Patents

Literature

37results about How to "Convenient process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

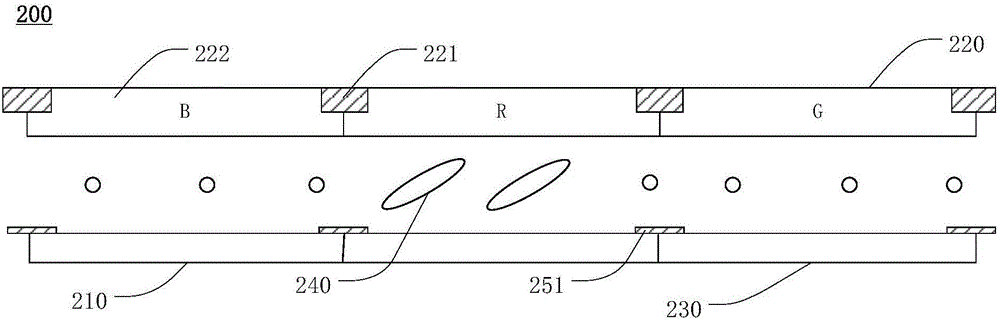

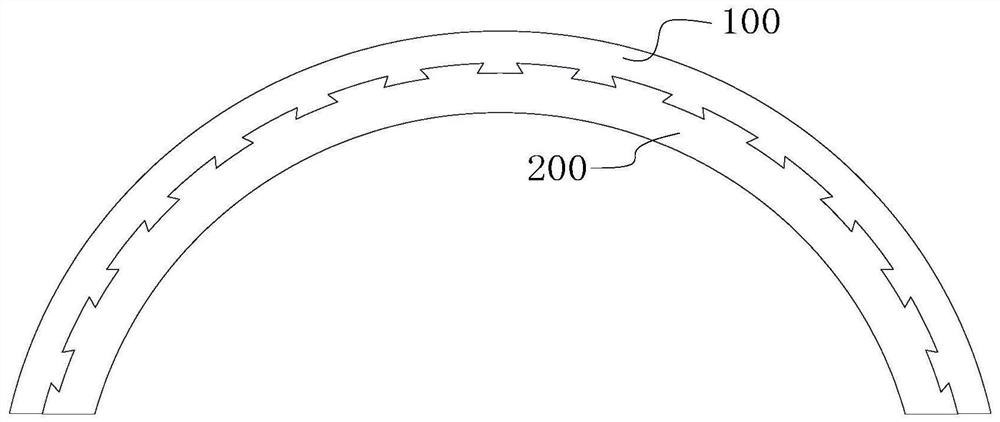

Array substrate and manufacturing method thereof, and display device

InactiveCN109671719AEffective dispersionImprove adhesionSolid-state devicesIdentification meansDisplay deviceEngineering

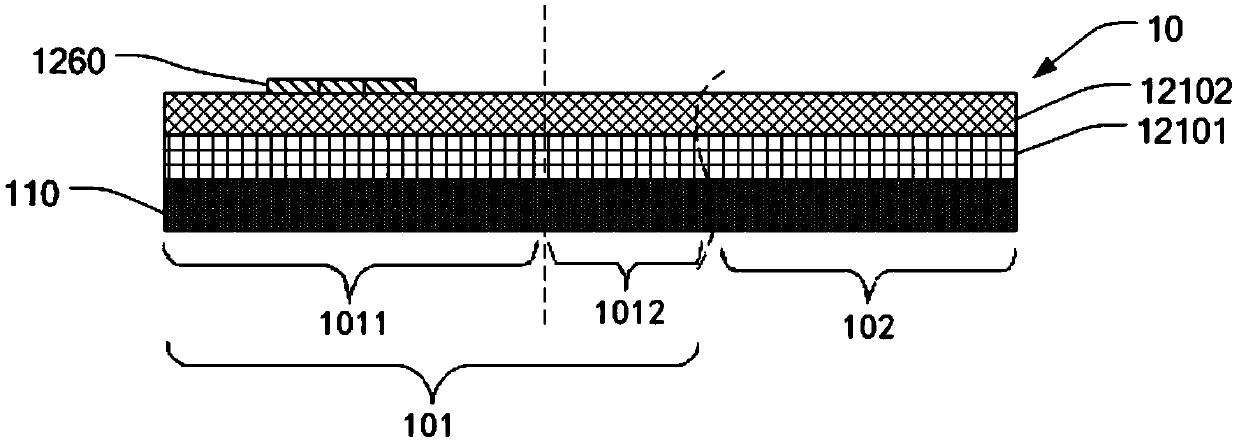

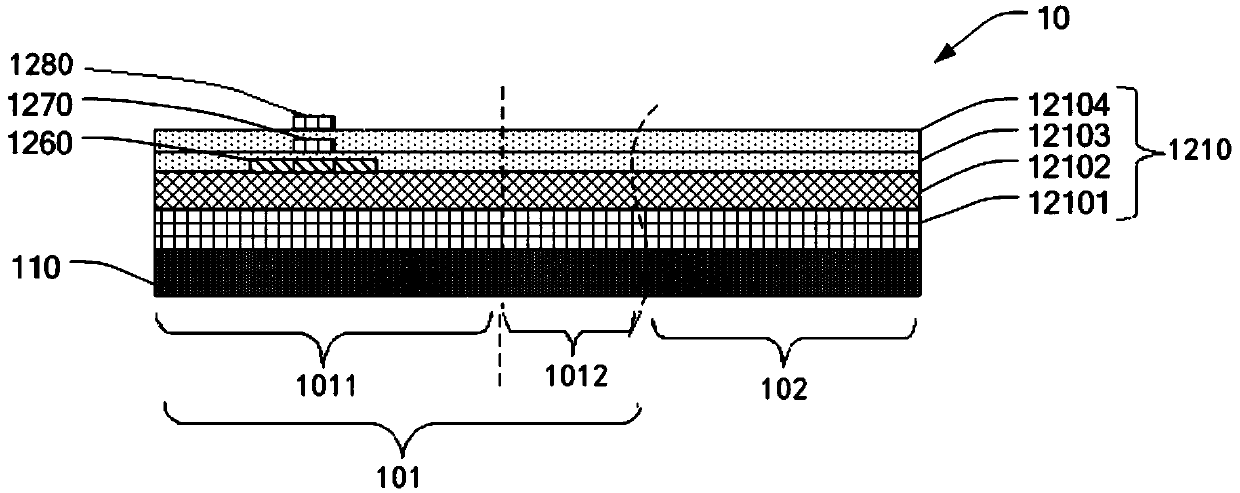

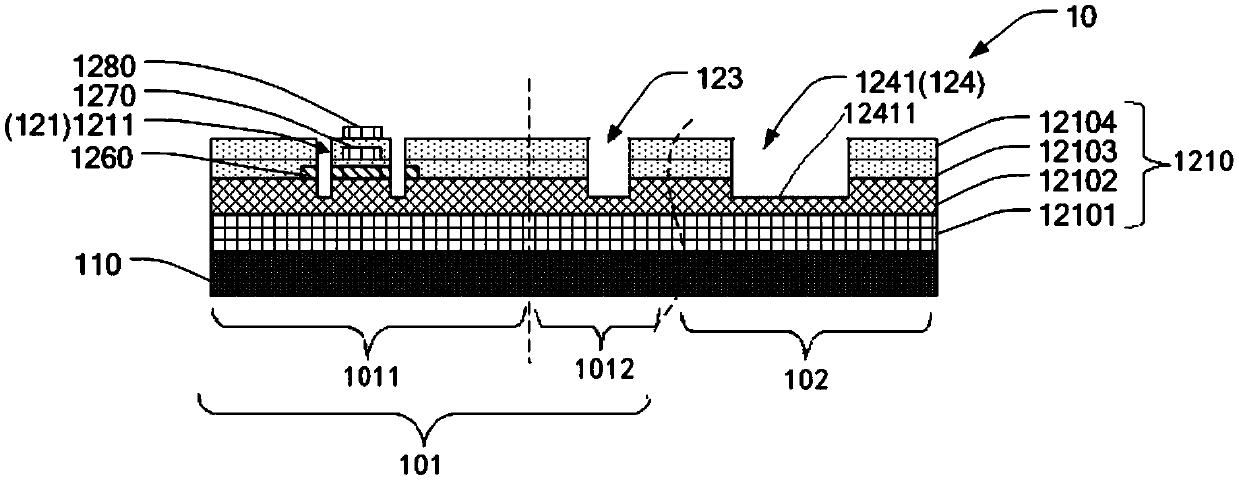

The invention discloses an array substrate and a manufacturing method thereof, and a display device. The array substrate has a bending area and a pixel area adjacent to the bending area, the pixel area has a plurality of pixel unit areas and a non-pixel unit area connected with the pixel unit area; the array substrate includes: a flexible substrate and an array layer, wherein the array layer includes an array base layer having a first groove and a second groove, the first groove corresponds to the non-pixel unit area in the pixel area, and the second groove corresponds to the bending area; a filling layer filled in the first groove and the second groove; and an organic dielectric layer covering the array base layer and the filling layer, wherein the organic dielectric layer and the fillinglayer employ organic photoresist materials. The array substrate and the manufacturing method thereof, and the display device having the array substrate effectively reduce the stress of each film layer in the array substrate when the film layers are bent so as to achieve bending of the pixel area.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

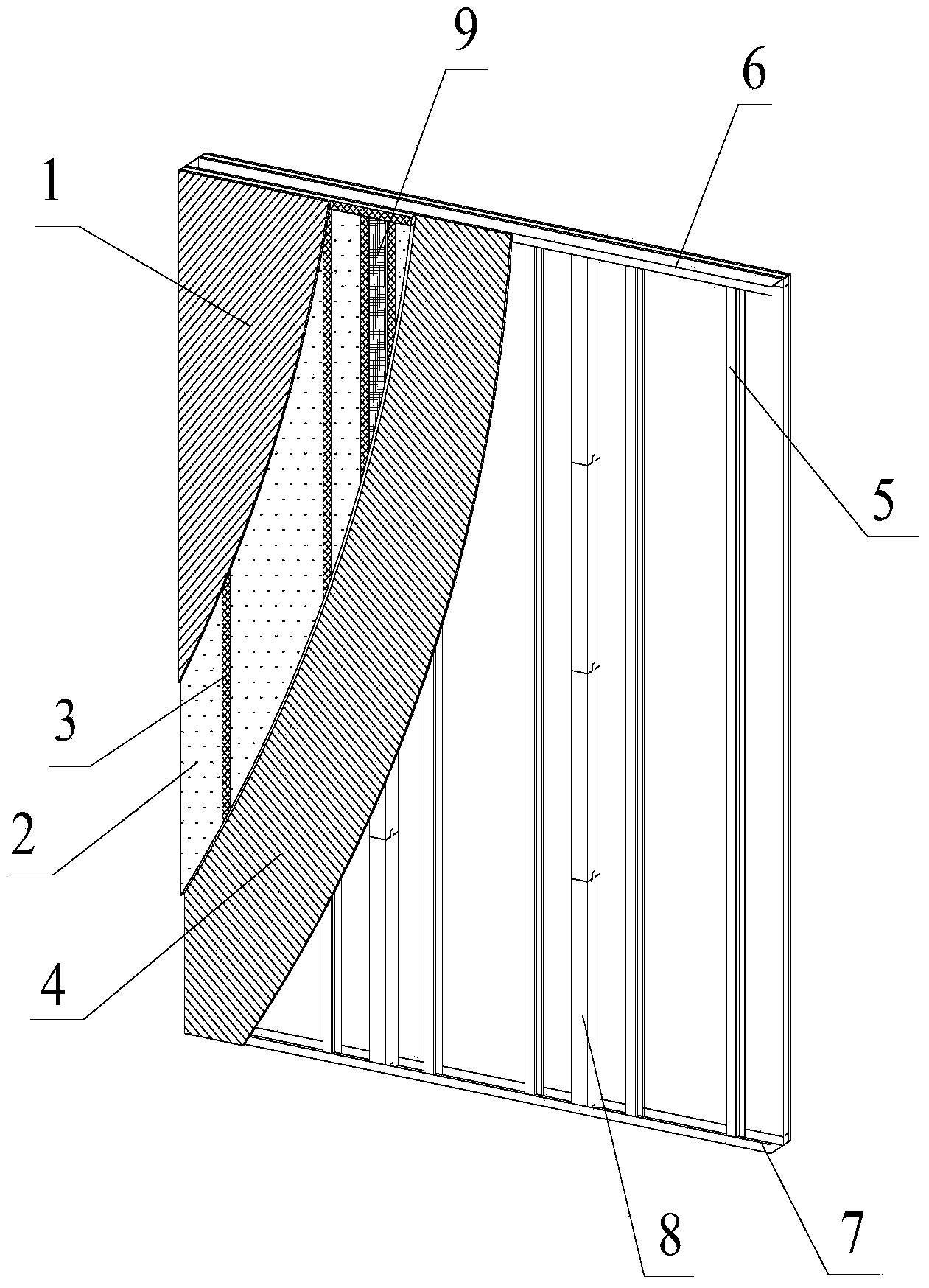

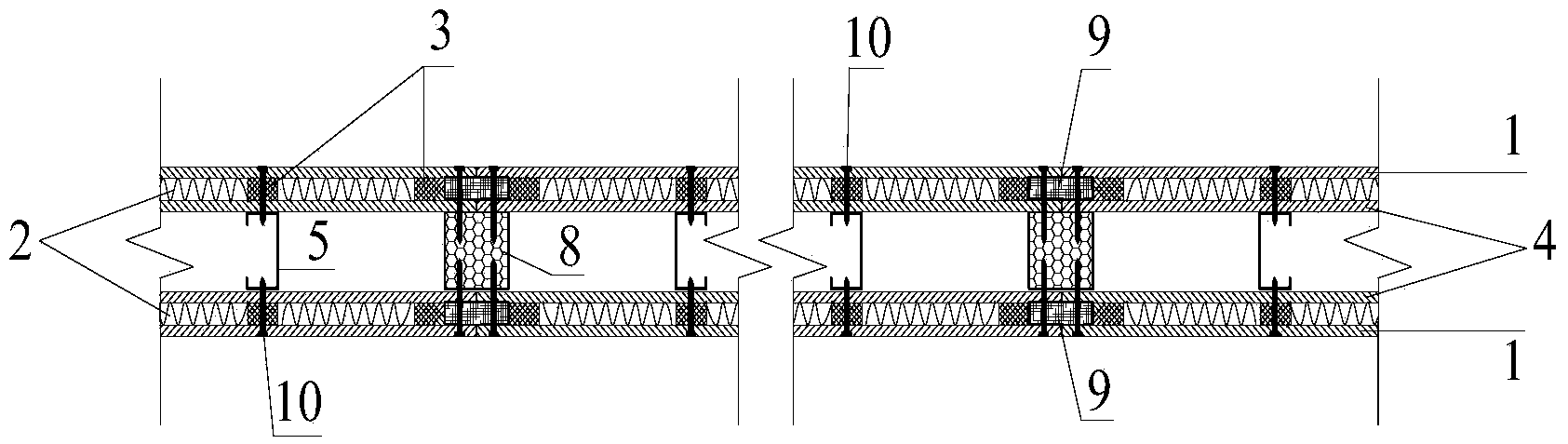

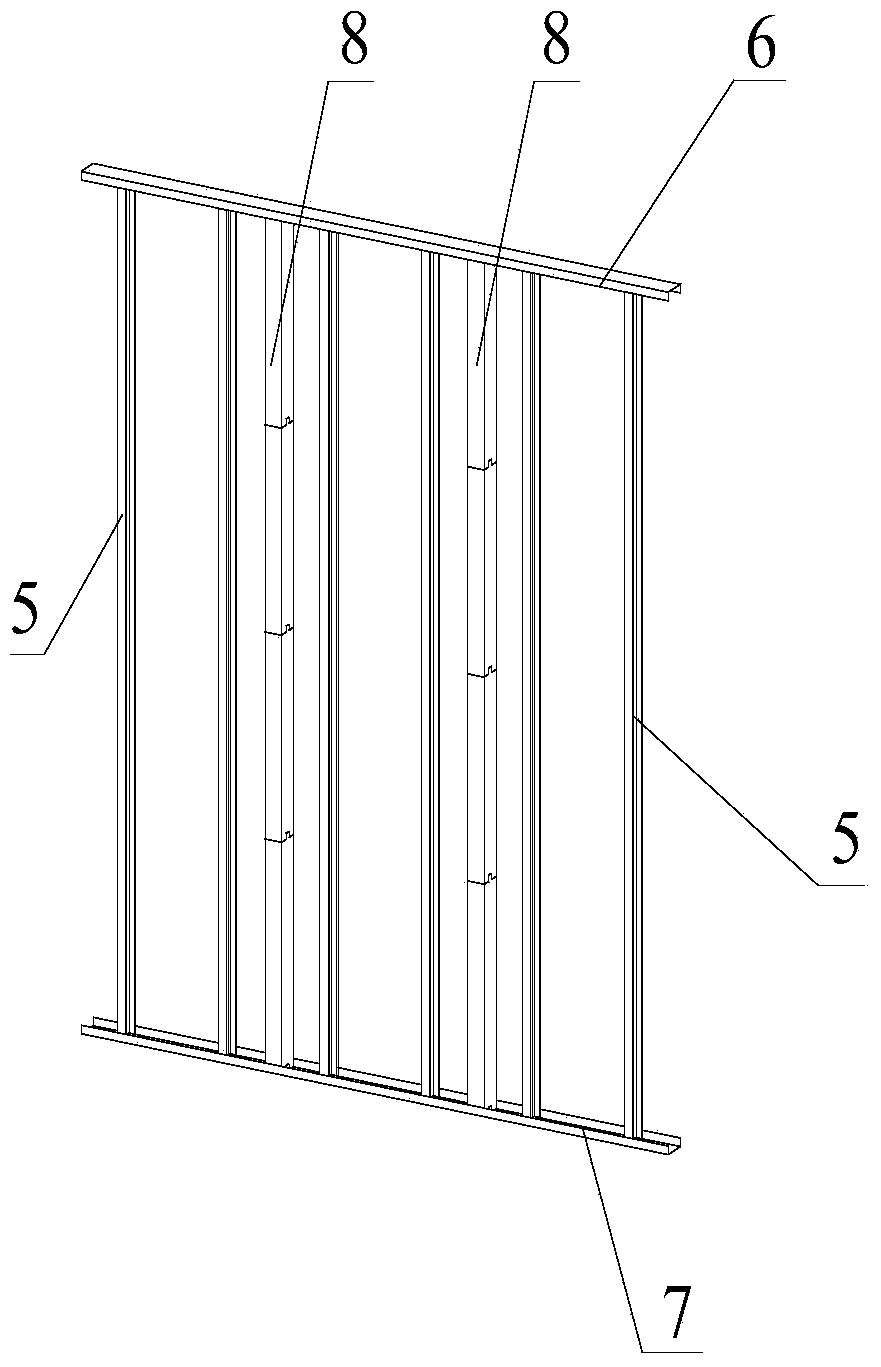

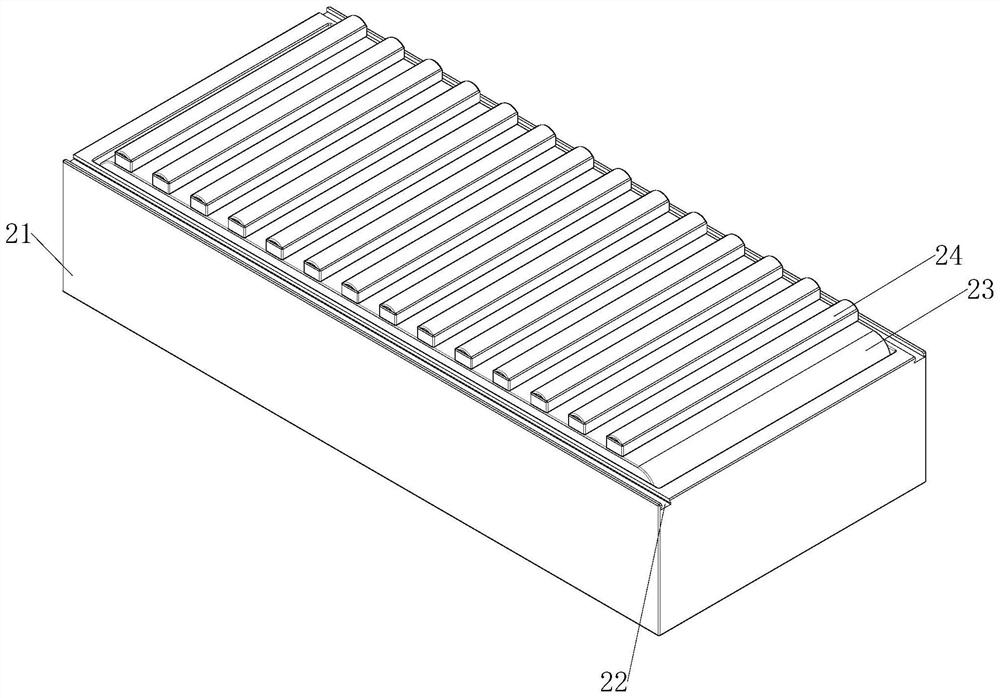

Prefabricated light steel fireproof load-bearing combined wall structure

InactiveCN103437463AFacilitate batch prefabricationNo significant effect on fire resistanceWallsHeat proofingThermal insulationKeel

The invention discloses a prefabricated light steel fireproof load-bearing combined wall structure which is formed by fixedly connecting sandwich wallboard units on two sides and a light steel joist framework unit at the middle. Each sandwich wallboard unit comprises an A-side wall board and a B-side wall board; and an autoclaved aerated concrete slat (3) and thermal insulation cotton (2) are spaced between the A-side wall board and the B-side wall board. The light steel joist framework unit is formed by fixedly connecting a cold-formed steel upright (5), a cold-formed steel guide rail and an autoclaved aerated concrete short column (8) of which the thickness is equal to the height of a web of the cold-formed steel upright. Adjacent sandwich wallboard units on the same side are inserted into an autoclaved aerated concrete butt-joint slat (9) through grooves (13) in the long sides thereof to realize splicing. The sandwich wallboard units and the light steel joist framework unit are connected through self-tapping screws to realize wall splicing. By adopting the structure disclosed by the invention, full prefabrication can be realized, the structure is light, and the steel consumption is reduced; and moreover, the structure has the characteristics of thermal insulation, sound insulation and fire resistance and is suitable for a load bearing wall system of a multi-story building.

