Patents

Literature

378 results about "Container tops" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

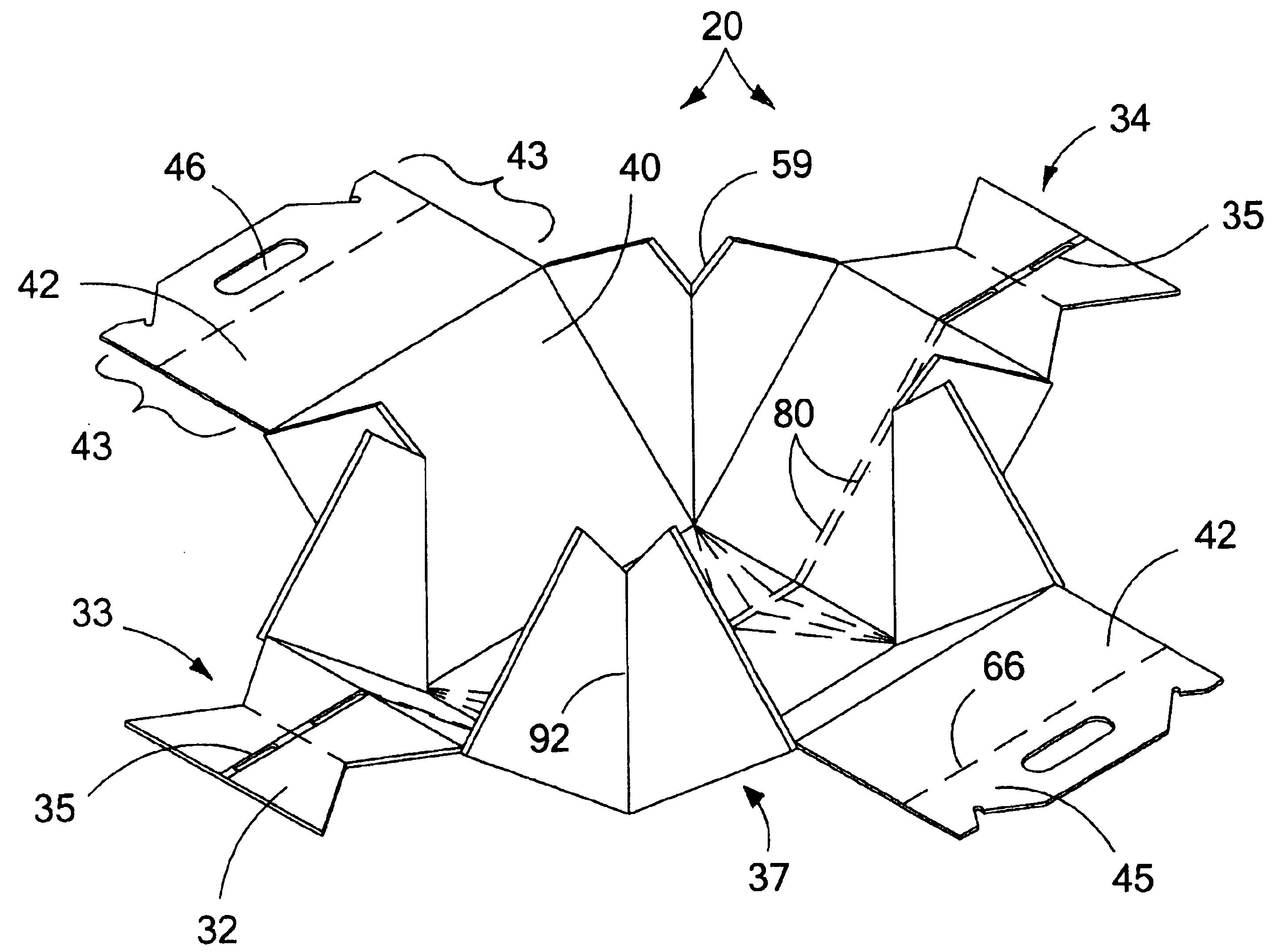

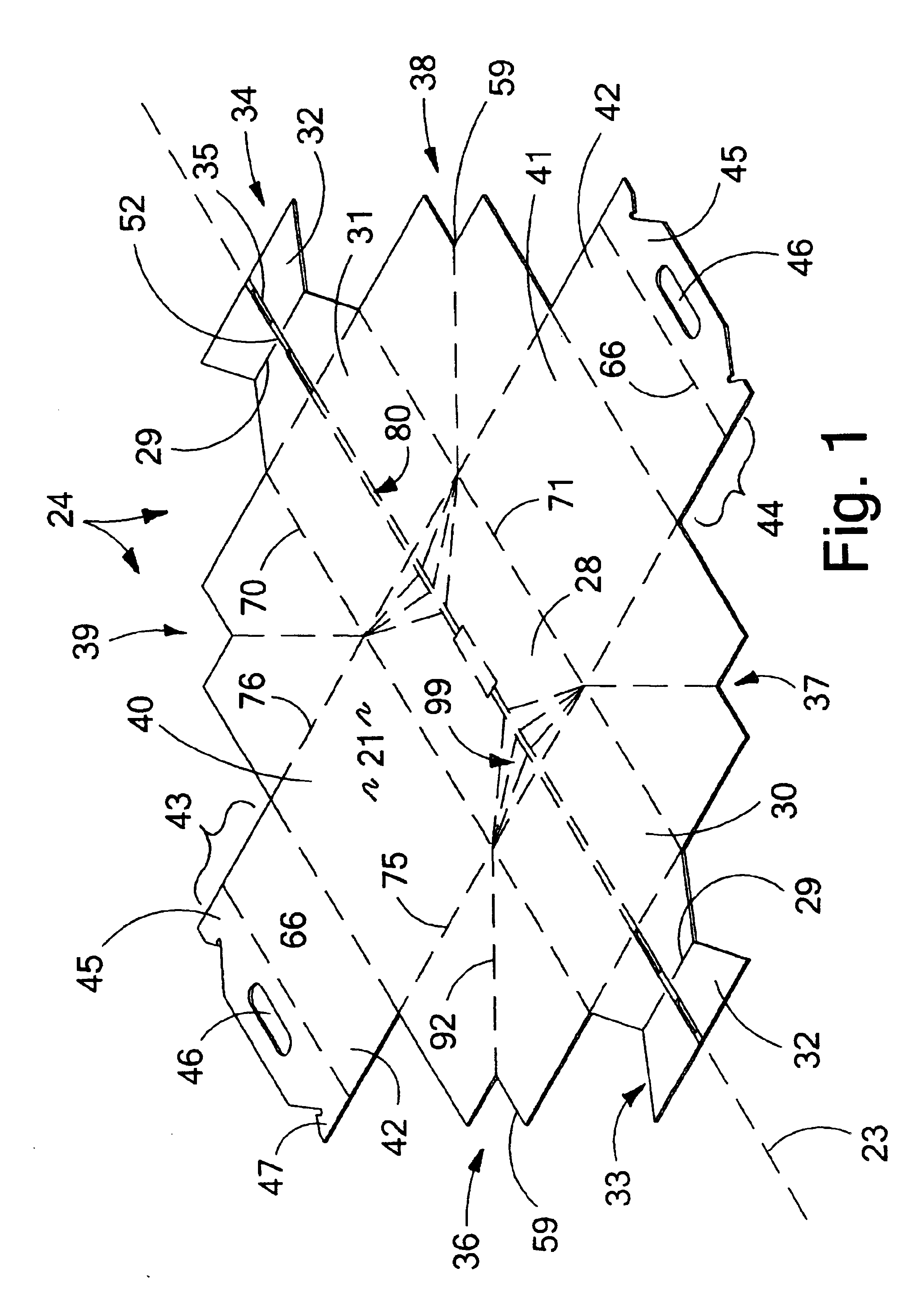

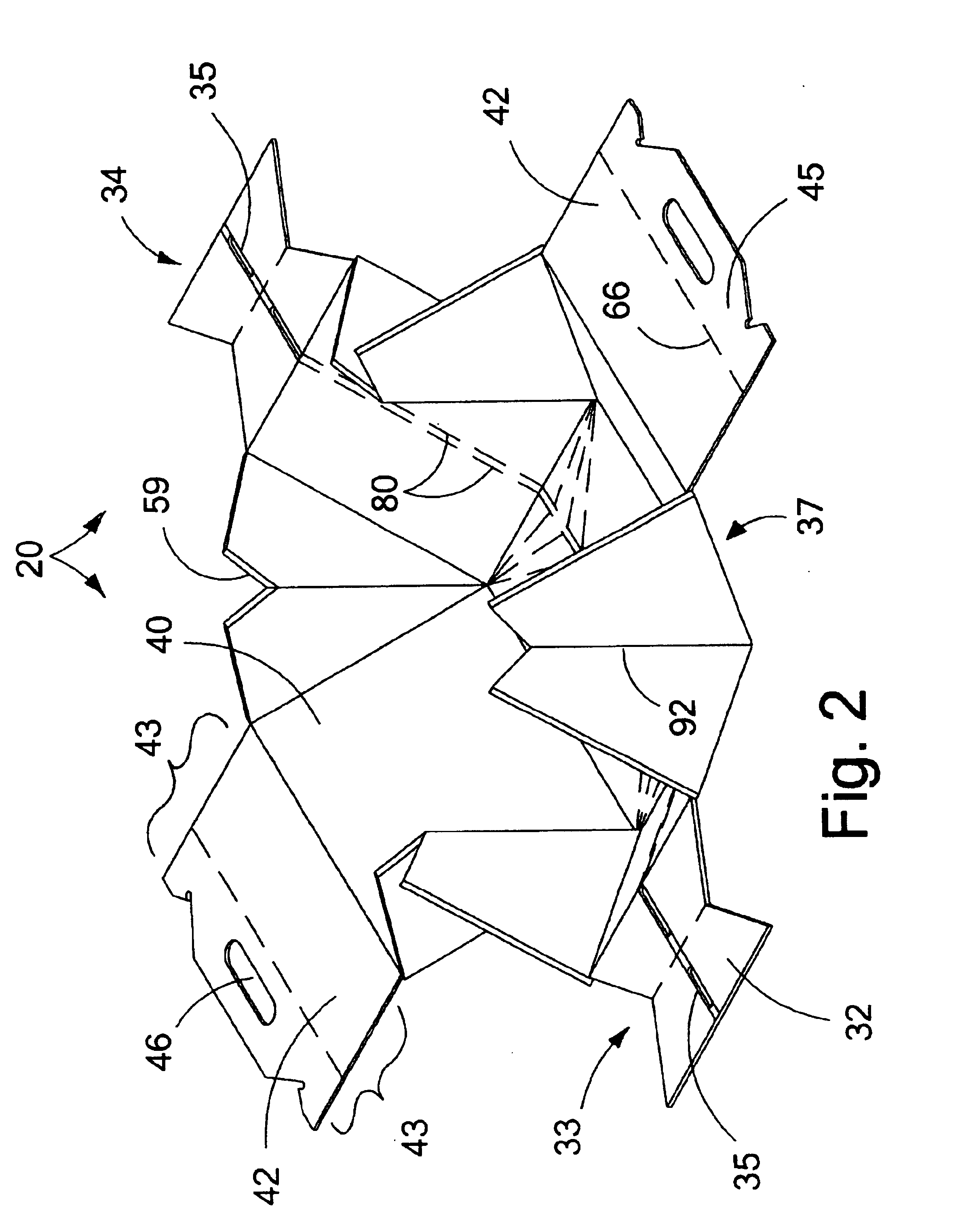

Foldable portable cooler with enhanced over-center locking handle

InactiveUS6837420B2Deployed quickly and efficientlyStrong and secure connectionLighting and heating apparatusClimate change adaptationHand heldCarton

A rugged, hand-held container for storing beverage containers is formed by folding together multiple panels defined in a pre-scored, slot-less blank. Each blank comprises a rectangular center panel integrally bordered by a pair of end panels and side panels. Integral, diametrically spaced apart corner panels interconnect the center panel with the other panels. Score lines between the adjacent panels facilitate folding. The center panel forms a cooler bottom, and blank end and side panels respectively form carton ends and sides. Each end panel has an outer locking panel comprising an elongated receptive slot. Each side panel has an integral outer handle panel comprising an inner roof segment that forms the container top and handle segments with locking tabs that are captivated within the receptive slot. A radiused locking tab ramp comprises an enlarged portion providing an overcenter action. Notches adjacent the tabs captivate the locking panels.

Owner:PRATT CORRUGATED HLDG

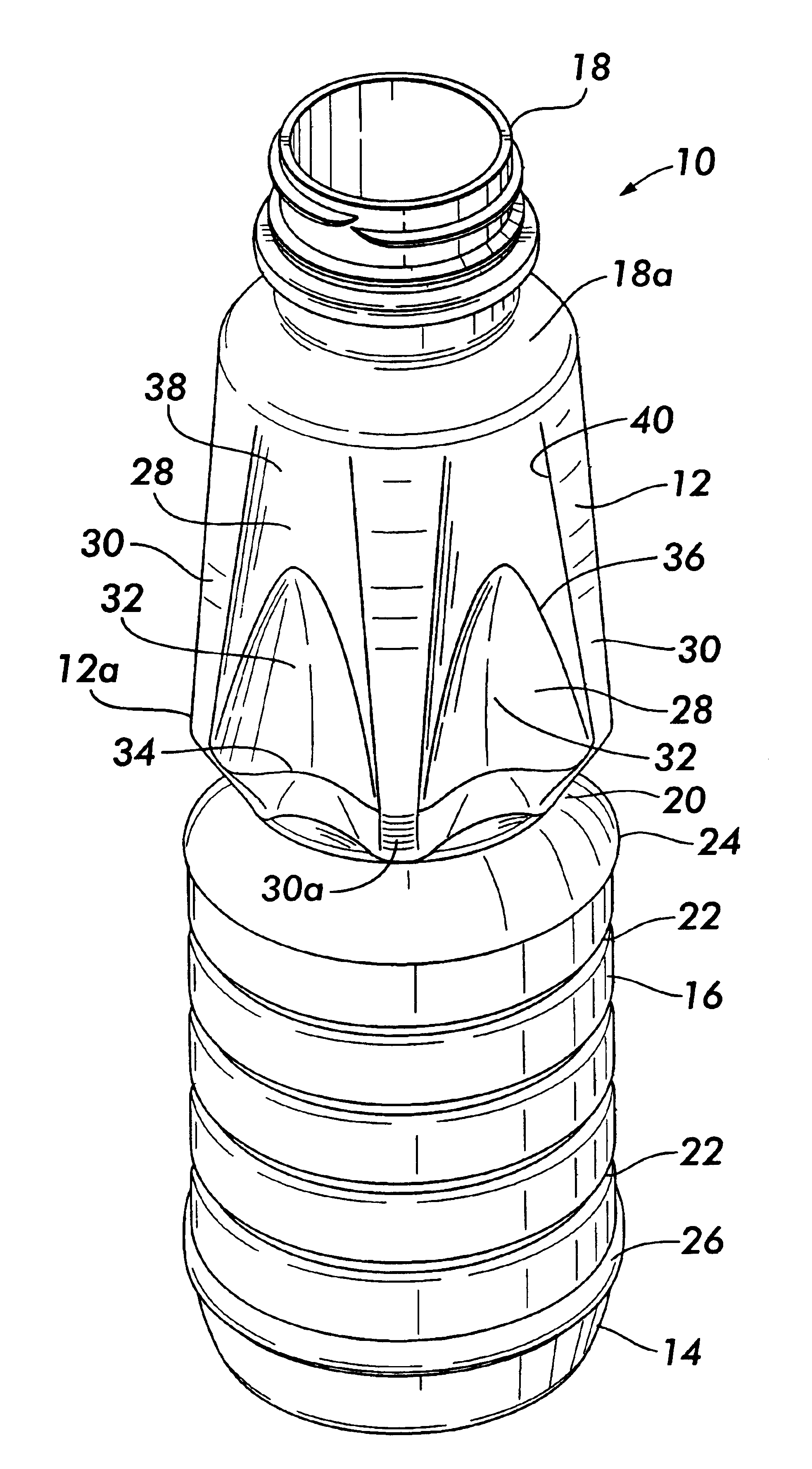

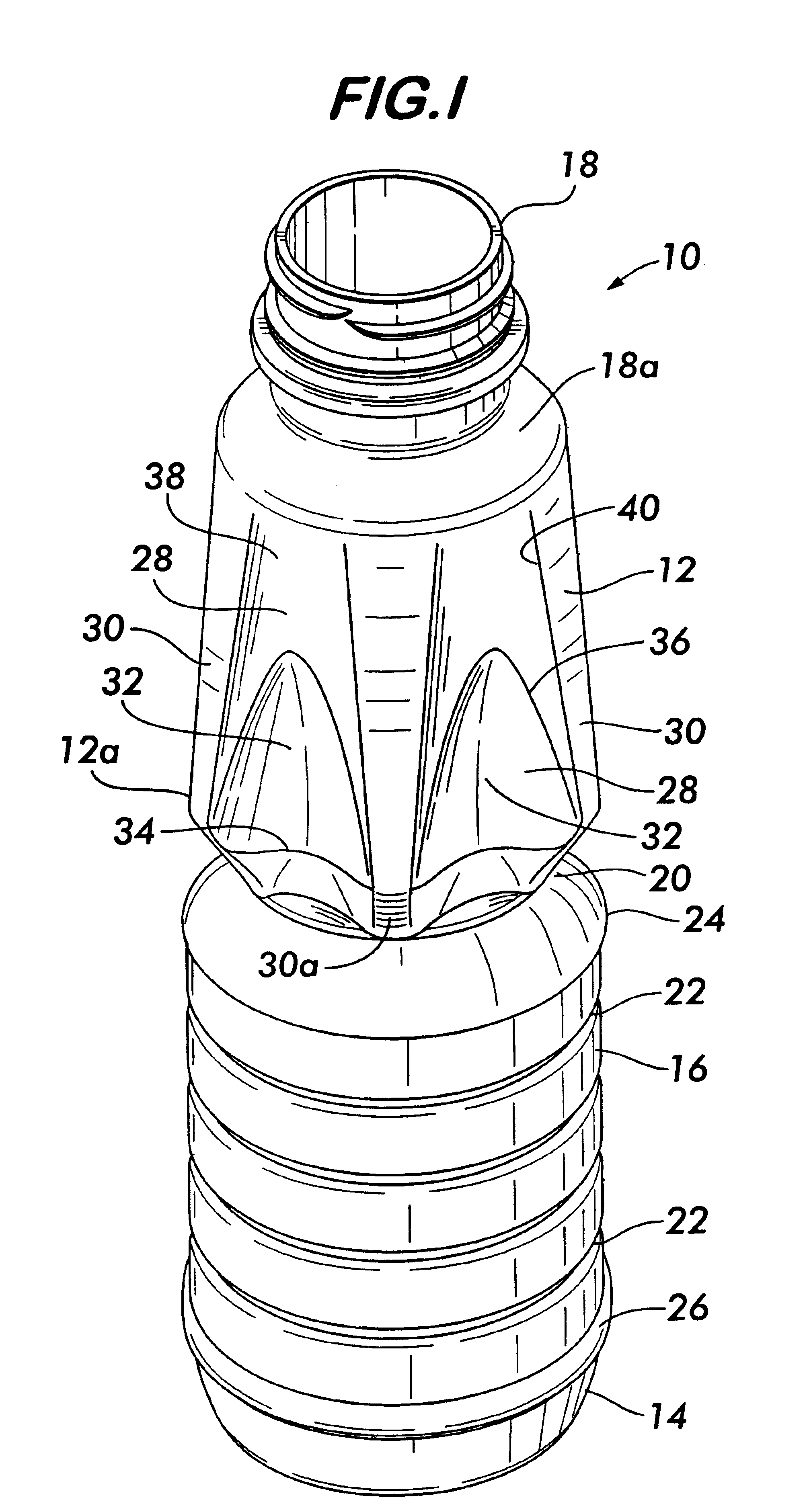

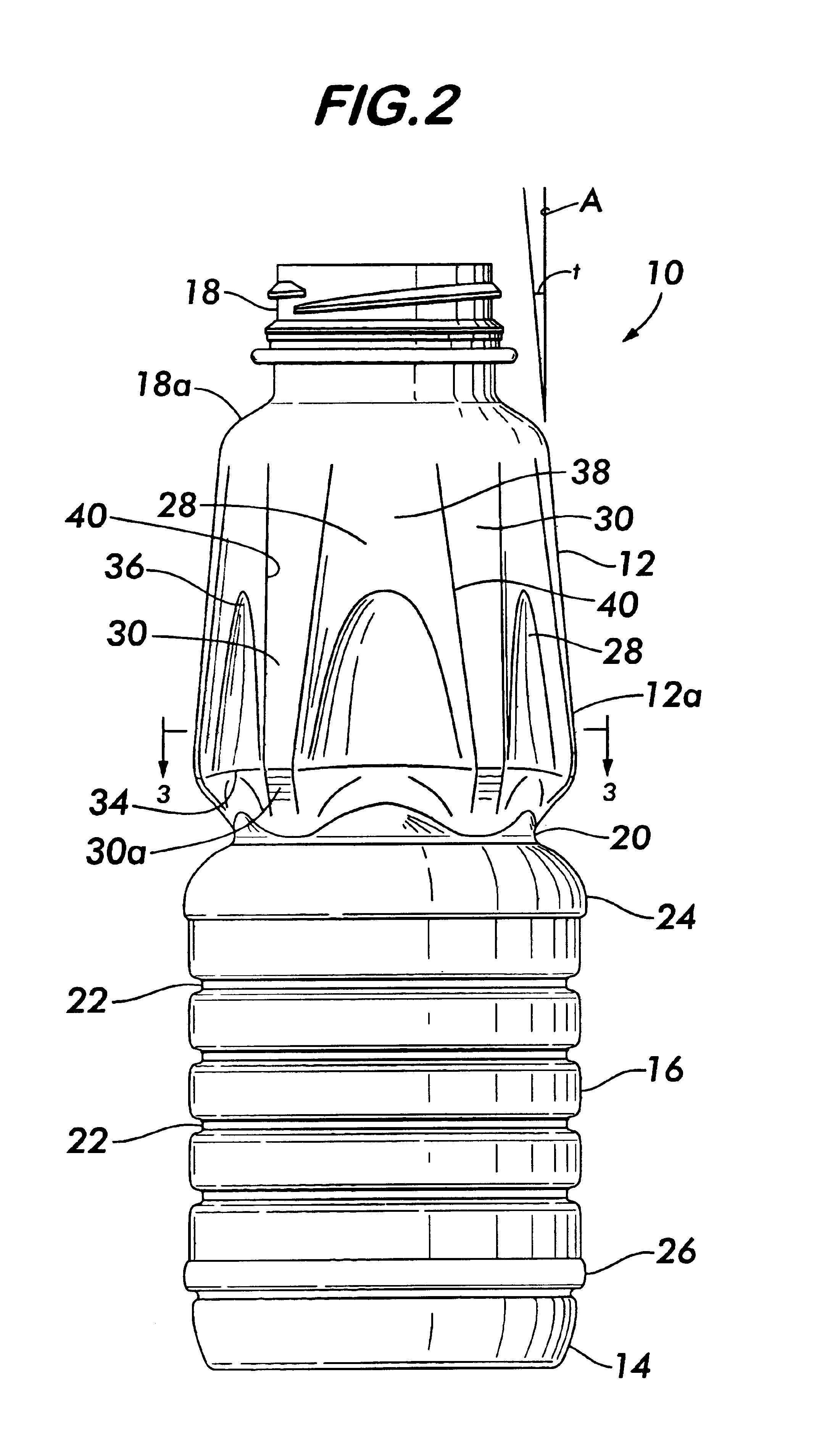

Blow molded slender grippable bottle having dome with flex panels

A blow-molded plastic bottle body for use in containing hot-filled beverages. The bottle body has a dome with various interactive functional zones. For example, some of the zones are primarily responsible for accommodating vacuum absorption, while other zones are primarily intended to rigidify the container such as by providing column strength to improve container top loading capability. Although each zone may have a primary function, each zone also aids adjacent zones in providing their functions. Thus, the entire dome, and not merely selected locations, reacts in a progressive manner to the forces generated by the hot-fill process on the bottle body. Preferably, the bottle body is slender and capable of readily being gripped by a single hand, and preferably the flex panels in the dome accommodate at least 90% of the total vacuum absorption required by the bottle.

