Press-down twist lock autorotation hanger

A self-rotating and twist-locking technology, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of high manufacturing and maintenance costs, large installation space, etc., and achieves a simple structure and saves manufacturing costs and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

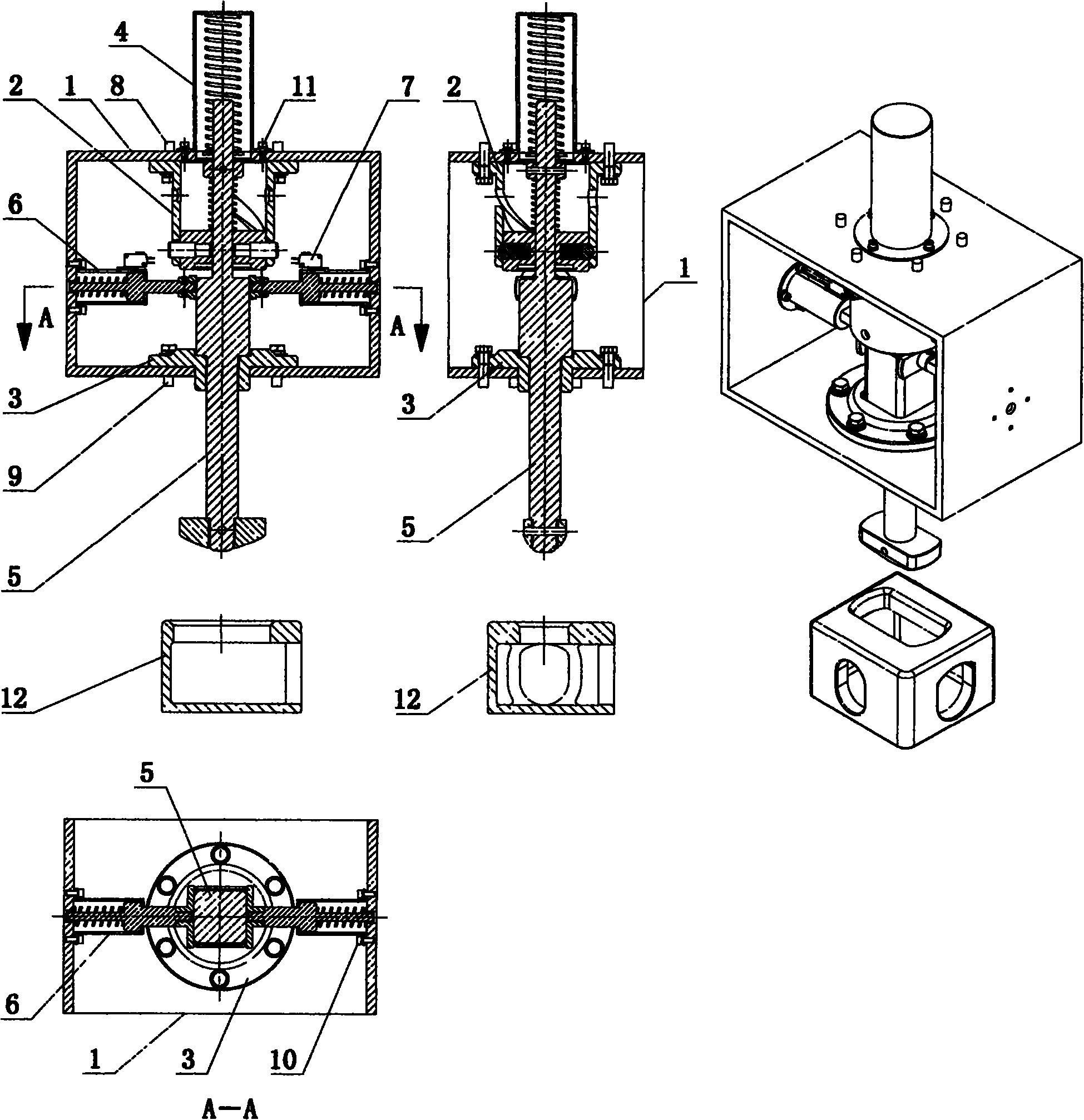

[0036] as attached figure 1 Shown: the push-down twist-lock self-rotating spreader, including spreader frame (1), upper mounting base (2), lower mounting base (3), return spring cover (4), twist-lock assembly (5) , top tightening device (6) and twist lock state signal switch (7).