Owner:SOUTHEAST UNIV

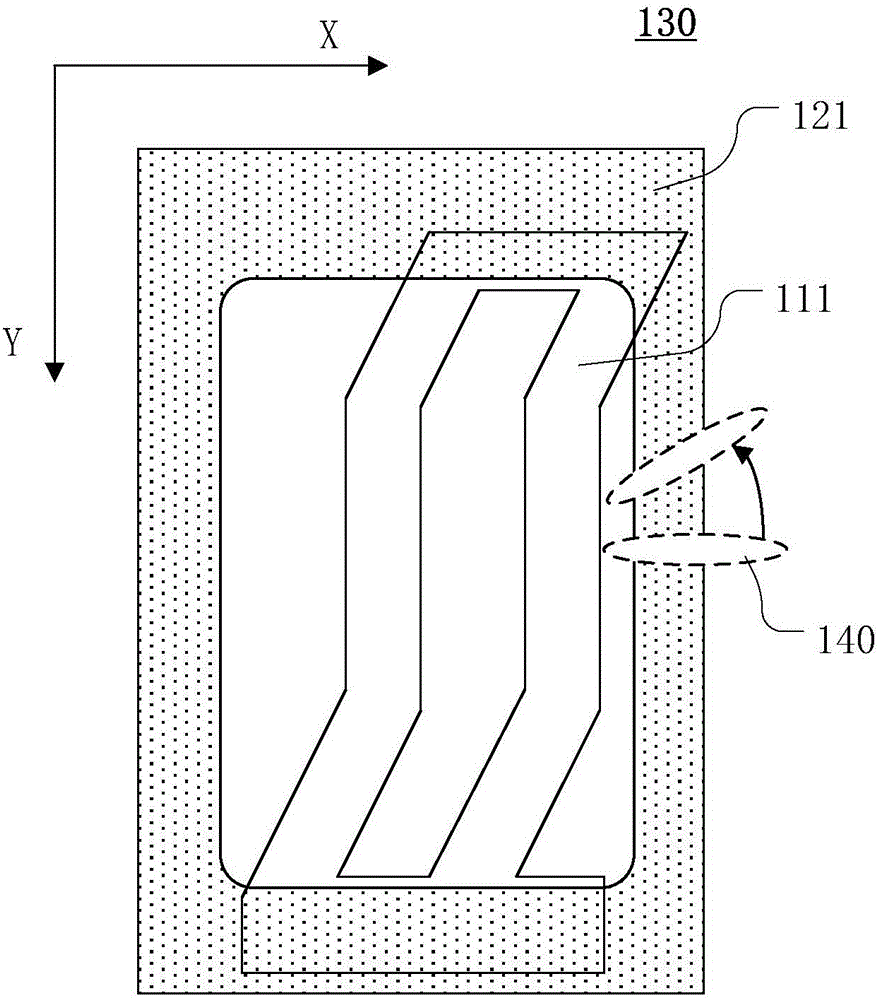

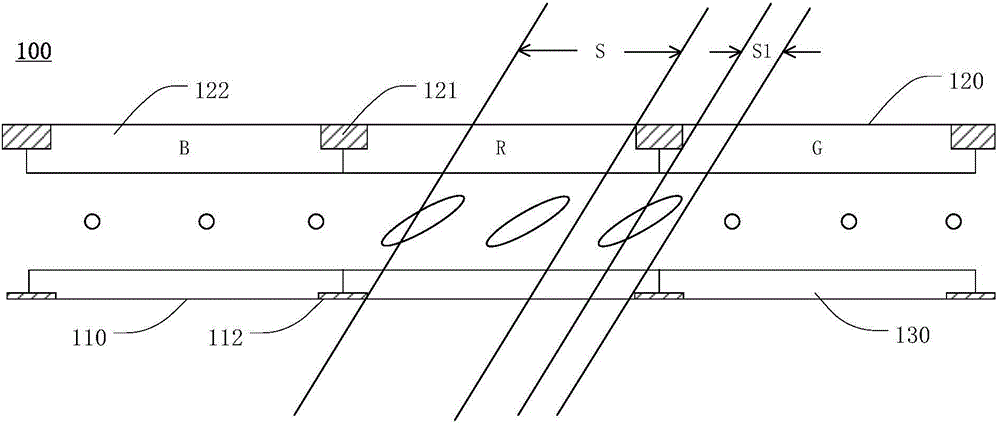

Liquid crystal display panel and liquid crystal display device

The invention provides a liquid crystal display panel and a liquid crystal display device comprising the same.The liquid crystal display panel comprises a first substrate, a second substrate, liquid crystal molecules, a black matrix and a first electrode layer, wherein the first substrate comprises a plurality of pixel areas, the second substrate is opposite to the first substrate, the liquid crystal molecules are located between the first substrate and the second substrate and has an initial orientation direction, the black matrix is arranged on the second substrate and provided with openings corresponding to all the pixel areas, the first electrode layer is arranged on the first substrate and comprises first electrodes arranged in the pixel areas, and each first electrode comprises a first branch electrode shielded by the black matrix and a plurality of second branch electrodes connected with the first branch electrode, wherein the initial orientation direction of the liquid crystal molecules is set according to the extension direction of the first branch electrodes so that the liquid crystal molecules corresponding to the first branch electrodes can basically not deflect, and angles are formed between the extension direction of the second branch electrodes and the extension direction of the first branch electrodes.By means of the liquid crystal display panel and the liquid crystal display device, the display effect is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

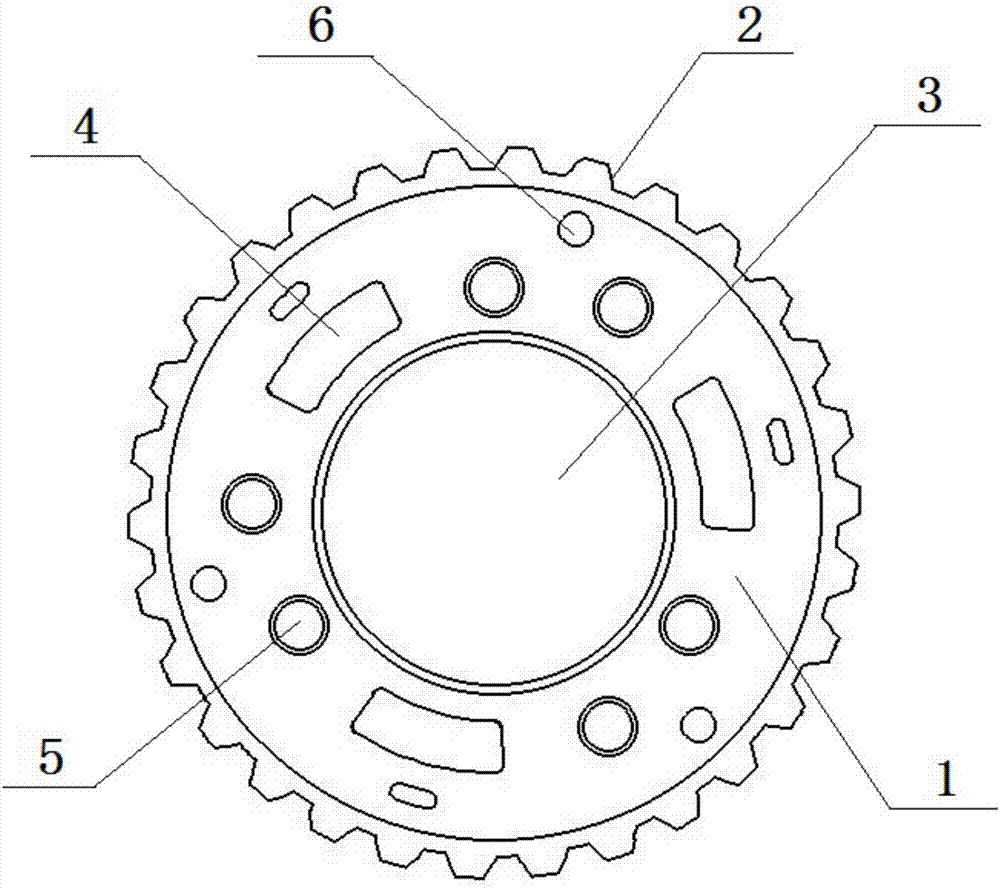

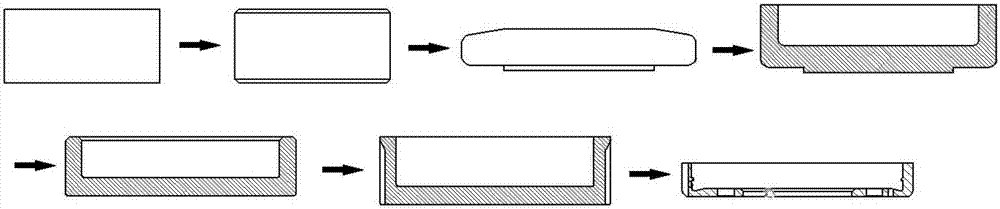

Manufacturing process for bearing plate of planetary carrier of automobile CVT automatic transmission

ActiveCN107186450AThe technical route of the manufacturing process is reasonableImprove tooth surface strengthGearing detailsAutomatic transmissionGraphite

The invention discloses a manufacturing process for a bearing plate of a planetary carrier of an automobile CVT automatic transmission. The manufacturing process comprises the following steps: (1) blanking; (2) blank making before warm forging; (3) shot blasting; (4), warm forging and extrusion forming: heating a blank to 210+ / -20 DEG C, coating graphite, then continuing to heat to 820-860 DEG C, firstly upsetting and extruding and then performing backward extrusion forming to form a round plate and forming a metal ring vertically extending to one side on the edge of the circumference of the round plate, and then punching a central hole of the round plate; (5) residual heat annealing; (6) blank making and shot blasting after the warm forging; (7) lubricating treatment; (8) outer tooth forming by cold forging extrusion: placing the lubricated blank into a female die, and performing cold extrusion to form an outer gear ring; and (9) nitriding, wherein an effective oxide layer on the surface has a depth of 0.007-0.3mm. The manufacturing process is reasonable in technical route, metal flows are not cut off, a tooth surface strength of the product is high, raw materials are saved, and the production efficiency is high.

Owner:江苏威鹰机械有限公司

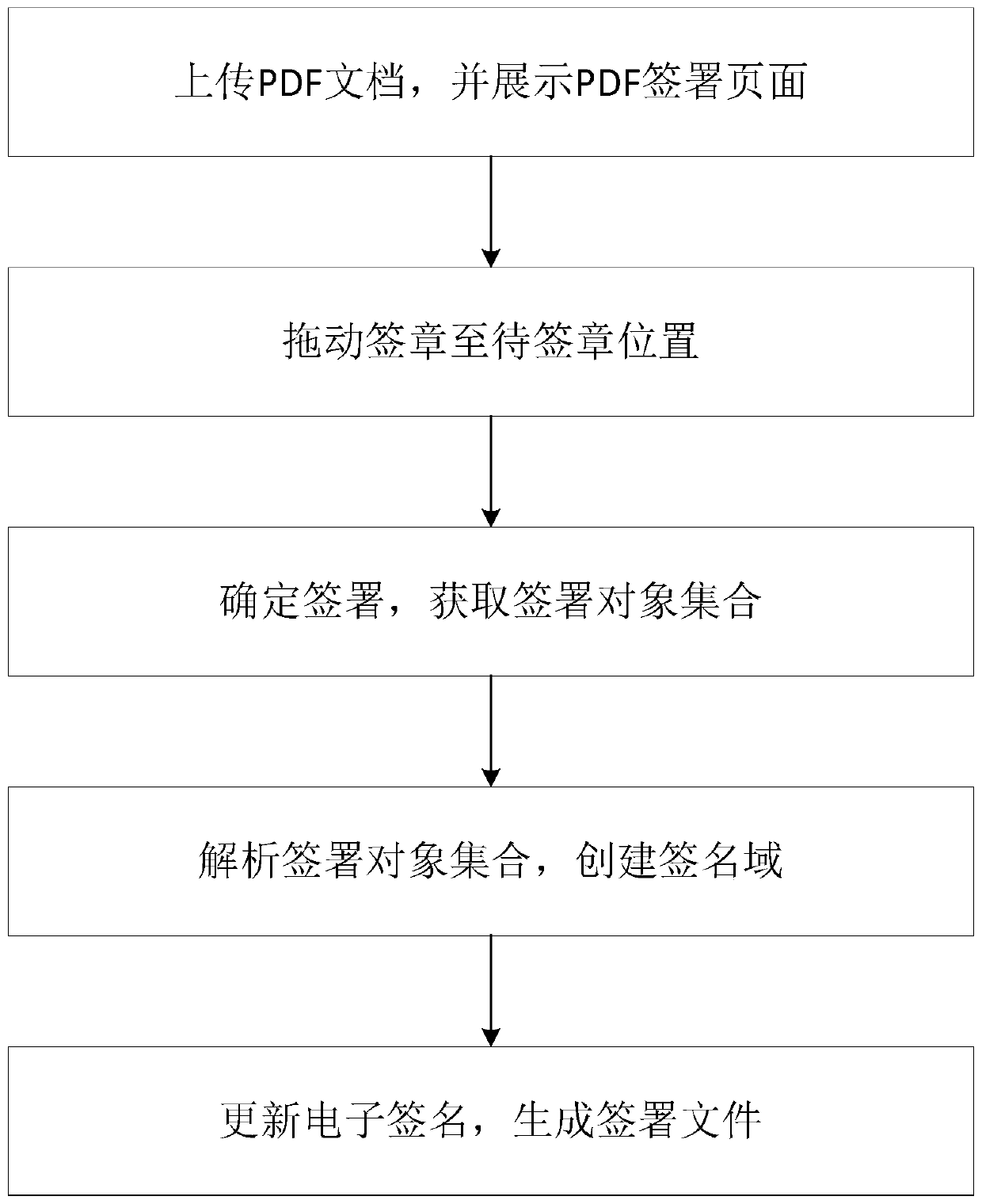

PDF signature method and PDF signature system

ActiveCN110532811AImprove the efficiency of batch signing and stampingImprove efficiencyDigital data protectionSpecial data processing applicationsSignature filePortable document format

The invention discloses a PDF (Portable Document Format) signature method which comprises the following steps: firstly, uploading a PDF document, and displaying a PDF signature page; dragging the signature to a to-be-signed position; signature is determined, and a signature object set is obtained; analyzing the signature object set, and creating a signature domain; and finally performing electronic signature to generate a signature file. The invention further discloses a PDF signature system adopting the PDF signature method to work. According to the method, a common signature dictionary signVis mainly created, a signature result is updated to the signature dictionary, then each signature domain in the PDF document points to the reference of the signature dictionary signV, and finally thepurpose that a plurality of position signatures in one PDF document correspond to the same digital certificate is achieved.

