Device for automatically and uniformly spraying paint surface on wooden door

A technology of spraying device and paint surface, applied in spraying device, device for coating liquid on surface, spraying room, etc., can solve problems such as waste, small internal volume, paint solidification, etc., to avoid waste, clean up effect is good and easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS It should be understood that the specific embodiments described herein are intended to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the invention.

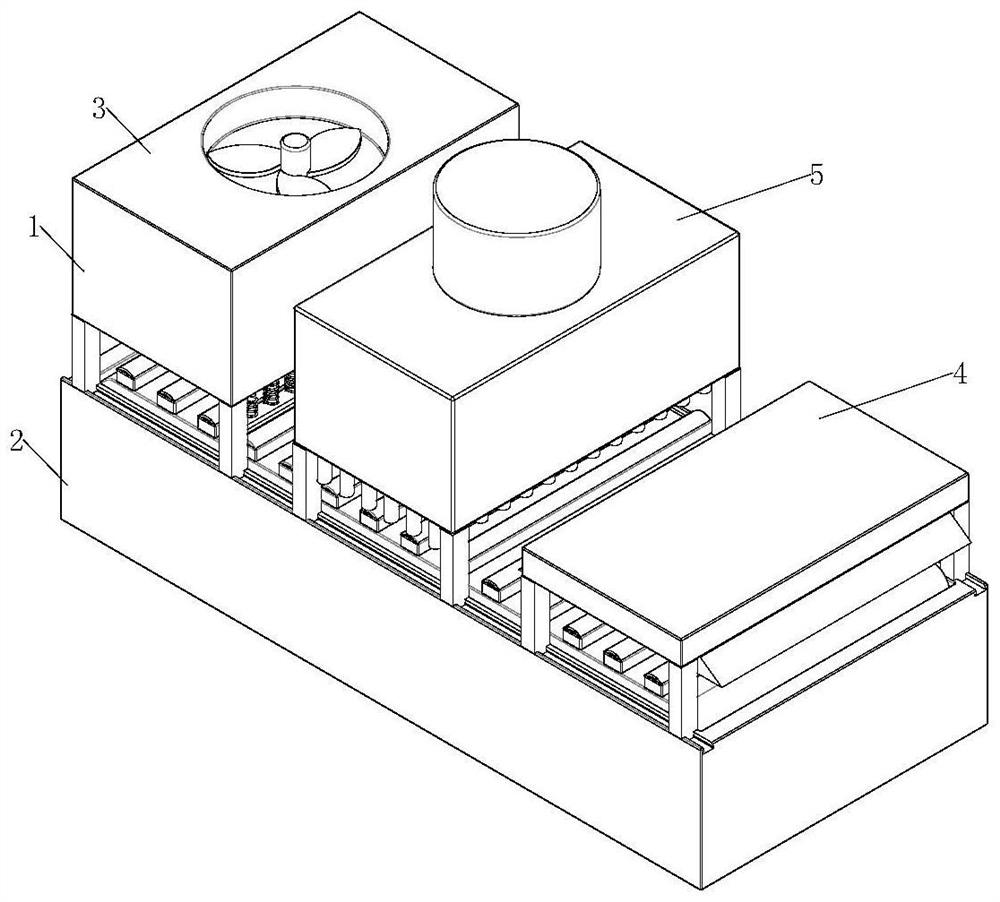

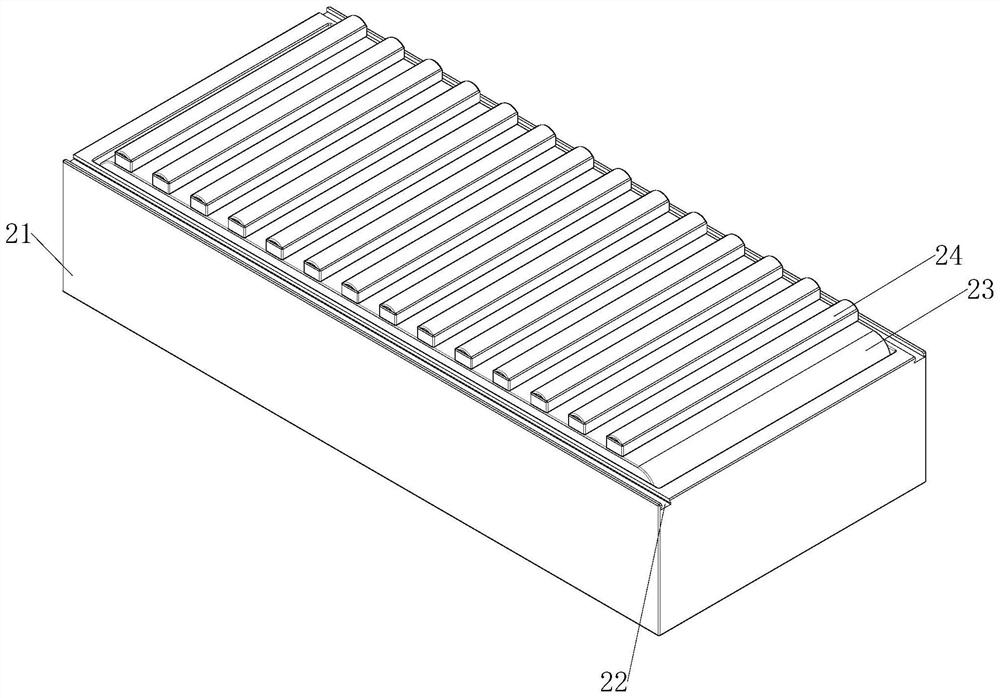

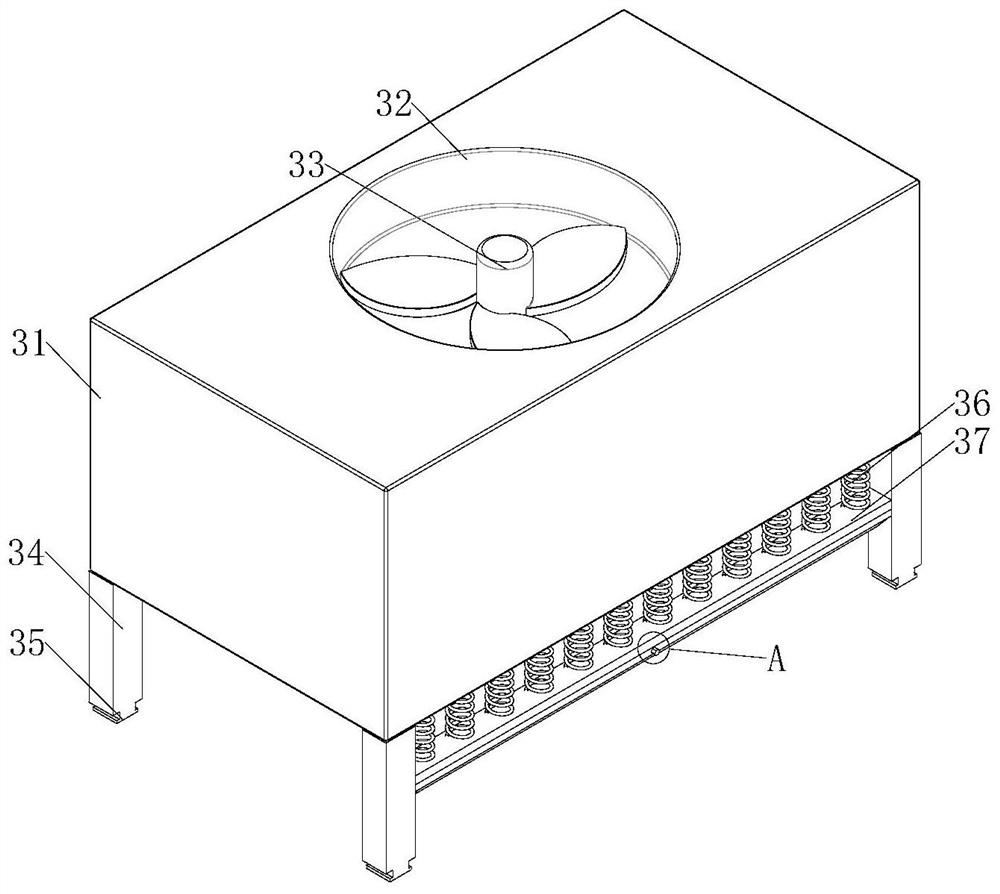

[0041] Such as figure 1 As shown, it is a schematic structural diagram of a wooden door automatic uniform spraying surface device according to a preferred embodiment of the present invention, and a wooden door of the present embodiment automatically sprayed the painted surface device, including a spray painted surface device assembly 1, said The spray paint surface device assembly includes a transmission device assembly 2, a cleaning device 3, a drying device 4, and a spray apparatus 5, the cleaning device 3 and the drying device 4 are fitted on both sides of the end surface of the transmission device assembly 2. The spray device 5 is fitted between the transmitting device assembly 2 upper end surface cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com