[0037] The spreader frame (1) is used for installing various components.

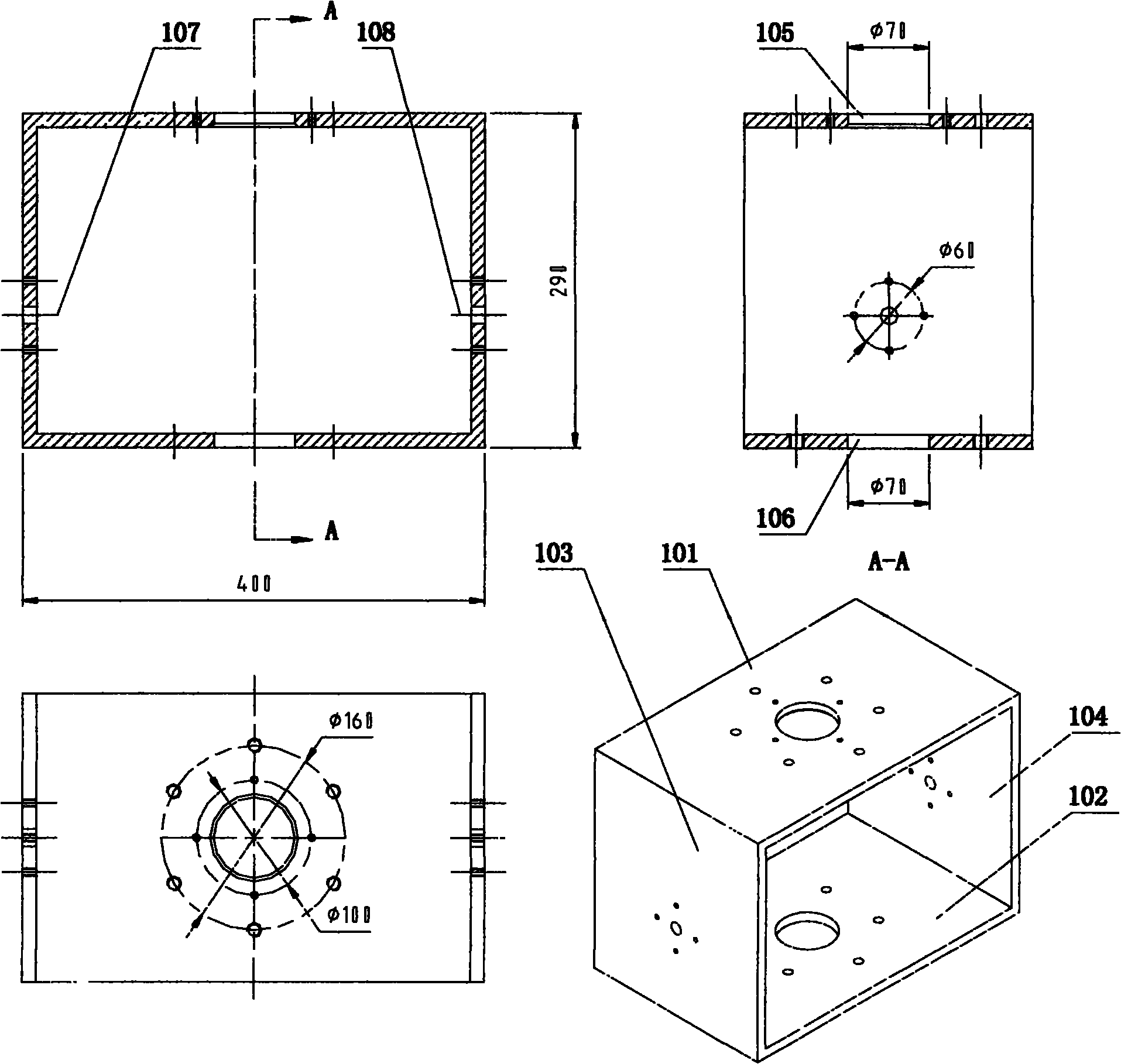

[0038] The upper mounting base (2) is installed on the lower surface of the upper mounting plate (101) of the spreader frame (1), and is fixed by screws (8).