Owner:TIANGU INFORMATION SCI TECH HANGZHOU

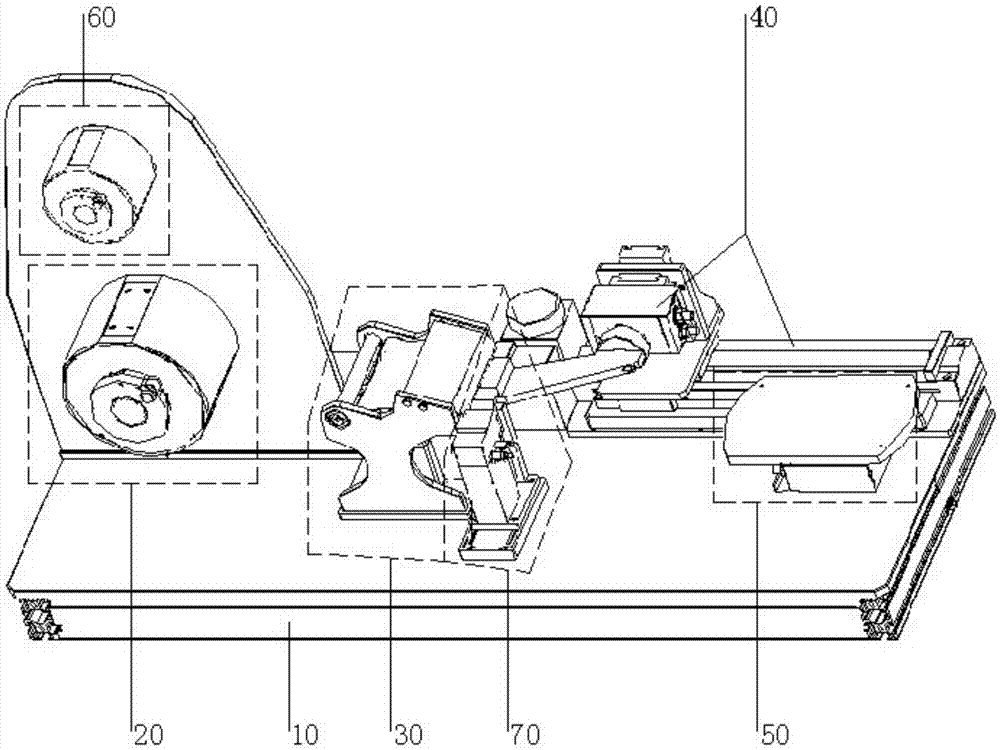

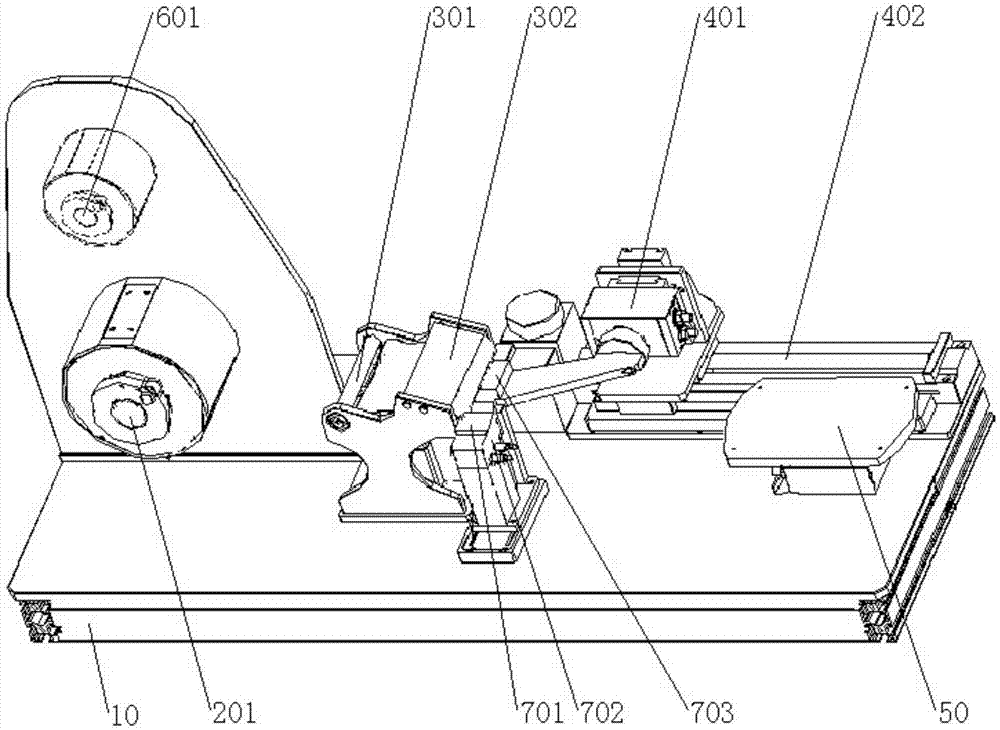

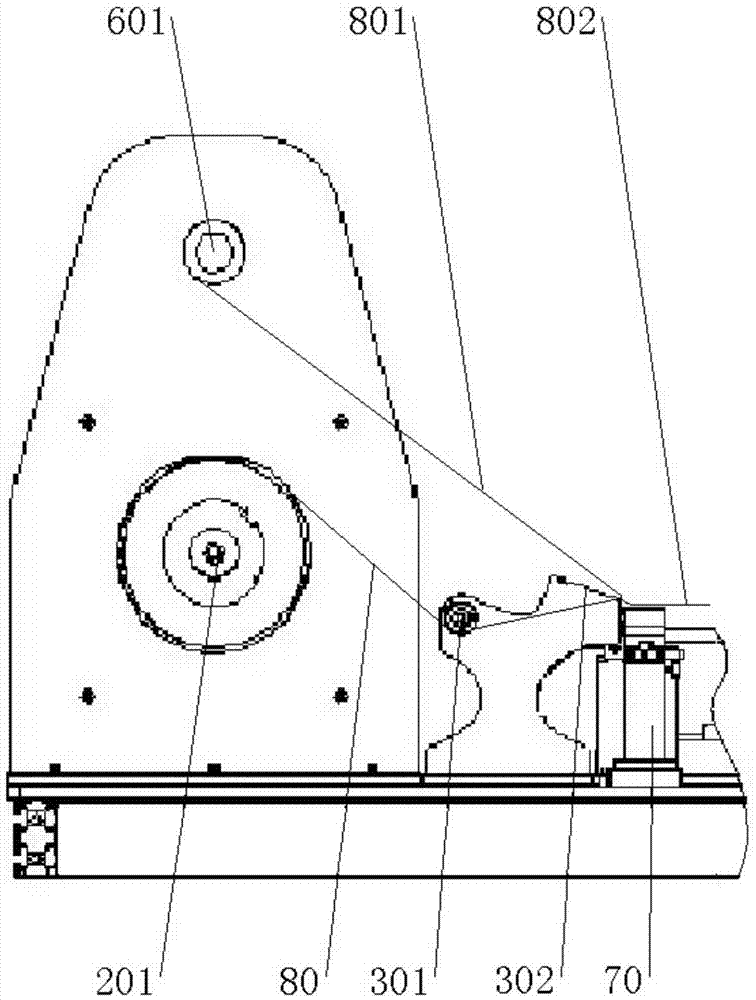

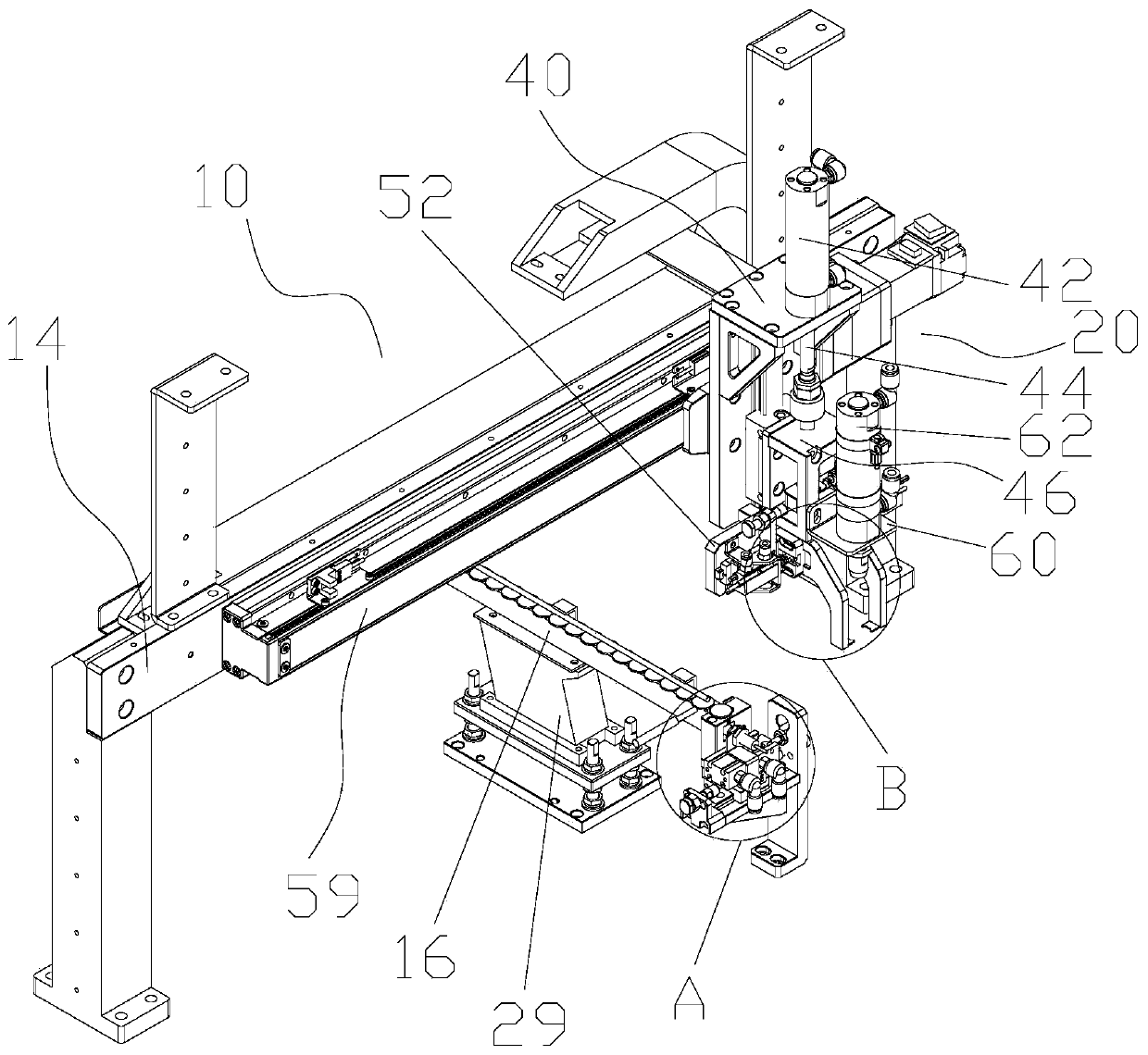

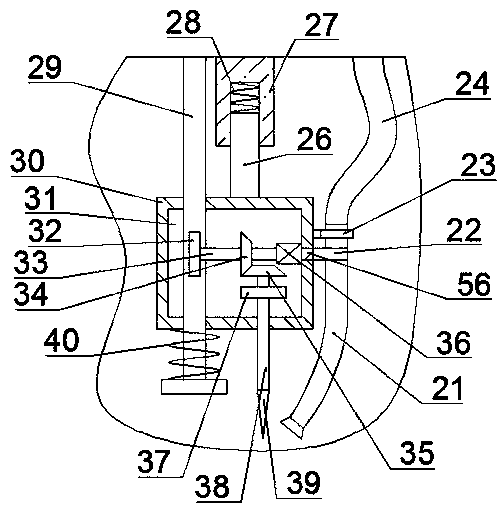

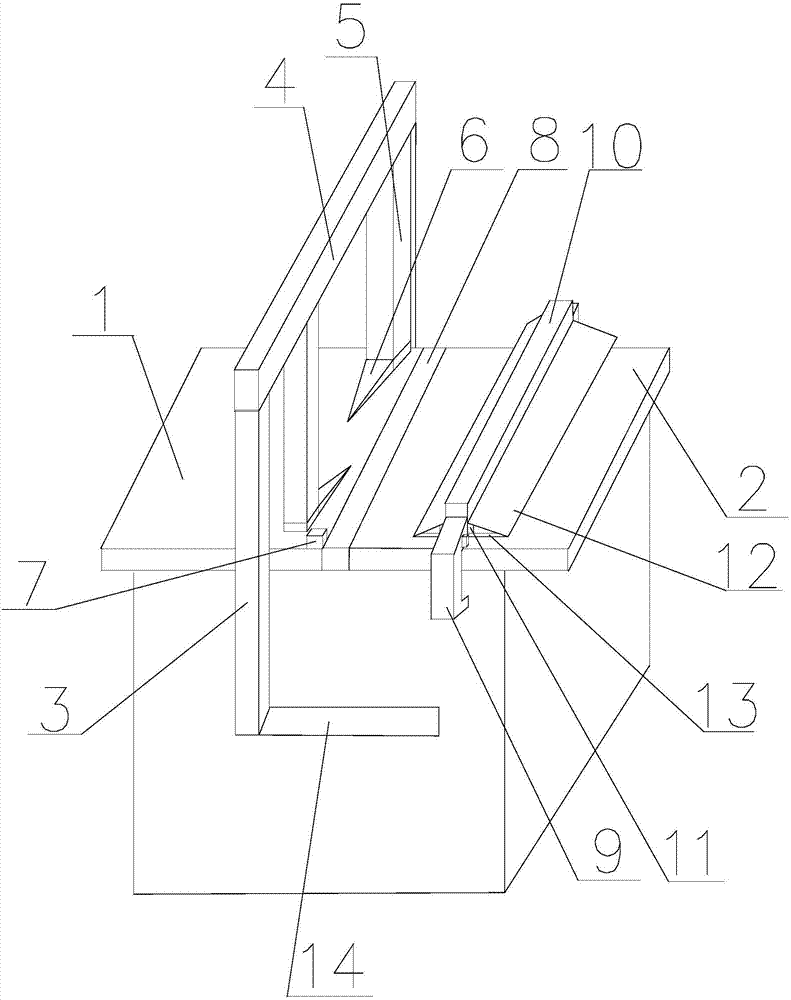

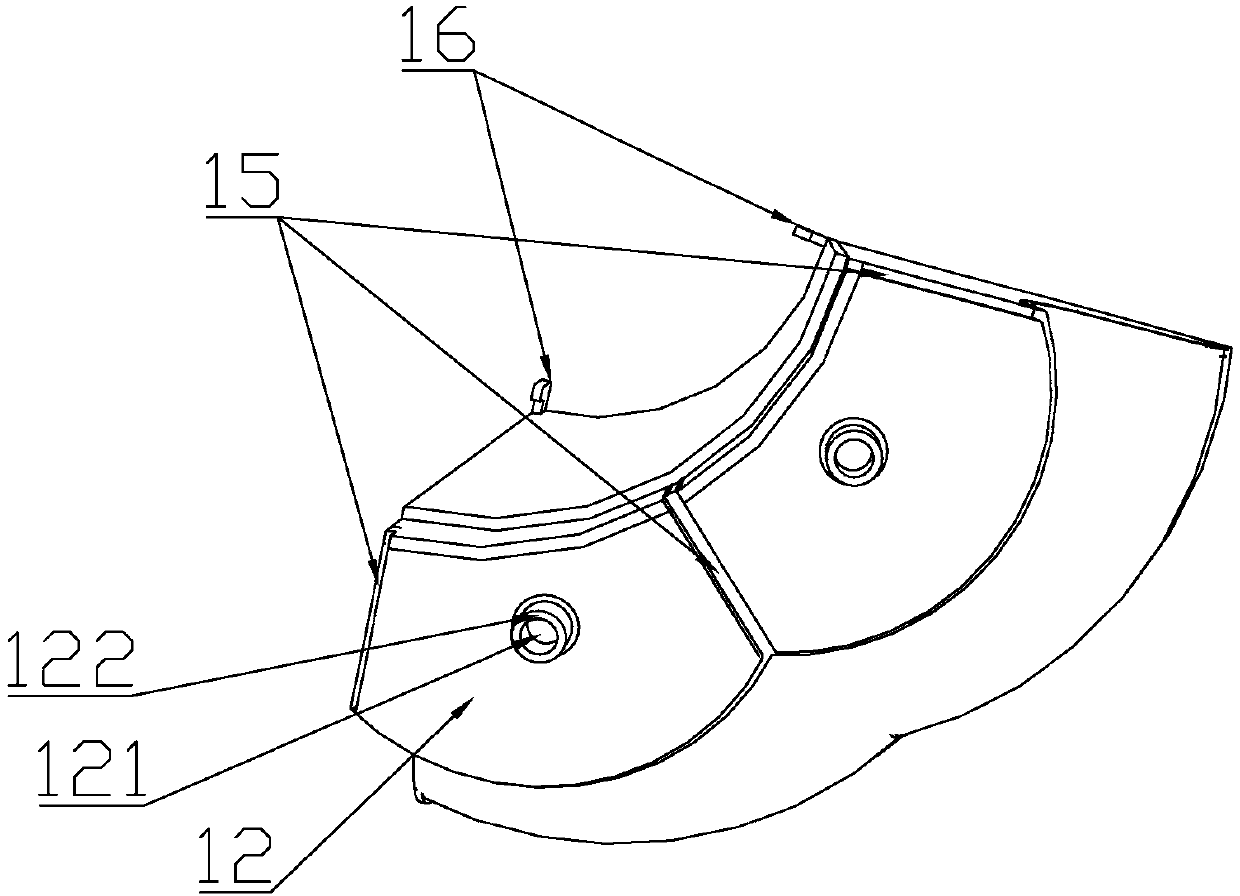

Tape discharging mechanism and tape attaching device

InactiveCN105437725AFix damageAvoid serious wasteLamination ancillary operationsLaminationTectorial membraneAdhesive belt

The invention provides a tape discharging mechanism and a tape attaching device, which belong to the technical field of displays, and can solve the problem that the efficiency is low and the cost is high due to the fact that the tape is manually cut and attached to assemble backlight products in the prior art. The tape discharging mechanism comprises a coil stock tape discharging unit and a protective film stripping unit, wherein the coil stock tape discharging unit comprises a discharge air swelling shaft used for rotationally transporting the coil stock tape; the protective film stripping unit is arranged at the rear opposite to the coil stock tape discharging unit, is used for stripping the protective film from the tape, and transporting the tape. The tape discharging mechanism realizes an automatic discharging and stripping process of the coil stock tape, and the problems of low operation efficiency and high cost due to manual operation are solved. The tape attaching device comprises a manipulator and the tape discharging mechanism, can further complete a process of automatic tape attaching, the efficiency and precision of attaching are further improved, and the cost is reduced.

Owner:BOE OPTICAL SCI & TECH +1

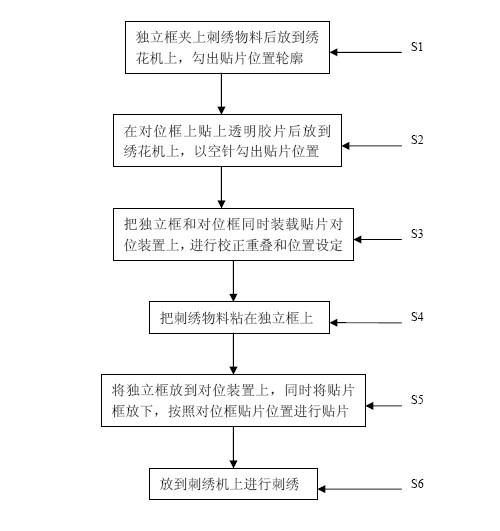

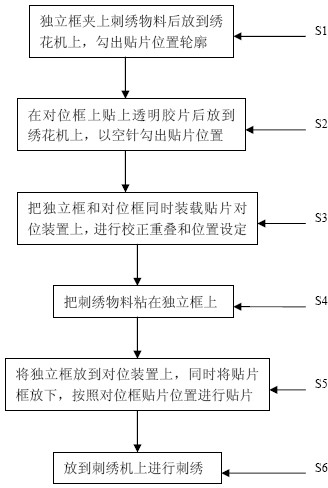

Counterpoint method of applique embroidery surface mounting

ActiveCN102182025ABeautiful appearanceSolve the disadvantages of misalignmentAutomatic machinesSurface mountingEngineering

The invention discloses a counterpoint method of applique embroidery surface mounting. By the method, the defect that the surface mounting counterpoint for multiple times is irregular is overcome. A surface mounting process is convenient to operate, quick, precise, simple in operation, practical and reliable. The operation flow comprises the following steps of: firstly, clamping an embroidery material on an independent embroidery frame, placing the embroidery frame on an embroidery machine, and embroidering the outlines of the embroidery material and a placing position of surface mounting through weaving with a single needle; secondly, sticking a transparent adhesive sheet on a counterpoint frame of a counterpoint device, correcting and superposing the embroidering independent embroidery frame and the surface mounting position of the surface mounting counterpoint frame, and setting the position; and finally, sticking the material required to be embroidered onto the independent embroidery frame, sticking surface mounting sheets onto the material required to be embroidered according to the surface mounting position of the counterpoint frame, and placing the independent embroidery frame on the embroidery machine to embroider. The whole pattern can be embroidered at one time, so the counterpoint time of surface mounting is reduced, the production efficiency of the embroidery machine is improved, mass production can be realized, and the manufacturing cost of applique embroidered clothes is greatly reduced.

Owner:HUI ZHOU SHENTIAN PRECISION MACHINES

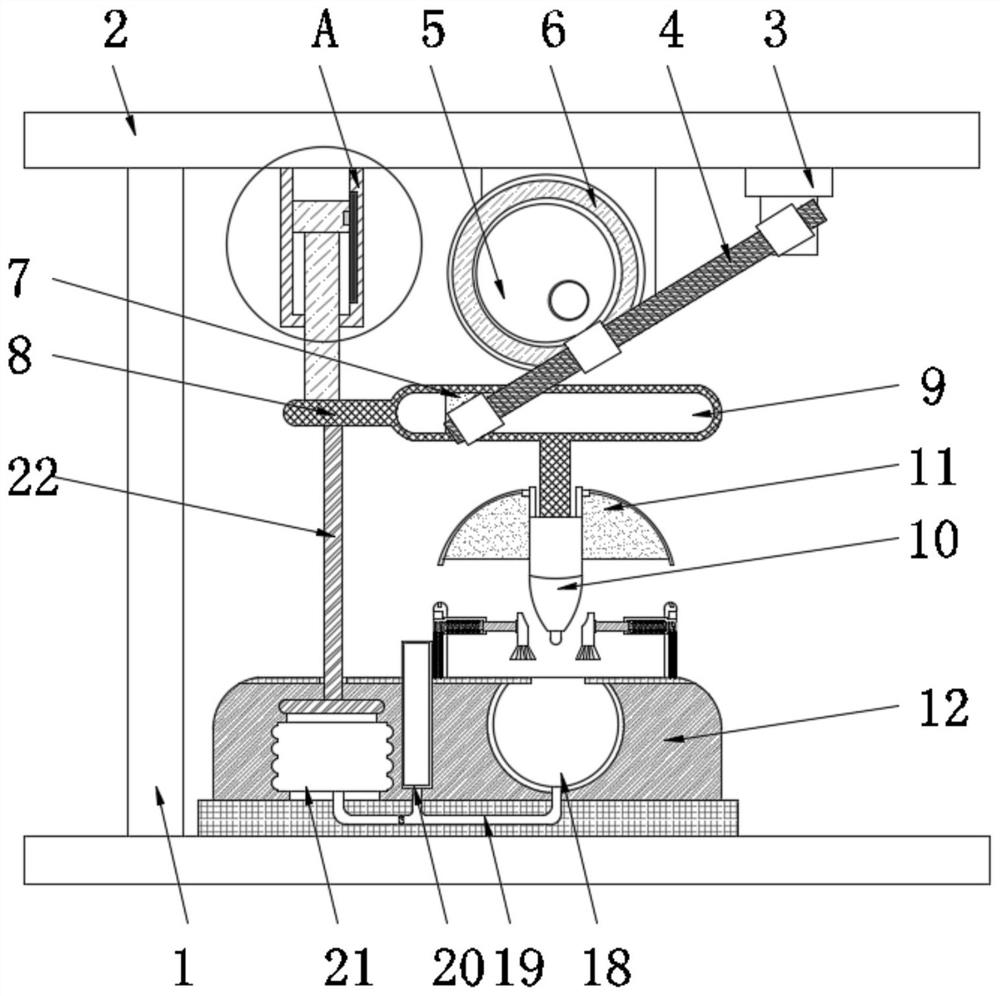

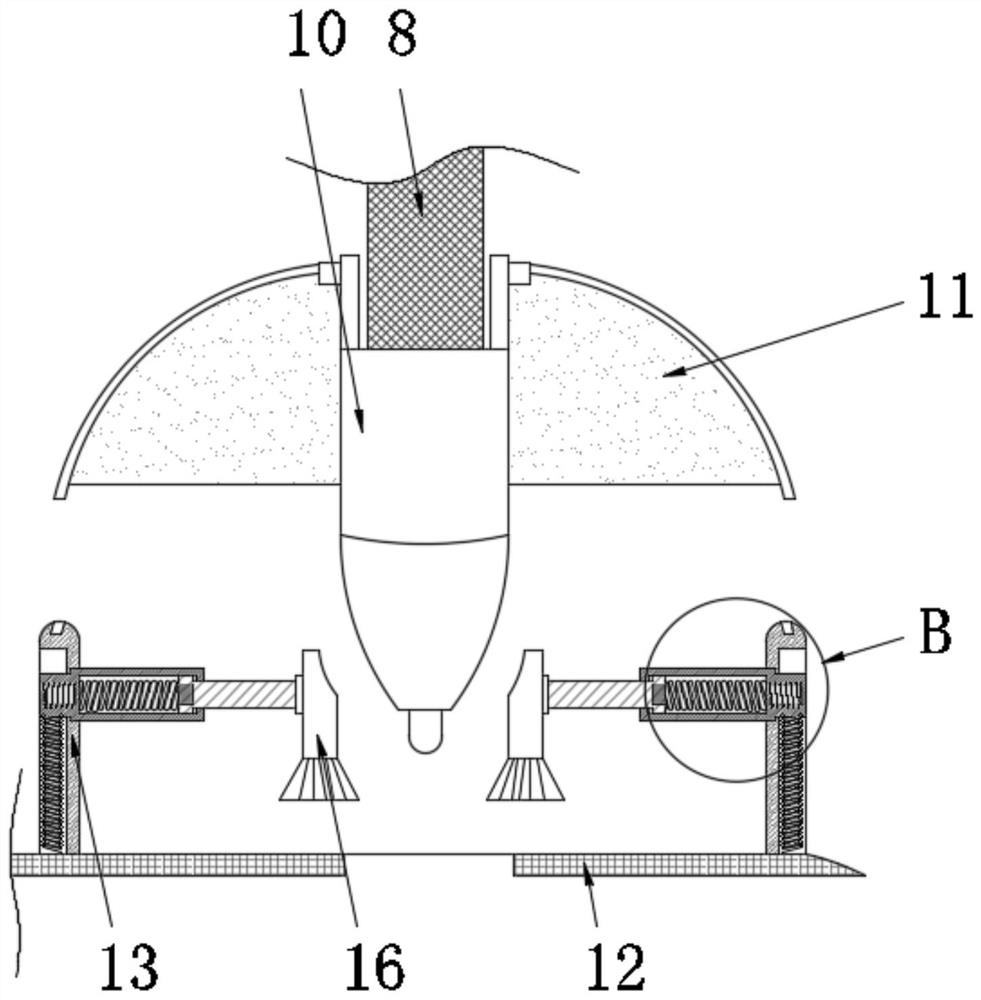

Automatic surface cleaning and protecting device for drilled hardware fittings

InactiveCN112008119AImprove drilling efficiencyImprove stabilityFeeding apparatusBoring/drilling componentsComputer hardwareSurface cleaning

