Patents

Literature

79results about How to "Reduce width requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lateral taping mechanism of full automatic edge bander

The invention discloses the improvement of a lateral taping mechanism of a full automatic edge bander; the lateral taping mechanism is provided with a frame; the frame is provided with a conveying platform; the mechanism is characterized in that both sides of the conveying platform are provided with a positioning beam and a flanging device; the positioning beam can move up and down relative to the conveying platform; the flanging device is installed at the outer side of the positioning beam; the flanging device comprises a flanging base and a flanging plate; the flanging plate is installed onthe flanging base; the flanging plate can move up and down on the flanging base and is mutually matched with the positioning beam; and the flanging base can move left and right relative to the conveying platform of the frame. The mechanism has low requirement for the width of paperboard side, relatively wide use range, clean and flat surface of the produced paperboard.

Owner:薛迪虎

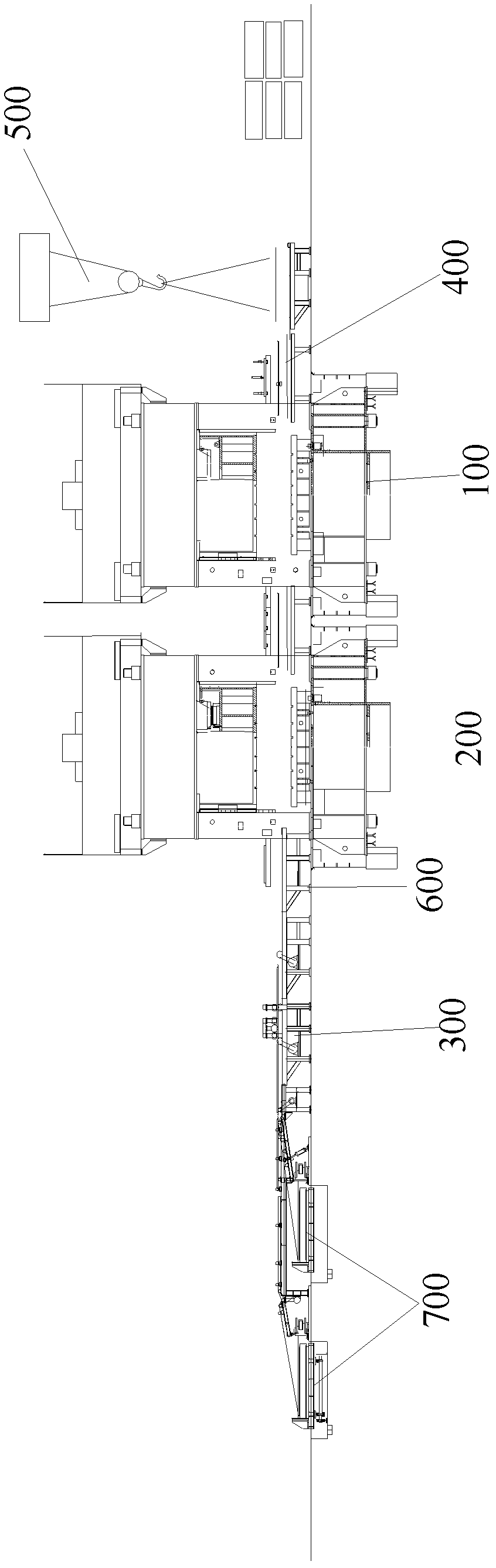

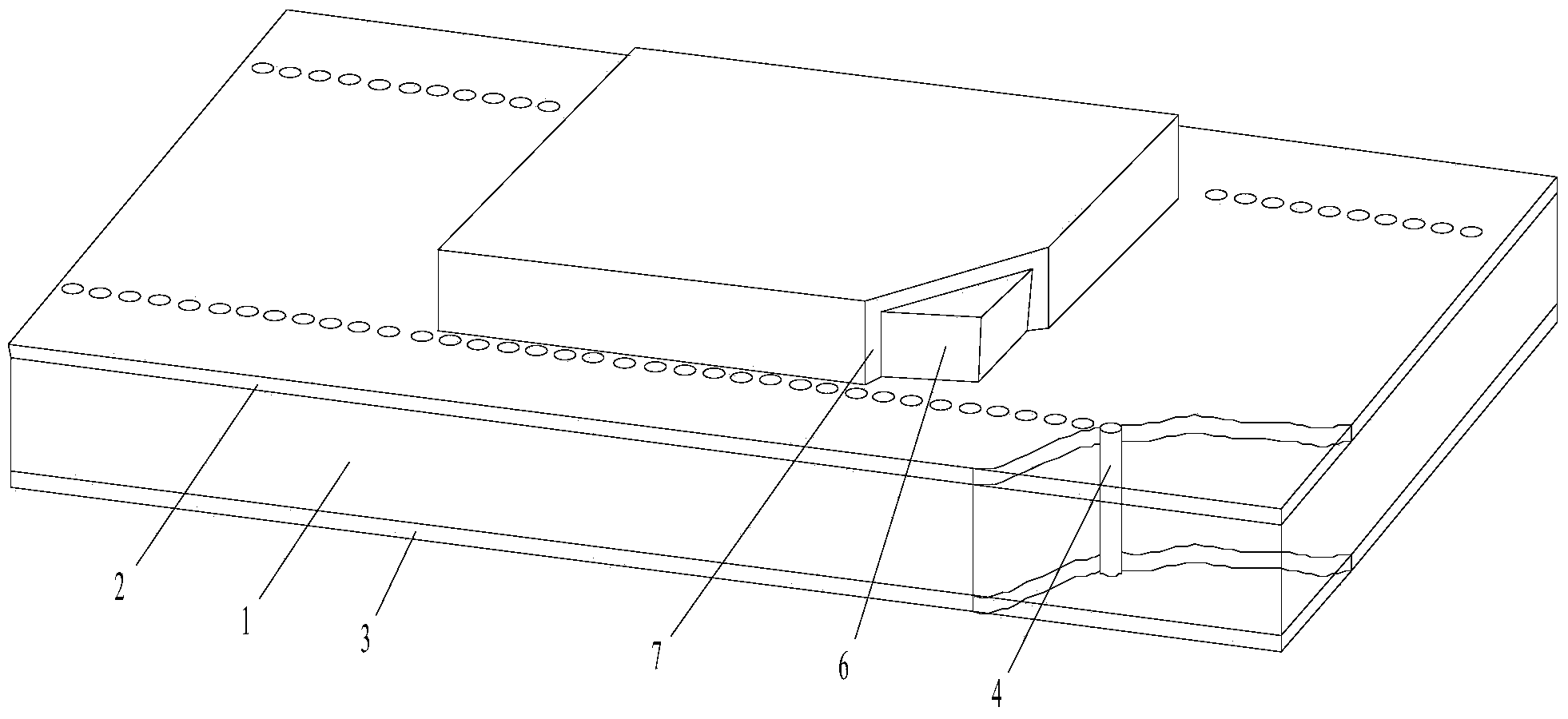

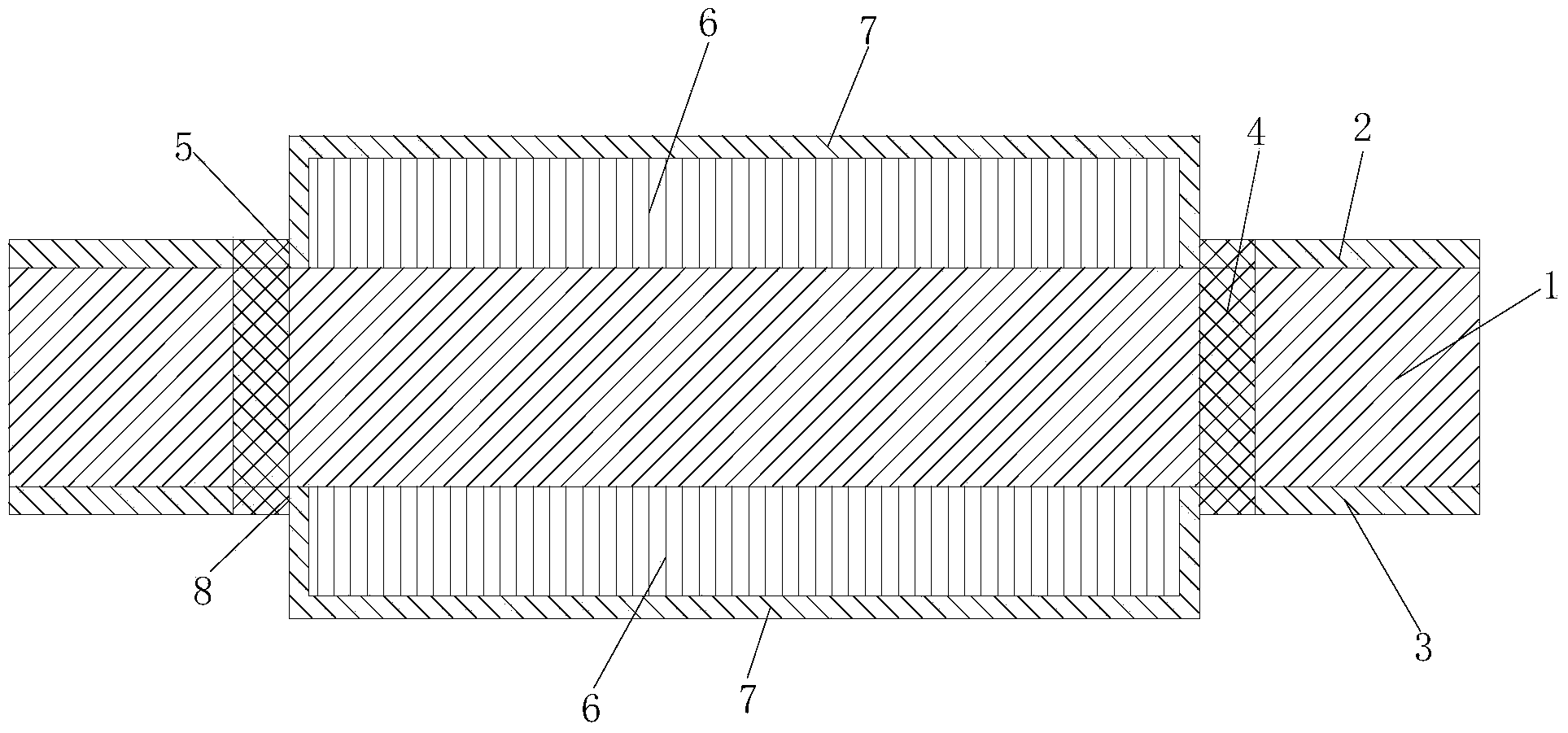

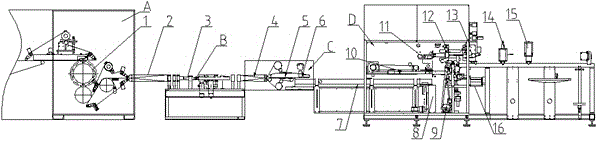

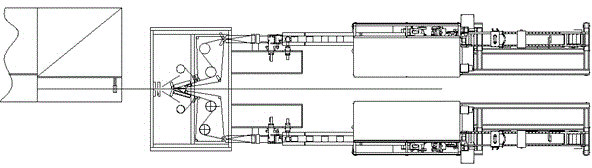

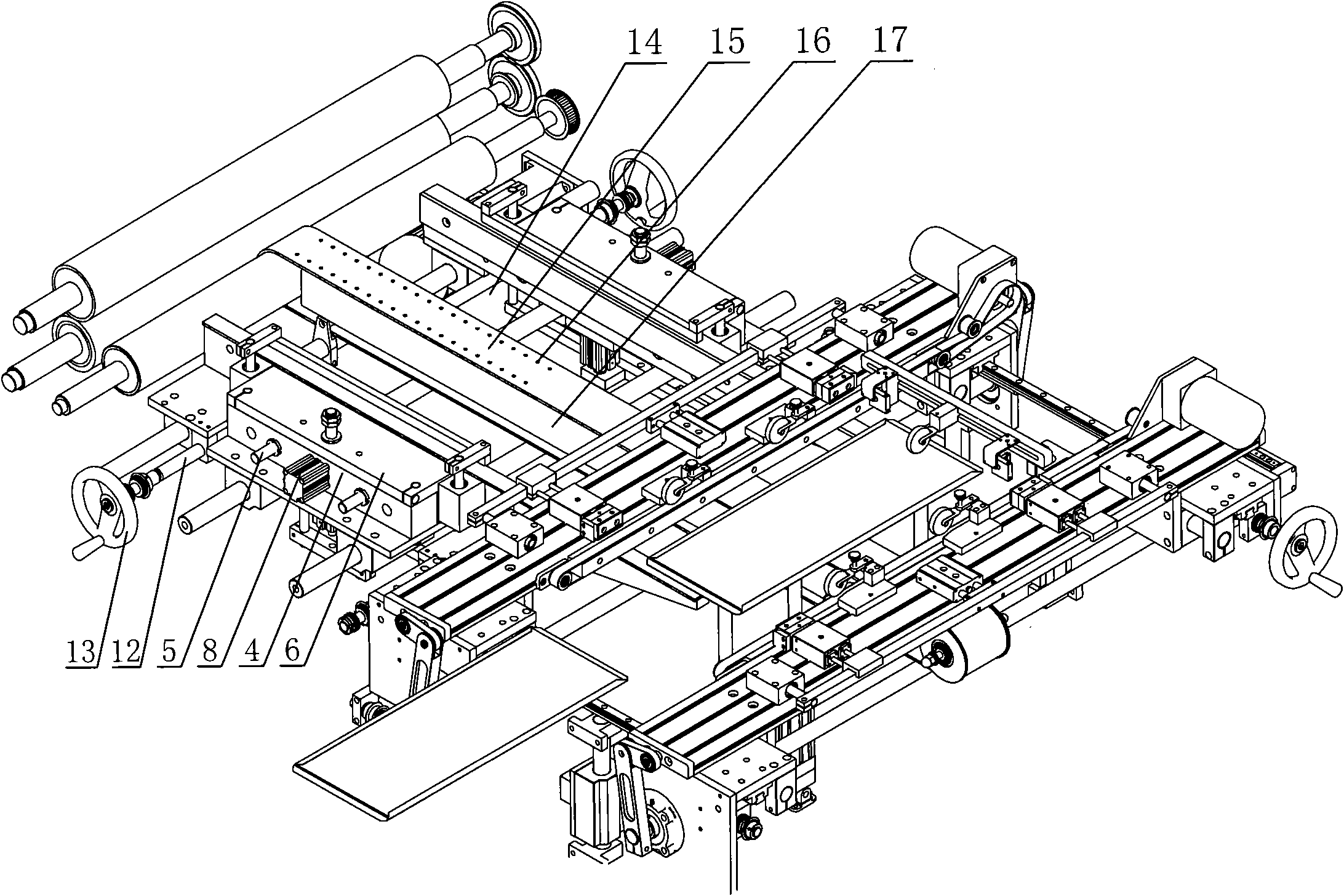

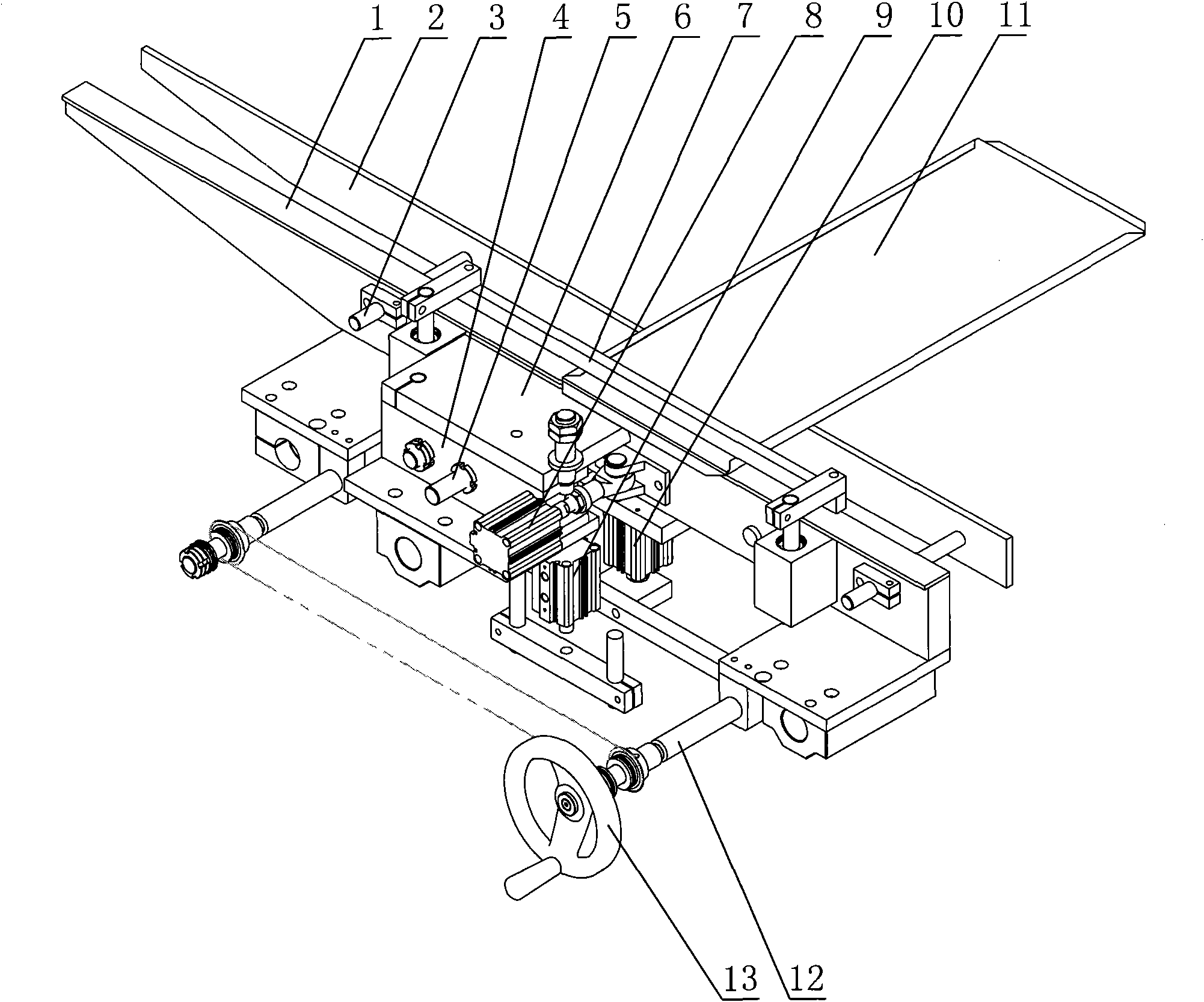

Molding technology and equipment for container top panels

ActiveCN103008447AReduce width requirementsRealize continuous automatic moldingMetal-working feeding devicesPositioning devicesCompression moldingHigh volume manufacturing

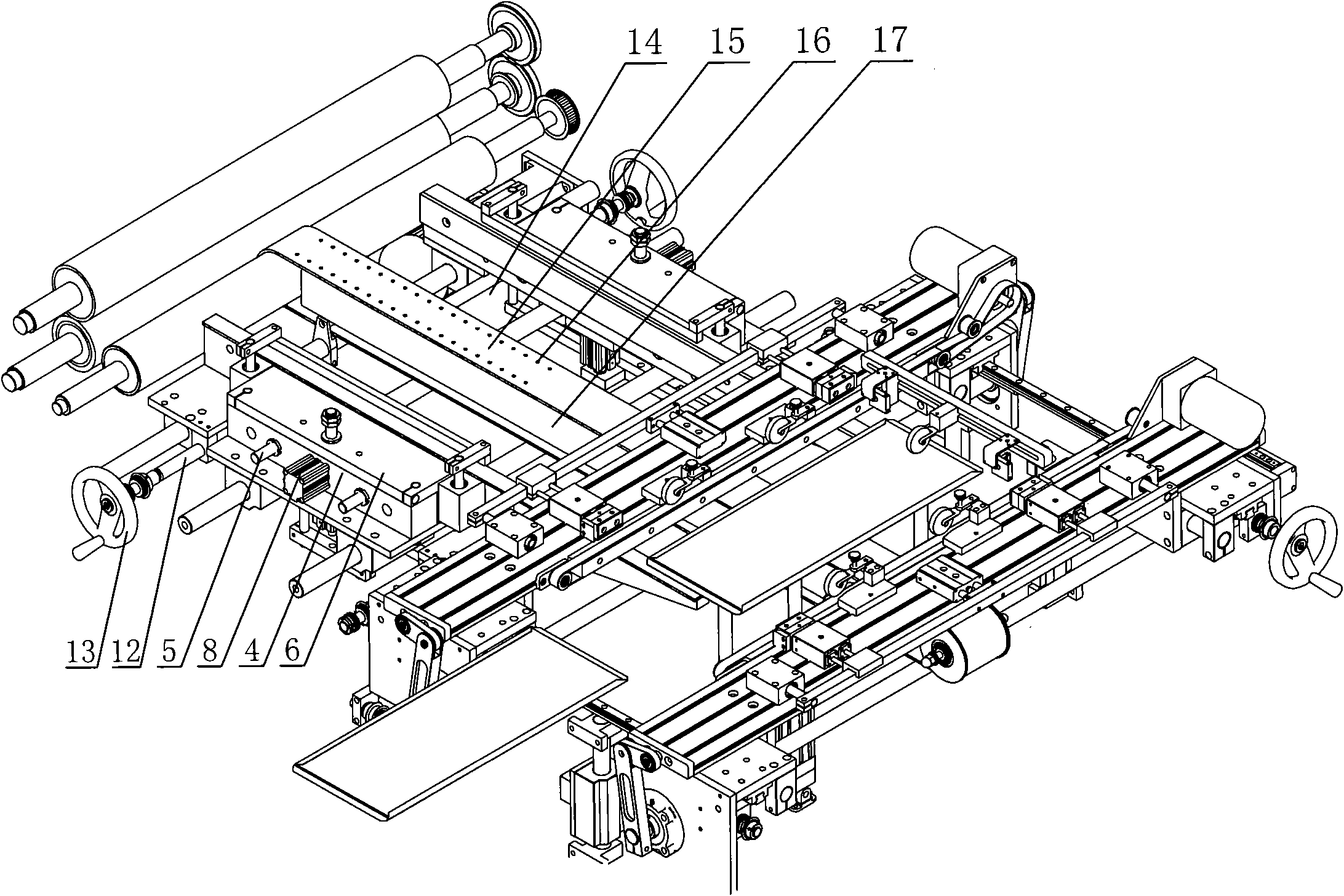

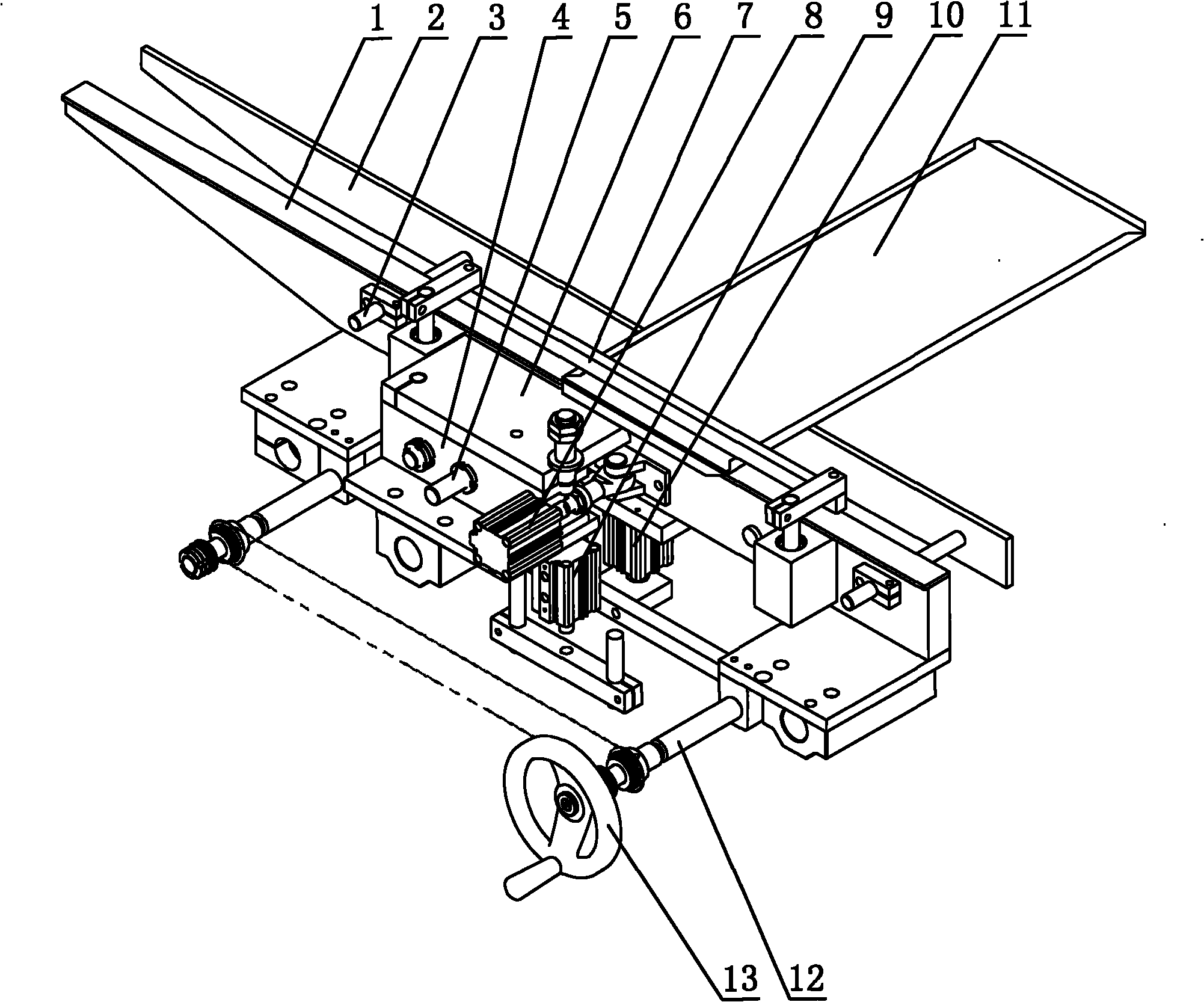

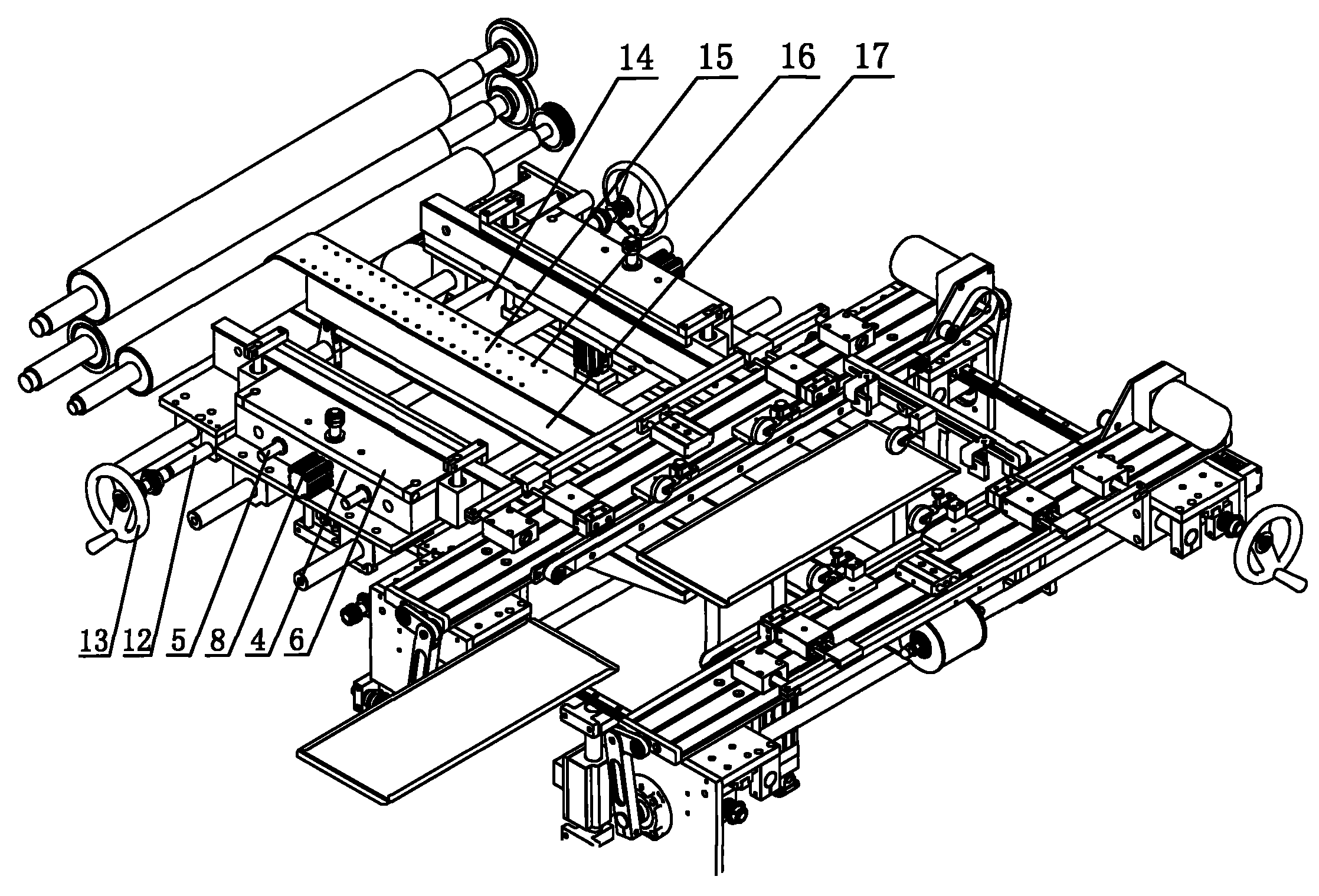

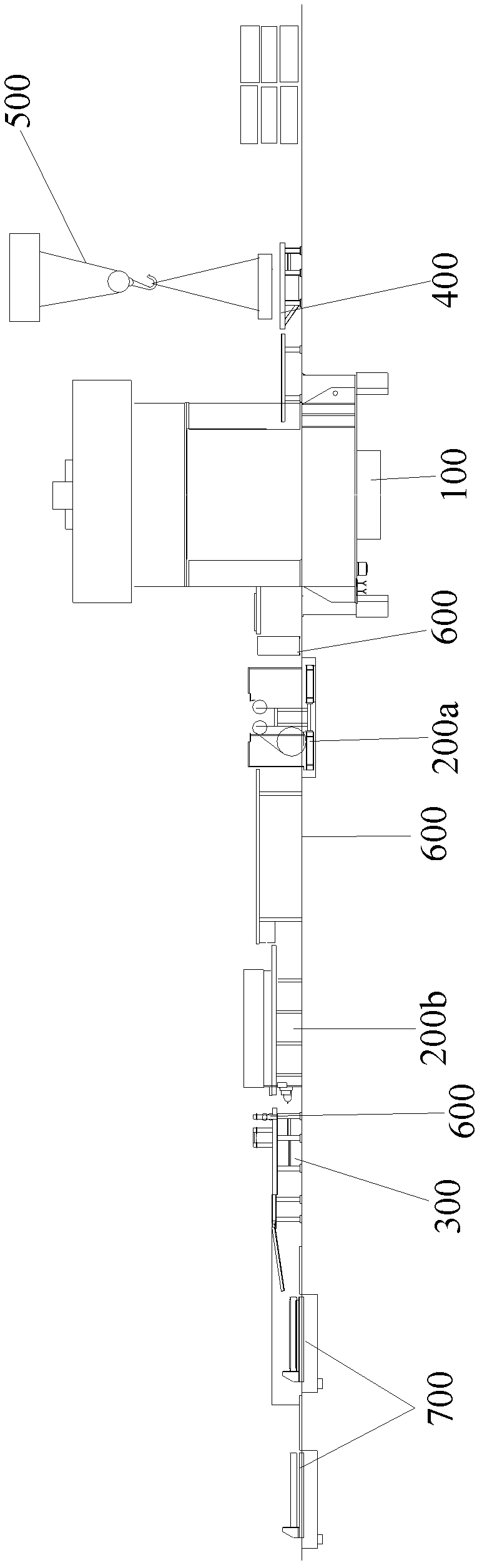

The invention relates to the processing of container parts and provides a molding technology and equipment for container top panels. The molding technology comprises the following steps of: uncoiling, cutting materials into steel plates, carrying out compression molding on the steel plates one by one so as to form at least two bosses on each steel plate at a time, locating and trimming the molded steel plates, shaping the trimmed steel plates and stacking. According to the invention, at least two bosses are formed on the steel plates at a time in the compression molding. On one hand, at least two bosses are formed in one-time compression molding, the size is stable, the requirement on the width of the materials is lowered, the materials are saved, and the cost is lowered. On the other hand, the production efficiency is largely improved. The invention further provides molding technical equipment for the container top panels, corresponding to the technical method. Through the adoption of the set of equipment, the top panels are continuously and automatically molded. The equipment is suitable for mass production so that the production efficiency is greatly increased.