[0039] The lower mounting seat (3) is installed on the upper surface of the lower mounting plate (102) of the spreader frame (1), and is installed in the round hole (106), fixed by screws (9).

[0040] The return spring cover (4) is installed on the upper surface of the upper mounting plate (101) of the spreader frame (1), and is fixed by screws (11).

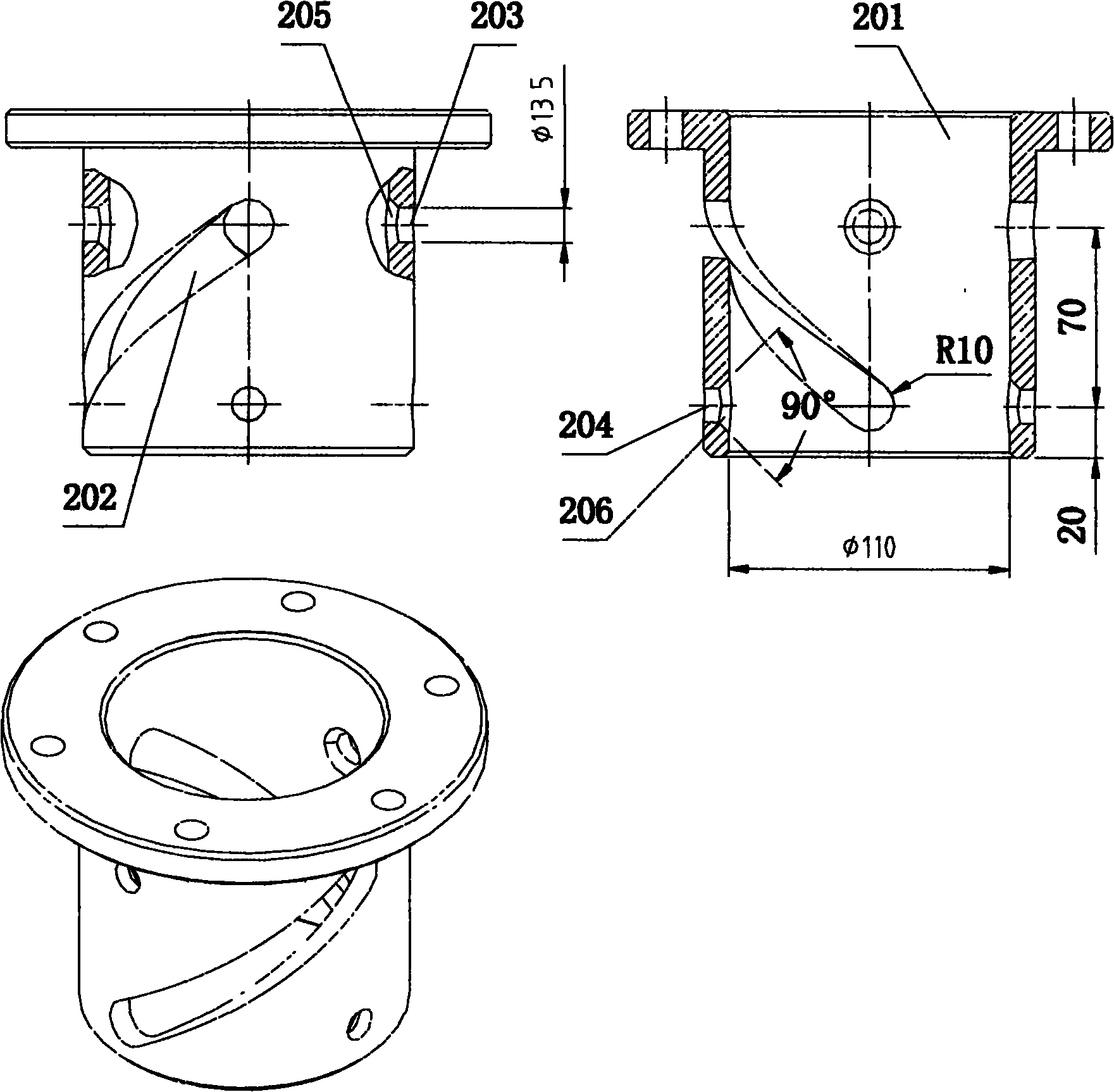

[0041] The twist lock assembly (5) is installed in the holes of the upper mounting base (2) and the lower mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com