Owner:广州一纪电子商务有限公司

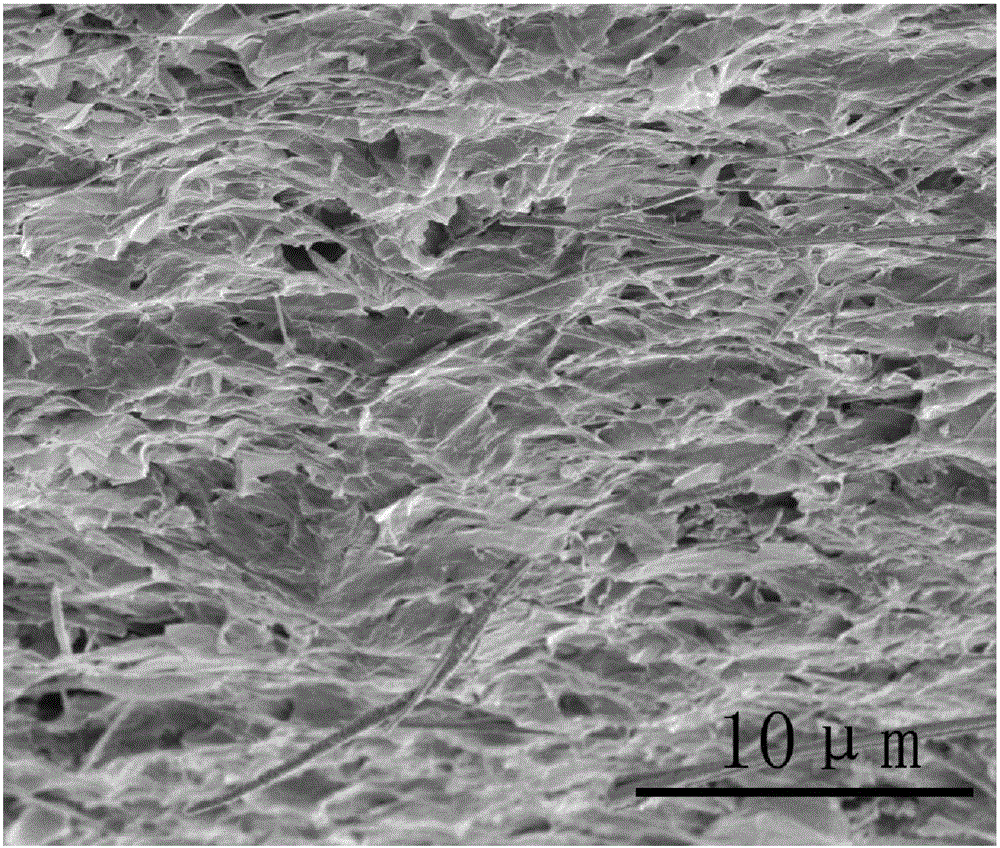

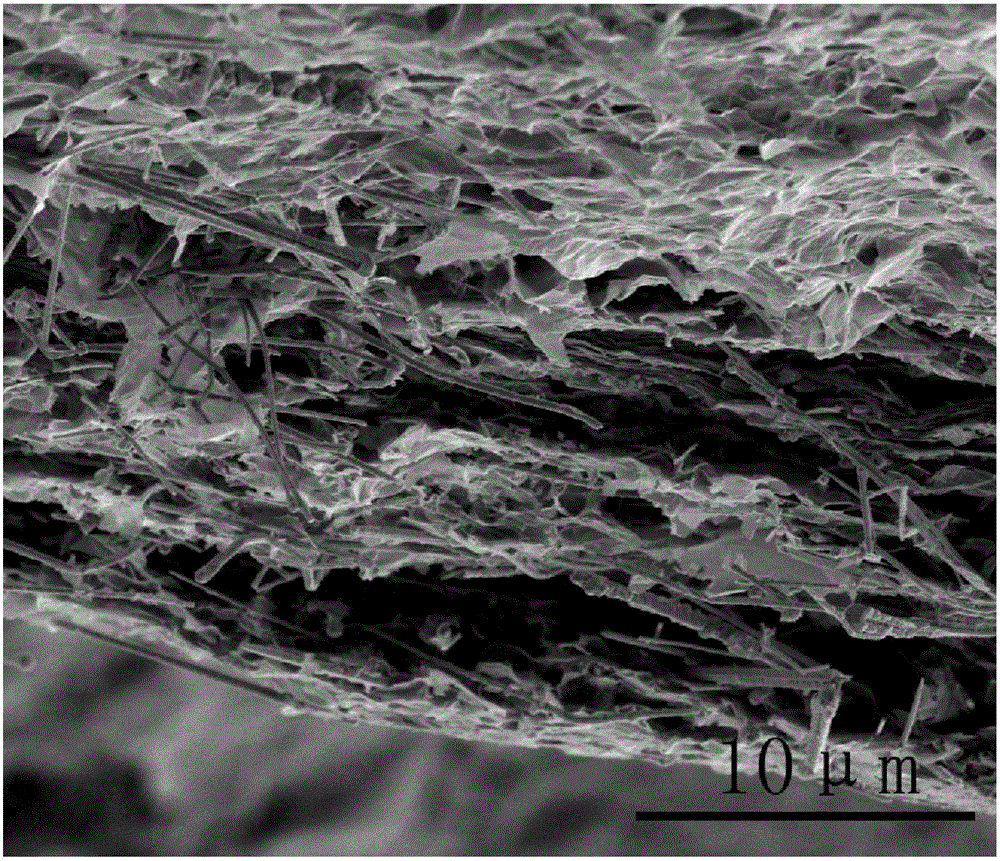

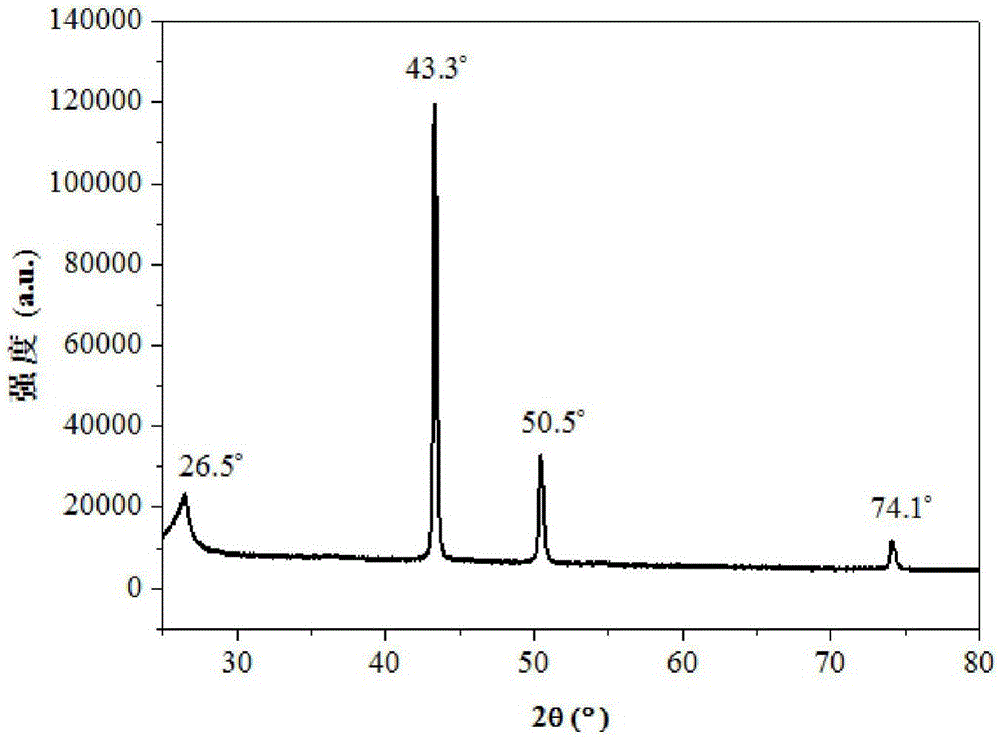

Copper nanowire/graphene composite material and preparation method and application thereof

InactiveCN106710890AConductivity limitImprove antioxidant capacityMaterial nanotechnologyHybrid capacitor electrodesRoom temperatureCvd graphene

The invention relates to a preparation method of copper nanowire / graphene composite material. The preparation method comprises the following steps that (1) a copper nanowire and graphene are dispersed in deionized water so as to obtain mixed dispersion liquid, wherein the average sheet thickness of graphene is 0.5-5nm; and (2) the mixed dispersion liquid obtained in the step (1) is filtered and then a filter cake is dried so as to obtain the copper nanowire / graphene composite material. The preparation method is simple and efficient, convenient and rapid in experimental flow, simple in process, moderate in condition and high in universality. Compared with the method of reduction of graphene oxide in the prior art, reduction of the graphene oxide is not required so that the limitation of conductivity of the composite material by using binders can be avoided, the electric conductivity of the prepared copper nanowire / graphene composite material can be more than 5x103S / m, the composite material also has great oxidation resistance, and the electric conductivity can still be maintained for over 90% of the initial electric conductivity after the composite material is arranged in room temperature for 60 days.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

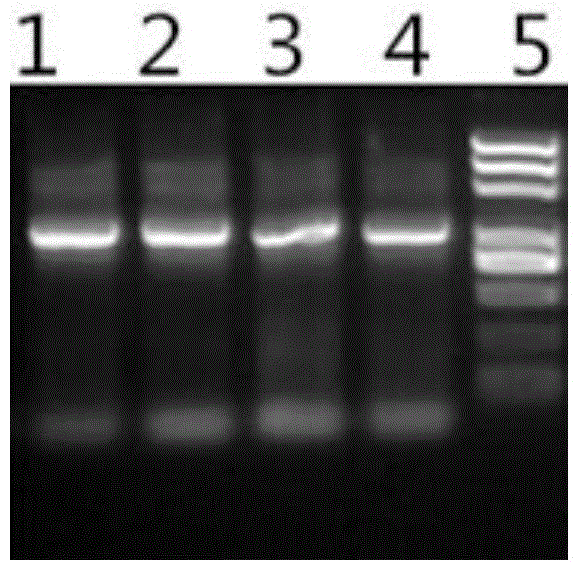

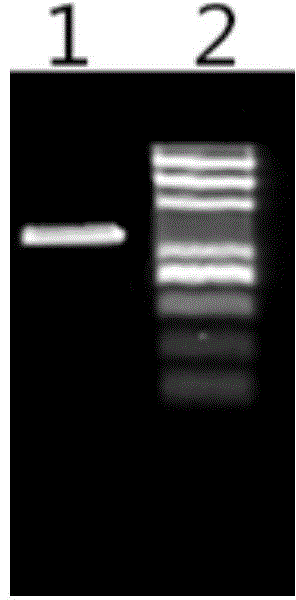

Method for purifying non-specific amplification PCR product based on paramagnetic particle method

InactiveCN104560954AConvenient processFast purificationDNA preparationNon specificParamagnetic particles

The invention discloses a method for purifying a non-specific amplification PCR product based on a paramagnetic particle method. The method comprises the following steps: detecting a PCR product by using agarose gel, when observing that a non-specific strip is separated from a target strip, cutting off the target strip by using a knife, and purifying the non-specific amplification PCR product by using the paramagnetic particle method. The method has the significant advantages that the operation is automatic and the whole process is simple and rapid, and compared with an ordinary purification method, the method is relatively convenient and rapid, and no large-size machine such as a centrifuge is needed in the method, so that relevant study of molecular biology can be relatively well implemented in small-size laboratories.

Owner:FUJIAN NORMAL UNIV

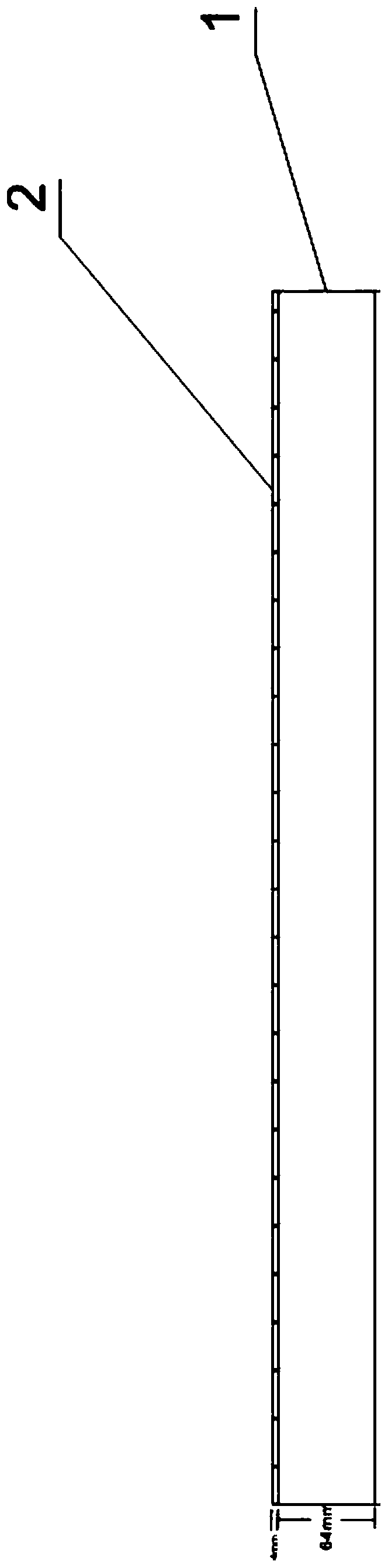

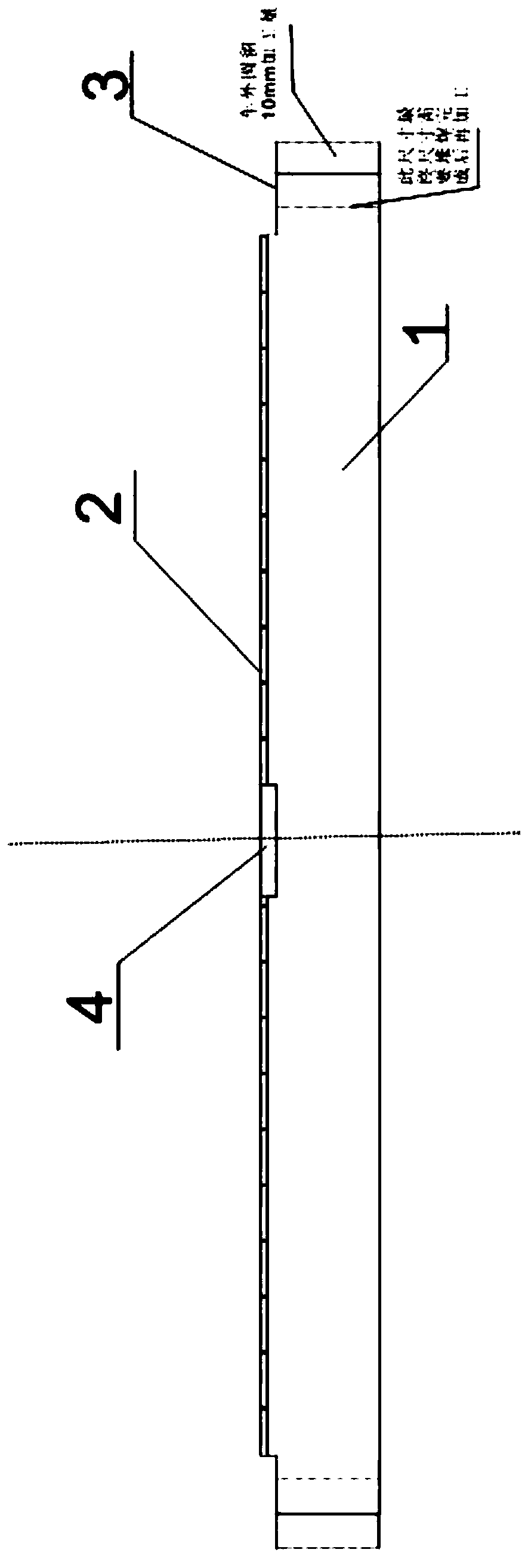

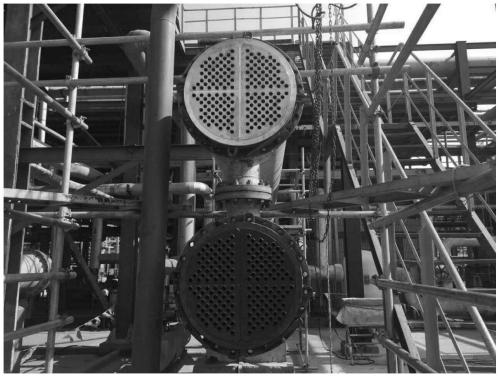

Welding technology of high-purity ferrite stainless steel heat exchanger

ActiveCN111390339AAvoid processing difficultyLow costTesting metalsWelding/soldering/cutting articlesForgeWelding process

The invention provides a welding technology of a high-purity ferrite stainless steel heat exchanger. The technology comprises two steps including overlaying welding of a tube plate and welding of thetube plate and a heat exchange tube, wherein the tube plate comprises a tube plate basic layer and a tube plate multiple layer; the tube plate basic layer is 64 mm thick and made of 16MnIII; the tubeplate multiple layer is S11972 with the thickness of 4 mm; a processing amount of 10 mm is preserved at an outer circular diameter is roughly lathed on a whole forge piece; a seal face is lathed on the tube plate multiple layer to a to-be-overlaid surface, and a baffle groove is dug to the to-be-overlaid surface; then, overlaying welding of nickel base alloy ENiCrMo-3 is conducted on the to-be-overlaid surface, and the heat exchange tube is made of an S11972 material; and during welding of the tube plate and the heat exchange tube, a welding joint is connected through strength welding and pasting expansion, welding is conducted on two layers, self-fluxing is conducted for the first time, and welding wires are added on the second layer. The welding technology provided by the invention has the beneficial effects that the feasible welding technology of the high-purity ferrite stainless steel heat exchanger is formulated, and layering welding of the tube plate, and welding of the tube plate and the heat exchange tube are successfully carried out, so that defects such as hot cracks, inter-granular corrosion and multilayer damage during welding are solved, and product quality is good after welding.

Owner:TIANJIN JINBIN PETROCHEM EQUIP

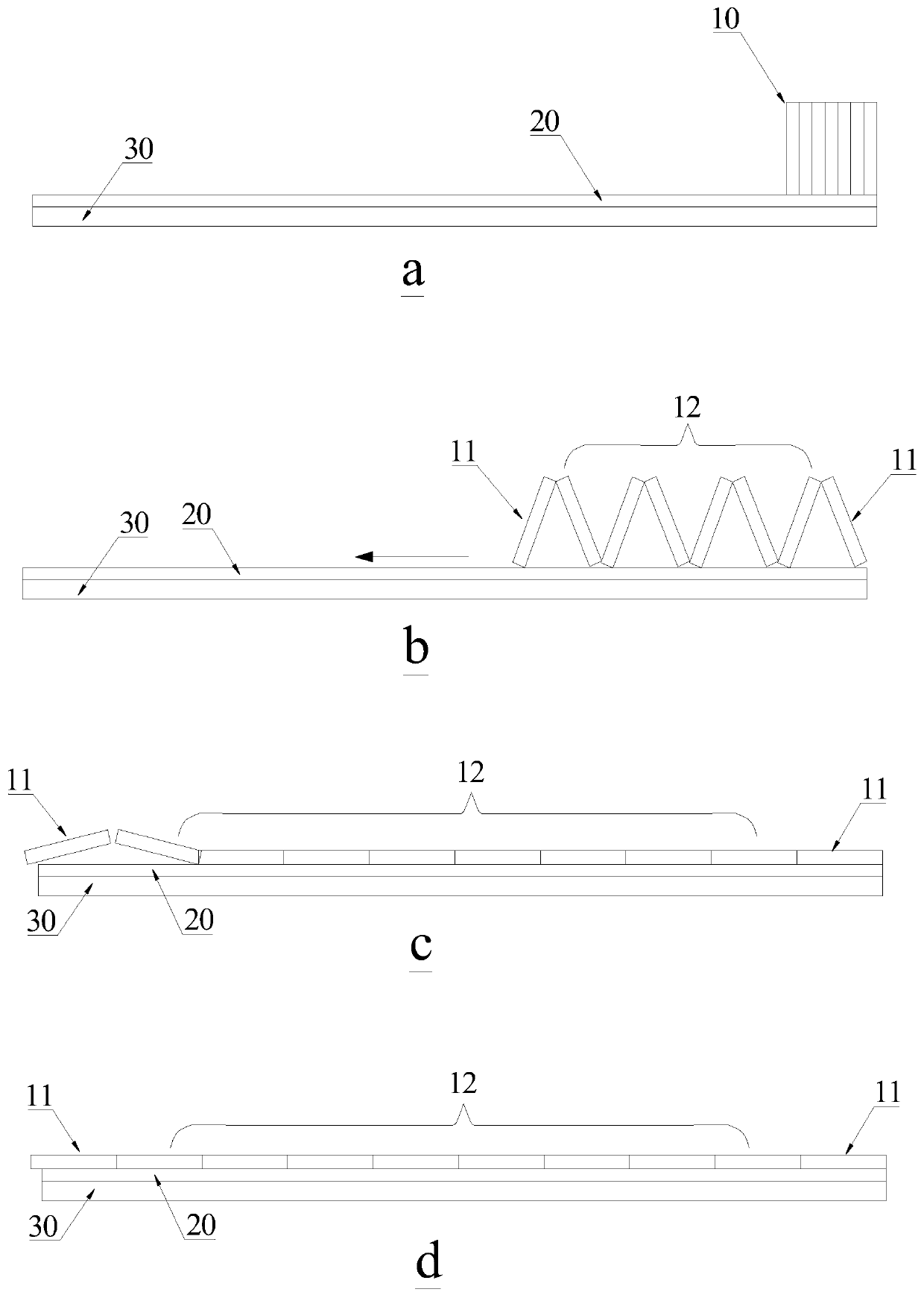

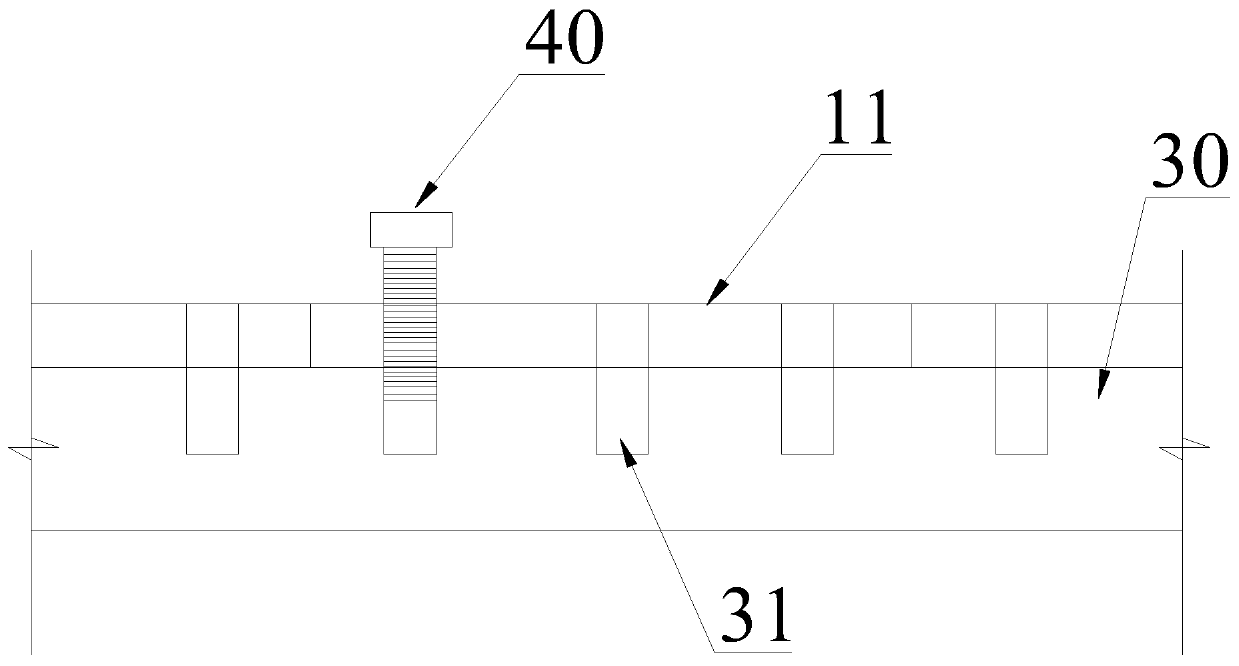

Roof panel assembly and construction method thereof

PendingCN110670782AFast construction and installationReduce in quantityBuilding roofsArchitectural engineeringStructural engineering

The invention discloses a roof panel assembly and a construction method thereof. The roof panel assembly comprises a plurality of single roof panels; the roof panels comprise the first roof panels andthe second roof panel, the first roof panels are roof panels at the two ends of the roof panel assembly, and the second roof panel is a roof panel at the middle part of the roof panel assembly; and one end of each first roof panel is rotatably connected with the end of the adjacent roof panel, and the two ends of the second roof panel are rotatably connected with the ends of the adjacent roof panels. The construction method comprises the steps of assembling, slide rail installation, hoisting, paving and fixing. The roof panel assembly can be conveyed to the roof through one-time hoisting, andthe hoisting cost is saved; and in addition, installation and construction of the roof panel can be quickly completed, the procedure is simple, time-saving and convenient, the construction time and manpower are greatly saved, the construction difficulty is reduced, the number of needed constructors is greatly reduced, and potential safety hazards existing in aerial work are avoided.