Owner:东莞南方中集物流装备制造有限公司 +2

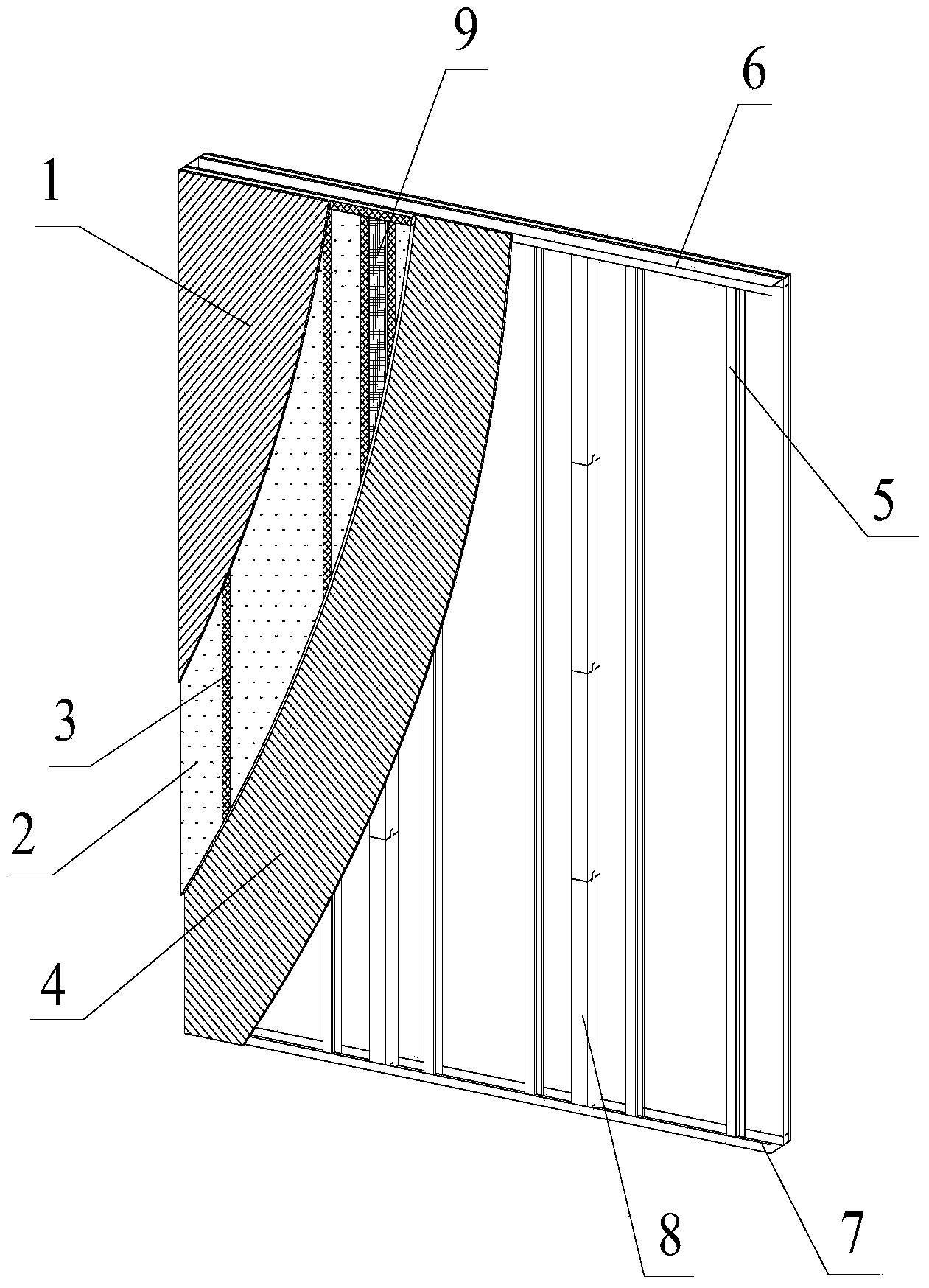

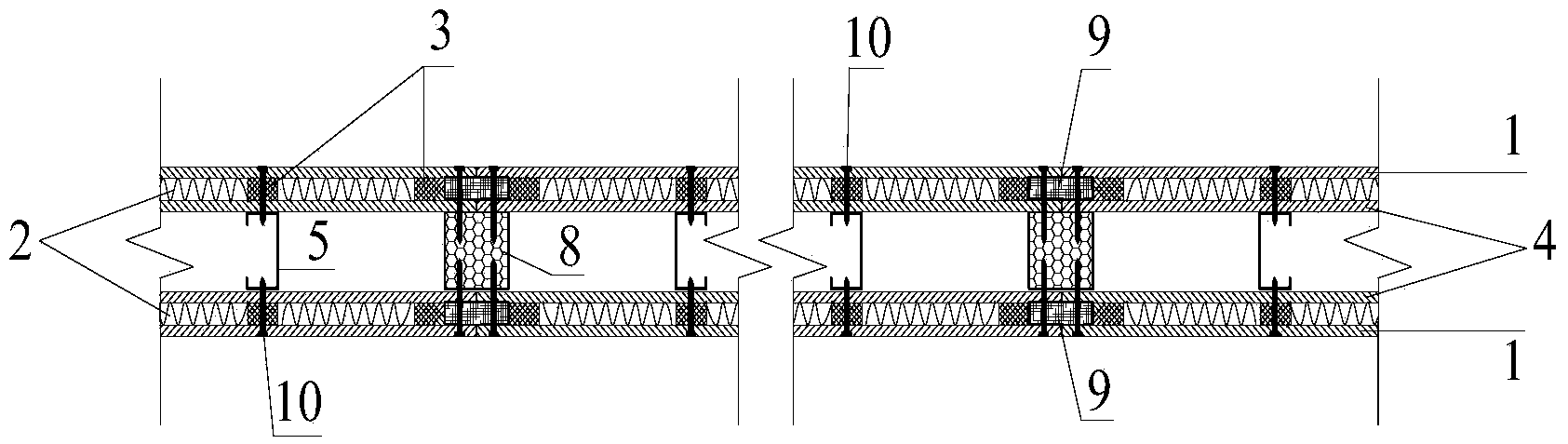

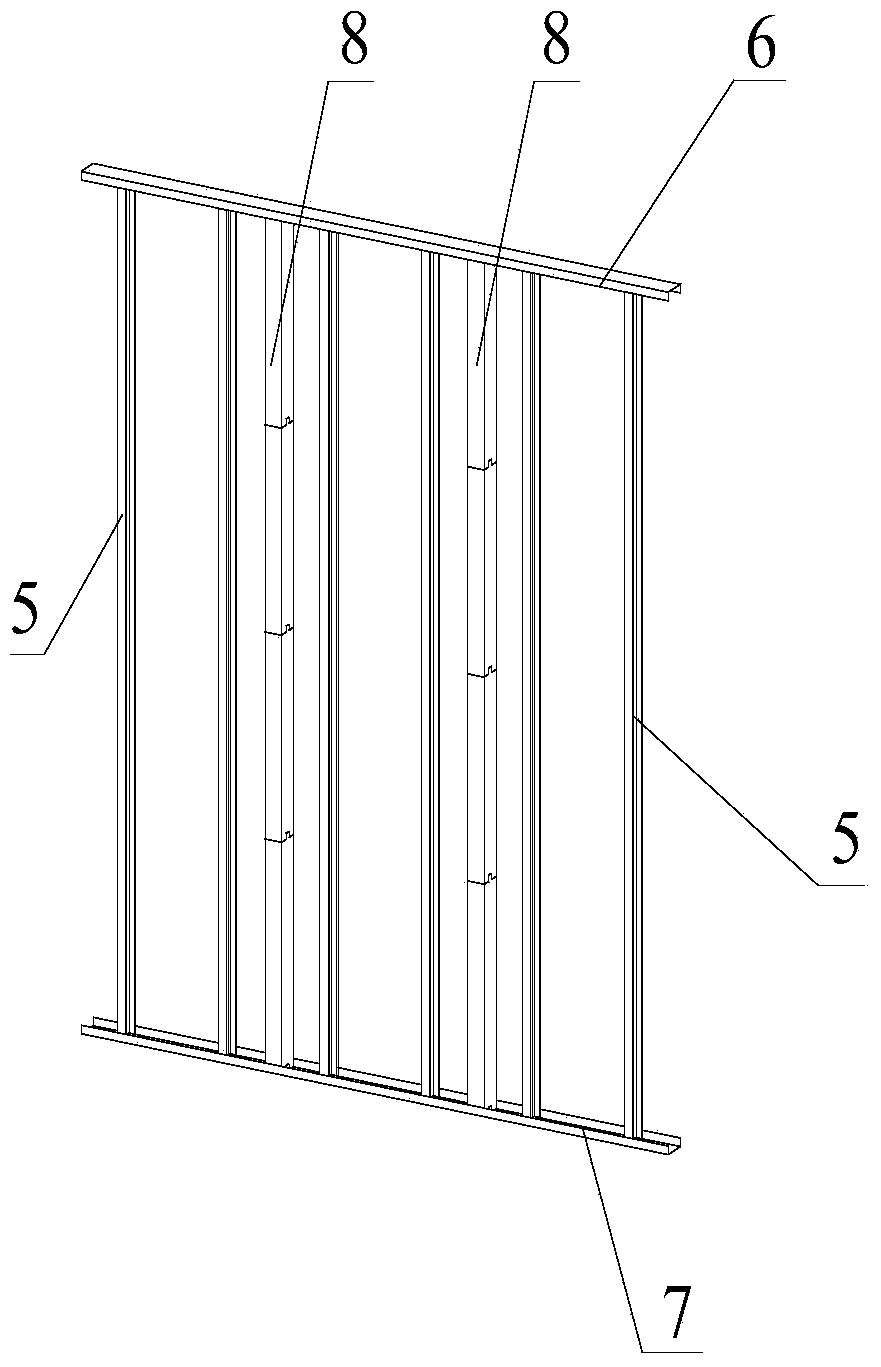

Prefabricated light steel fireproof load-bearing combined wall structure

InactiveCN103437463AFacilitate batch prefabricationNo significant effect on fire resistanceWallsHeat proofingThermal insulationKeel

The invention discloses a prefabricated light steel fireproof load-bearing combined wall structure which is formed by fixedly connecting sandwich wallboard units on two sides and a light steel joist framework unit at the middle. Each sandwich wallboard unit comprises an A-side wall board and a B-side wall board; and an autoclaved aerated concrete slat (3) and thermal insulation cotton (2) are spaced between the A-side wall board and the B-side wall board. The light steel joist framework unit is formed by fixedly connecting a cold-formed steel upright (5), a cold-formed steel guide rail and an autoclaved aerated concrete short column (8) of which the thickness is equal to the height of a web of the cold-formed steel upright. Adjacent sandwich wallboard units on the same side are inserted into an autoclaved aerated concrete butt-joint slat (9) through grooves (13) in the long sides thereof to realize splicing. The sandwich wallboard units and the light steel joist framework unit are connected through self-tapping screws to realize wall splicing. By adopting the structure disclosed by the invention, full prefabrication can be realized, the structure is light, and the steel consumption is reduced; and moreover, the structure has the characteristics of thermal insulation, sound insulation and fire resistance and is suitable for a load bearing wall system of a multi-story building.

Owner:SOUTHEAST UNIV

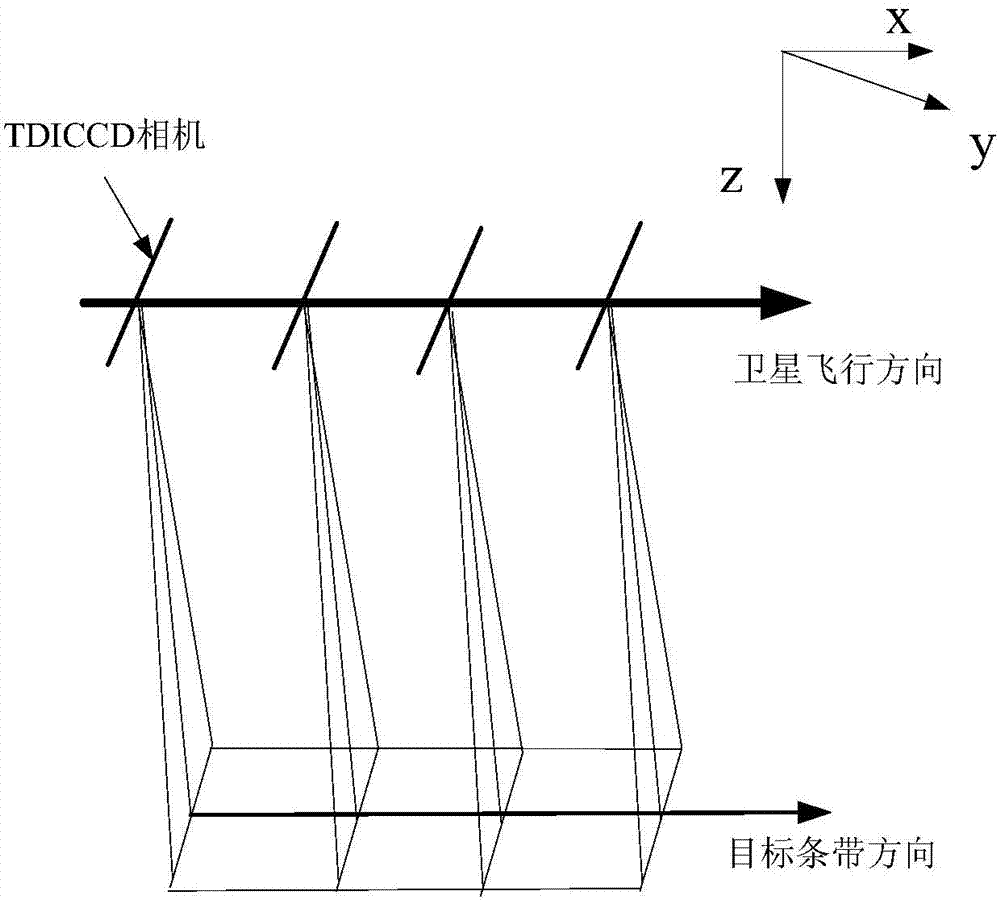

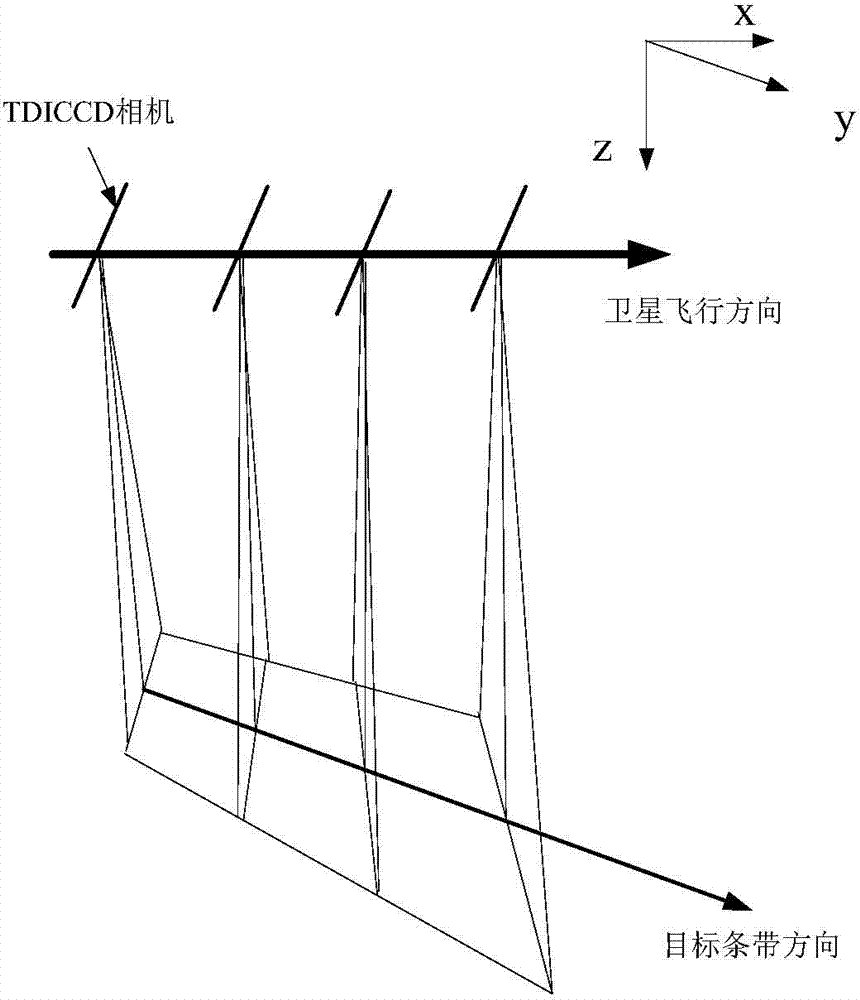

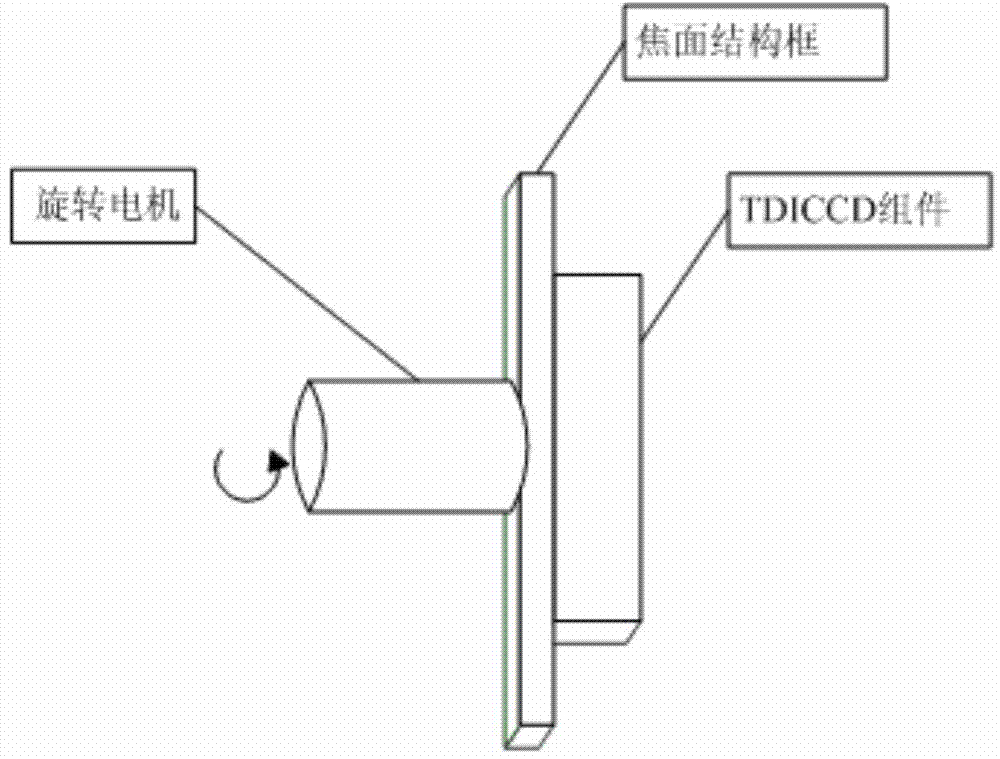

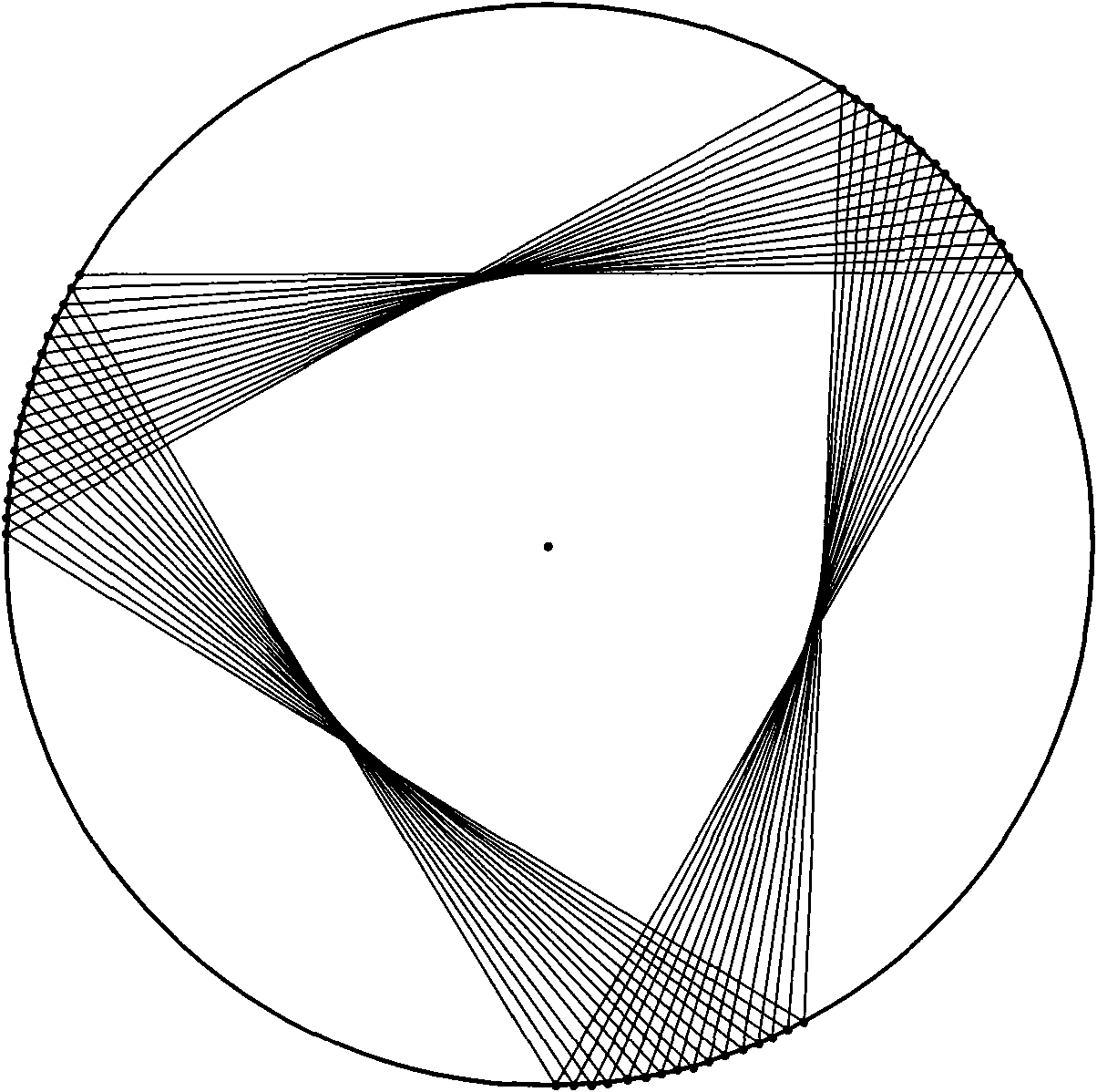

High-resolution optical satellite maneuvering imaging drift angle correction method

ActiveCN103886208AReduce width requirementsImprove observation efficiencySpecial data processing applicationsFlight directionDrift angle

The invention discloses a high-resolution optical satellite maneuvering imaging drift angle correction method. A drift angle correction model under a maneuvering imaging mode is set up according to a satellite attitude maneuver scheme, a method for calculating a drift angle is derived based on the satellite position and ground point position coordinates, and a scheme for installing a drift angle correction device at the focal plane position is provided. Thus, a satellite can have the imaging capacity on a target strip deviating from the flying direction, the observation range and the observation efficiency of the satellite are greatly improved, and meanwhile, the satellite can have the dynamic pushing and blooming imaging capacity in the vertical direction of a sub-satellite point. Large-width imaging of a sub-satellite point area is achieved in a multi-strip splicing manner, and the requirement for the TDICCD camera width is lowered.

