Multi-stage airbag cooperative buffering seat for airborne occupant

A passenger and airbag technology, applied in the field of manned airborne safety protection, can solve the problems of secondary collision between the human body and the chariot, slow outward exhaust speed, airborne crew damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

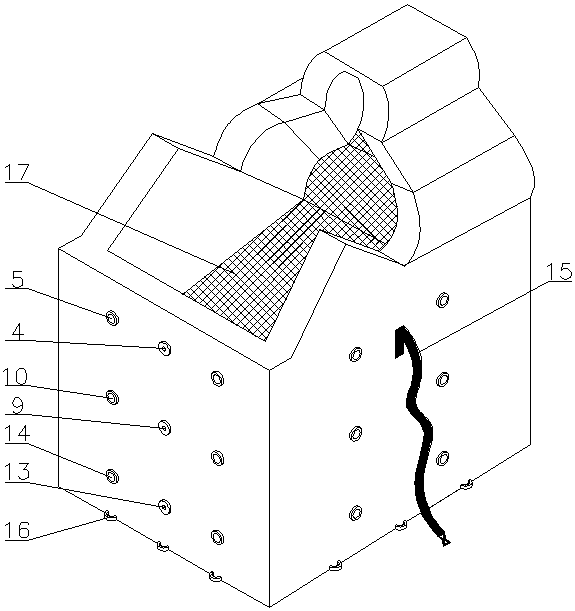

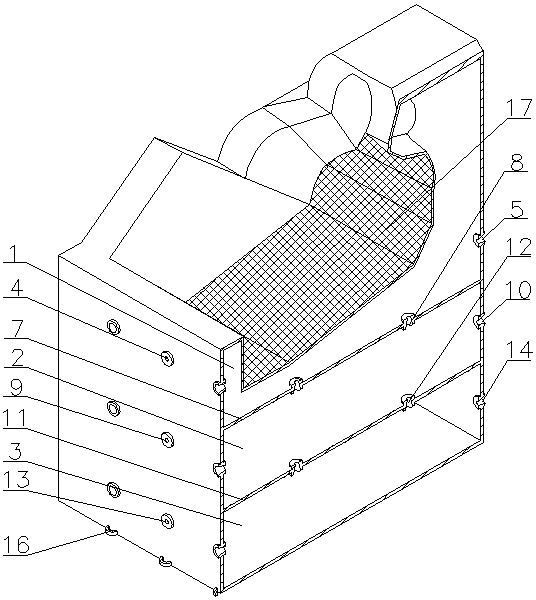

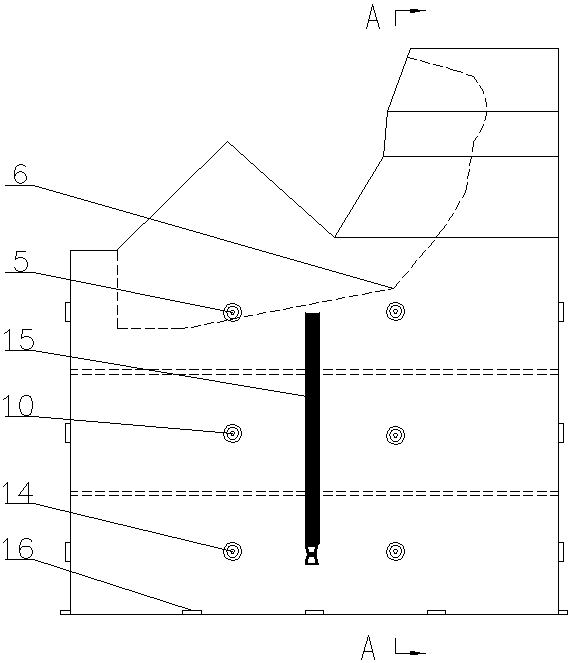

[0032] As shown in the figure: a multi-stage airbag cooperative cushion seat for airborne occupants, including an upper air chamber 1, a middle air chamber 2 and a lower air chamber 3; the upper air chamber 1, middle air chamber 2 and lower air chamber 3 adopt Arranged from top to bottom; the upper air chamber 1 is provided with an upper air chamber concave platform 6 that matches the best landing posture of the airborne crew; the upper air chamber 1 surface is provided with an upper air chamber inflation valve 4, and the upper air chamber 1 surface is provided with eight upper air chamber exhaust valves 5, an air chamber diaphragm-7 is arranged between the upper air chamber 1 and the middle air chamber 2, and four joint exhaust valves-8 are arranged on the air chamber diaphragm-7.

[0033] As shown in the figure: a middle air chamber inflation valve 9 is arranged on the surface of the middle air chamber 2, eight middle air chamber exhaust valves 10 are arranged on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com