Owner:MELROSE DAVID MURRAY

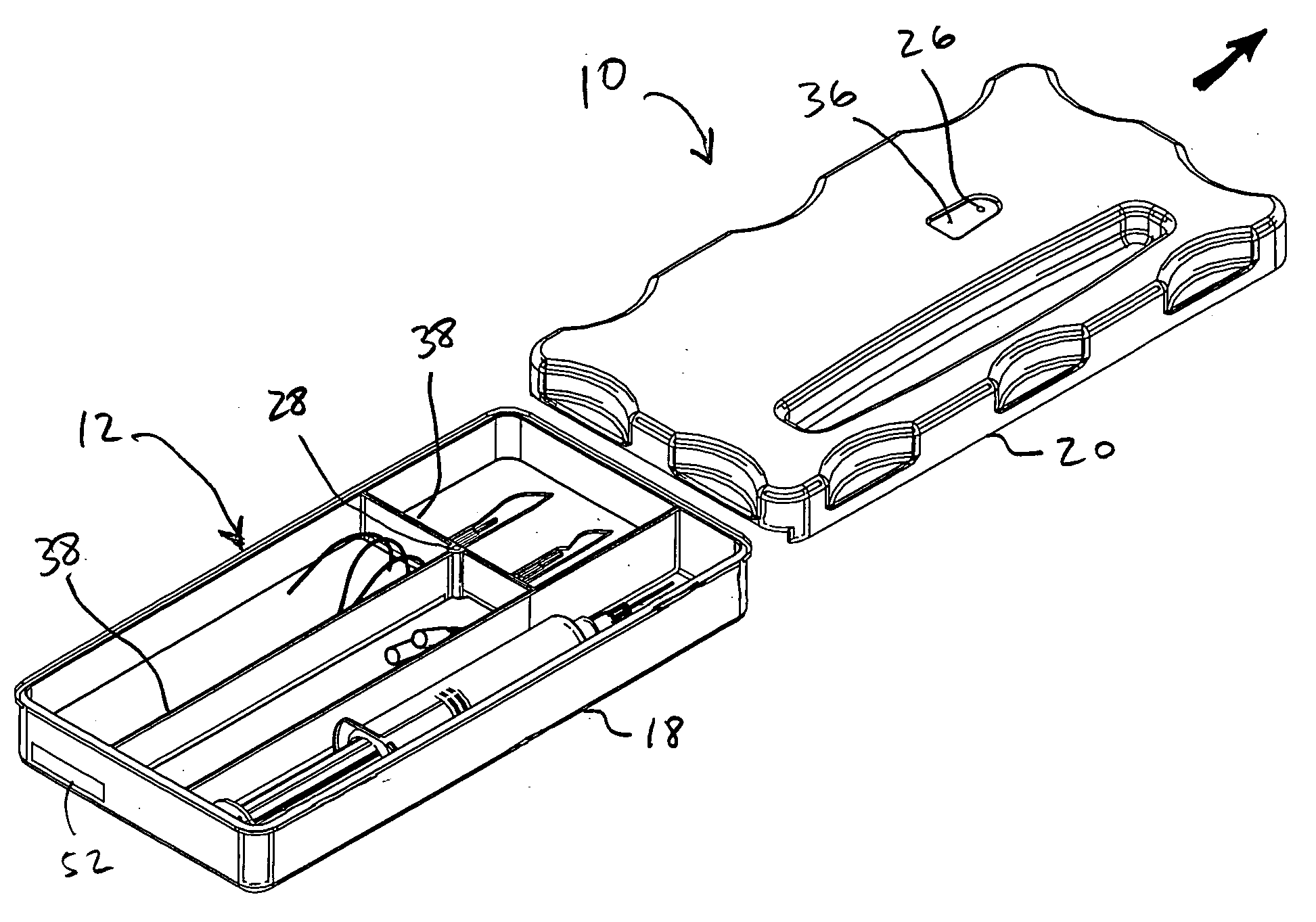

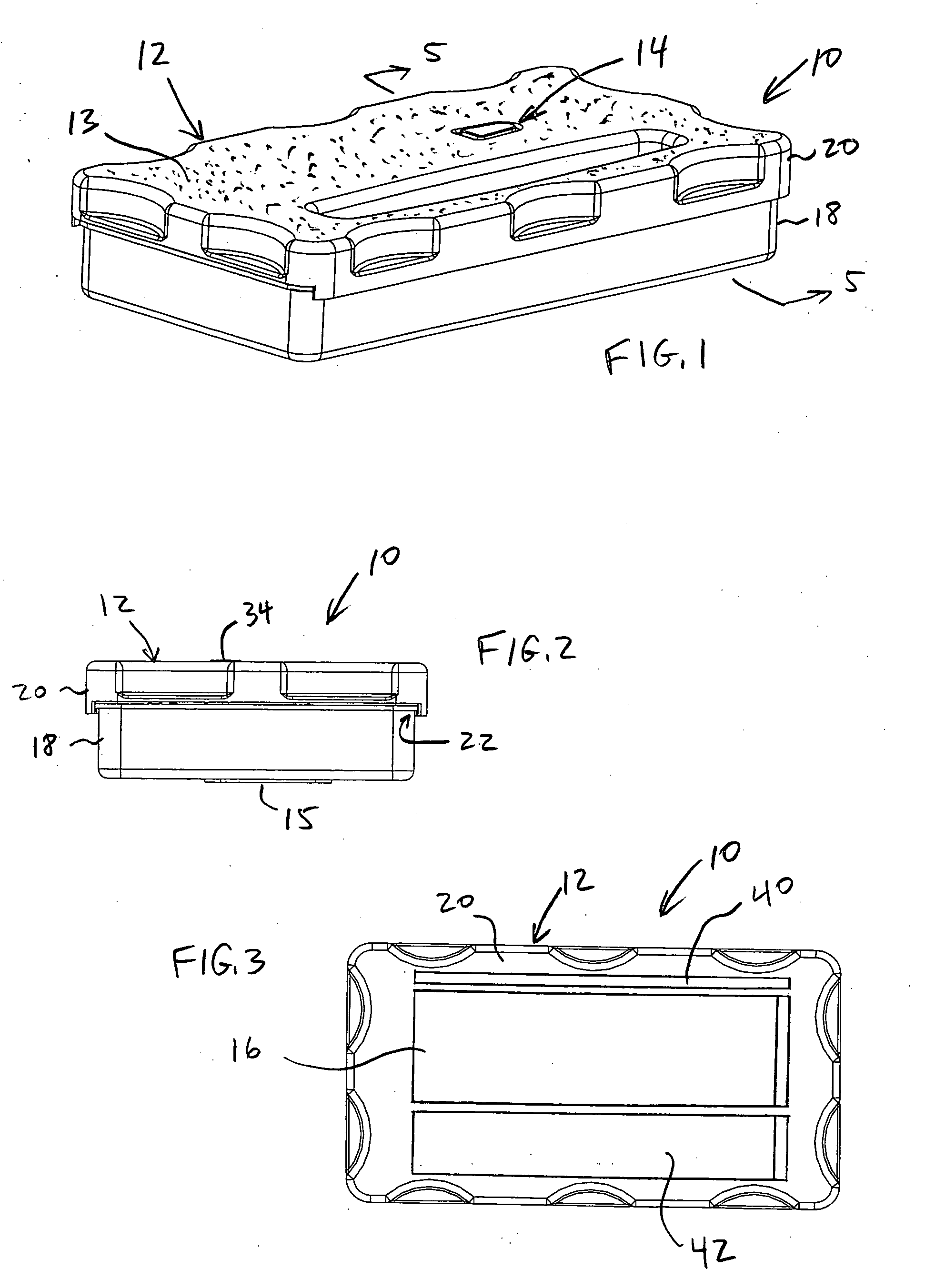

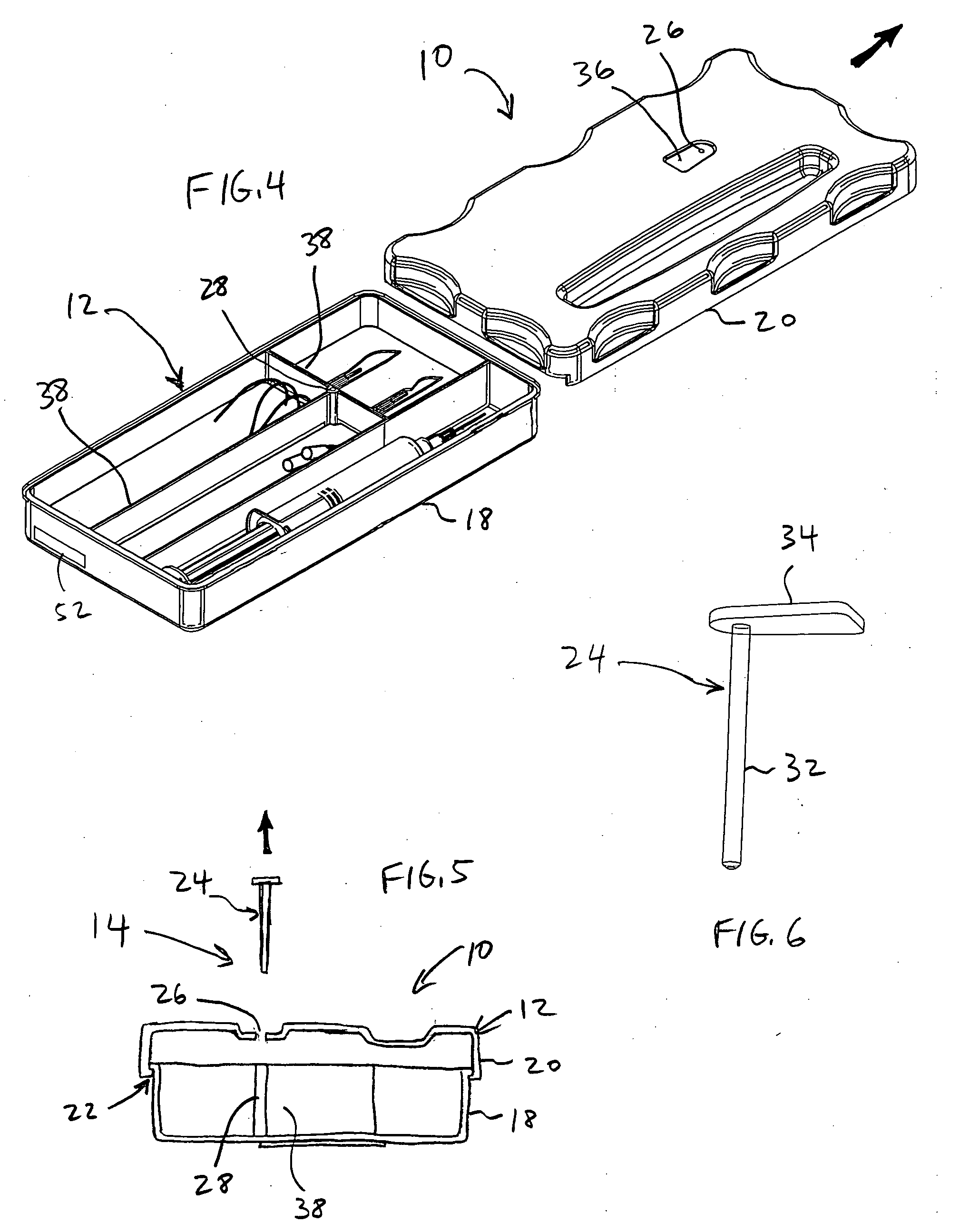

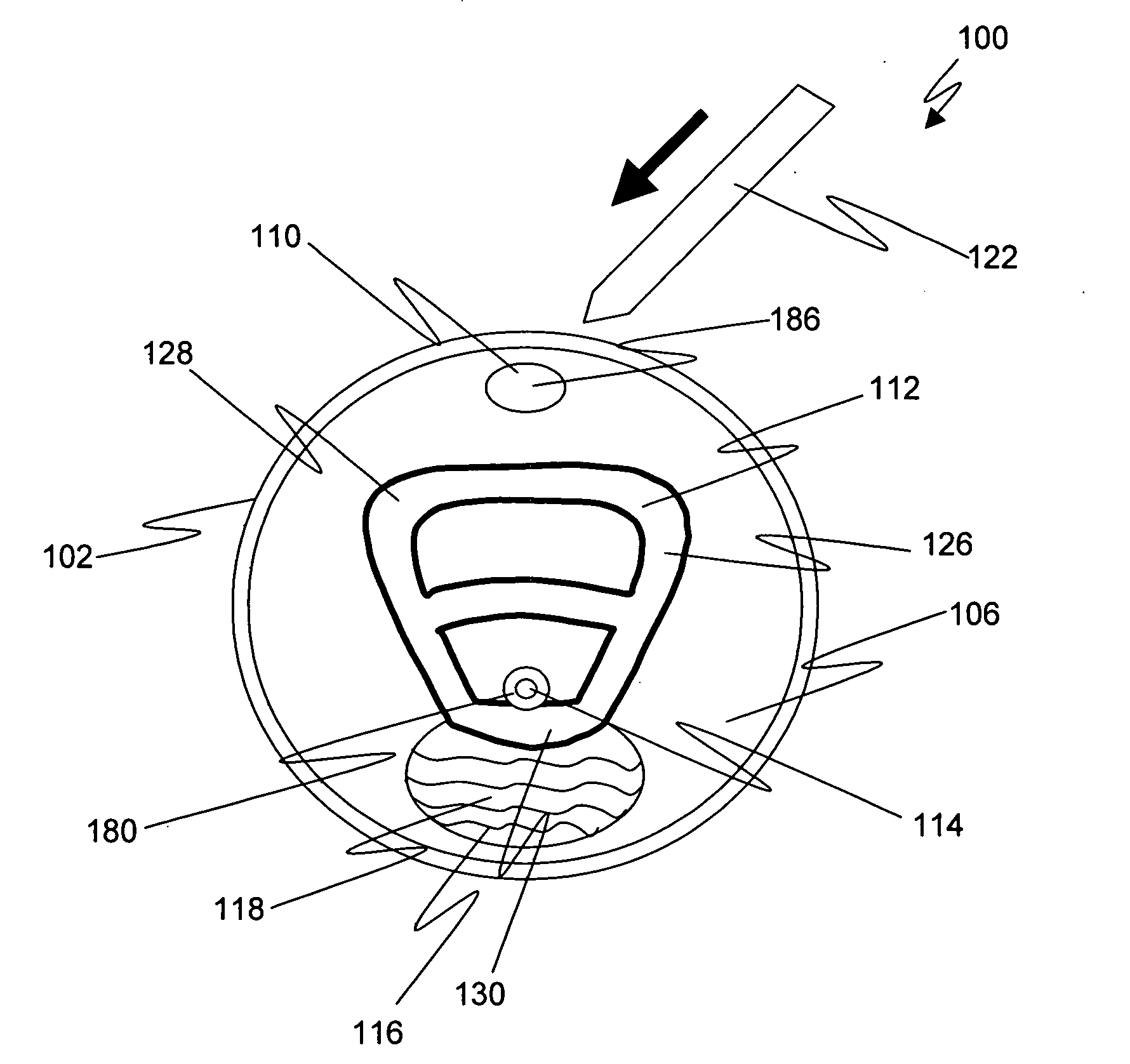

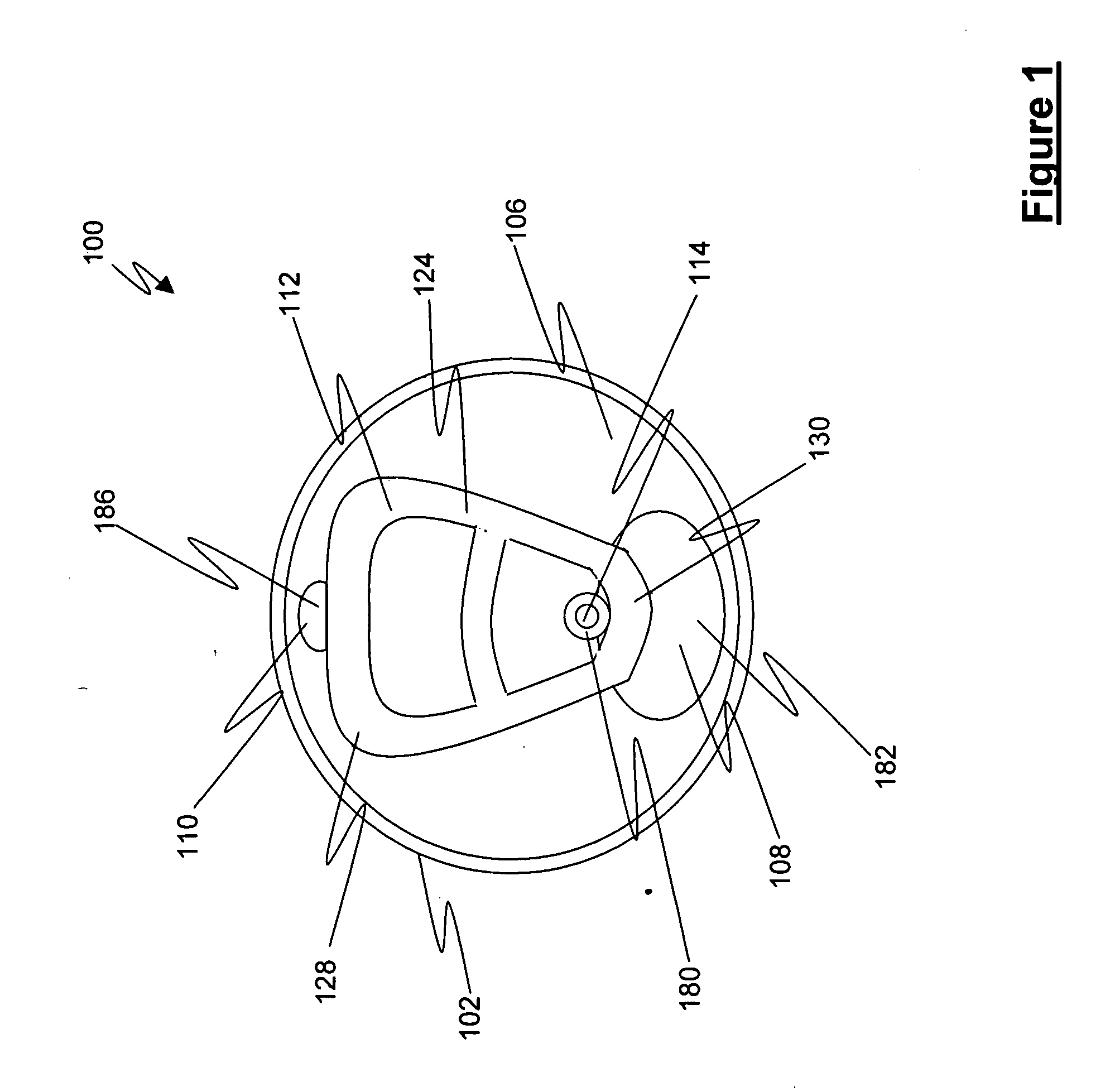

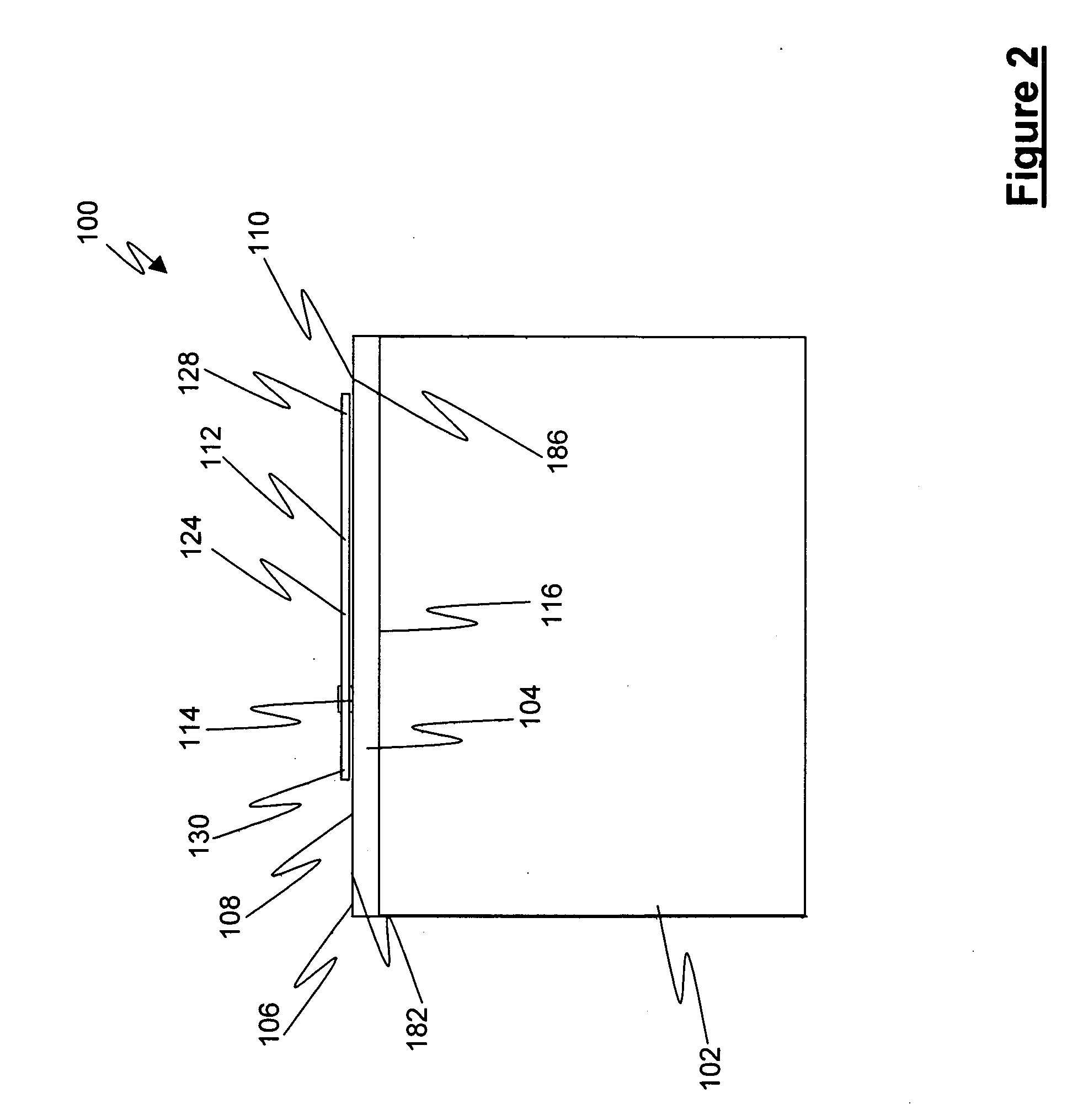

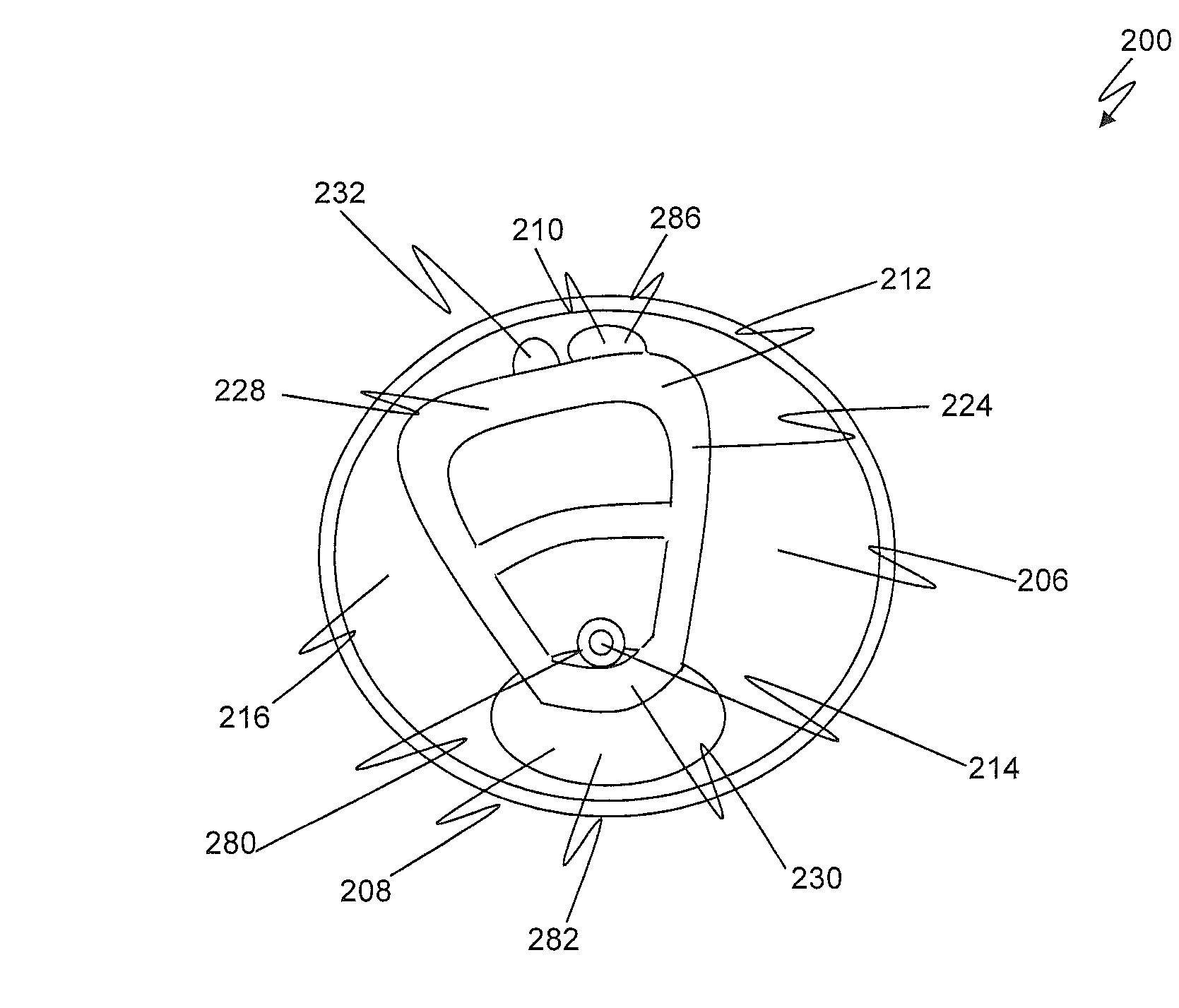

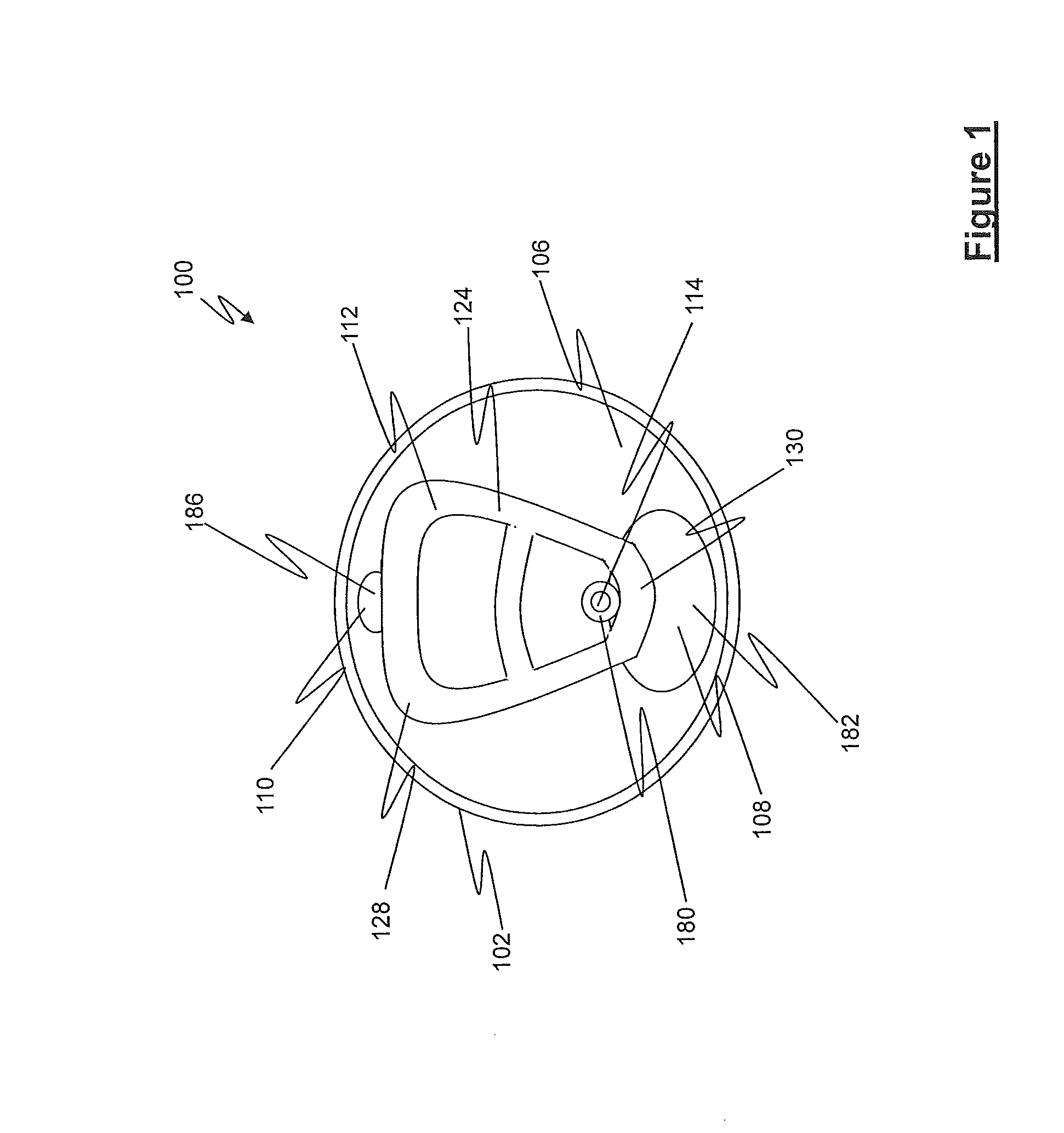

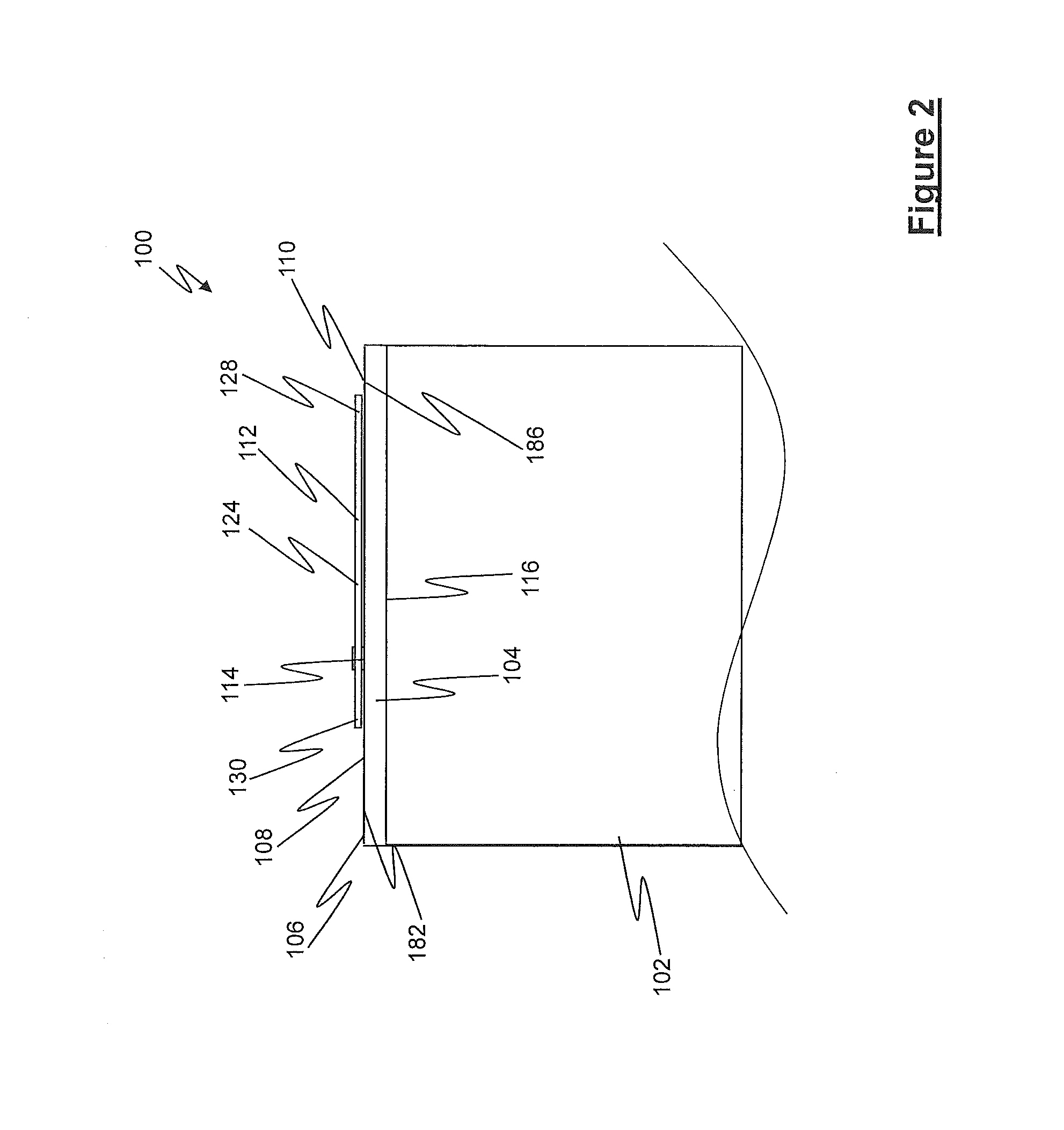

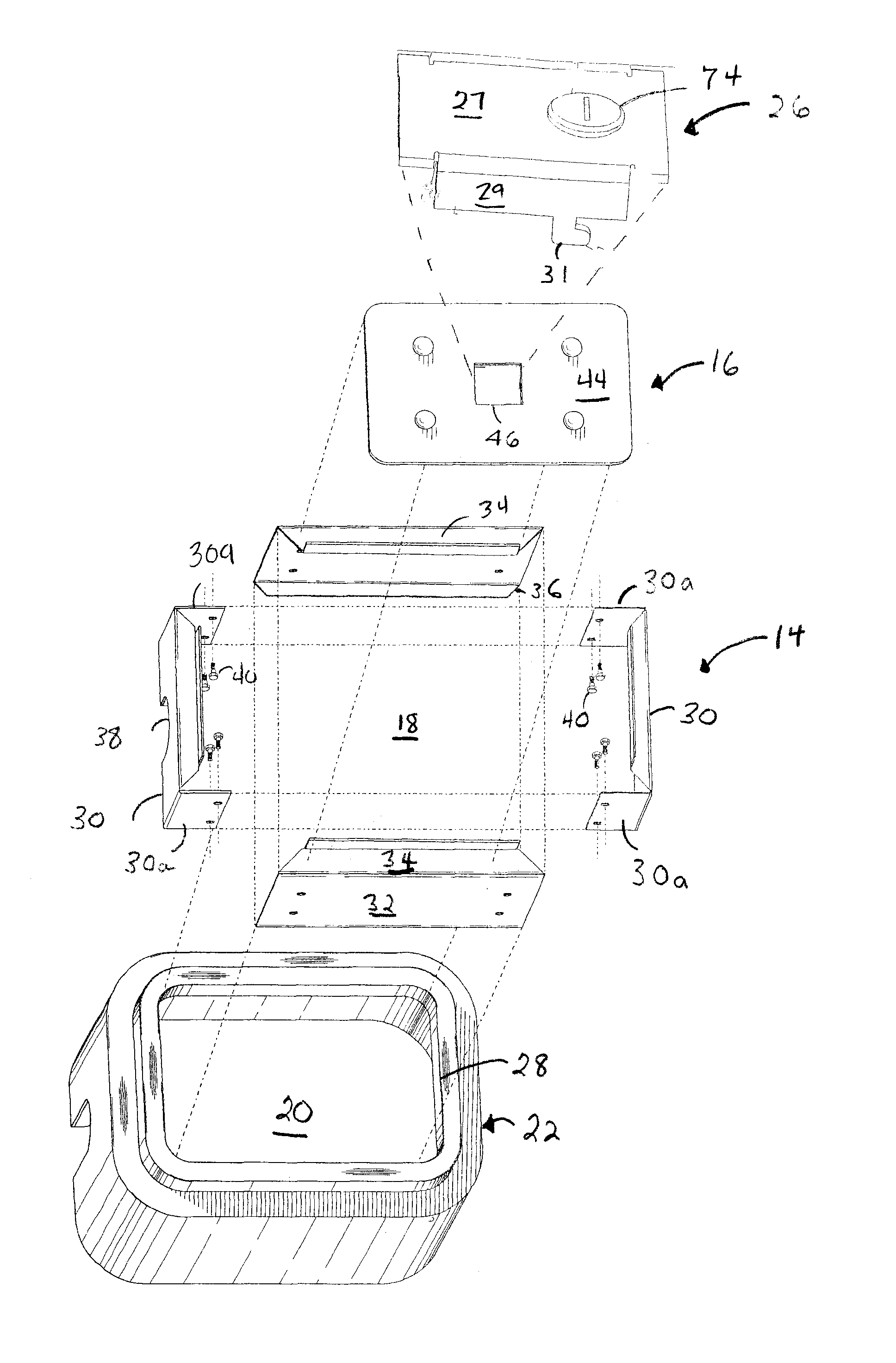

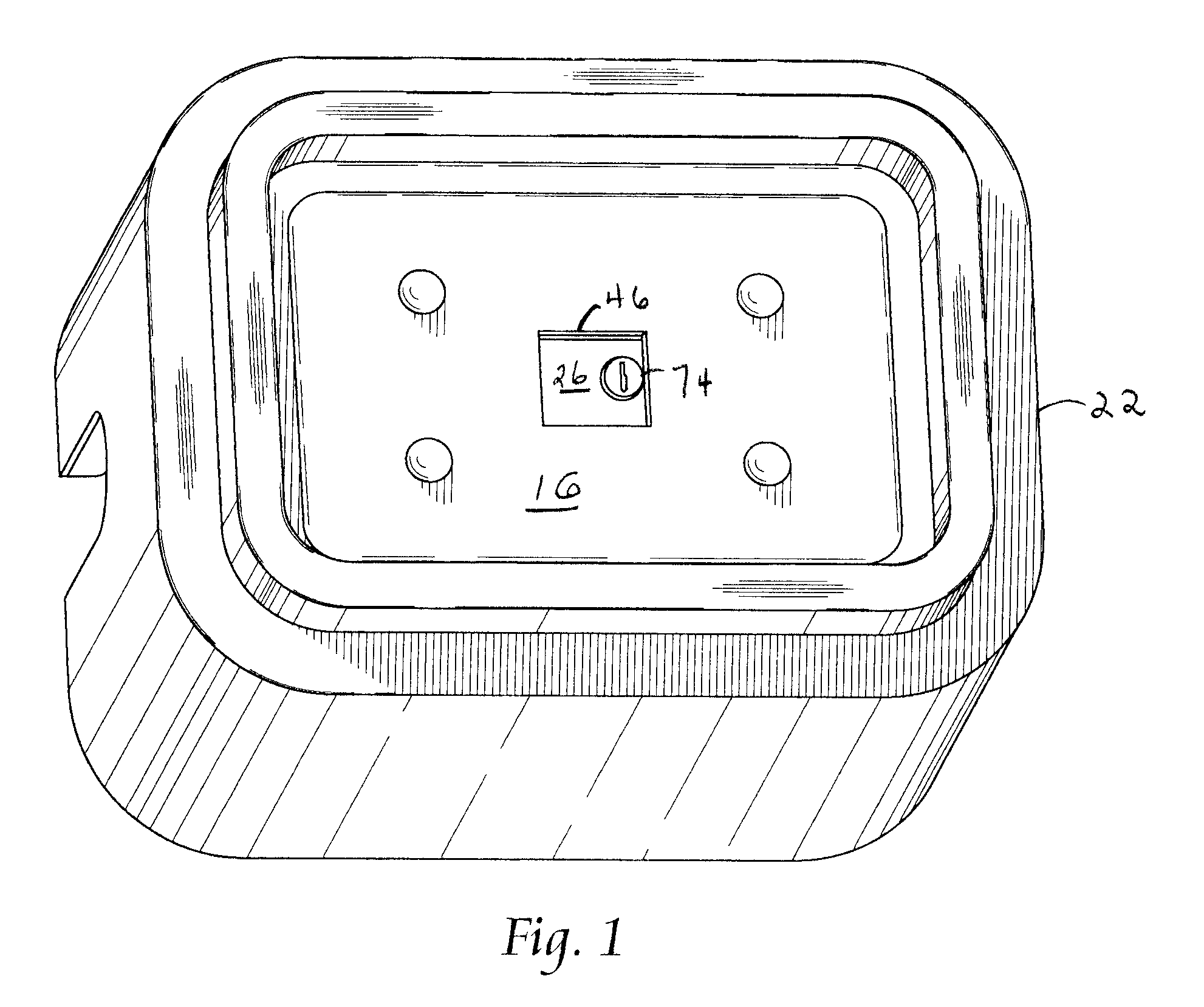

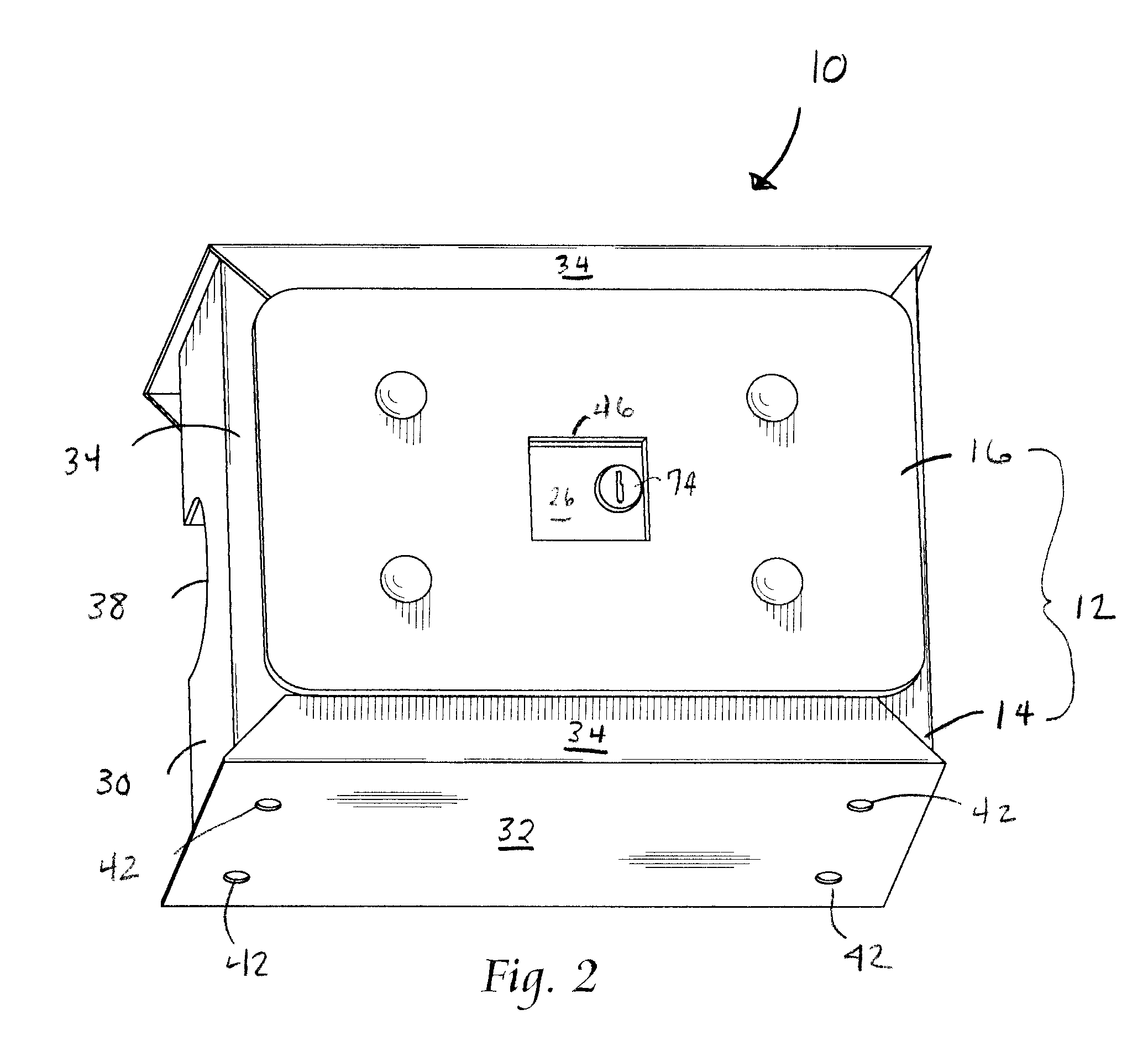

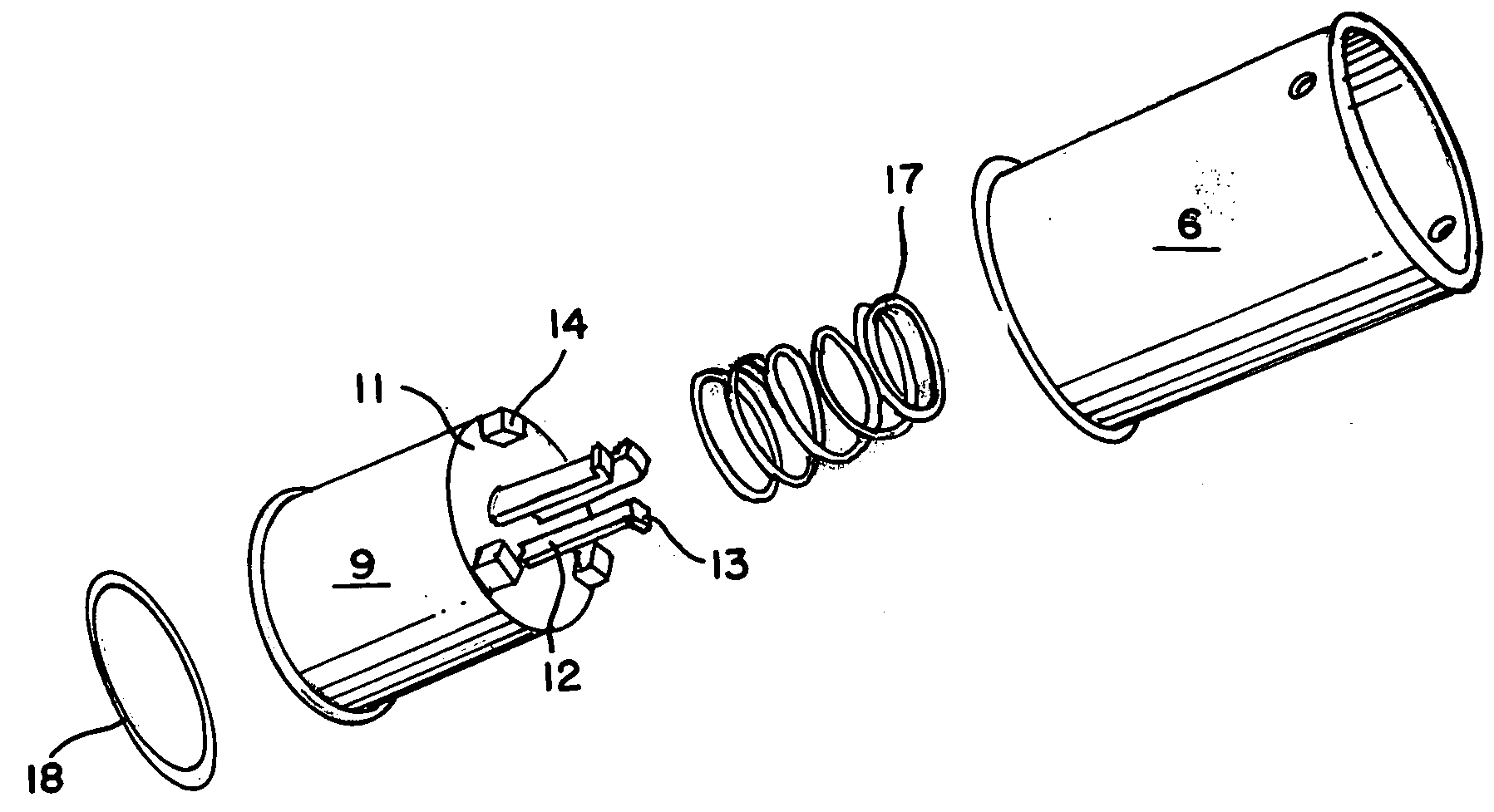

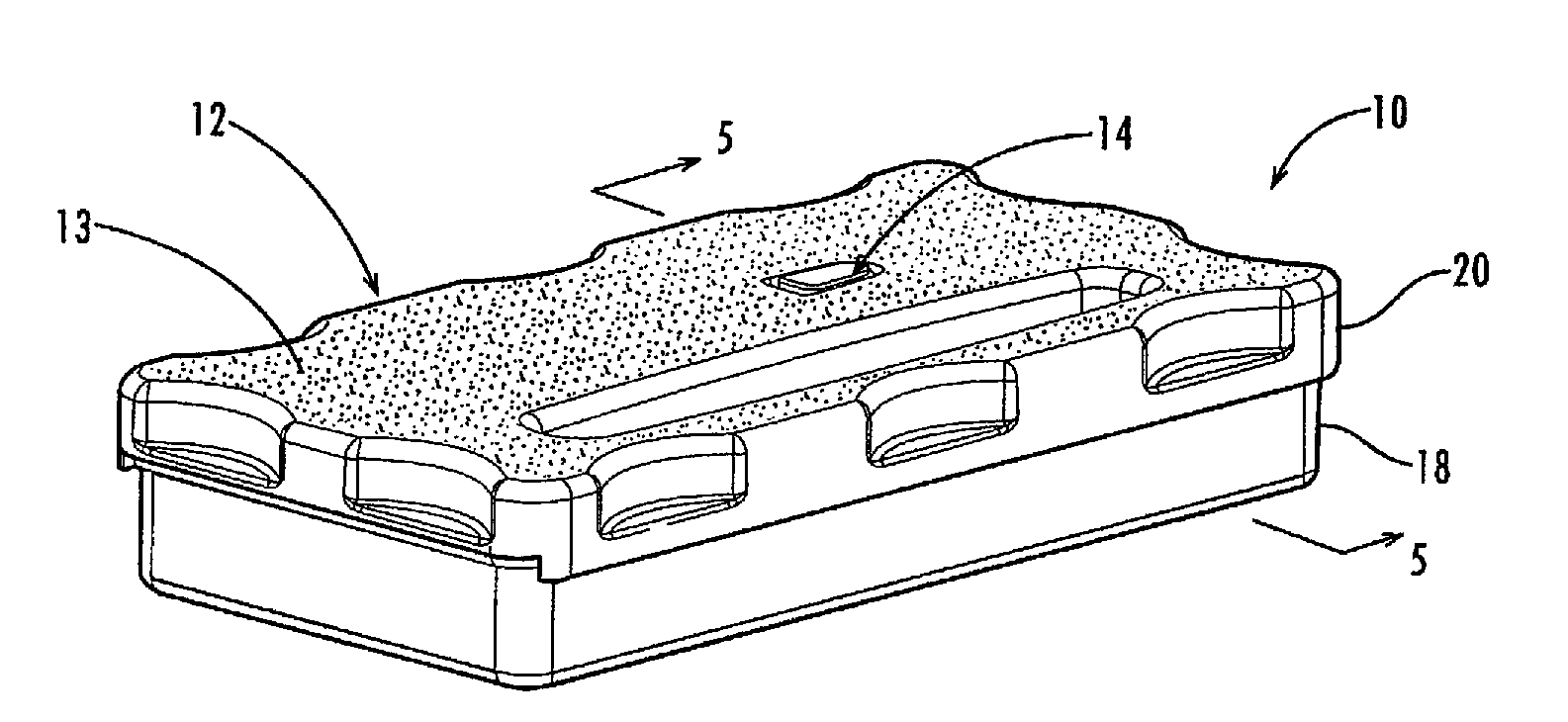

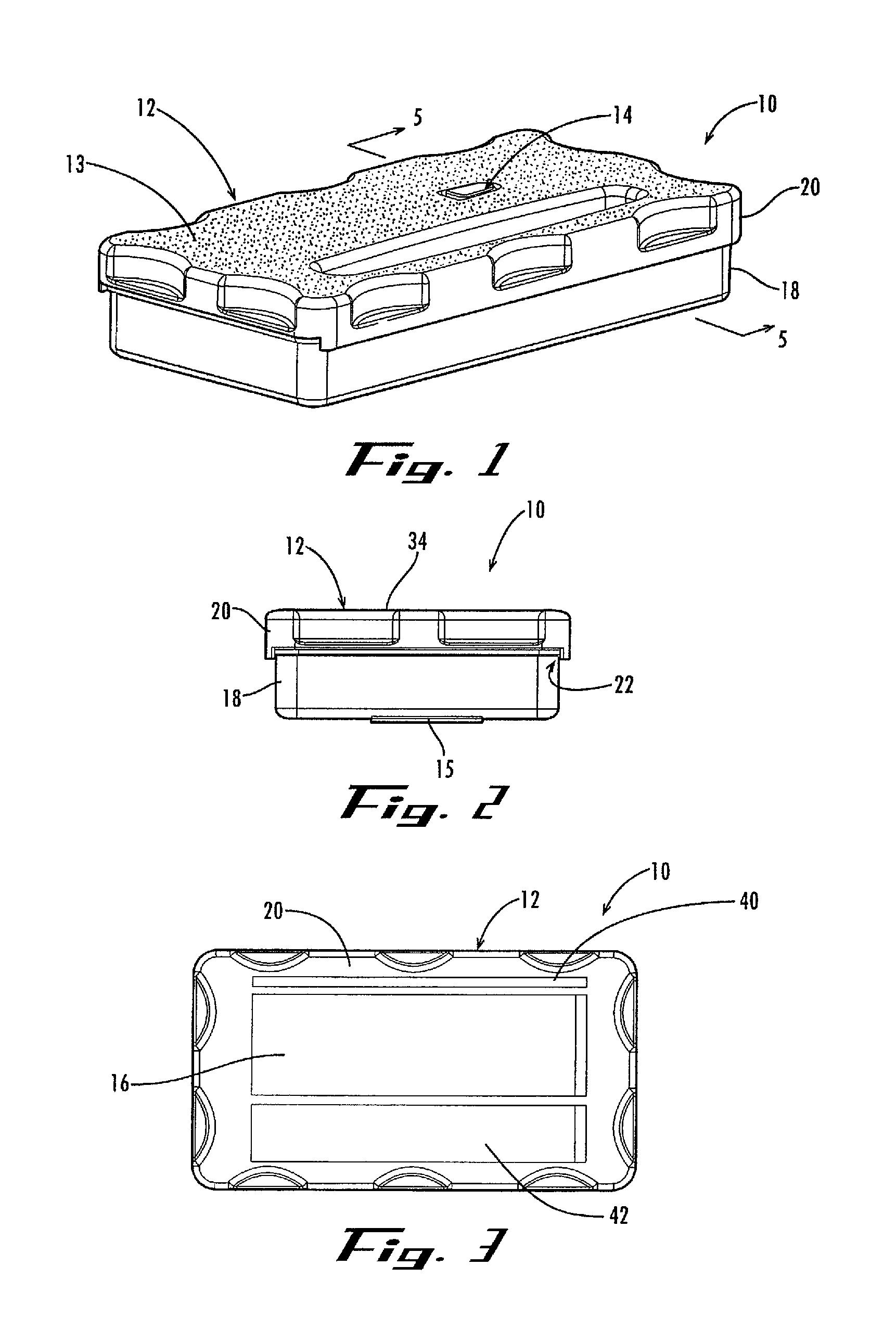

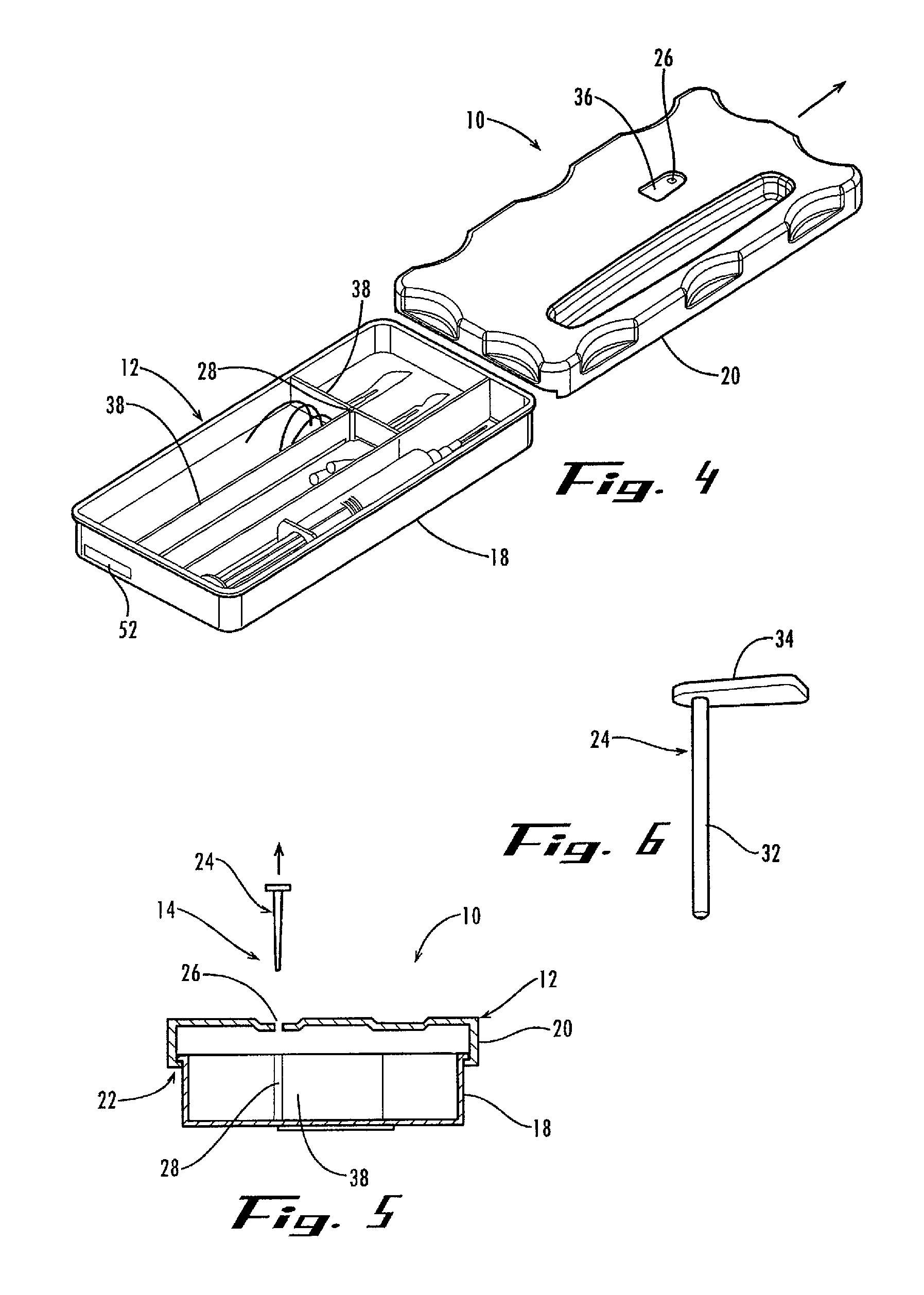

System and method for preventing wrong-site surgeries

ActiveUS20060096877A1Preventing wrong-site surgeryPreventing wrong-site surgeriesSurgical furnitureDispensing apparatusMedical recordLocking mechanism

A container holds at least one surgical implement, has a lock mechanism, and has a signature label that impedes access to the surgical implement until the correct surgical site is confirmed. A method of using the container includes the steps of confirming the correct surgical site, signing the label and removing it from the container, placing the label in the medical record, unlocking the container, removing the implement, and beginning the surgery, wherein the surgical team is forced to pause to confirm the correct surgical site before starting the surgery. Preferably, the container top may be removed and placed between the surgeon and surgical technician to define a no-hands “neutral zone” to avoid being stuck by the sharps. Also, the container preferably includes compartments for storing used sharps and / or a local anesthetic-loaded syringe, and the top may be replaced and secured for safely disposing of the sharps after the surgery.