Owner:AEROSPACE DONGFANGHONG SATELLITE

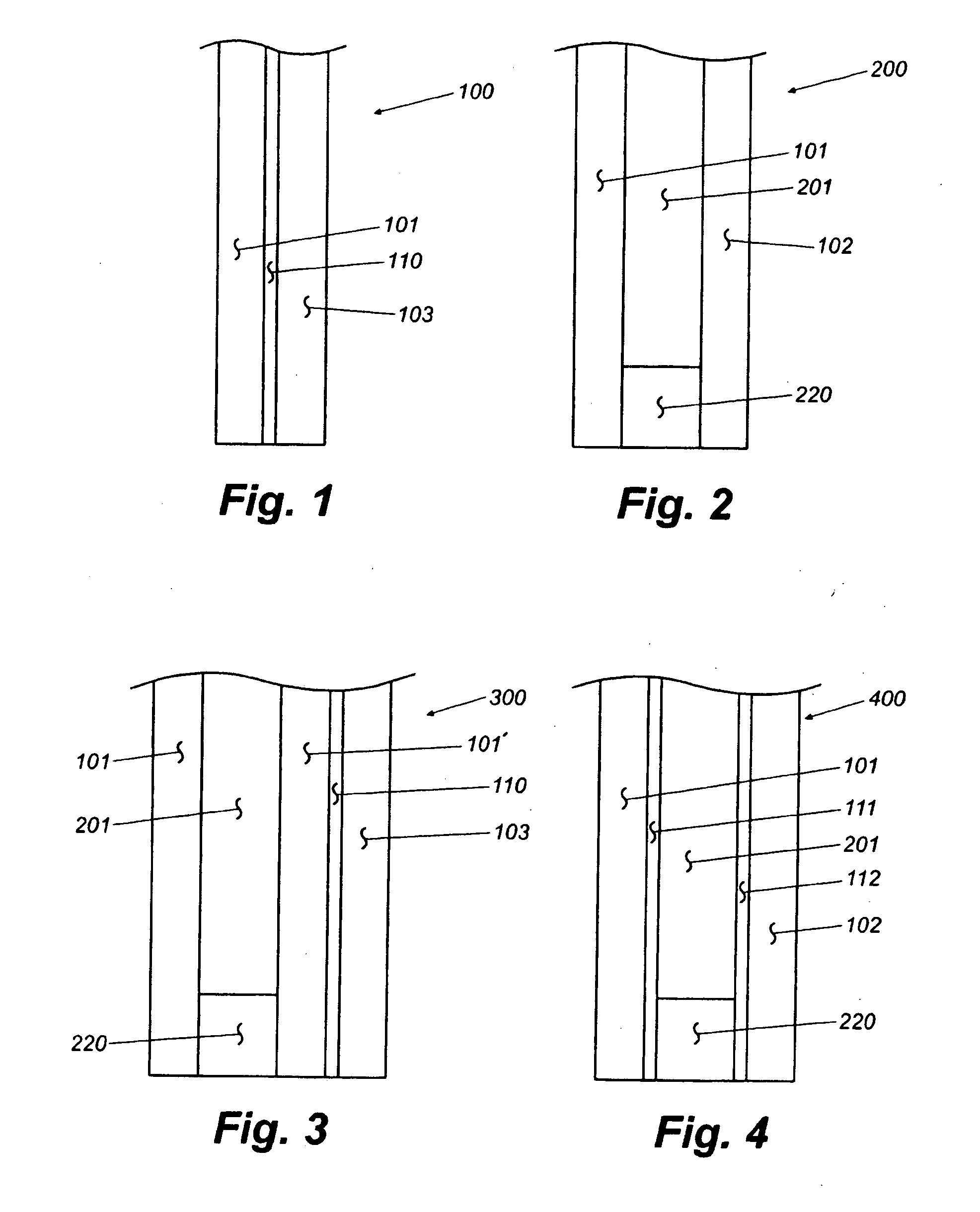

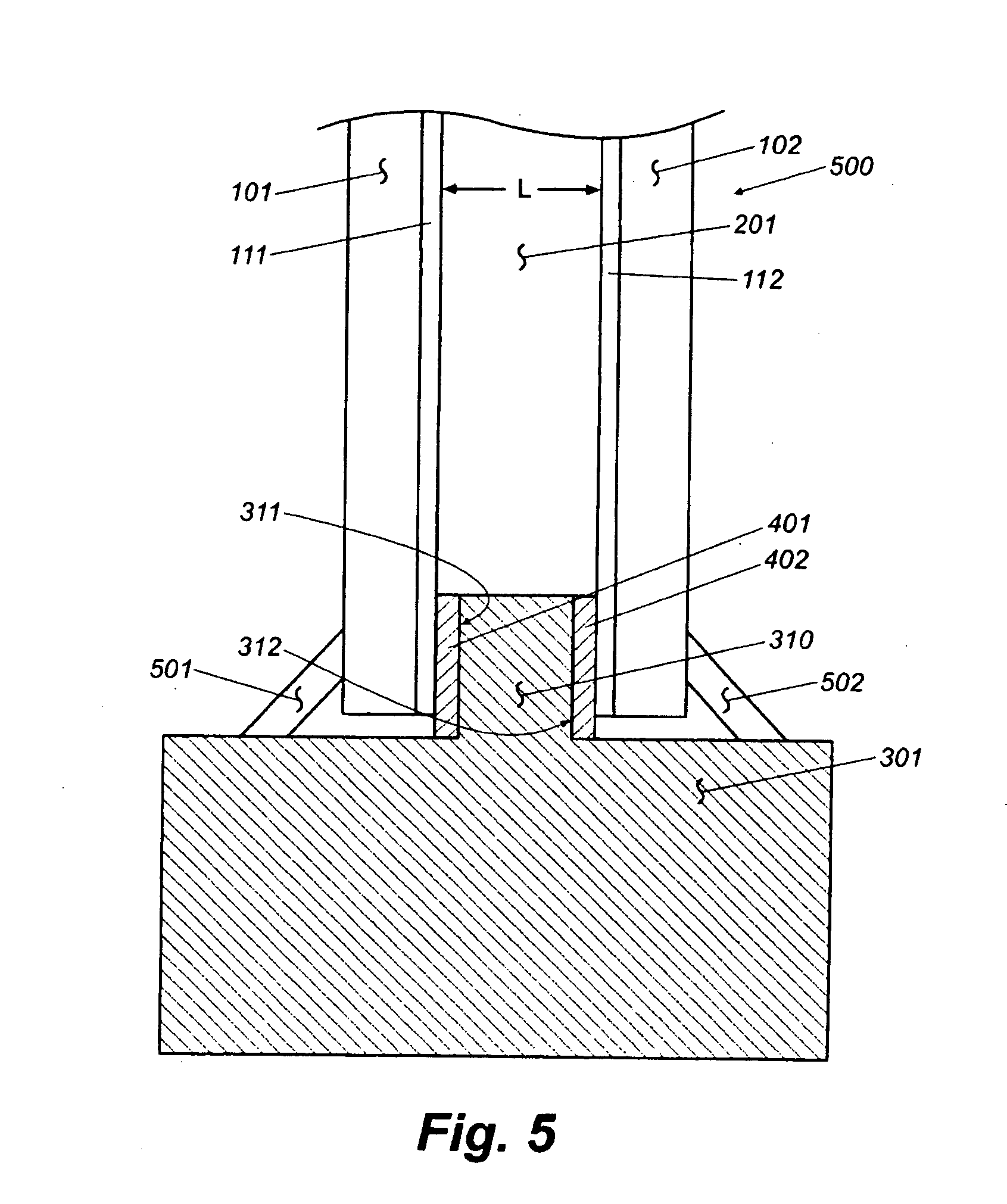

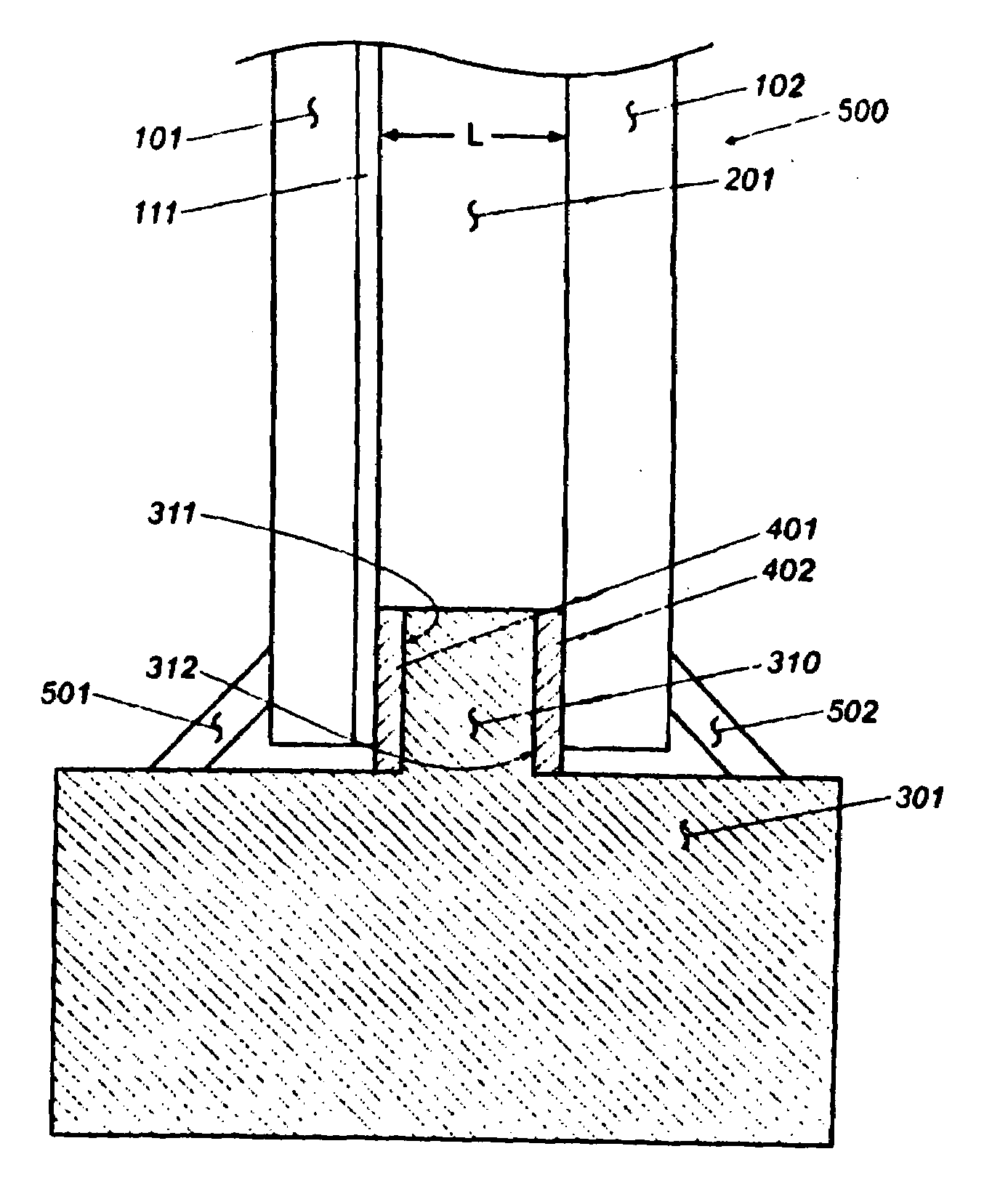

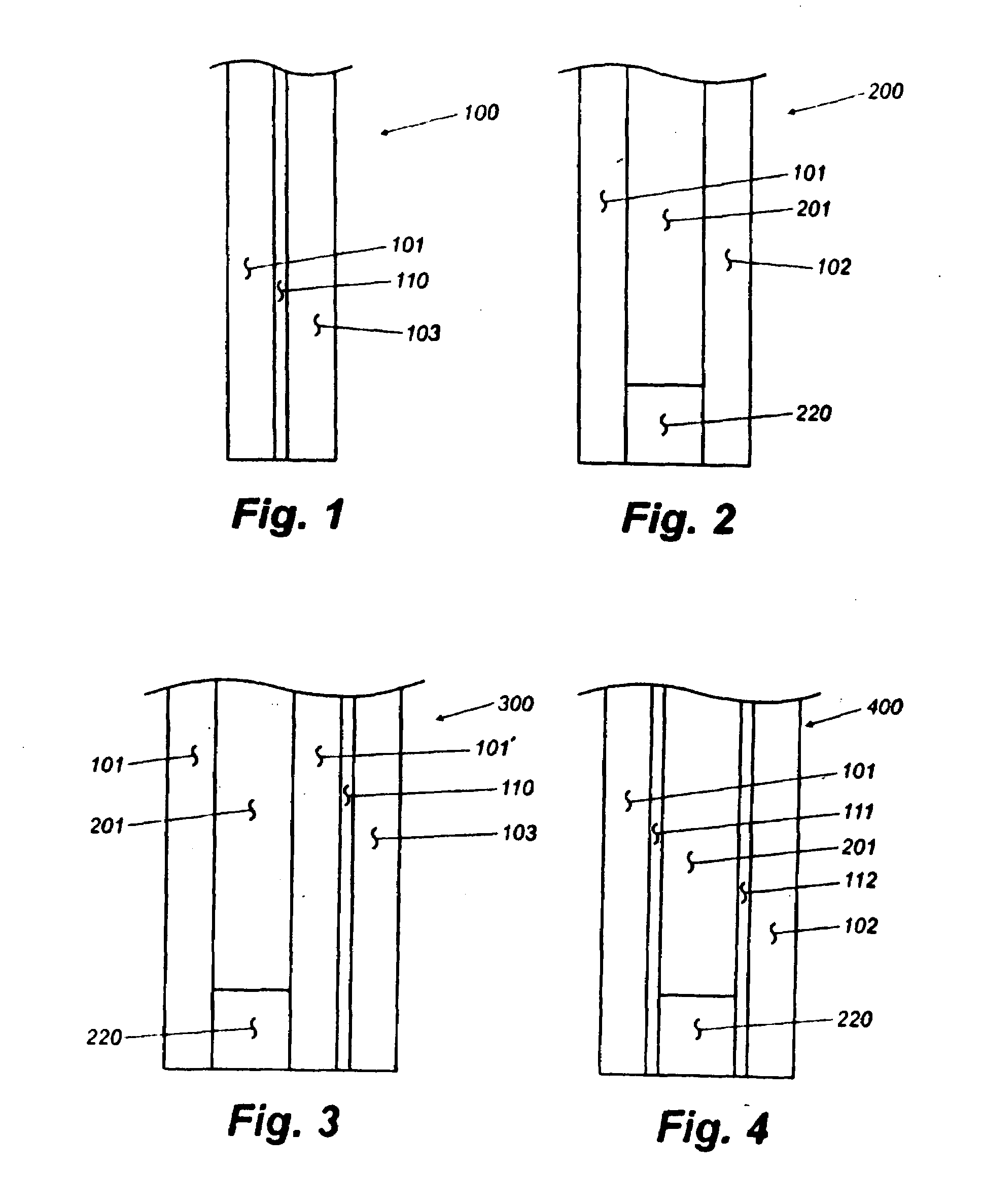

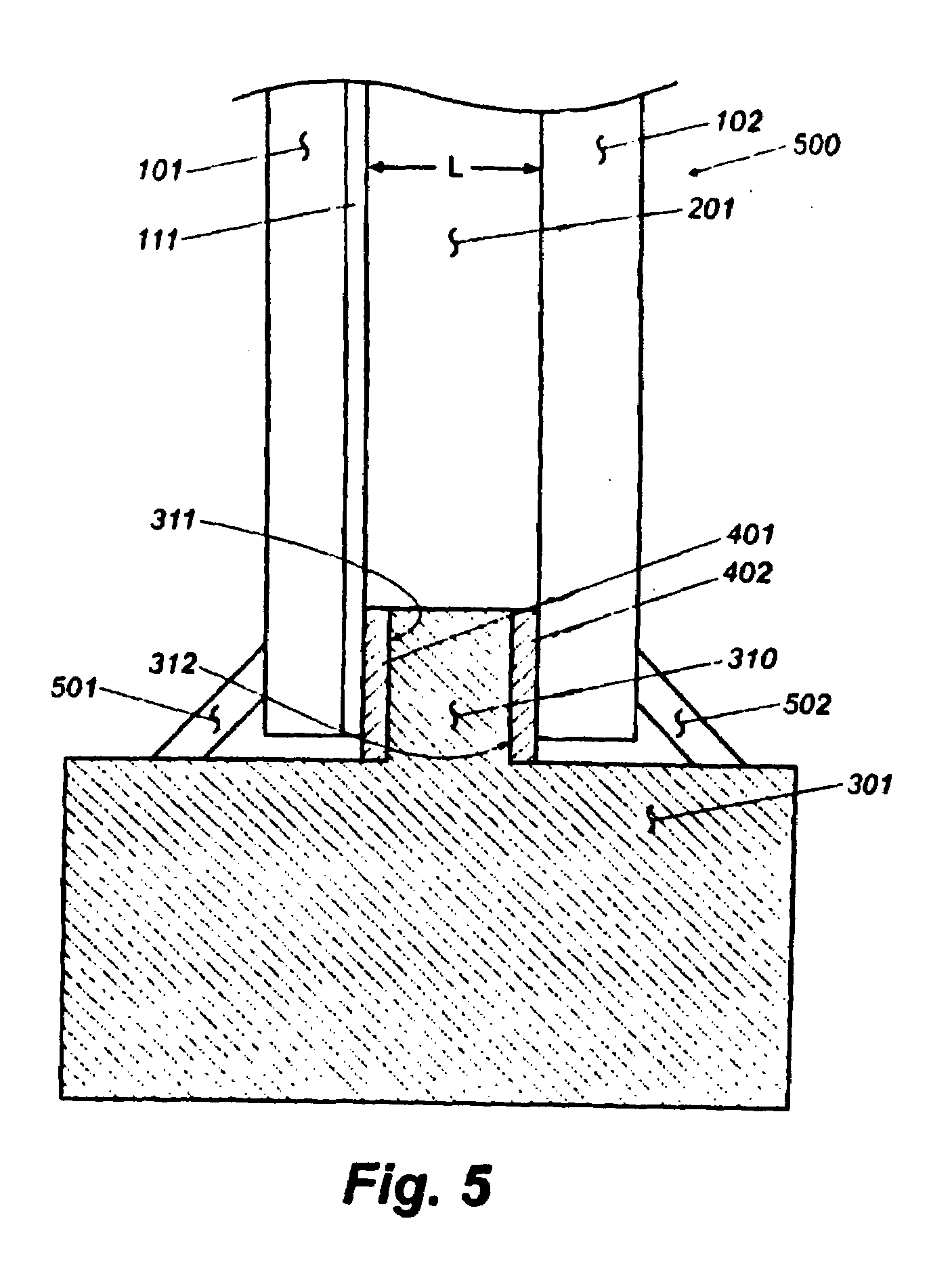

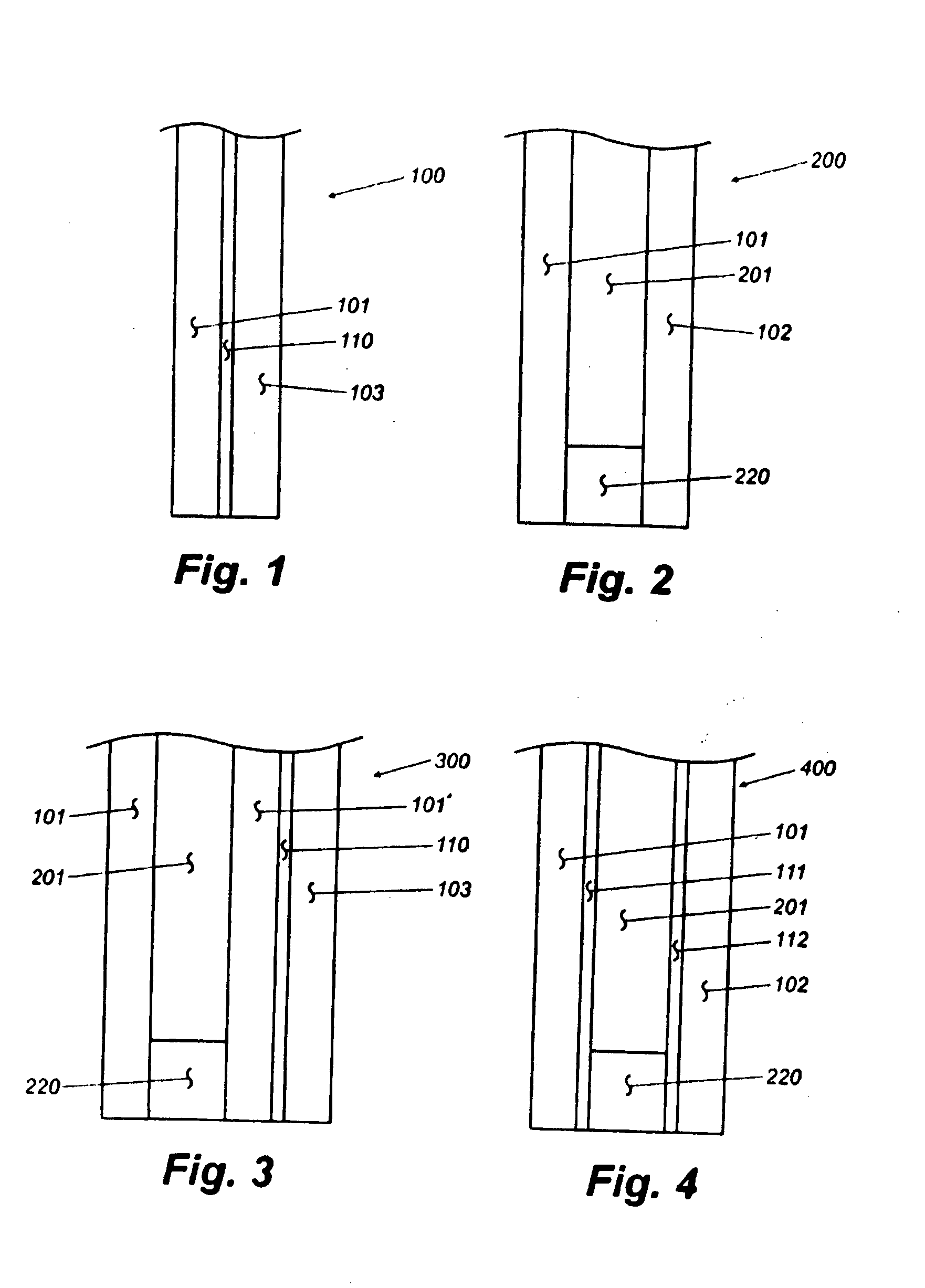

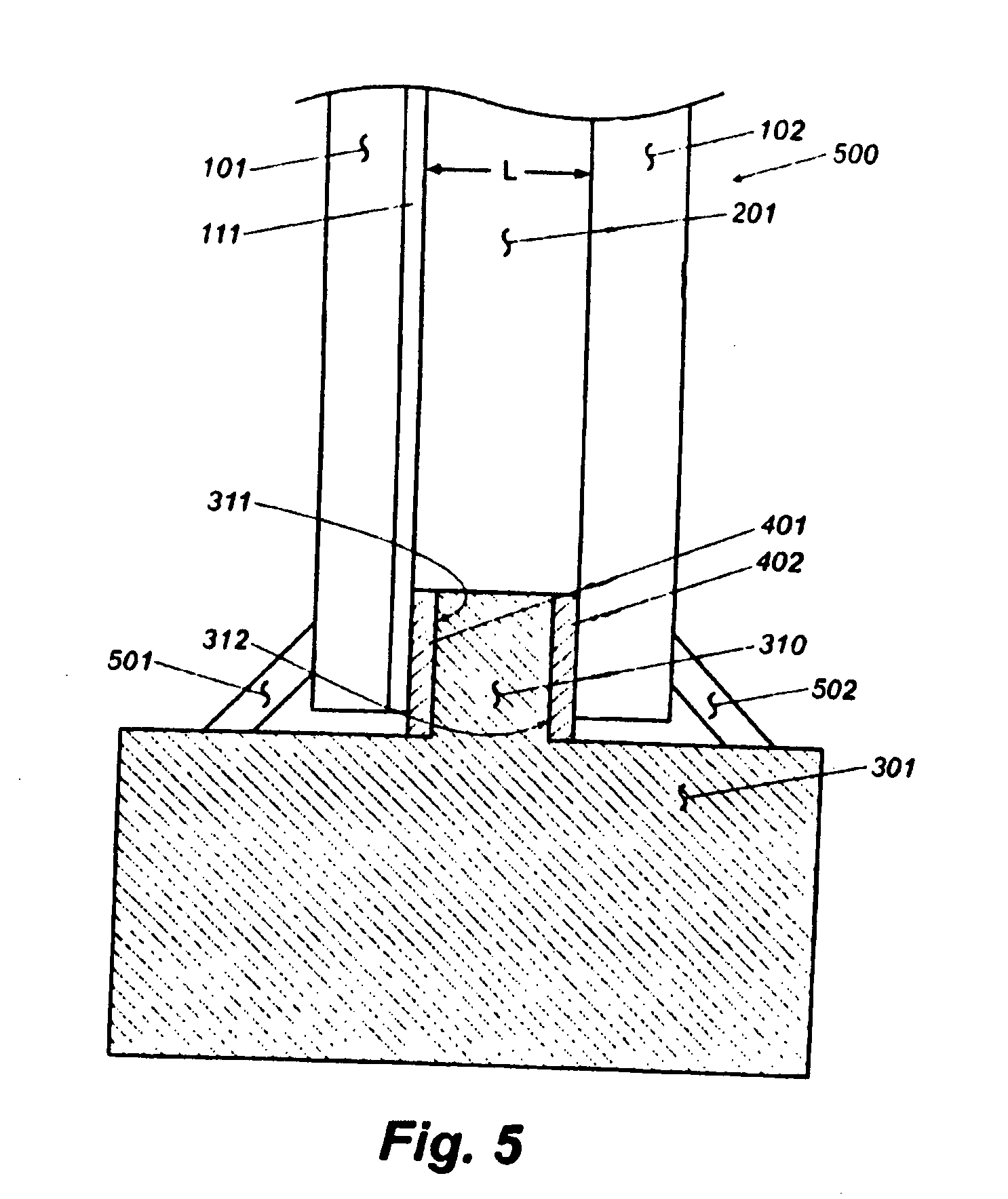

Impact resistant multipane window

InactiveUS20080196317A1Easy to makeLess laborWing framesUnits with parallel planesEngineeringMechanical engineering

Briefly, therefore the present invention is directed to a novel method of making a double glazed impact resistant window, the method comprising: forming a window sash that delineates a mounting space for mounting a first pane and a second pane opposite and parallel to and spaced apart from each other, the sash having an integral spacer that forms a sealing surface of the mounting space for each pane; adhering a durable transparent polymer film to a surface of the first pane; attaching a protective layer to at least a portion of the durable transparent polymer film to protect the durable transparent polymer film from damage prior to assembling the double glazed impact resistant window; conforming the pane to the size and shape of the mounting space; removing the protective layer; mounting the first pane in the mounting space with the film covered surface of the pane facing the sealing surface of the integral spacer; and repeating the previous steps for the second pane.

Owner:MUHLER LAMINATED GLASS

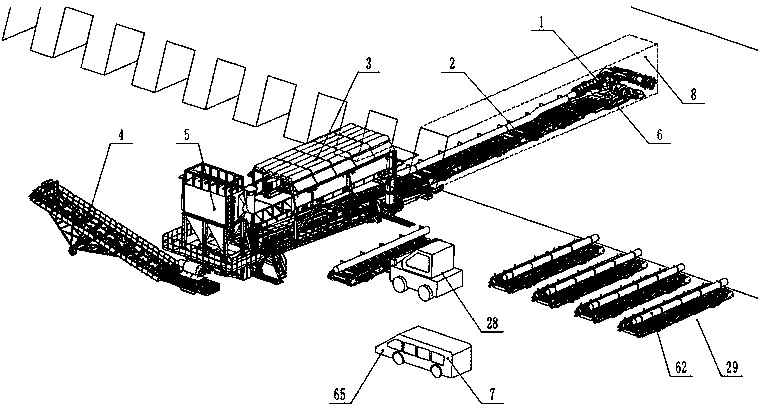

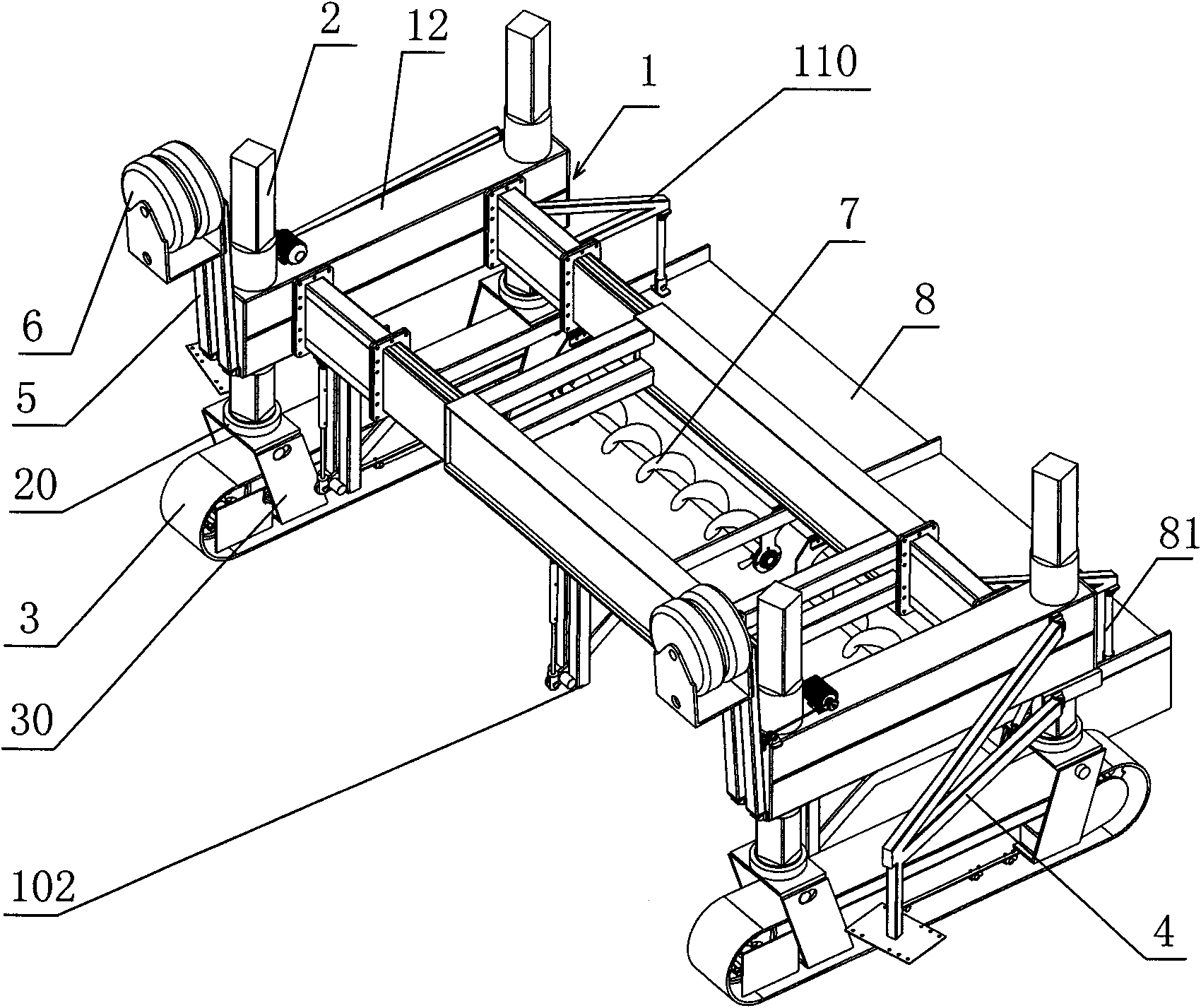

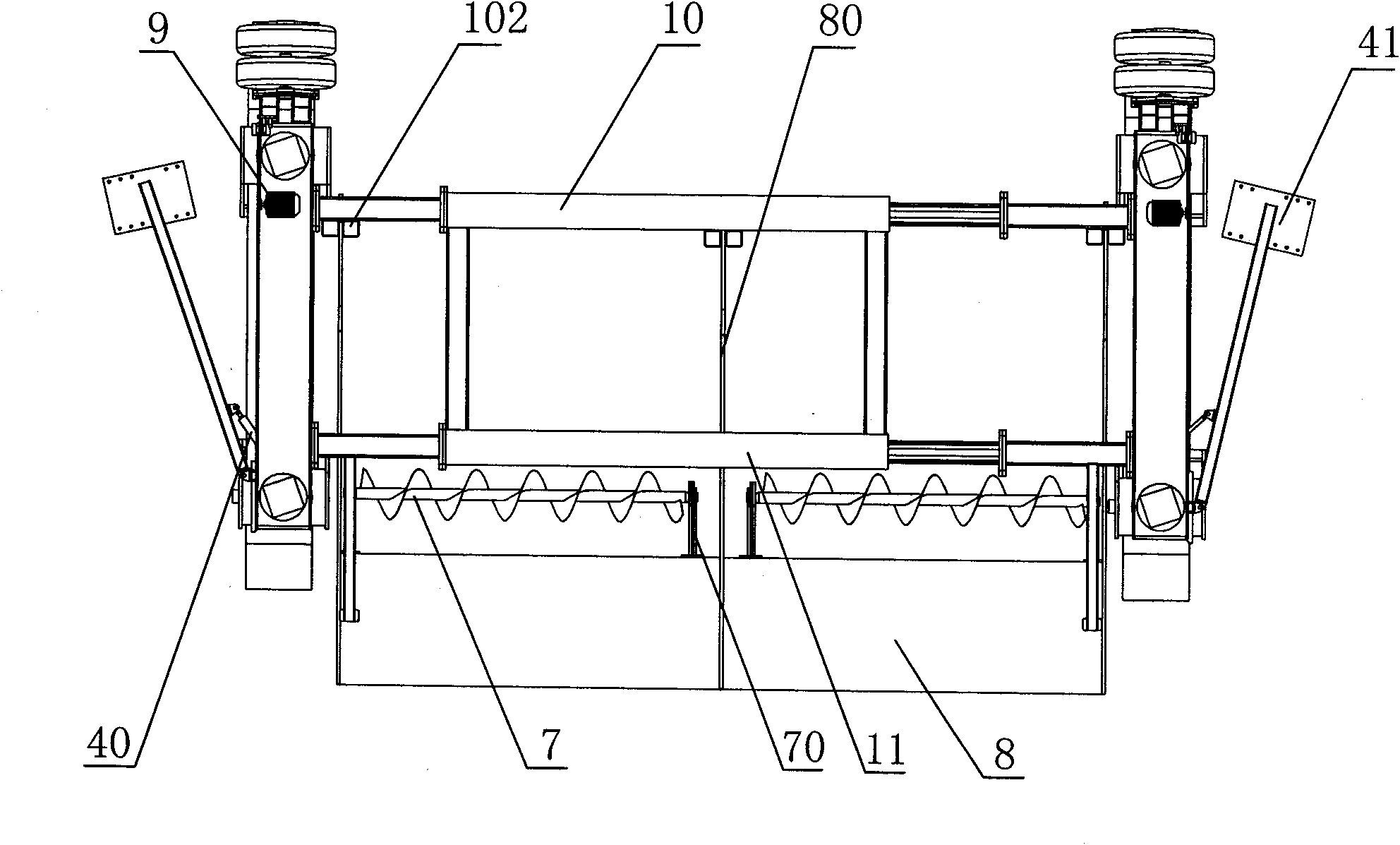

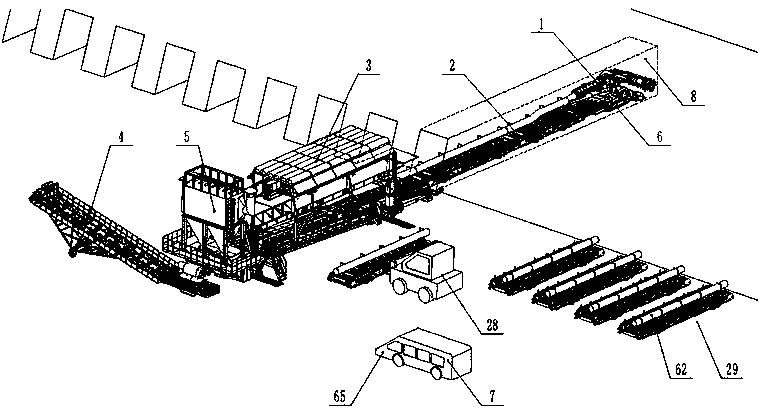

Slope mining system for open-pit mines

ActiveCN109931066AImproving the technical strength of side miningRealize intelligenceDust removalFire preventionAdhesiveEngineering