Owner:GUANGZHOU JISHI CONSTR GRP

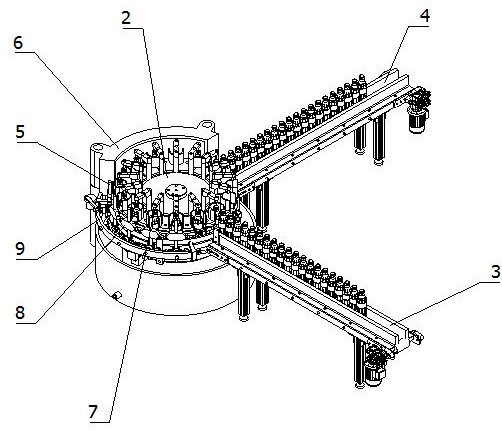

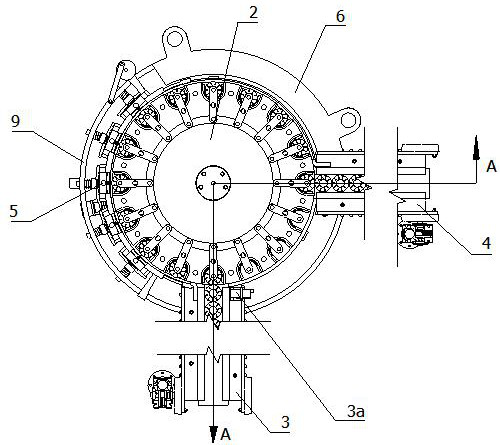

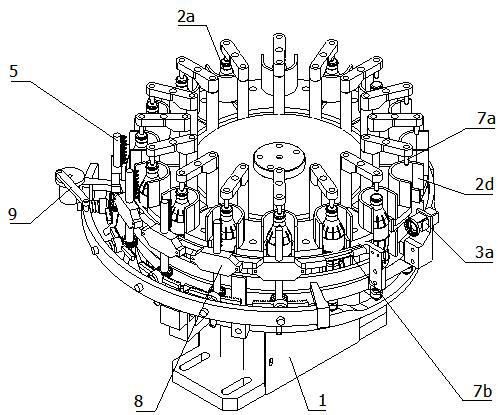

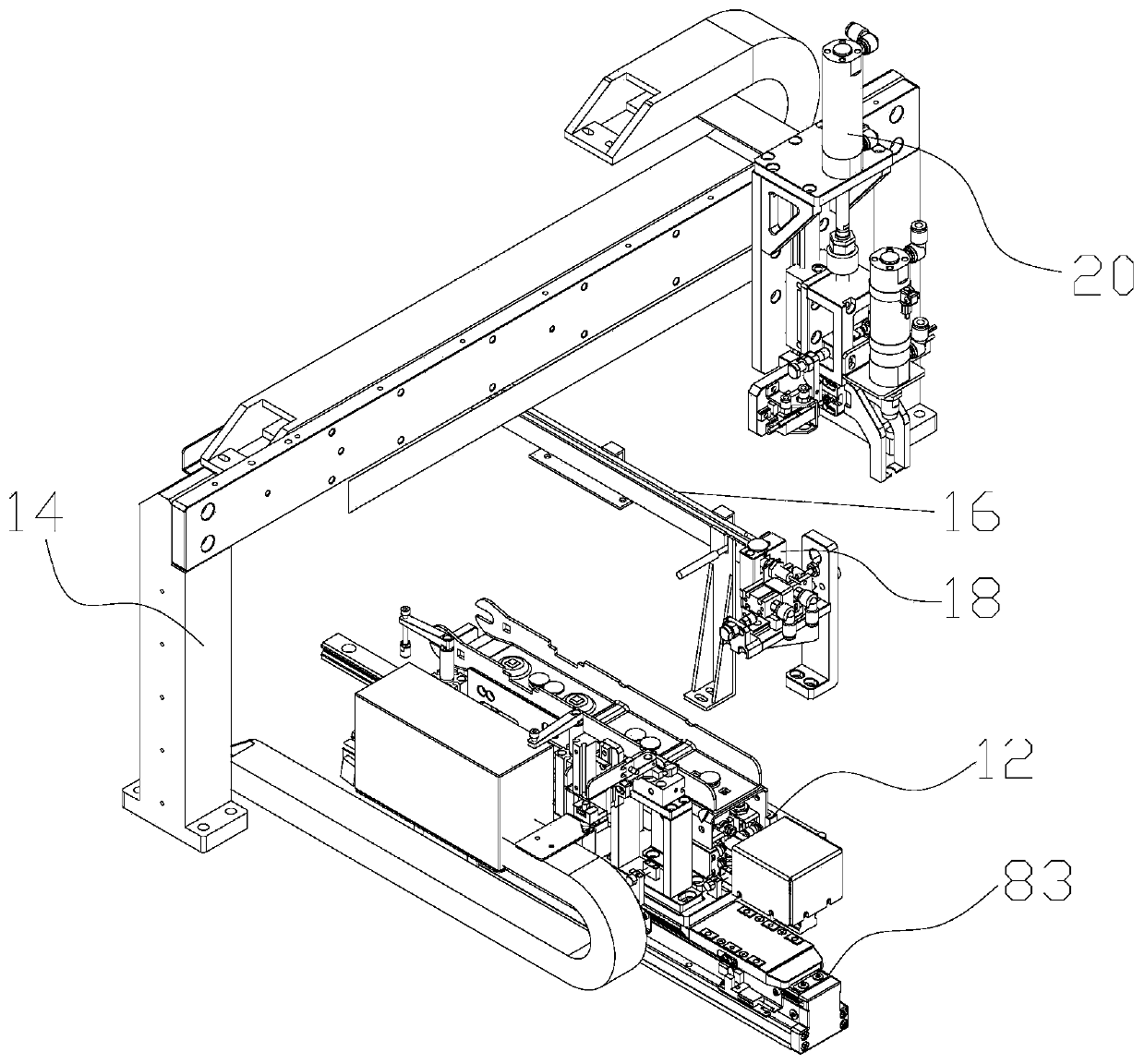

Device for cleaning bottled beverage after filling

ActiveCN114655912AImplement auto-rotationEnsure complete cleaningSynchronising machinesHollow article cleaningEngineeringBottle

The invention relates to the field of food, in particular to a device for cleaning bottled drinks after filling, which comprises a workbench, a transfer disc is arranged on the workbench, a feeding conveyor and a discharging conveyor are arranged beside the transfer disc, a plurality of bayonets are uniformly formed in the edge of the transfer disc along the circumferential direction, and the bayonets are arranged on the periphery of the transfer disc. A supporting table is further arranged below the transfer disc, a plurality of water spraying pieces and a drying box are arranged between the feeding conveyor and the discharging conveyor, an electric push rod is further arranged on the workbench, the auxiliary cleaning device comprises a plurality of shaft top suspension mechanisms and an auxiliary rotation mechanism, the shaft top suspension mechanisms are arranged on the supporting table, and the auxiliary rotation mechanism is arranged between the shaft top suspension mechanisms and the auxiliary rotation mechanism. According to the beverage bottle cleaning device, through cooperation of the shaft top suspension mechanism and the auxiliary rotation mechanism, it is guaranteed that the surfaces of beverage bottles are completely cleaned, the cleaning effect is improved, and the subsequent procedure of labeling the surfaces of the beverage bottles is facilitated.

Owner:南通迈克包装科技有限公司

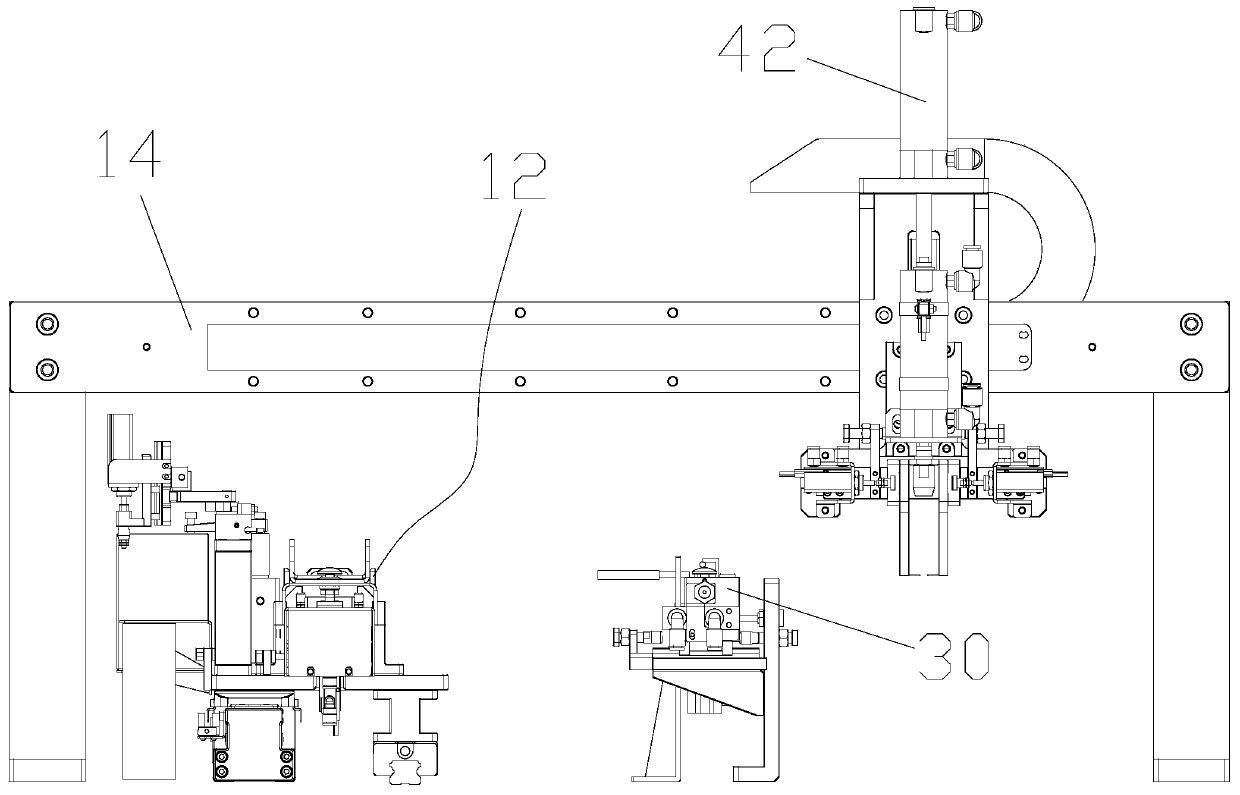

Automatic feeding and positioning mechanism for special-shaped bolt

PendingCN110576304ARealize automatic feeding processAchieve positioningMetal working apparatusButt jointEngineering

The invention relates to an automatic feeding and positioning mechanism for a special-shaped bolt. The mechanism comprises a feeding mechanism and a positioning mechanism, the feeding mechanism comprises a rack, a conveying mechanism and a taking mechanism installed on the rack, the conveying mechanism comprises a material guide strip and a profiling jig in butt joint with a discharging port of the material guide strip, and the taking mechanism comprises a driving mechanism and a taking assembly installed on the driving mechanism; the positioning mechanism comprises a baseplate and a limit mechanism installed on the baseplate, the limit mechanism is used for containing a product, and the driving mechanism drives the taking assembly to move the special-shaped bolt in the profiling jig intothe product. According to the automatic feeding and positioning mechanism, the processes of manual feeding, positioning and the like are replaced, by arranging the feeding mechanism and the positioning mechanism, the special-shaped bolt is automatically fed and positioned, the production efficiency is improved, the cost is lowered, positioning is stable, and convenience is provided for the following nut locking process.

Owner:JIANGSU BVM INTELLIGENT TECH

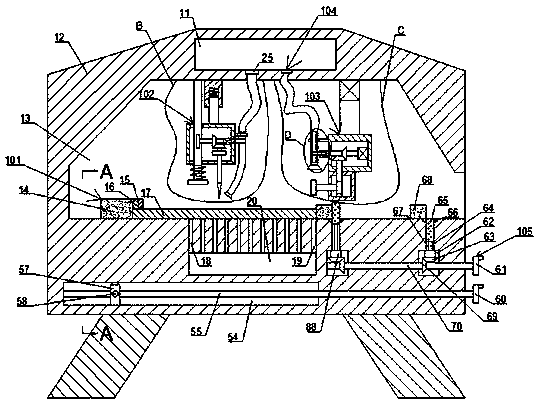

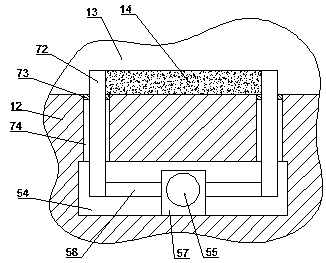

Adjustable water-based cutting device based on brittle materials

InactiveCN110238978AEasy to cutLow costWorking accessoriesStone-like material working toolsWater basedShortest distance

The invention discloses an adjustable water-based cutting device based on brittle materials. The device comprises a main body, wherein a working cavity is formed in the main machine body, a material plate can be placed on the bottom wall of the working cavity, the left side of the material plate is provided with a clamping mechanism which can enable the material plate to be clamped and slide rightwards, a positioning box is arranged on the upper side of the material plate, five rotating rods which are symmetrically arranged in a front and back mode are arranged on the bottom surface of the positioning box in a rotating mode, fine drills are fixedly arranged on the lower side surface of the rotating rods, and five small holes can be drilled in the top surface of the material plate through rotation and up-down short-distance vibration of the fine drills. The cost of cutting equipment of the brittle materials can be effectively reduced, on the basis that expensive laser positioning and laser cutting equipment is not used, only a water-based cutting mode is used, so that the materials can be prevented from being damaged during size cutting.

Owner:金华表征电子科技有限公司

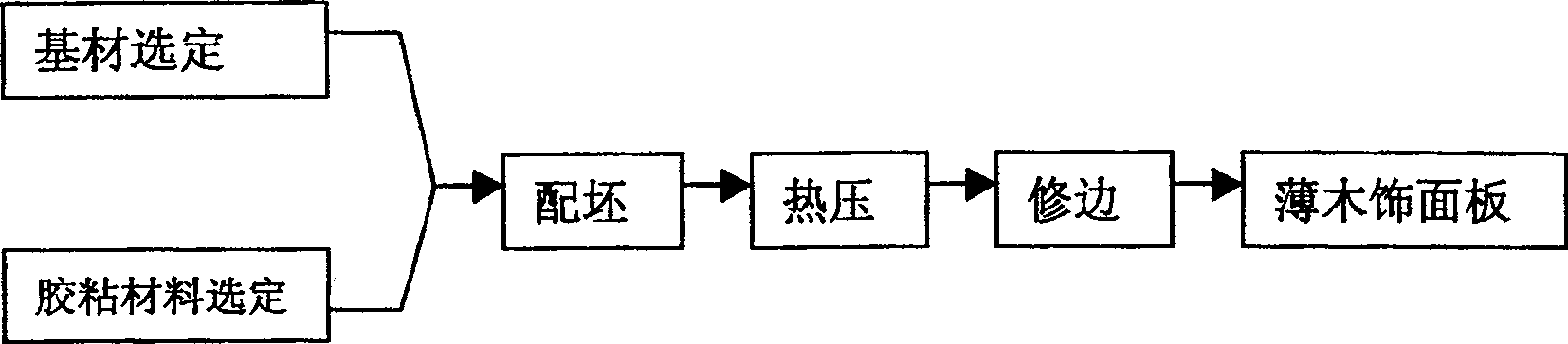

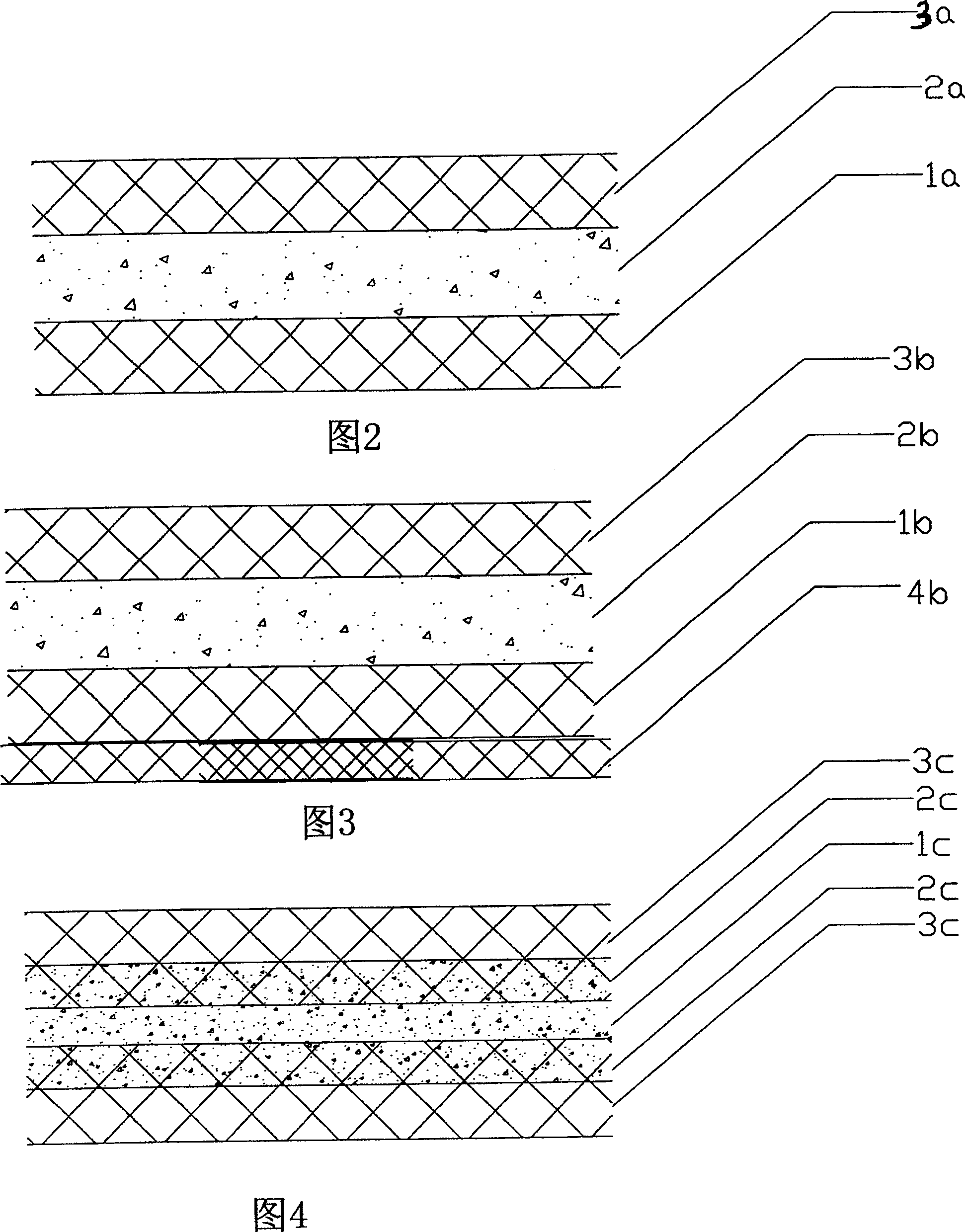

Solid elastomer coating-free veneer overlay technique

InactiveCN100537270CEasy accessLow priceThicknessing machinesOrnamental structuresElastomerFilm base

The invention discloses a process of dry glue-free veneer veneer, which includes the steps of selecting base material, selecting the adhesive material, preparing blanks, hot pressing and trimming. The step of selecting the base material includes selecting sanding Wood-based panels and thin veneers that have been properly spliced; wood-based panels require sanded density boards and particle boards suitable for veneering; among them, the adhesive material selected in the step of selecting adhesive materials is melamine film paper, the film The base paper of the film paper is impregnated and dried with melamine resin or melamine-modified urea-formaldehyde resin; the base paper of the film paper is made of α-cellulose pulp with high cellulose content; the blank preparation step is made into a slab; the slab It is formed by laminating film paper and veneer on at least one side of the wood-based panel in sequence; the hot pressing step sends the slab into the hot press for heating and pressing to complete the veneer veneer process; the trimming step is for the slab coming out of the hot press Proper trimming is the finished veneer veneer. It simplifies the process links, facilitates processing and has good environmental protection performance.