Owner:STARTBOX

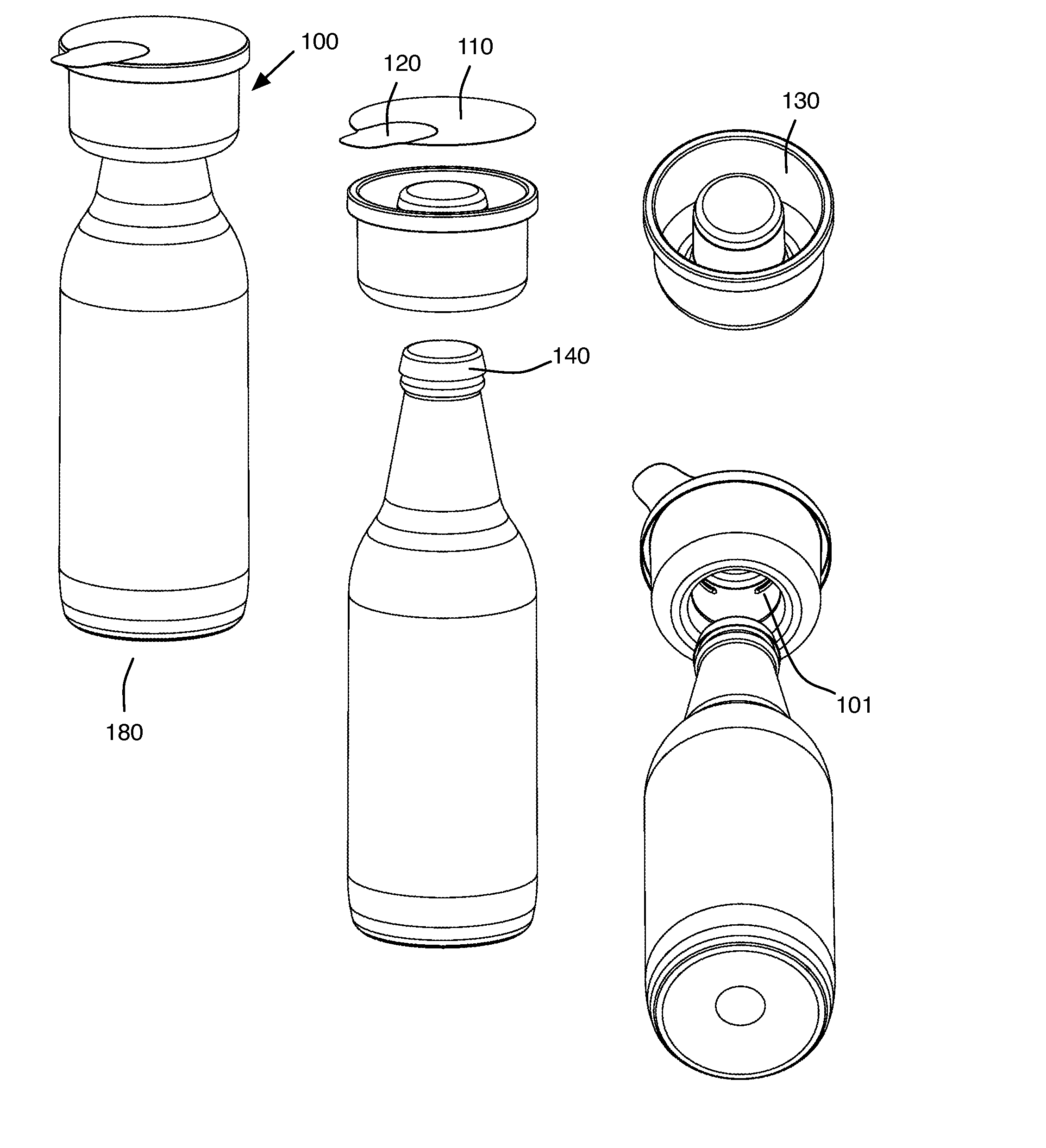

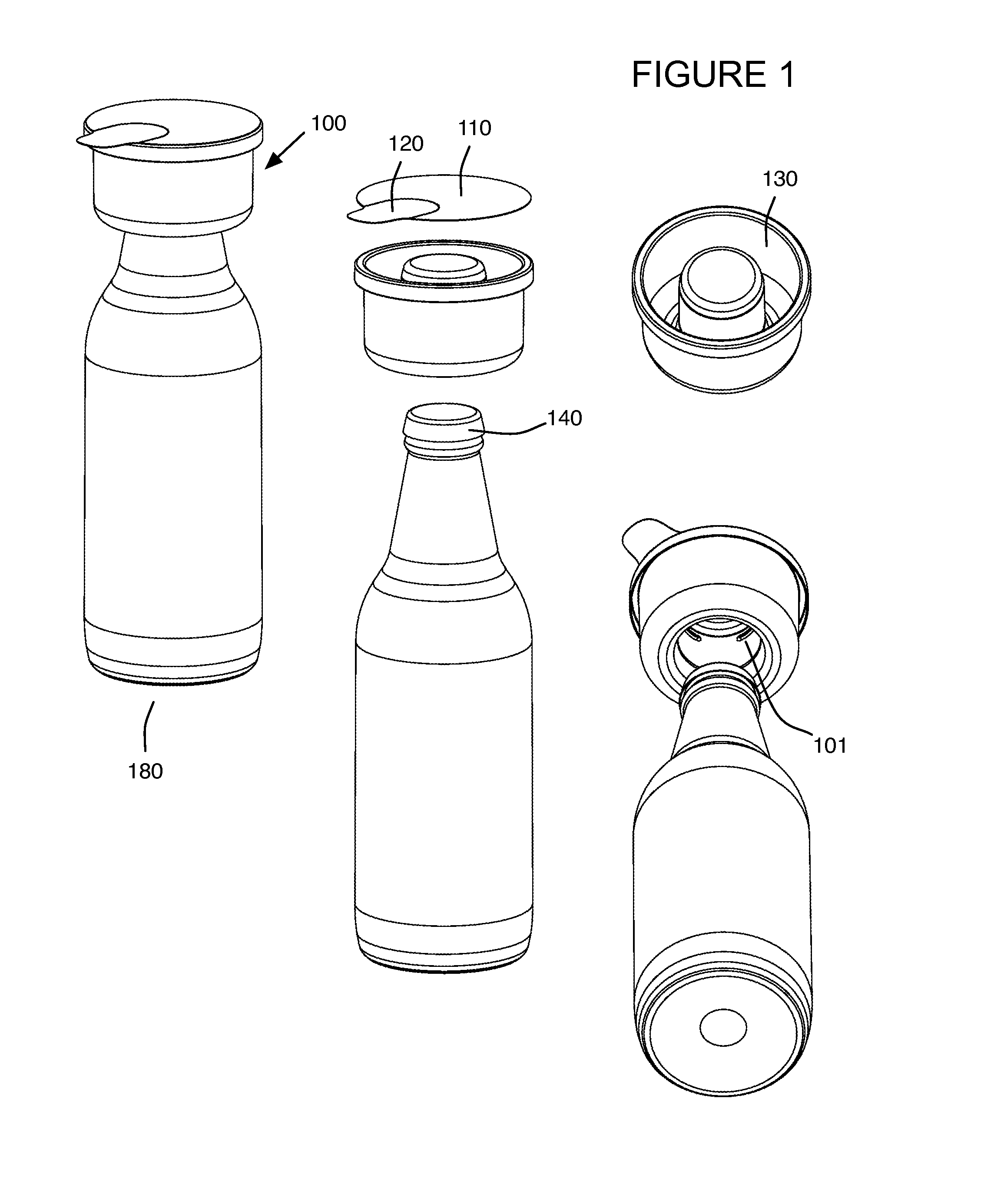

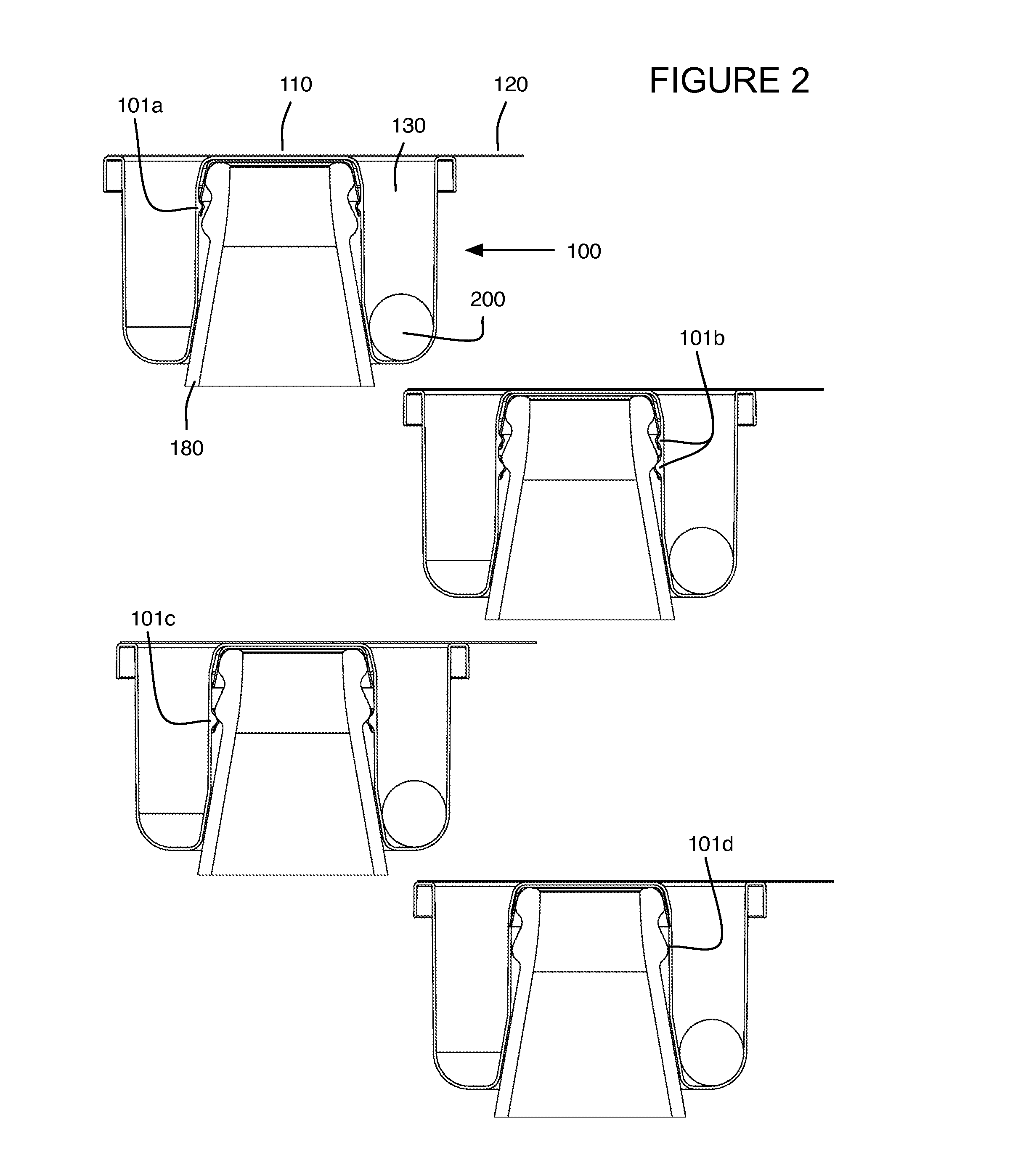

Top mounting bottle container

InactiveUS20130228486A1Quick alignmentFacilitates lift and shakeClosure with auxillary devicesRemovable lids/coversFresh foodContainer tops

Top mounting bottle container that couples with a bottle. A tab and cut-out in the cover provides for spill free snacking from an independent removable vessel. Salty snacks such as BEER NUTS® for example may couple to the top of a beer bottle for example. Various configurations enable the inclusion of fresh food, eating and drinking from a straw if desired while standing and walking and simultaneous access of solid or liquid in the container and bottle. Coupling elements that couple the top mounting bottle container to the bottle, may utilize any type of easily removable or semi-removable technology. Simplifies eating and drinking from one container and bottle in a theater or stadium having seats for example that provide one beverage holder per seat. Provides one free hand to hold a child's hand for safety while in stadiums and amusement parks.

Owner:SNACKTOPS

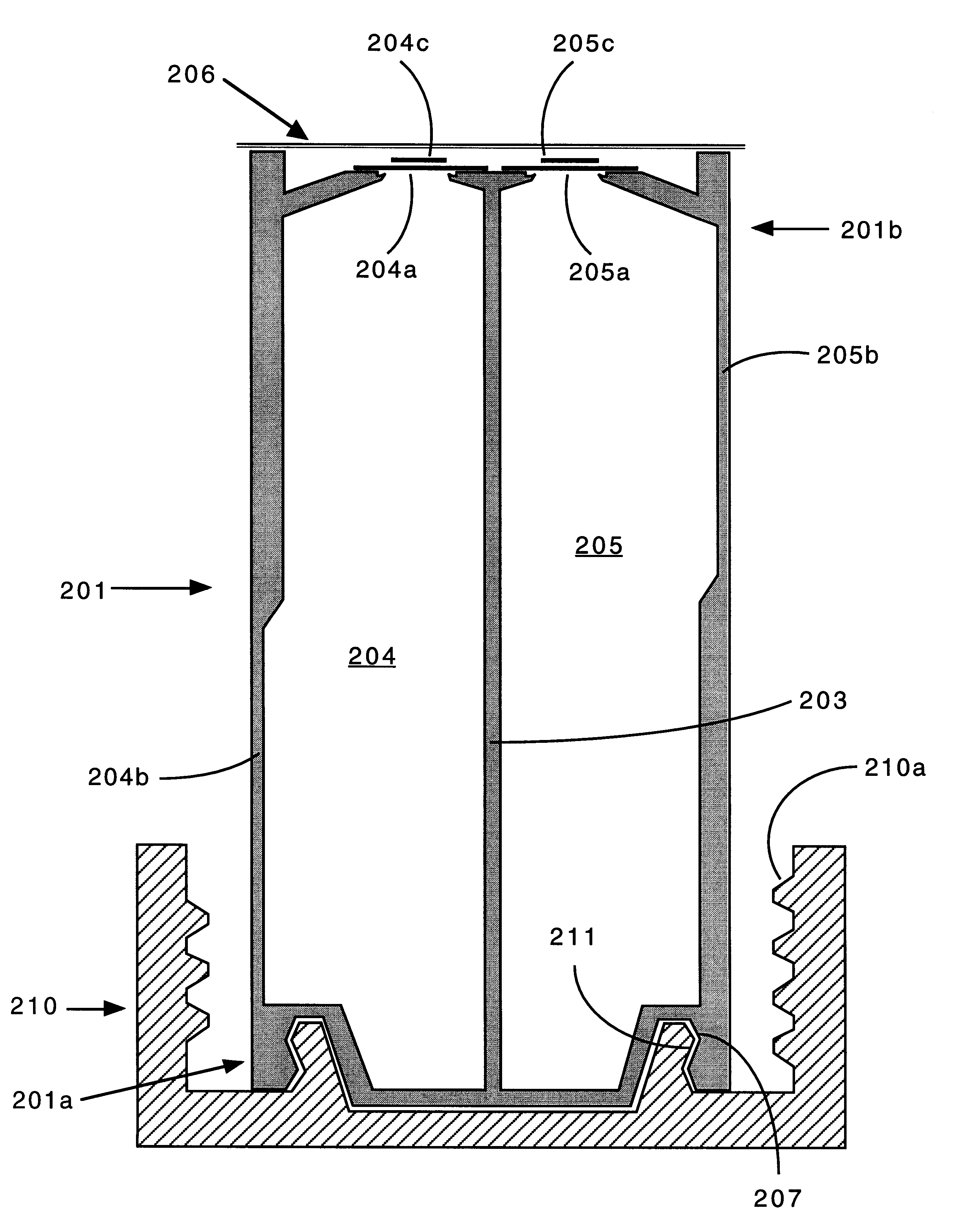

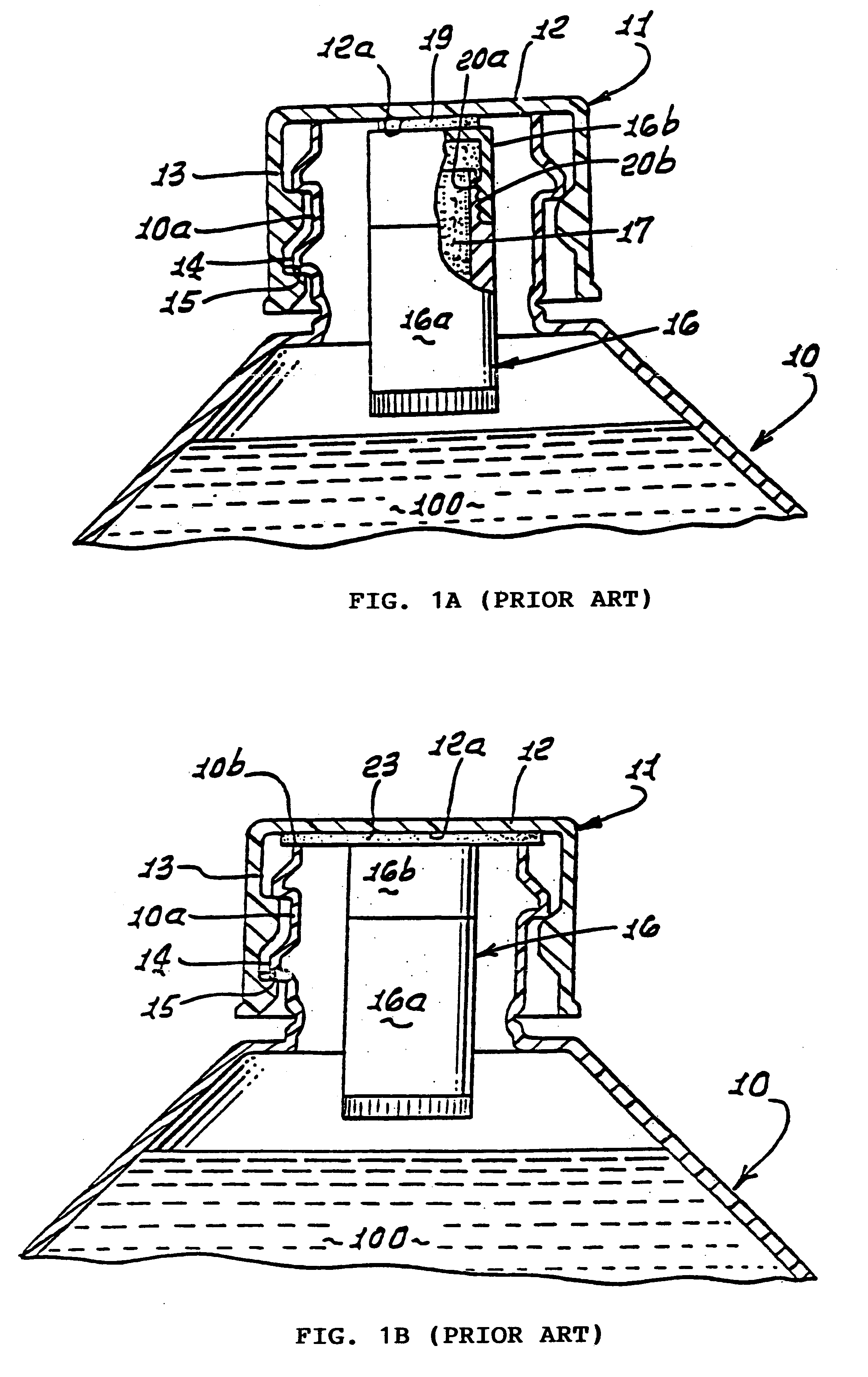

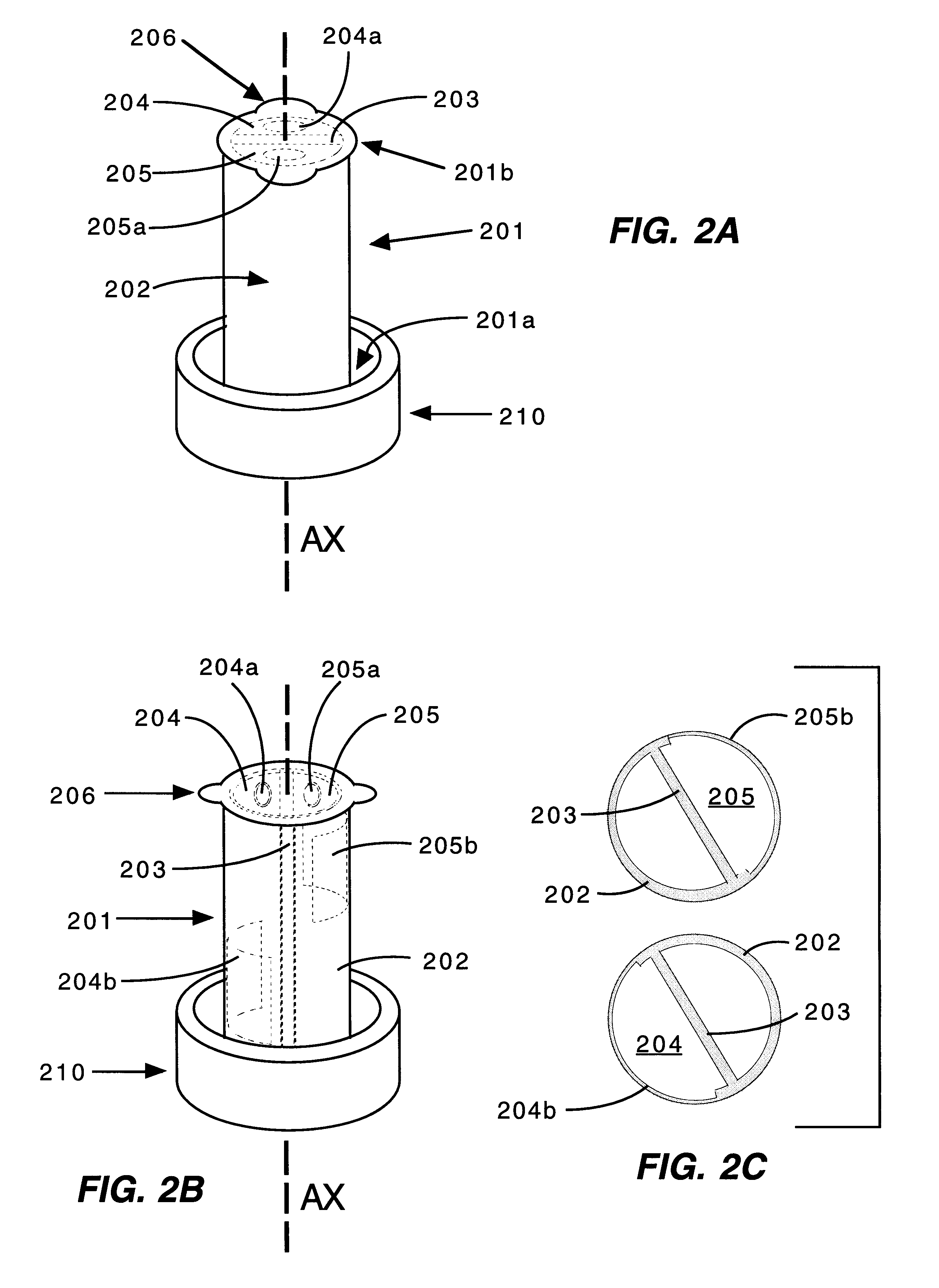

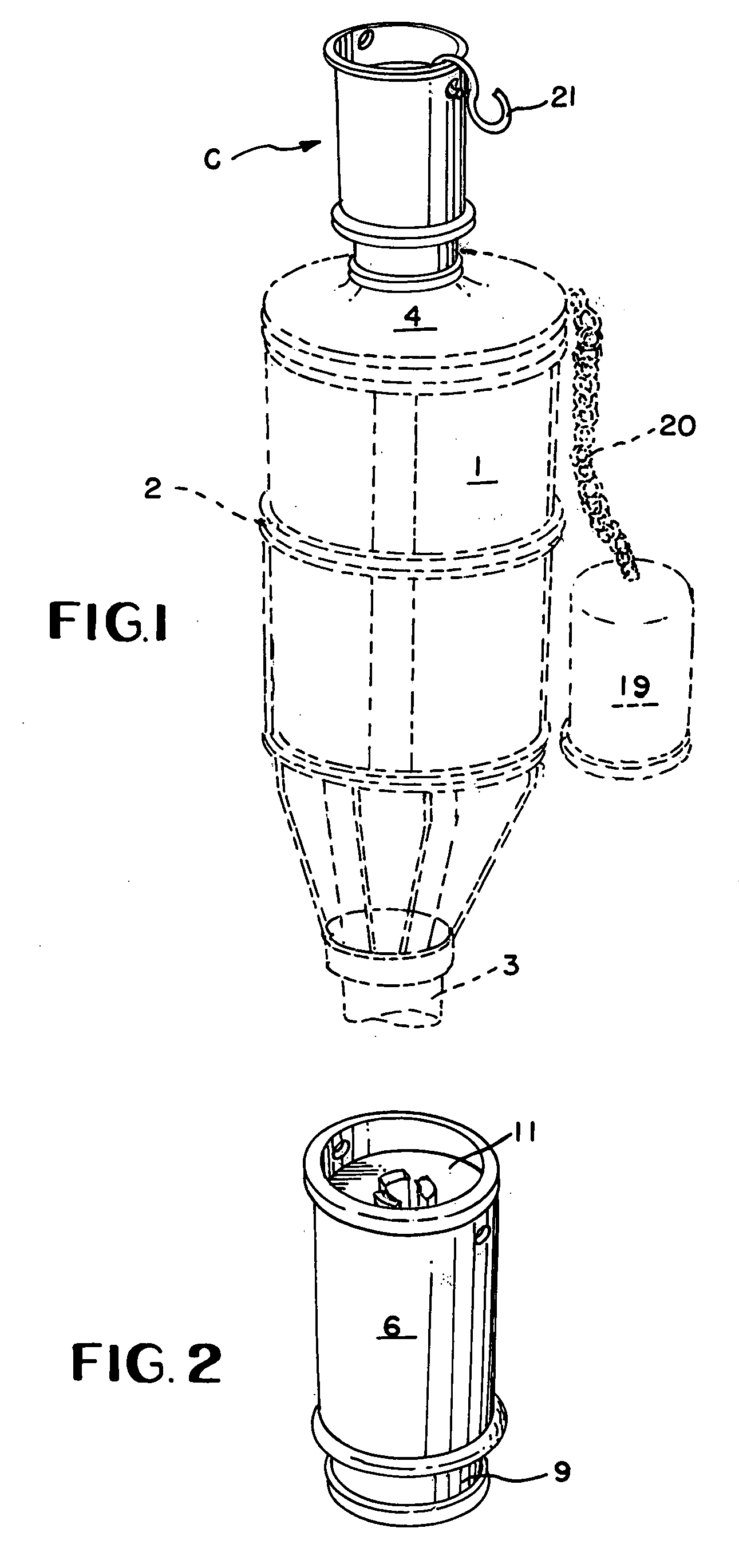

Device for maintaining separate ingredients in liquid food products

InactiveUS6250346B1Extrusion process is simpleSafe storageCapsLiquid fillingAdditive ingredientEngineering

A device for maintaining ingredients separately within a bottle container of the type having a removable container cap has a sub-container body formed with squeezable plastic outer walls and inner divider walls forming multiple compartments having respective orifices for dispensing the ingredients contained therein. Each compartment can be separately opened (by removing a sealing element) and its ingredient can be dispensed into the container by squeezing on corresponding portions of the outer walls. In different embodiments, the device may be formed with the sub-container body in a cylindrical shape, the divider wall aligned with the cylinder axis or transverse to the cylinder axis, and the cylinder body snap-fitted to the underside of the cap or fixed to a collar which is held on the container neck by the cap. In another approach, a device, for use with a can container having a fixed can top and pull tab, has a one or more sub-container vessels held in exterior well(s) recessed in the surface of the container top, and held in place by and protected by the pull tab. When the pull tab is removed and the tab opening is exposed, the sub-container vessel (s) can be removed from the exterior well(s) to dispense their separate ingredients into the container. These improved devices allow multiple ingredients to be safely stored separately from the carrier liquid and conveniently used and controllably metered to the user's tastes.

Owner:CASTILLO JAMES ANZAI

Container

Owner:CML&J

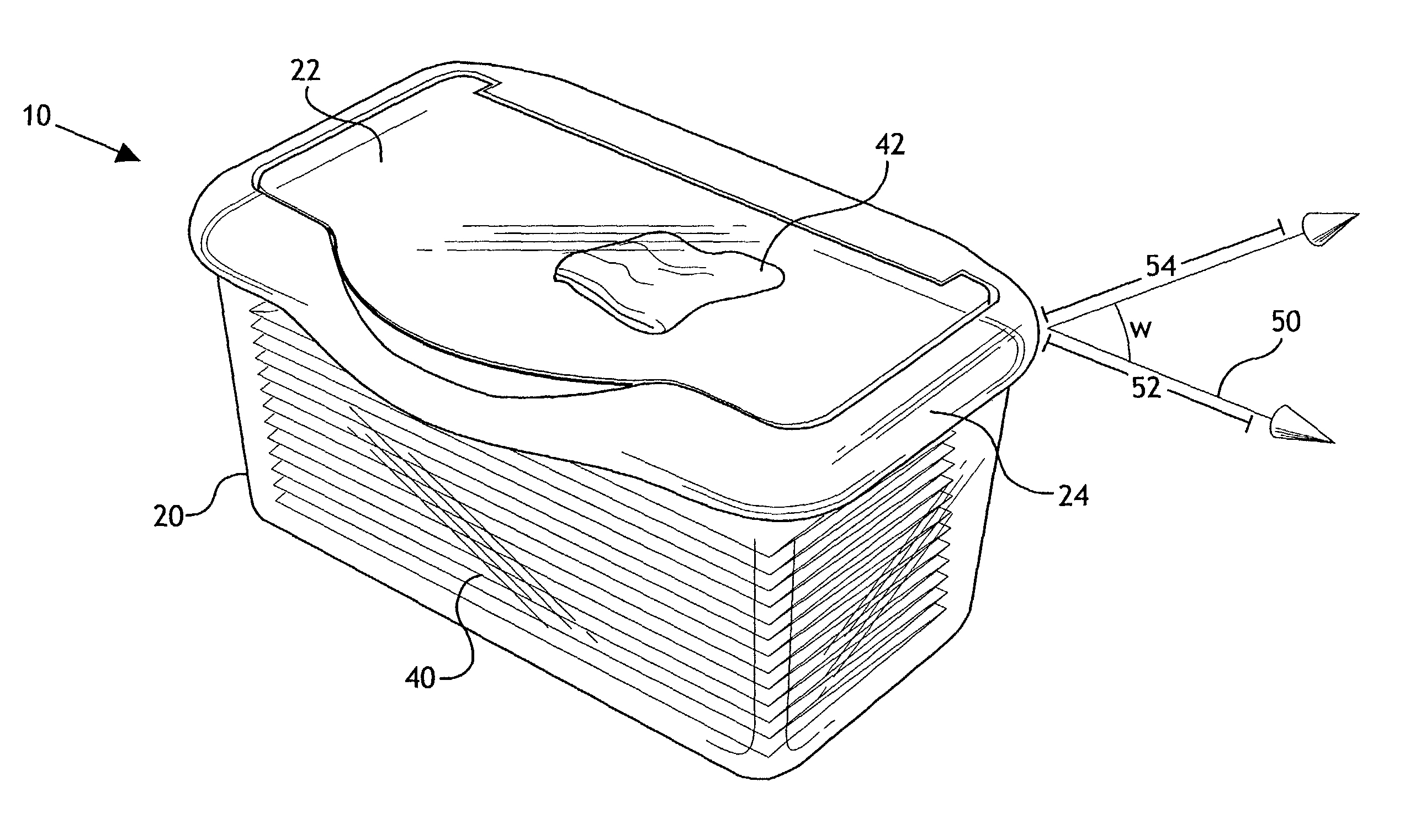

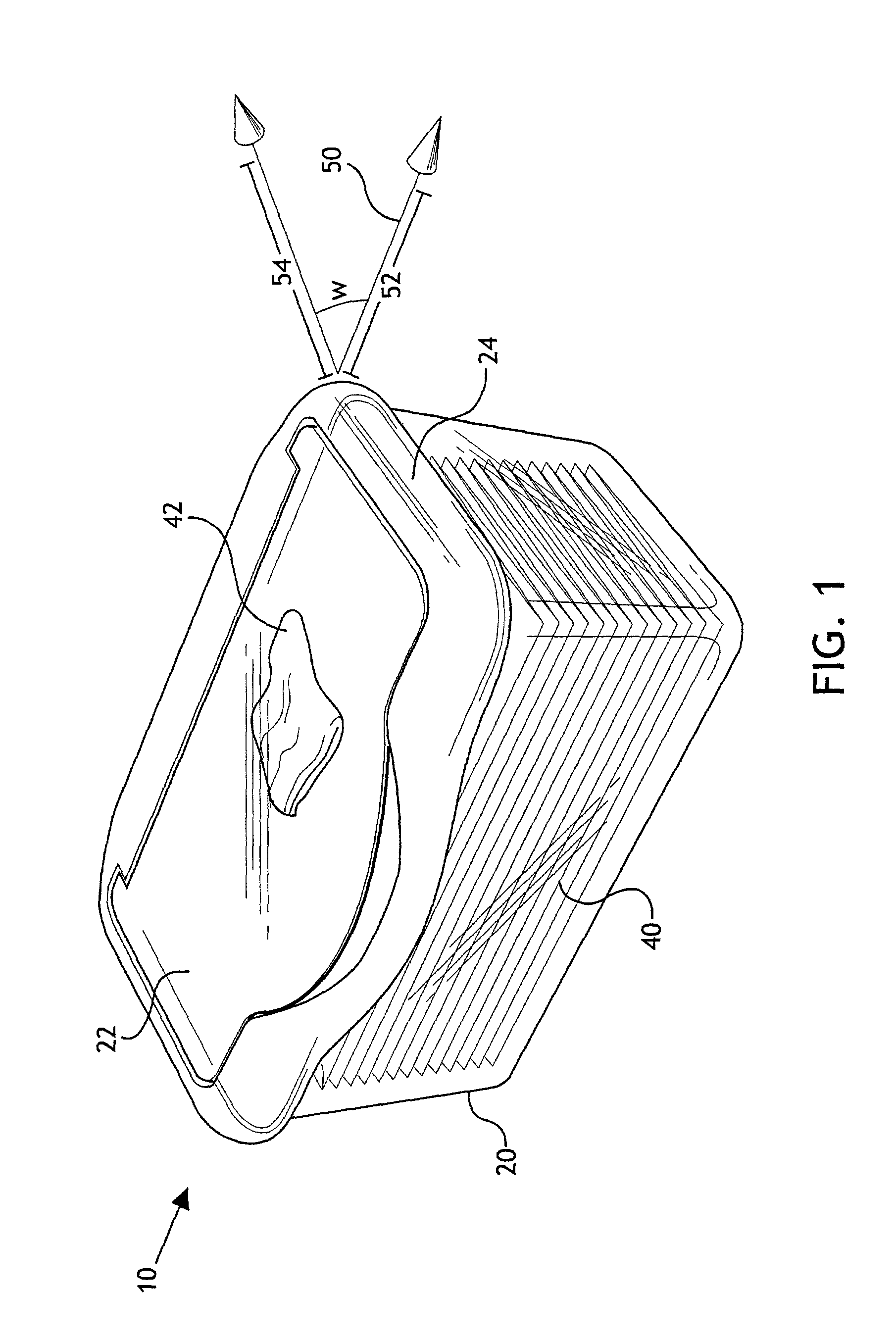

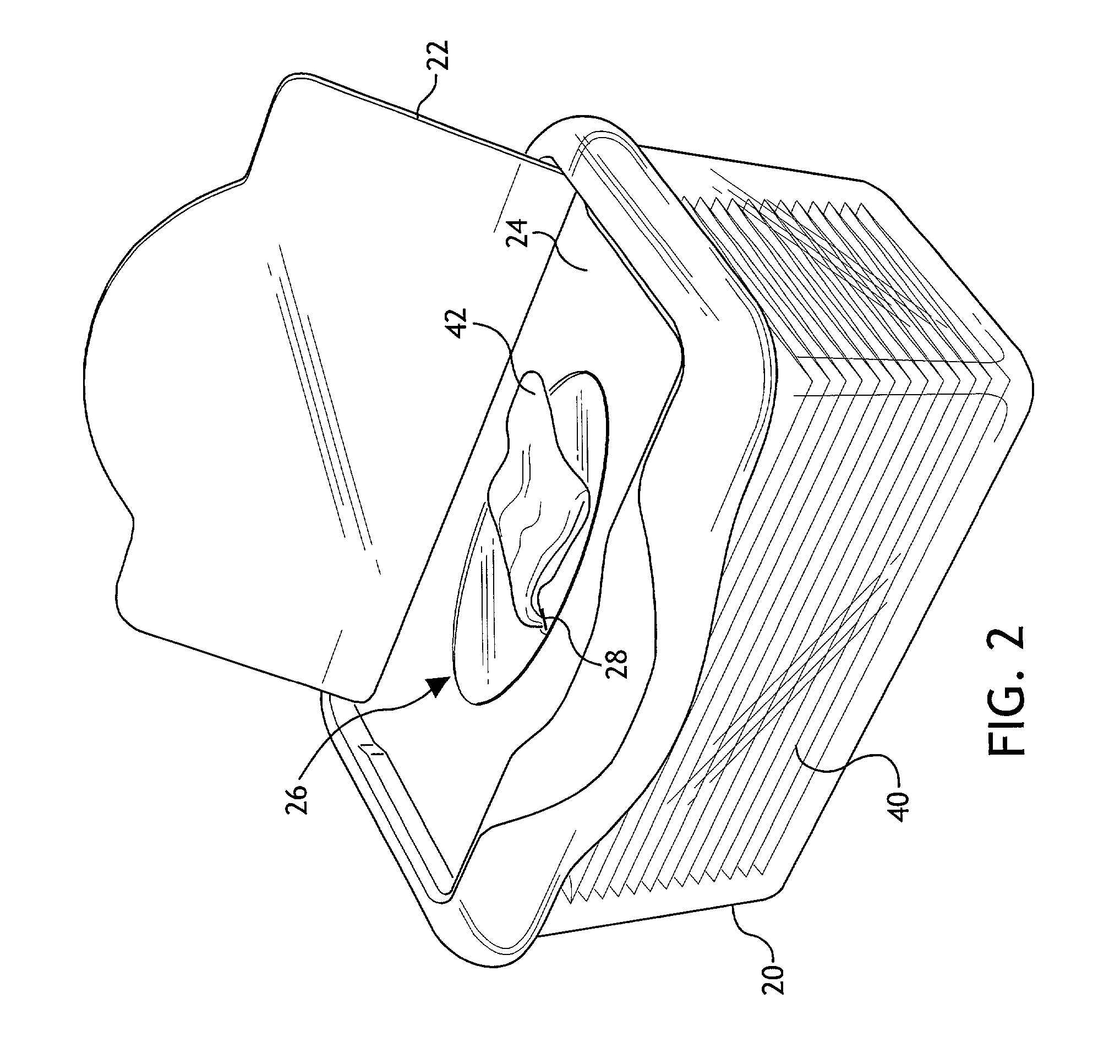

Package and method for storing and dispensing wet wipes in a pop-up format

InactiveUS7028840B2Informative and reliable to userConvenient to accommodateOther accessoriesContainer/bottle contructionVisibilityWet wipe

The invention relates to a package and method for storing and dispensing wet wipes in a pop-up format. A group of wet wipes are positioned in a container base between the container base and a pop-up style dispensing partition, each wipe in the group of wet wipes having a first visibility index. The container top has a second visibility index and the pop-up style dispensing partition has a third visibility index and the first visibility index is different than the third visibility index such that when the container top is closed the wipe from the group of wet wipes is visibly indicated at the container top as being in-position or not-in-position for pop-up dispensing as soon as the container top is next opened.