The invention relates to the technical field of slope mining of open-pit mines and particularly relates to a slope mining system for the open-pit mines, and realizes safe, efficient and green mining of slope briquettes of the open-pit mines. The slope mining system comprises a slope continuous coal mining machine for carrying out roadway type mining, a multi-unit rapid connection adhesive tape conveying system for carrying out rapid conveying, a stepping type walking platform for carrying out external propelling and whole movement, a movable type unloading part for carrying out external conveying, a pulling-out type ventilation and dust removal system for carrying out roadway ventilation and dust removal, a navigation and stability monitoring system for carrying out remote accurate controland slope stability monitoring, and a remote control platform for carrying out remote control. According to the slope mining system for the open-pit mines, provided by the invention, the safe, efficient and green mining of slope briquette resources can be realized, the strength of an slope mining technology of the open-pit mines in China can be remarkably improved, and remarkable economic benefits and social benefits can be brought for enterprises.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

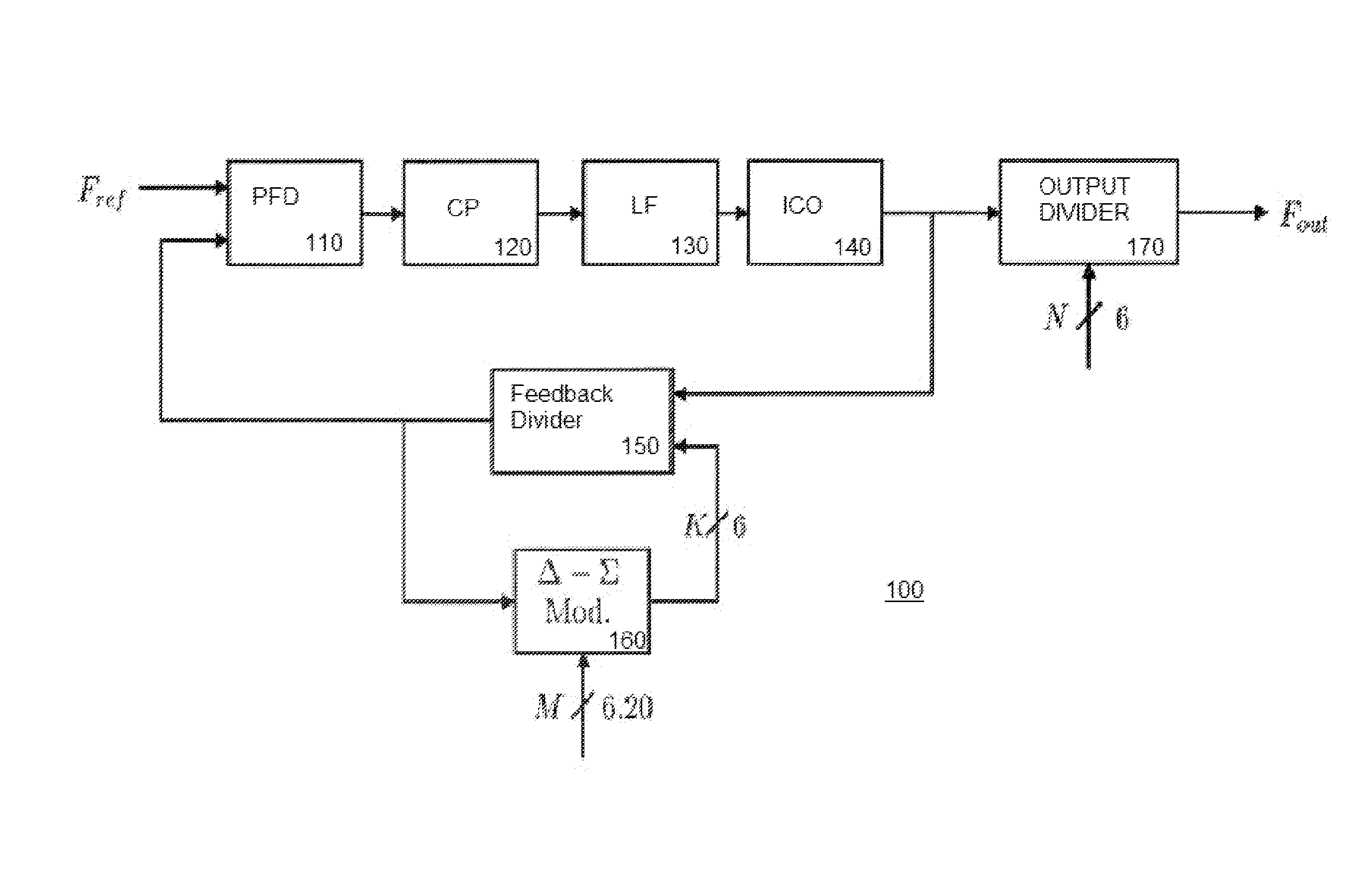

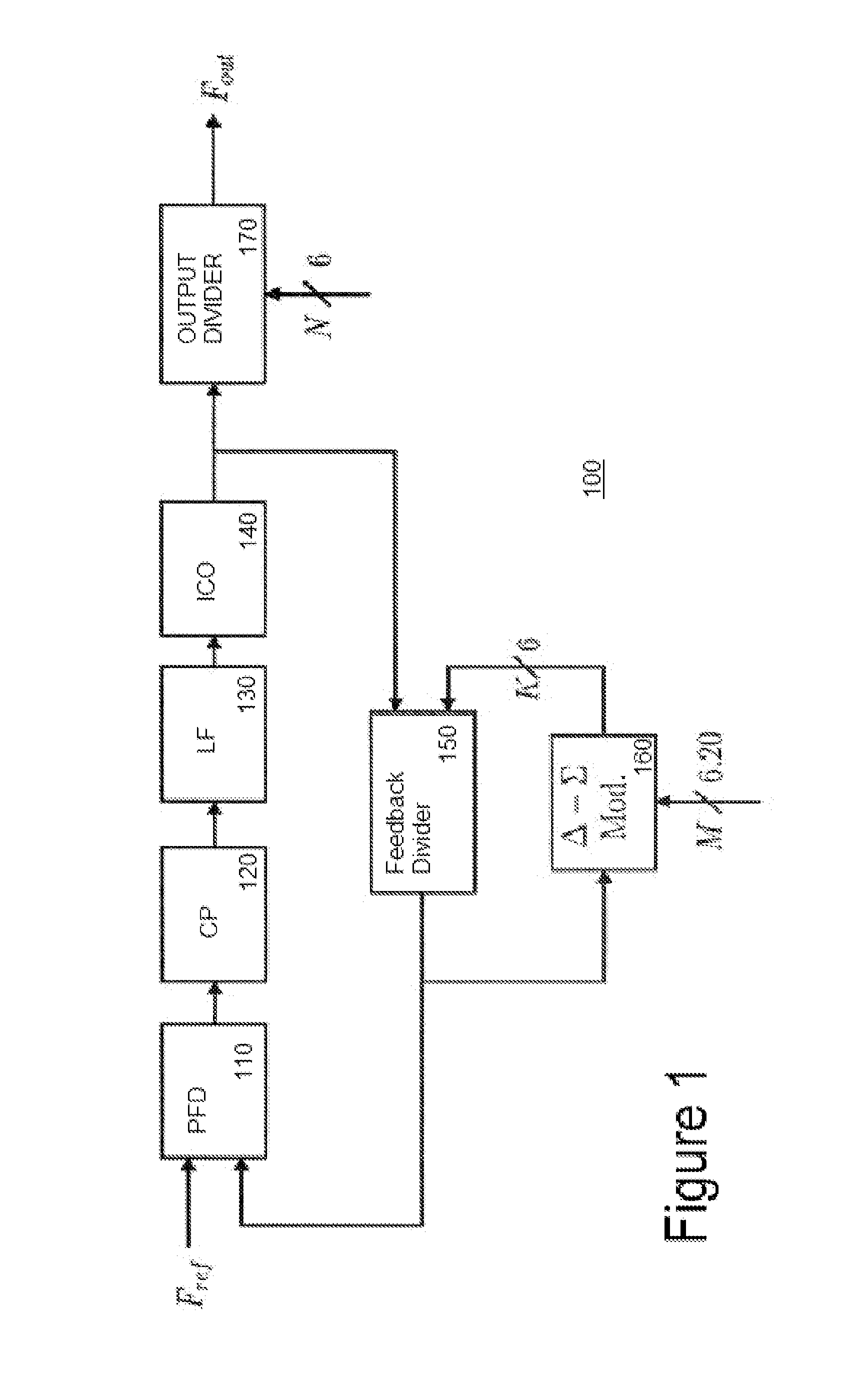

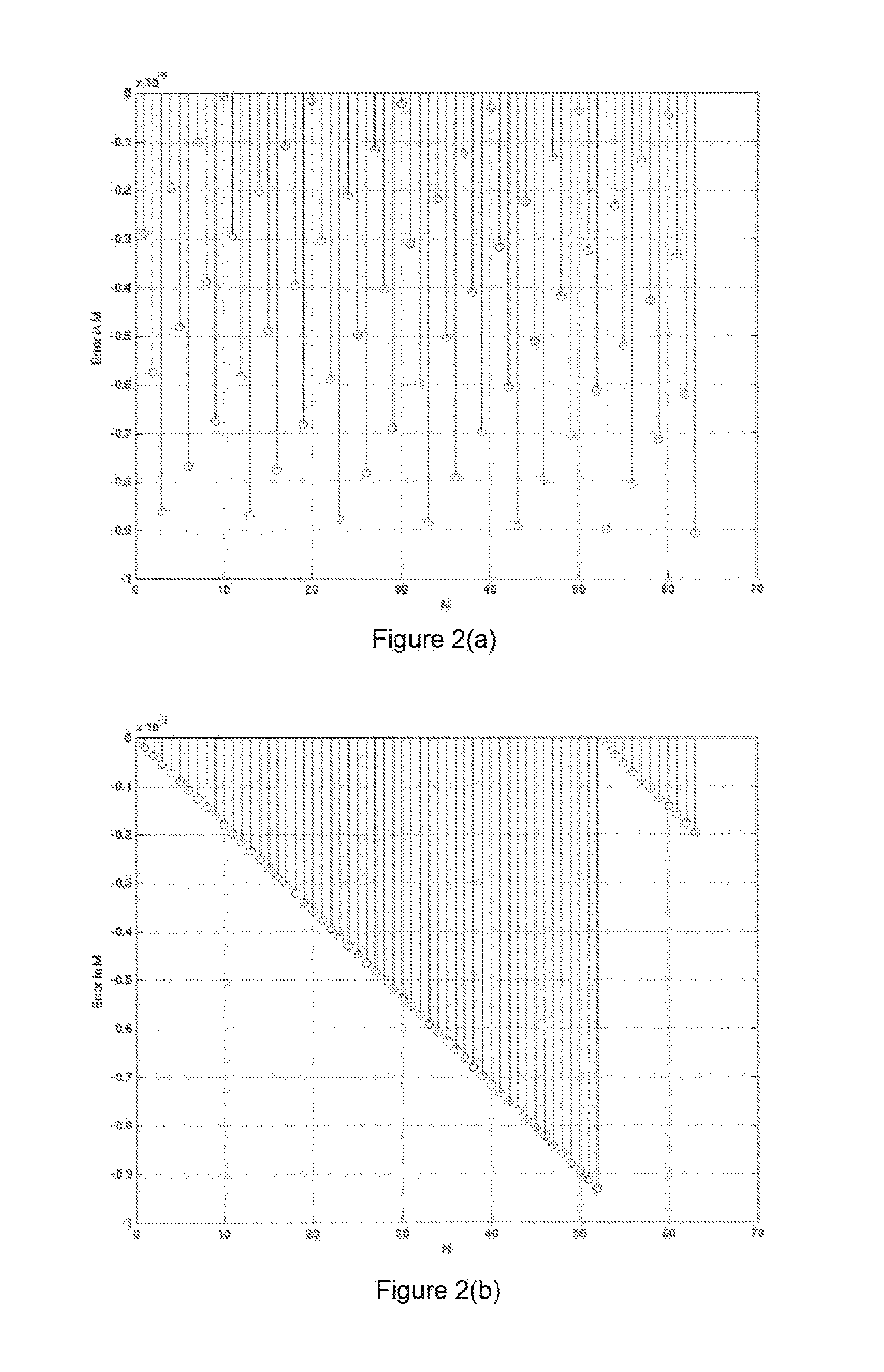

Method to increase frequency resolution of a fractional phase-locked loop

InactiveUS8664989B1Accurate representationSmall sizePulse automatic controlImage resolutionEngineering

The ratio of the output frequency of the PLL to the reference frequency is governed by the ratio of the feedback divider to the output divider. For the case of a fixed-point delta-sigma modulator based PLL, the feedback divide factor can only be a non-recurring / terminating rational number in base-2 (binary) system and the output divide ratio is constrained to be an integer. Hence, the range or resolution of the output frequencies that are possible is inherently limited. To solve this problem, an additional gain factor is introduced in the feedback loop. The gain factor is determined by finding an initial gain factor for which the value of the feedback divide ratio can be represented precisely in the binary format. The closest power of two larger than the initial gain factor is used as the denominator to divide the initial gain factor. The present system and method increases the resolution of such a PLL, while actually saving area / power, by introducing an additional factor within the modulator and also by not affecting the analog part of the circuit.

Owner:CIRRUS LOGIC INC

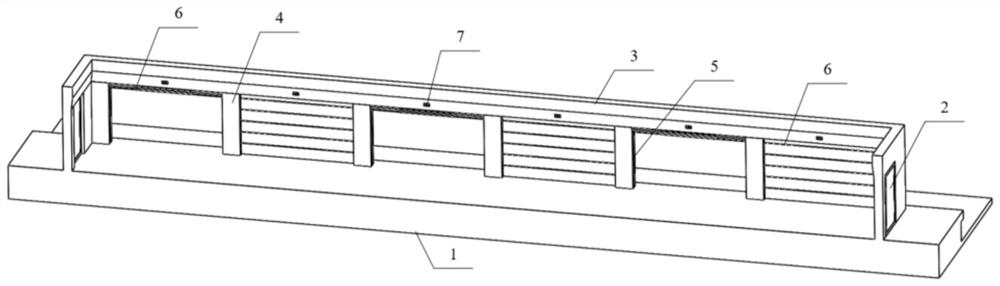

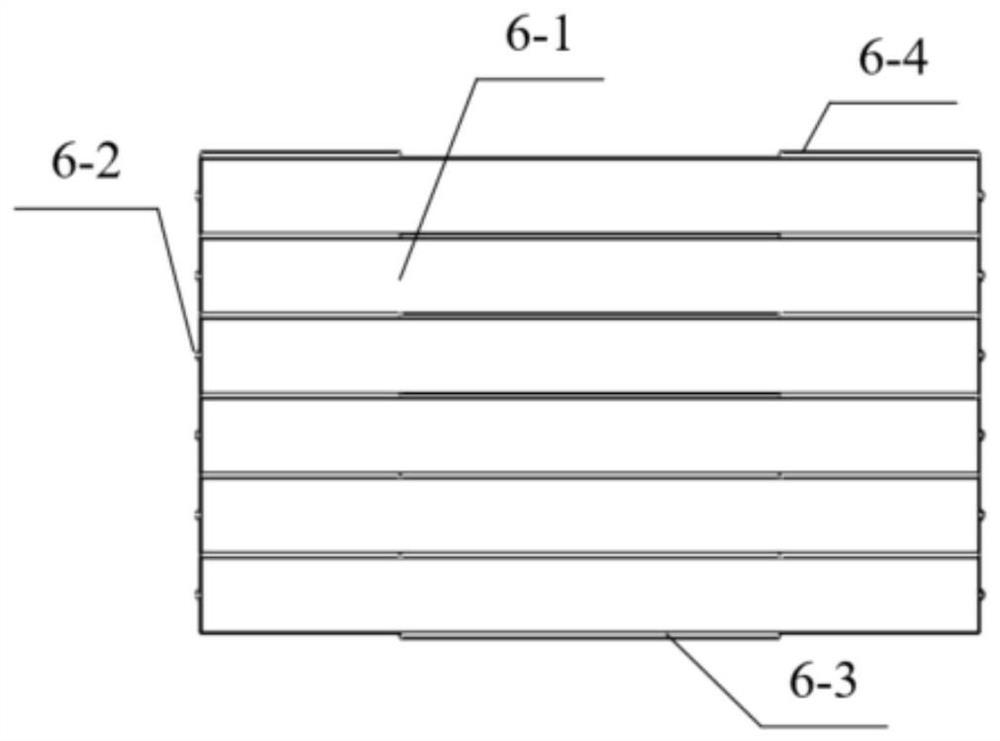

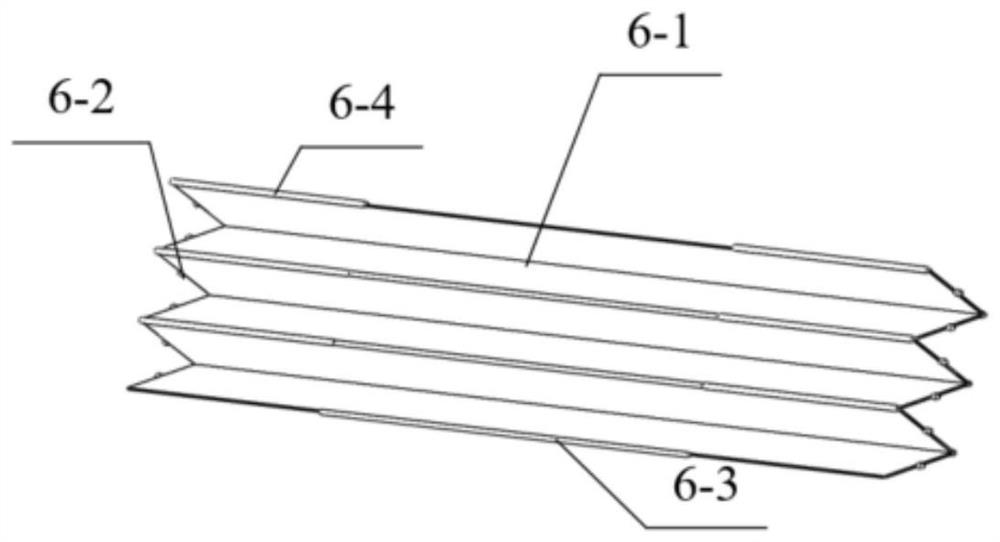

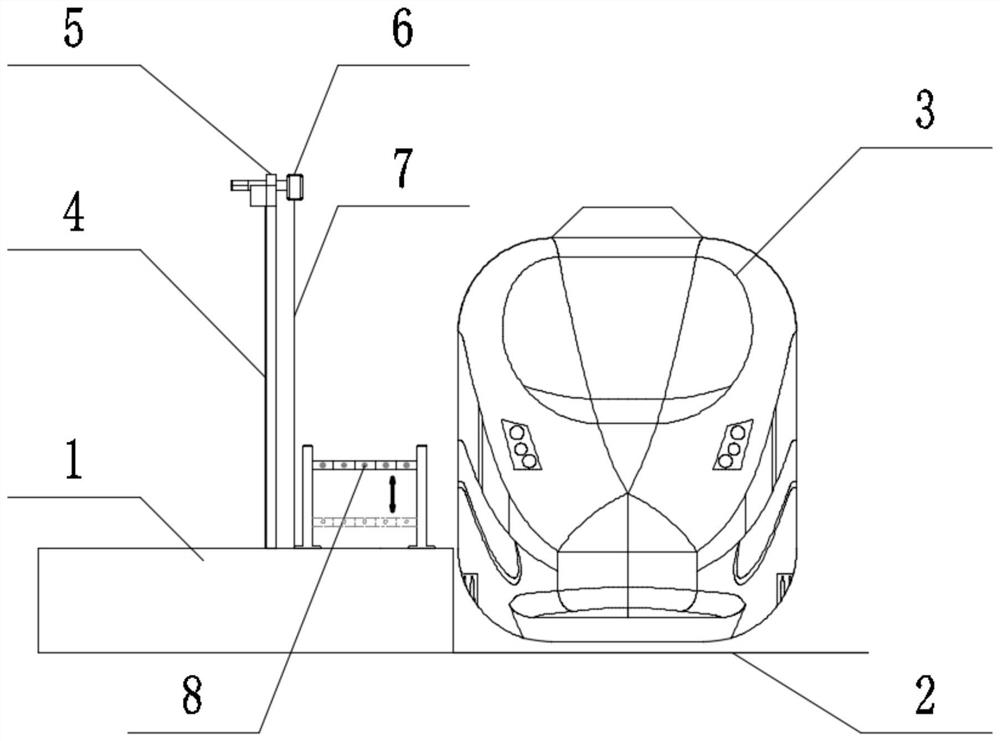

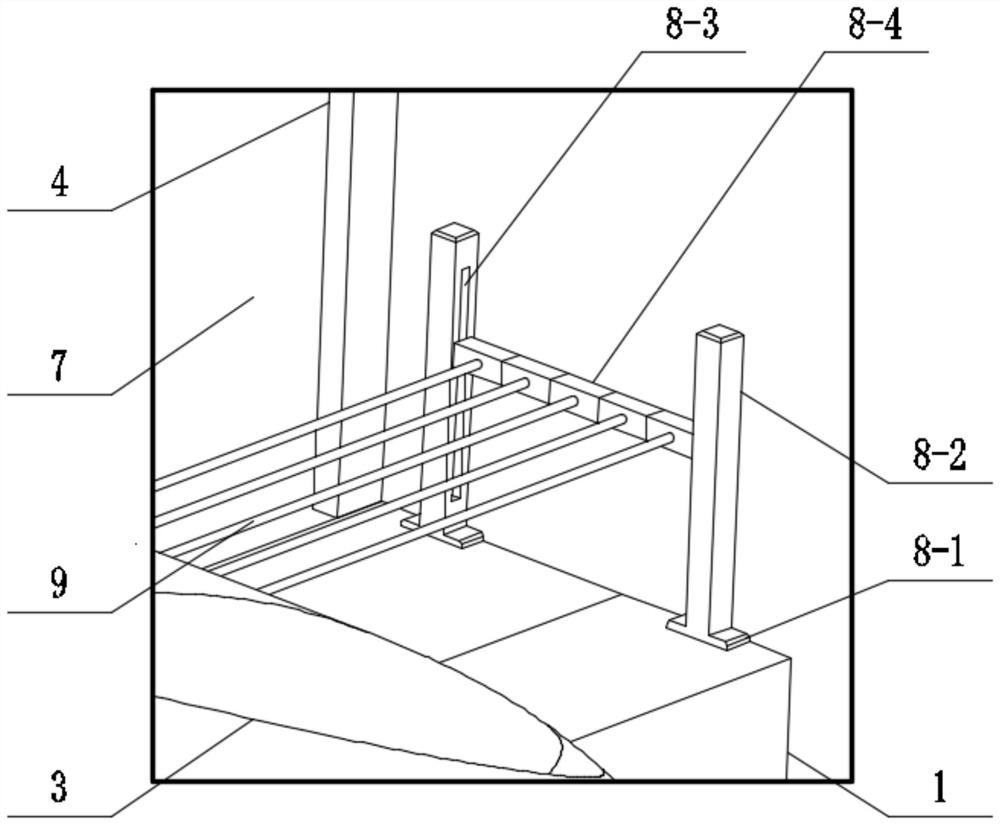

Lifting folding type platform protection device suitable for various vehicle types

PendingCN111762204ALower requirementSimple structureRailway componentsRailway stationEngineeringStructural engineering

The invention discloses a lifting folding platform protection device suitable for various vehicle models, which is characterized by comprising lifting folding platform doors (6), stand columns (4) andan end door (2), wherein the plurality of lifting folding platform doors and the stand columns are sequentially and alternately arranged in the longitudinal direction of the rail to form longitudinalplatform doors, and the transverse end doors are arranged at the two ends of each longitudinal platform door; the widths of all the lifting folding platform doors are equal, and the sum of the widthsof all the lifting folding platform doors accounts for 80% or above of the total length of the longitudinal platform doors; and the lifting folding platform door comprises a plurality of shielding folding pieces (6-1) which are sequentially hinged up and down, and the two ends of each shielding folding piece (6-1) can slide up and down on the stand columns on the two sides. Fixed doors and sliding doors of traditional platform doors are replaced by folding and unfolding the lifting folding platform doors up and down, and the shielding function of the platform door is achieved. On the premisethat the platform door device is arranged without retreating to reduce the width of the platform, the platform protection device can adapt to various railway vehicle types through linkage of the control system.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

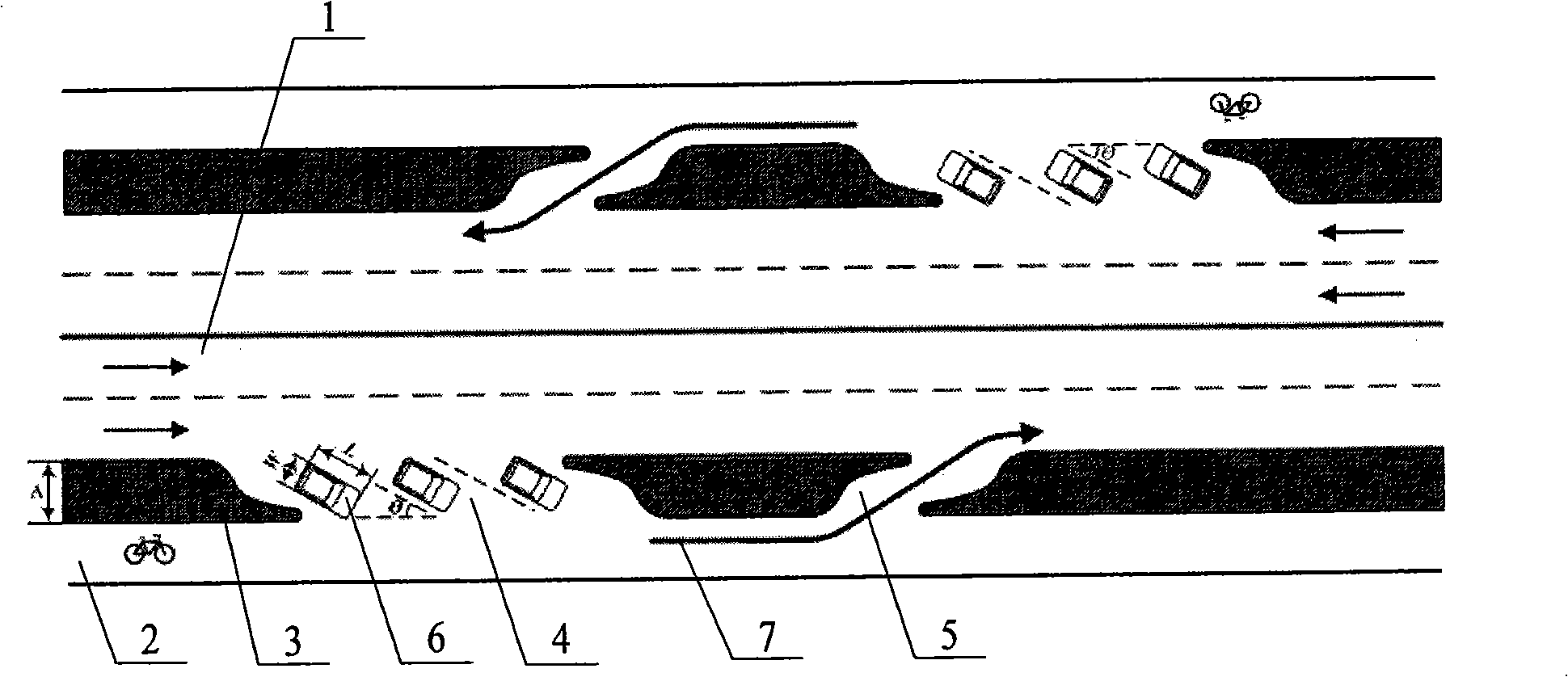

Control method for setting temporary stop area for automobile by vehicle-bicycle separation zone

InactiveCN101333794AImprove traffic capacityReduce traffic safety hazardsRoadwaysClimate change adaptationParking spaceMotorized vehicle

Disclosed is a control method utilizing a road vehicle-bicycle dividing strip to arrange a motor vehicle temporary parking strip, wherein, a vehicle-bicycle dividing strip (3) is arranged at the middle parts of a motor vehicle road (1) and a non-motorized vehicle road (2), then a motor vehicle parking strip (4) and a motor vehicle direct moving special road (5) are disposed on the vehicle-bicycle dividing strip (3) for communicating the roads at both sides of the vehicle-bicycle dividing strip (3); and the arrangement of the vehicle-bicycle dividing strip at the section of the road as well as the motor vehicle parking strip and the direct moving special road for parking vehicles disposed on the vehicle-bicycle dividing strip can avoid the parking strip arranged at the roadside from directly occupying the space resources of the motor vehicle lane and the non-motorized vehicle lane and interfering the dynamic traffic operation in traditional ways, and can also fully utilize the breadth of the vehicle-bicycle dividing strip to arrange the diagonal motor vehicle parking space and increase the number of parking berths under the condition of equal road length, meanwhile, the control method can also reduce the requirements to the breadth of the non-motorized vehicle lane by the parking berths at the roadside, and is favorable for improving the road traffic operating efficiency and the supply efficiency of the parking berths.

Owner:SOUTHEAST UNIV

Impact resistant multipane window

InactiveUS20100000181A1Easy to makeLess laborGlass/slag layered productsWing framesMechanical engineeringPolymer

Briefly, therefore the present invention is directed to a novel method of making a double glazed impact resistant window. The method includes forming a window sash that delineates a mounting space for mounting a first pane and a second pane opposite and parallel to and spaced apart from each other and adhering or coating at least two layers of a durable transparent polymer film to a surface of the first pane such that the at least two layers are not adhered or coated in directions that are parallel to one another. The method further includes conforming the pane to the size and shape of the mounting space, mounting the first pane in the mounting space with the non-film covered surface of the pane directly adjacent the sash, conforming the second pane to the size and shape of the mounting space, wherein the second pane is free of the durable transparent polymer film, and mounting the second pane in the mounting space.

Owner:MUHLER LAMINATED GLASS

Impact resistant multipane window

InactiveUS20090229216A1Easy to makeLess laborFixed grillesBuilding repairsEngineeringMechanical engineering

A novel method of making a double glazed impact resistant window is provided. The method includes forming a window sash that delineates a mounting space for mounting a first pane and a second pane opposite and parallel to and spaced apart from each other, the sash having an integral spacer that forms a sealing surface of the mounting space for each pane and adhering or coating at least two layers of a durable transparent polymer film to a surface of the first pane such that the at least two layers are not adhered or coated in directions that are parallel to one another. The method further includes conforming the pane to the size and shape of the mounting space, mounting the first pane in the mounting space with the film covered surface of the pane facing the sealing surface of the integral spacer, conforming the second pane to the size and shape of the mounting space, wherein the second pane is free of the durable transparent polymer film, and mounting the second pane in the mounting space.