Owner:张青云

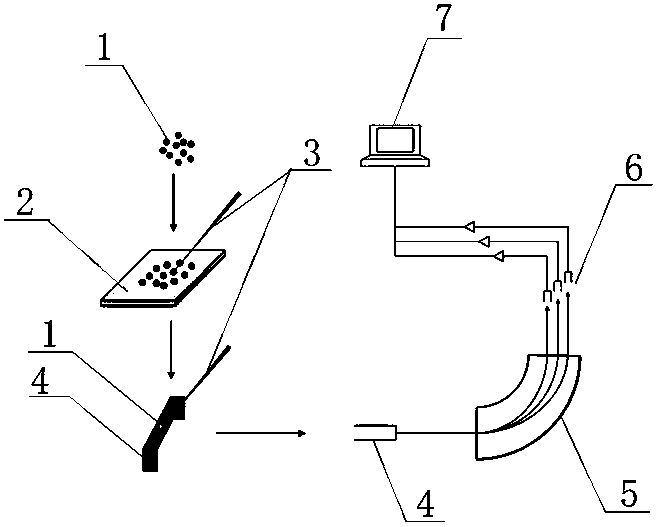

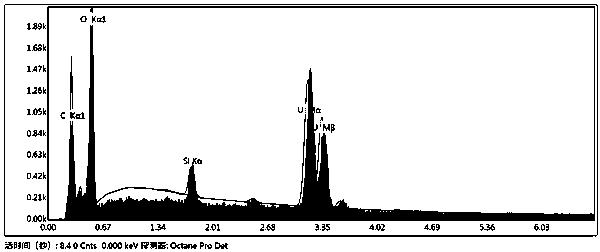

Method for measuring isotopic ratios of uranium-bearing particles by using FIB-TIMS

InactiveCN109342481AReduce preprocessing timeConvenient processMaterial analysis using wave/particle radiationMaterial analysis by electric/magnetic meansRheniumPretreatment method

The invention discloses a method for measuring isotopic ratios of uranium-bearing particles by using FIB-TIMS. Problems of complicated process, long consumed time, high probability of damages on samples, poor result accuracy and the like in the prior art are solved. The method for measuring the isotopic ratios of the uranium-bearing particles by using FIB-TIMS comprises the following steps: firstly, identifying and positioning the uranium-bearing particles by using SEM and EDS functions of a focused ion beam; secondly, controlling a tungsten needle to transfer the uranium-bearing particles toa rhenium filament by using a micro-operation arm of the focused ion beam; welding and fixing the uranium-bearing particles on the rhenium filament by using an ion beam deposition technology; and thirdly, measuring the isotopic ratios of the uranium-bearing particles by using thermal ionization mass spectrometry. The method for measuring the isotopic ratios of the uranium-bearing particles by using FIB-TIMS, disclosed by the invention, has the advantages that a solid sample of the rhenium filamenturanium-bearing particle can be directly analyzed by fixing an uranium-bearing particle sample onthe surface of the rhenium filament; a pretreatment method is simple, fast, stable and reliable; the sample utilization rate is high; reagent pollution and sample loss are avoided; the accuracy and precision of an analysis result are high; and the isotopic ratios, including 235U / 238U, 234U / 238U and 236U / 238U, of the uranium can be analyzed.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Novel conveying device with both paper folding and upwarp-preventing functions

ActiveCN106865327AAvoid liftingShorten the timeFolding thin materialsEngineeringMechanical engineering

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD

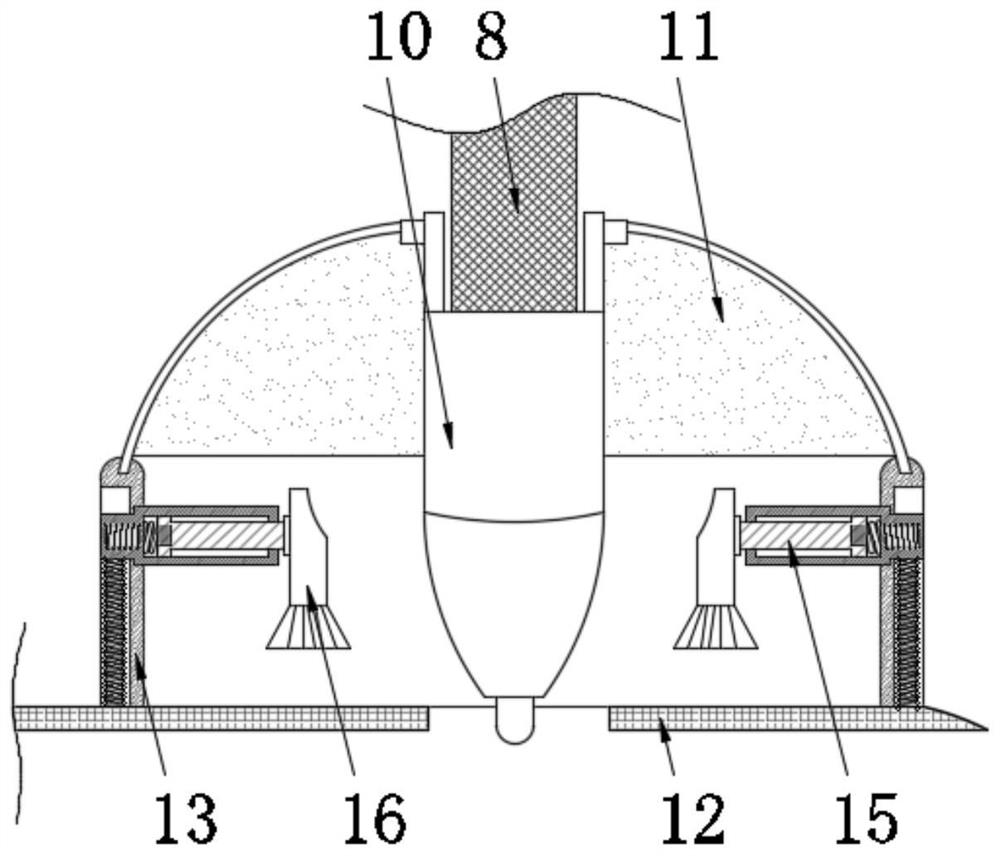

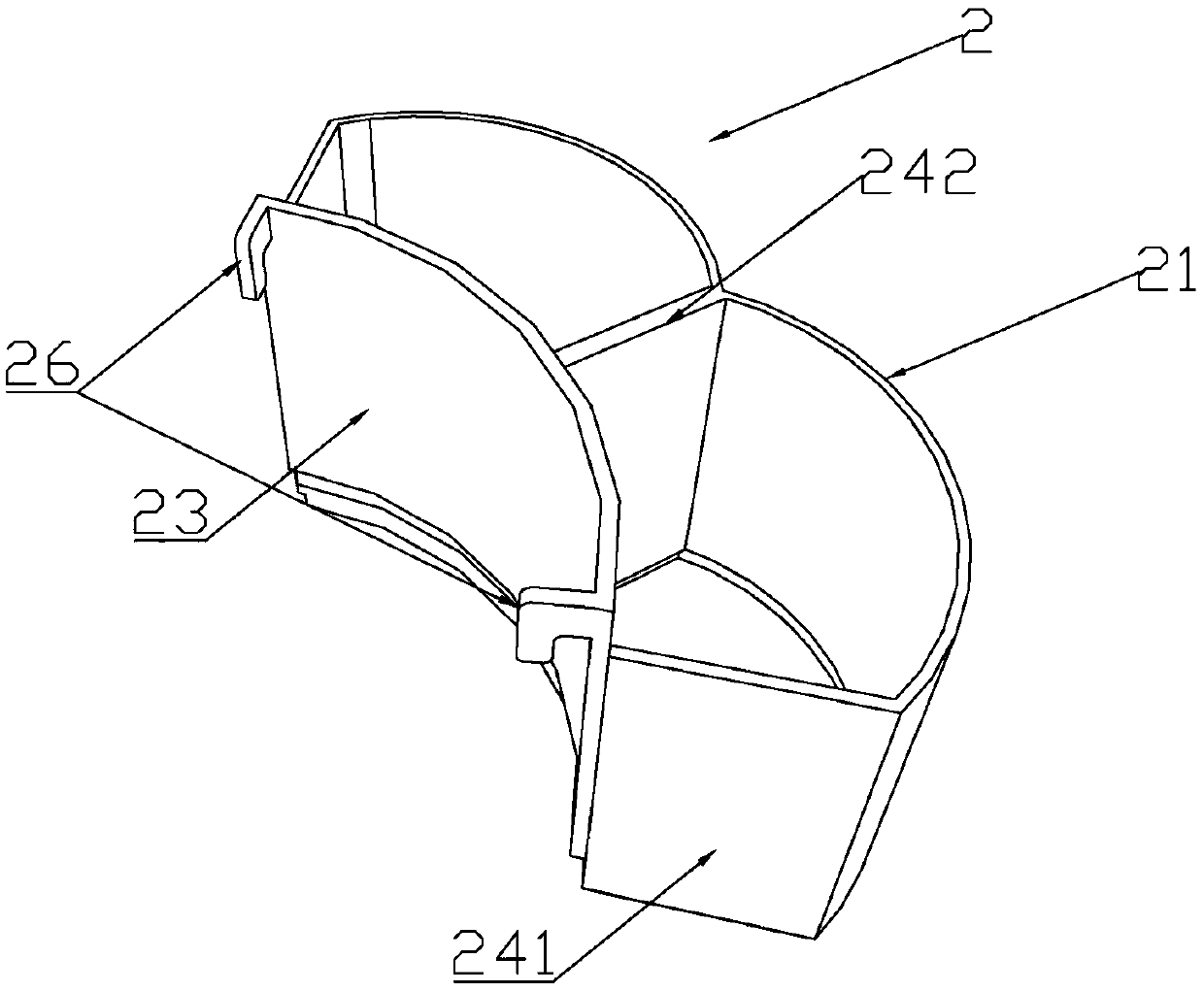

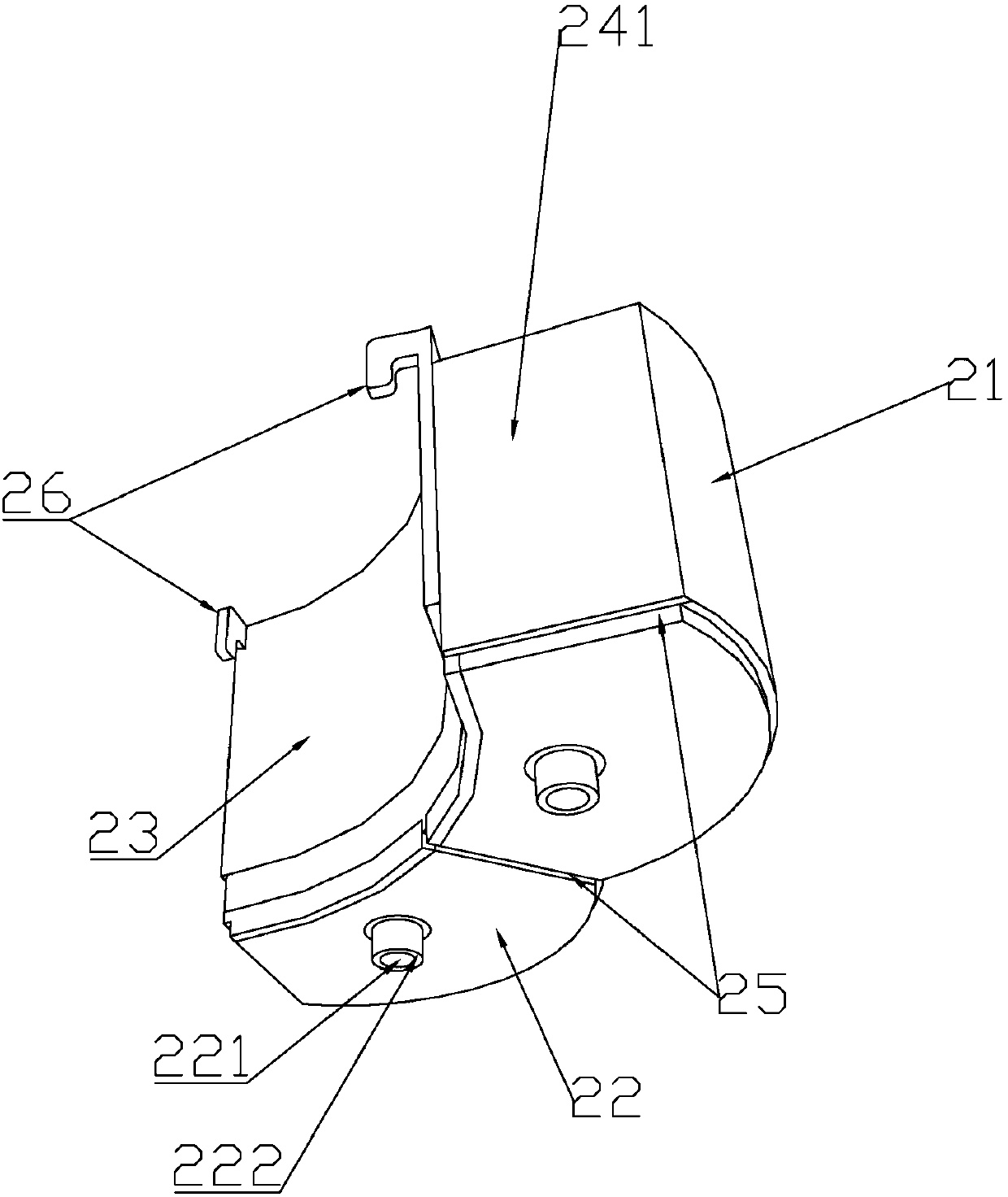

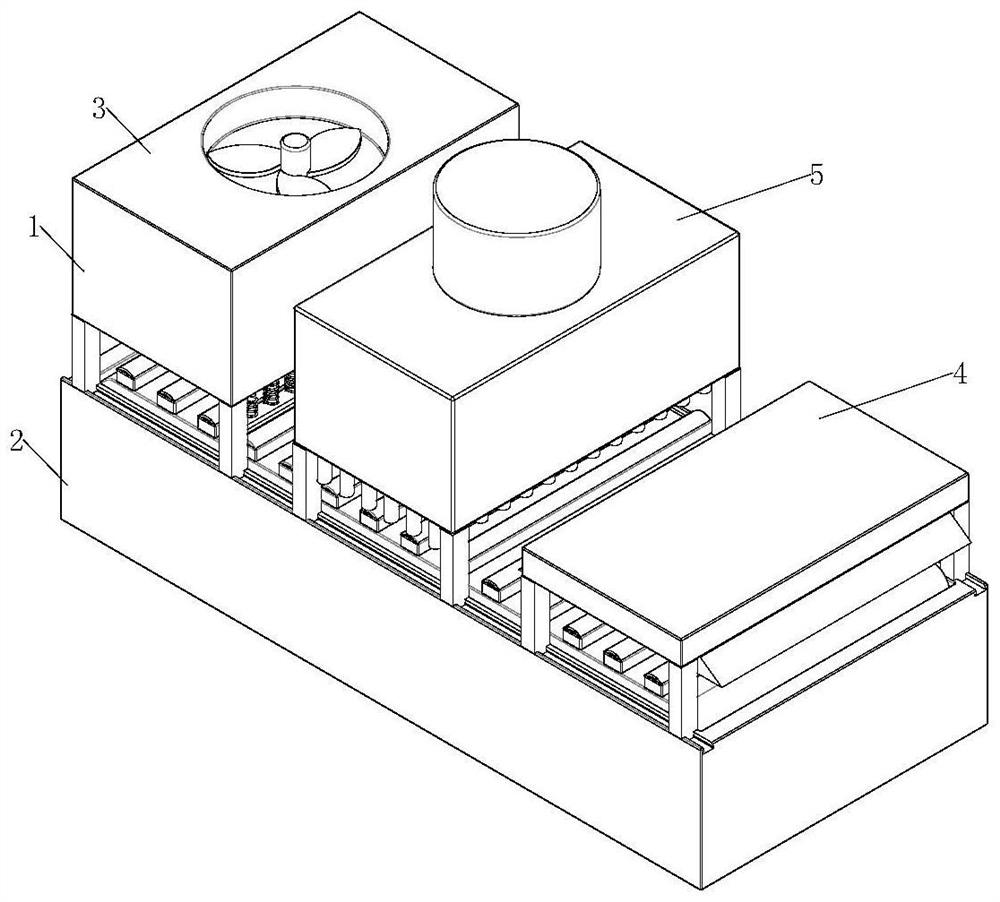

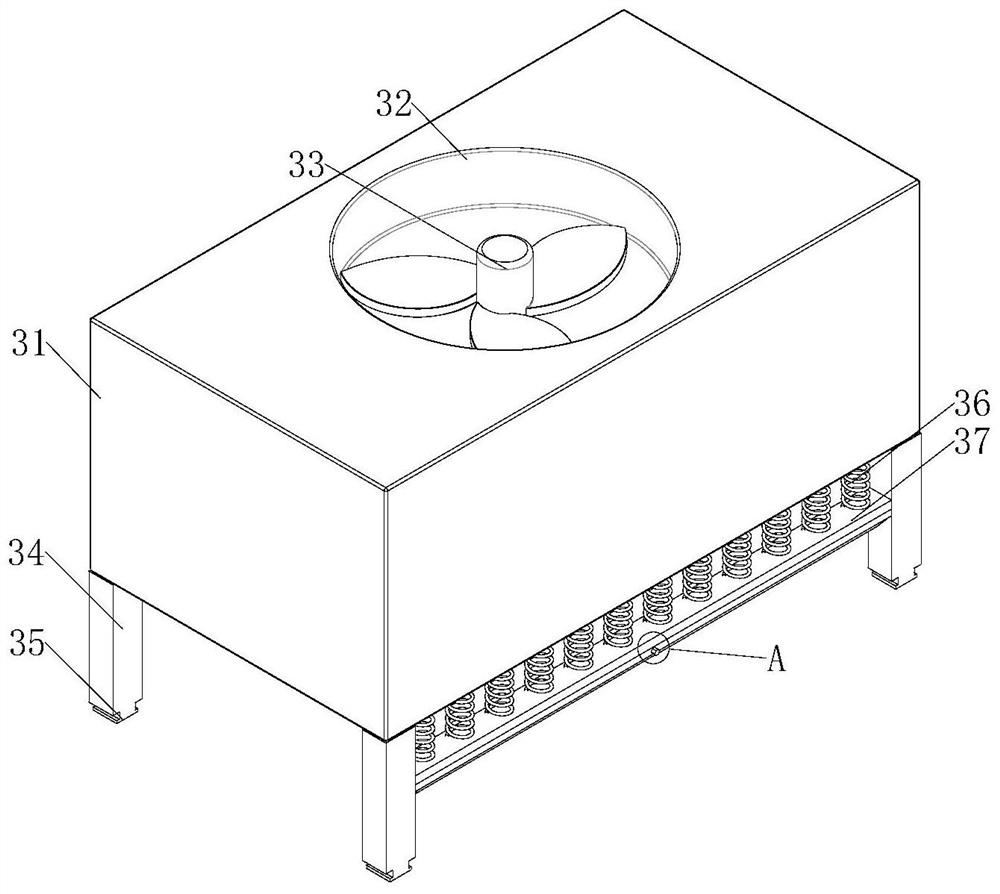

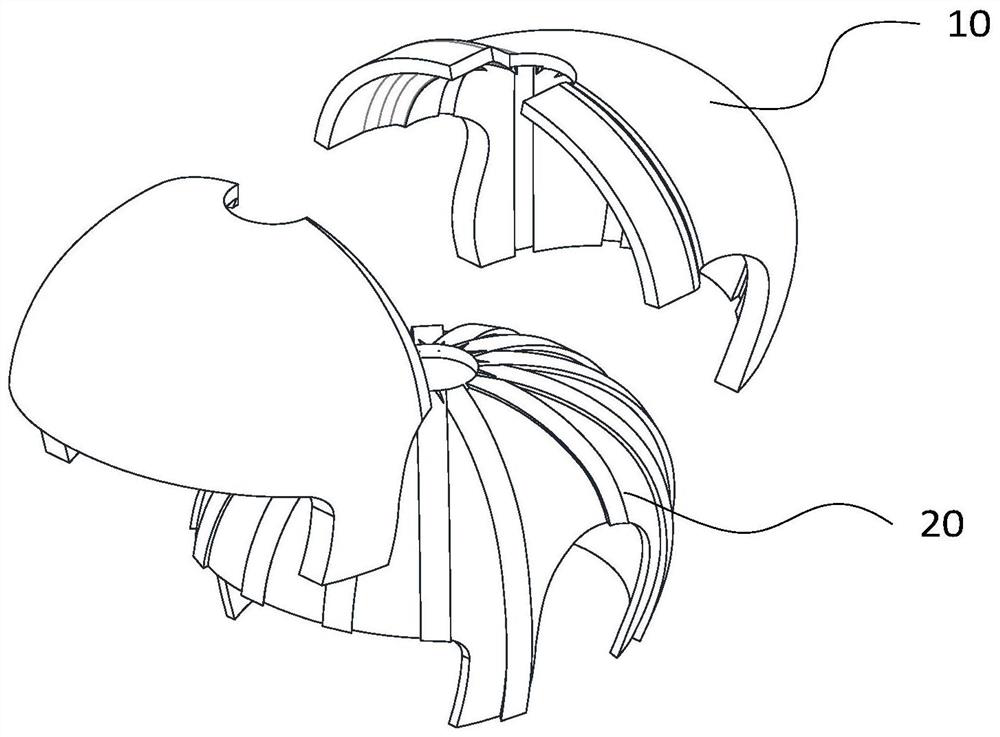

Combined type stereoscopic soilless culture equipment capable of being stacked

InactiveCN103120116AMeet the different needs of growing spaceMeet different needsAgriculture gas emission reductionCultivating equipmentsAgricultural engineeringMechanical engineering

The invention provides combined type stereoscopic soilless culture equipment capable of being stacked. The combined type stereoscopic soilless culture equipment capable of being stacked comprises a plant container unit which is provided with a bottom, an outer wall, an inner wall, a partition plate and a liquid drainage hole. The outer wall is an arc-shaped extension wall arranged on the outer side of the bottom. The inner wall is a vertical wall arranged on the inner side of the bottom. The partition plate is arranged between the inner wall and the outer wall. The lower end of the inner wall contracts in the direction close to the outer wall. The lower end of the outer wall contracts in the direction closes to the inner wall. A portion, close to the inner wall, of the upper end of the partition plate concaves downwards. A radial groove is formed in the bottom. The combined type stereoscopic soilless culture equipment capable of being stacked can be combined to various stereoscopic culturing models, can be installed and used by attaching on outer wall face, outer wall angle and inner wall angle of construction, and can be combined to a stereoscopic circular culturing column in an embracing mode by vertically dislocation stacking of the container, and especially can achieve random adjustment of lower gap (by arrangement of a connecting container) of the plant container, and thereby achieving green planting in various conditions and abundant and colorful plant landscape, and meeting various requirements of grow spaces of various plants.