Owner:KIMBERLY-CLARK WORLDWIDE INC

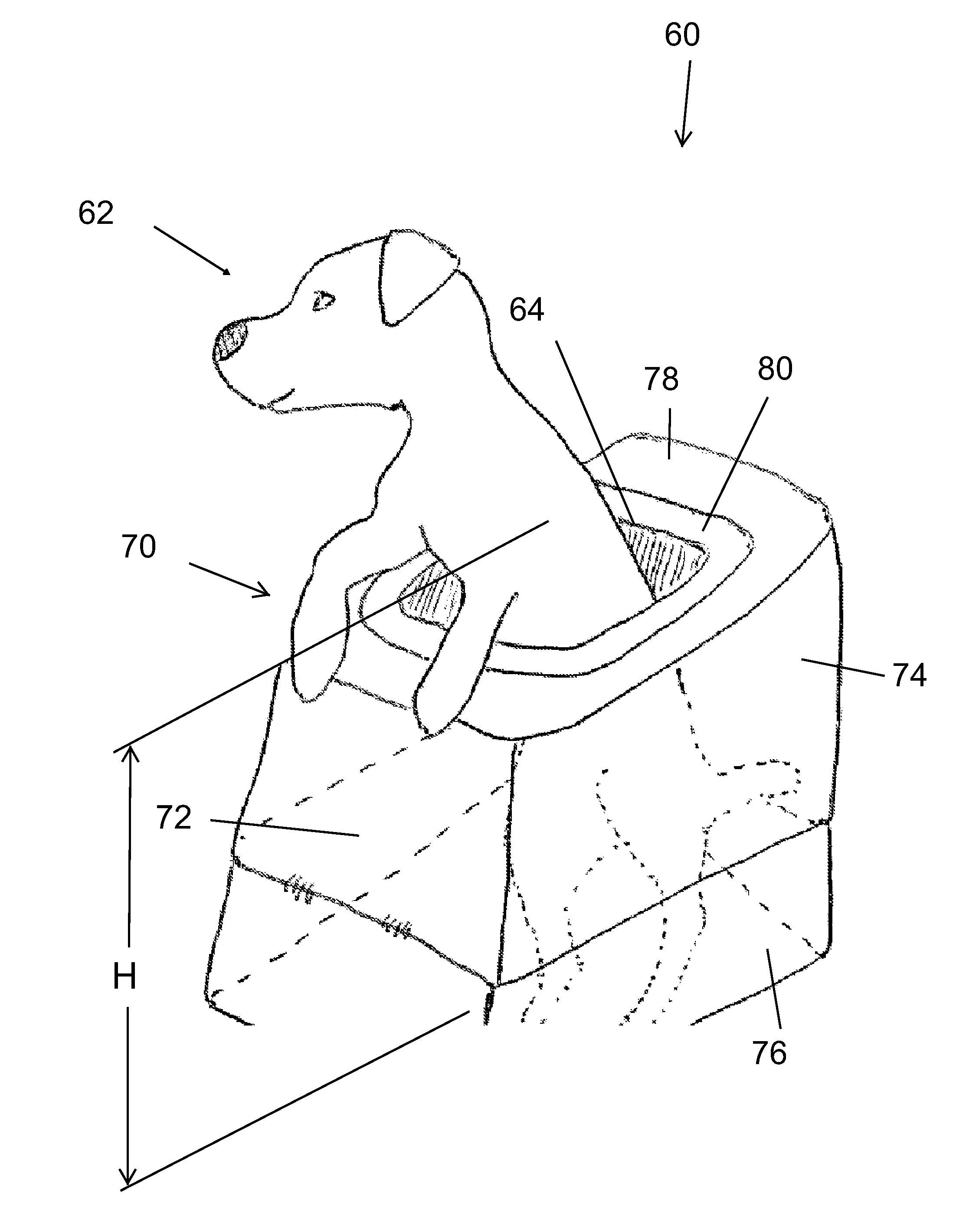

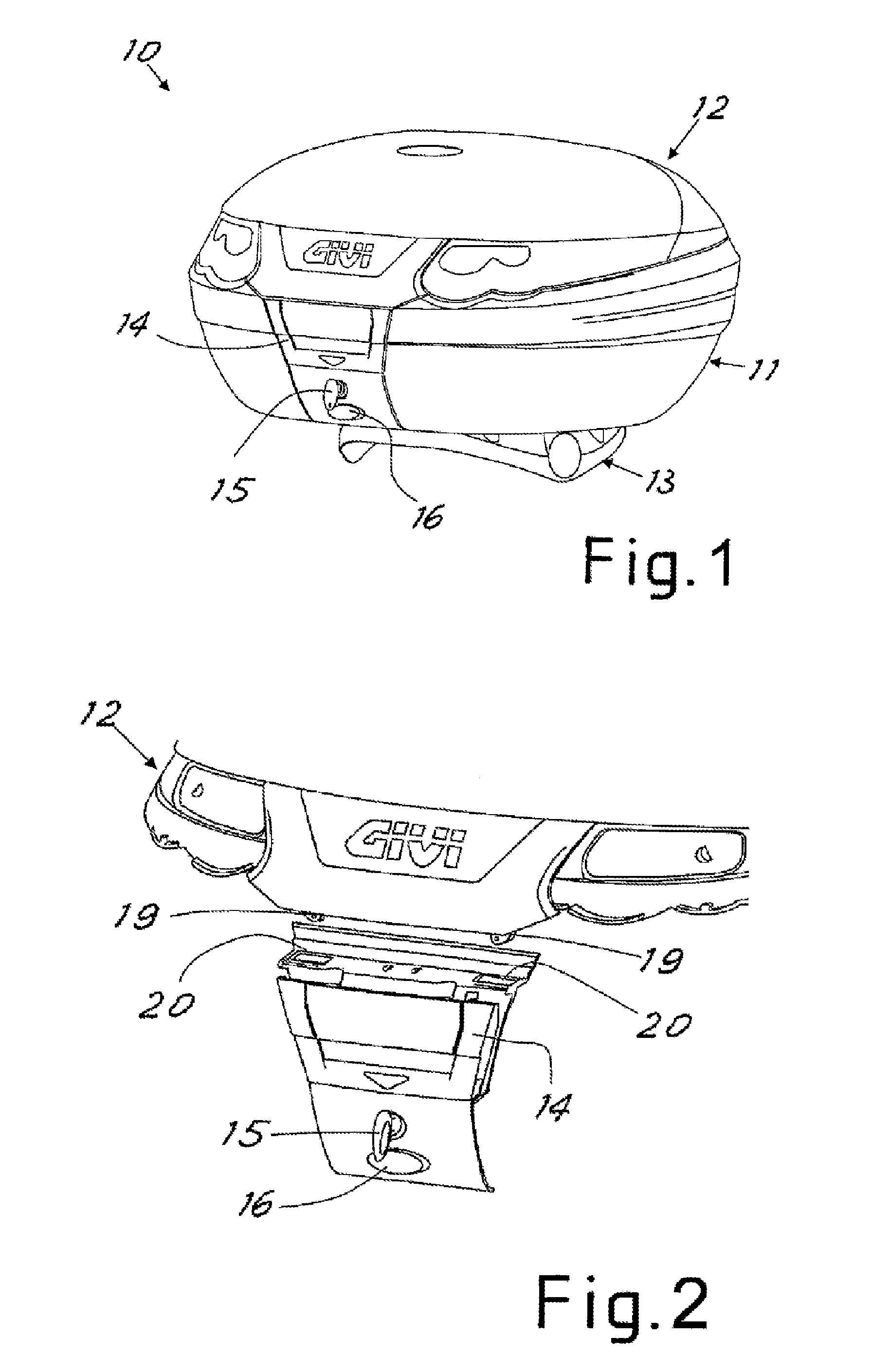

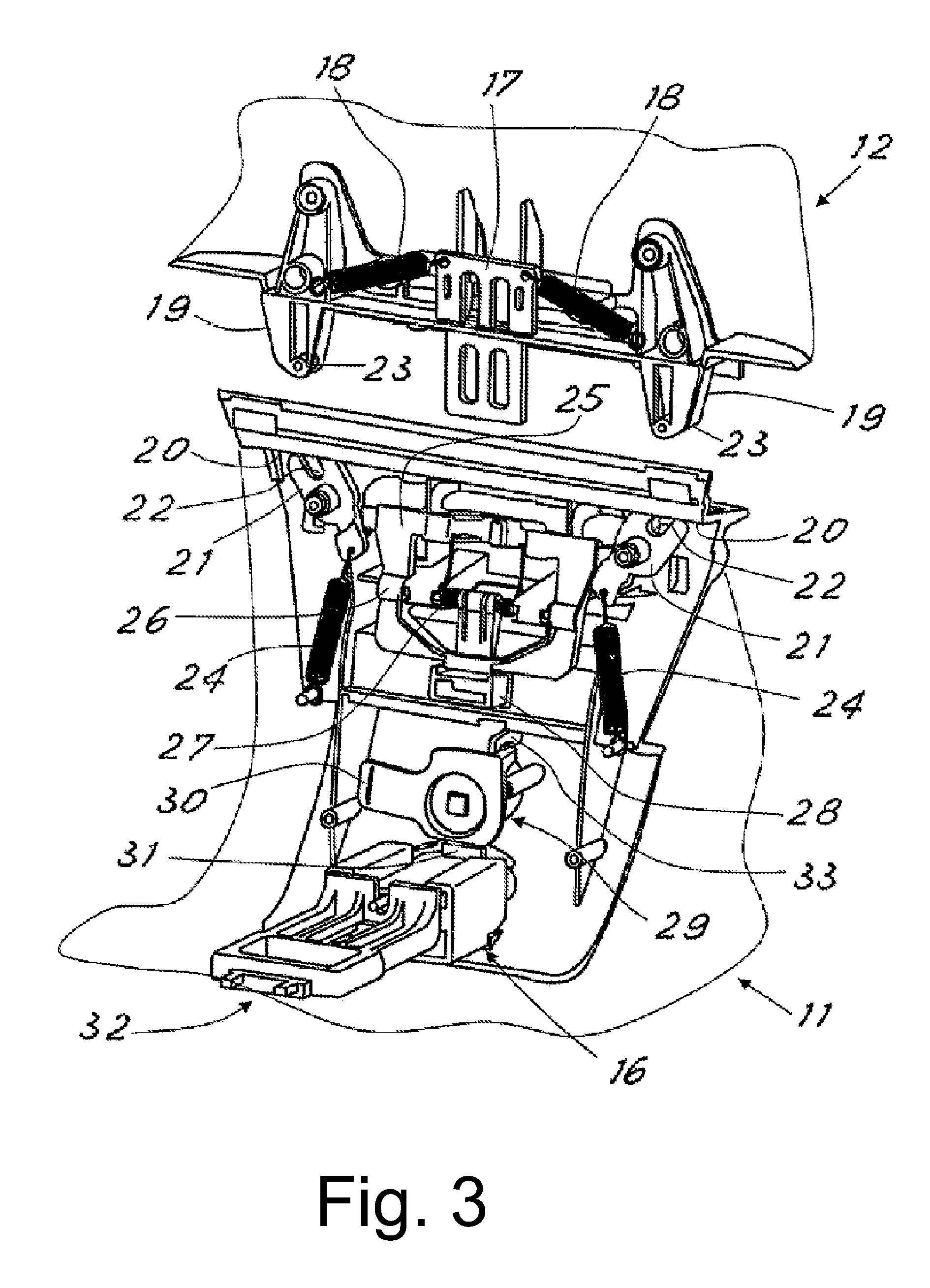

Small animal carrier for mounting on or in vehicles

A detachable carrier for small pets that can be attached to vehicles, such as bicycles, motorcycles, motor scooters, ATV's, golf carts or watercraft. The carrier allows not only for the transportation of the pet, but also for the enjoyment of the ride, by way of an open top hatch through which the pet can extend its head allowing for an “open air” ride and visibility. The carrier for transporting a small pet on a vehicle includes a box-like container provided with an upper opening that forms part of the container top. The opening has padded edges and is large enough so that an animal such as a dog can stand up in the container with his / her front legs on the padded front edge. Anchoring structure on the container bottom is arranged to detachably couple to a luggage rack or support plate on a luggage rack that is mounted on the vehicle.

Owner:HOVSEPIAN RICHARD W

Container

Owner:CML&J

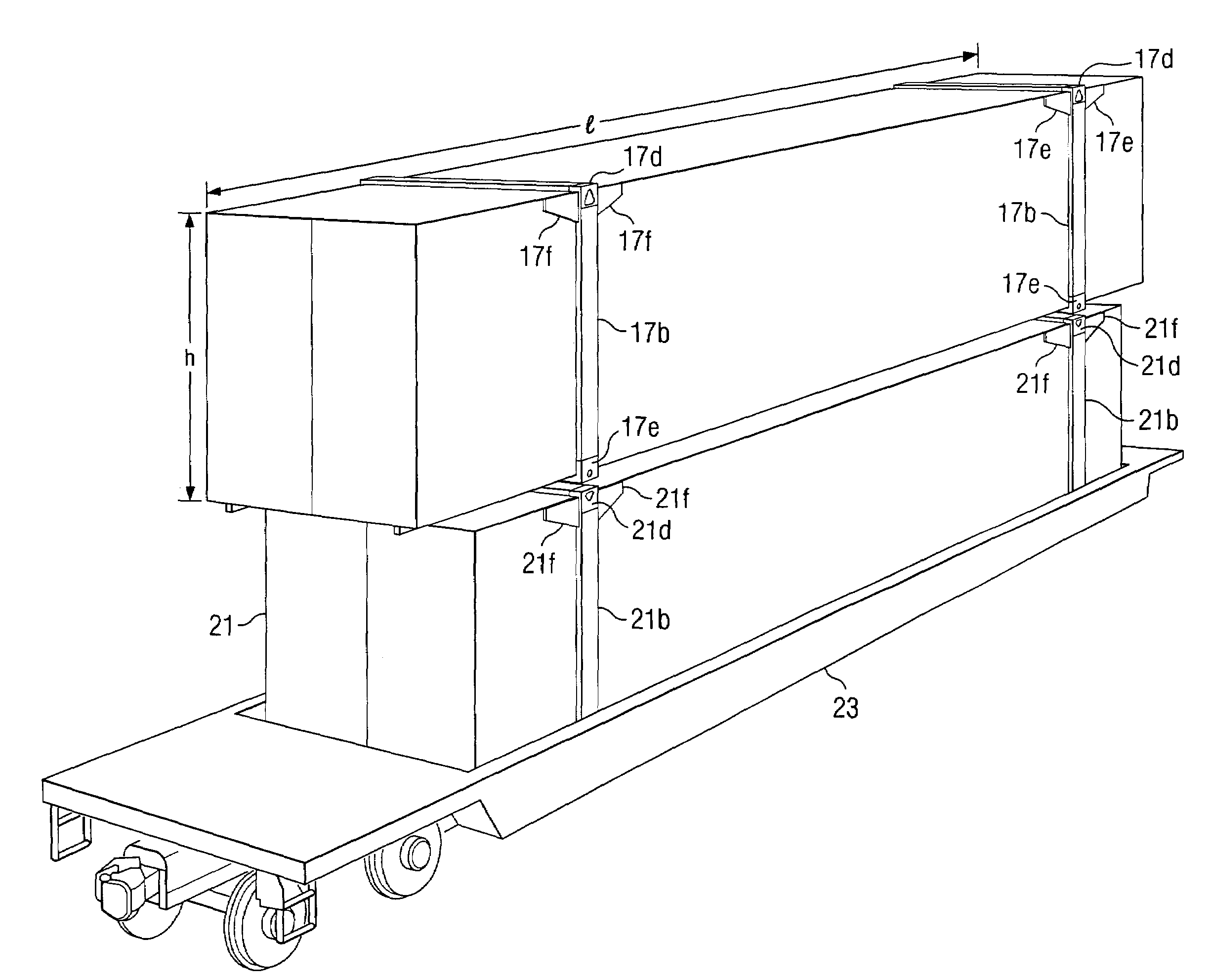

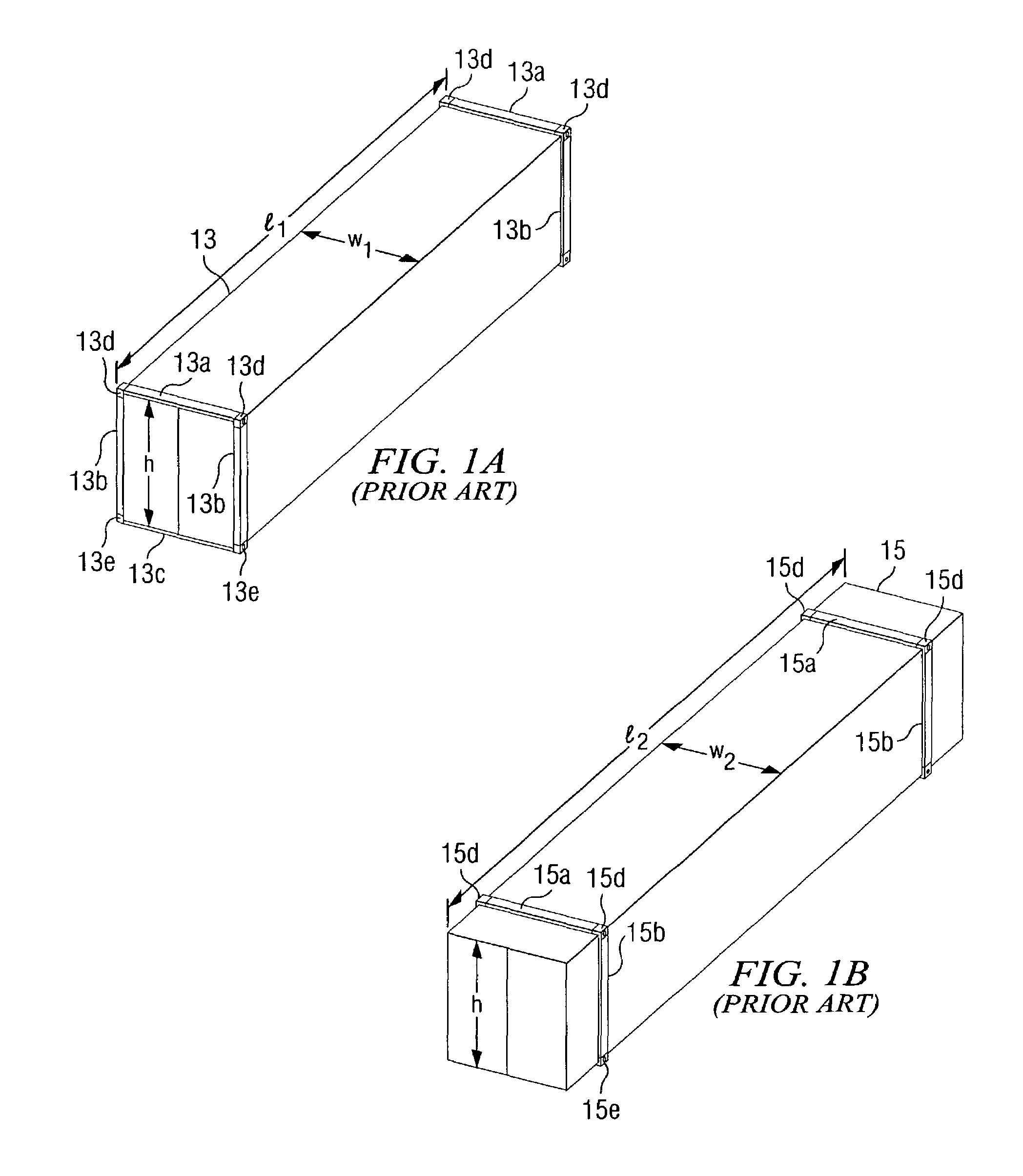

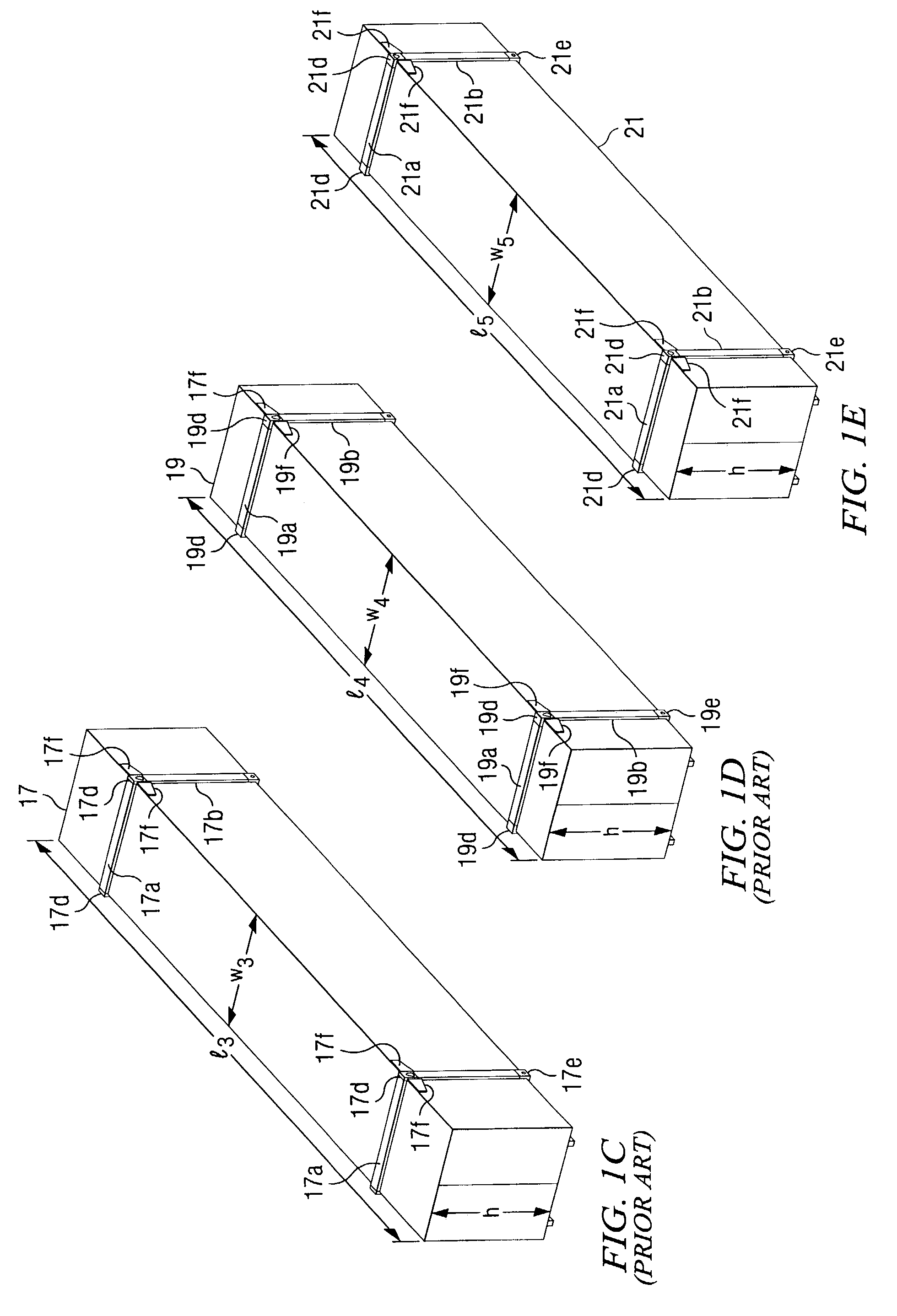

Freight container and lift casting therefore and method for lifting and transporting same

InactiveUS7056081B2Reduce intrusionShort heightClosuresElectric locomotivesMechanical engineeringCasting

An improved freight container for use in intermodal freight transportation systems that includes lift castings having a top lift aperture located on the lift casting at an outboard position, such that when other containers are stacked on top of the improved container, loads are properly distributed through reinforcement beams of the improved container, thereby substantially reducing bending stresses in the improved container, substantially reducing the possibility fatigue failure of the improved container, and reducing the costs of maintenance and inspection of the improved container.

Owner:BNSF RAILWAY

Tamper resistant locking device for underground enclosures and method

InactiveUS7975515B2Deters theftDeters vandalismKeyhole guardsCoupling device detailsContainer topsEngineering

Owner:YGNELZI GIANNI +1

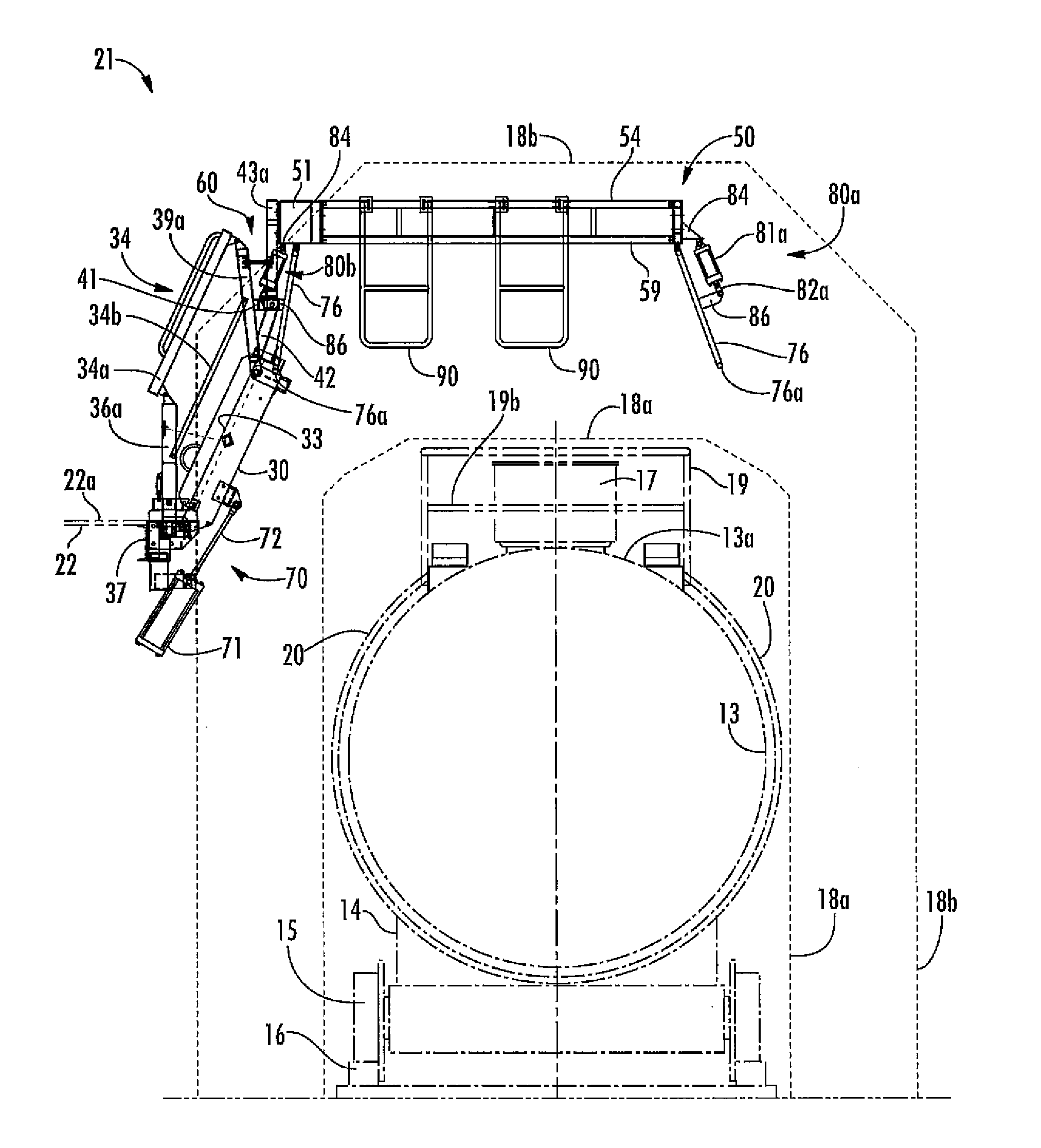

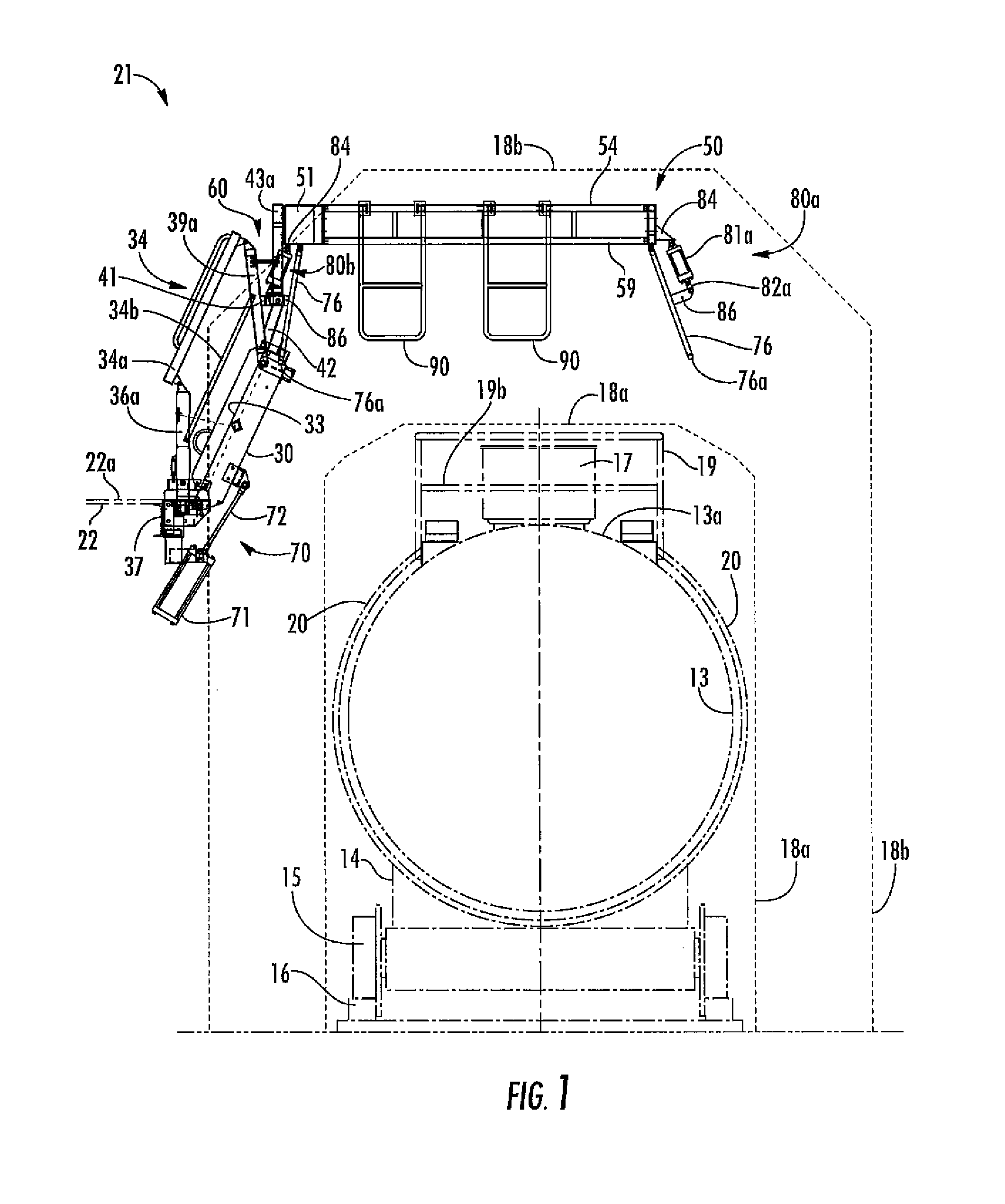

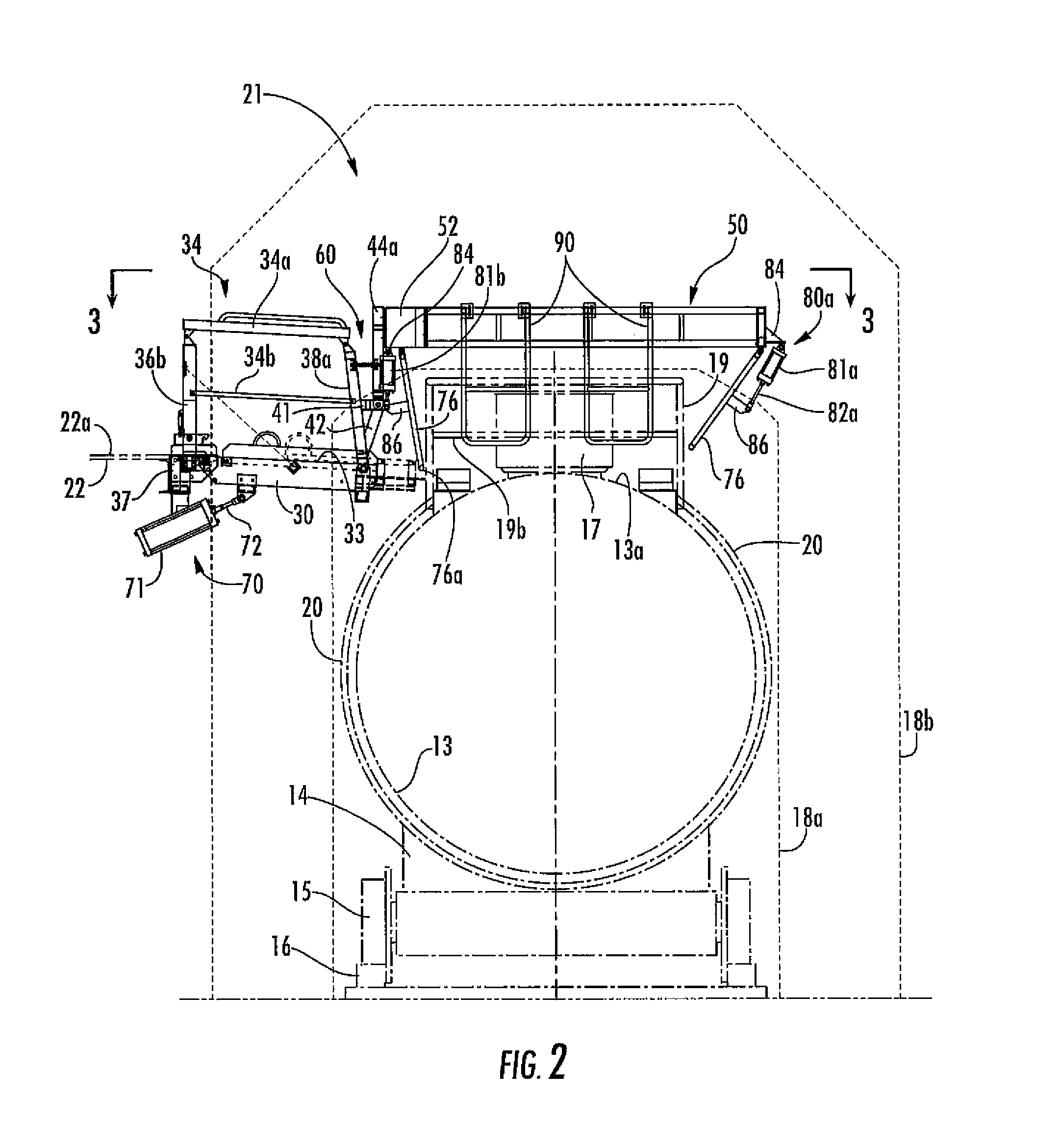

Fall protection cage with adjustable outboard upright

An apparatus that provides selectively deployable worker access with fall protection to at least a portion of the top of a container has a gangway that is configured to be retrofitted to an elevated platform from which the gangway and a fall protection cage is selectively deployable over the top of the container. The fall protection cage is connected to the gangway via a fixed stanchion and an abutment that is adjustably disposed outboard of the fixed stanchion and connected thereto via at least one selectively length adjustable screw member.