Owner:MUHLER LAMINATED GLASS

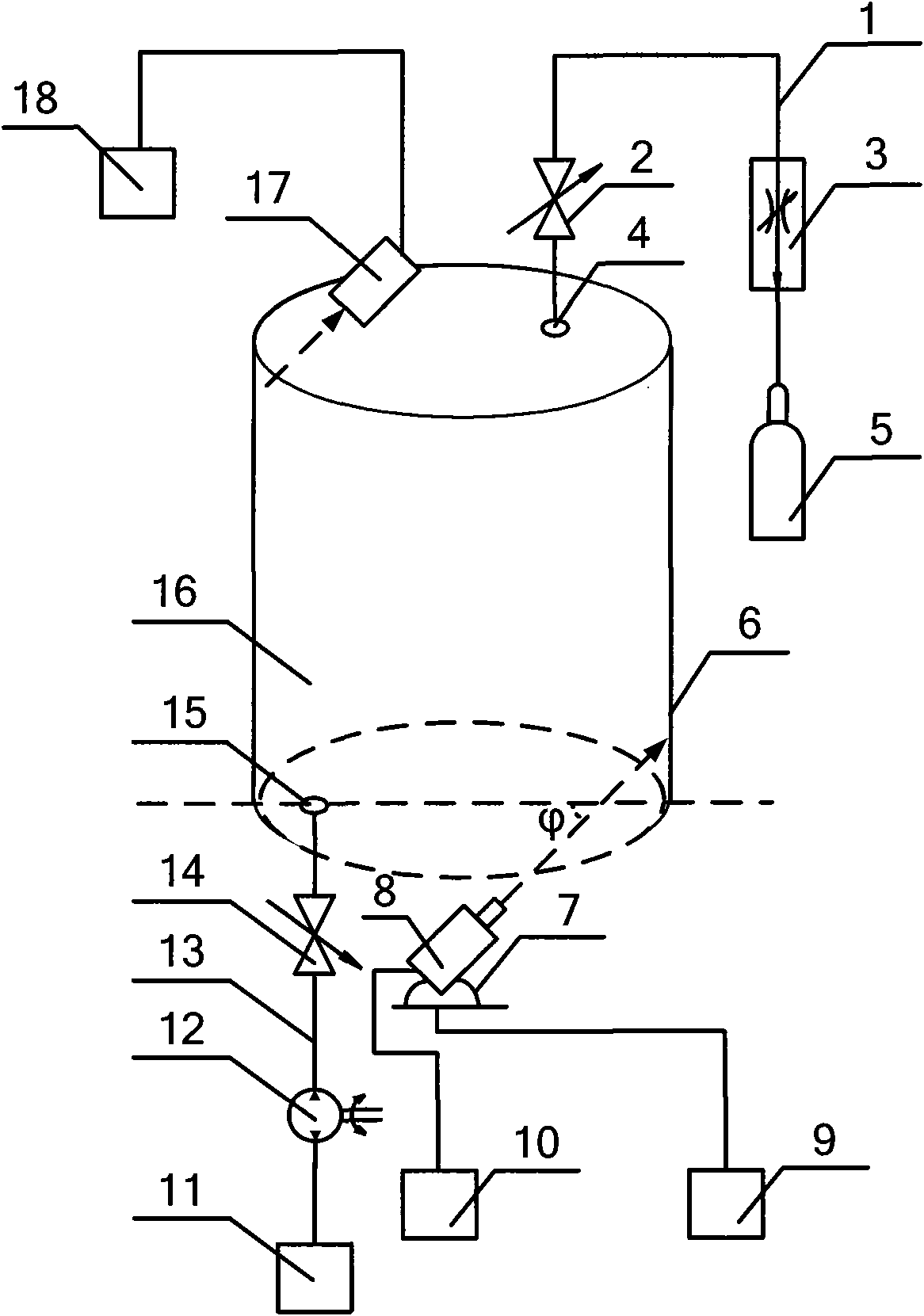

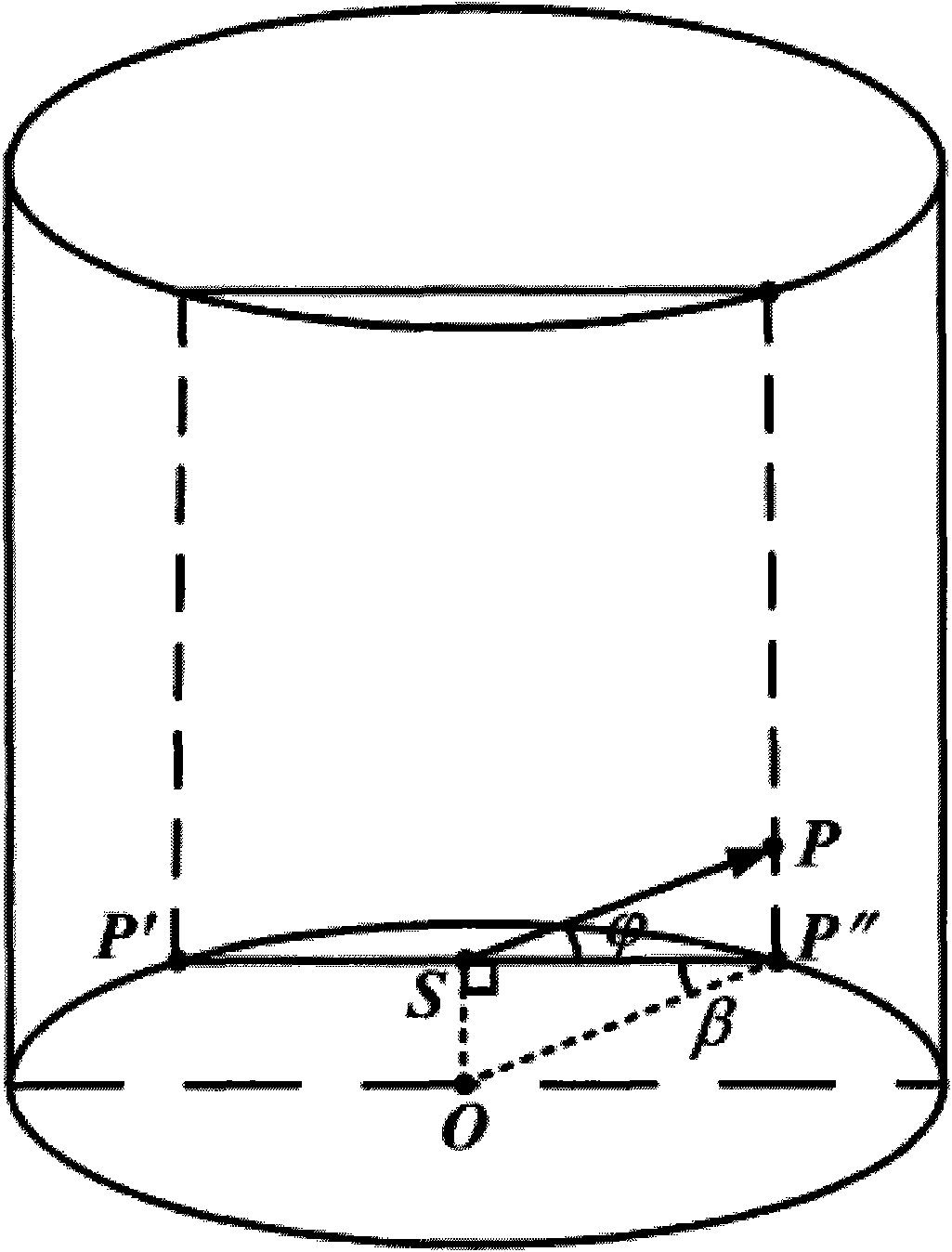

Device for measuring gas concentration

InactiveCN101625306AEasy to processSimple structureColor/spectral properties measurementsInlet valveProduct gas

The invention relates to a device for measuring gas concentration. The prior art has the defects of longer length or high processing precision requirement of a gas chamber, high manufacture cost and hardly controlled optical length. The device for measuring gas concentration comprises a gas chamber, a laser, a detector, a waste gas processor, a signal processor and a flowmeter, wherein a total-reflection film is coated on the inner side wall of the cylindrical glass gas chamber; a top cover of the gas chamber is provided with a gas inlet which is hermetically connected with a gas inlet pipe; the gas inlet pipe is sequentially provided with a gas inlet valve and the flowmeter; a bottom cover of the gas chamber is provided with a gas outlet which is hermetically connected with a gas output pipe; the gas output pipe is sequentially provided with a gas outlet valve and a vacuum pump; the detector is arranged above the top cover corresponding to a laser-emitting hole of the top cover; and the signal outlet end of the detector is in signal connection with the signal input end of the signal processor. The device has the advantages of simple processing, low cost and high signal-to-noise ratio and detection sensitivity.

Owner:ZHEJIANG UNIV

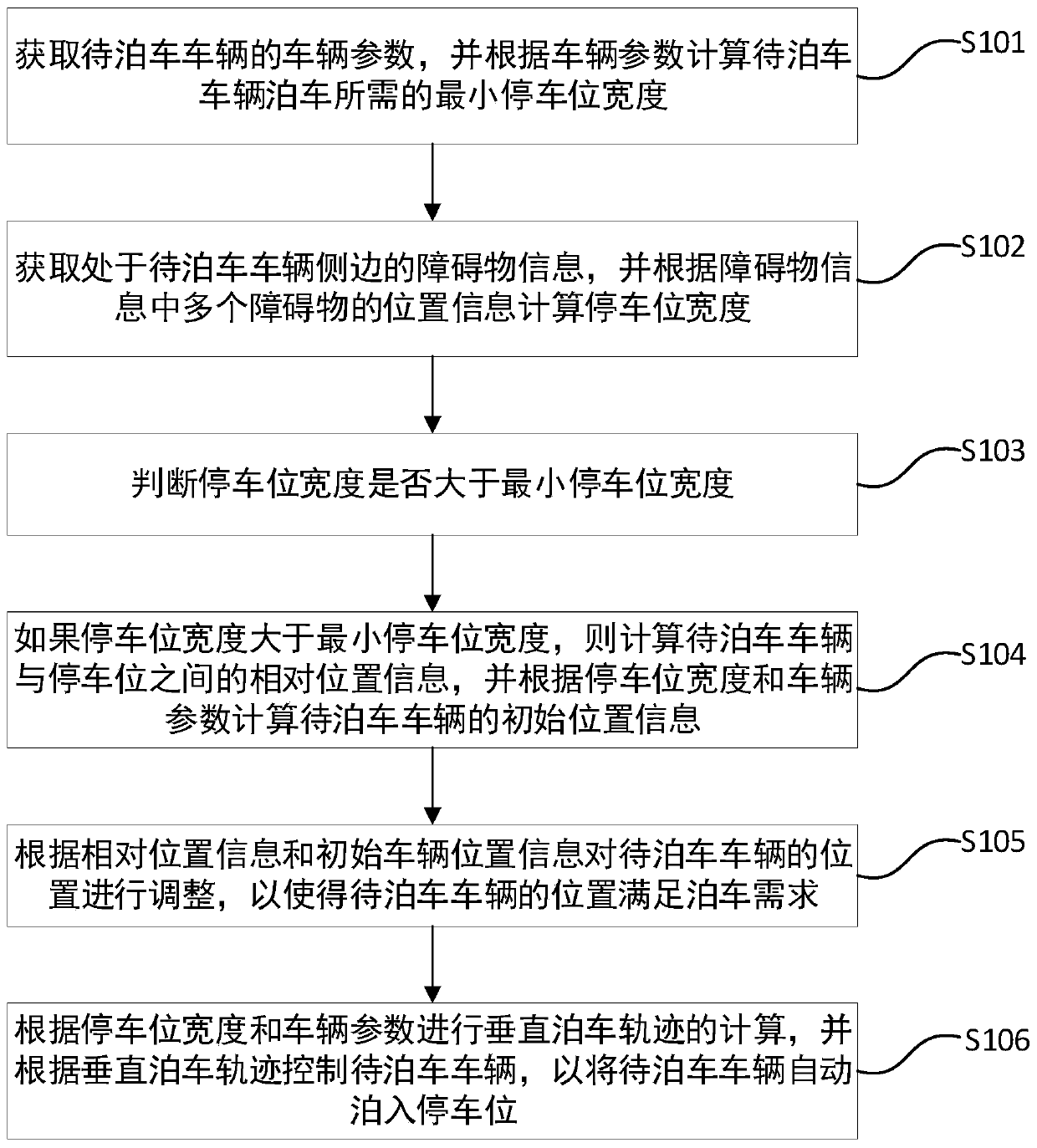

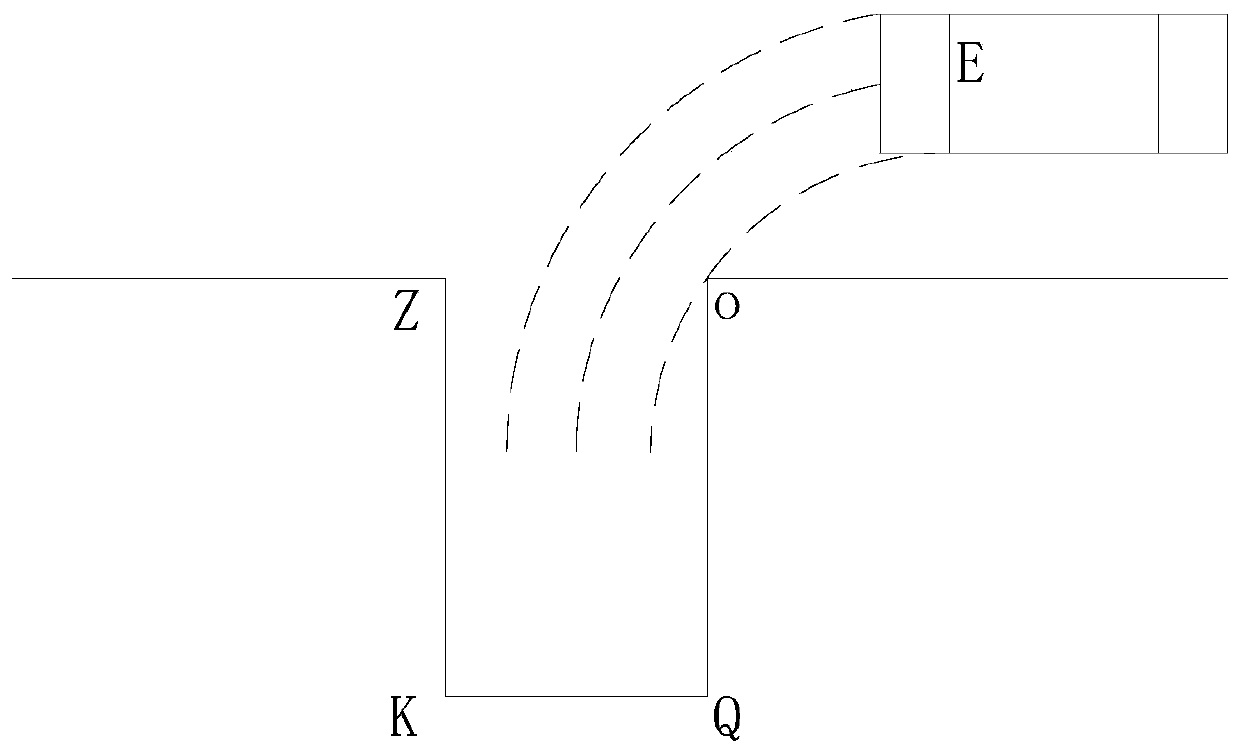

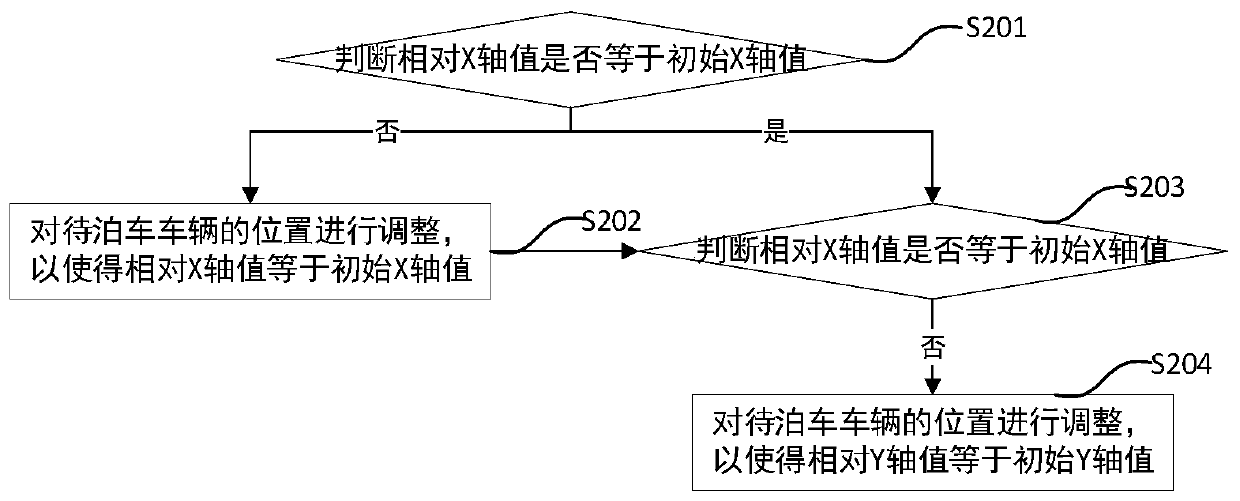

Automatic vertical parking method and device, medium and equipment

The invention discloses an automatic vertical parking method and device, a medium and equipment. The automatic vertical parking method comprises the steps that vehicle parameters of a to-be-parked vehicle are obtained, and the minimum parking space width is calculated; the parking space width is calculated according to position information of a plurality of obstacles in obstacle information; weather the parking space width is larger than the minimum parking space width or not is judged; if yes, relative position information between the to-be-parked vehicle and the parking space is calculated,and initial position information of the to-be-parked vehicle is calculated according to the parking space width and the vehicle parameters; the position of the to-be-parked vehicle is adjusted to meetthe parking requirements; a vertical parking track is calculated according to the parking space width and the vehicle parameters, and the to-be-parked vehicle is controlled according to the verticalparking track to park the to-be-parked vehicle in the parking space automatically; the requirements for the parking space size are effectively lowered, the automatic vertical parking process is adjusted according to the specific vehicle parameters and the parking space size, and the applicability of the automatic vertical parking method is greatly improved.

Owner:厦门金龙汽车新能源科技有限公司

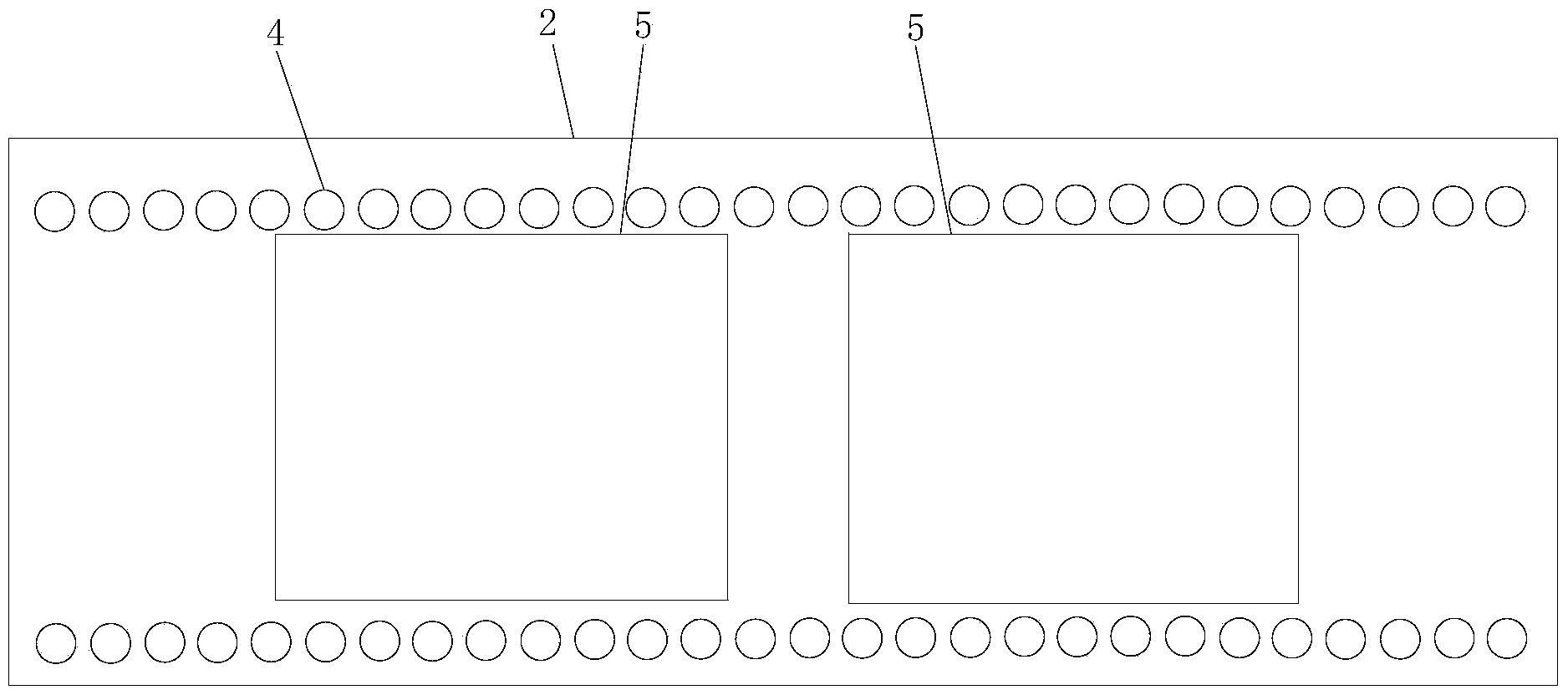

Substrate integrated waveguide ferrite switch

ActiveCN103594761AReduce width requirementsImprove toleranceWaveguide type devicesBroadbandWaveguide

The invention discloses a substrate integrated waveguide ferrite switch which is good in allowance, wide in broadband and relatively high in isolation. The substrate integrated waveguide ferrite switch comprises a medium substrate, wherein the upper surface of the medium substrate is provided with a first metal copper-coated layer, the lower surface of the medium substrate is provided with a second metal copper-coated layer, the medium substrate is provided with two rows of metallization through holes which are parallel to each other, the first metal copper-coated layer is provided with at least one first ferrite installation hole, a ferrite block is arranged in the first ferrite installation hole, and the upper surface and the side surface of the ferrite block are respectively coated with a metal coating. External loading is adopted to replace traditional internal inserting, processing is easier, the requirement for the width of the ferrite block is low, and allowance is good. Meanwhile, the contact area between the ferrite block and the outside is relatively large, and heat dissipation ability is high. Under the same length, the broadband width of the substrate integrated waveguide ferrite switch is greatly larger than that of an existing switch, the isolation is higher, and the substrate integrated waveguide ferrite switch is suitable for being popularized and applied in the technical field of ferrite switches.

Owner:成都宁锦威通信技术有限公司

Bag folding machine and bag folding method

ActiveCN107672869AGood connection suitabilityIncrease the number of channelsFolding thin materialsPackagingStructural engineeringMechanical engineering

The invention discloses a bag folding machine and a bag folding method. A left folding mechanism and a right folding mechanism of the bag folding machine repeatedly use a feeding mechanism and a discharging mechanism, so that the occupied space of the bag folding machine is not multiplied while the number of passes of the folding mechanisms is increased and the production efficiency is improved. In the bag folding process, when one folding mechanism is folding a bag while the other folding mechanism has already folded a bag and is idle, a bag on the feeding mechanism can be conveyed to the idle folding mechanism through a bag distribution mechanism, and the cycle is repeated. According to the scheme, when the feeding mechanism feeds materials to the folding mechanisms, the feeding mechanism needs to wait until the folding mechanisms fold the bags well, and the production efficiency is improved.

Owner:ZHONGSHAN TAILI HOUSEHOLD PROD MFG

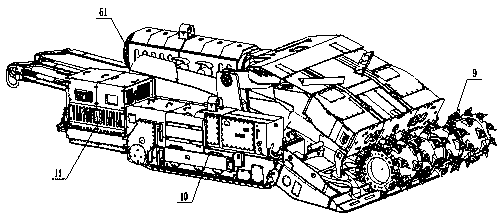

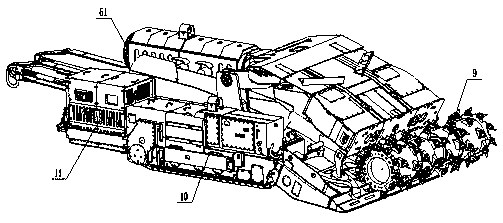

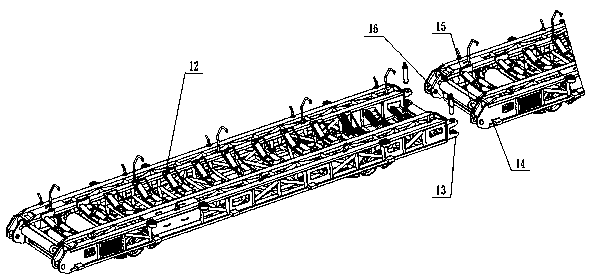

Two-crawler material paving machine

InactiveCN101880999AReduce width requirementsSolve the problem of not being able to conveniently transition by yourselfRoads maintainenceEndless track vehiclesEngineeringIndependent walking

The invention relates to a two-crawler material paving machine capable of realizing self-site transfer, which comprises a main frame, wherein two walking crawlers are respectively arranged on two sides of the main frame, and a material distributing device and a paving device are arranged below the main frame; the walking crawlers are mounted below a side beam of the main frame through one or two mounting seats which can rotate in the horizontal plane, the walking crawlers can rotate around the mounting seats which are used as fixed shafts, and the mounting seats are connected with mounting parts of the walking crawlers through connecting parts; and at least one walking crawler is mounted below the side beam of the main frame through the two mounting seats, at least one walking crawler can rotate around one of the mounting seat which is used as the fixed shaft, when the walking crawlers rotate around the fixed shafts, an independent walking device is detachably mounted on the other mounting seat, and the independent walking device is connected with the other mounting seat through the connecting part; and steering mechanisms are arranged between the walking crawlers and the main frame. The two-crawler material paving machine can solve the problems that the existing large two-crawler material paving machine only adopts a large transport vehicle for transmission and can not carry out the site transfer conveniently.

