresponds, and the middle section of each pair of corresponding connecting rings 16 is on the same plane, so as to be connected with the buffer spring 7; the two ends of each buffer spring 7 are all provided with buffer spring tail hooks 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com