Owner:SAM CARBIS ASSET MANAGEMENT

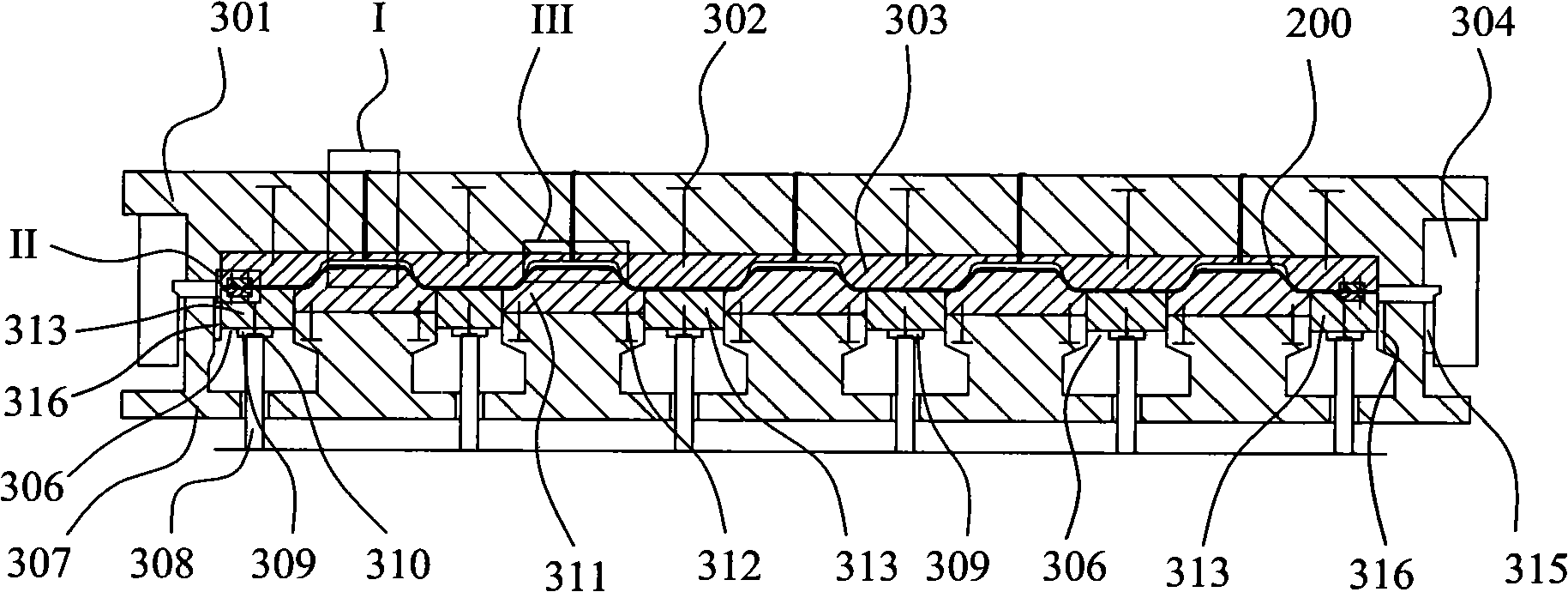

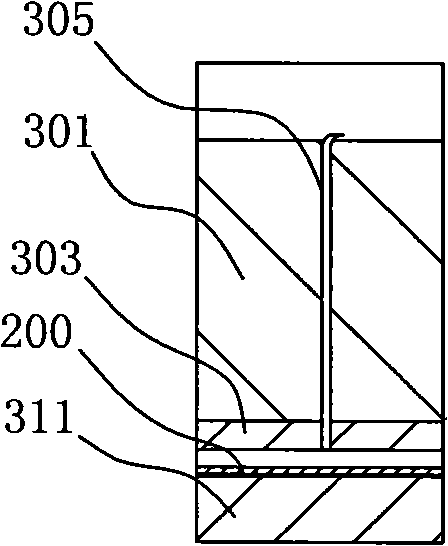

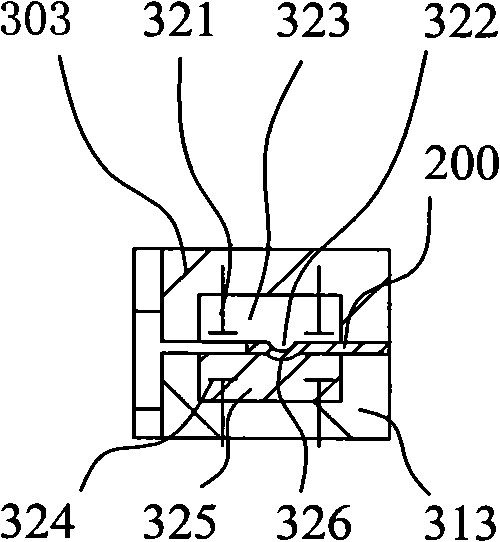

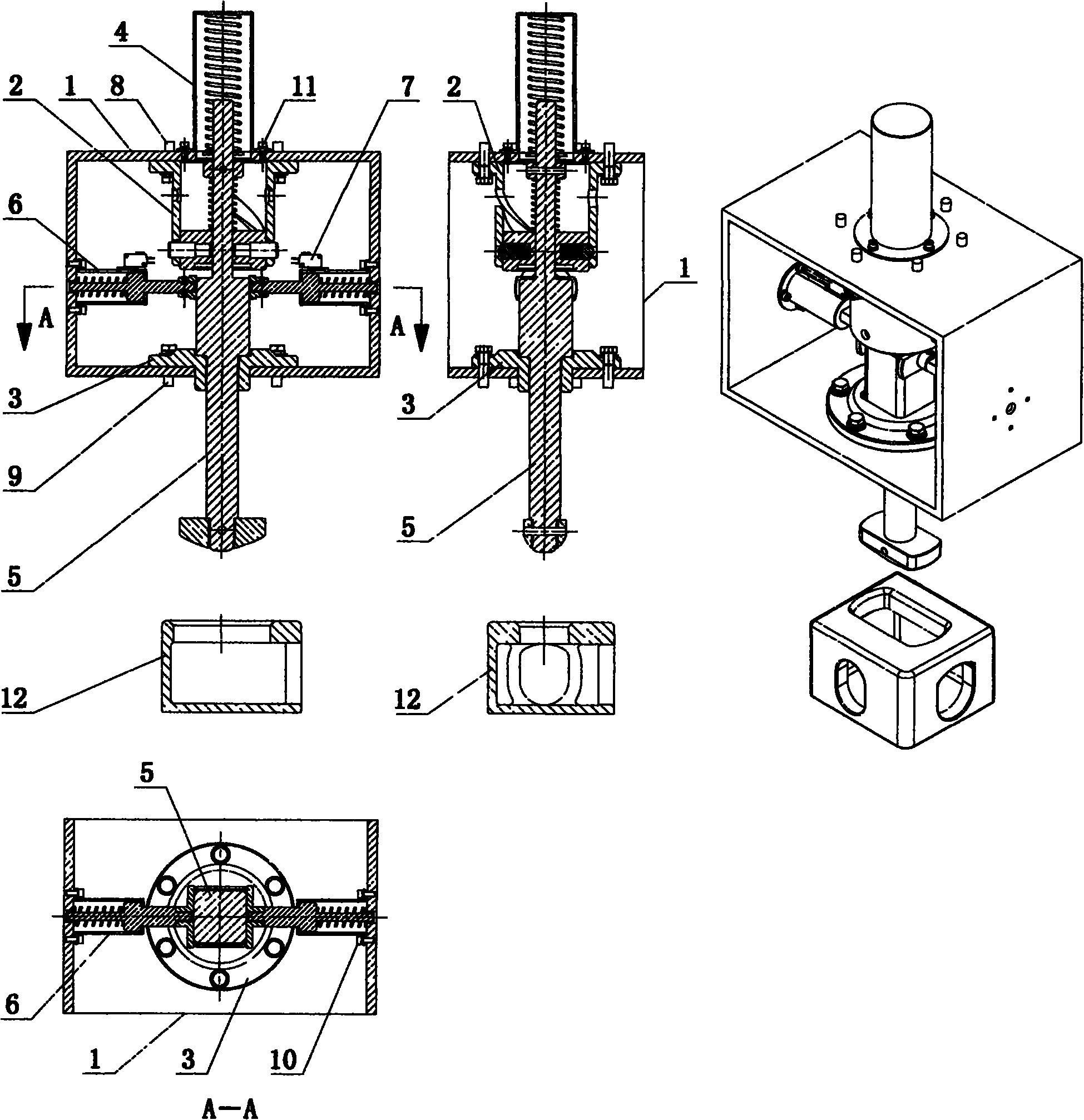

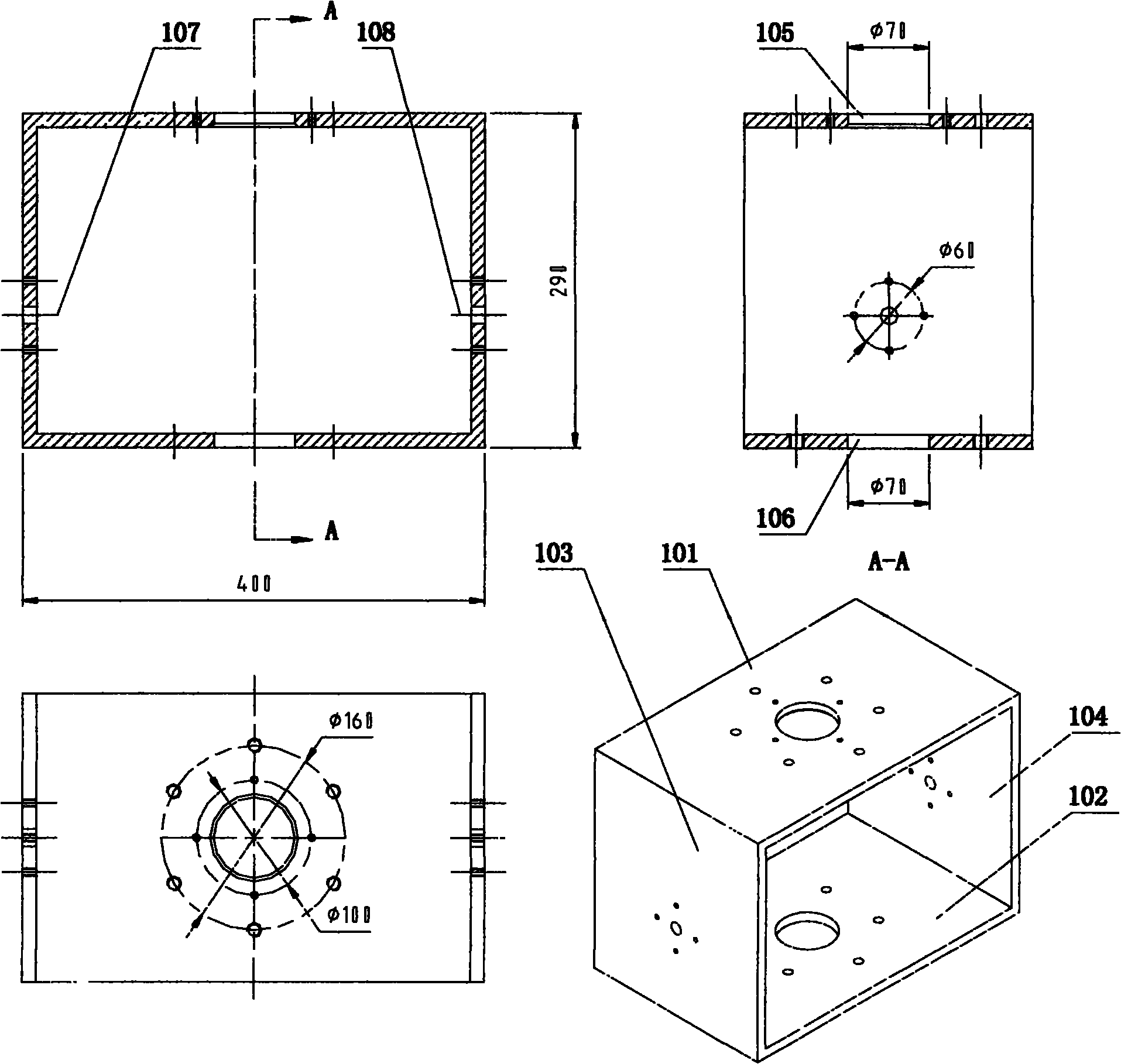

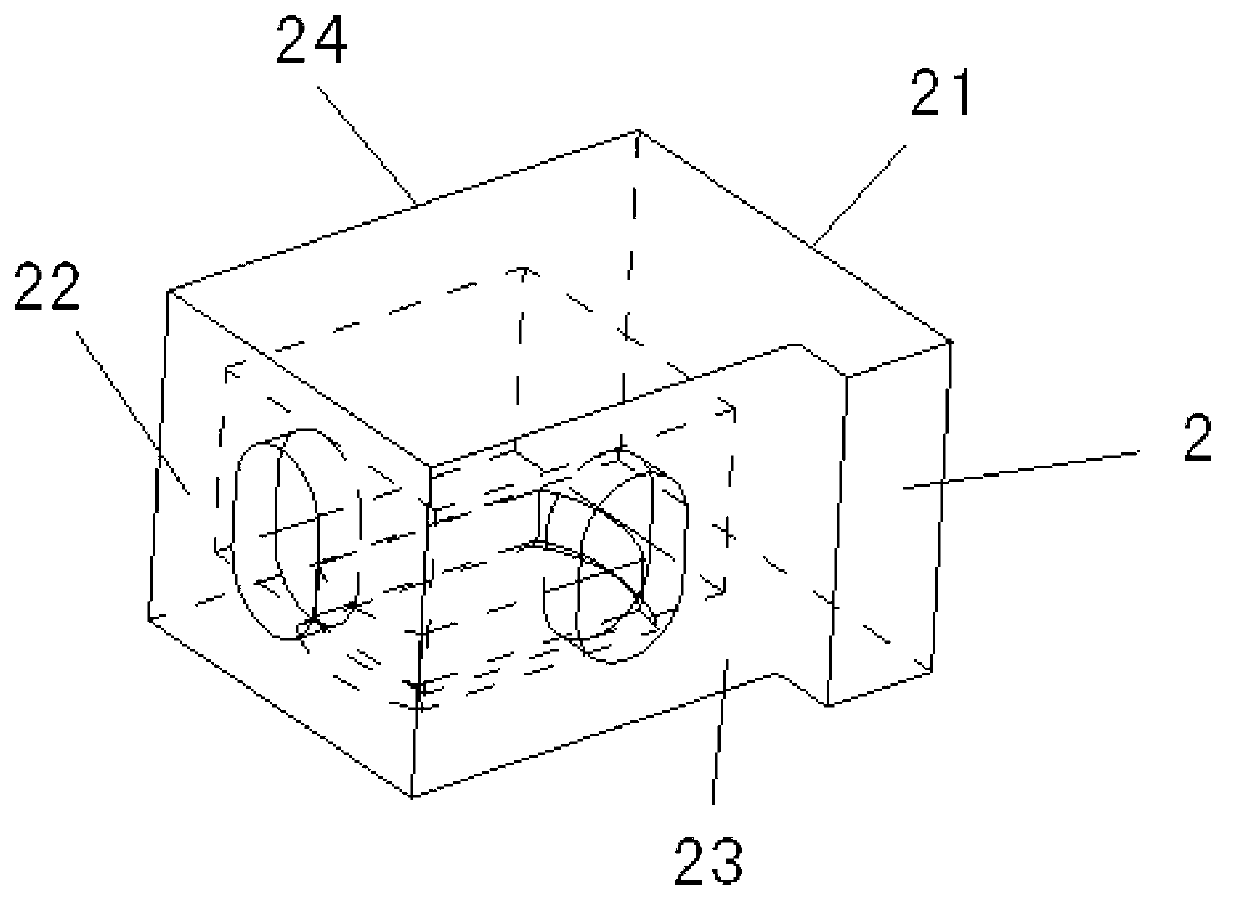

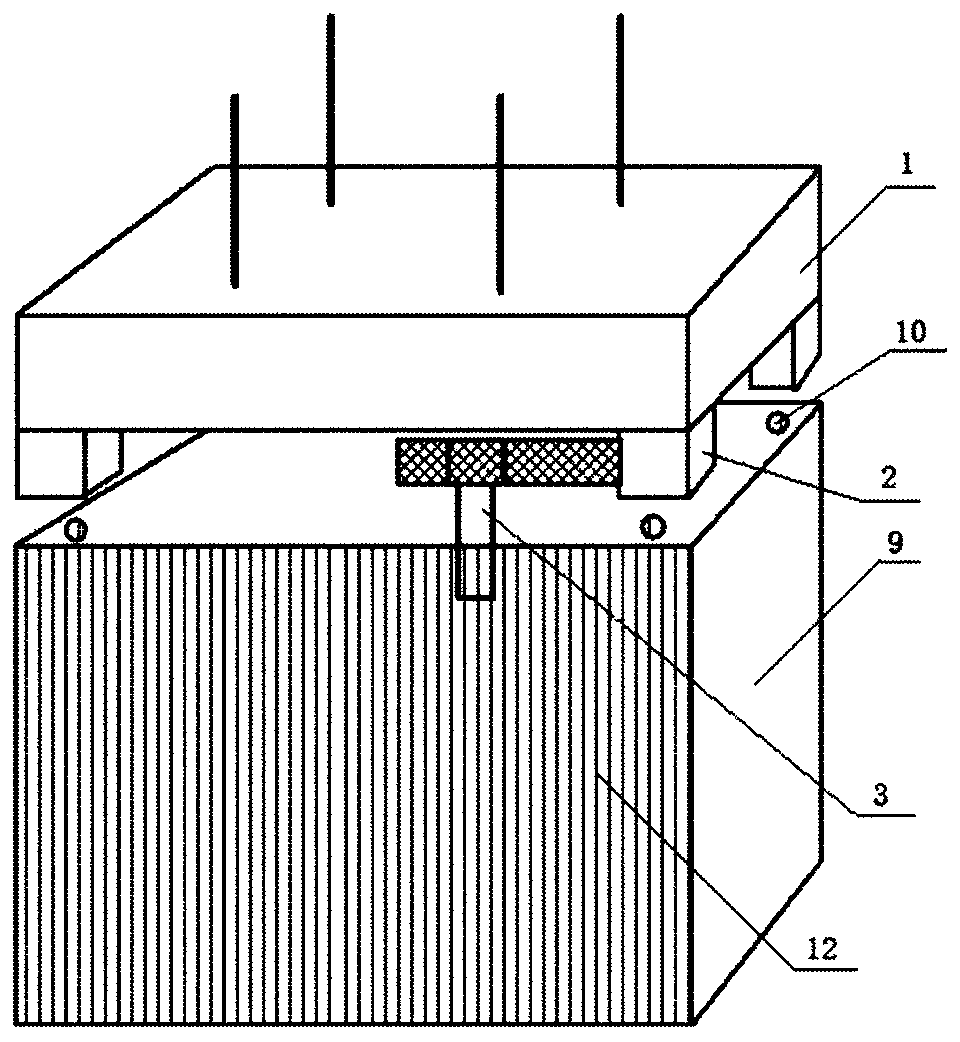

Container top board forming mold

ActiveCN101301670AIncrease productivityDimensionally stableShaping toolsEjection devicesMaterial removalContainer tops

The invention relates to a container top plate forming die. The container top plate forming die is provided so as to solve the problems in the prior art that the container top plate forming device has low production efficiency and unstable dimension of the finished products. The container top plate forming die comprises an upper die, a lower die, and a material removal plate; the upper die comprises an upper die seat and a concave die which is arranged on the upper die seat; the lower die comprises a lower die seat and a convex die which is arranged on the lower die seat and matched with the concave die; the concave die comprises at least two concave troughs which are intermittently arranged; the convex die comprises convex die embeddings which have the same quantity with the concave troughs on the concave die and match with the concave troughs; the material removal plate is hollowly provided with a trough where the convex die embedding can move up and down; the lower die seat is provided with a die cavity; the material removal plate is arranged in the die cavity and slide up and down by matching with and guiding the die cavity. The container top plate forming die of the invention has the advantages of high production efficiency and saving material; meanwhile, the operators during the production process can be greatly reduced correspondingly to the previous condition; furthermore, a plurality of top plate bosses are formed in one-step forming, thus having the advantages of stable dimension.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

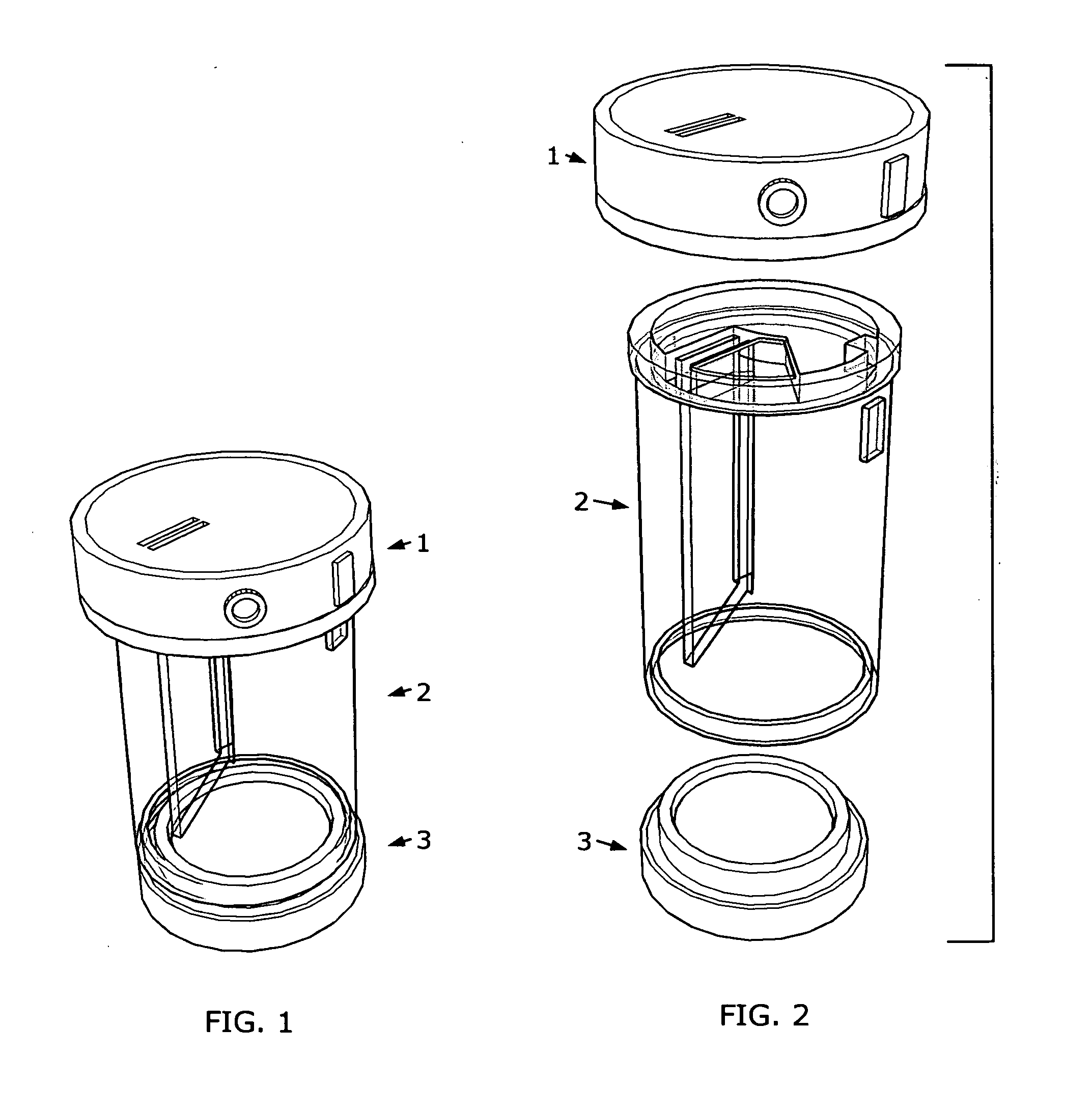

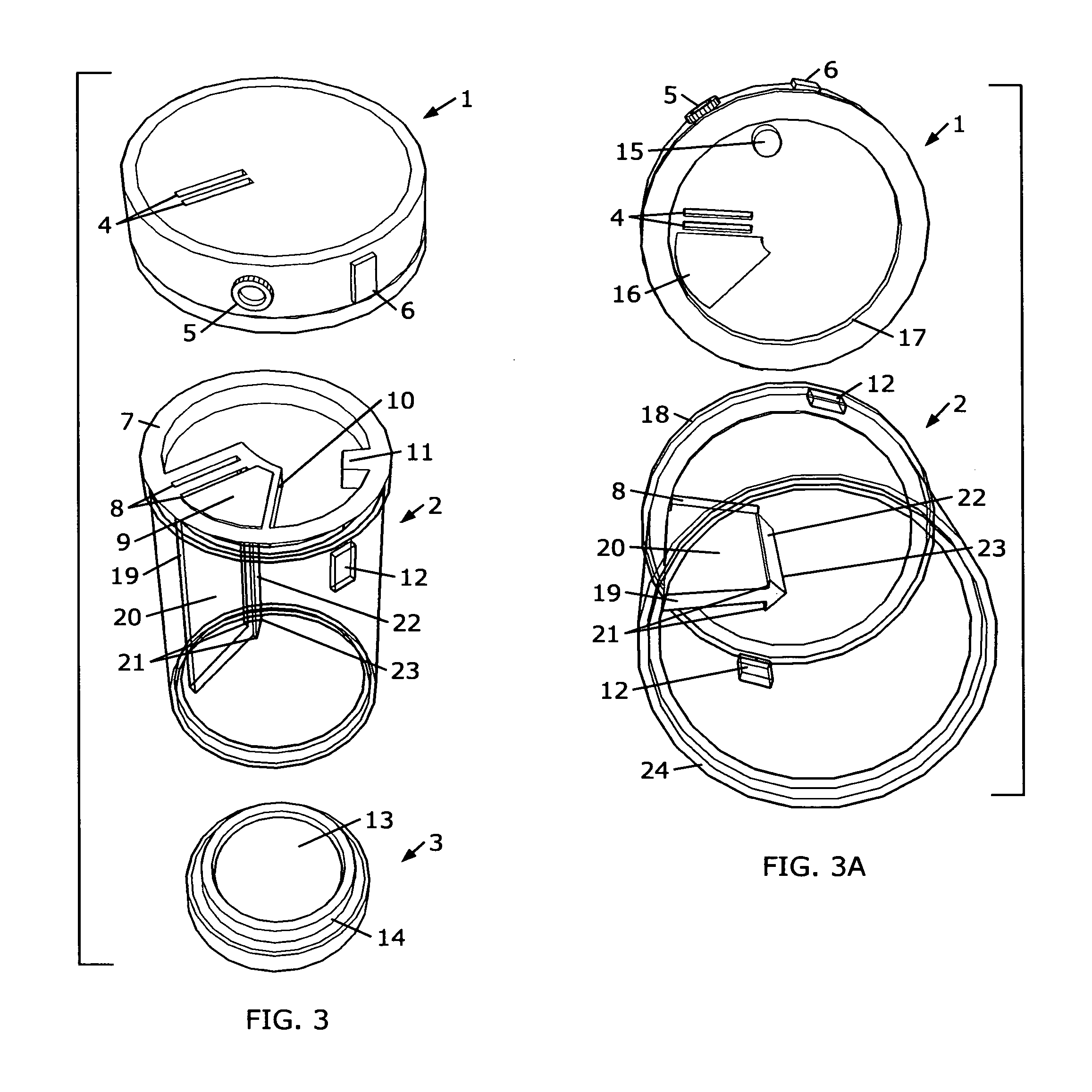

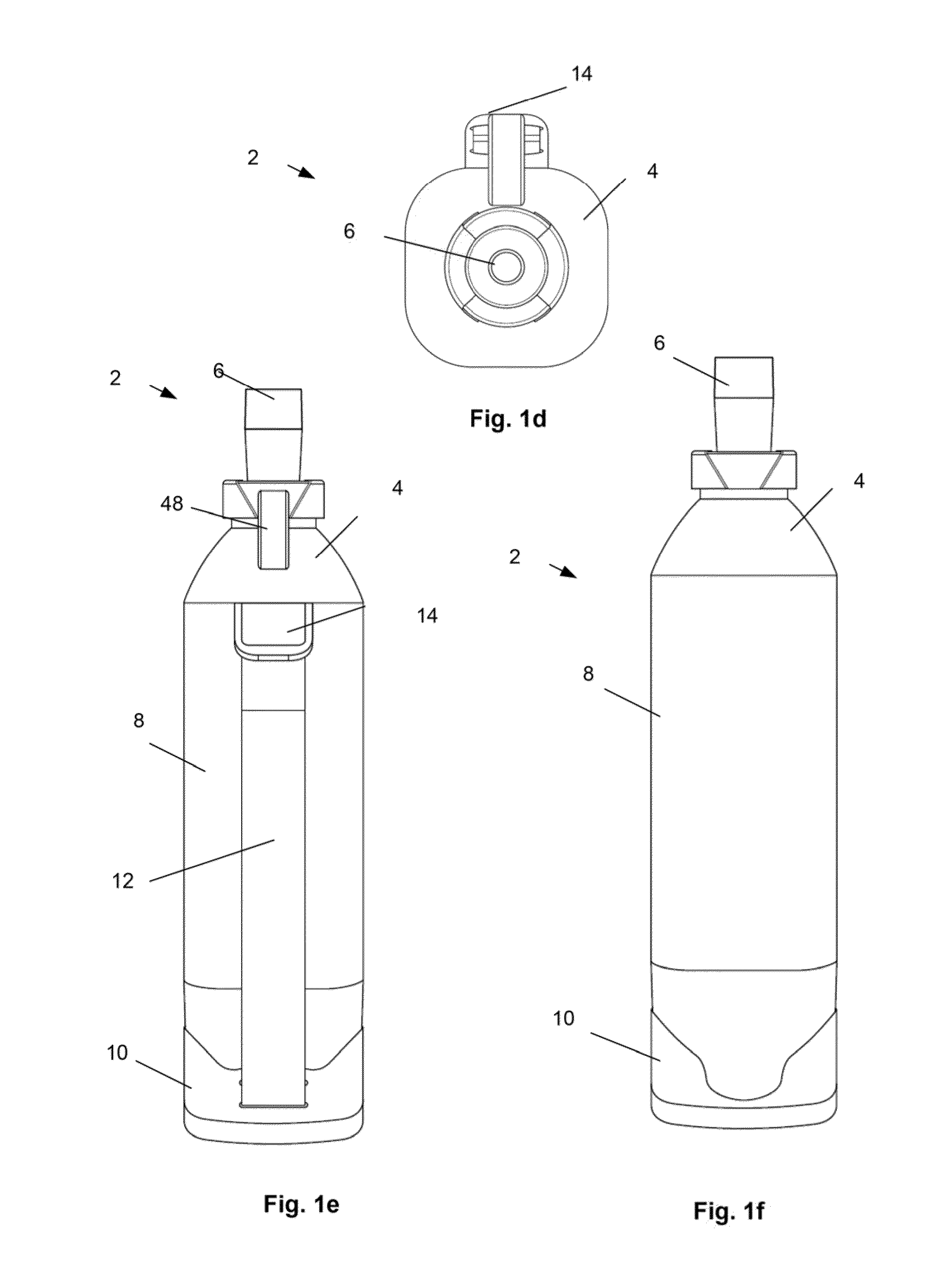

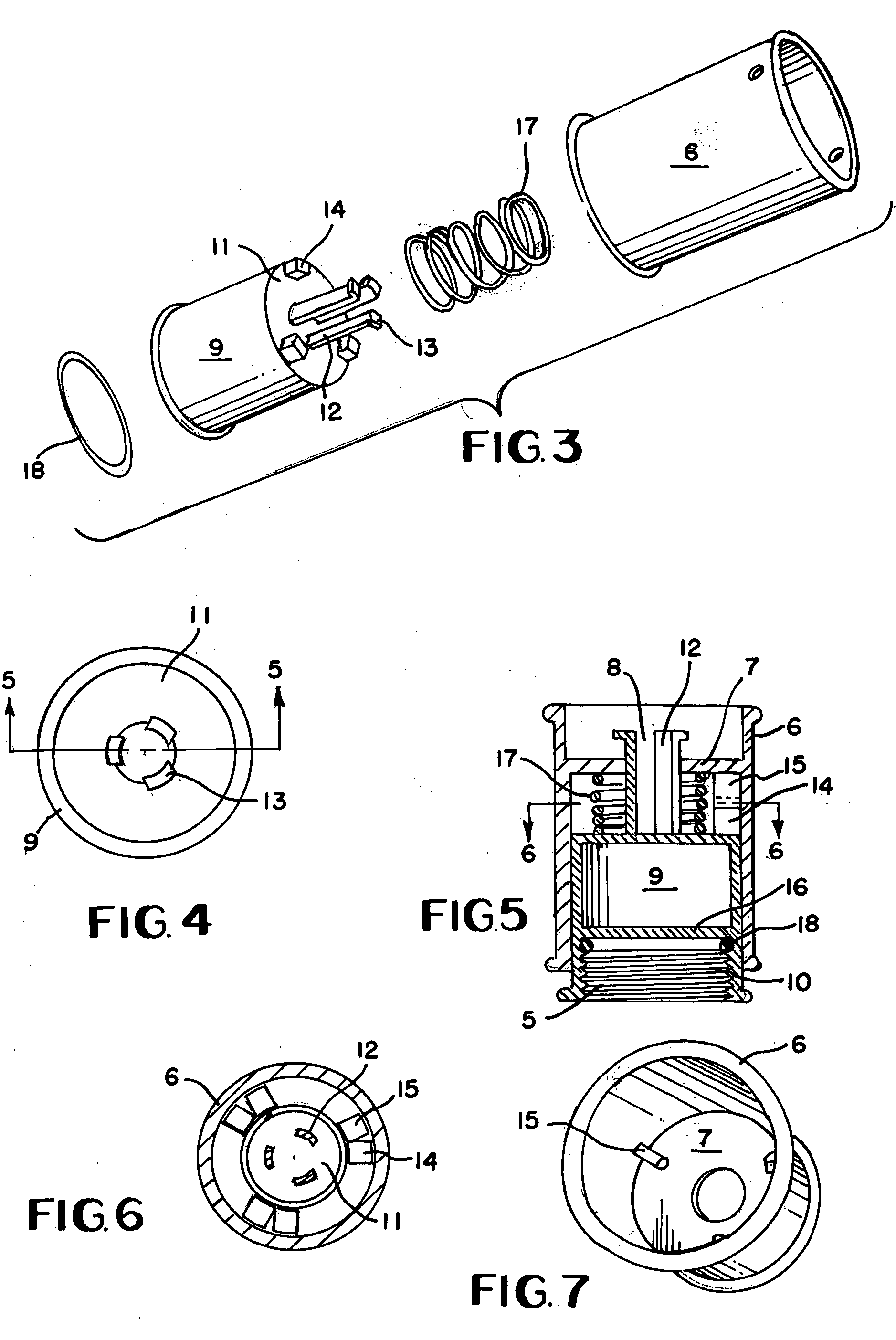

Device for singulating and dispensing rigid and semi-rigid strips

ActiveUS20120199601A1Easy positioningSimple and inexpensiveRacksCoin-freed apparatus detailsAnalyteDesiccant

A container device for storing, singulating and dispensing rigid and semi-rigid strips such as diagnostic test strips. A plurality of strips is contained and protected within a transparent container having an internal capture element for capturing and positioning a single strip adjacent a narrow normally-closed dispensing aperture. The aperture is exposed by rotating a spring-loaded container top cap to an open position. A detachable container base cap contains a desiccant and is replaceable. An optional stand stores the device in an upright position, and incorporates a tool to facilitate removal of the base cap for replenishing the container's contents or replacing the desiccant. A radio frequency identification (RFID) tag can be incorporated for electronic inventory control. The device can also be used as an integrated test strip container / single strip dispensing means for an automated analyte meter module.

Owner:SAWA KEVIN G

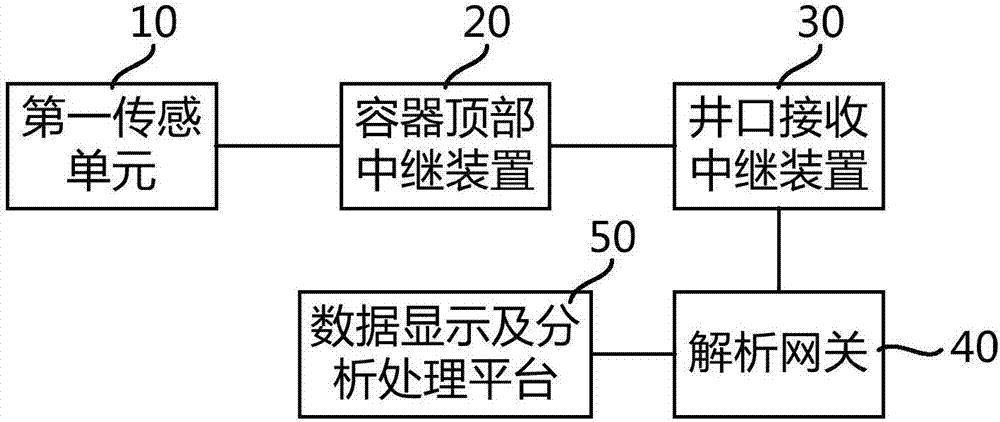

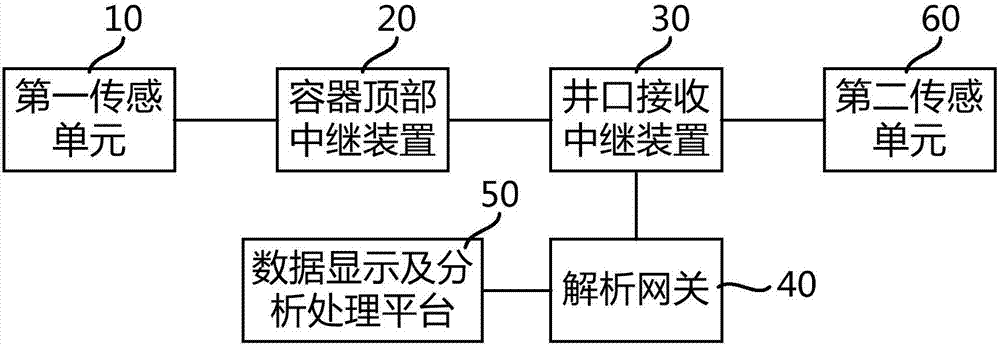

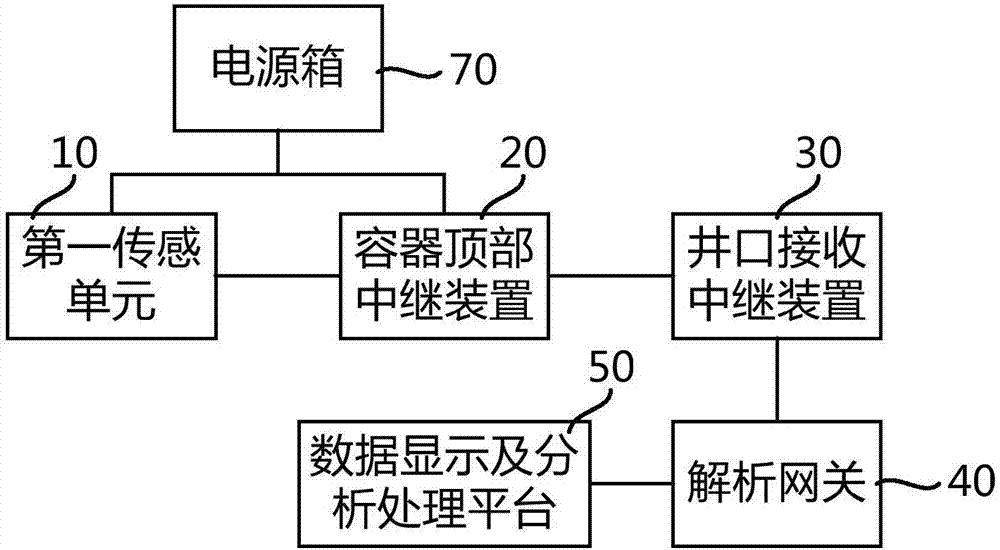

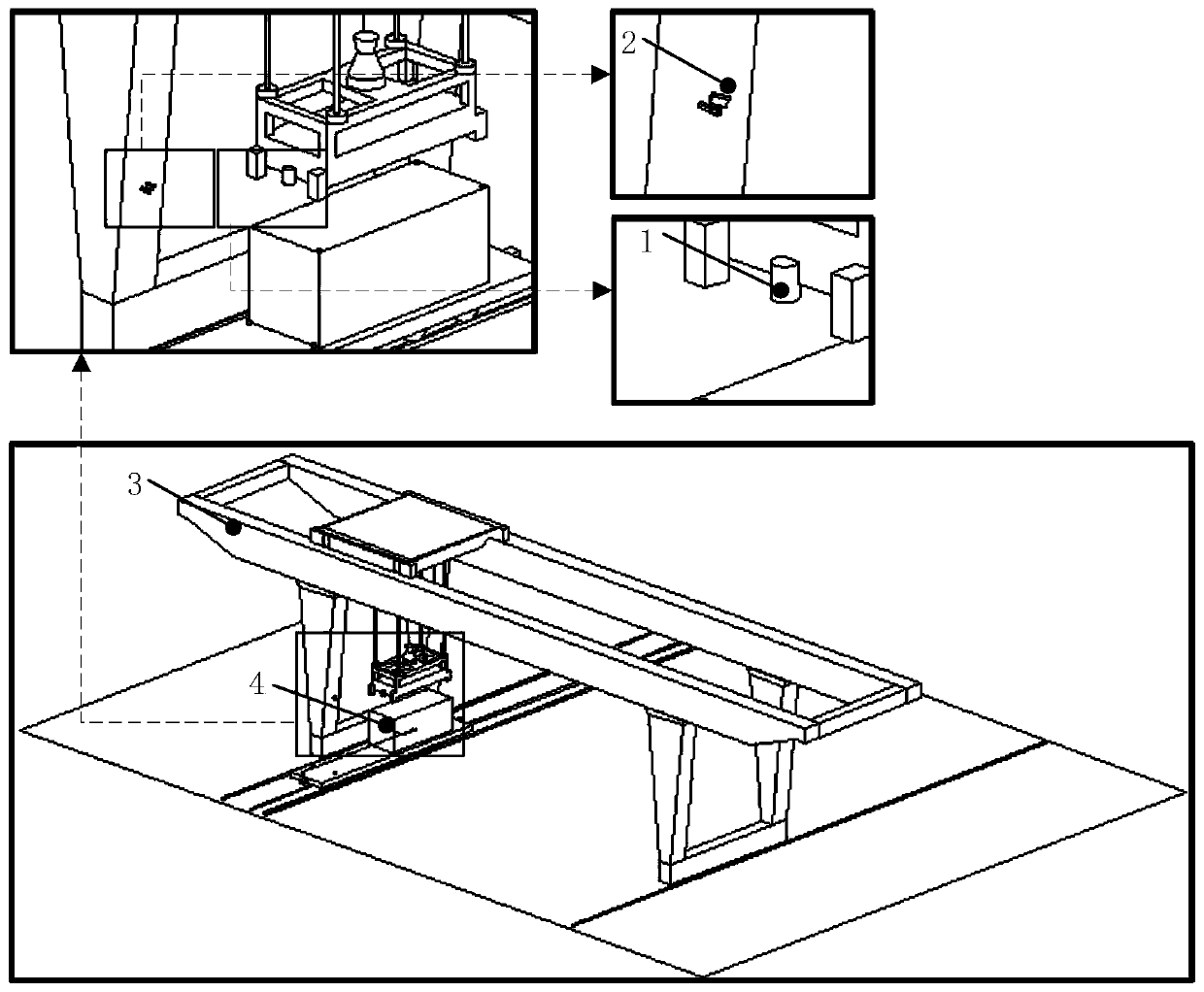

On-line monitoring system and method for suspension steel wire rope for hoisting container

InactiveCN106865375AImprove real-time uninterrupted monitoringImprove stabilityElevatorsElectricityFrequency-hopping spread spectrum

The present invention relates to an online monitoring system and method for a steel wire rope suspended from a lifting container. The system includes: a first sensing unit, a relay device at the top of the container, a receiving relay device at the wellhead, an analysis gateway, and a data display and analysis processing platform; the first The sensing unit is used for real-time acquisition of the first state parameter that can characterize the suspension wire rope; the container top relay device is arranged on the top of the lifting container and is electrically connected with the first sensing unit for receiving the first state parameters, and transmit them to the wellhead receiving relay device through frequency hopping spread spectrum and time division multiple access wireless technology; the wellhead receiving relay device is set on the inner wall of the wellbore or the wellhead, and is used to pass the received data through the analysis gateway Send to the data display and analysis processing platform. The invention can realize the real-time uninterrupted monitoring of the hoisting container suspension steel wire rope during periodic operation, and ensure the reliability and safety of the hoisting system in the deep well environment.