Owner:SHAANXI CHANGDA INDAL

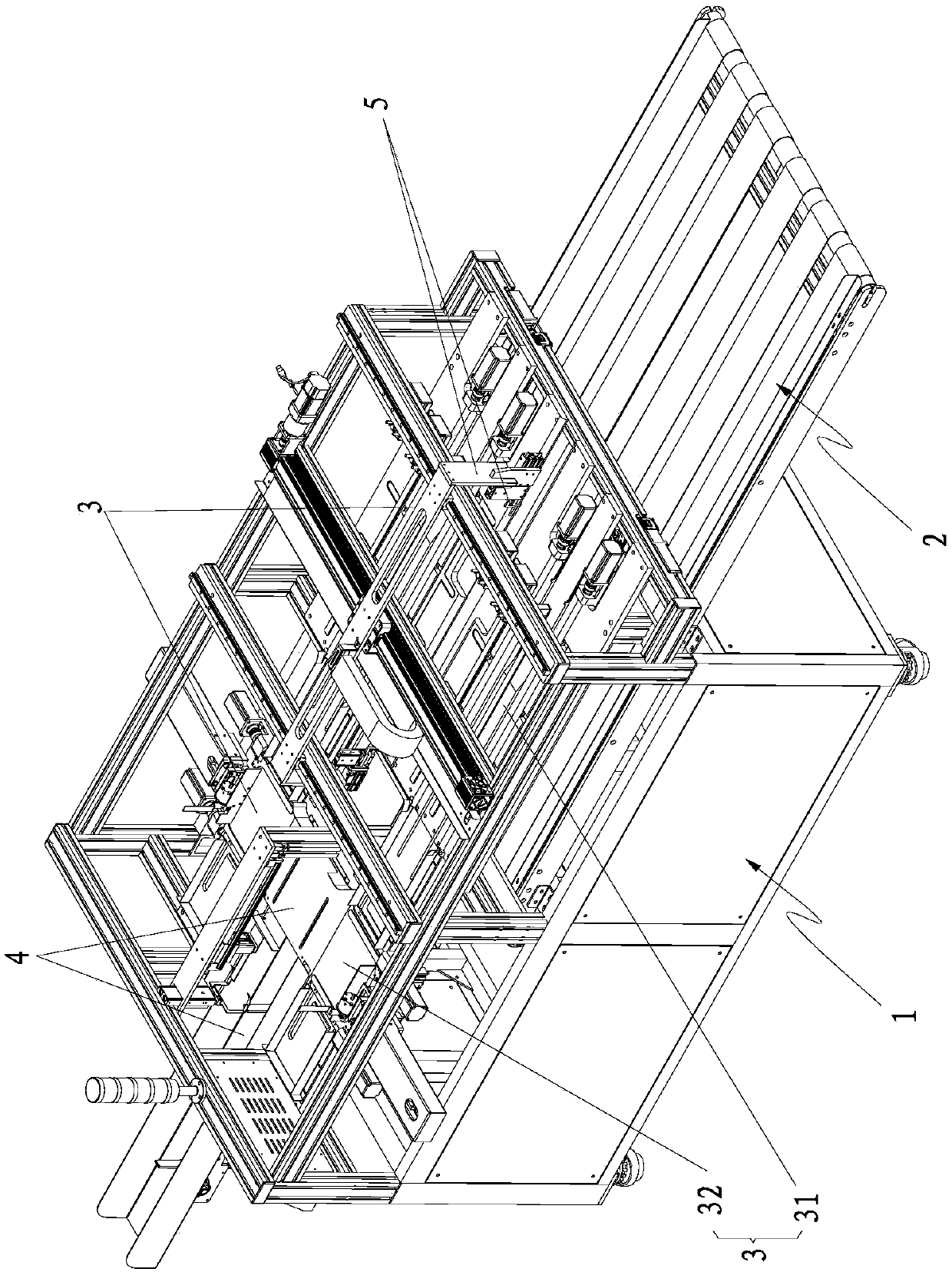

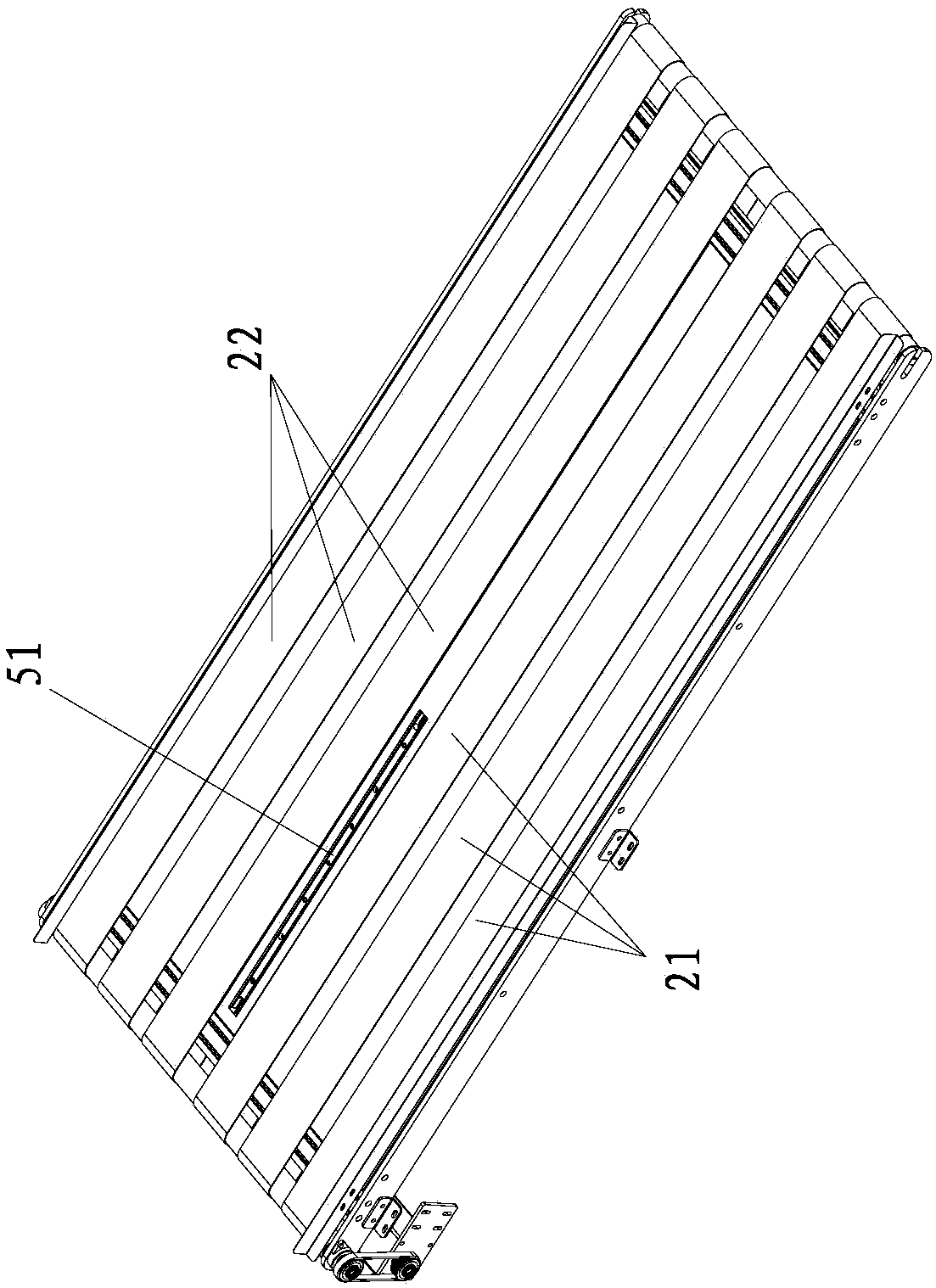

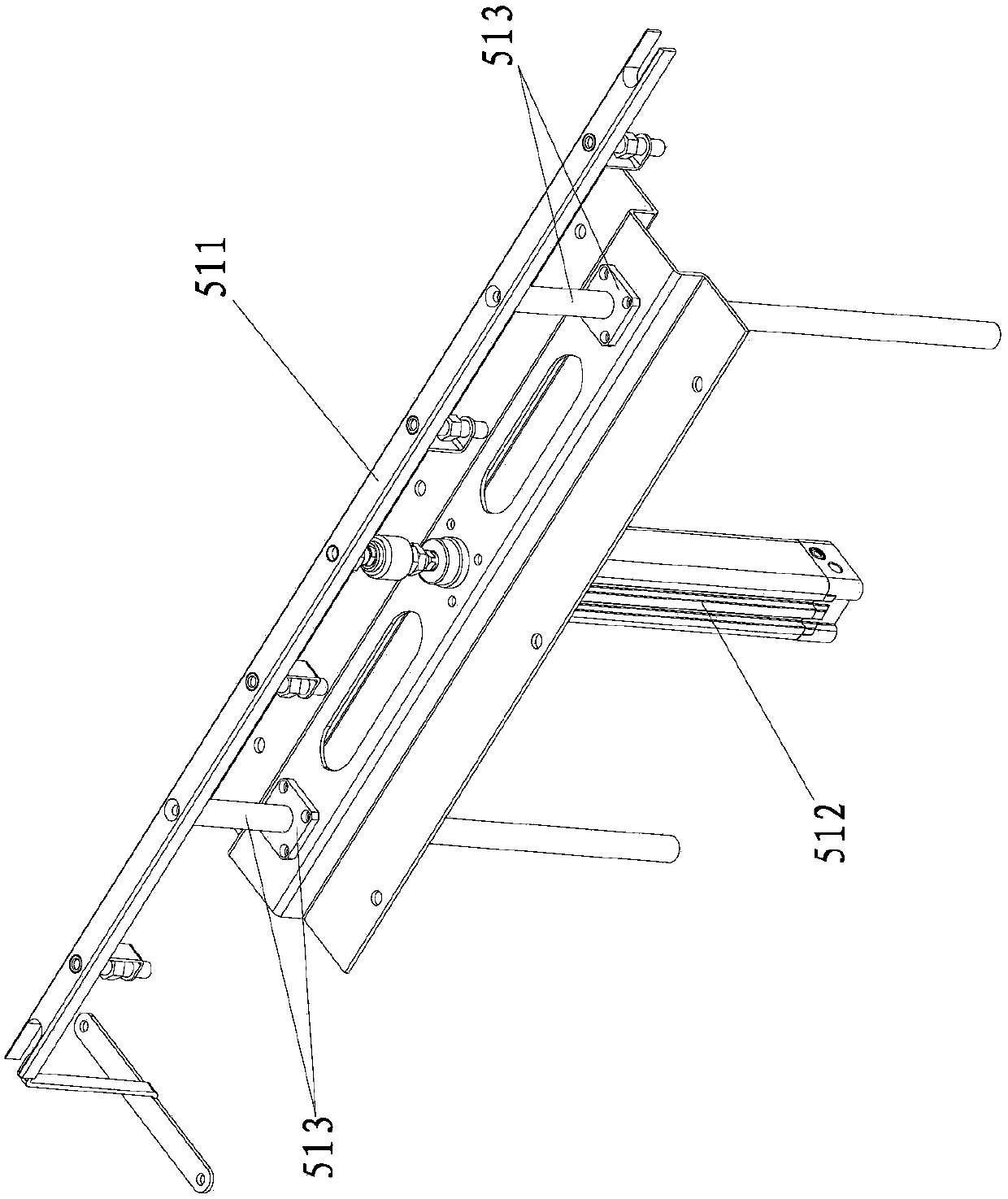

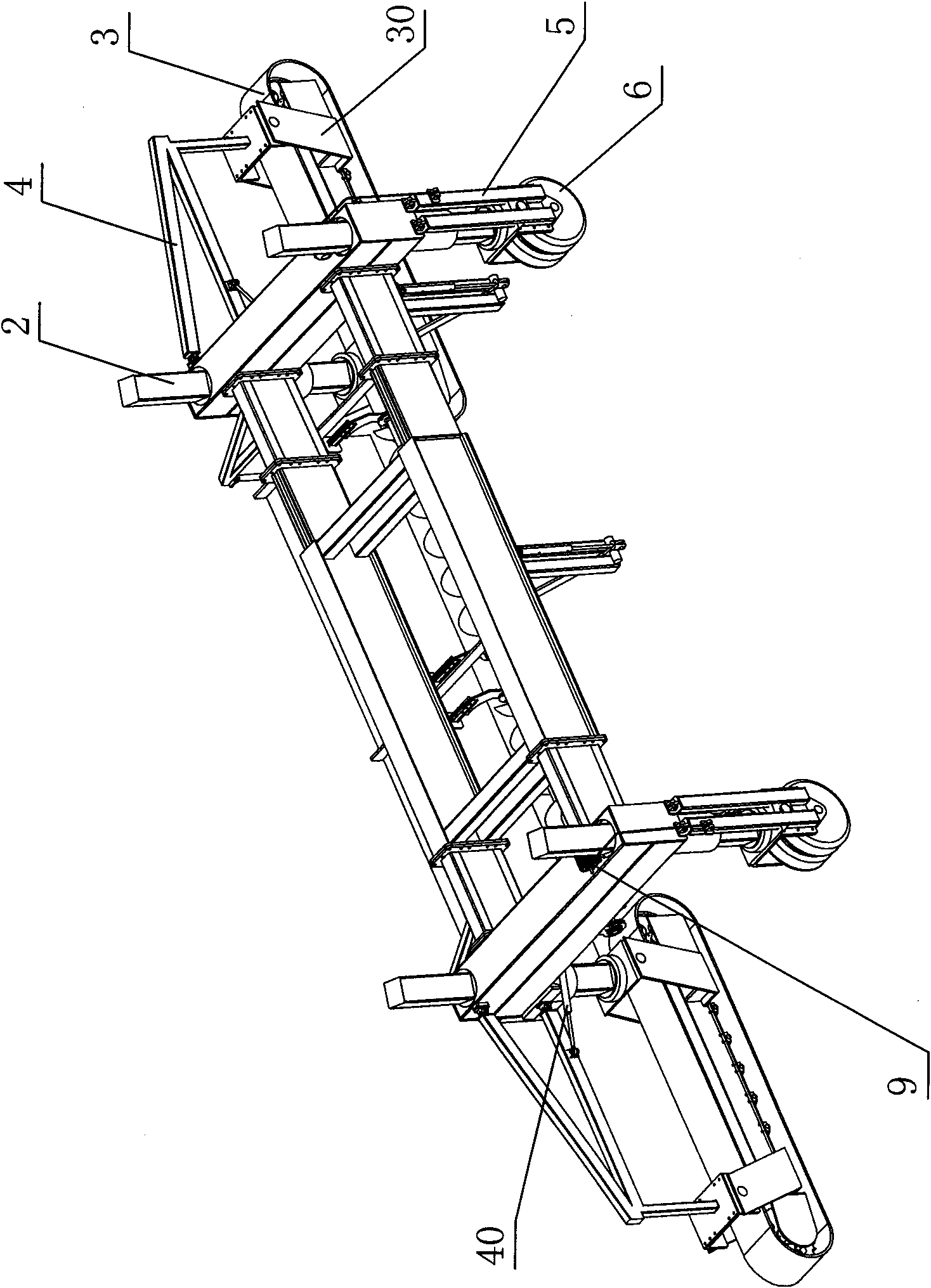

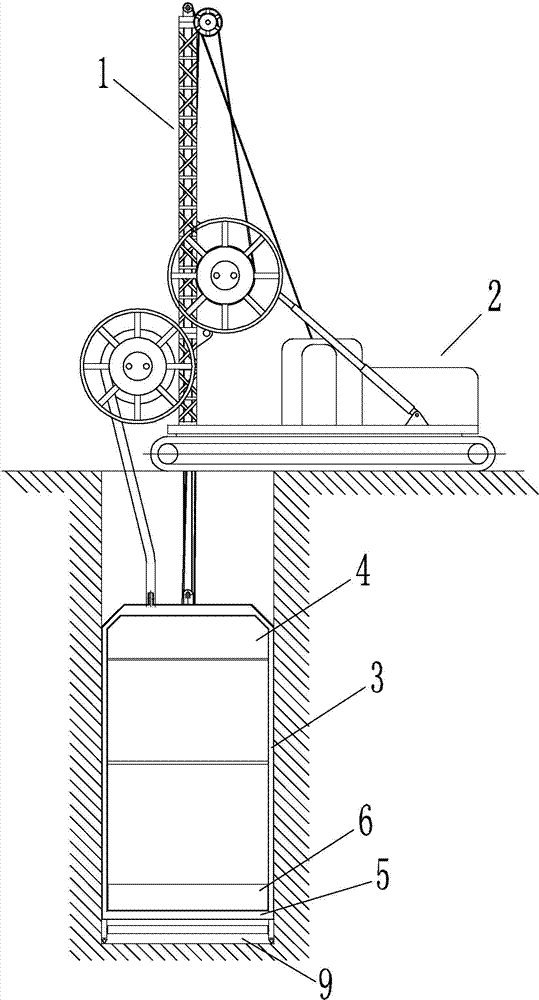

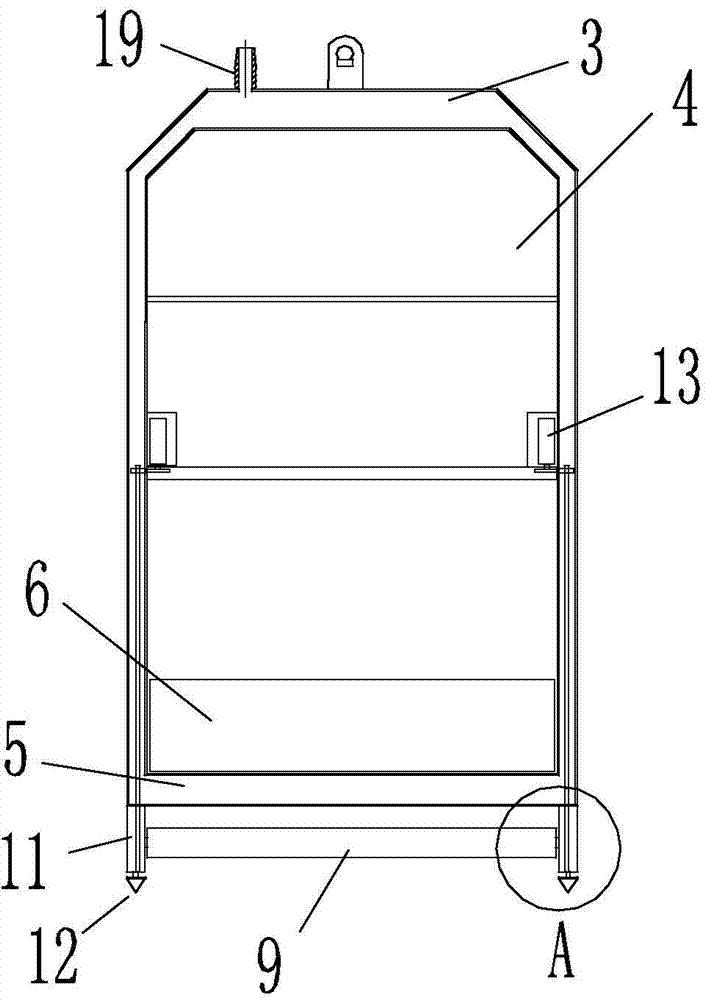

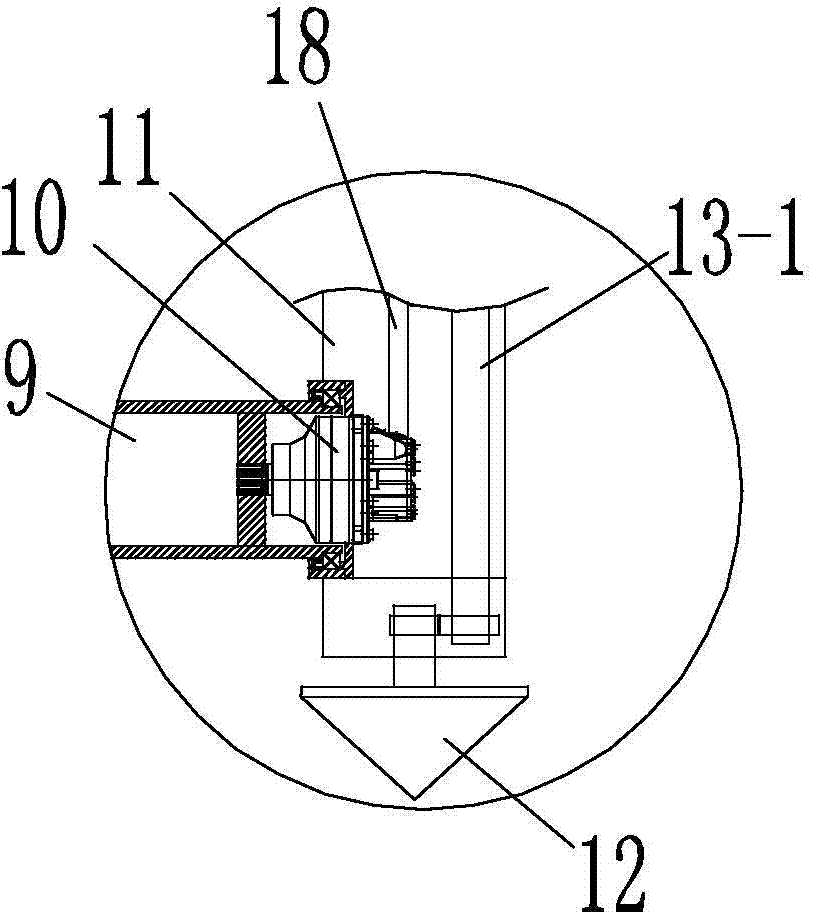

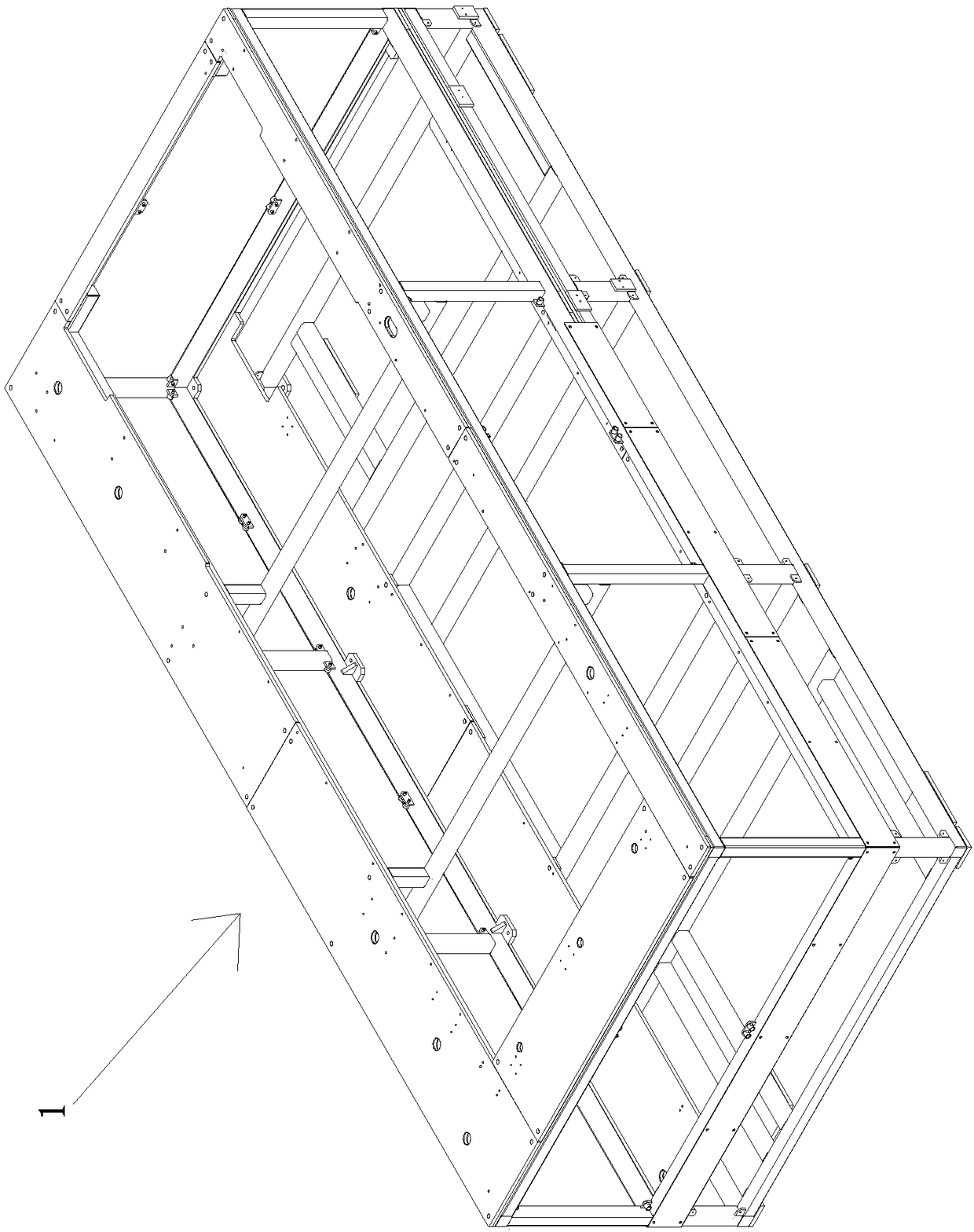

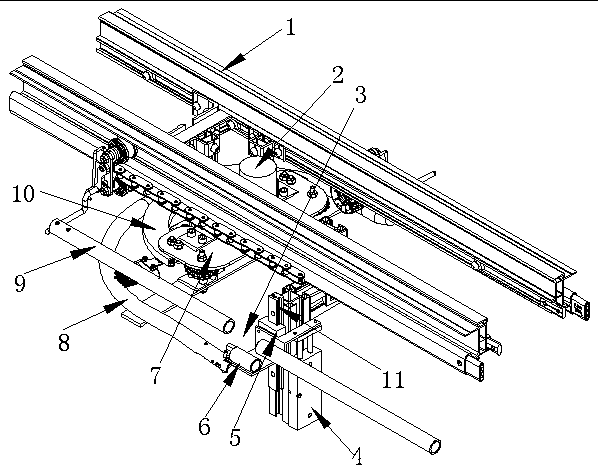

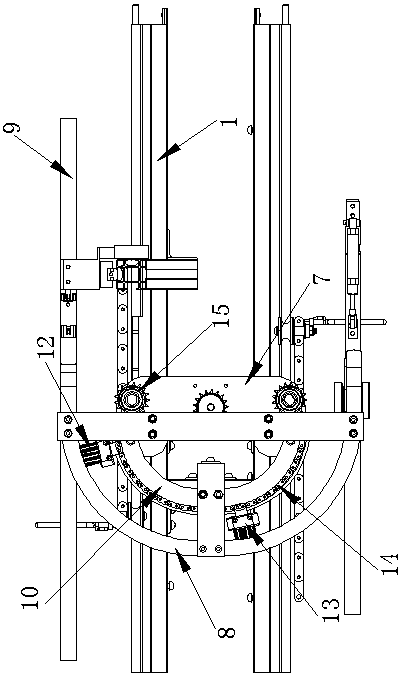

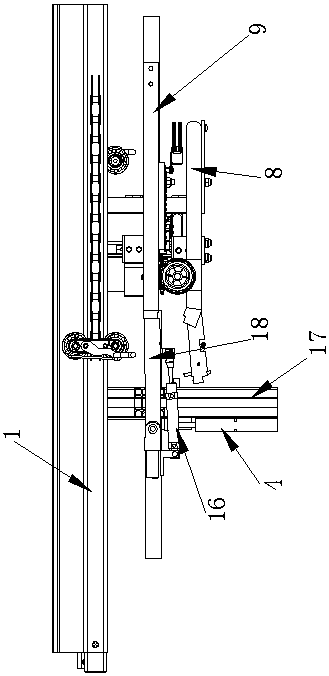

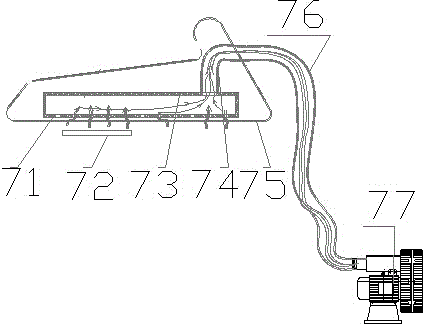

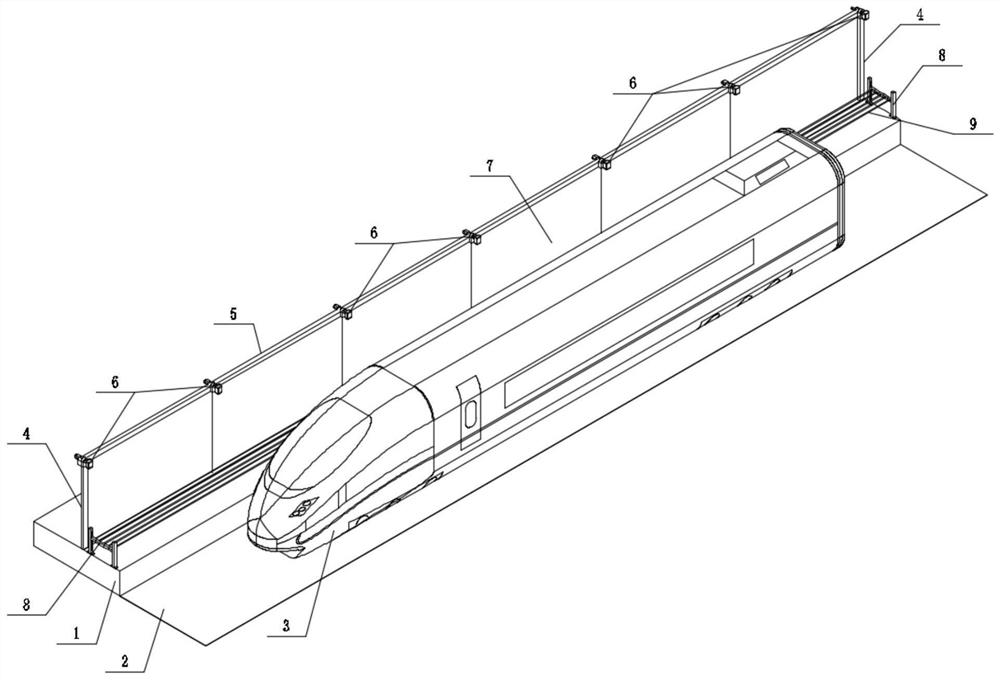

Stepping type walking platform

ActiveCN110056356ASafe and efficient green miningReduce width requirementsOpen-pit miningAgricultural engineeringCoal

The invention relates to the technical field of strip mine slope mining, in particular to a stepping type walking platform. The safe and efficient green mining of remanent coal in a strip mine slope is achieved, the demands of strip mine slope mining are met, and the recovery rate of slope remanent coal is effectively improved. The stepping type walking platform is located outside a mining cavern,and includes an upper platform, a lower chassis and a moving mechanism; and the upper platform and the lower chassis are integrally connected through the moving mechanism, the upper platform is provided with an electrical system, a hydraulic system and a cable rolling roller, and a working platform is arranged on the upper part of the lower chassis. The stepping type walking platform can realizethe safe and efficient green mining of slope remanent coal resources, significantly improve the technical strength of the strip mine slope mining in China, and bring significant economic and social benefits to enterprises.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Milling vibration smashing type engineering grooving machine

ActiveCN104763010AEasy to moveFlexibleSoil-shifting machines/dredgersDrilling drivesEngineeringDrill bit

The invention relates to a milling vibration smashing type engineering grooving machine. The milling vibration smashing type engineering grooving machine comprises winch equipment, a power system, a walking device and a monitoring device. A vibration smashing milling device is suspended to the traction end of the winch equipment and comprises a longitudinal guiding frame, a rudder plate deviation correction device, a milling shaft with a milling cutter, and a vibration punch hammer. The axis of the milling shaft is located inside the plane where the guiding frame is located and the milling shaft is horizontally arranged and driven by a hydraulic motor. The milling shaft has the rotating milling state, and the external contour of the milling shaft eccentrically rotates when the milling shaft is in the rotating milling state. The hydraulic motor has the driving state and covers the rotating direction according to the preset period when in the driving state. The guiding frame is provided with a hydraulic oil pipeline communicated with the hydraulic motor. The suspension type frame is adopted for omitting a stroke drill rod, the milling shaft is adopted for replacing the multi-drill-bit structure, meanwhile, a reversing device is omitted or the size of the reversing device is decreased so that the size of a grooving machine tunneling device can be decreased, the grooving machine can cut narrow and deep grooves in various rock stratums, and the rudder plate deviation correction device is adopted for ensuring the grooving perpendicularity.

Owner:项栋才

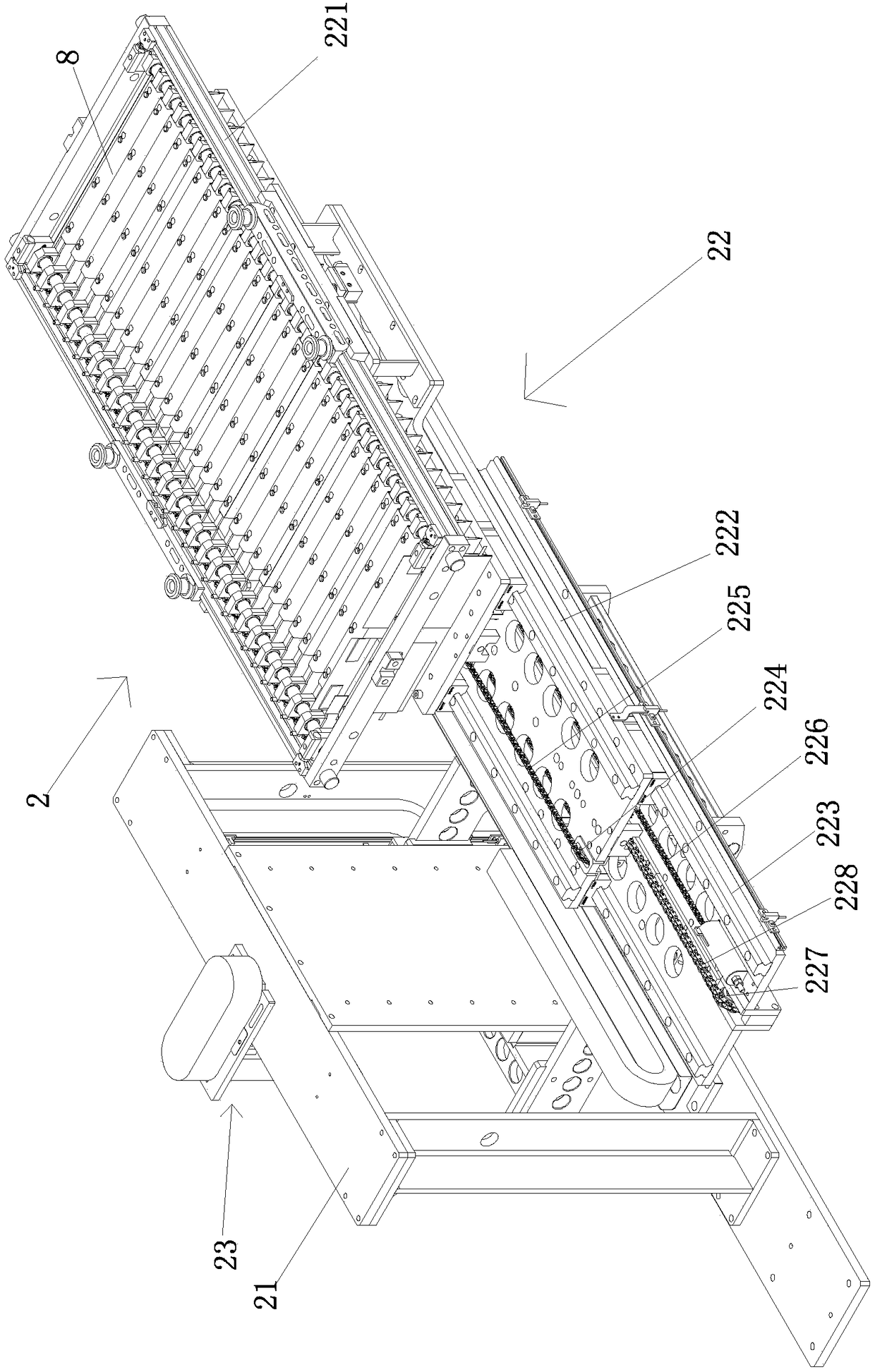

Lithium battery tool transfer machine

PendingCN108082883ALow production costLow costFinal product manufactureSupporting framesEngineeringCantilever

The invention discloses a lithium battery tool transfer machine. The lithium battery tool transfer machine comprises a frame-shaped rack provided with an upper layer and a lower layer, a tool telescopic mechanism arranged in the left end of the lower layer of the rack, a lower-layer conveying mechanism arranged on the lower layer of the rack in a left-right extending mode, a jacking mechanism arranged in the right end of the rack and used for conveying tools conveyed from the lower-layer conveying mechanism to the upper layer of the rack, an opening and closing conveying mechanism arranged atthe right end of the upper end of the rack and used for receiving the tools conveyed up from the jacking mechanism, an upper-layer conveying mechanism located on the left side of the opening and closing conveying mechanism and connected to the upper layer of the rack and a tool positioning mechanism arranged on the left side of the upper end of the rack and used for positioning the tools. The tooltelescopic mechanism comprises a cantilever structure. The cantilever structure comprises an upper cantilever, a middle cantilever and a lower cantilever which can stretch out and retract. The threecantilevers are overlapped up and down. When the cantilever structure stretches out, the upper cantilever stretches out of one side of the lower layer of the rack, so that operation is safe.

