Container top board forming mold

A technology for forming molds and containers, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unstable product size and low forming efficiency, and achieve the effects of stable size, high production efficiency and reduced production personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

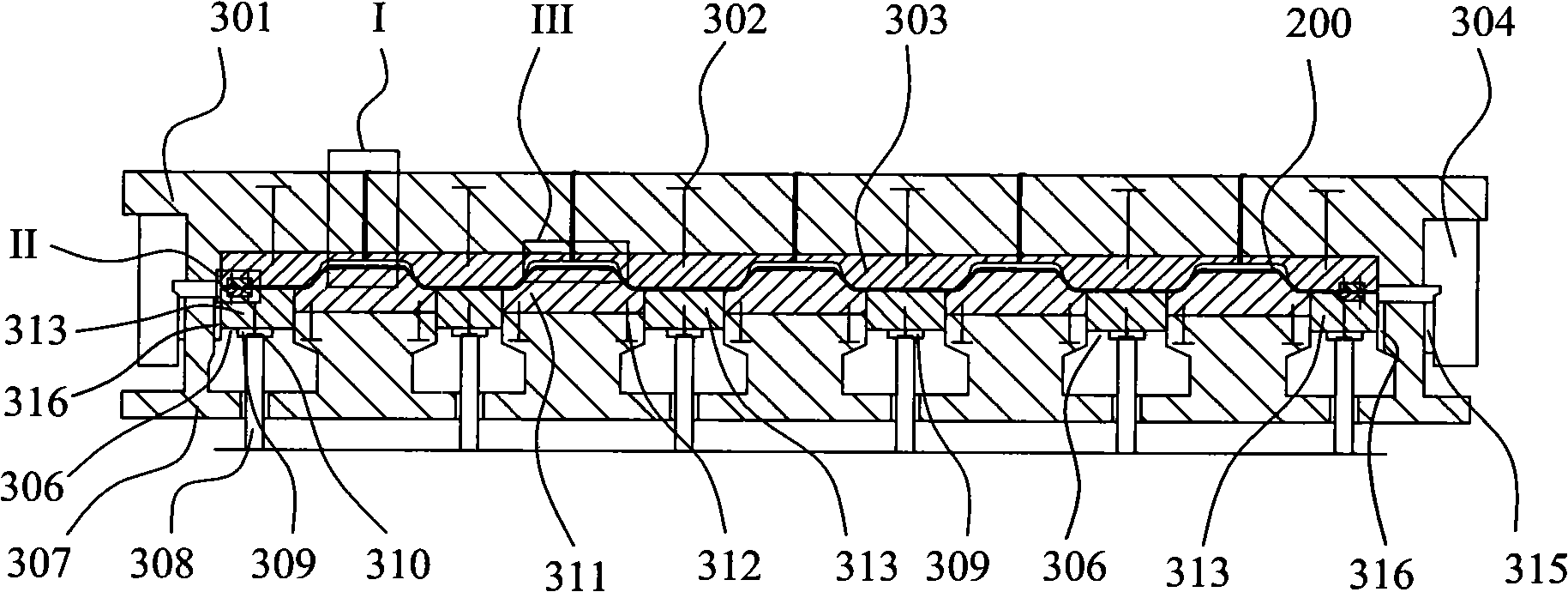

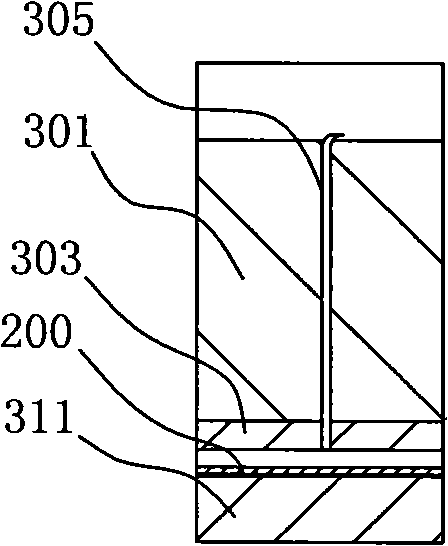

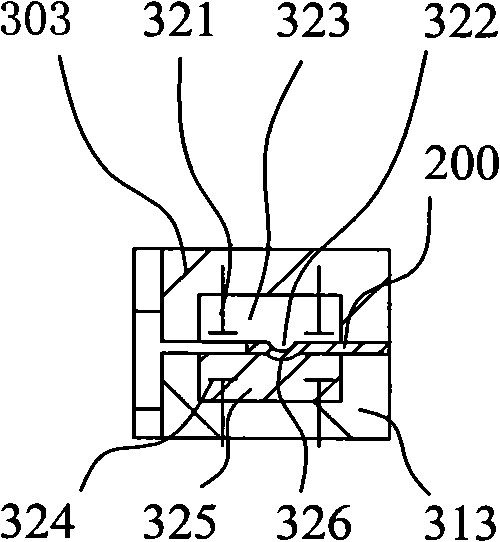

[0020] Figure 1 to Figure 4 A preferred embodiment of the invention is shown.

[0021] A container roof forming mold, such as figure 1 As shown, the upper die base 301, the lower die base 307, and the discharge plate 313 are included, and the upper die base 301 and the lower die base 307 are respectively equipped with a mating die 303 and a punch, and the die 303 is fixed by connecting bolts 302 On the upper mold base 301, the die 303 includes five equally spaced and parallel grooves (the grooves can also be set to be non-parallel according to the product requirements during specific implementation, that is, the grooves form a certain angle with each other) , the punch includes five punch inserts 311 corresponding to the grooves, and the punch inserts 311 are fixed on the lower mold base 307 through connecting bolts 312 . The stripper plate 313 is hollowed out and provided with a groove for the punch insert to move up and down relatively therein, and a mold cavity 306 is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com