Owner:TAIYUAN UNIV OF TECH

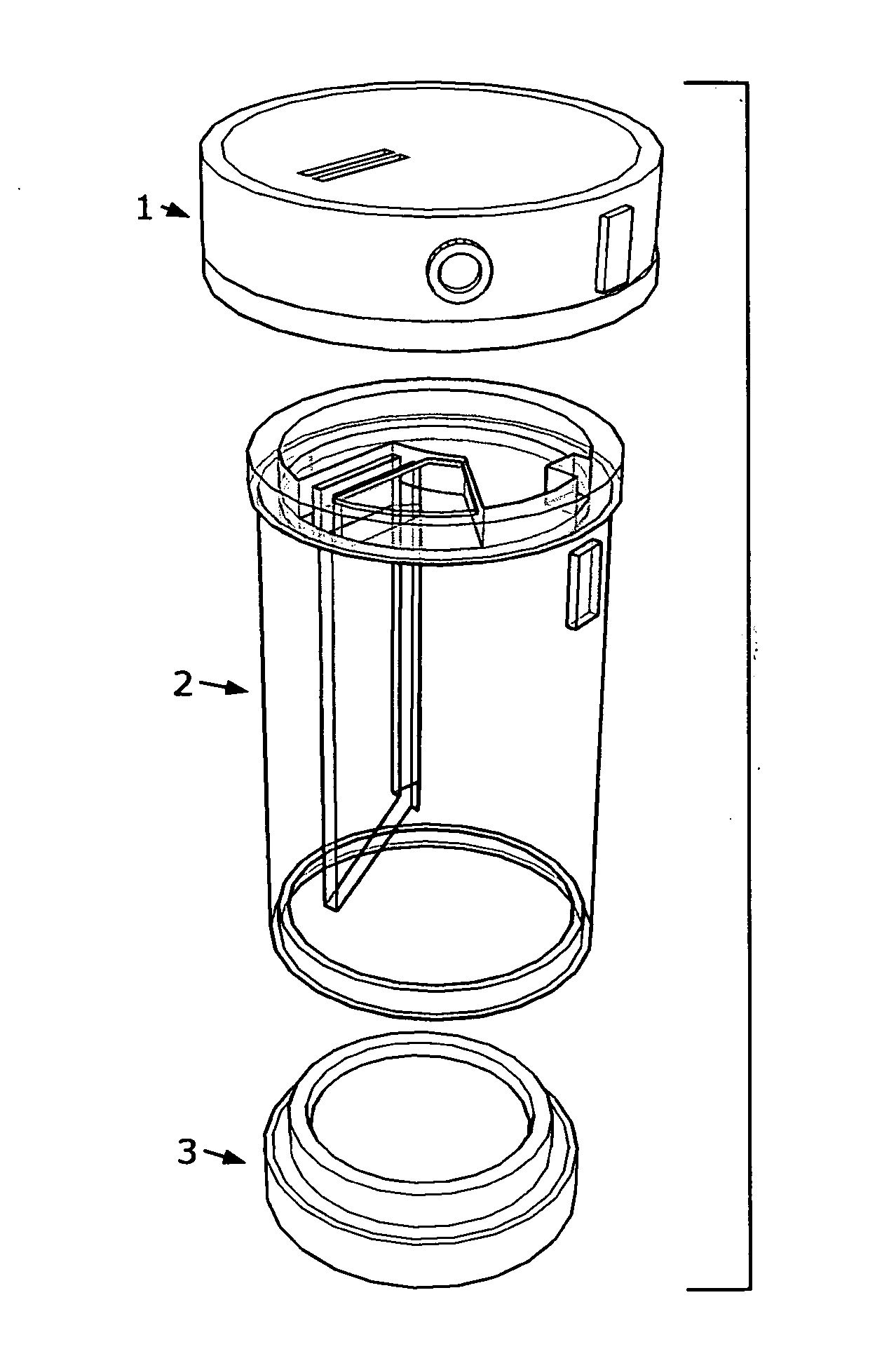

Reagent container and reagent carousel

InactiveCN101583877ALow costSave materialLaboratory glasswaresMaterial analysisEngineeringContainer tops

The present invention relates to a reagent container for liquid reagents, said container having a container base in the shape of a circular sector, a trapezoid or a triangle and a container top and container side walls which extend in the vertical direction from the container base to the container top and taper towards one another from a container rear wall to a container front side, wherein the container top has an opening. In order to be able to adjust reagent containers of different sizes such that they are exactly positioned and reliably fixed in a reagent carousel, the invention proposesproviding at least one positioning groove or positioning stop surface, which starts from the container base and extends vertically in the direction of the container top, on at least one side wall of the reagent containers. In order to be able to use as many different reagent containers as possible for a particular reagent carousel, the invention also proposes a reagent carousel having an essentially circular carousel base area and compartments which are radially arranged on the latter, are bounded by radially extending boundaries and are intended to hold reagent containers, wherein the boundaries which bound a compartment have at least one projection which points towards the interior of the compartment and is intended to engage with a positioning groove or a positioning stop surface of a reagent container.

Owner:DIASYS TECH R L

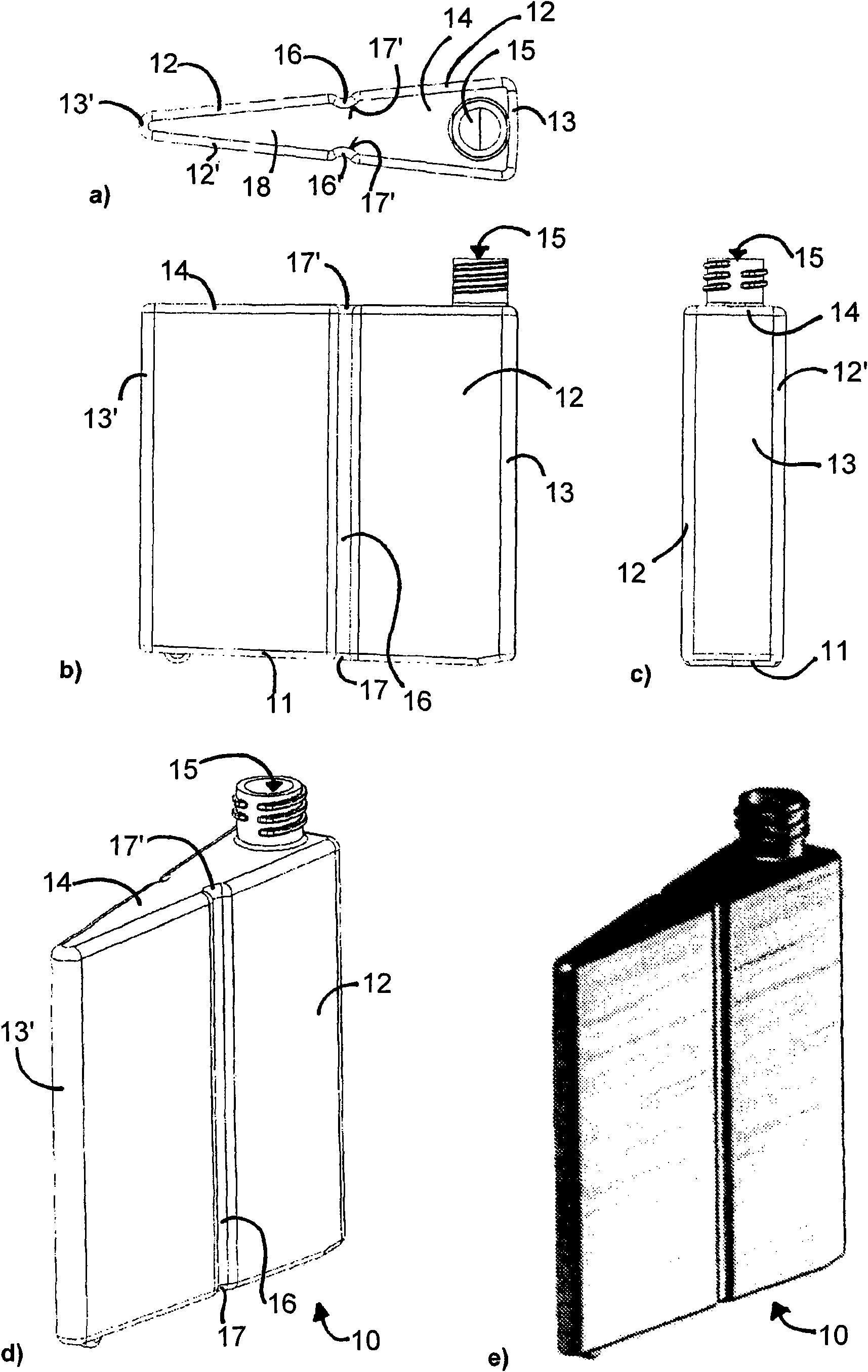

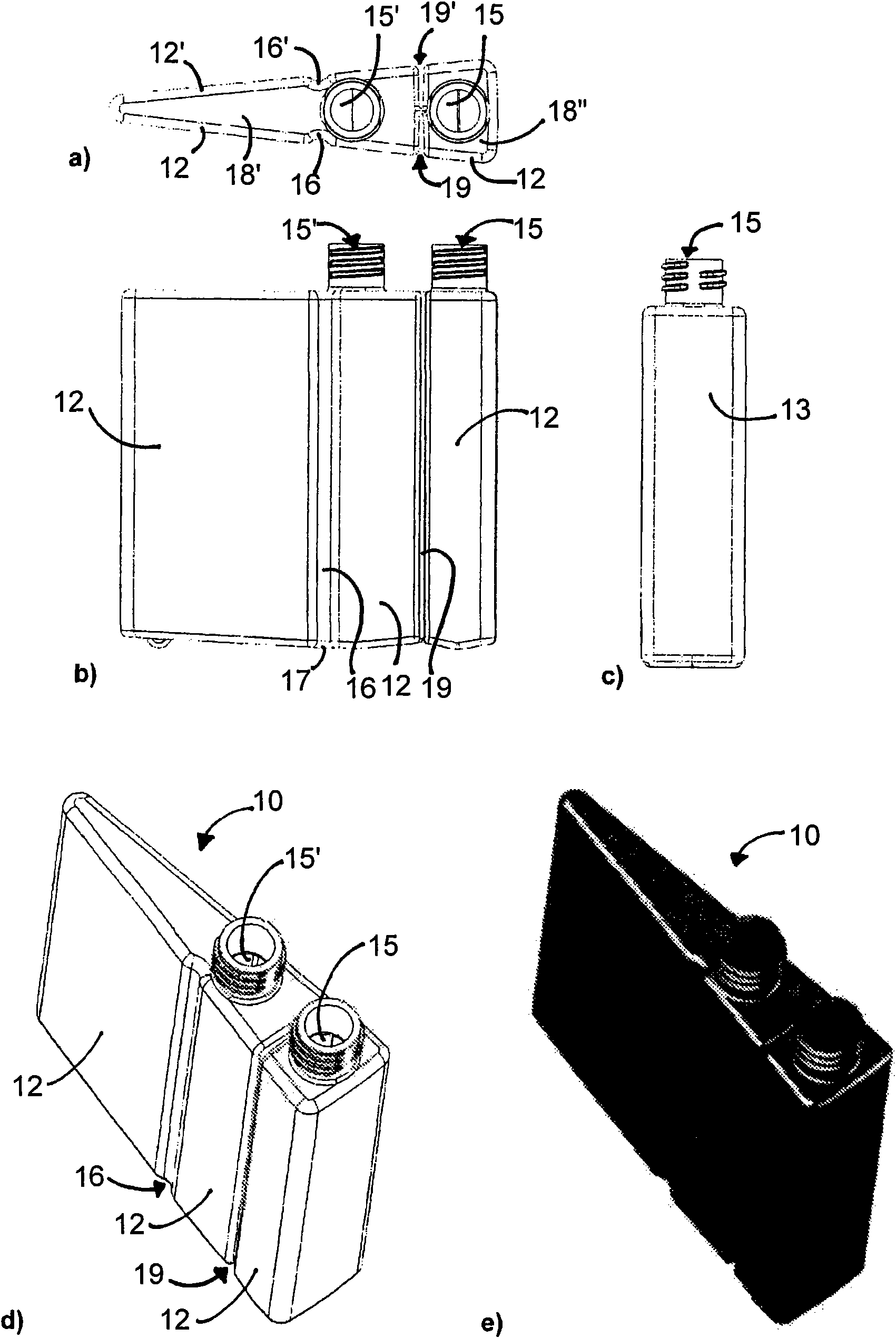

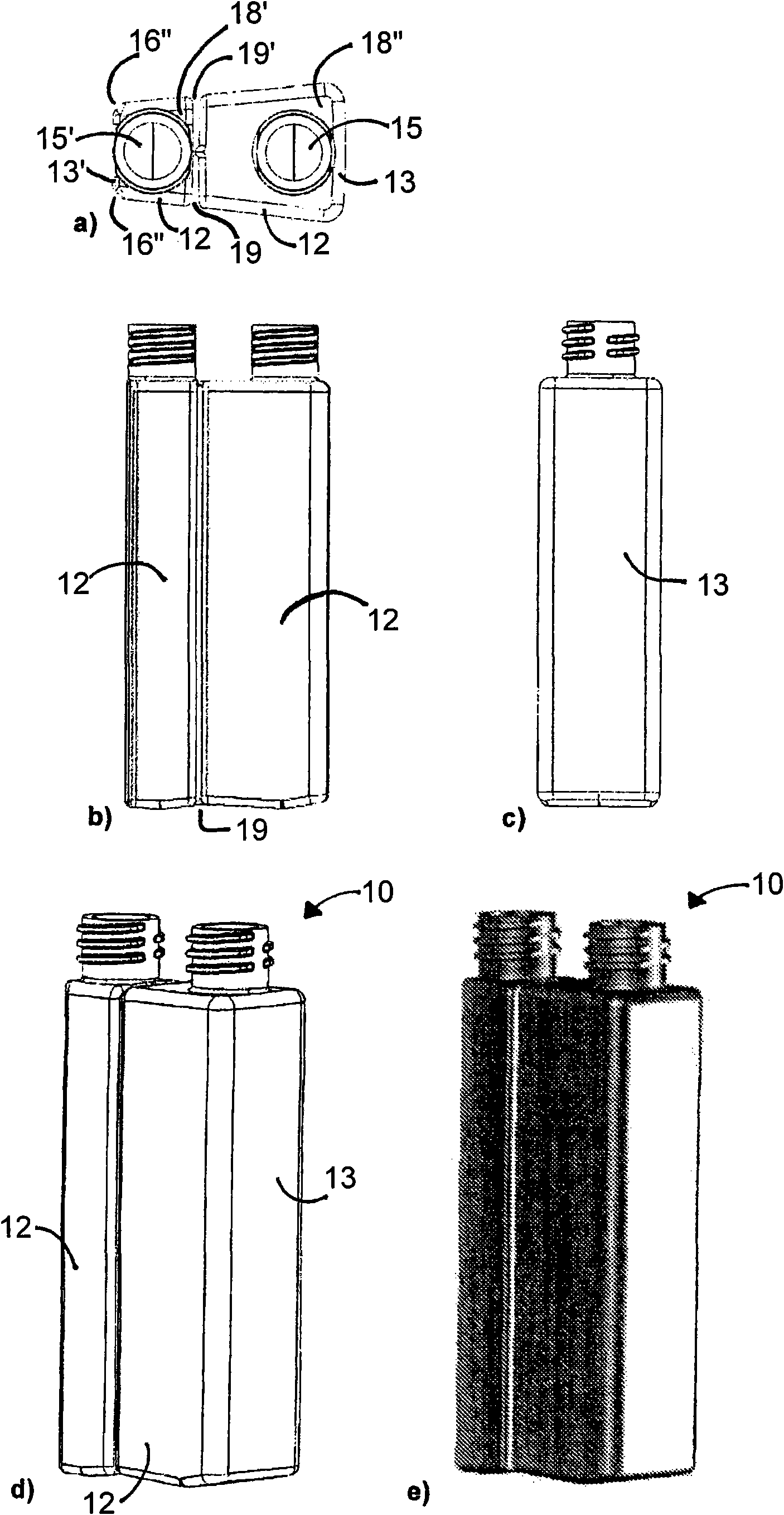

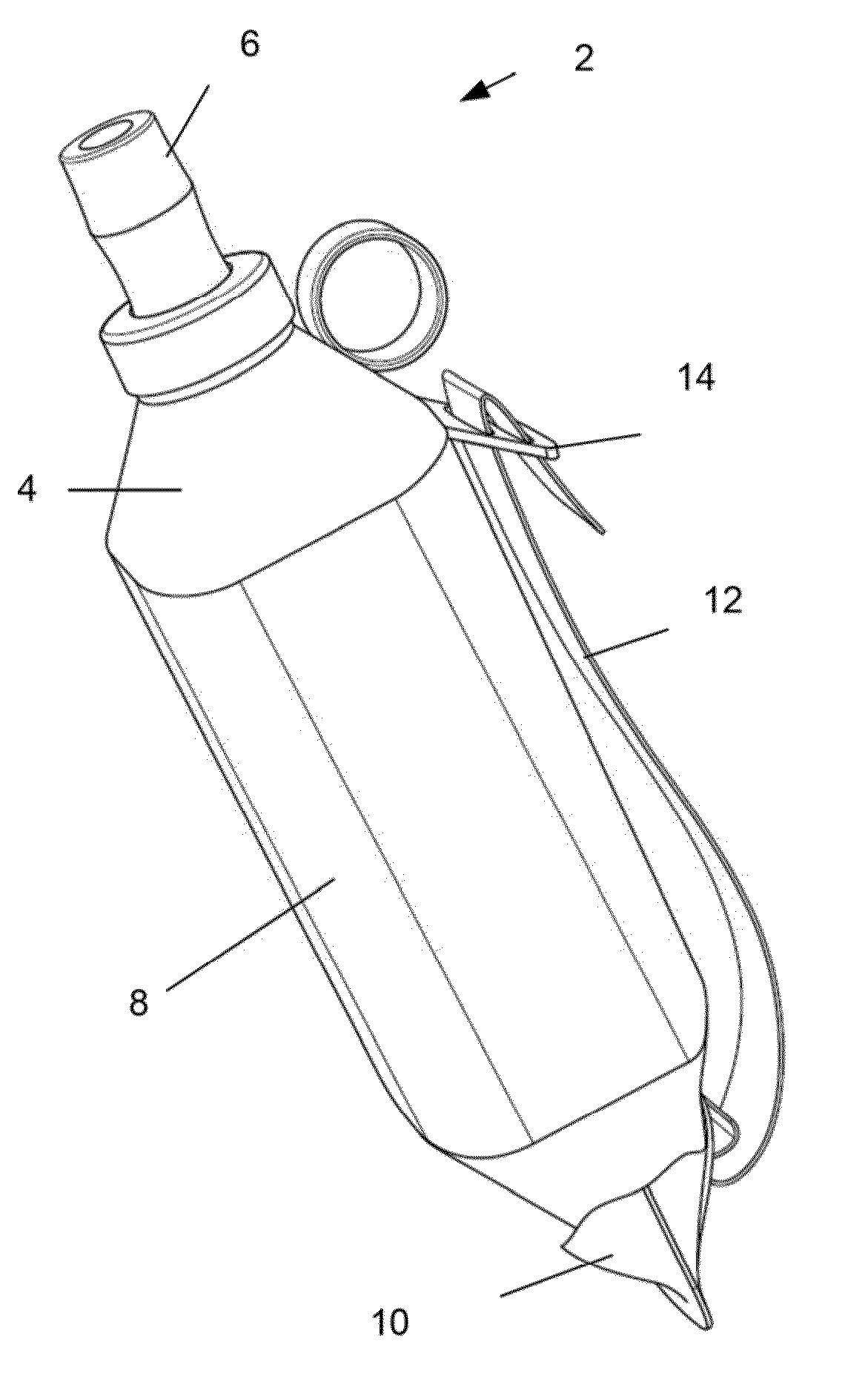

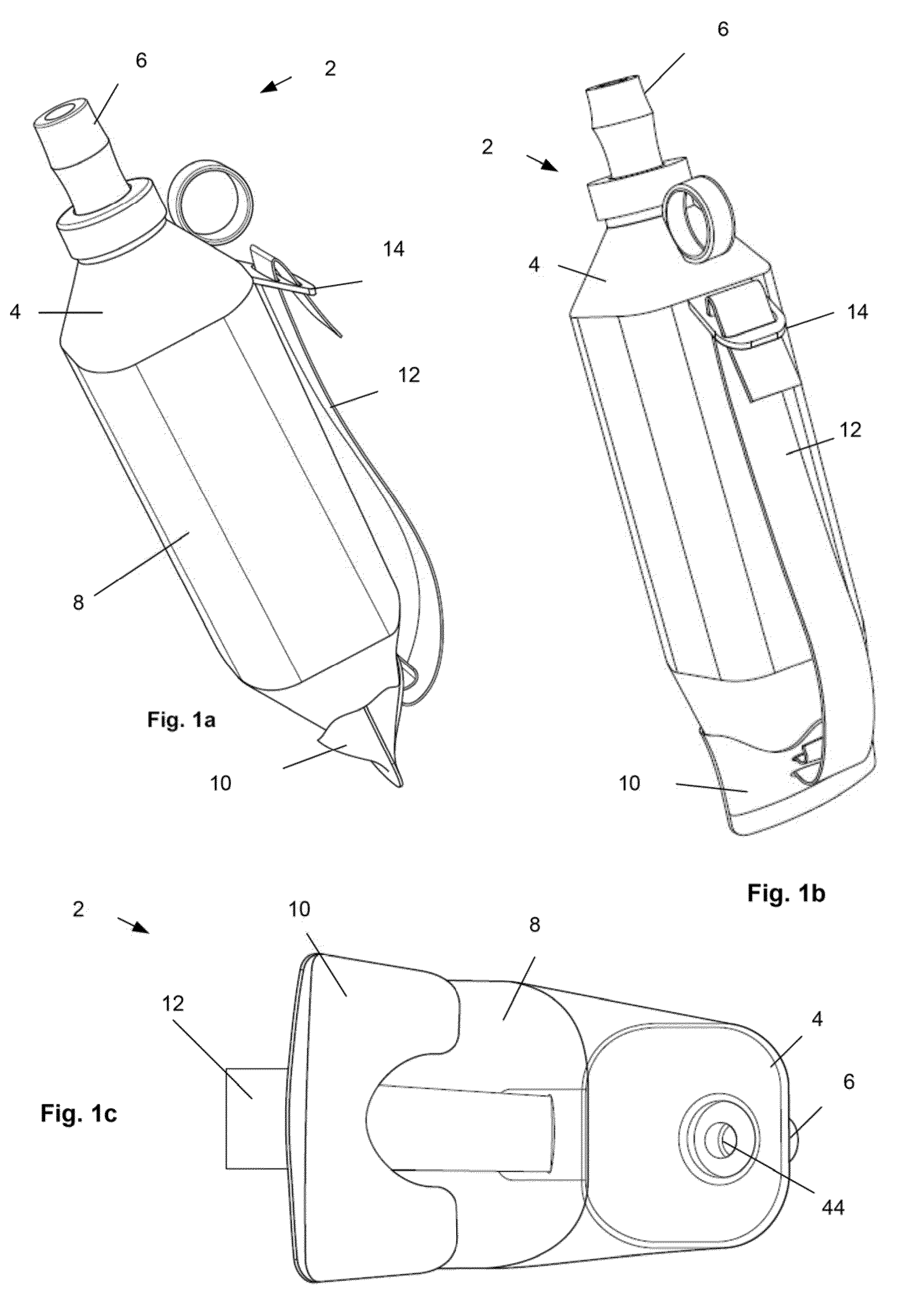

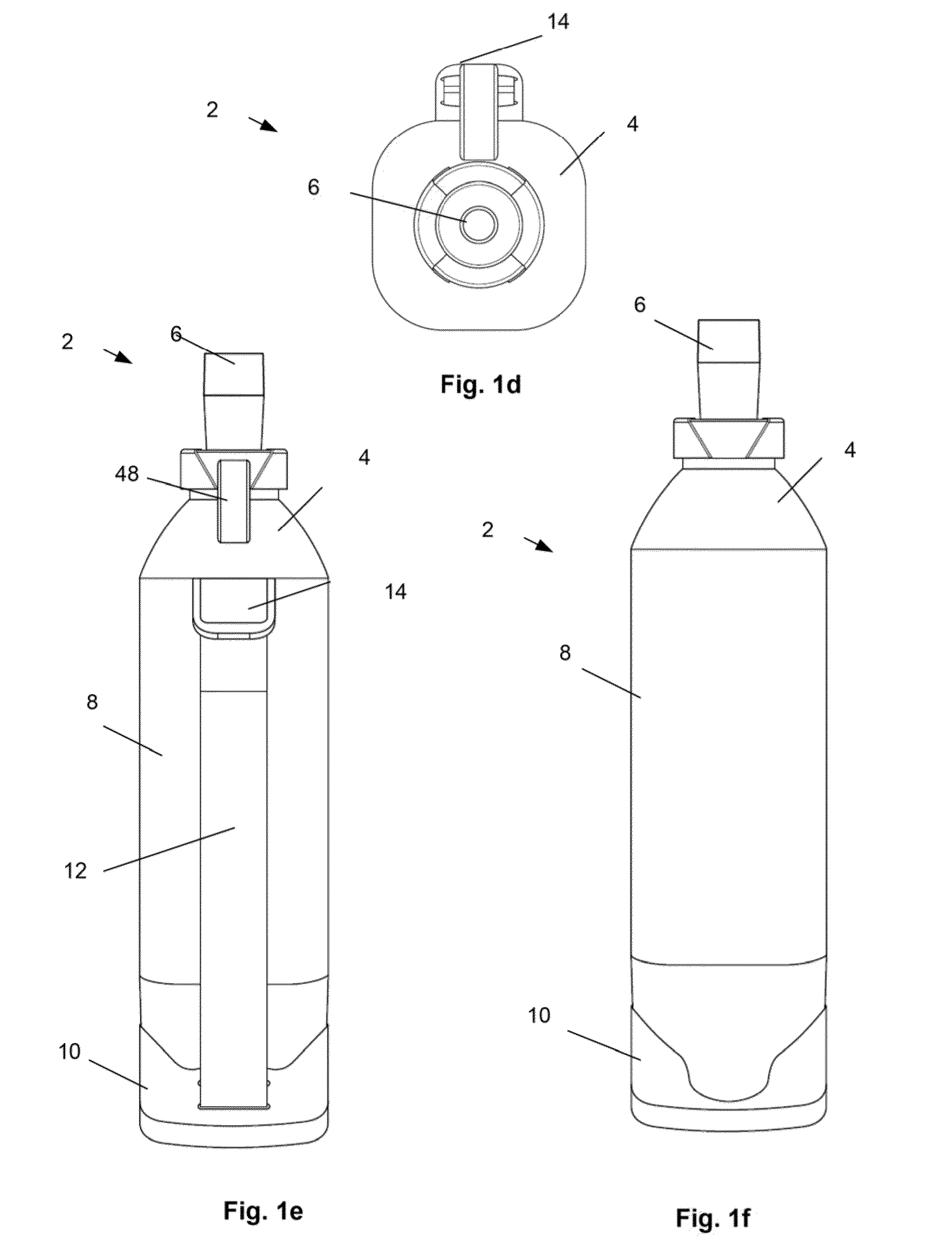

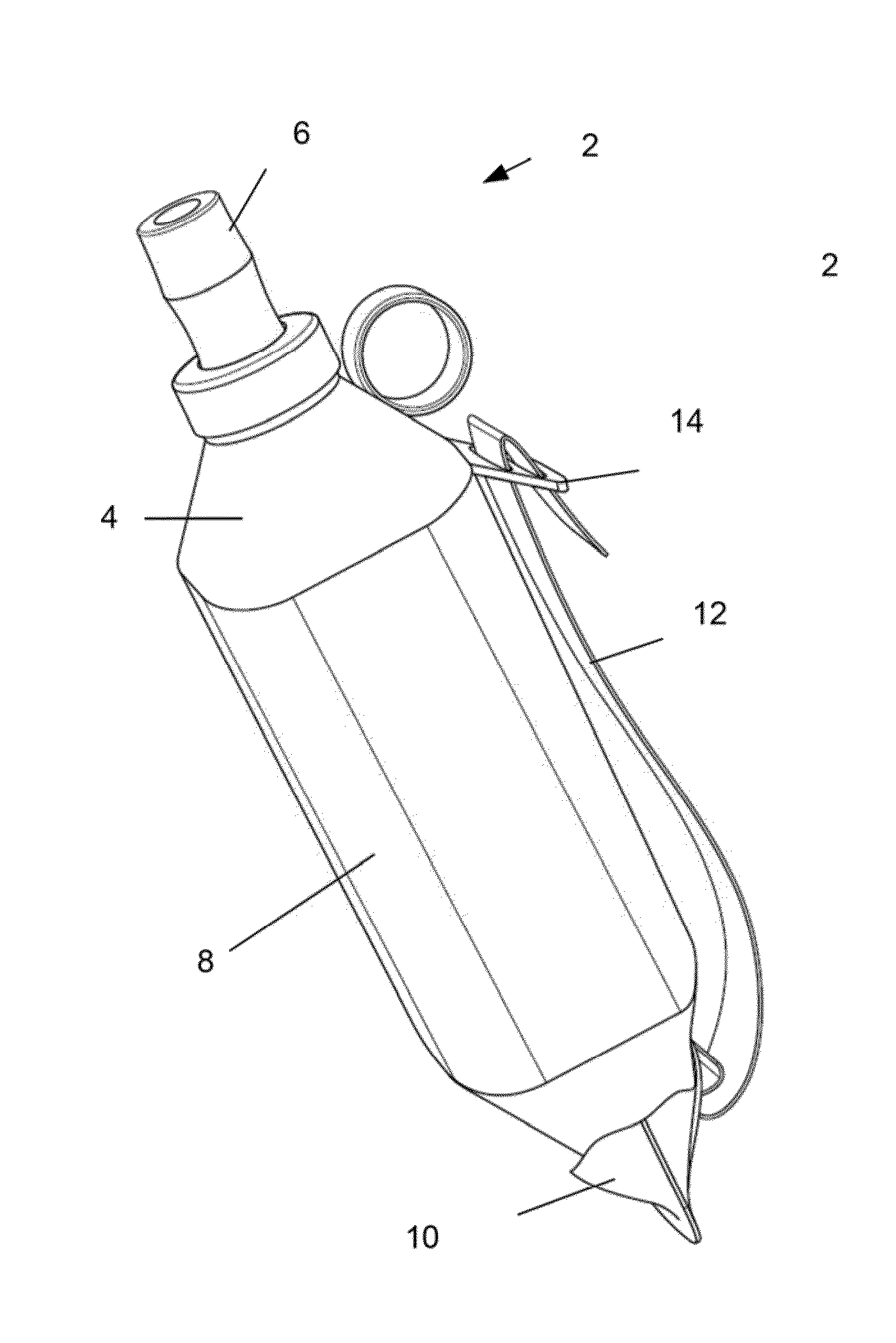

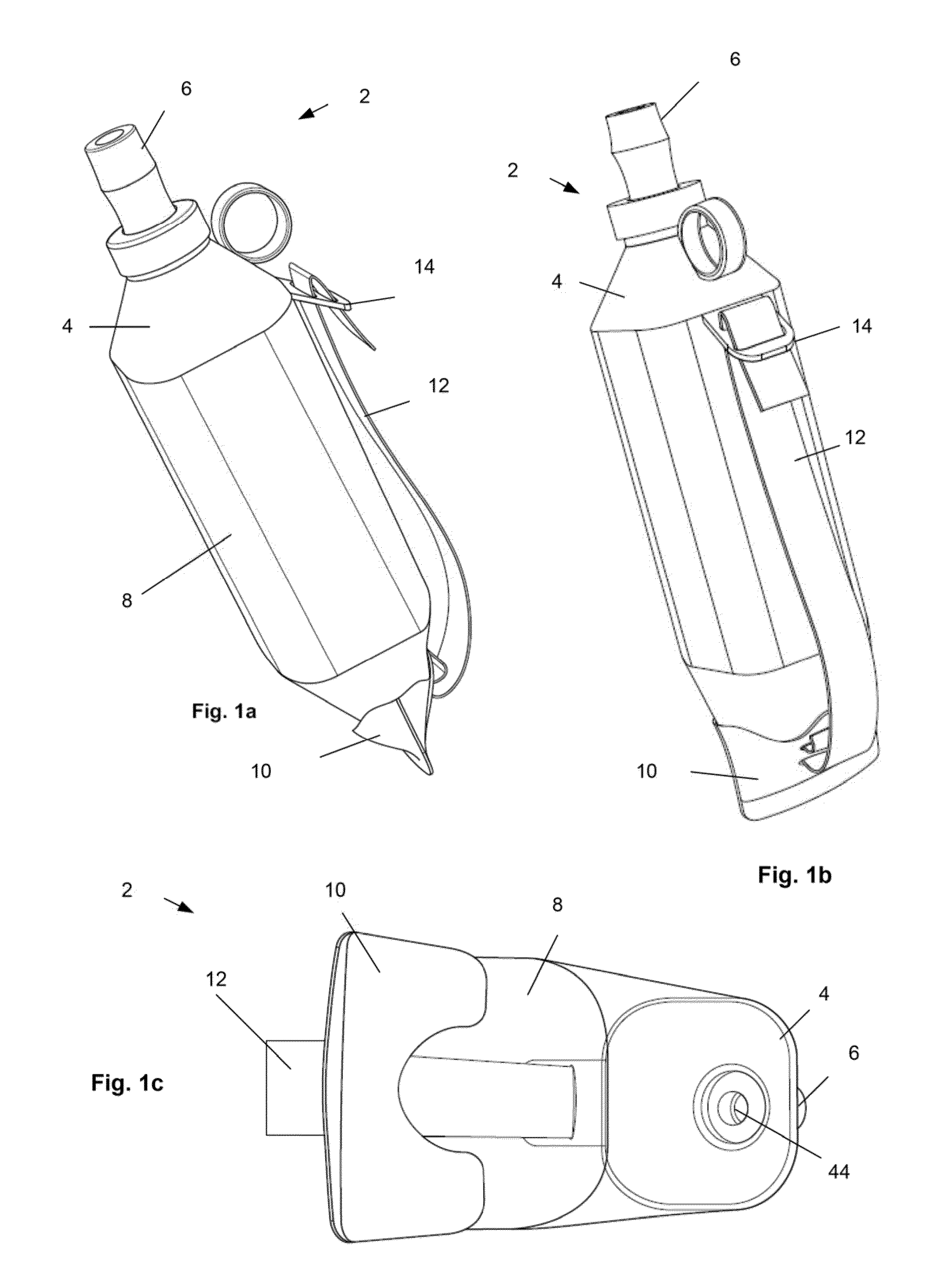

Flexible container

A container for holding and delivering liquids is disclosed. A method of making the same is disclosed. The container can have a molded container top, a molded container bottom, a flexible film reservoir, and a handle extending from the container top to the container bottom. The reservoir can be laterally exposed around the entire circumference of the reservoir along a part of the longitudinal length of the reservoir. A thermally insulated reservoir system is disclosed. The reservoir system can have a bag having a multi-layered bag wall. The bag wall can have a first layer sealed to a second layer. The volume defined between the first layer and the second layer can be partially or completely filled with a fluid insulator, such as air or saline solution. The volume defined between the first layer and the second layer can also or alternately be partially or completely filled with a solid insulator, such as a matted fiber layer.