Owner:深圳市精实机电科技有限公司

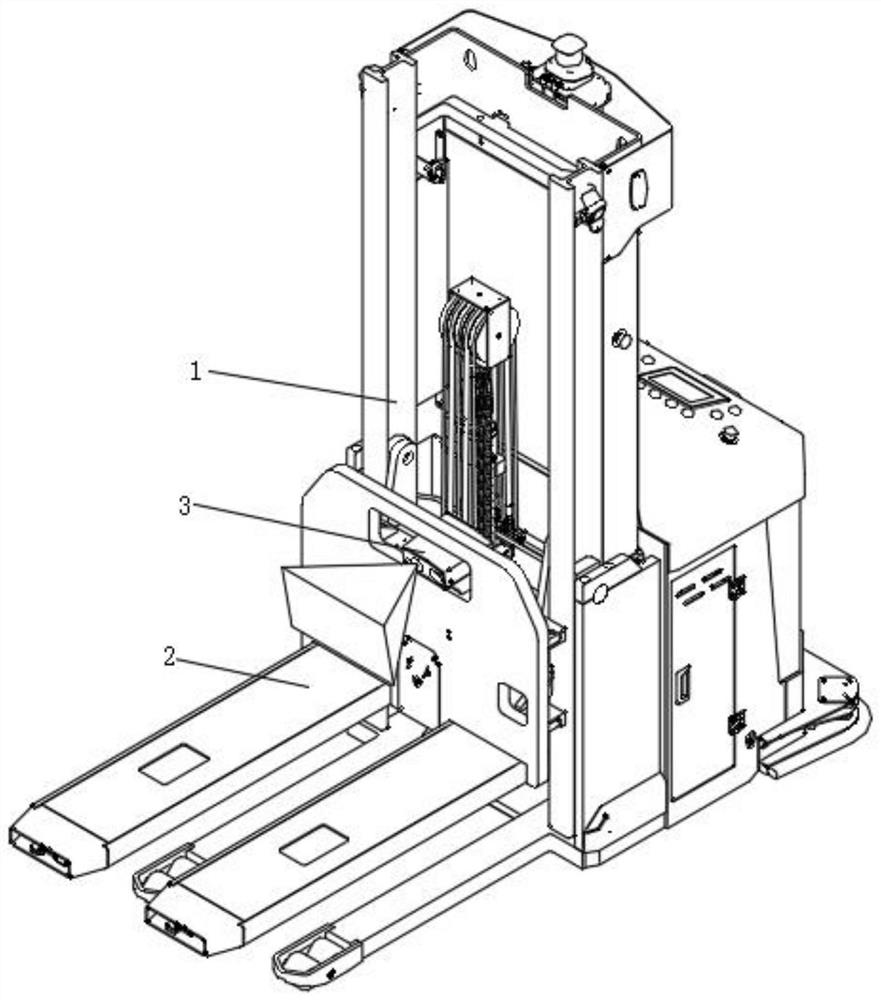

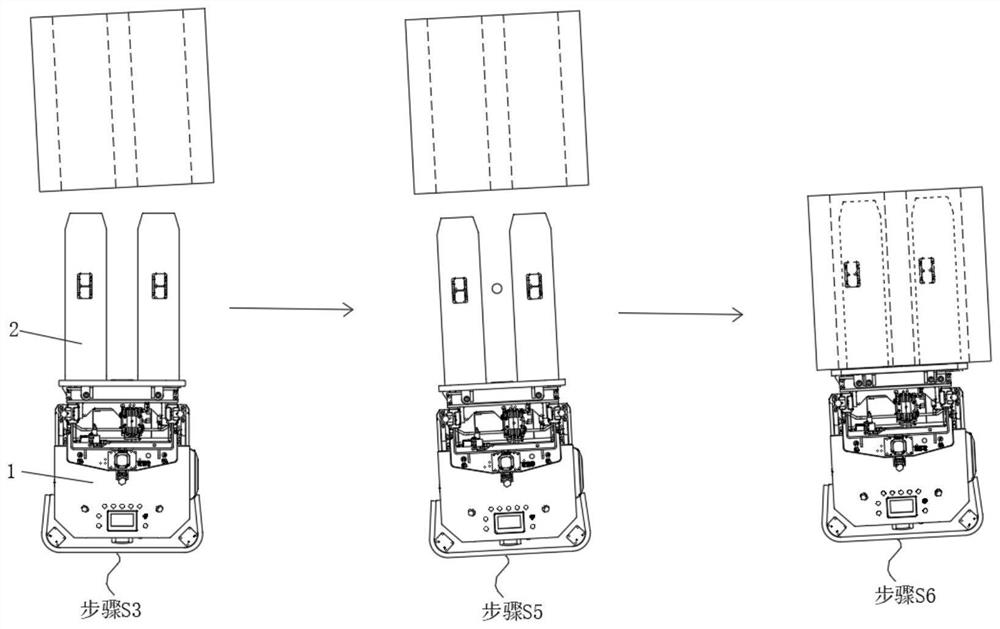

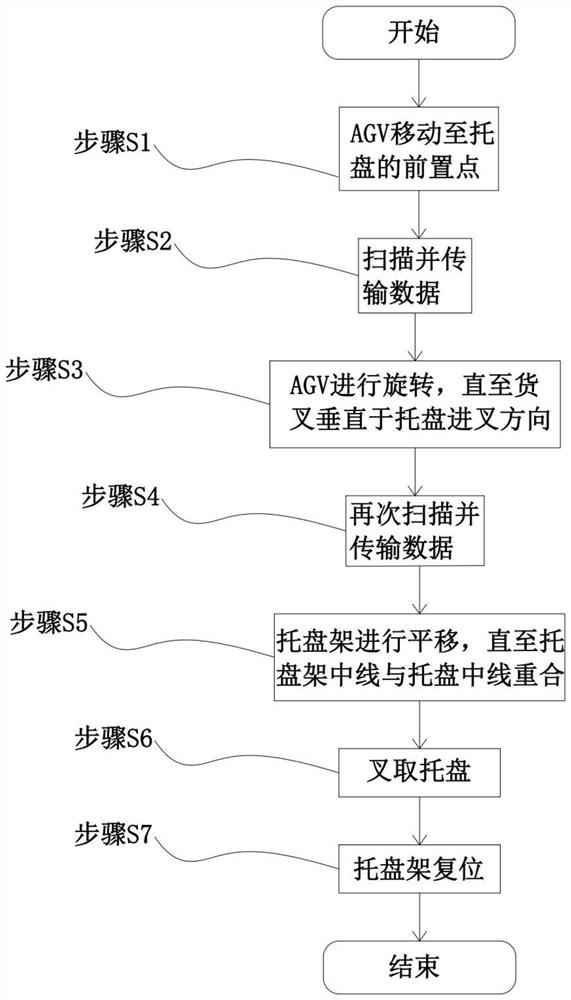

AGV attitude adjusting method applied to tray identification/positioning

PendingCN113998626AGuaranteed accuracyReduce cost and difficulty of software developmentLifting devicesUsing optical meansAngular deviationPallet fork

The invention discloses an AGV attitude adjusting method applied to tray identification / positioning. The method comprises the following steps: S1, moving an AGV to a front point of a tray; S2, scanning the position and posture of the tray through a 3D visual sensor, and transmitting data to a controller; S3, enabling the controller to receive the data, control the AGV body to rotate in situ according to the angular deviation data of the tray and adjust the direction of the AGV body until the pallet fork is perpendicular to the fork entering direction of the tray; and S4, after the state of the AGV body is adjusted to make the fork entering direction completely perpendicular to the fork entering face of the tray with the center line of the AGV does not coinciding with the center line of the tray at the moment, enabling the 3D vision sensor to scan again and transmit data to the controller. According to the invention, the combined use of 3D visual data and a navigation algorithm is not needed any more, and the method only needs to rotate in situ and move the tray rack on the AGV, so that the requirement on the width of a roadway is low, and the method can be suitable for various working occasions.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD +1

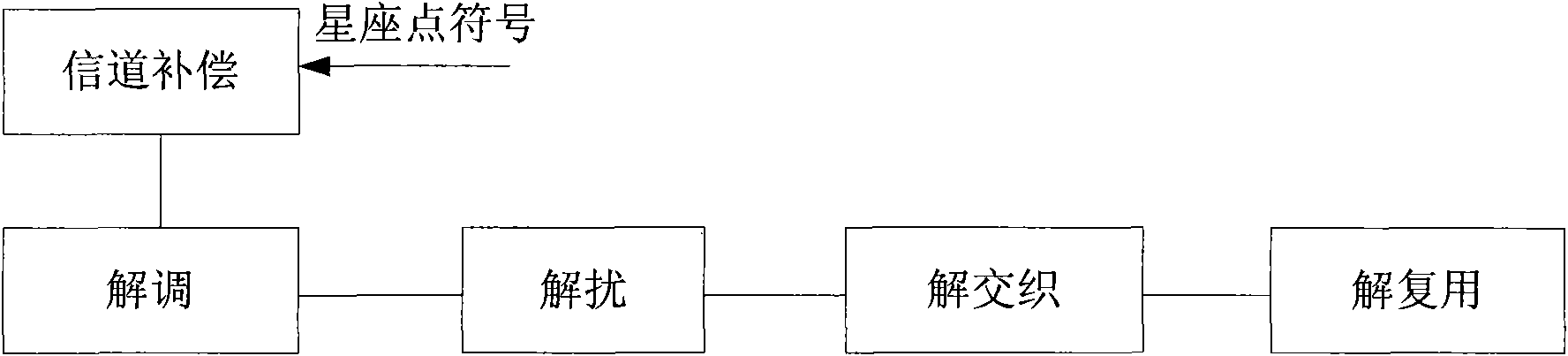

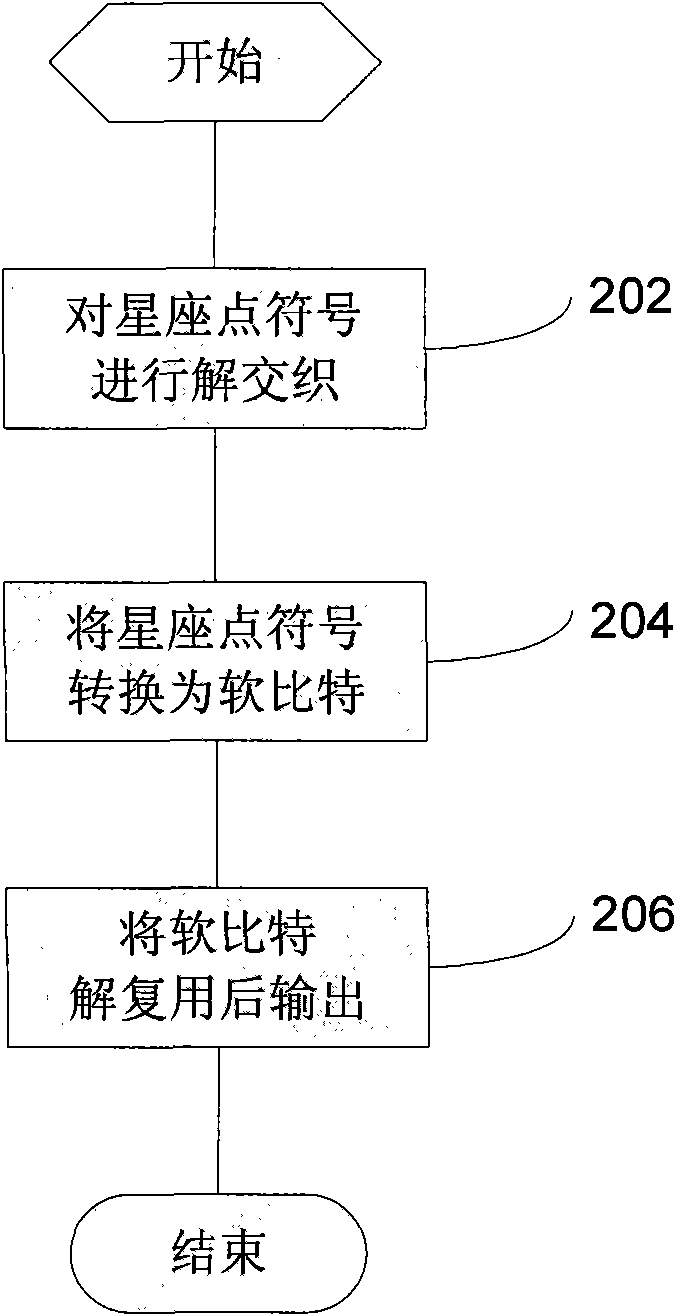

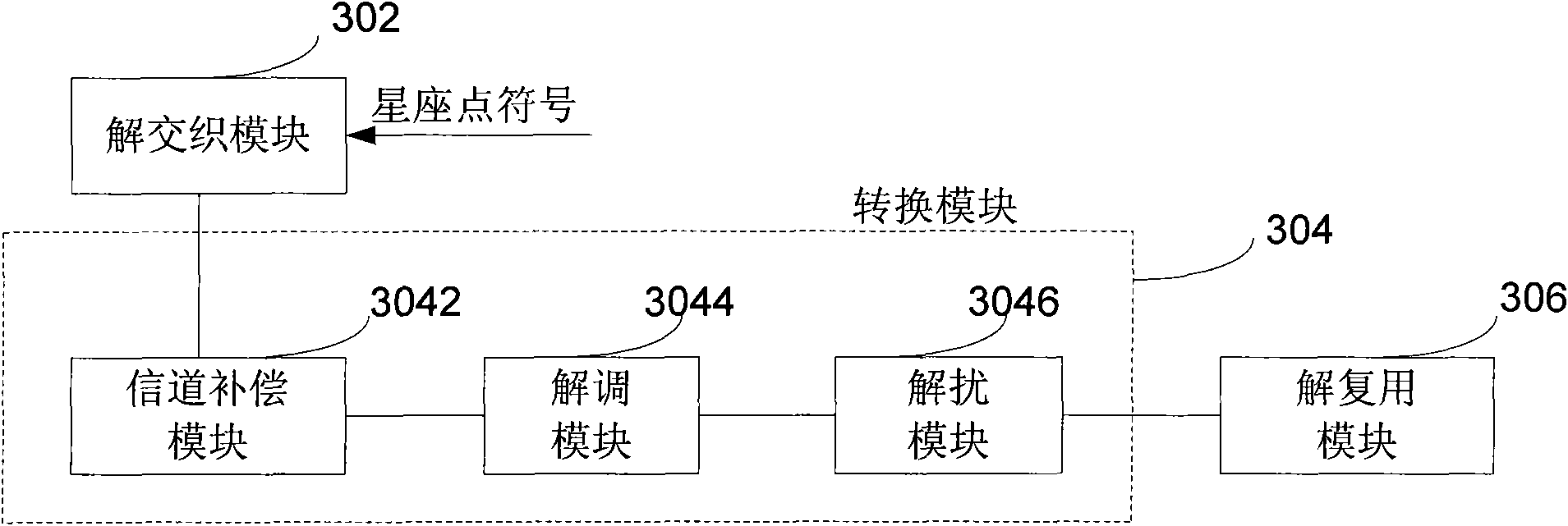

Method and device for processing uplink data and base station

InactiveCN101777962AReduce width requirementsReduce the number of bitsError preventionMultiple carrier systemsMultiplexingComputer science

The embodiment of the invention provides an uplink data processing device, which comprises a de-interleaving module, a conversion module and a de-multiplexing module, wherein the de-interleaving module is used for de-interleaving received uplink constellation-point symbols; the conversion module is used for converting the de-interlaced constellation-point symbols into soft bits; and the de-multiplexing module is used for de-multiplexing the soft bits and outputting the soft bits. The device provided by the embodiment of the invention can save storage space in the de-interleaving module. Besides, the embodiment of the invention also provides an uplink data processing method.

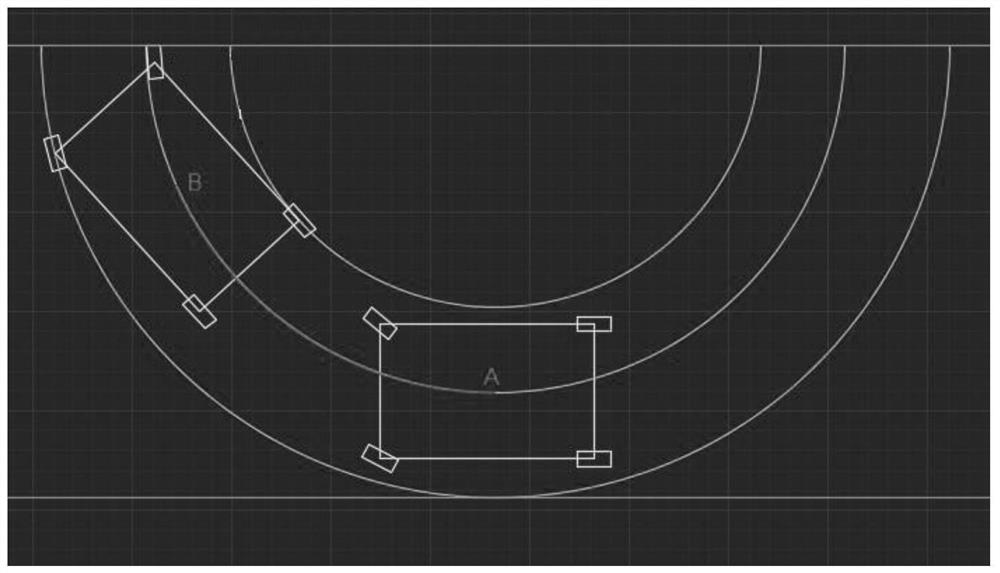

Quick conveying device for clothes hanger of garment hanging system

The invention discloses a quick conveying device for a clothes hanger of a garment hanging system and solves the problem that a quick rotating rail device in an existing garment hanging system is relatively complicated in structure and is inconvenient to arrange. The quick conveying device for the clothes hanger of the garment hanging system is used for conveying the clothes hanger between two opposite sides of a circular track; one side of the circular track is provided with an opening; the other side of the circular track is provided with an isolating opening; the quick conveying device is characterized in that the lower side of the circular track is provided with a curved track; a driving mechanism is arranged in a manner of adapting to the movement direction of the curved track; the driving mechanism is provided with a plurality of driving parts; the driving parts are used for driving the clothes hanger on the curved track from an inlet end to an outlet end under the driving of thedriving mechanism; a descending mechanism is arranged between the inlet end of the curved track and the opening; the descending mechanism is used for moving the clothes hanger on the circular track downwards to the inlet end of the curved track; a lifting mechanism is arranged between the outlet end of the curved track and the isolating opening; and the lifting mechanism is used for lifting the clothes hanger on the curved track from the outlet end of the curved track to the circular track.

Owner:INA INTELLIGENT TECH (ZHEJIANG) CO LTD

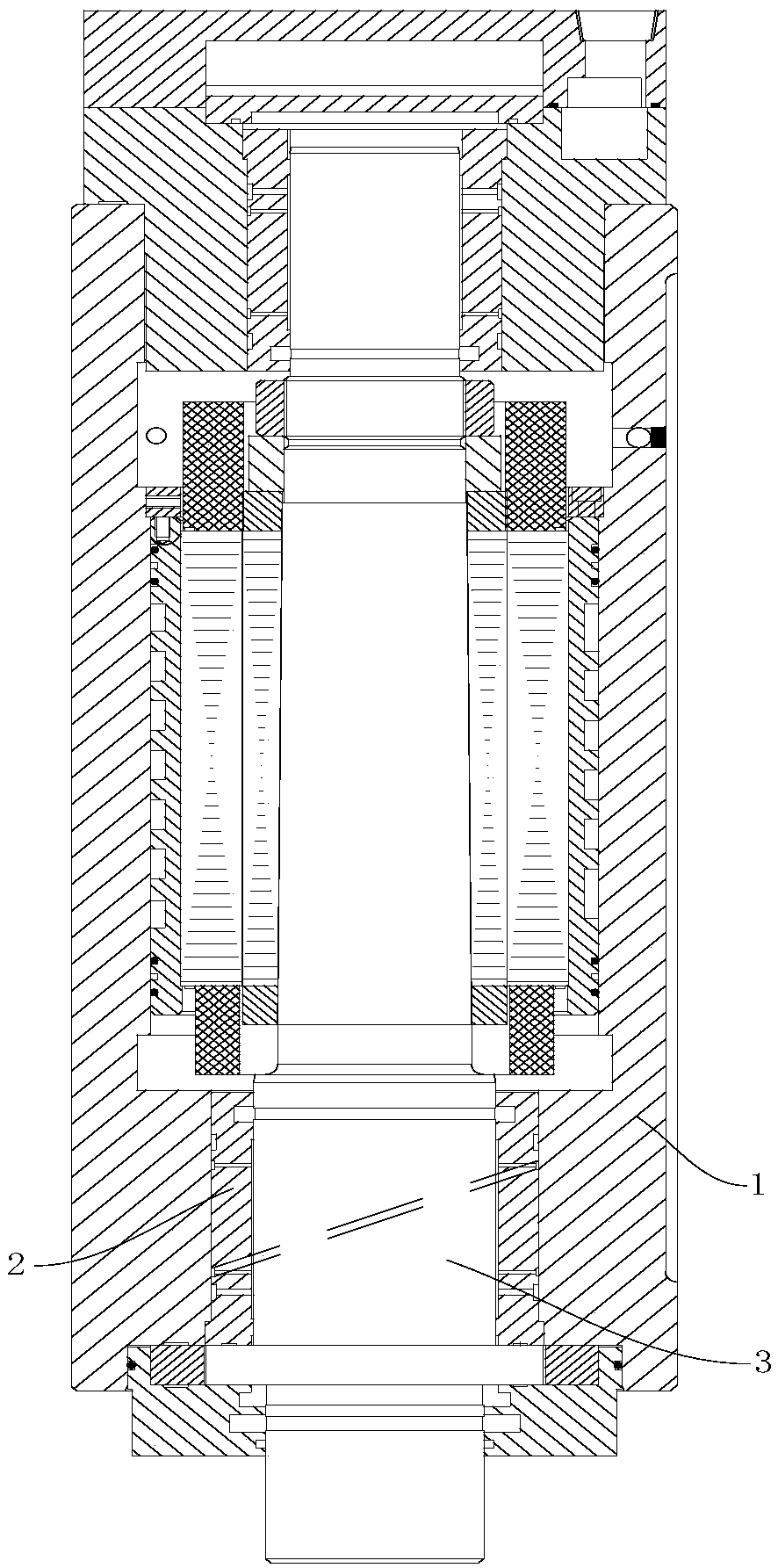

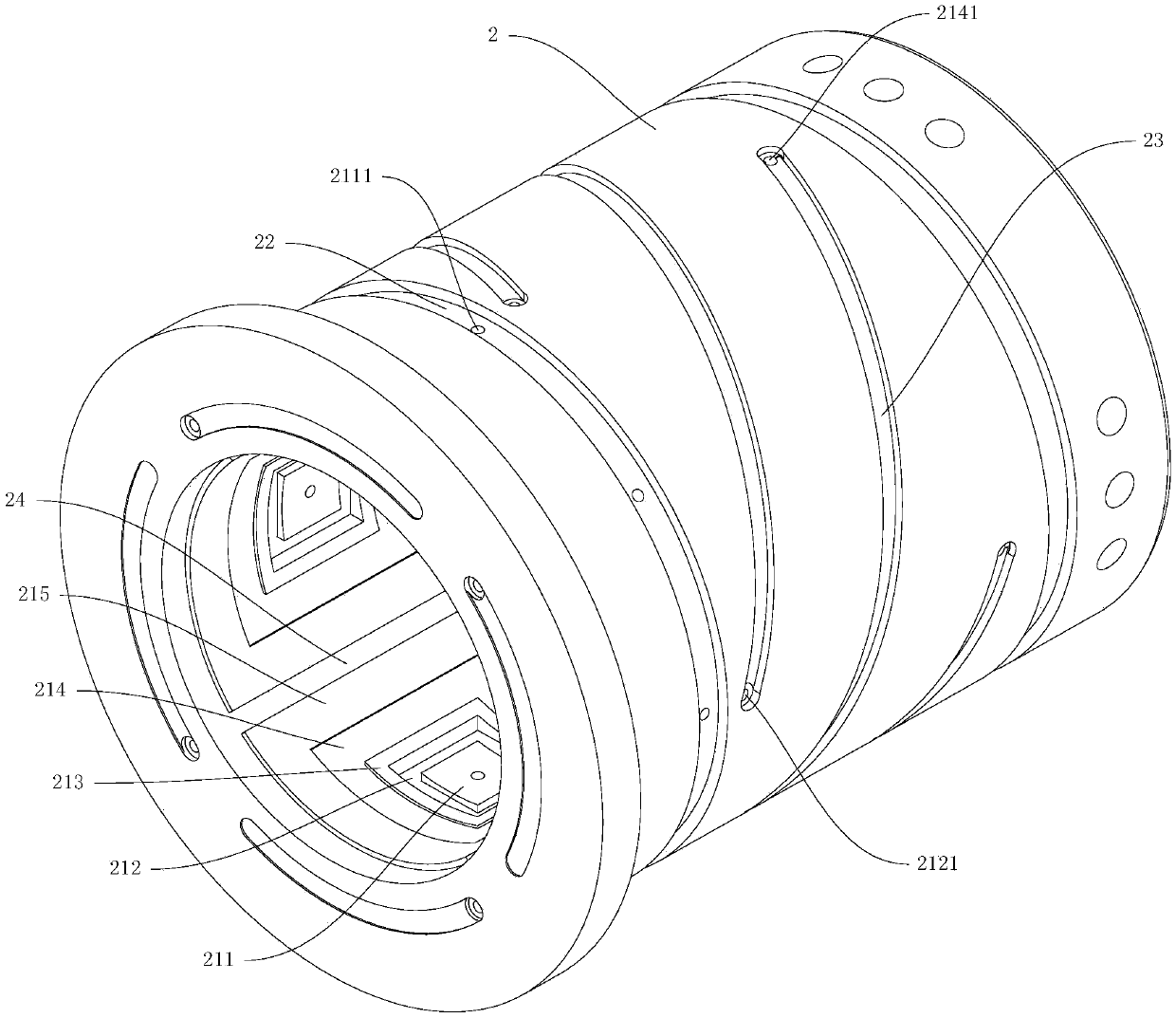

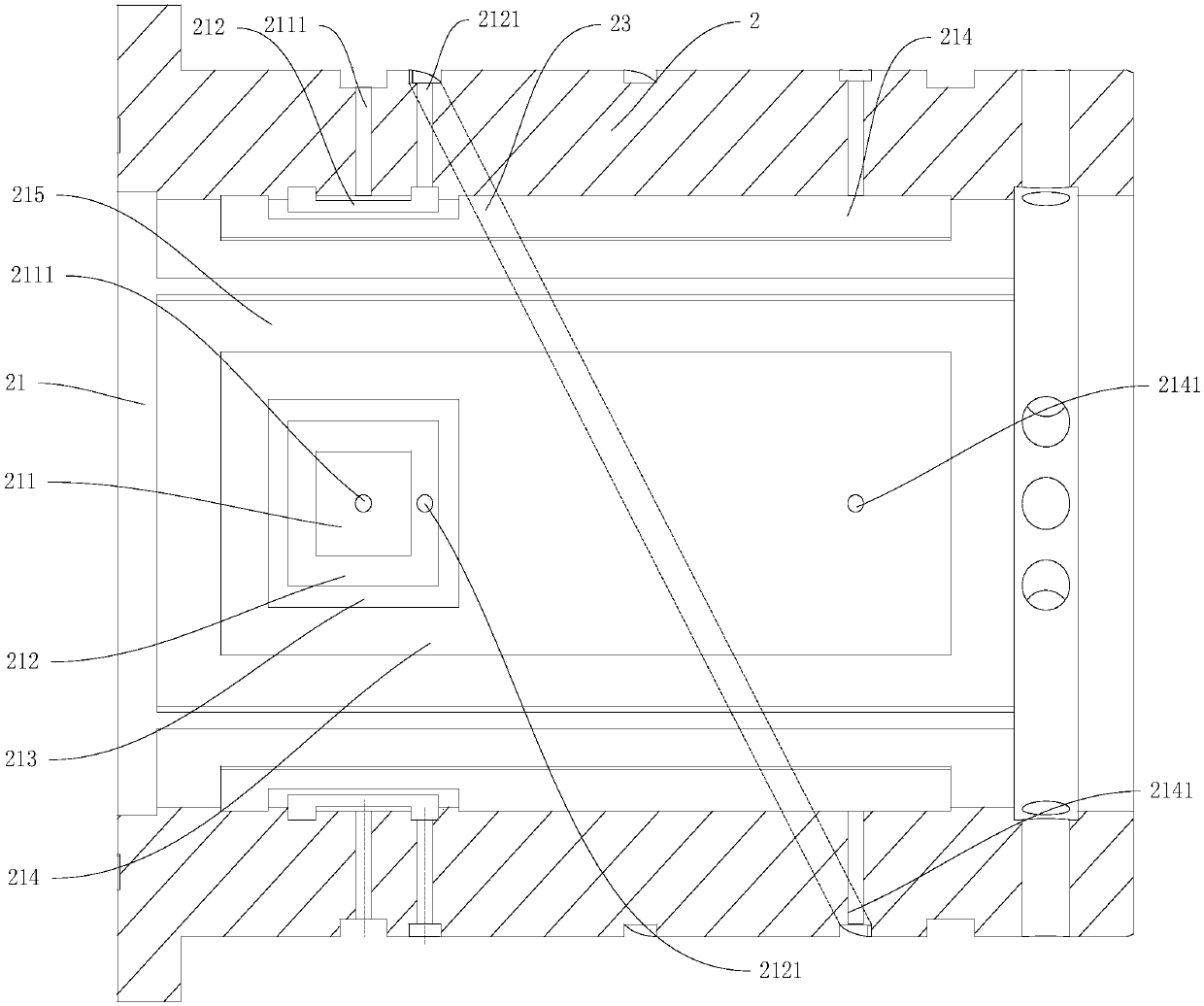

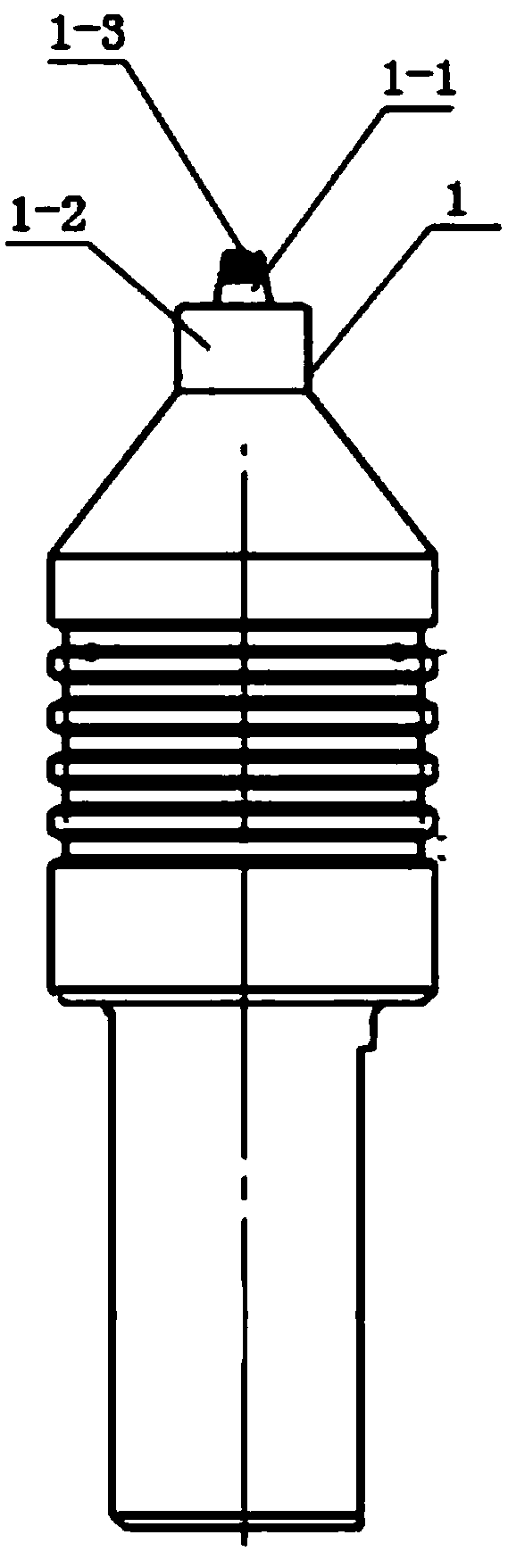

Intracavity internal feedback throttling liquid static electric spindle

ActiveCN109676520AImprove radial load capacityImprove rigidityGrinding machine componentsLarge fixed membersEngineeringMachining