Owner:北京绿东国创农业科技有限公司

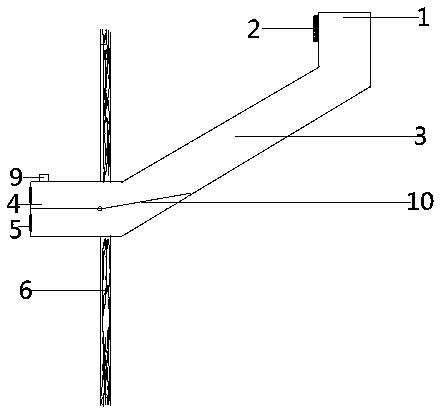

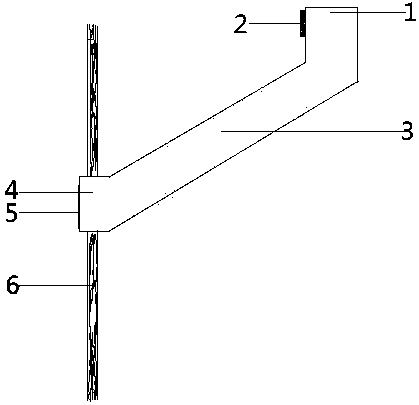

Unmanned aerial vehicle delivery receiving device

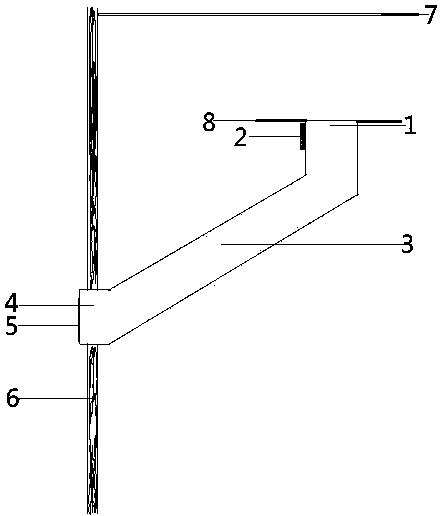

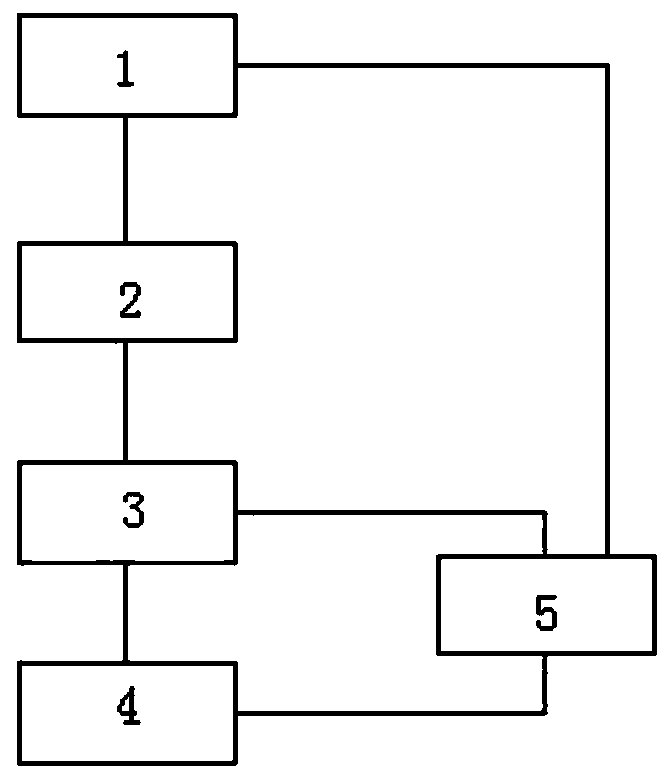

InactiveCN111196364AEnsure safetyShorten the timeFreight handlingLogistics managementUncrewed vehicle

The invention belongs to the field of unmanned aerial vehicle logistics and relates to an unmanned aerial vehicle delivery receiving device. According to the technical schemes of the invention, in thefigure 1, one end of a goods conveying channel (3) is connected with a goods receiving opening (1), and the other end of the goods conveying channel (3) is connected with a goods receiving box (4); an emitter (2) is fixed to a receiving opening (1); a goods taking opening (5) is communicated with the interior of an enclosure structure (6). After an unmanned aerial vehicle arrives a position nearthe goods receiving device, the receiver of the unmanned aerial vehicle receives signals sent by the emitter (2) to accurately find the receiving opening (1), places the goods are in the receiving opening (1); the goods enter the goods receiving box (4) through a chute (3); a recipient takes away the goods through the goods taking opening (5). According to the goods storing and taking device, an intermediate link is added for goods transfer between the unmanned aerial vehicle and the signer; when the receiving opening is used for the unloading of the unmanned aerial vehicle, the receiving opening has a certain height from the ground and is isolated by the building enclosure structure, so that direct contact between the unmanned aerial vehicle and the signer is avoided, and therefore, the safety of both the signer and the unmanned aerial vehicle is effectively protected, the safety of the unmanned aerial vehicle in a goods delivery and taking process is improved, and the goods deliveryoperation of the unmanned aerial vehicle is effectively matched.

Owner:胡修武

Method for preparing nano composite permanent magnetic material by adding chromium in waste magnetic steel

InactiveCN105234396AReduce process stepsLower requirementMagnetic materialsRare-earth elementMagnetic phase

The invention discloses a method for preparing a nano composite permanent magnetic material by adding chromium in waste magnetic steel. The method comprises the following steps of pre-classifying the collected waste magnetic steel according to the classification standard that the waste magnetic steel, containing the same rare earth elements, of the same batch and the same model are classified together to obtain a pre-treated magnetic material, and directly conducting hydrogen decrepitation pulverization on the obtained pre-treated magnetic material to obtain rare earth hydrogen decrepitation magnetic powder; and then conducting sampling analysis on the rare earth hydrogen decrepitation magnetic powder, adding chromium in the rare earth hydrogen decrepitation magnetic powder according to requirements to obtain mixed powder, and finally carrying out isopressing, sintering and annealing to prepare the required nano composite permanent magnetic material. The method effectively solves the problem that an alloy ingot obtained after smelting is segregated, which is caused by factors, such as different melting points of all the components and manual operation, and has the beneficial effects that through the pre-classification, not only is the recovering time shortened, but also the processing step of extracting the rare earth elements is omitted; chromium is added in the rare earth hydrogen decrepitation magnetic powder to facilitate changing the hard magnetic phase of the nano composite permanent magnetic material; and the nano composite permanent magnetic material obtained by a precipitation separation method is high in magnetism and low in rare earth content.

Owner:SUZHOU SABO IND DESIGN

Method for preparing rare earth permanent magnet material by adding liquid-phase nano terbium into magnetic steel scrap

InactiveCN105234401AShorten the timeReduce process stepsMagnetic materialsRare-earth elementBiological activation

The invention discloses a method for preparing a rare earth permanent magnet material by adding liquid-phase nano terbium into magnetic steel scrap. The method comprises the following steps: according to the classifying standard that waste magnet steel with same batch, same model and same contained rare earth elements is classified as the same class, pre-classifying collected waste magnet steel to obtain a pretreated magnet material, and directly carrying out hydrogen crushing and pulverizing on the obtained pretreated magnet material to obtain rare earth hydrogen-crushed magnet powder; then, sampling and analyzing the rare earth hydrogen-crushed magnet powder, adding, according to needs, liquid-phase nano terbium into the rare earth hydrogen-crushed magnet powder to obtain mixed powder; and finally, carrying out static pressing, sintering and annealing to prepare the required rare earth permanent magnet material. According to the method, the problem that alloy ingot obtained by smelting generates segregation due to different melting points of components and artificial operation factors is effectively solved; recycling time is reduced by pre-classifying, and a process step of extracting rare earth element is reduced; and the liquid-phase nano terbium is added into the pre-treated magnet material, so that activation performance of the rare earth permanent magnet material for preparing a fluorescent raw material can be improved, and the fluorescent material under an excited state uniformly emits green light.

Owner:SUZHOU SABO IND DESIGN

Oil field polymer-containing sewage viscosity reduction treatment method

PendingCN112028292ALow viscositySimple processWaste water treatment from quariesWater treatment compoundsReduction treatmentSewage

The invention provides an oil field polymer-containing sewage viscosity reduction treatment method. According to the method, a metal cation compound is added into polymer-containing sewage of an oil field to generate a charge shielding effect, so that a polymer molecular chain is shrunk, and a viscosity reduction effect is achieved, an oxidizing agent is added into polymer-containing sewage of anoil field, free radical chain reaction is induced to be reversed, a polymer chain is broken, and the viscosity reduction effect is achieved. Therefore, viscosity reduction of the polymer-containing sewage in the oil field is realized, and subsequent conventional treatment is facilitated. The method is suitable for treatment of oilfield polymer flooding produced water.

Owner:武汉谦豫科技有限公司

Device for automatically and uniformly spraying paint surface on wooden door

PendingCN114273115AAvoid blockingAvoid wastingPretreated surfacesCleaning using toolsElectric machineryStructural engineering

The embodiment of the invention provides an automatic and uniform paint surface spraying device for a wooden door, and belongs to the field of wooden door spraying, the device comprises a paint surface spraying device assembly, the paint surface spraying device assembly comprises a conveying device assembly, a cleaning device, a drying device and a spraying device, paint is added through the interior of a paint box, the paint in the paint box is sprayed out through a spray head, and the paint surface spraying device is used for spraying paint. A motor rotates to drive a rotating shaft and a stirring rod to rotate, so that internal paint can be continuously stirred, the situation that the internal paint is solidified to block a spray head is avoided, and when the rotating shaft rotates, a lifting rod can drive a scraping plate to rotate around the inner wall of the paint box, so that the paint adhering to the inner wall of the paint box can be scraped off; and the pull-up rod can stretch and retract along with the increase of the distance between the stirring rod and the inner wall of the bottom shell or alkalinity, so that the scraping plate can rotate around the inner wall of the paint box, waste is avoided, cleaning is easier, and the situation that the internal volume is reduced due to too much contaminated paint can be avoided.

Owner:安徽尚佰智能家居有限公司

System and method for flame detection based on Shandong Jinan

PendingCN111414514AConvenient processEasy to compareVideo data clustering/classificationMetadata video data retrievalComputer visionFire detection

The invention discloses a flame detection system based on Shandong Jinan. The system comprises a video acquisition module used for acquiring smoke and fire videos in a fire scene in Jinan, and a videoscreening module used for screening and marking smoke and fire sample videos acquired by the video acquisition module and then forming a sample library, an image model module used for carrying out sample training on each screening result of the video screening module and then obtaining a smoke and fire image model, and a smoke and fire detection module and a database which are used for comparingthe smoke and fire image model with the smoke and fire image model in the database to carry out smoke and fire detection. The system is provided with the video acquisition module, the video screeningmodule, the image model module, the smoke and fire detection module and the database. The video acquired on site can be compared and analyzed with the video in the original database, a conclusion is rapidly obtained and recorded, the recording efficiency and accuracy are improved, and errors generated manually are reduced so as to solve the problems in the prior art.

Owner:山东雷火网络科技有限公司

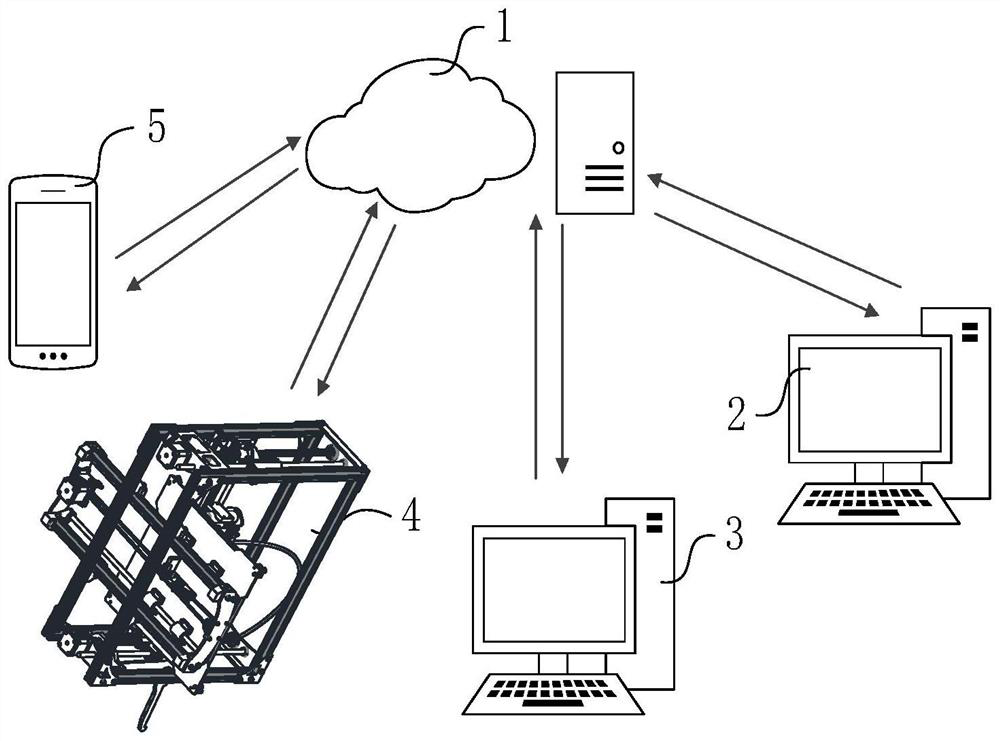

Cloud system for achieving 3D printing of orthopedic helmet and 3D printing method of orthopedic helmet

ActiveCN113199760AShort manufacturing cycleFast and easy orthopedicsAdditive manufacturing apparatusManufacturing data aquisition/processing3d printOrthotic helmet

The invention provides a cloud system for achieving 3D printing of an orthopedic helmet and a 3D printing method of the orthopedic helmet. The cloud system comprises a cloud server, a doctor terminal, an engineer terminal and 3D printing equipment, wherein the doctor terminal, the engineer terminal and the 3D printing equipment are in communication connection with the cloud server; the doctor terminal transmits the collected head type data of a patient to the cloud server to be matched with a corresponding helmet model, and the model information of the helmet model is issued to the doctor terminal; the doctor terminal uploads a first confirmation instruction for confirming the model information to the cloud server; the cloud server generates a 3D printing path of the helmet model based on the first confirmation instruction for simulation printing, and a simulation printing result is obtained and issued to the engineer terminal; the engineer terminal uploads a second confirmation instruction for confirming the simulation printing result to the cloud server; and the cloud server controls the 3D printing equipment to print according to the 3D printing path to obtain the orthopedic helmet. The cloud server controls the 3D printing equipment to print the orthopedic helmet, so that rapid collaborative preparation of the orthopedic helmet is realized.

Owner:JIAXING JIACHUANGZHI MEDICAL EQUIP CO LTD

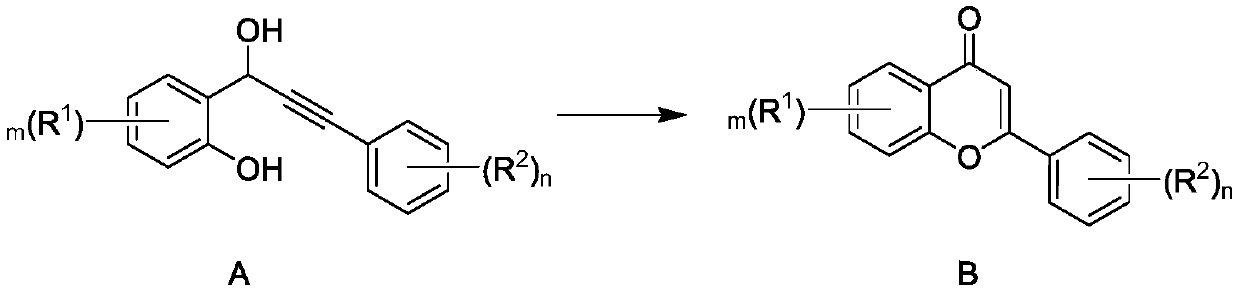

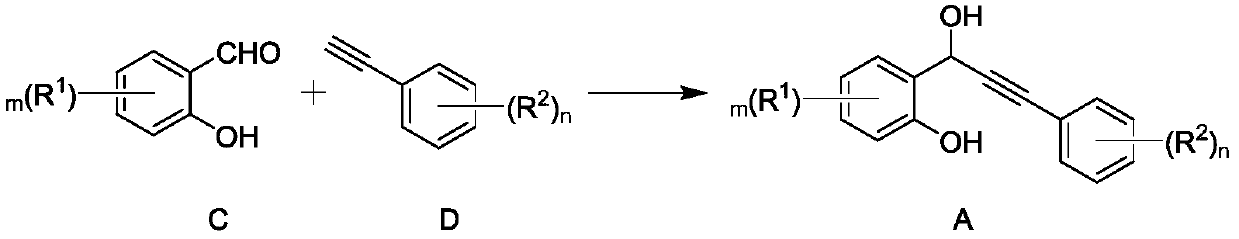

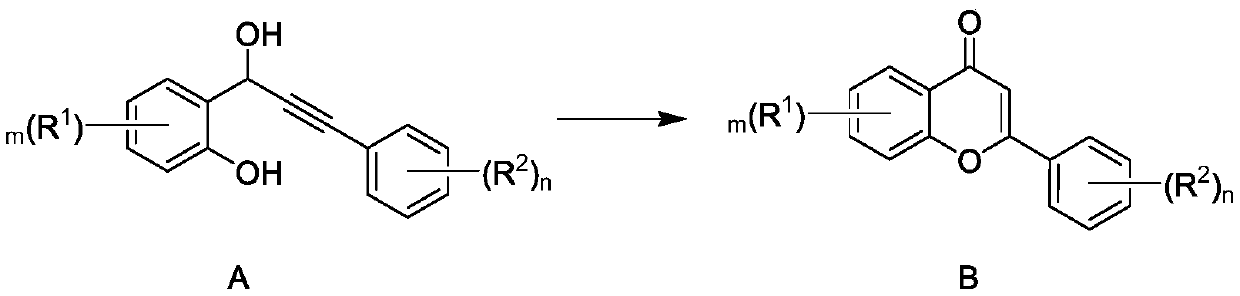

Synthetic method of flavonoid compound

ActiveCN110229133AHigh yieldGood reaction selectivityOrganic chemistryPhysical/chemical process catalystsArylHydrogen

The invention discloses a synthetic method of a flavonoid compound. The synthetic method comprises the following step: in the oxygen atmosphere, a compound as shown in the formula A is subjected to areaction in a reaction system containing a catalyst Co-NC to generate a flavonoid compound as shown in the formula B, wherein R1 and R2 are respectively and individually selected from hydrogen, halogen, cyano group, nitro group, sulfonic group, trifluoromethyl group, amino group, alkyl group having 1 to 12 carbon atoms, alkoxy group having 1 to 12 carbon atoms, alkenyl group having 2 to 12carbon atoms, alkynyl group having 2 to 12 carbon atoms, acyl group having 2 to 12 carbon atoms, aryl group having 6 to 40 carbon atoms, heteroaryl group having 3 to 40 carbon atoms, and a nucleus-fused carbon ring or heterocyclic ring having 3 to 40 carbon atoms; m is an integer selected from 1-4; and n is an integer selected from 1-5. By selecting the catalyst Co-NC with high activity as the catalyst and oxygen as an oxidizing agent in the synthetic method, one-step synthesis of the flavonoid compound under the condition of room temperature is realized. The synthetic method has advantages of mild reaction condition, good selectivity and high yield.