Owner:HYDRAPAK LLC

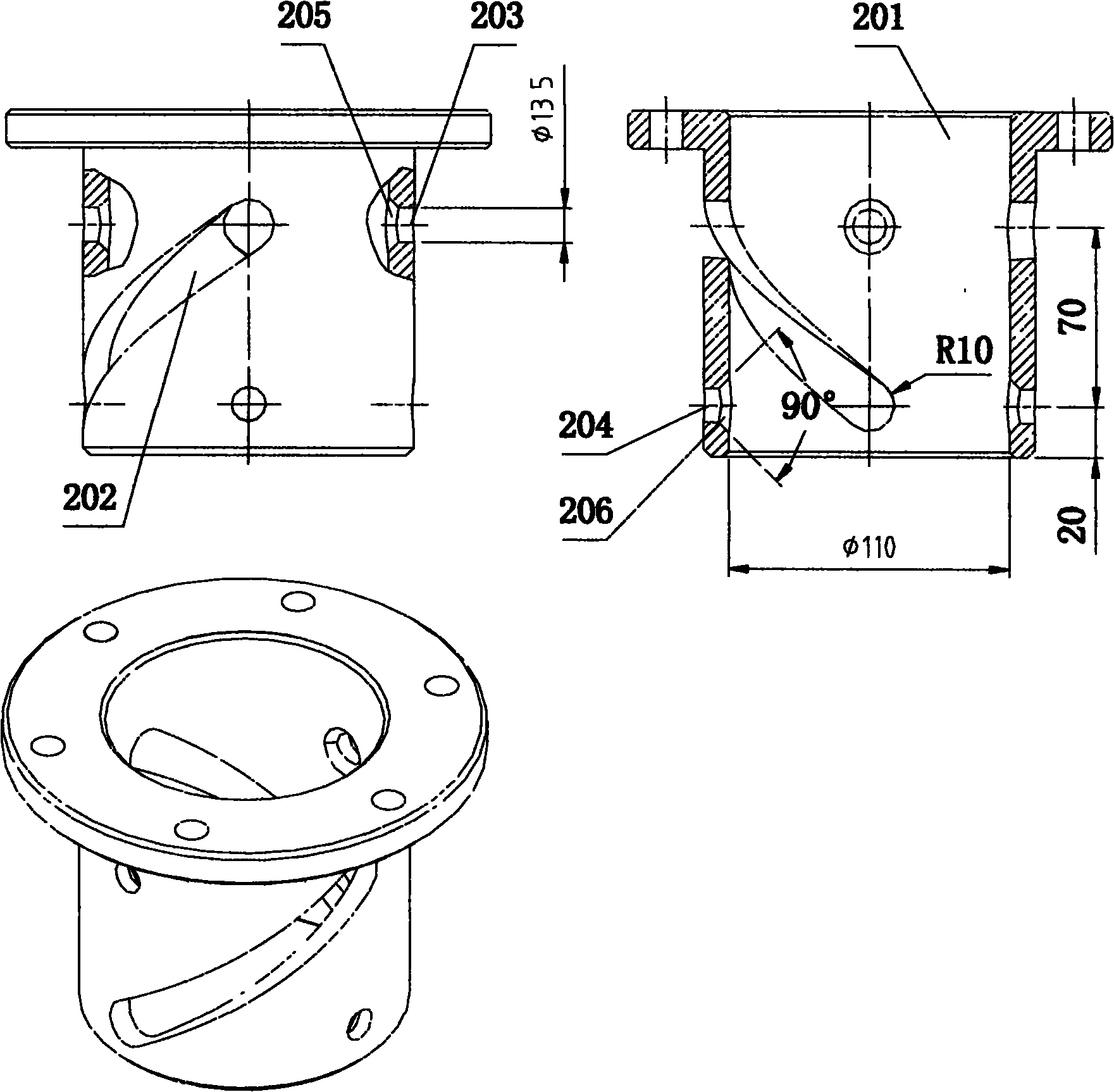

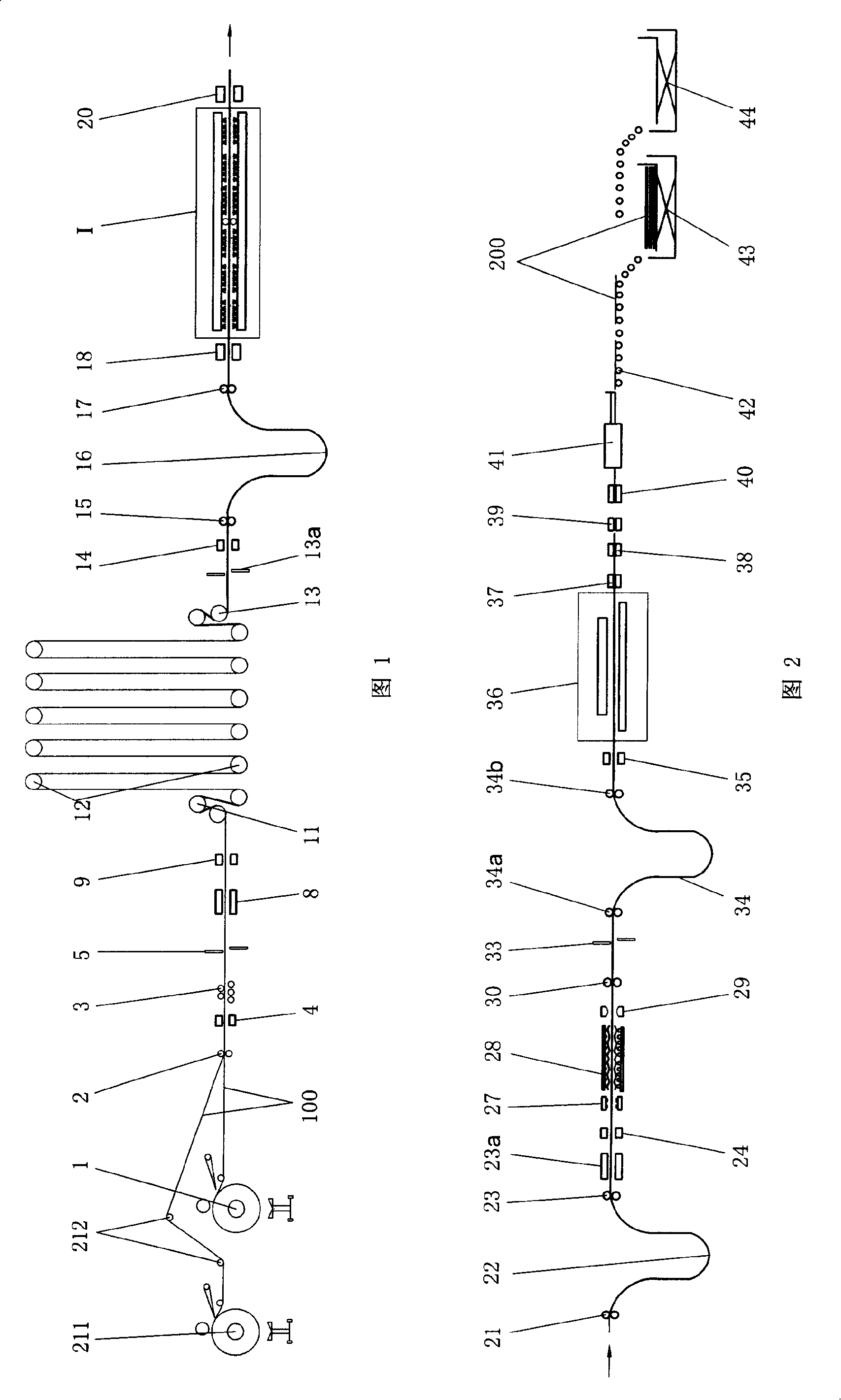

Press-down twist lock autorotation hanger

The invention discloses a press-down twist lock autorotation hanger for hoisting a container. The hanger is directly arranged on a hoisting beam of hoisting equipment, and does not need hydraulic, pneumatic or electric drive; and by using downward pressing of the hoisting equipment, a twist lock head rotates for 90 degrees, hooking or loosening of a vertex angle member of the container is finished, and the hoisting operation is realized. The press-down twist lock autorotation hanger is characterized by comprising a hanger framework, an upper mounting seat, a lower mounting seat, a return spring enclosure, a twist lock assembly, a jacking device and a signal switch. The hanger framework has a frame-shaped structure and is used for installing each member. The twist lock assembly comprises the twist lock head, a twist lock rod, a rotary pin, a rotary block, a rotary block return spring, a spring stop block, a thrust bearing, a return spring, a stop block pin, a clamping spring, a clamping steel ball and a twist lock pin. The upper mounting seat is provided with a spiral groove, the middle of the lower mounting seat is provided with a circular hole, and a square groove is processed on the upper end face of the lower mounting seat. The signal switch is used for giving twist lock state signals. The press-down twist lock autorotation hanger has simple and compact structure, reduces the manufacture and maintenance costs, and has good practical effect.

Owner:杨征华

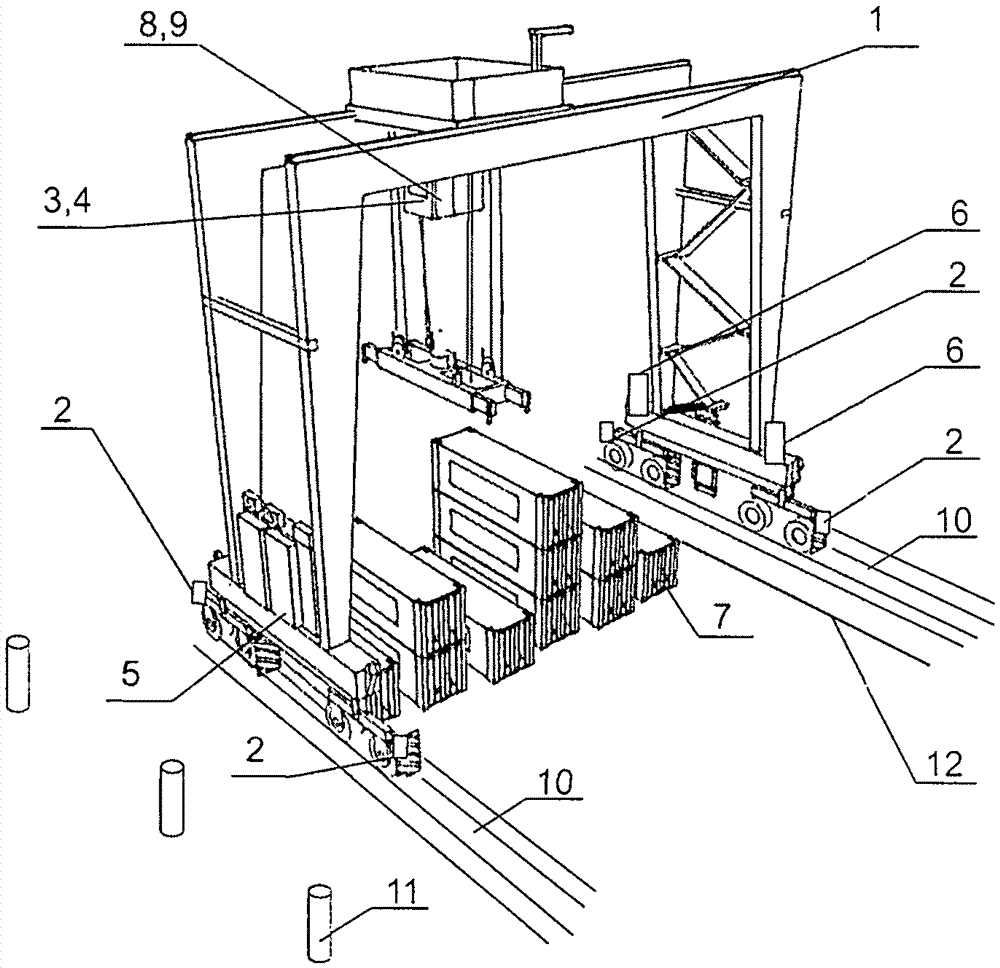

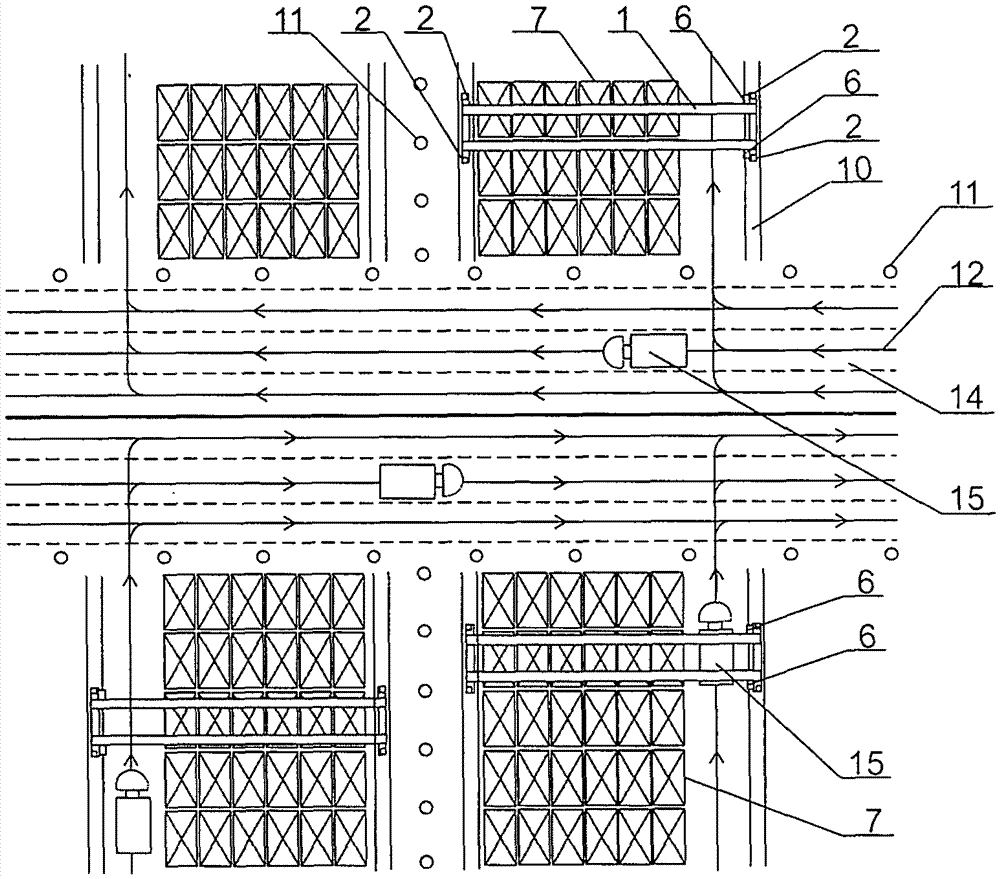

Container wharf flow equipment automatic walking method

InactiveCN106946049ARealize automatic walking correctionRealize automatic walkingStorage devicesImaging processingSimulation

The invention provides a container wharf flow equipment automatic walking method. Laser scanners are installed on four door leg tire front wheel brackets of a tire crane correspondingly, vertical columns are installed between the back surfaces of two tire crane lanes by a certain distance or the length of a container at intervals and are located in a straight line, the positions of the vertical columns are detected through the tire crane laser scanners, and automatic walking of the tire crane is achieved. Meanwhile, vertical columns are installed on the two sides of a road lane by a certain distance and are located in a straight line; vertical columns are installed on the inner sides of two door legs, close to the lane, of the tire crane correspondingly; and vertical columns are installed on the inner side and the outer side of each door leg of a bridge crane correspondingly. An ordinary container lorry is improved into an automatic navigation vehicle, the vertical columns higher than the top surface of the container, a camera and the laser scanners are installed on the navigation vehicle, walking datum line paint is at the center of the ground lane, the navigation vehicle shoots the walking datum line through the camera so as to conduct image processing and alignment, the positions of the vertical columns are detected through the scanners, and automatic walking of the navigation vehicle is achieved.

Owner:SHANGHAI HAILEI LASER TECH

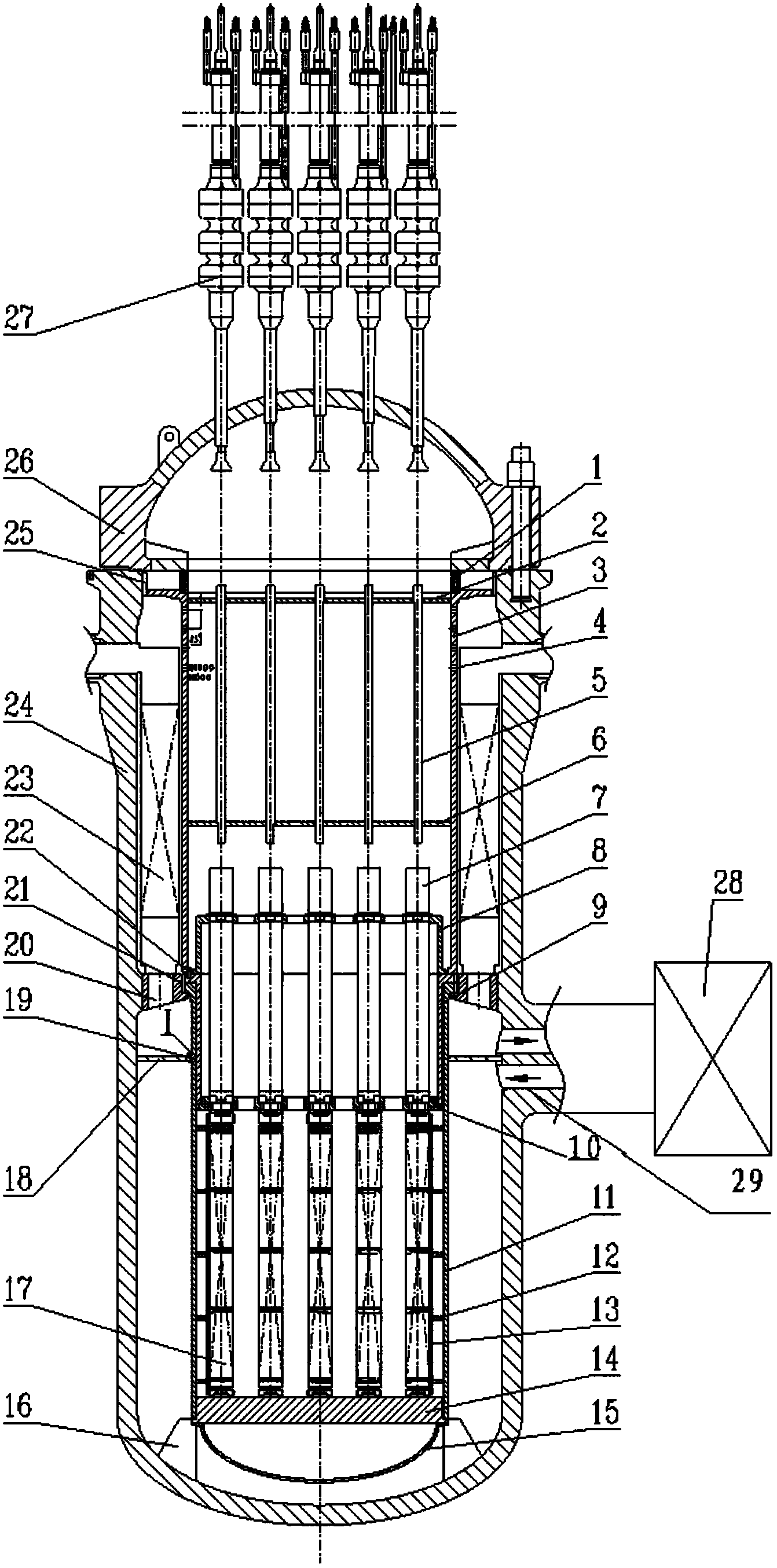

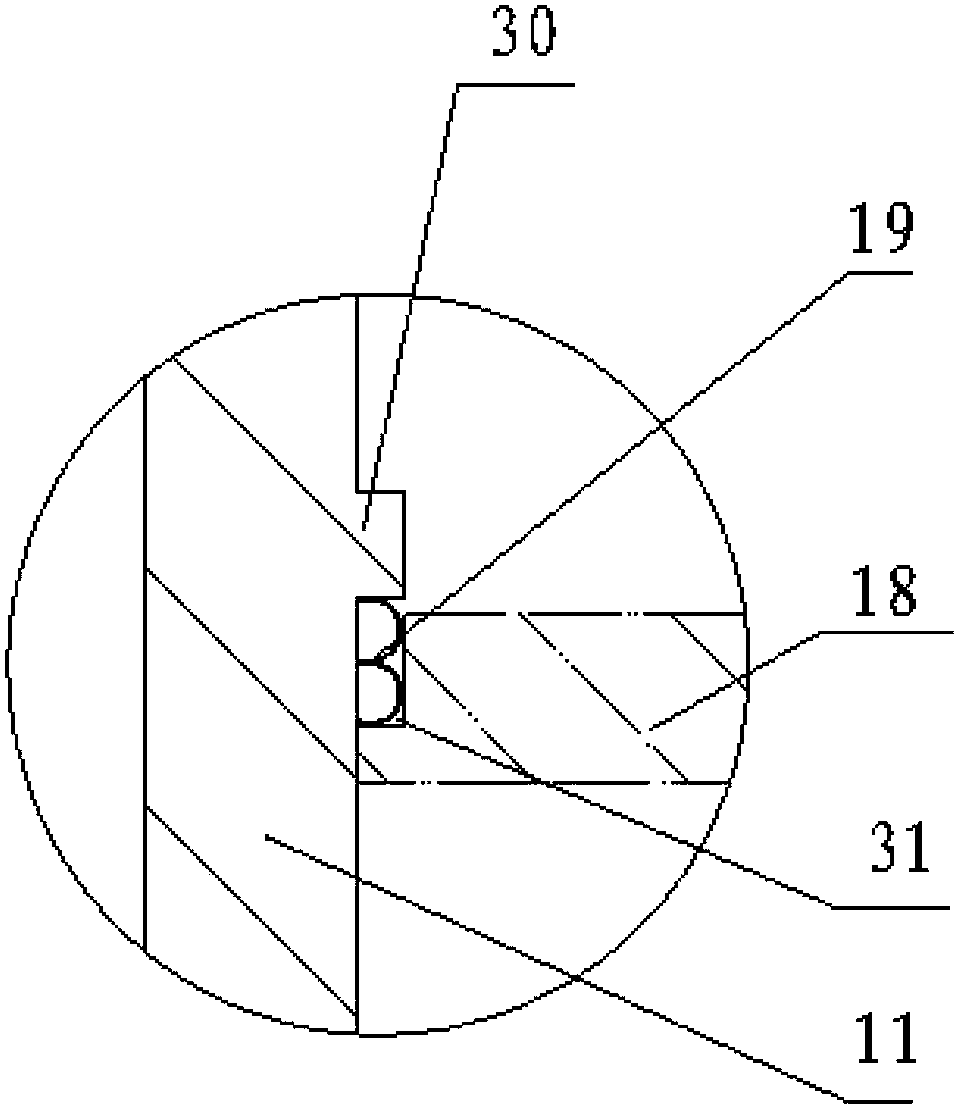

Split-type integral pressurized water reactor with down-suspended basket

ActiveCN103474104AEasy to check in serviceGuaranteed integrationNuclear energy generationShieldingPressurized water reactorNuclear power

The invention relates to the technical field of nuclear power integral reactors and particularly discloses a split-type integral pressurized water reactor with a down-suspended basket. The split-type integral pressurized water reactor comprises a pressure container cylinder, wherein a pressure container top cover is arranged on the pressure container cylinder, the side face of the pressure container cylinder is connected with a main coolant pump, a down-suspended basket component and an impaction component are arranged inside the pressure container cylinder, the impaction component is positioned above the down-suspended basket component, a fuel component is arranged in the down-suspended basket component, a flow shunting cover is arranged below the down-suspended basket component, a guide Component is in the impaction component, a control rod driving mechanism fixed on the pressure container top cover is positioned above the impaction component, and the control rod driving mechanism is fixed on the pressure container top cover. By virtue of integrated double-flow holes on the side face of a pressure container, coolant inlet and outlet structures of a main pump and the pressure container are simplified to facilitate the in-service inspection of welding seams of the pressure container. The down-suspended basket structure is mounted at the middle lower part of the pressure container cylinder, so that the axial dimension is greatly reduced, the axial dimension of the impaction component is correspondingly reduced, the whole structure is simplified, the reliability is improved, and the mounting and dismounting are convenient.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Flexible container

A container for holding and delivering liquids is disclosed. A method of making the same is disclosed. The container can have a molded container top, a molded container bottom, a flexible film reservoir, and a handle extending from the container top to the container bottom. The reservoir can be laterally exposed around the entire circumference of the reservoir along a part of the longitudinal length of the reservoir. A thermally insulated reservoir system is disclosed. The reservoir system can have a bag having a multi-layered bag wall. The bag wall can have a first layer sealed to a second layer. The volume defined between the first layer and the second layer can be partially or completely filled with a fluid insulator, such as air or saline solution. The volume defined between the first layer and the second layer can also or alternately be partially or completely filled with a solid insulator, such as a matted fiber layer.

Owner:HYDRAPAK LLC

Outdoor torch safety cap

Owner:IBM CORP

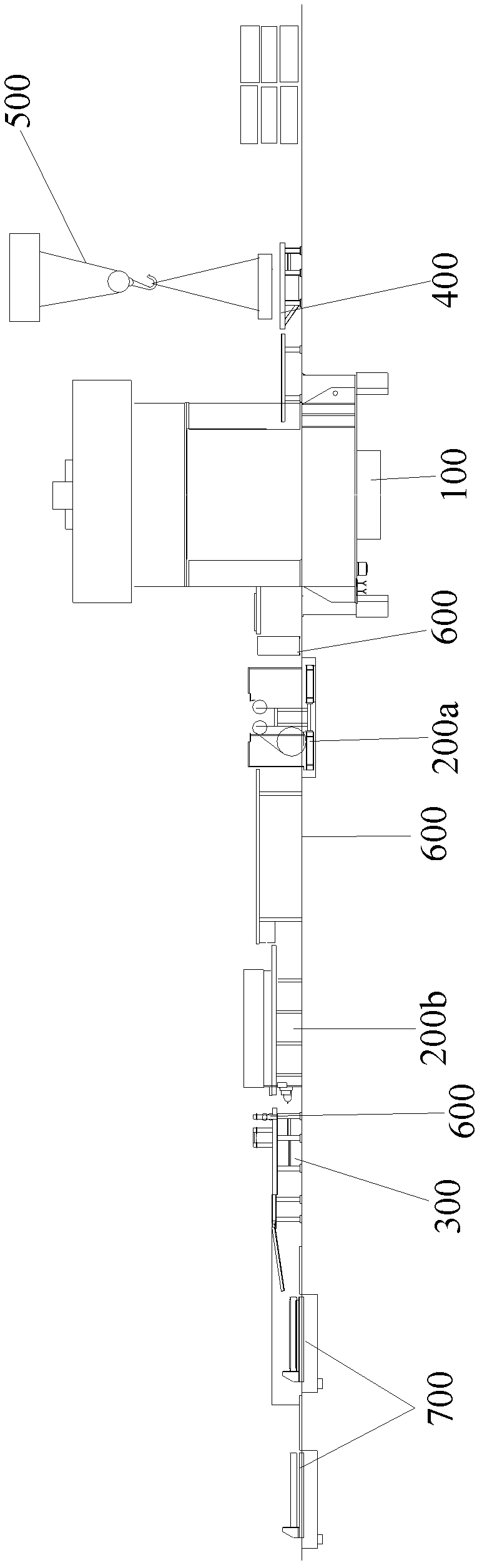

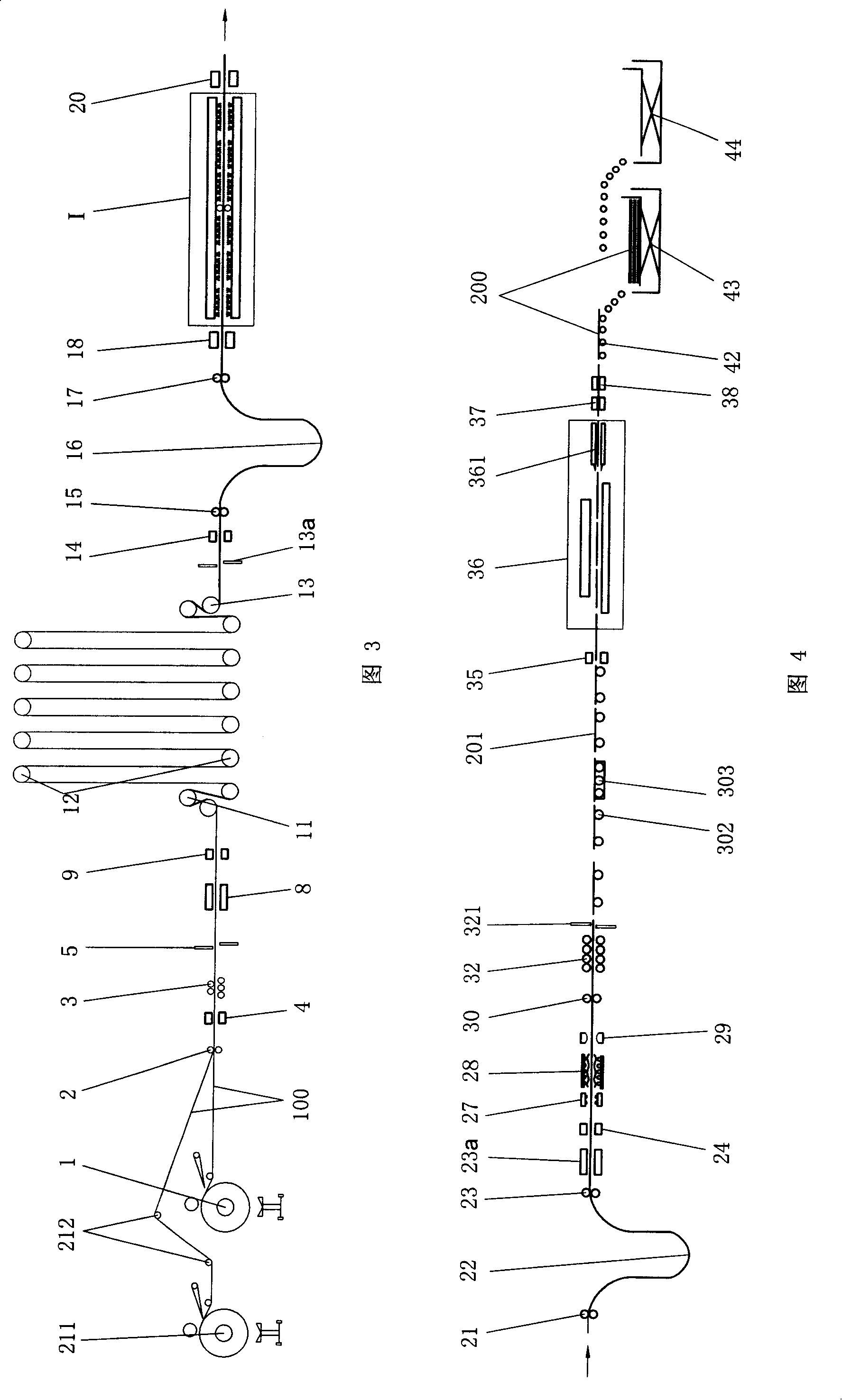

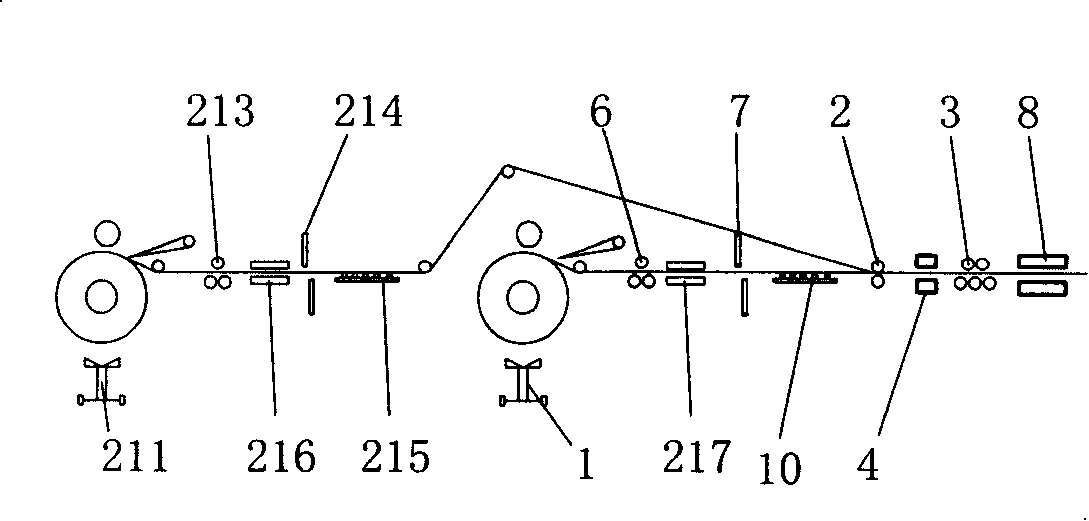

Molding technology and equipment for container top panels

ActiveCN103008447AReduce width requirementsRealize continuous automatic moldingMetal-working feeding devicesPositioning devicesCompression moldingHigh volume manufacturing

The invention relates to the processing of container parts and provides a molding technology and equipment for container top panels. The molding technology comprises the following steps of: uncoiling, cutting materials into steel plates, carrying out compression molding on the steel plates one by one so as to form at least two bosses on each steel plate at a time, locating and trimming the molded steel plates, shaping the trimmed steel plates and stacking. According to the invention, at least two bosses are formed on the steel plates at a time in the compression molding. On one hand, at least two bosses are formed in one-time compression molding, the size is stable, the requirement on the width of the materials is lowered, the materials are saved, and the cost is lowered. On the other hand, the production efficiency is largely improved. The invention further provides molding technical equipment for the container top panels, corresponding to the technical method. Through the adoption of the set of equipment, the top panels are continuously and automatically molded. The equipment is suitable for mass production so that the production efficiency is greatly increased.

Owner:东莞南方中集物流装备制造有限公司 +2

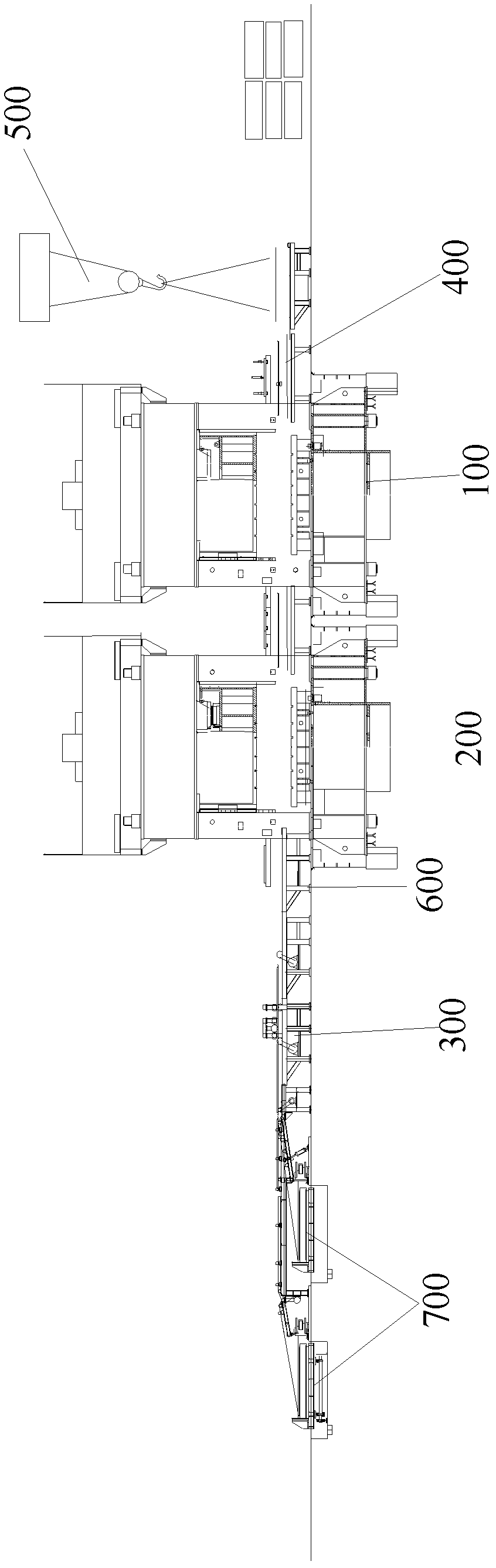

Method of preparing container roof plate

ActiveCN101190494AReduce in quantityLow investment costMetal-working feeding devicesPretreated surfacesSheet steelContainer tops

The invention relates to a container top plate fabrication method, comprising processes of coiling and leveling of coiled plates, after the centering, storage and traction after storage of continuous steel plate which is leveled, continuous blasting of the two surfaces of the continuous steel plate, continuous painting disposal of the two surfaces of the continuous steel plate, continuous drying, traction before the storage of the continuous steel plate, storage and traction after storage, centering the continuous steel plate, pressing and forming a top plate, edging, size fixing and cutting into single top plate which is then conveyed to finished product collection and transfer device for collection and transfer storage. The invention has the advantages of implementing the automatic production of the container top plate, reducing the occupying area of equipment, the mounting content of the equipment and the number of required workers, improving production efficiency and the utilization ratio of the equipment, greatly reducing the labor intensity of workers and having determining meaning for improving the technical level of container production and reducing production cost.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

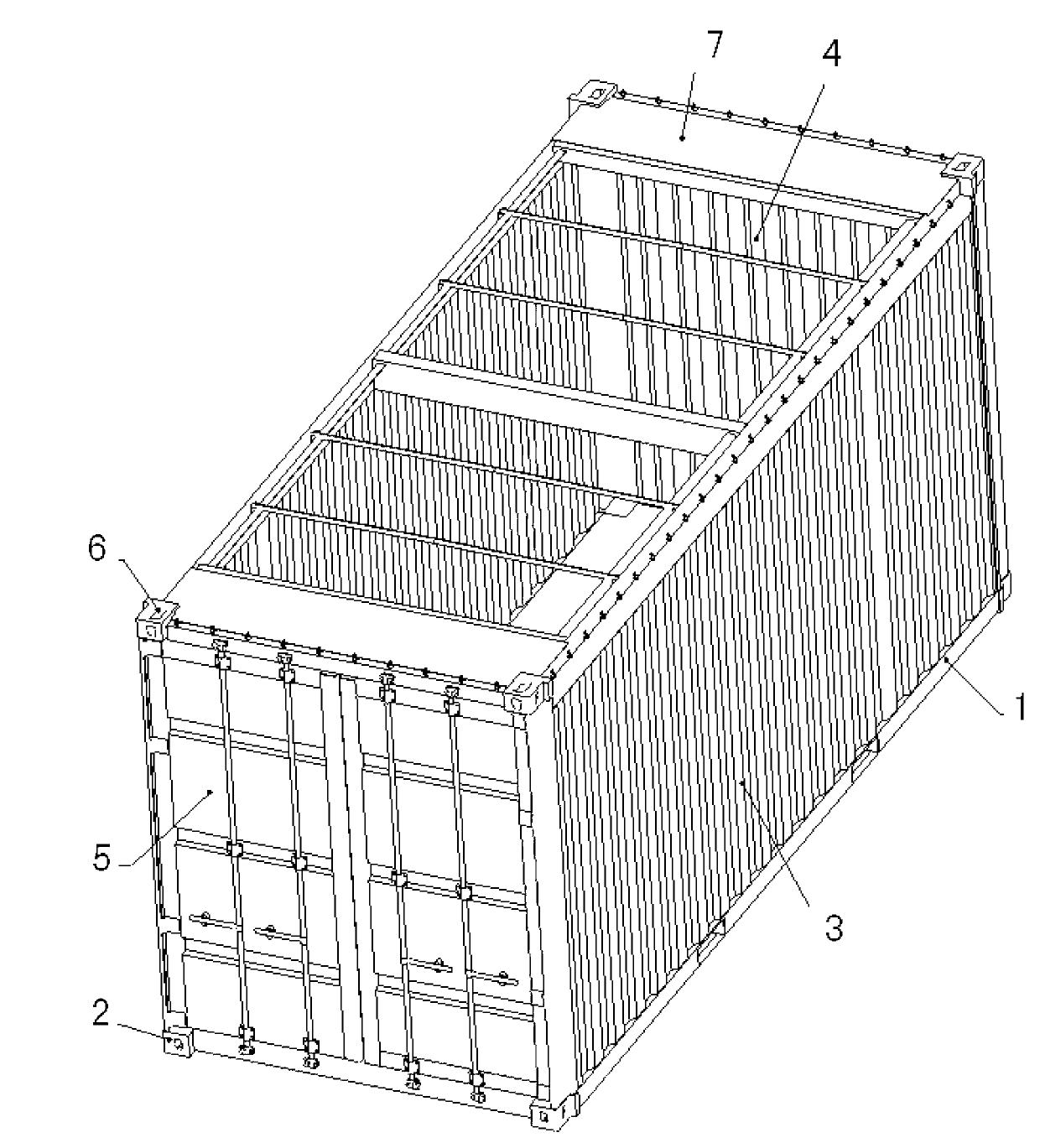

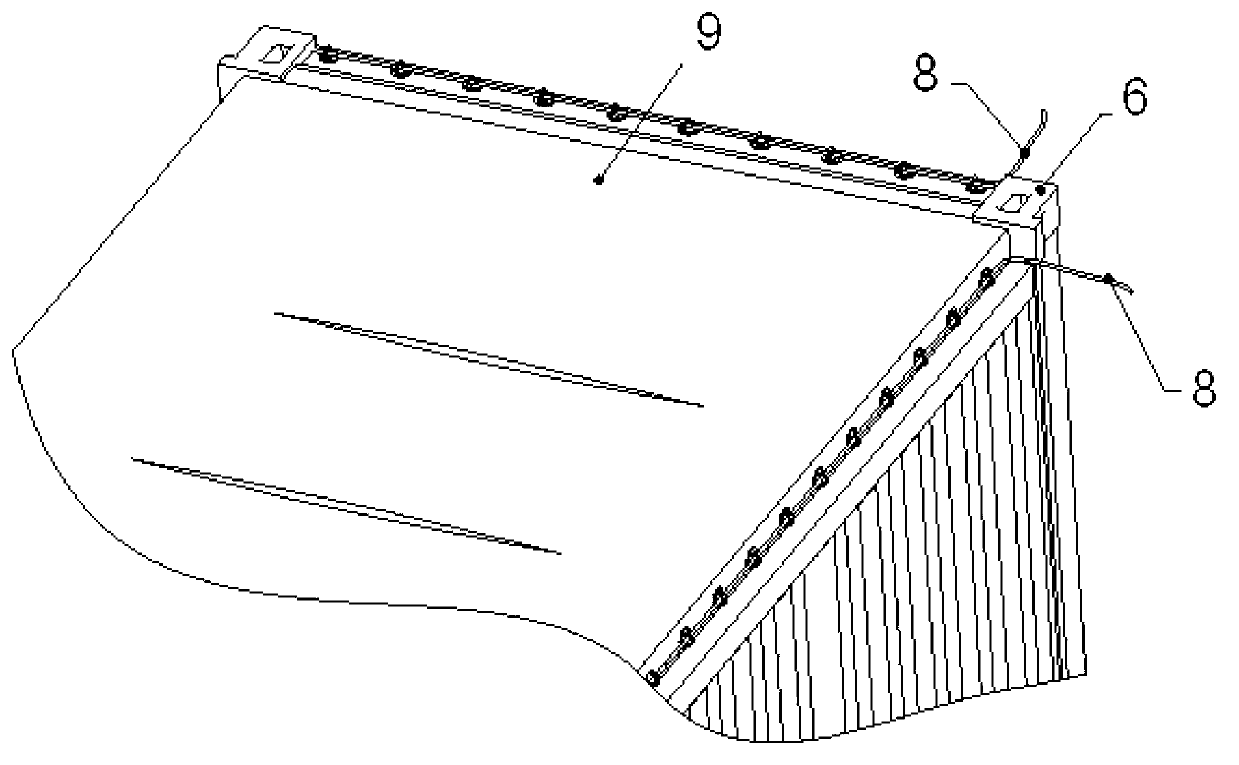

Large-volume dry bulk cargo transportation container for railway

The invention relates to a large-volume dry bulk cargo transportation container for a railway. The large-volume dry bulk cargo transportation container is characterized by comprising a container bottom assembly, four bottom corner pieces, two side wall assemblies, an end wall assembly, an end door assembly, four top corner pieces, a container top assembly, a soft rope and a PVC (poly vinyl chloride) tarpaulin, wherein the container bottom assembly is connected with the bottom parts of two side wall assemblies, the end wall assembly and the end door assembly through the four bottom corner pieces, the top parts of the two side wall assemblies, the end wall assembly and the end door assembly are connected with the container top assembly through the four top corner pieces, and the container top assembly is fixedly provided with the PVC tarpaulin through the soft rope. The large-volume dry bulk cargo transportation container has the characteristics of large volume, long service life, and good adaptability of cargo to the container. The large-volume dry bulk cargo transportation container can be widely applied to the railway transportation field.

