Gas-liquid-solid coupled airborne loading combined buffer device

A buffer device, gas-liquid-solid technology, applied in launch devices, transportation and packaging, aircraft parts, etc., can solve the problems of direct contact of airdrop equipment, single structure, airbag explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

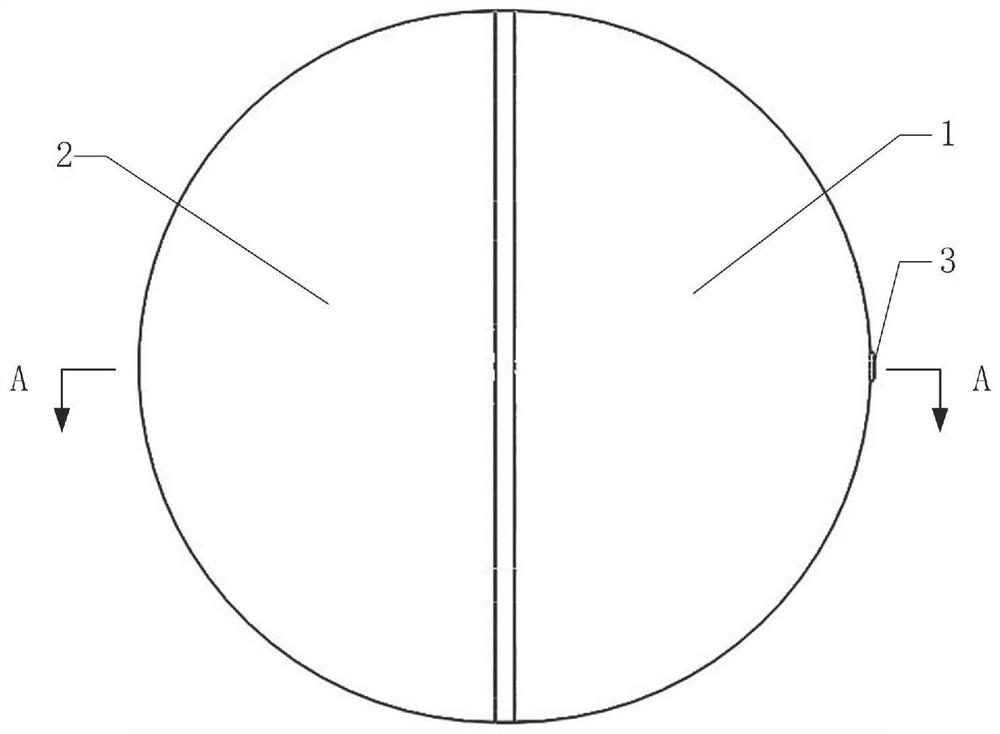

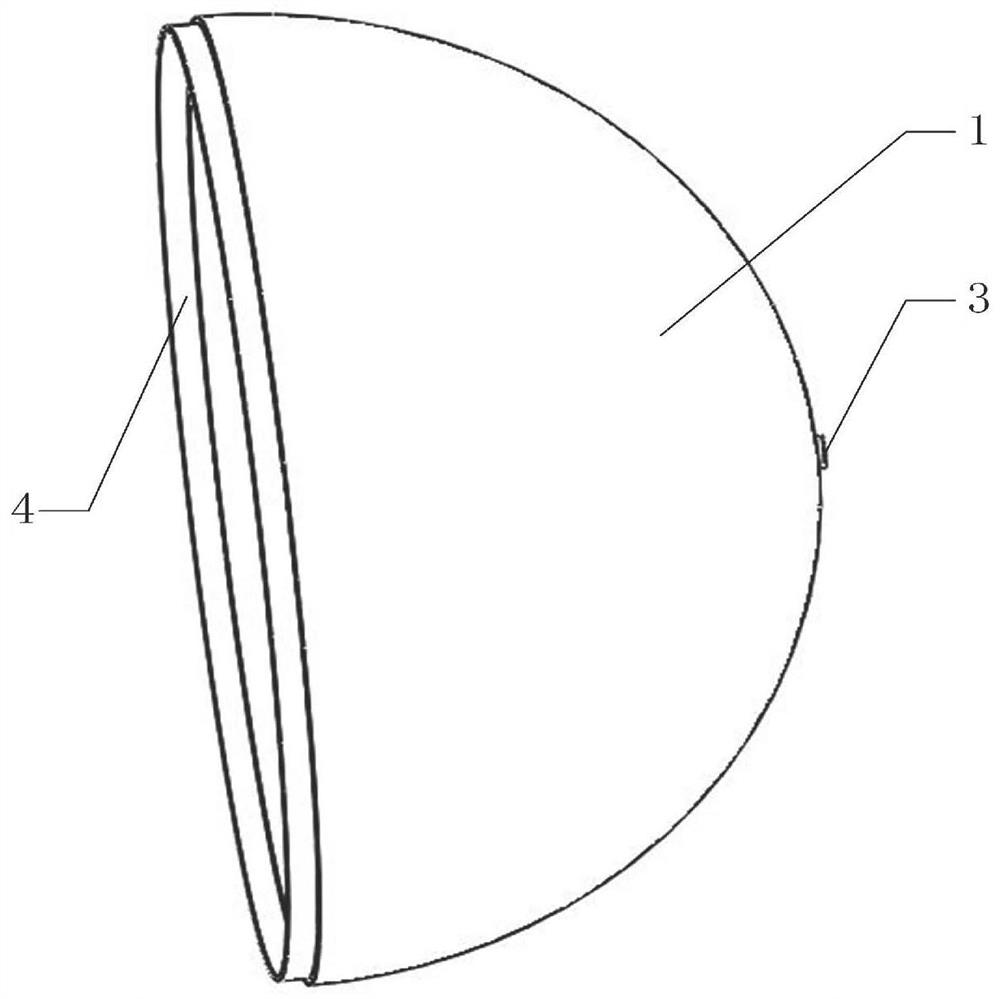

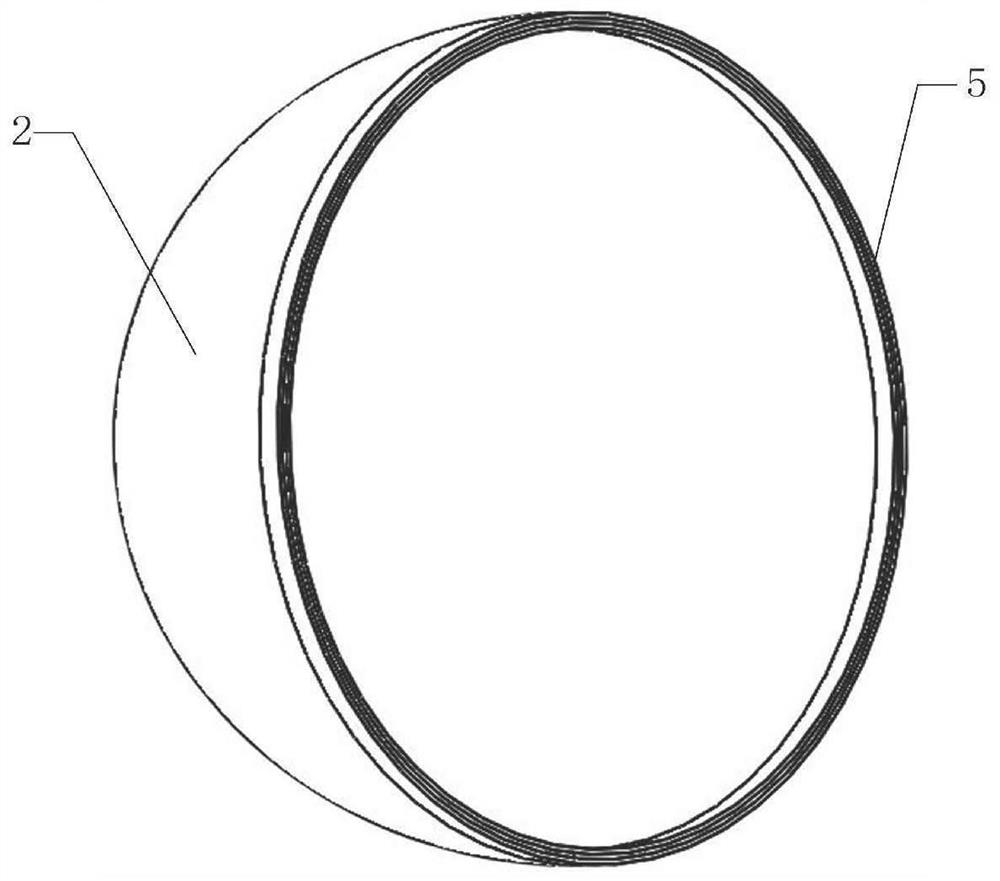

[0030] As shown in the figure: a gas-liquid-solid coupling airborne load combined buffering device, the airborne load combined buffering device is spherical in overall shape, including an airborne material storage box 6, a buffer airbag 8, an inner spherical shell, and a buffer liquid And the outer spherical shell; the airborne material storage box 6, the buffer airbag 8, the inner spherical shell, the buffer liquid and the outer spherical shell are arranged in a manner of wrapping airborne materials layer by layer from the inside to the outside; the surface of the airborne material storage box 6 and Eight connecting rings 16 are uniformly arranged on the inner surface of the inner spherical shell; the connecting rings 16 arranged on the airborne material storage box 6 correspond to the connecting rings 16 arranged on the inner surface of the inner spherical shell, and each pair corresponds to each other The middle section of the connecting ring 16 is on the same plane to connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com