Owner:NANJING XIAOZHUANG UNIV

Method for preparing rare earth permanent magnetic material by adding liquid phase nano yttrium to magnetic steel waste

A method for preparing a rare earth permanent magnetic material by adding liquid phase nano yttrium to magnetic steel waste includes the steps that collected waste magnetic steel is pre-classified according to the classification standard that waste magnetic steel containing same rare earth elements in the same batch and same model is regarded as one category, a preprocessed magnetic material is obtained, the obtained preprocessed magnetic material is directly subjected to hydrogen decrepitation and pulverization, and rare earth hydrogen decrepitation magnetic powder is obtained; then the rare earth hydrogen decrepitation magnetic powder is sampled and analyzed, liquid phase nano yttrium is added into the rare earth hydrogen decrepitation magnetic powder according to needs to obtain mixed powder, and finally the needed rare earth permanent magnetic material is prepared through static pressing, sintering and annealing. The method effectively solves the problem that due to different melting points of components and manual operation factors, segregation of alloy ingots obtained after smelting is caused, and pre-classification is conducted so that recycling time can be saved; process steps for extracting rare earth elements are reduced; liquid phase nano yttrium is added into the rare earth hydrogen decrepitation magnetic powder, so that the use amount of neodymium and praseodymium is reduced easily, and when outside temperature changes a lot, the magnetic properties of the permanent magnetic material can be effectively kept unchanged.

Owner:SUZHOU SABO IND DESIGN

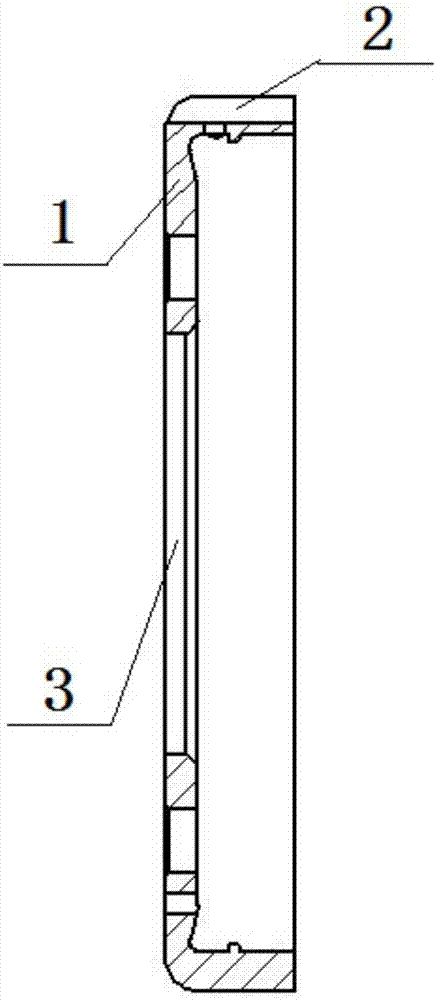

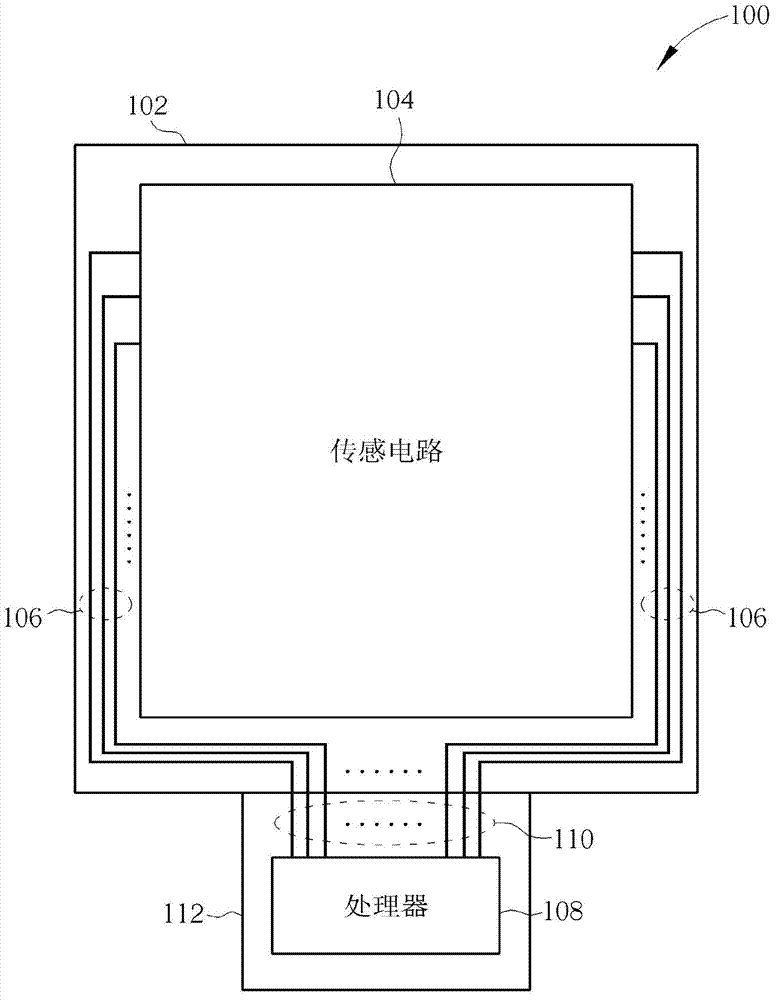

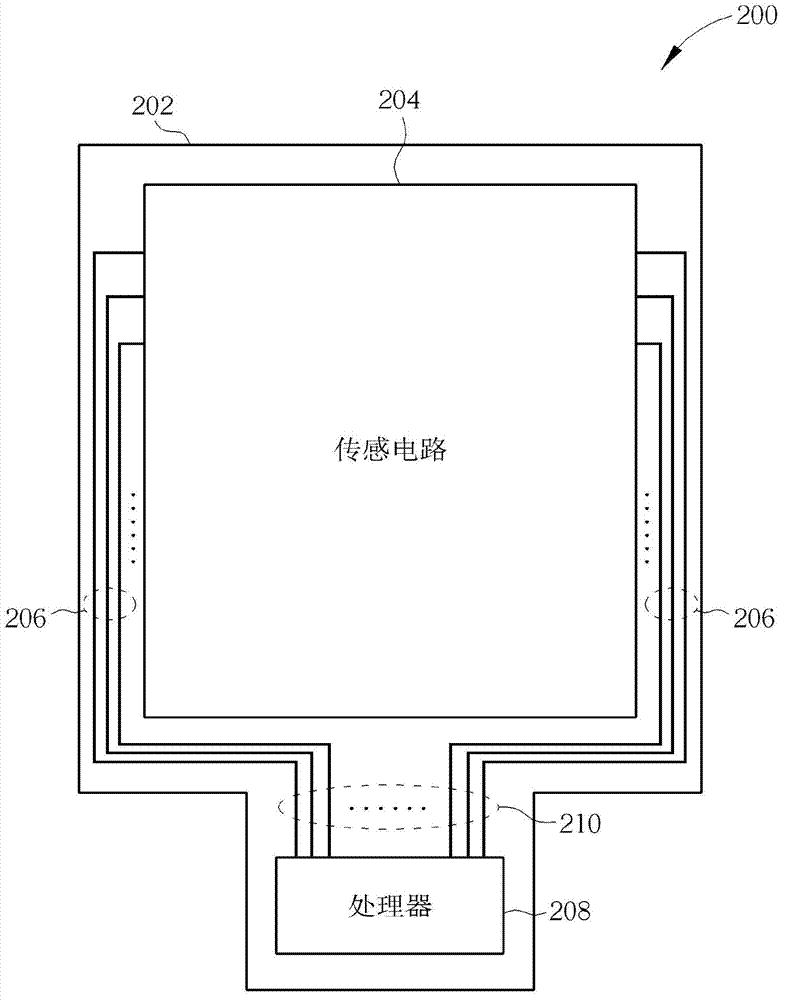

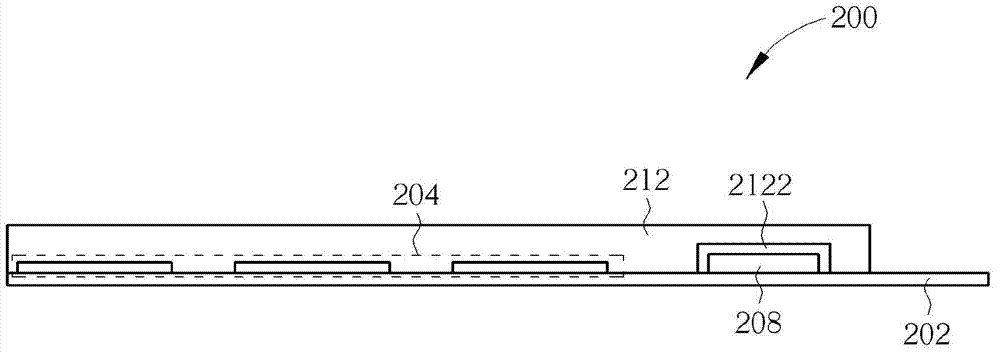

Touch panel and method for forming touch panel

InactiveCN103593079AConvenient processNo disconnection problemInput/output processes for data processingEngineeringTouch panel

The invention discloses a touch panel and a method for forming the touch panel. The touch panel comprises an adhesive film and a protection glass. A sensing unit of a sensing circuit, a first guide line coupled with the sensing circuit and a second guide line coupled between the first guide line and a processor are formed on the adhesive film. The adhesive film is attached below the protection glass in an attaching manner. Therefore, by the aid of the touch panel and the method, the touch panel can be quick and convenient in processing, poor connection of the first guide line and the second guide line can be avoided, precise positioning is not required, disconnection of the first guide line and the second guide line is not caused, and the touch panel is easier in processing.

Owner:YOMORE TECH

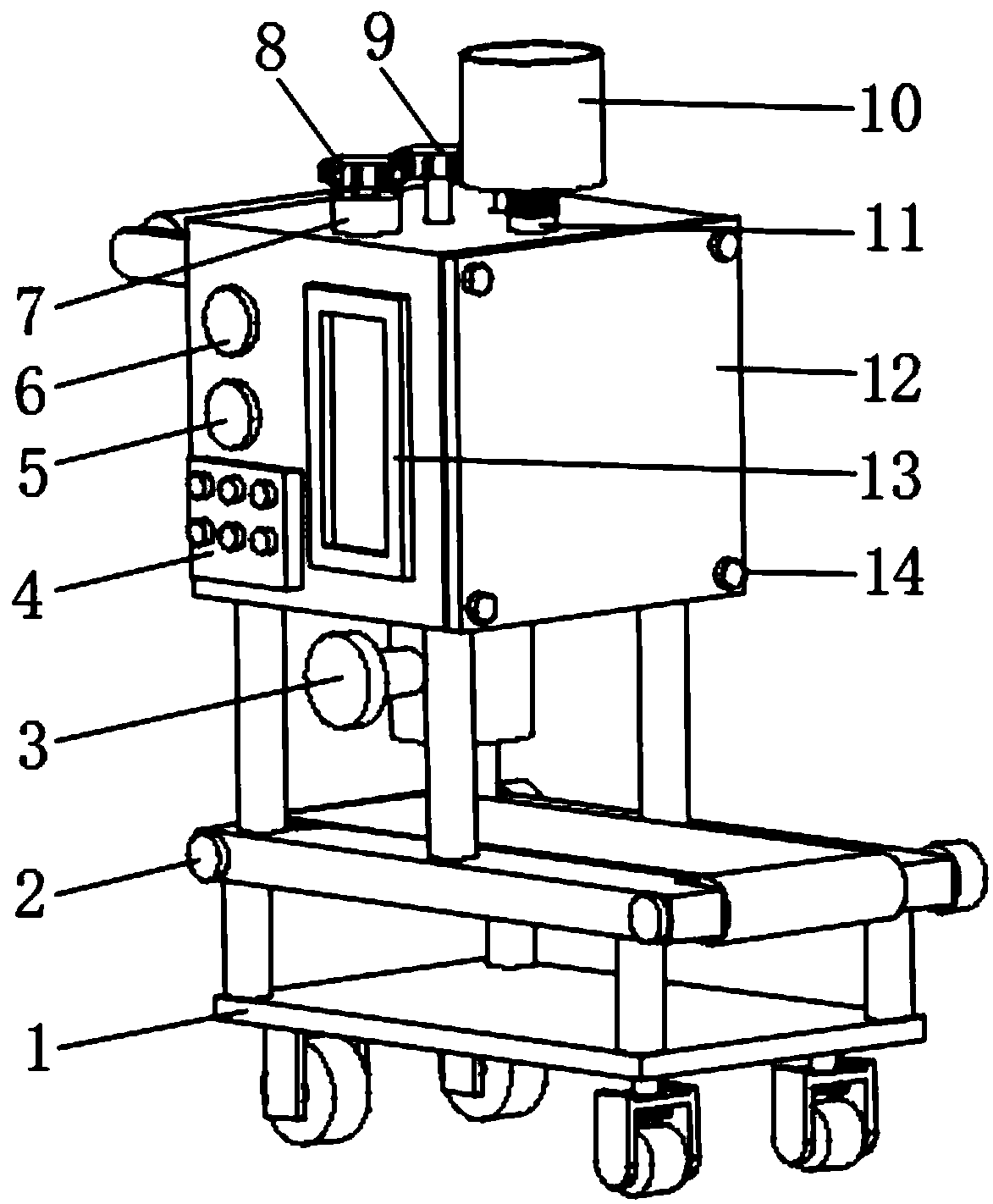

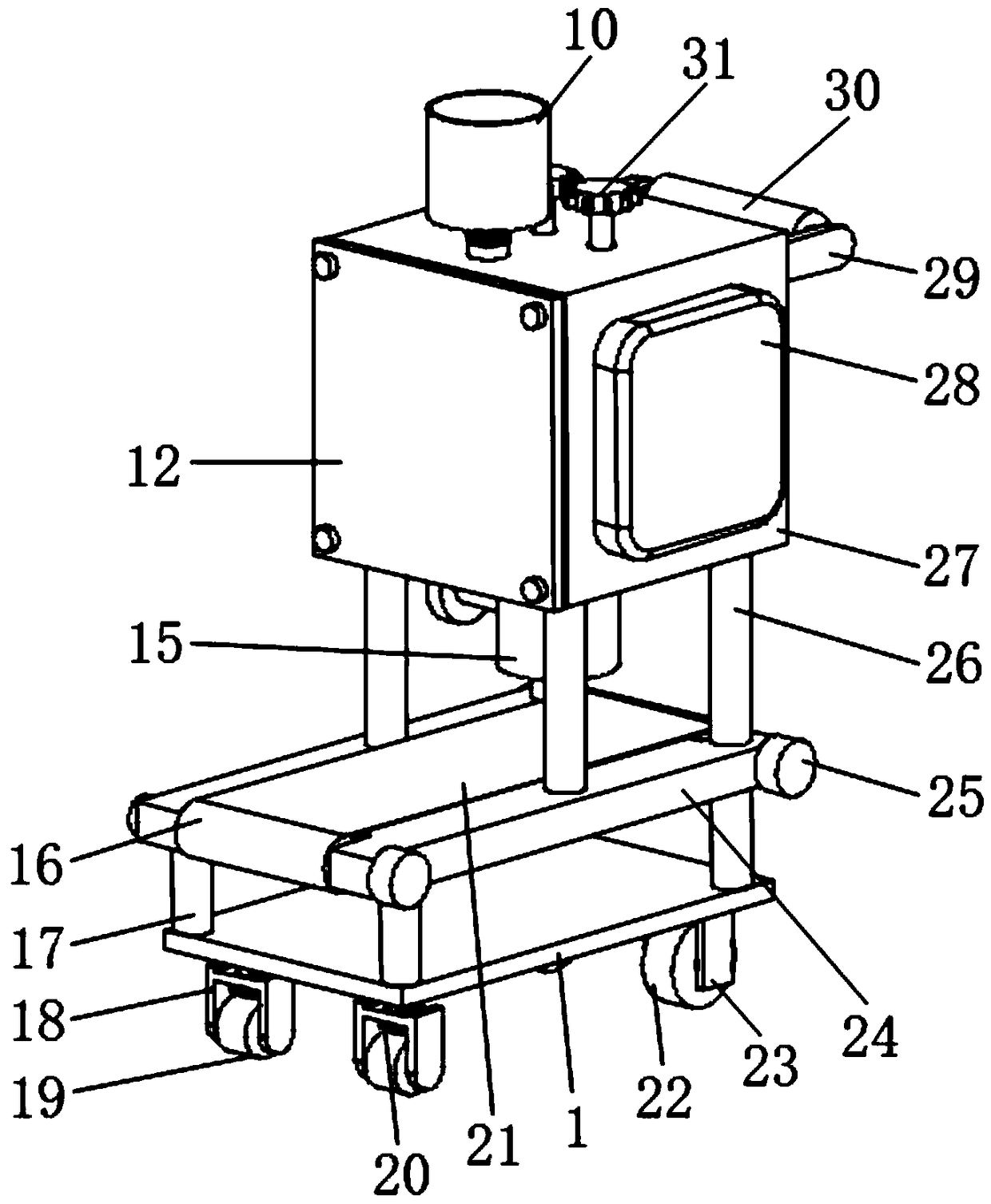

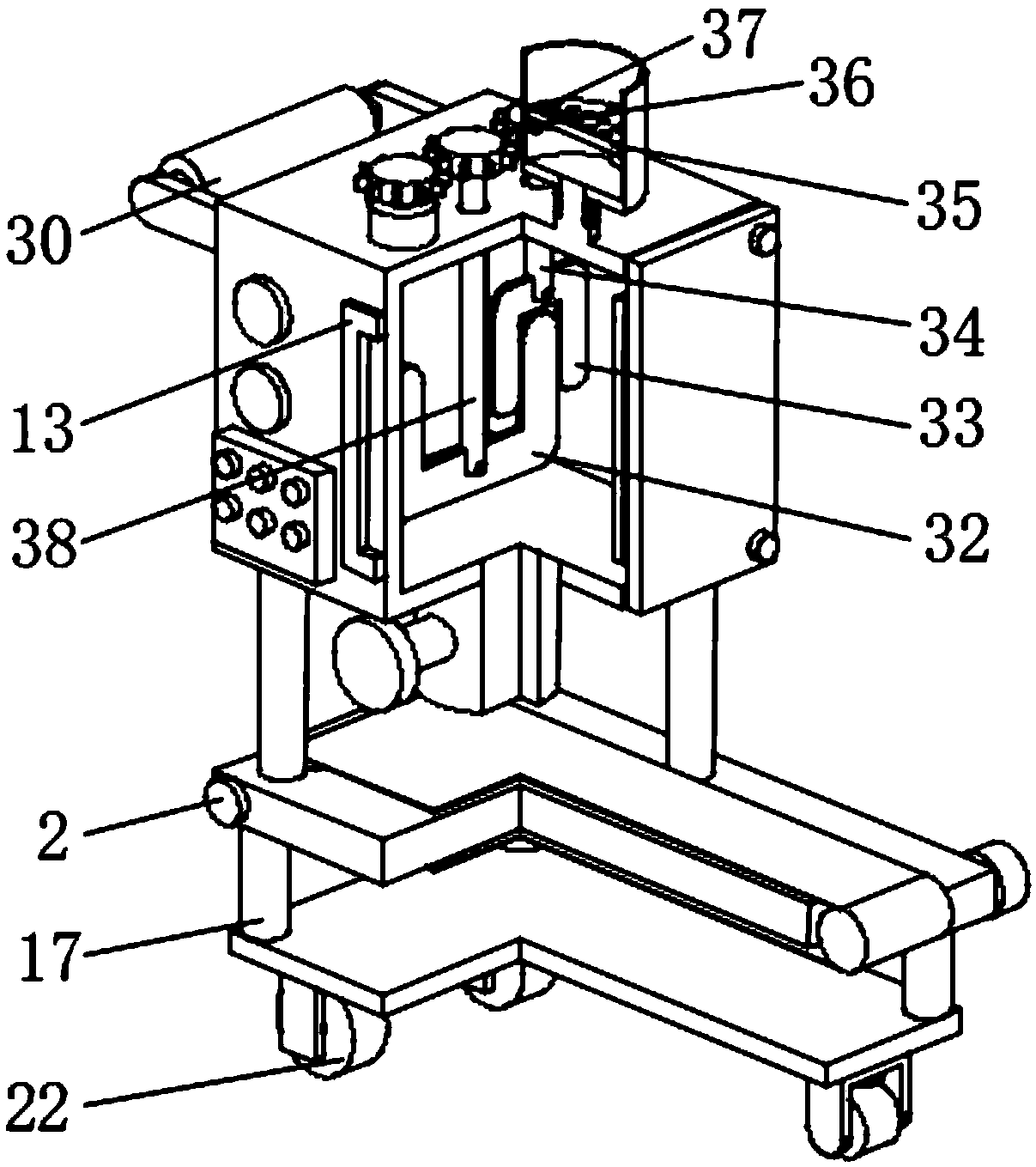

Lithium ion battery raw material mixing device convenient to move

InactiveCN109433076AEasy to moveEasy to fixRotary stirring mixersTransportation and packagingEngineeringLithium-ion battery

The invention discloses a lithium ion battery raw material mixing device convenient to move. The lithium ion battery raw material mixing device convenient to move comprises a bottom plate; one end ofthe lower surface of the bottom plate is connected with universal wheels; the other end of the lower surface of the bottom plate is connected with rollers; four first load bearing posts which are uniformly distributed are arranged on the upper surface of the bottom plate; a fixed frame is arranged at the top ends of the first load bearing posts; mounting grooves are respectively formed in the twoends of the fixed frame; the interiors of the mounting grooves are rotatably connected with rotating shafts; a second servo motor is arranged at the end part of each rotating shaft; according to the lithium ion battery raw material mixing device convenient to move, the rollers and second connecting frames are arranged so as to facilitate the movement of the lithium ion battery raw material mixingdevice; first connecting frames, the universal wheels and the connecting posts are arranged, so that the lithium ion battery raw material mixing device convenient to move is conveniently driven to steer; and a foot brake is arranged, so that the fixing of the lithium ion battery raw material mixing device convenient to move is facilitated, and processes are facilitated.

Owner:阜阳市人民电气实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com