Owner:CRRC BEIJING ERQI VEHICLE CO LTD

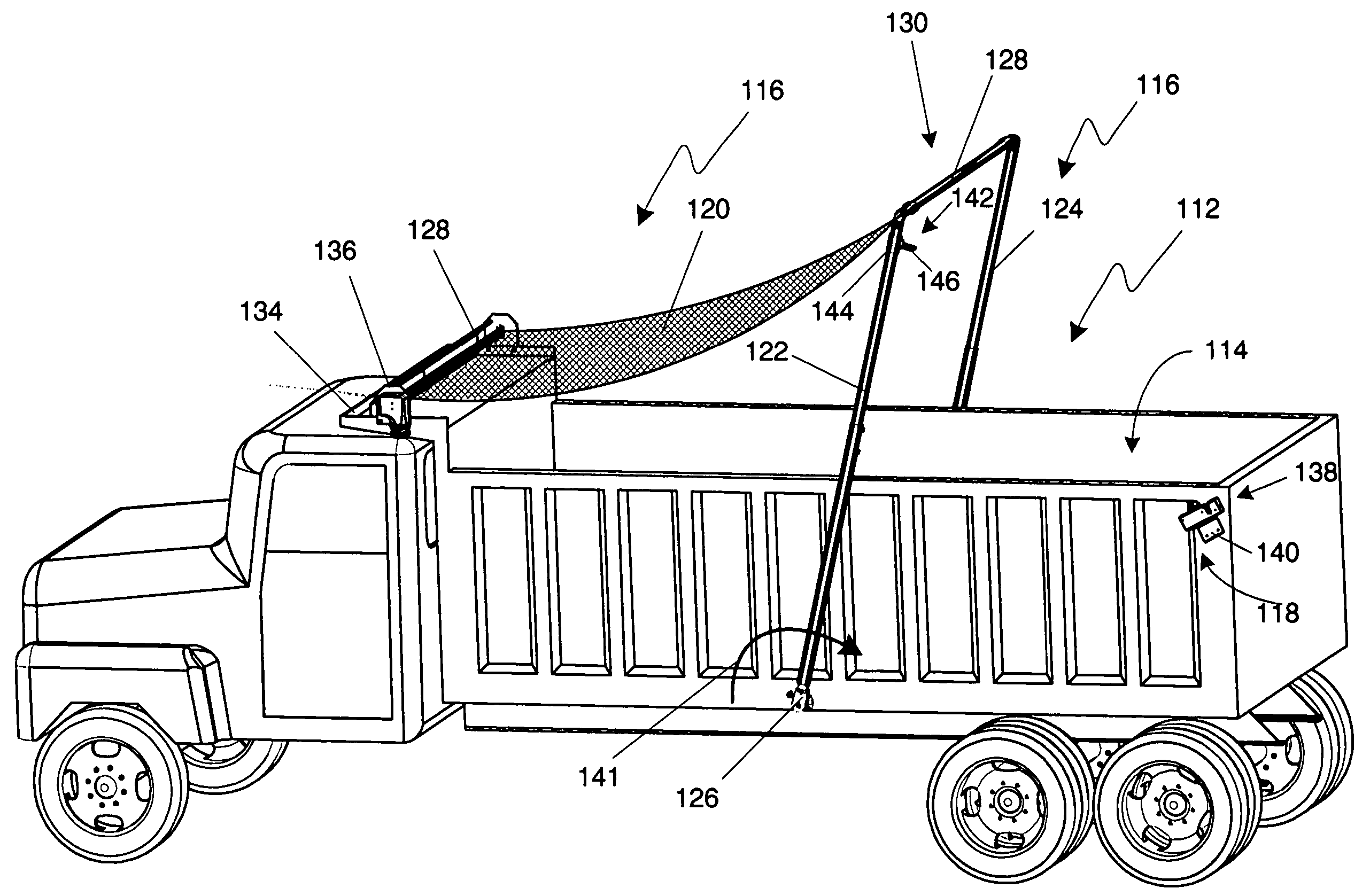

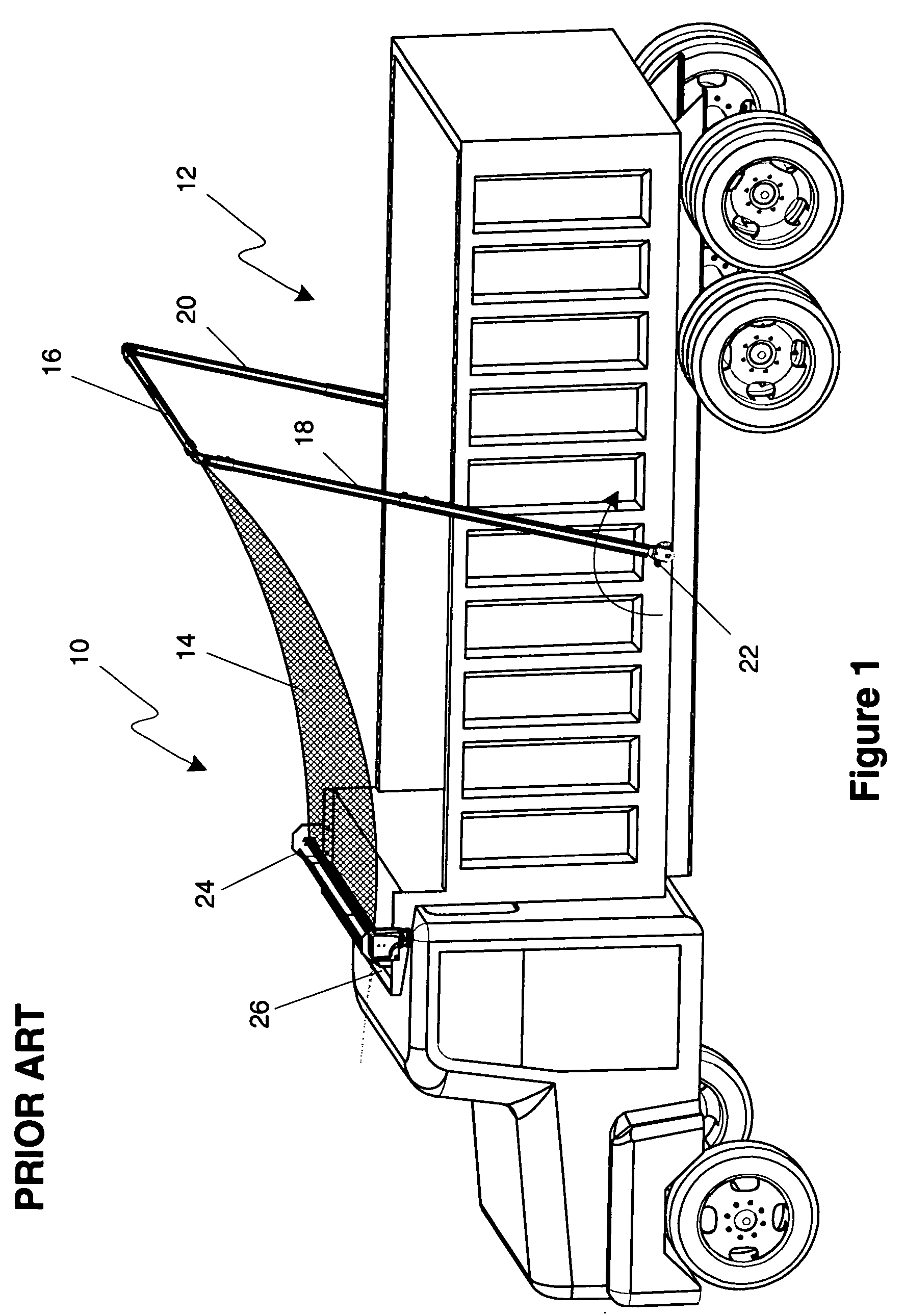

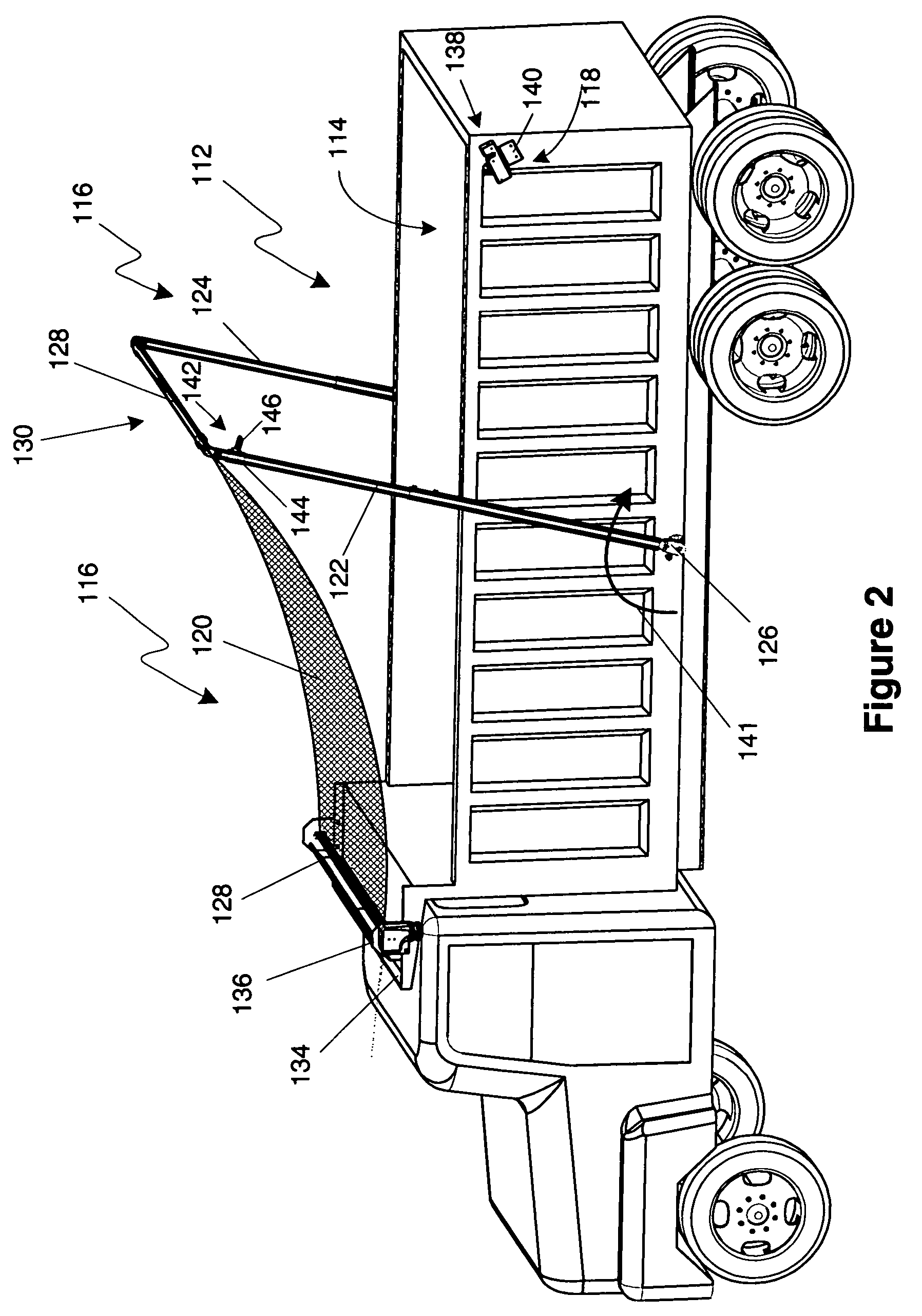

Lock mechanism for container covering apparatus

ActiveUS7296842B2Removable external protective coveringsLoad coveringLocking mechanismContainer tops

An apparatus for covering a top of an open container is provided that includes a cover, an arm assembly, and a lock mechanism. The arm assembly can move between a stowed position in which the container top is substantially open to an extended position in which the container top is substantially covered. The lock mechanism can easily and automatically lock the arm assembly in the extended position as part of the container covering operation. The lock mechanism may include a latch and a latch block that cooperate to automatically and mechanically engage and retain a hook mechanism. The lock mechanism may also include an actuator that, when energized, permits the latch to release the hook mechanism.

Owner:SHUR

System and method for preventing wrong-site surgeries

ActiveUS20140110298A1Preventing wrong-site surgeryPreventing wrong-site surgeriesSuture equipmentsSurgical furnitureAnesthetic AgentMedical record

A container holds at least one surgical implement, has a lock mechanism, and has a signature label that impedes access to the surgical implement until the correct surgical site is confirmed. A method of using the container includes the steps of confirming the correct surgical site, signing the label and removing it from the container, placing the label in the medical record, unlocking the container, removing the implement, and beginning the surgery, wherein the surgical team is forced to pause to confirm the correct surgical site before starting the surgery. Preferably, the container top may be removed and placed between the surgeon and surgical technician to define a no-hands “neutral zone” to avoid being stuck by the sharps. Also, the container preferably includes compartments for storing used sharps and / or a local anesthetic-loaded syringe, and the top may be replaced and secured for safely disposing of the sharps after the surgery.

Owner:STARTBOX

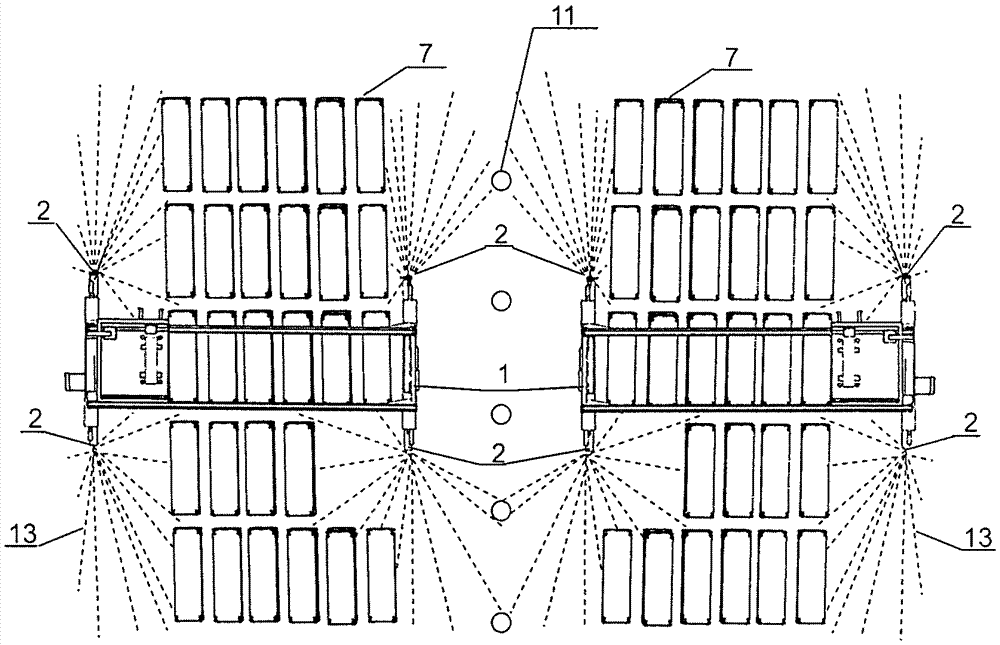

Container number automatic acquisition and identification method in railway container loading and unloading process

ActiveCN110348451AAccurate identificationImprove recognition accuracyCharacter and pattern recognitionContainer topsNetwork model

The invention discloses a container number automatic acquisition and identification method in a railway container loading and unloading process, which comprises the following steps of: respectively acquiring images of the top surface and the side surface of a container, and carrying out general preprocessing on the images of the containers with different container body colors; judging the printingcolor of the container number on the basis of image binaryzation; analyzing and positioning a printing area of the box number through a connected domain; judging the arrangement mode of the containernumbers according to the length-width ratio threshold of the minimum external moment of the container number area, and respectively carrying out character segmentation in different direction projection sequences; building three neural network model classifiers to recognize three parts of characters in the container number, and mutually verifying container number recognition results of the top face and the side faces of the container. According to the method, the influence of local character stripping caused by abrasion on an identification result is overcome, container numbers of different colors and arrangement modes are identified, and rapid and accurate identification of the container numbers is completed in combination with mutual inspection of the container numbers of different surfaces and self-inspection of container check codes.

Owner:SOUTHWEST JIAOTONG UNIV

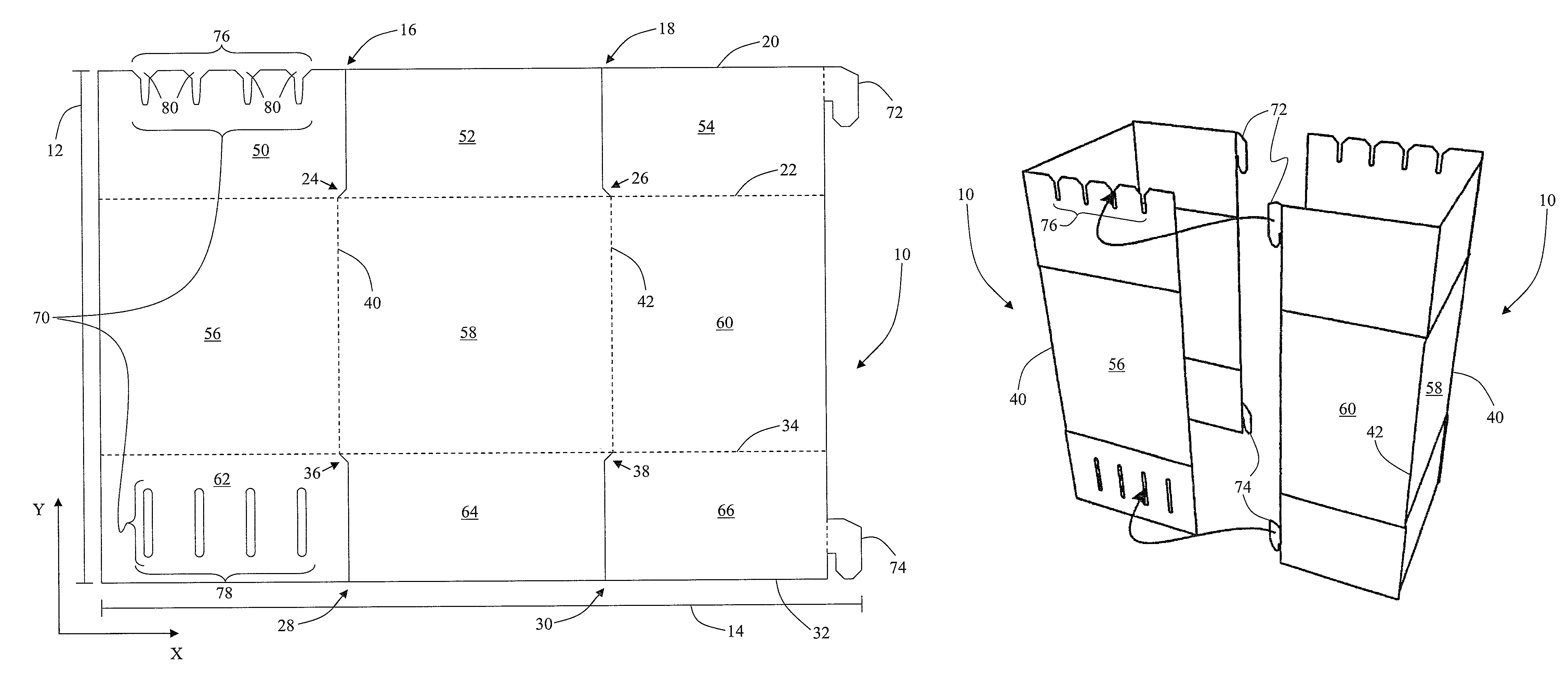

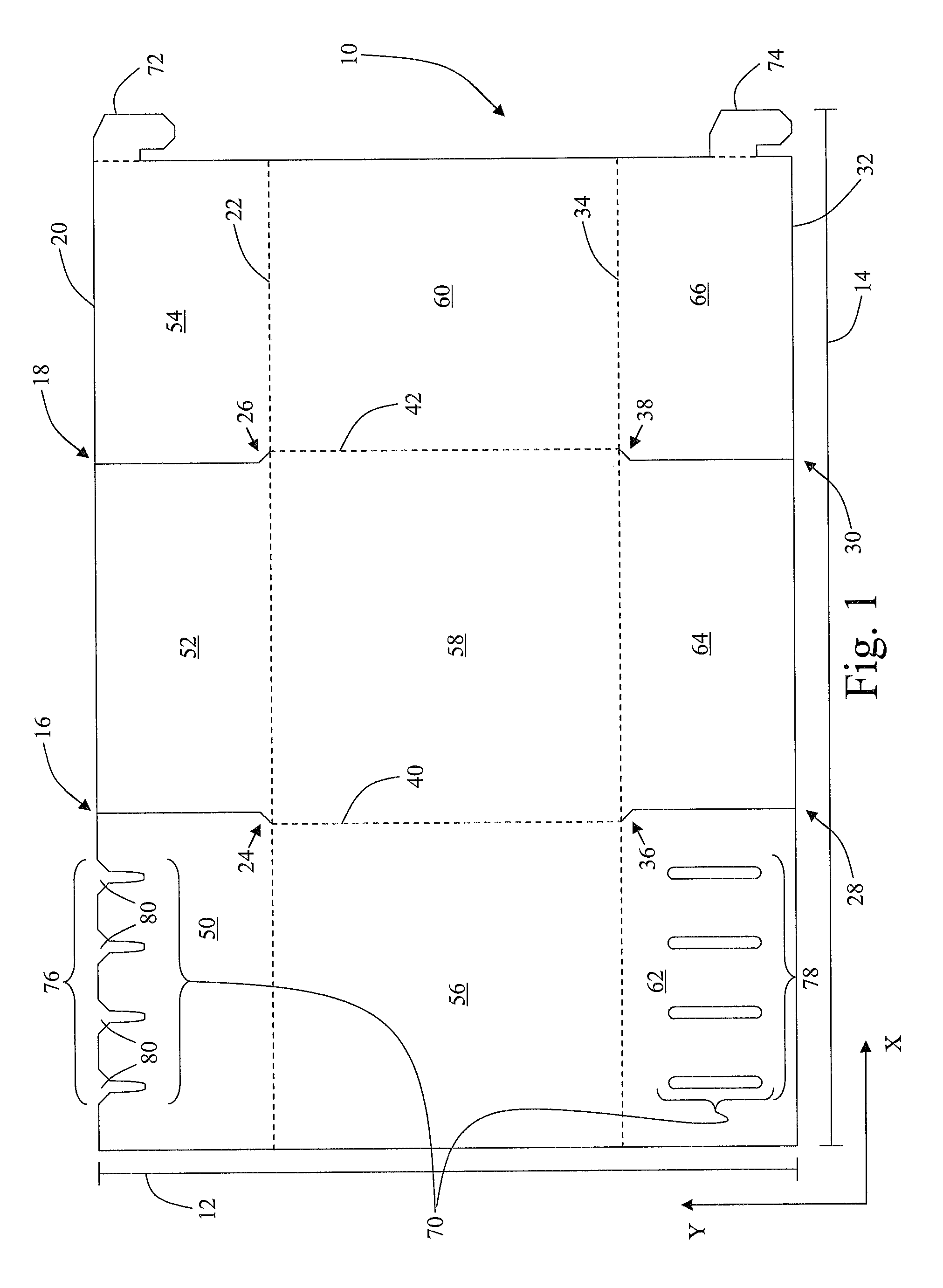

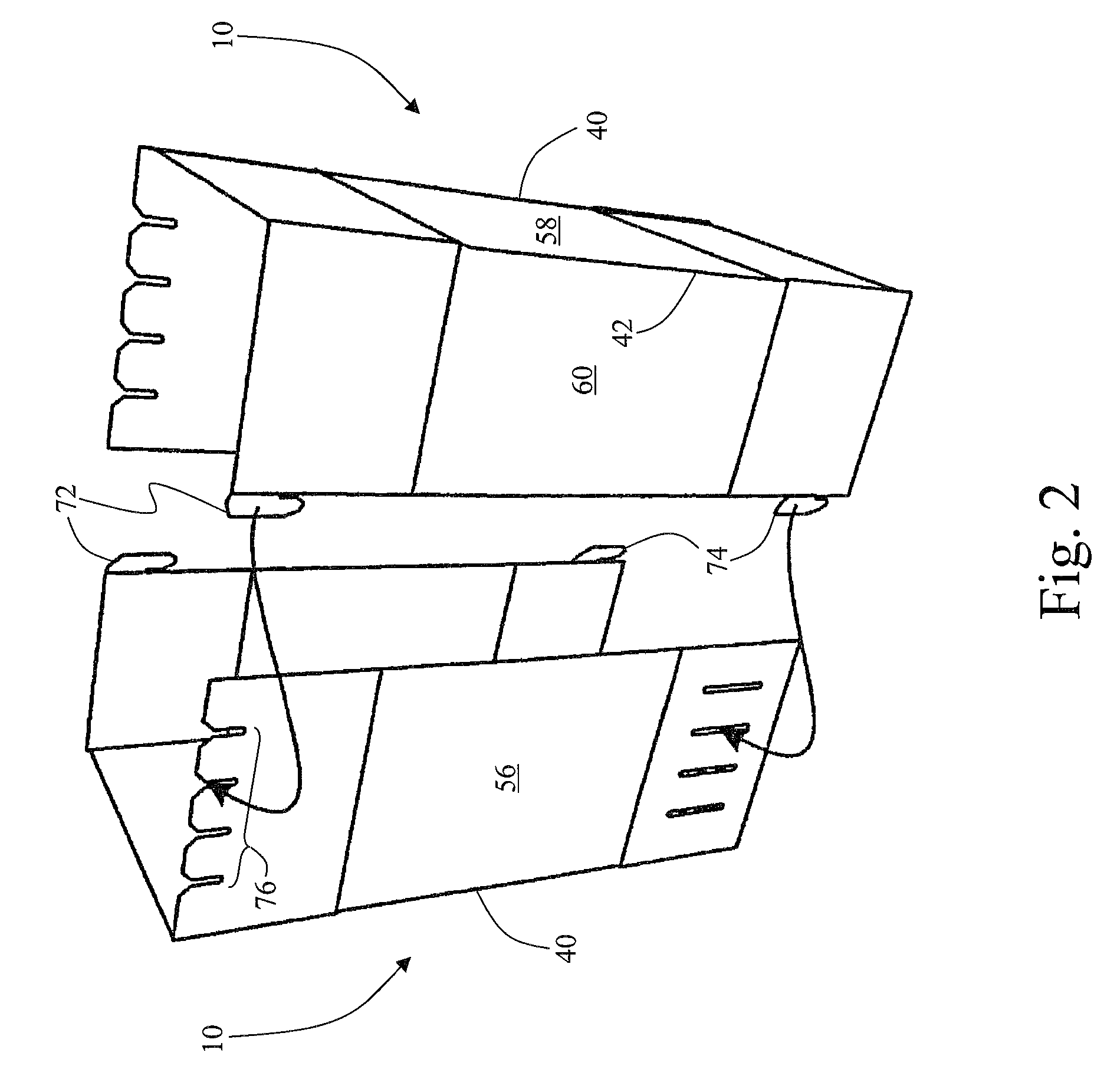

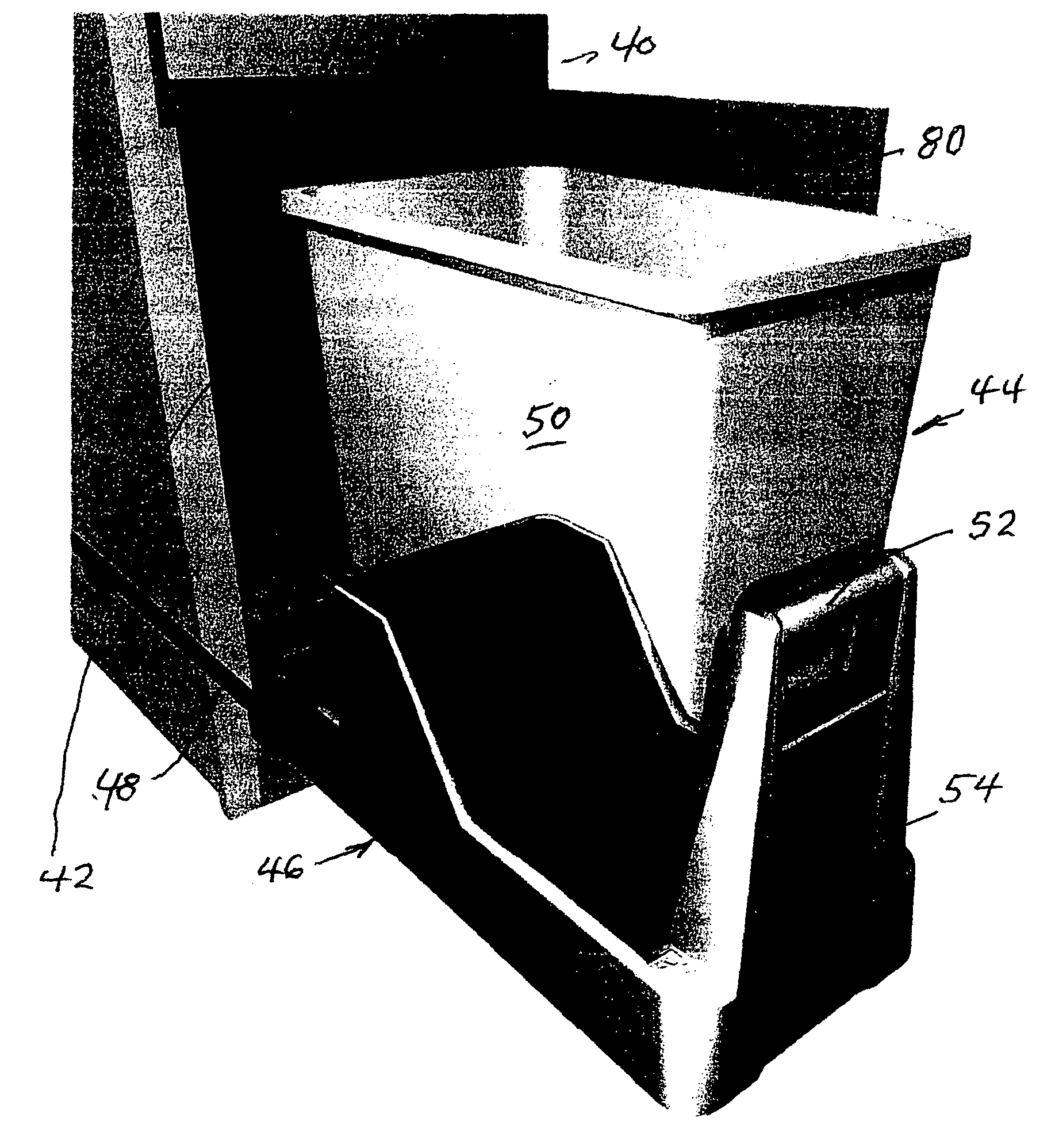

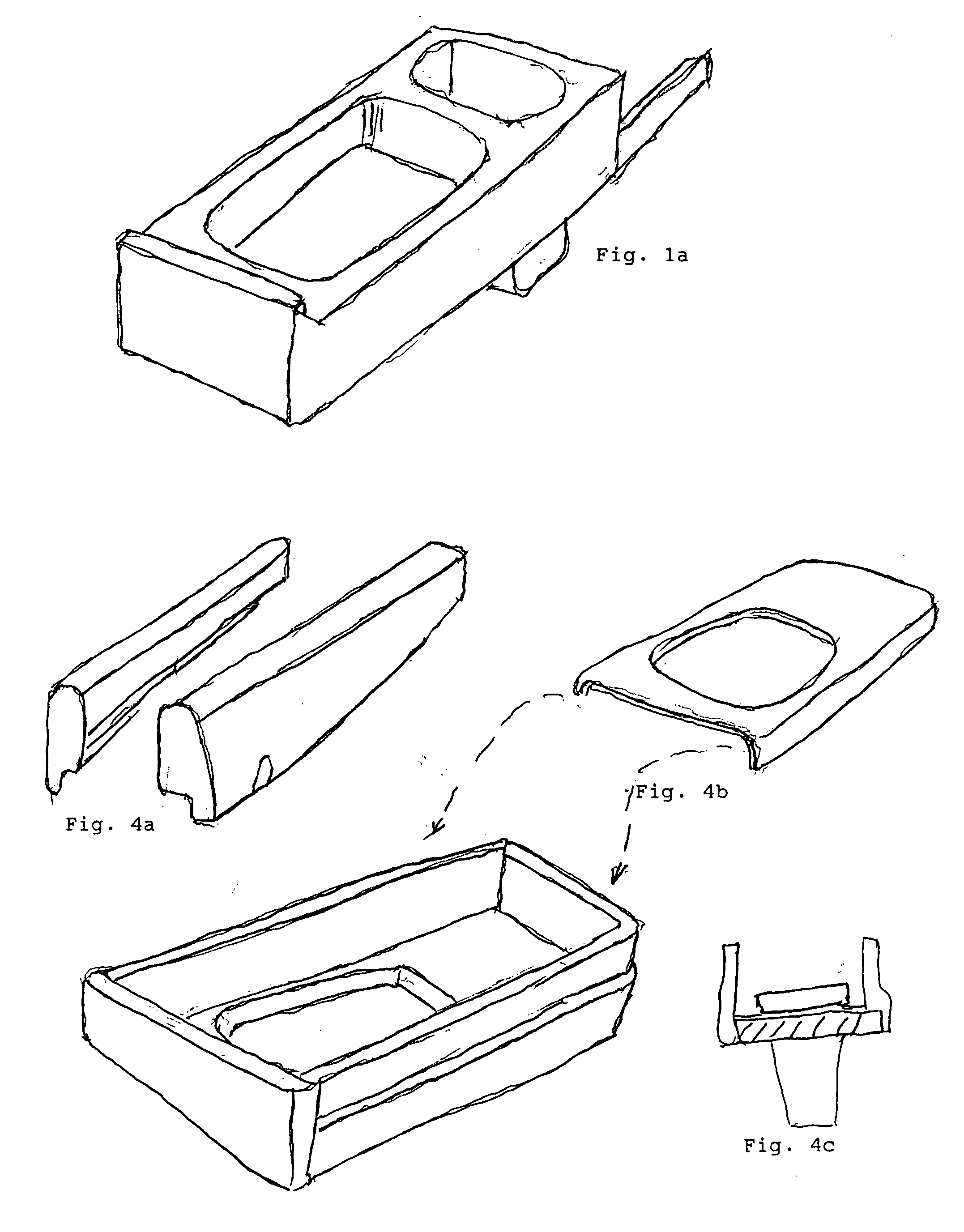

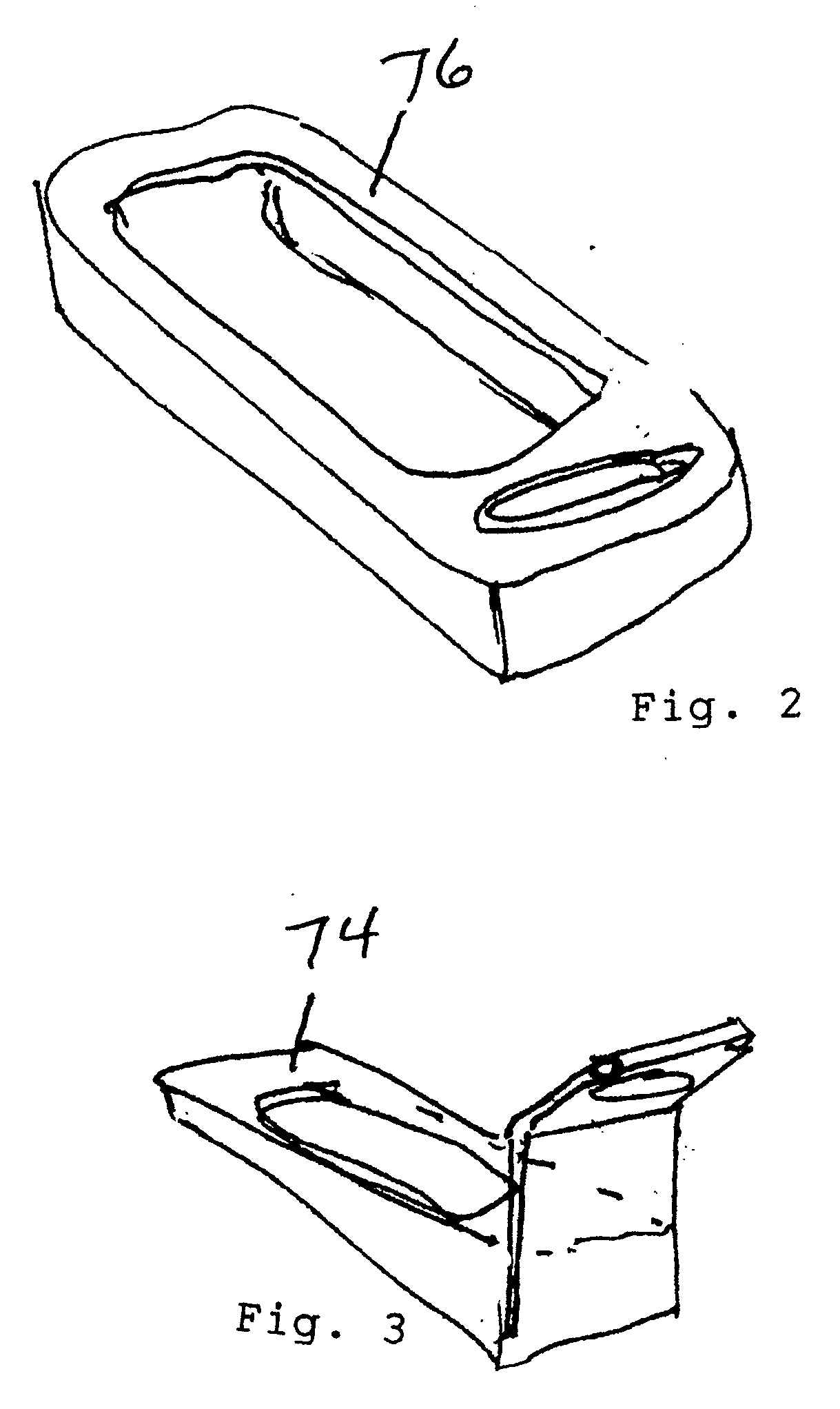

Adjustable volume storage container

The present application contemplates an adjustable volume storage container. The container is formed from two panels (10). The panels are made from a heavy duty paper board or corrugated cardboard, or the like, and are foldable. The panels (10) are prefabricated, each having a slot array (70) and two tabs (72, 74). The panels (10) are also cut to form sub-panels. The panels (10) are folded along lines (40) and (42) so that the tabs (72, 74) of one panel (10) can mate with the slot array (70) of the other panel (10). The particular slot selected determines the length of the container. Once the tabs (72, 74) are mated with the slot arrays (70), the bottom sub-panels (62, 64, 66) are folded under and fastened to form the container bottom. The container is filled, and then the upper sub-panels (50, 52, 54) are folded over and fastened creating the container top.

Owner:SHURTAPE TECH LLC

Waste container with hidden slides

InactiveUS20050006994A1Easy to removeEasy to introduceRefuse receptaclesKitchen cabinetsContainer topsEngineering

A kitchen trash container system that has a tray slidably movable into and out of a kitchen cabinet when waste is placed in a container carried by the tray. A slide mechanism is positioned on the inside walls of the cabinet engaging another cooperating slide mechanism fastened to the top of the container or inside the tray walls or floor. The container top extends over both engaging slides on each side of the container to shield the mechanisms from dust and debris and hide them from view.

Owner:REV A SHELF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com