The invention discloses an intracavity internal feedback throttling liquid static electric spindle. The intracavity internal feedback throttling liquid static electric spindle comprises a machine body, a liquid static bearing and a rotary shaft. The rotary shaft is in rotary fit into the machine body through the liquid static bearing, an even number of throttlers are arranged on the inner wall face of the liquid static bearing, and every two throttlers are oppositely arranged. Each throttler comprises a throttling boss, an oil collecting oil cavity and a working oil cavity. The throttling bosses communicate with oil inflow branches outside the liquid static bearing, the oil collecting oil cavities surround the throttling bosses, the working oil cavities surround the oil collecting oil cavities, the working oil cavities are separated from the oil collecting oil cavities through first oil sealing flanges, and the oil collecting oil cavity of one of every two opposite throttlers communicates with the working oil cavity of the other one of every two opposite throttlers. By means of the intracavity internal feedback throttling liquid static electric spindle, effective throttling, stableperformance and easier machining can be guaranteed, and then the rigidity of the rotary shaft is improved.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

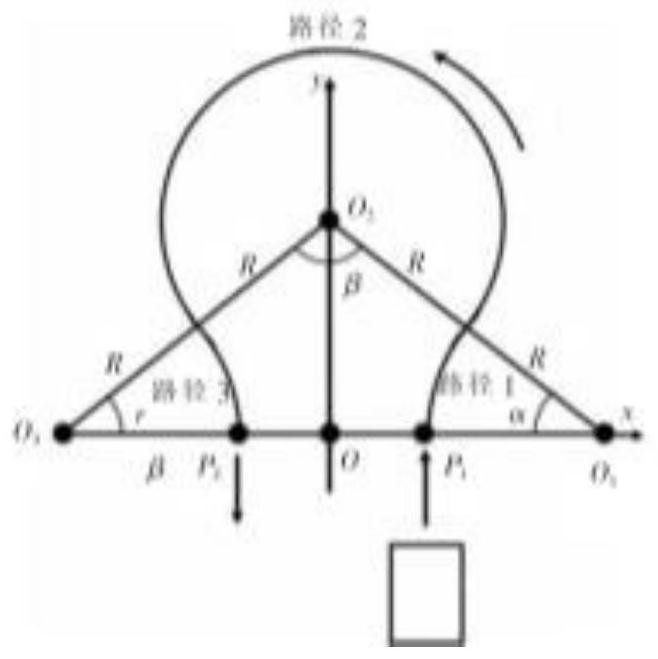

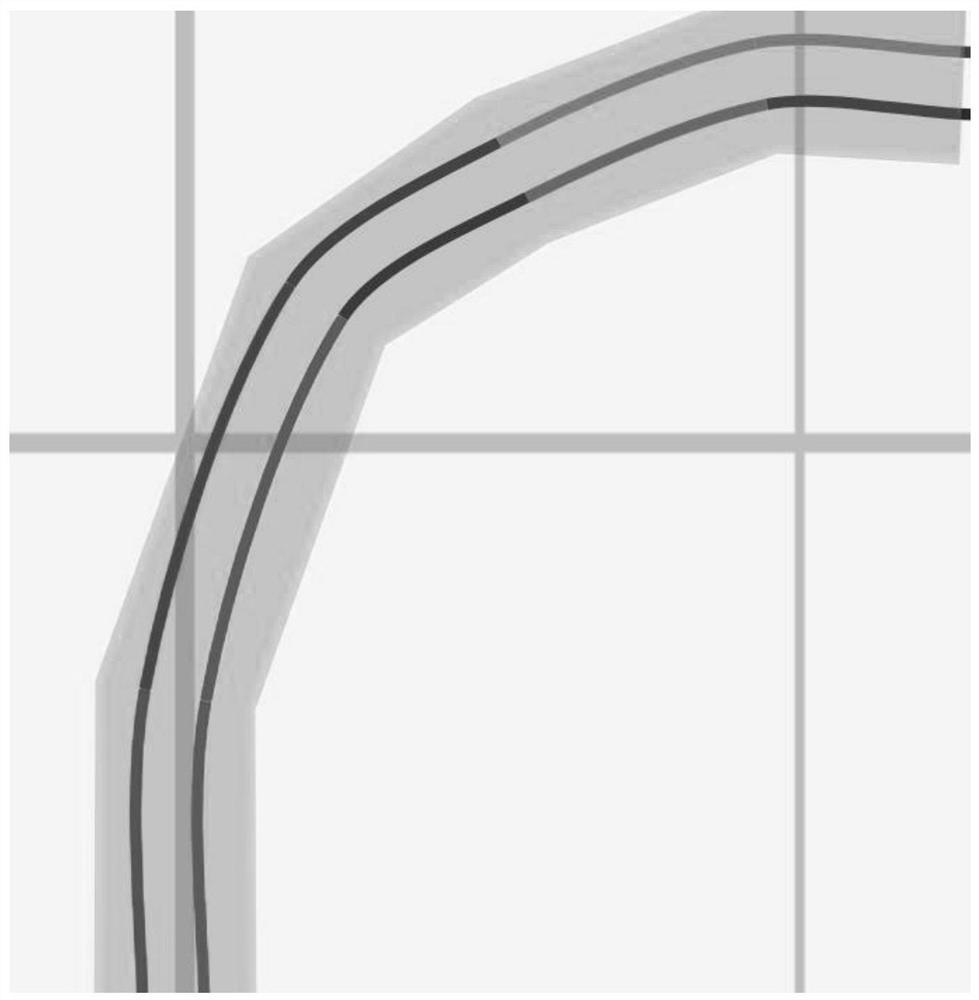

Pavement robot path planning method

PendingCN112269383AReduce width requirementsUnsmoothAutonomous decision making processPosition/course control in two dimensionsSimulationControl theory

The invention discloses a pavement robot path planning method. The method comprises the following steps: acquiring a discrete coordinate point set in a walking path of a pavement robot; connecting discrete coordinate points by adopting a Bezier curve algorithm to obtain a smooth curve set; performing left-right equidistant offset according to the widths of the left and right sides of the road andthe measurement width of the pavement robot to obtain a plurality of Bezier curve sets; according to the length, the width, the wheelbase, the wheel track and the center position of the pavement robot, obtaining the center turning radius, the inner side turning radius and the outer side turning radius of the pavement robot; taking the tail end of a Bezier curve of a walking path of the pavement robot as a starting point, and solving an intersection point of the turning vehicle body contour and a road edge line; taking the intersection point of the turning vehicle body outline of the pavement robot and the road edge line as the starting point, solving the intersection point of the outer turning curve and the lane edge, and repeating the advancing and retreating operations until the advancing direction of the pavement robot coincides with the adjacent Bezier curve.

Owner:成都圭目机器人有限公司

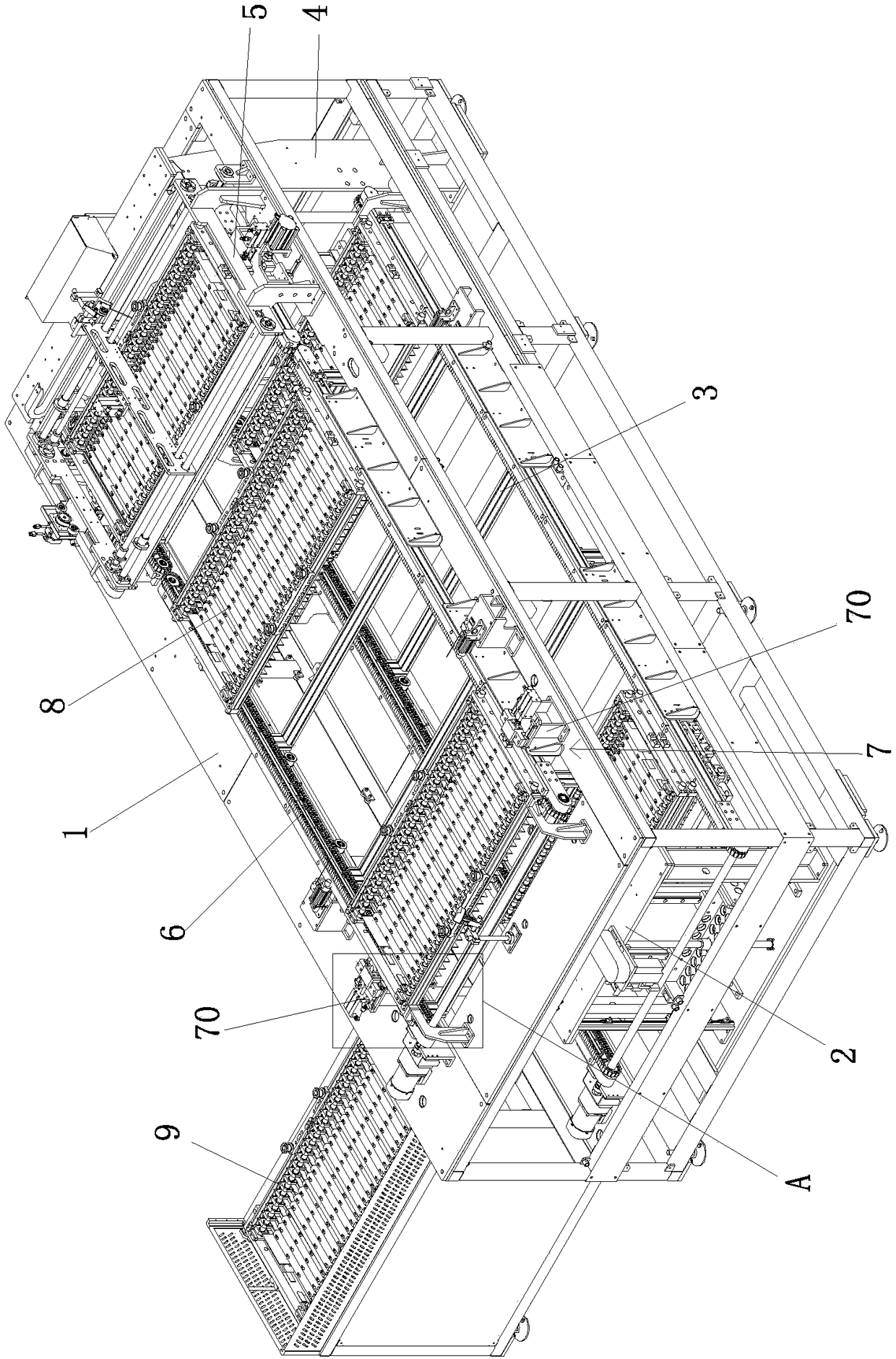

Protective pad automatic packaging production line device and production process thereof

ActiveCN104890962AImprove efficiencyReduce width requirementsPackaging machinesProduction lineDistributor

The invention discloses a protective pad automatic packaging production line device and a production process thereof. A transposition wheel mechanism is connected with a distributor mechanism through a first belt overturning mechanism, one end of the distributor mechanism is connected with a second belt overturning mechanism, one end of the second belt overturning mechanism is connected with a cam pushing mechanism, one end of the cam pushing mechanism is provided with an electric eye, and one end of the electric eye is provided with a product conveying platform unit. The packaging device achieves horizontal transposition of small bags, production line finished products are divided into two paths to be input in a packaging device, the two paths of the packaging device are parallelly connected to a production line, a cam pushes the finished products into an intermediate packaging device for piece tidying, and the protective pad automatic packaging production line device is simple in structure, convenient to use and high in packaging efficiency; devices that are used mainly comprise a product production line device, a product branching mechanism, a product conveying pushing and counting mechanism and the intermediate packaging device, in the process the two paths of the intermediate packaging device are parallelly connected to a main production line to automatically finish the packaging; the factory building width requirements are lowered, the packaging efficiency is improved, and the production cost is reduced.

Owner:GUANGZHOU XINGSHI EQUIPS

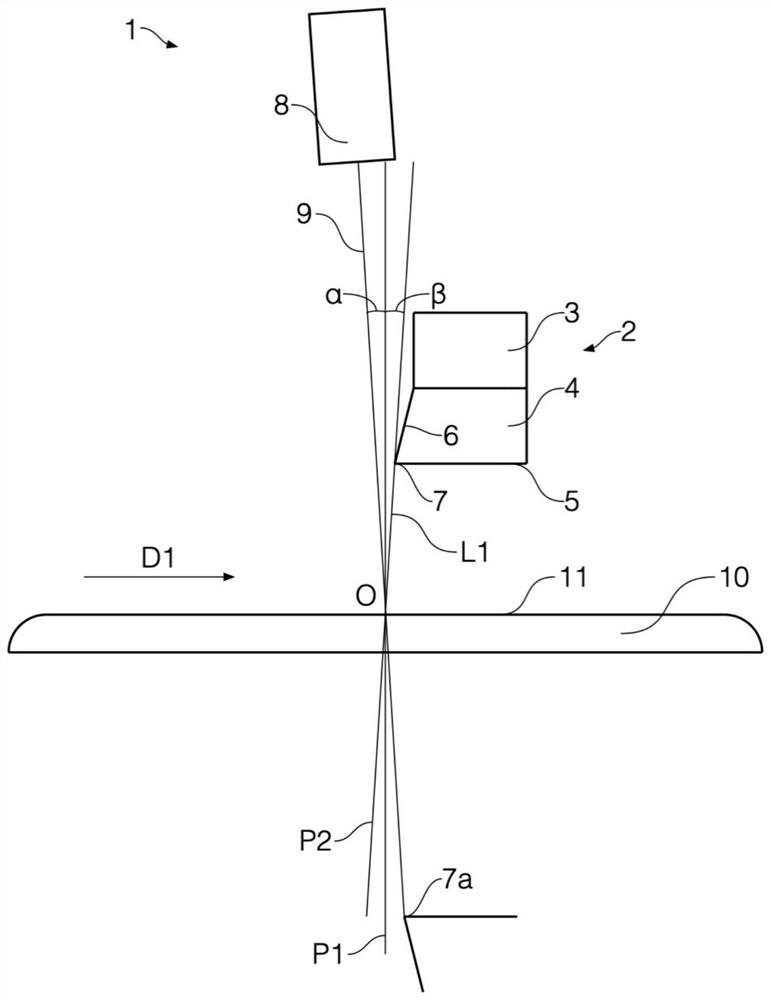

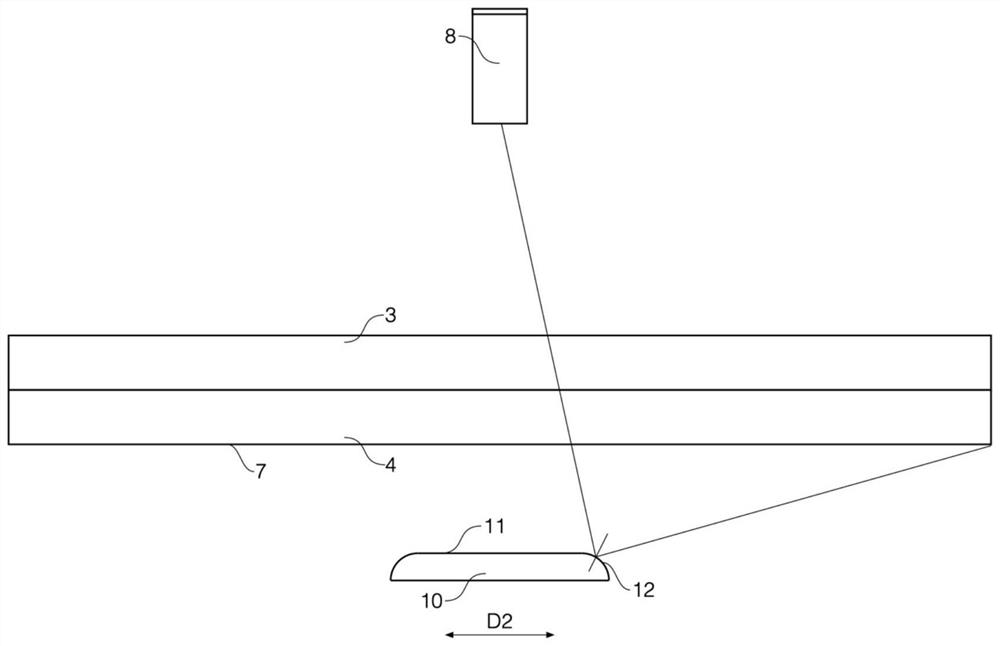

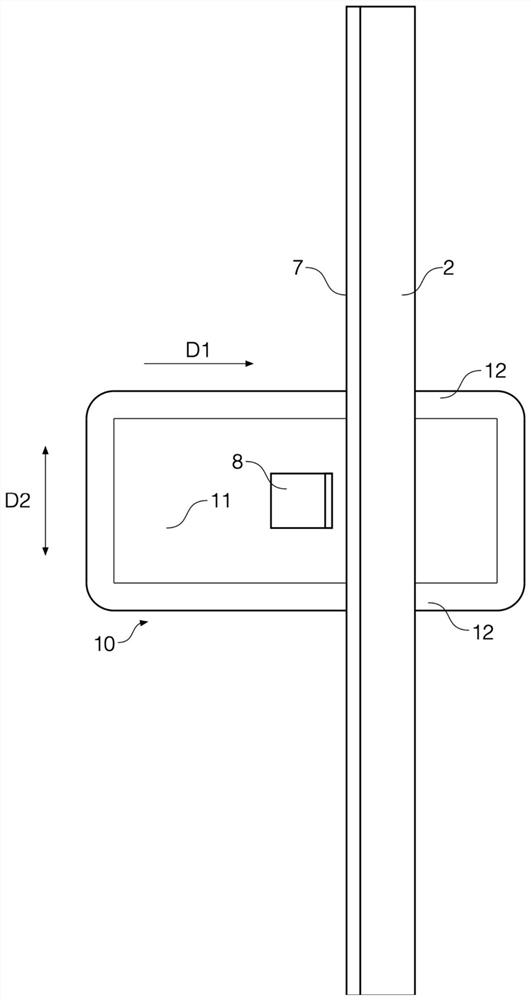

Surface defect developing device and surface defect detecting equipment

ActiveCN112964727AImprove the detection rateImprove work efficiencyOptically investigating flaws/contaminationOptical axisThresholding

The invention discloses a surface defect developing device and surface defect detecting equipment. The surface defect developing device comprises a light source and a camera, the light source is provided with a folded edge perpendicular to the moving direction of a to-be-detected object, the optical axis of the camera perpendicularly intersects with a virtual image of the folded edge and intersects with the first surface of the to-be-detected object at a first point, a first plane passes through the first point and is perpendicular to the moving direction of the to-be-detected object, and a second plane passes through the first point and the folded edge. The first included angle between the optical axis and the first plane is equal to the second included angle between the vertical line from the first point to the folded edge and the first plane, and any part of the light source is not located in the area between the first plane and the second plane. A surface defect detection device in the surface defect detection equipment synthesizes images continuously shot by the camera into a synthetic image, and judges that a to-be-detected surface has defects when identifying that the change of a gray value in a to-be-detected surface area in the synthetic image exceeds a threshold value. According to the scheme, the influence of interference reflected light on the modulation effect can be avoided under the condition that the light source is close to the surface of the to-be-detected object.

Owner:厦门威芯泰科技有限公司

Welding method for friction stir welding of aluminum alloy narrow step lap joint

InactiveCN108436249AImprove cooling efficiencyImprove applicabilityNon-electric welding apparatusFriction weldingShoulder width

The invention discloses a welding method for friction stir welding of aluminum alloy narrow step lap joint. The welding method comprises a stir-welding head body, the stir-welding head body comprisesa stir needle and a shaft shoulder, the upper portion of the stir needle is provided with a stir needle point, the stir needle is of a trapezoidal structure, the bottom of the stir needle is providedwith the shaft shoulder, the shaft shoulder is of a concentric circle type, and the height of the stir needle is the same as the depth of welding and is 4 mm, 5 mm or 6 mm correspondingly. The weldingmethod for friction stir welding of aluminum alloy narrow step lap joint has the beneficial effects that a friction stir welding stir-welding head of narrow step lap joint (the step width is obviously less than weld joint depth) is adopted, the novel narrow lap joint friction stir welding process method is developed, friction stir welding of aluminum alloy narrow step lap joint is realized, the cooling efficiency of friction stir welding cold plate structures is improved, the fluidity of materials in the welding process is increased, the welding pressure and stir-welding head shaft shoulder width are reduced, the welding structure design efficiency is improved remarkably, the space utilization rate and cooling efficiency of cold plates are improved, and the applicability of friction stirwelding for aluminum alloy is improved.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

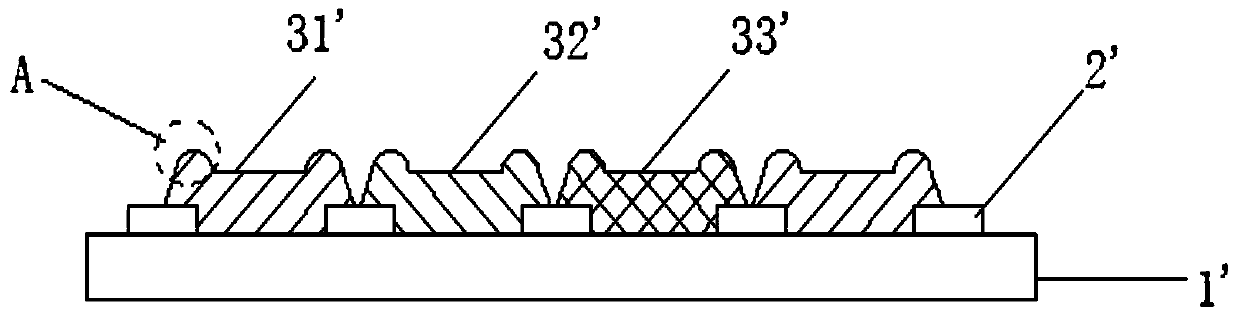

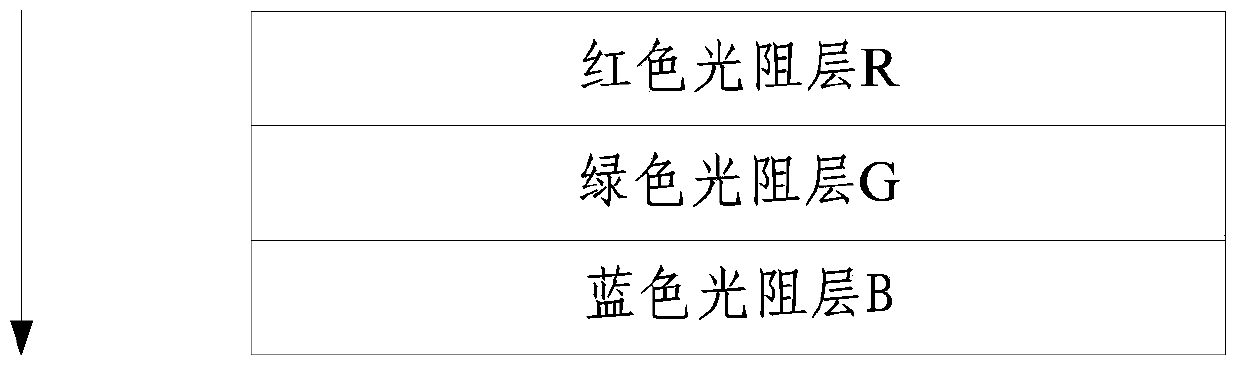

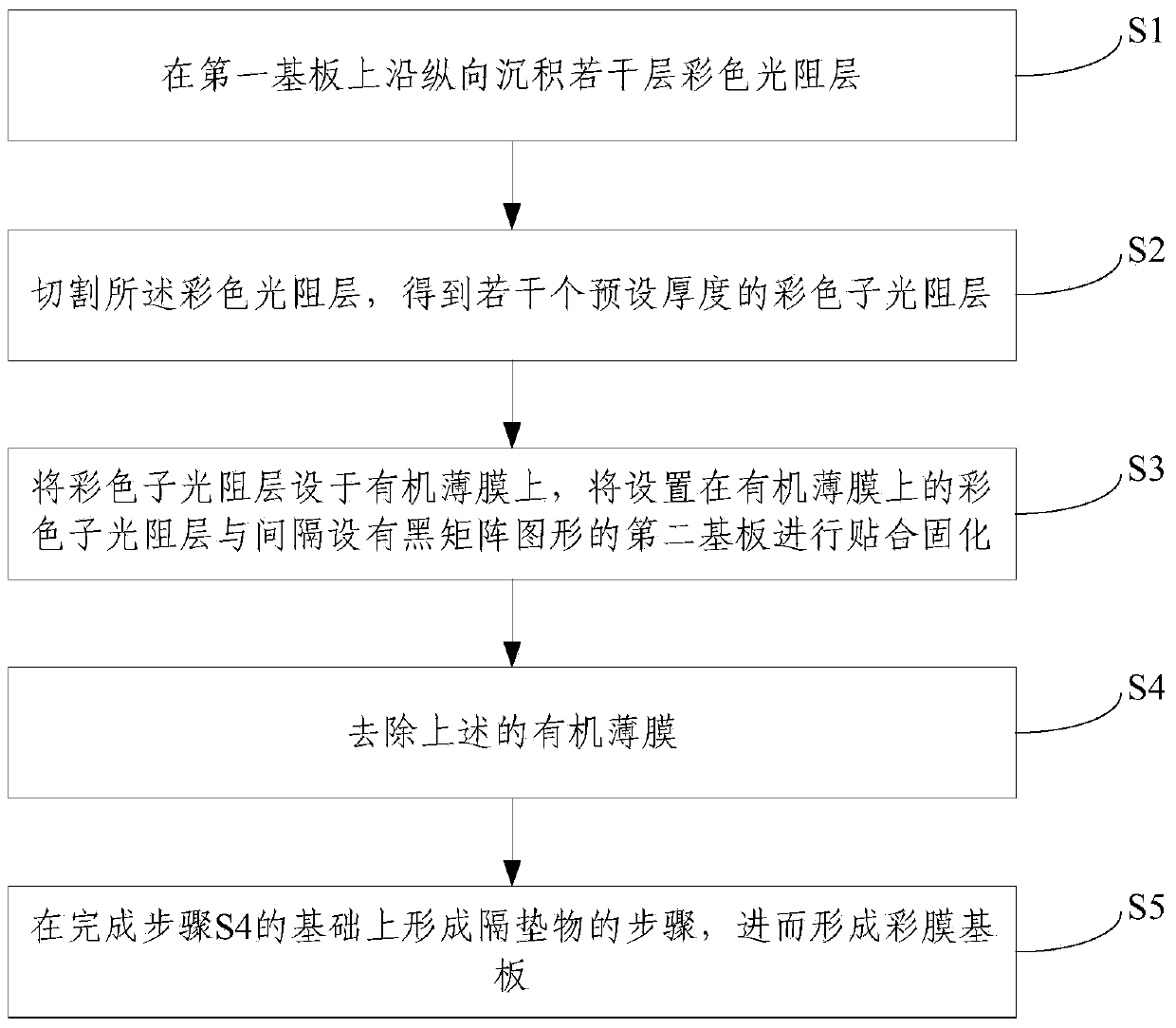

Display device and color film substrate and manufacturing method thereof

InactiveCN103744223AReduce width requirementsEliminate light leaksNon-linear opticsOrganic filmColor film

The invention relates to the technical field of displaying, in particular to a display device and a color film substrate and a manufacturing method thereof. The manufacturing method of the color film substrate includes that a plurality of colorful photoresist layers are vertically deposited on a first substrate, the colorful photoresist layers are cut to obtain a plurality of colorful sub photoresist layers with preset thickness, the colorful sub photoresist layers are arranged on an organic film, the colorful sub photoresist layers arranged on the organic film and a second substrate provided with black matrix patterns at intervals are bonded in a solidifying mode, and the organic film is removed to form the color film substrate. Due to the fact that the colorful sub photoresist layers arranged on the organic film and the substrate provided with the black matrix patterns are bonded in a solidifying mode, a gap-free colorful photoresist layer can be formed, the width requirement of the black matrix is reduced to the largest extent, and light leakage caused by angle section difference is effectively removed.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Lateral taping mechanism of full automatic edge bander

The invention discloses the improvement of a lateral taping mechanism of a full automatic edge bander; the lateral taping mechanism is provided with a frame; the frame is provided with a conveying platform; the mechanism is characterized in that both sides of the conveying platform are provided with a positioning beam and a flanging device; the positioning beam can move up and down relative to the conveying platform; the flanging device is installed at the outer side of the positioning beam; the flanging device comprises a flanging base and a flanging plate; the flanging plate is installed onthe flanging base; the flanging plate can move up and down on the flanging base and is mutually matched with the positioning beam; and the flanging base can move left and right relative to the conveying platform of the frame. The mechanism has low requirement for the width of paperboard side, relatively wide use range, clean and flat surface of the produced paperboard.

Owner:薛迪虎

Railway platform light curtain protection device combined with laser detection and control method thereof

PendingCN111746561AReduce widthReduce width requirementsRailway componentsOptical detectionContinuous lightLaser scanning

The invention discloses a railway platform light curtain protection device combined with laser detection. The railway platform light curtain protection device is characterized by comprising a virtualplatform door arranged on the edge of a platform and a safety detection device; the virtual platform door comprises light curtain stand columns, light curtain top beams between the light curtain standcolumns and a plurality of plasma light generators distributed on the light curtain top beams; the plasma light generators are used for emitting visible light beams to generate a continuous light curtain, and a virtual channel corresponding to a train door can be formed by selectively closing part of the plasma light generators to eliminate part of the light curtain. A light curtain replaces a traditional scheme that a platform door is arranged beside the platform, the protection device is arranged on the premise of not retreating or slightly retreating, the occupied width of the platform isreduced, and the requirement for the width of the platform is lowered; compared with a traditional platform door, the virtual light curtain can adapt to more vehicle types. The safety detection deviceadopts a laser scanning correlation device for dynamic scanning, the accuracy is high, the coverage is large, and the personnel safety and the driving safety of a platform side area are ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com